Gorman-Rupp Pumps 612L20-B User Manual

ACE

OM−01395−02

July 8, 1985

Rev. C 10-09-06

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

60 SERIES PUMP

MODEL

612L20−B

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

www.grpumps.com

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

eCopyright by the Gorman-Rupp Company

Register your new

Gorman-Rupp pump online at

www.grpumps.com/register.

Valid serial number and e-mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman-Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

TABLE OF CONTENTS

INTRODUCTION PAGE I − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY - SECTION A PAGE A − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION − SECTION B PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Dimensions PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREINSTALLATION INSPECTION PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POSITIONING PUMP PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SUCTION AND DISCHARGE PIPING PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Materials PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Configuration PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections to Pump PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gauges PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SUCTION LINES PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fittings PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strainers PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sealing PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Suction Lines In Sumps PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Suction Line Positioning PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISCHARGE LINES PAGE B − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siphoning PAGE B − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valves PAGE B − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALIGNMENT PAGE B − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coupled Drives PAGE B − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V-Belt Drives PAGE B − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V-Belt Jack Shaft Drives PAGE B − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION − SECTION C PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRIMING PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hand-Operated Priming Pump PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTING PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rotation PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leakage PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Liquid Temperature And Overheating PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strainer Check PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Vacuum Check PAGE C − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOPPING PAGE C − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cold Weather Preservation PAGE C − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEARING TEMPERATURE CHECK PAGE C − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING − SECTION D PAGE D − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREVENTIVE MAINTENANCE PAGE D − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

TABLE OF CONTENTS

(continued)

PUMP MAINTENANCE AND REPAIR - SECTION E PAGE E − 1. . . . . . . . . . . . . . . . .

STANDARD PERFORMANCE CURVE PAGE E − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS LIST:

Pump Model PAGE E − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E − 4. . . . . . . . . . . . . . . . . . . . . . . . .

Suction Head And Wear Ring Removal PAGE E − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Casing Removal PAGE E − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Removal PAGE E − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Removal PAGE E − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shaft and Bearing Removal and Disassembly PAGE E − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shaft and Bearing Reassembly and Installation PAGE E − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Reassembly and Installation PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Installation PAGE E − 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Casing Installation PAGE E − 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Suction Head And Wear Ring Installation PAGE E − 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION PAGE E − 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Assembly PAGE E − 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bearings PAGE E − 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Source PAGE E − 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

60 SERIES

OM−01395

INTRODUCTION

Thank You for purchasing a Gorman-Rupp pump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

This pump is a 60 Series, enclosed impeller, centrifugal model with straight-in suction, without a suction check valve. The pump is designed for handling wastewater, mud or slurries containing specified entrained solids. The basic material of construction for wetted parts is gray iron, with ductile

impeller, brass wear rings and a stainless steel impeller shaft.

This manual will alert personnel to known procedures which require special attention, to those

which could damage equipment, and to those

which could be dangerous to personnel. However,

this manual cannot possibly anticipate and provide

detailed precautions for every situation that might

occur during maintenance of the unit. Therefore, it

is the responsibility of the owner/maintenance personnel to ensure that only safe, established main-

tenance procedures are used, and that any procedures not addressed in this manual are performed

only after establishing that neither personal safety

nor pump integrity are compromised by such practices.

For information or technical assistance on the power source, contact the power source manufacturer’s local dealer or representative.

The following are used to alert maintenance personnel to procedures which require special attention, to those which could damage equipment, and

to those which could be dangerous to personnel:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

If there are any questions regarding the pump or

its application which are not covered in this manual or in other literature accompanying this unit,

please contact your Gorman-Rupp distributor, or:

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901−1217

Phone: (419) 755−1011

or:

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631−2870

Hazards or unsafe practices which COULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possible damage which could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I − 1INTRODUCTION

60 SERIES

OM−01395

SAFETY - SECTION A

This information applies to 60 Series basic pumps. Gorman-Rupp has no control over or particular knowledge of the

power source which will be used. Refer

to the manual accompanying the power

source before attempting to begin operation.

Because pump installations are seldom

identical, this manual cannot possibly

provide detailed instructions and precautions for each specific application.

Therefore, it is the owner/installer’s responsibility to ensure that applications

not addressed in this manual are performed only after establishing that neither operator safety nor pump integrity

are compromised by the installation.

Before attempting to open or service the

pump:

liquids which may damage the pump or

endanger personnel as a result of pump

failure.

Use lifting and moving equipment in

good repair and with adequate capacity

to prevent injuries to personnel or damage to equipment. Suction and discharge hoses and piping must be removed from the pump before lifting.

After the pump has been positioned,

make certain that the pump and all piping or hose connections are tight, properly supported and secure before operation.

1. Familiarize yourself with this manual.

2. Disconnect or lock out the power

source to ensure that the pump will

remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

This pump is designed to handle wastewater, mud or slurries containing specified entrained solids. Do not attempt to

pump volatile, corrosive or flammable

Do not operate the pump against a

closed discharge valve for long periods

of time. If operated against a closed discharge valve, pump components will

deteriorate, and the liquid could come

to a boil, build pressure, and cause the

pump casing to rupture or explode.

Do not remove plates, covers, gauges,

pipe plugs, or fittings from an overheated pump. Vapor pressure within the

pump can cause parts being disengaged to be ejected with great force. Allow the pump to cool before servicing.

Do not operate the pump without

PAGE A − 1SAFETY

shields and/or guards in place over the

drive shafts, belts, and/or couplings, or

other rotating parts. Exposed rotating

parts can catch clothing, fingers, or

tools, causing severe injury to personnel.

60 SERIESOM−01395

Pumps and related equipment must be installed and operated according to all national, local and industry standards.

PAGE A − 2 SAFETY

60 SERIES OM−01395

INSTALLATION − SECTION B

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section offers only general recommendations and

practices required to inspect, position, and arrange the pump and piping.

Most of the information pertains to a standard

static lift application where the pump is positioned

above the free level of liquid to be pumped.

If installed in a flooded suction application where

the liquid is supplied to the pump under pressure,

some of the information such as mounting, line

configuration, and priming must be tailored to the

OUTLINE DRAWING

specific application. Since the pressure supplied

to the pump is critical to performance and safety,

be sure to limit the incoming pressure to 50% of the

maximum permissible operating pressure as

shown on the pump performance curve (see Section E, Page 1).

For further assistance, contact your Gorman-Rupp

distributor or the Gorman-Rupp Company.

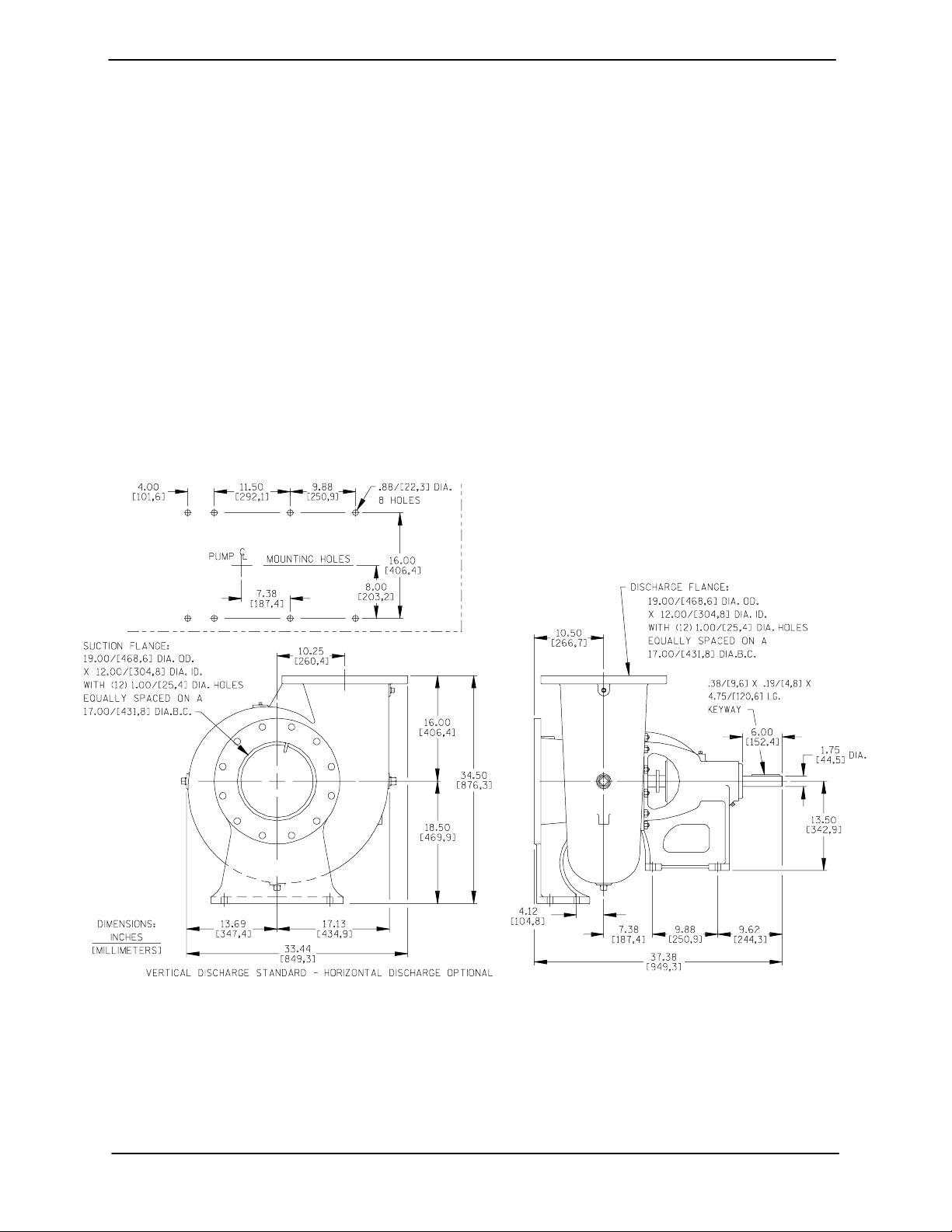

Pump Dimensions

See Figure B−1 for the approximate physical dimensions of this pump.

Figure B−1. Pump Model 612L20−B

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested before shipment from the factory. Before installation,

inspect the pump for damage which may have occurred during shipment. Check as follows:

a. Inspect the pump for cracks, dents, damaged

threads, and other obvious damage.

b. Check for and tighten loose attaching hard-

ware. Since gaskets tend to shrink after dry-

PAGE B − 1INSTALLATION

OM−01395 60 SERIES

ing, check for loose hardware at mating surfaces.

c. Carefully read all tags, decals, and markings

on the pump assembly, and perform all duties

indicated. Note that the pump shaft rotates in

the required direction.

Only operate this pump in the direction indicated by the arrow on the pump body

and on the accompanying decal. Otherwise, the impeller could become loosened

from the shaft and seriously damage the

pump.

d. Check levels and lubricate as necessary. Re-

fer to LUBRICATION in the MAINTENANCE

AND REPAIR section of this manual and perform duties as instructed.

e. If the pump has been stored for more than 12

months, some of the components or lubricants may have exceeded their maximum

shelf life. These must be inspected or re-

placed to ensure maximum pump service.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to determine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

The pump assembly can be seriously

damaged if the chains or cables used to lift

and move the unit are improperly wrapped

around the pump.

Mounting

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mounting is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibration.

SUCTION AND DISCHARGE PIPING

Pump performance is adversely effected by increased suction lift, discharge elevation, and friction losses. See the performance curve on Page

E-1 to be sure your overall application allows pump

to operate within the safe operation range.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatible with the liquid being pumped. If hose is

used in suction lines, it must be the rigid-wall, reinforced type to prevent collapse under suction. Using piping couplings in suction lines is not recommended.

Line Configuration

Keep suction and discharge lines as straight as

POSITIONING PUMP

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer-installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

PAGE B − 2 INSTALLATION

possible to minimize friction losses. Make minimum use of elbows and fittings, which substantially increase friction loss. If elbows are necessary,

use the long-radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it exactly with the pump port. Never pull a pipe line into

place by tightening the flange bolts and/or couplings.

Lines near the pump must be independently supported to avoid strain on the pump which could

Loading...

Loading...