Page 1

ABCDH

OM-01505-OB01

January 20, 1981

Rev. D 10/27/99

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH P ARTS LIST

DSERIESPUMP

4D --- B

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

eCopyright by the Gorman-Rupp Company

Page 2

TABLE OF CONTENTS

INTRODUCTION PAGE I --- 1...................................................

WARN ING S - SE CTI ON A PA GE A --- 1.........................................

IN STA L LAT ION --- S ECT ION B PA GE B --- 1.....................................

Pump Dimensions PAGE B --- 1........................................................

PREINSTALLATION INSPECTION PAGE B --- 1...............................................

ELECTRIC MOTOR INSTALLATION PAGE B --- 2.............................................

POSITIONING PUMP PA GE B --- 2..........................................................

Lifting PA GE B --- 2....................................................................

Mounting PA GE B --- 2................................................................

SUCTION AND DISCHARGE PIPING PAGE B --- 2............................................

Materials PA GE B --- 2.................................................................

Line Configuration PAGE B --- 2.........................................................

Fixed, Rigid Piping P AGE B --- 3........................................................

Gauges PA GE B --- 3..................................................................

SUCTION LINES PAGE B --- 4..............................................................

Fittings PA GE B --- 4..................................................................

Strainers PA GE B --- 4.................................................................

Sealing PAGE B --- 4..................................................................

DISCHARGE LINES PA GE B --- 4...........................................................

Siphoning PA GE B --- 4................................................................

Valves PA GE B --- 4...................................................................

ALIGNMENT PAGE B --- 5.................................................................

ELECTRICAL CONNECTIONS PAGE B --- 5..................................................

OPER AT IO N --- S EC T IO N C PA GE C --- 1.......................................

STARTING PA GE C --- 1...................................................................

Rotation PA GE C --- 1.................................................................

OPERATION PAGE C --- 1.................................................................

Priming PA GE C --- 2..................................................................

OPERATION CHE CKS PA GE C --- 2.........................................................

Gearbox Check PAGE C --- 2...........................................................

Leakage Check PAGE C --- 2...........................................................

Strainer Check PAGE C --- 2............................................................

Accumulator Chamber Check PAGE C --- 2..............................................

STOPPING PA GE C --- 2...................................................................

Cold Weather Preservation PAGE C --- 2.................................................

GEARBOX TEMPERATURE CHECK PAGE C --- 2.............................................

TR OUB LES HOO TI NG --- SE C TIO N D PA GE D --- 1...............................

PUMP MAINTENANCE AND REPAI R - SECTION E PAGE E --- 1..................

STANDARD PERFORMANCE TEST DATA PAGE E --- 1.......................................

PARTS LISTS:

Pump Model PA GE E --- 3.............................................................

i

Page 3

TABLE OF CONTENTS

(continued)

Diaphragm Pot Assembly PAGE E --- 5..................................................

Plunger Rod Assembly PAGE E --- 7....................................................

Gearbox Assembly PAGE E --- 9........................................................

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E --- 10...........................

Suction And Discharge Flap Valve Removal PAGE E --- 10.................................

Diaphragm Removal PAGE E --- 10......................................................

Plunger Rod Removal And Disassembly PAGE E --- 11....................................

Gearbox Removal And Disassembly PAGE E --- 11........................................

Gearbox Reassembly And Installation P AGE E --- 12......................................

Plunger Rod Reassembly And Installation PAGE E --- 14...................................

Diaphragm Installation PAGE E --- 15....................................................

Suction And Discharge Flap Valve Installation P AGE E --- 15...............................

LUBRICATION PA GE E --- 15...............................................................

Plunger Rod Assembly PAGE E --- 15...................................................

Gearbox PA GE E --- 16................................................................

Motor PAGE E --- 16...................................................................

ii

Page 4

DSERIES

OM--01505

INTRODUCTION

This Installation, Operation, and Maintenance

manual is designed to help you achieve the best

performance and longest life from your GormanRupp pump.

This is a DSeries, positivedisplacement pumputilizing a single-action diaphragm to produce a

straight-through flow of liquid. The pump is provided with an explosion-proof electric motor and

ideallysuitedtoindustrial andcontractor’s applications since it will handle liquids ranging from clear

water to construction-site muck. The basic material of construction for wetted parts is aluminum,

with neoprene flap valves and diaphragm.

If there are any questions regarding the pump or

its application which are not covered in this manual or in other literature accompanying this unit,

please contact your Gorman -Rupp distributor, or

write:

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901--1217

or

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

The following are used to alert maintenance personnel to procedures which requirespecial attention, tothose whichcould damage equipment, and

to those which could be dangerous to personnel:

Immediate hazards whichWILL result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULDresult in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result fromfailure to follow

the procedure.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed in structions and precautions for every aspect of

each specific application. Therefore, it is the responsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operator safety norpumpintegrity arecompromised by the installation. Pumps and related

equipment must be installed and operated ac-

cording to all national, local and industry stan dards.

HazardsorunsafepracticeswhichCOULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possibledamage which couldresult from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation,and

maintenance, or which clarify a procedure.

PAGE I -- 1INTRODUCTION

Page 5

DSERIES

SAFETY- SECTION A

These warnings apply to D Series Basic

Diaphragm pumps. Gorman-Rupp has

no control over or particular knowledge

of the power source which will be used.

Refer to the manual accompanying the

power source before attemp ting to b egin operation.

Beforeattempting toopenorservic e the

pump:

1. Familiarize yourself with this manual.

2. Lock out incoming power to the

power source to ensure that the

pump will remain inoperative.

3. Allowthe pump to completelycool

if overheated.

4. Close the discharge valve (if

used).

5. Drain the pump.

This pump is designed to handle nonvolatile non-flammable liquids containing specified entrained solids. Do not

attempt to pump volatile, corrosive, or

flammable liquids which may damage

the pump or endanger personnel as a

result of pump failure.

Afterthe pump hasbeeninstalled,block

the wheels and secure the pump to prevent creeping. Make certain that the

pump and all piping or hose connections are tight, properly supported and

secure before operation.

OM--01505

Donot operate the pump without the eccentric and coupling guards in place

over the rotating parts. Exposed rotating parts can catch clothing, fingers, or

tools, causing severe injury to personnel.

The gearbox provided on this pump is

designed for operation at 1750 RPM

maximum input speed. If operated at a

higher RPM, pump componentsmay be

destroyed.

Install and operate only an explosion

proof motor in an explosive atmosphere. Install, connect, and operate

the motor in accordance with the National Electric Code and all local codes.

Ifthereisa conflictbetween the instructions in the manual accompanying the

unit and the National Electric Code or

the applicable local code, the National

or local code shall take precedence.

Never install a positive shut-off valve inthe

discharge line; discharge restrictions will

cause excessive friction loss resulting in

overloading and destruction of pump and

drive components. It is strongly recommended that unless absolutelynecessary,

nopositiveshut-off valvebe installedinthe

suction line; excessive restriction will

cause incomplete filling of the diaphragm

chamber and result in shortened diaphragm life.

PAGE A -- 1WARNINGS

Page 6

DSERIES OM--01505

INSTALLATION --- SECTION B

Review all SAFETY information in Section A.

Since pump installations areseldom identical,this

section offers only general recommendations and

practices required to inspect, position, and arrange the pump and piping.

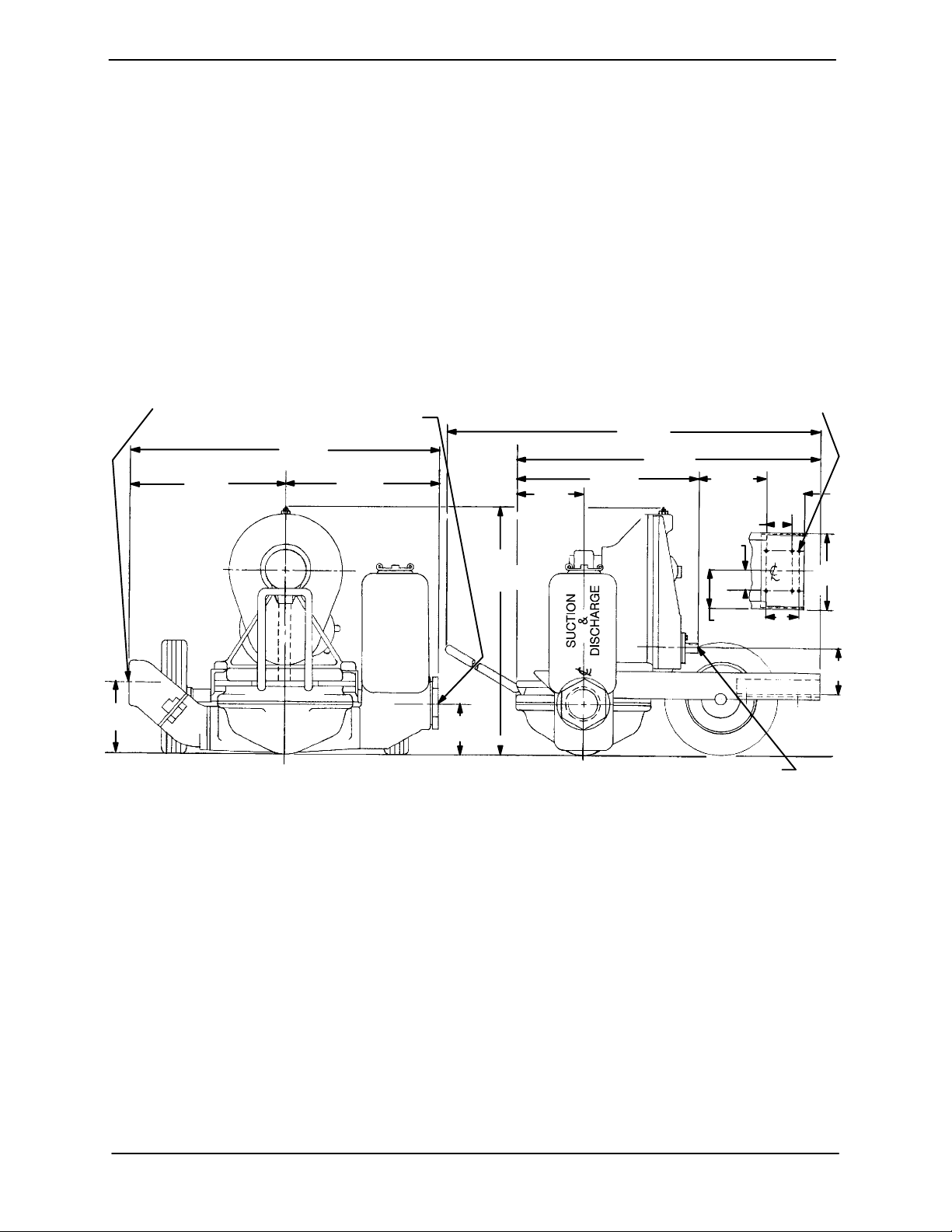

OUTLINE DRAWING

DISCHARGE - 4” NPT

16.88

[428,75]

SUCTION - 3” (OR 4”) NPT

33.88

[860,55]

17.00

[431,80]

Forfurther assistance,contact yourGorman-Rupp

distributor or t he Gorman-Rupp Company.

Pump Dimensions

SeeFigure1fortheapproximatephysicaldimensionsofthispump.

APPROX

26.62

[676,15]

7.31

[185,67]

[1370,08]

19..69

[500,13]

53.94

34.94

[887,48]

.44

[11,18]

7.25

[184,15]

5.50

[139,70]

4.25

[107,95]

8.25

[209,55]

-(6)HOLESDIA

7.00

[177,80]

1.00

[25.40]

16.25

[412,75]

7.00

[177,80]

DIMENSIONS: INCHES

[MILLIMETERS]

Figure 1. Pump Model 4D-B

PREINSTALLATION INSPECTION

Thepump assembly wasinspected and tested beforeshipment fromthe factory. Beforeinstallation,

inspect the pump fordamage which may have occurred during shipment. Check as follows:

a. Inspect the pump forcracks,dents, damaged

threads, and other obvious damage.

b. Check for and tighten loose attaching hard-

ware. Since gaskets tend to shrink after drying, check for loose hardware at mating sur faces.

5.31

[134,87]

[133,35]

.75 DIA SHAFT W/ .19 X .09 X 1..06 LONG

[19,05] [4,83][2,29][26,92]

USEABLE KEYWAY

c. Carefully read all tags, decals, and markings

onthepumpassembly,and performallduties

indicated.

d. Check levels and lubricate as necessary. Re-

fer to LUBRICATION in the MAINTENANCE

AND REPAIR section of this manual and perform duties as instructed.

e. If the pump and motor have been stored for

more than 12 months, some of the components or lubricants may have exceeded their

maximumshelflife.Thesemustbeinspected

or replaced to ensure maximum pump service.

5.25

PAGE B -- 1INSTALLATION

Page 7

OM--01505 DSERIES

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to determinethe repairor updating policy. Donotputthe

pump into service until appropriate action has

been taken.

ELECTRIC MOTOR INSTALLATION

The pump is designed tobe flex-coupledto a1750

RPMsynchronousspeed electricmotor.The pump

basewillaccepteither a182Tor184T motorframe.

Be sure the motor tobe used meets these specifications and is compatible with the intended application.

Install and operate only an explosion

proof motor in an explosive atmosphere. Install, connect, and operate

the motor in accordance with the National Electric Code and all local codes.

Ifthereisa conflictbetween the instructions in the manual accompanying the

unit and the National Electric Code or

the applicable local code, the National

or local code shall take precedence.

POSITIONING PUMP

andmovetheunitareimproperlywrapped

around the pump.

Mounting

Locatethepumpinanaccessibleplaceascloseas

practicalto the liquid being pumped. Levelmounting is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibration.

After the pump has been positioned, block the

wheels and secure the pump t o prevent creeping.

SUCTION AND DISCHARGE PIPING

Pump performance is adversely effected by increased suction lift, discharge elevation, and friction losses. See Page E-1 to be sure your overall

application allows the pump to operate within the

safe operation range.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatiblewith theliquidbeingpumped.If hoseis

used insuction lines, it mustbe the rigid-wall, reinforcedtype toprevent collapseunder suction.Using piping couplings in suction lines is not recommended.

Lifting

This pump is designed to be easily positioned for

operationusing the drawbar and wheels. The total

pump weight is approximately295 pounds (133,8

kg), not including accessories or motor.Customer

installed equipment such as suction and dischargepipingmustberemovedbeforeattempting

to lift.

Thepumpassemblycanbeseriously

damaged ifthecables or chains used tolift

PAGE B -- 2 INSTALLATION

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make minimum use of elbows and fittings, which substantiallyincreasefriction loss.If elbowsarenecessary,

use the long-radius type to minimize friction loss.

Never pull a line into place by t ightening connectionsatthe pump.Lines near thepump mustbe independently supported to avoid strain on the

pump which could cause excessive vibration and

increased diaphragm and gear train wear. If hosetype lines are used, they should have adequate

support to secure them wh en filledwith liquidand

under pressure.

Page 8

DSERIES OM--01505

Fixed, Rigid Piping

This pump is equipped with an integral suction accumulator chamber which promotes an efficient

flow of liquid and acts as an air cushion against

shock. Since the air in this chamber will leak away

during pump operation, the air must be replenished periodically. To introduce air into the chamber, stop the pump and remove the suction accumulator plug and integral gasket; this will break

prime and allow the liquid in the chamber to drain

away through the suction line.

AIR CHAMBERS

(18TO24INCHLENGTHSOF

6 TO 8 INCH DIAMETER PIPE

WITH WELDED CAPS)

DISCHARGE

CHAMBER

If the pump is mounted in a system with fixed, rigid

piping, it is recommended that a flexible connectionbeinstalledatornearthesuctionanddischarge ports to absorb shock which would otherwise be transmitted through the drive train and

greatly accelerate pump wear.

In a fixed piping installation, properly sized surge

suppressorsmust be installed in both suction and

discharge lines. If commercial surge suppressors

are not readilyavailable, air chambers may be fabricated from pipe as shown in Figure 2.

1/2-INCH VALVE FOR

RECHARGING AIR

CHAMBER WITH

COMPRESSED AIR

(ALSO ON DISCHARGE

CHAMBER)

DISCHARGE

FLEXIBLE JOINT

NOTE: INSTALL AIR CHAMBERS OFF FLOW LINE TEES

TO AVOID SURFACE TURBULENCE WITHIN CHAMBERS.

Figure 2. Fixed Piping Installation

Notethat the airchambers have not been installed

directly in the flow line, but have been installed off

tees to avoid turbulence within the chambers. The

airchambersarefittedwithvalvestopermitintroductionof small amounts of compressed air to further dampen shock; this compressed air will leak

away during operation, and should be replaced

from time to time. If the suction chamber floods,

open the suction chamber valve to break prime

and allow the liquid in chamber to drain through

the suction line.

SUCTION

CHAMBER

FLEXIBLE JOINT

SUCTION

Gauges

Ifdischarge pressure and vacuum suction gauges

aredesired, drilland tapthesuctionanddischarge

lines not less than 18 inches (457,2 mm) from the

suction and discharge ports and install the lines.

Installationcloserto the pump may result in erratic

readings.

PAGE B -- 3INSTALLATION

Page 9

OM--01505 DSERIES

SUCTION LINES

To avoidairpockets whichcould affect pumppriming, the suction line must be as short and direct as

possible.When operationinvolvesasuctionlift,the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

NOTE

Maximumpumpperformanceis realized atsuction

lifts of 5 feet or less. Use the shortest possible

lengthof suction hose or piping; lengths of 25 feet

or longer will reduce the capacity of the pump.

It is strongly recommended that no positive shutoff valve be installed in the suction line; excessive

restrictions will cause incomplete filling of the diaphragm chamber and result in short diaphragm

life.

Fittings

Suction lines shouldbe the same size as the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be installedwith the flat part ofthe reducers uppermost

to avoid creating air pockets. The suction line

shouldnot be restricted morethan 1 inch belowthe

nominal suction size.

The use of pipe couplings in the suction line is not

recommended.

of solids larger than the solids handling capability

of the pump.

This pump is designed to handle up to 2-1/4 inch

(57,2 mm) diameter spherical solids.

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an airtight seal. Follow the sealant manufacturer’s recommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

DISCHARGE LINES

Thedischargelinemustbethesamesize

as,or largerthan,thesuctionline. Neverinstall or operate thepump with a discharge

line smaller than the suction; a restricted

dischargeline will cause excessive friction

loss resulting in overloading and destruction of pump and drive components.

Siphoning

Donot terminate the discharge lineat a level lower

than that of the liquid being pumped unless a siphon breaker is used in the line. Otherwise, a siphoning action causing damage to the pump

could result.

Valves

Strainers

If a strainer is furnished with the pump, be certain

touseit; any sphericalsolidswhichpass througha

strainer furnished with the pump will also pass

through the pump itself.

If a s trainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

three or four times the crosssection of the suction

line,and that the openings will not permit passage

PAGE B -- 4 INSTALLATION

Thepumpisprovidedwithintegralsuctionanddischarge check valves.

Never install a positive shut-off valve inthe

discharge line; discharge restrictions will

cause excessive friction loss resulting in

overloading and destruction of pump and

drive components. It is strongly recom-

Page 10

DSERIES OM--01505

mended that unless absolutely necessary,

nopositiveshut-off valvebe installedinthe

suction line; excessive restriction will

cause incomplete filling of the diaphragm

chamber and result in shortened diaphragm life.

ALIGNMENT

Beforeattempting toopenorservic e the

pump:

1. Familiarize yourself with this manual.

2. Shut off incoming powertothemotorand lock itouttoensurethatthe

pump will remain inoperative.

3. Allowthe pump to completelycool

if overheated.

4. Close the discharge valve (if

used).

5. Drain the pump.

To check parallel adjustment, lay a straightedge

acrossbothcouplinghalvesatthe top, bottomand

sides. The horizontal parallel adjustment is correct

when the straightedge rests evenlyon both halves

ofthe couplingatall points.Use afeeler gaugebetween the coupling to measure any misalignment.

Donot operate the pump without the eccentric and coupling guards in place

over the rotating parts. Exposed rotating parts can catch clothing, fingers, or

tools, causing severe injury to personnel.

ELECTRICAL CONNECTIONS

Beforeconnecting the motorto the incomingpower, check that the electrical service available

matches the pump motor requirements stamped

on the motor nameplate.

It is imperative that alignment be checked

before the pump is operated.

The pump and gearbox were aligned andsecured

at the factory, but fastening hardware may have

loosenedduring shipment. It is imperative thatthis

hardware and the alignment be checked after the

pump is installed and before operation. Adjustments may be made by loosening the securing

hardware and shifting or shimming components

as required.

This pump is designed to be driven by a flexcoupled electric motor.

Tocheck couplingalignment,use a feelergaugeor

taper gauge between the coupling halves every

90_. The coupling is in alignment when the hubs

are the same distance apart at all points.

The pump must be operated in the direction indicated bythe arrow on thegearbox

andon the accompanying decals.Reverse

rotationcould causepumpcomponentsto

be destroyed.

Install and operate only an explosion

proof motor in an explosive atmosphere. Install, connect, and operate

the motor in accordance with the National Electric Code and all local codes.

Ifthereisa conflictbetween the instructions in the manual accompanying the

unit and the National Electric Code or

the applicable local code, the National

or local code shall take precedence.

PAGE B -- 5INSTALLATION

Page 11

DSERIES

OM--01505

OPERATION --- SECTION C

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and

decals attached to the pump.

This pump is designed to handle nonvolatile non-flammable liquids containing specified entrained solids. Do not

attempt to pump volatile, corrosive, or

flammable liquids which may damage

the pump or endanger personnel as a

result of pump failure.

Afterthe pump hasbeeninstalled,block

the wheels and secure the pump to prevent creeping. Make certain that the

pump and all piping or hose connections are tight, properly supported and

secure before operation.

Pump applicationwill affectits performance,especially discharge velocities. Consult the GormanRupp factory for actual performance levels for the

pump.

Install the pump and piping as described in IN-

STALLATION. Make sure that the piping connections are tight, and t hat the pump is securely

mounted. Check that componentsare properly lubricated (see LUBRICATION in MAINTENANCE

AND REPAIR).

valve should be installed in the discharge

line.

STARTING

Consult the operations manual furnished with the

motor before starting the pump. Open any valves

installed in the suction line and start the pump.

Rotation

The correct direction of rotation is indicated by an

arrowon the gearboxaccompanying decals. If the

pump is operated in the wrong direction, pump

components may be seriously damaged or destroyedsince the integral check valves permit flow

in only one direction.

The pump must be operated in the direction indicated bythe arrow on thegearbox

andon the accompanying decals.Reverse

rotationcould causepumpcomponentsto

be destroyed.

If an electric motor is used to drive the pump, remove V-belts, couplings, or otherwise disconnect

the pump from the motor before checking motor

rotation. Operate the motor independently while

observingthe direction of the motor shaft, or cooling fan.

Ifrotationisincorrect on athree -phase motor,have

a qualified electrician interchange any two of the

three phase wires to change direction.If rotationis

incorrect on asingle-phase motor,consult theliterature supplied with the motor for specific instructions.

OPERATION

Make certain that any positive shut-off

valve installed in the suction line is open

before operating the pump; excessive restriction will cause incomplete filling of the

diaphragm chamber and result in shortened diaphragm life. No positive shut-off

OPERATION PAGE C -- 1

The pump is designed to operate at approximately 52 cycles per minute through

Page 12

OM--01505 DSERIES

a gearbox with A 33.34:1 ratio and a 1750

RPM maximum input drive. Make certain

that the electric motor installed does not

exceed this rpm; otherwise, pumpcomponents may be destroyed.

Priming

Thepumpmaynotprimeimmediatelybecausethe

suction linemust firstfill with liquid. Ifthe pumpfails

to prime within five minutes, stop the motor and

check the suction line for leaks.

OPERATION CHECKS

Gearbox Check

Check that the gearbox is properlylubricated (see

LUBRICATION in MAINTENANCE AND REPAIR).

Leakage Check

Ifthepumpwillbeidleformorethanafew hours,or

if it has been pumping liquids containing a large

amount of solids, flush it with clean water .

Cold Weather Preservation

The primary construction materials of this

pump are aluminum, with neoprene flap

valves and diaphragm. Do not attempt to

clean or flush this pump with any liquid

which would attack pump fittings or components. avoid cleaning with cleaning solvent.

In below freezing conditions, drain the water from

thepump and thelineswhen the pump isnotinoperation.Also,cleanoutanysolidsbyflushingwitha

hose.

No leakage should be visible at pump matingsurfaces,connectionsor fittings. Keepalllineconnections and fittings tight to maintain maximum pump

efficiency.

Strainer Check

If a suction strainer has been installed, check and

cleanit as necessary. It shouldbe cleanedif pump

flowbeginsto drop. Ifa vacuum suction gaugehas

been installed, monitor and record the readings

regularly to detect strainer blockage.

Accumulator Chamber Check

Check periodicallyto ensure that there is sufficient

air in the integral suction accumulator chamber.

Replenish as required (see Fixed, Rigid Piping in

Section B for details).

STOPPING

After stopping the pump, shut off incoming power

tothemotorand lockitouttoensurethat thepump

will remain inoperative.

GEARBOX TEMPERATURE CHECK

The gearbox runs higher than ambient temperatures because of heat generated by friction. Temperatures of approximately 200_F(93_C) are con-

sidered normal, and can operate intermittently at

250_F (121_C).

Checking gearbox temperatures by hand is inaccurate. Place a contact-type thermometer against

the housing and recordthis temperature for future

reference.

A sudden increase in gearbox temperature is a

warningthat thebearings are at the pointof failing.

Make certain that the bearing lubricant is of the

proper viscosity and at the correct level (see LU-

BRICATION in Section E). Bearing overheating

can also be caused by shaft misalignment and/or

excessive vibration.

When pumps are first started, the bearings may

seem to run at temperatures above normal. Continued operation should bring t he temperatures

down to normal levels within 20 minutes or less.

OPERATIONPAGE C -- 2

Page 13

DSERIES OM--01505

TROUBLESHOOTING --- SECTION D

Review all SAFETY information in Section A.

Beforeattemptingto open orservicethe

pump:

1. Familiarize yourselfwith this manual.

2. Shut off incoming power to the motor

and lock it out to ensure that the

pump will remain inoperative.

3. Allow the pump to completely cool if

overheated.

4.Closethedischargevalve(ifused).

5. Drain the pump.

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PUMP FAILS TO

PRIME

PUMP STOPS OR

FAILS TO DELIVER

RATED FLOW OR

PRESSURE

Air leak in suction line. Correct leak.

Lining of suction hose collapsed. Replace suction hose.

Integral suction or discharge check Clean valves, check that flange nuts

valve clogged, binding, or not seating are tight.

properly.

Cracked or broken diaphragm. Replace diaphragm.

Diaphragm not securely in place. Secure diaphragm.

Strainer clogged. Checkstrainerandcleanifnecessary.

Air leak in suction line. Correct leak.

Suction intake not properly submerged. Check installation.

Lining of suction hose collapsed. Replace suction hose.

Cracked or broken diaphragm. Replace diaphragm.

Diaphragm not securely in place. Secure diaphragm.

Strainer clogged. Checkstrainerandcleanifnecessary.

Integral suction or discharge check Clean valves, check that flange nuts

valve clogged, binding, or not seating are tight.

properly.

TROUBLESHOOTING PAGE D -- 1

Page 14

OM--01505 DSERIES

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PUMP REQUIRES

TOO MUCH

POWER

PUMP

CLOGS FREQUENTLY

EXCESSIVE NOISE

BEARINGS

RUN TOO HOT

Liquid solution too thick. Dilute if possible.

Integral discharge check valve clogged Clean valve.

or binding.

Bearings in motor or gearbox Check bearings.

worn or binding.

Integral suction or discharge check Clean valves, check that flange nuts

valve clogged, binding, or not seating are tight.

properly.

Liquid solution too thick. Dilute if possible.

Pump, gearbox, or motor not Check and tighten mounting bolts.

securely mounted.

Gearbox or motor not properly See LUBRICATION in MAINTE-

lubricated. NANCE AND REPAIR.

Bearing temperature is high, but within Check bearing temperature regularly

limits. to monitor any increase.

Low or incorrect lubricant. Check for proper type and level of

lubricant.

Drive misaligned. Align drive properly.

TROUBLESHOOTINGPAGE D -- 2

Page 15

DSERIES OM--01505

PUMP MAINTENANCE AND REPAIR - SECTION E

MAINTENANCE AND REPAIROF THEWEARING PARTSOFTHEPUMP WILLMAINTAINPEAKOPERATING PERFORMANCE.

INGALLONSPERMINUTEAT52STROKESPERMINUTE

STATIC

LIFT

IN FEET

5 150 119 113 112

10 126 108 105 105

20 94 74 73 66

STATIC

LIFT

IN METERS

1,5 567,8 450,4 427,7 423,9

3,0 476,9 408,8 397,4 397,4

4,6 370,9 283,8 280,1 276,3

6,1 355,8 280,1 276,3 249,8

0101520

IN LITERS PER MINUTE AT 52 STROKES PER MINUTE

0 3,0 4,6 6,1

STATIC DISCHARGE HEAD IN FEET

5

125

118

97

82

82

STATIC DISCHARGE HEAD IN METERS

1,5

473,1

446,6

367,1

310,3

25

104

100

7374759815

6066707425

70

63

52

7,6

393,6

378,5

264,9

238,4

7,6 280,1 264,9 249,8 227,1

STANDARD PERFORMANCE TEST DATA FOR PUMP MODEL 4D-B

Based on 70_ F(21_ C) clear water at sea level

with minimum suction lift, using 3 inch (7,62 cm)

suctionhoseand4inch(10,16cm) non-collapsible

discharge hose. Since pump installations are seldom identical, your performance may be different

due to such factors as viscosity, specific gravity,

MAINTENANCE & REPAIR PAGE E -- 1

310,3

elevation, temperature, and impeller trim.

If your pump serial number is followed by an “N”,

your pump is NOT astandardproductionmodel.

Contact the Gorman-Rupp Company to verify performance or part numbers.

196,8

Page 16

SECTION DRAWING

DSERIESOM--01505

Figure 1. Pump Model 4D-B

MAINTENANCE & REPAIRPAGE E -- 2

Page 17

DSERIES OM--01505

PARTS LIST

Pump Model 4D-B

(From S/N 461594 up)

Ifyour pump serialnumber is followedbyan “N”,your pumpis NOT a standard production model. Contact

the Gorman-Rupp Company to verify part numbers.

ITEM

PART NAME PART

NO.

NUMBER

MAT’L

CODE

QTY ITEM

NO.

PART NAME PART

NUMBER

MAT’L

CODE

QTY

1 COUPLING DRIVE SHAFT 34355---105 --------- 1

2 COUPLING MTR SHAFT 24355---112 --------- 1

3

SPIDER 24355---267 ------ --- 1

4 COUPLING GUARD 34613---045 15020 1

5 KEY N0405 15990 1

6 MOTOR NOT FURNISHED

7 BASE 13485 24000 1

8 AXLE 6619 15990 1

9 SPACER 6619A 15070 2

10 COTTER PIN M0306 15990 2

11 FLAT WASHER S1532 -- ------- 4

12

PN EU MATIC WHE EL S263 --- --- --- 2

13 U---BOLT 6945 15000 2

14 HEX NUT D06 15991 4

15 LOCKWASHER J06 15991 4

16 HEX HD CAPSCREW B0404 15991 2

17 FLAT WASHER K04 15991 2

18 LOCKWASHER J04 15991 2

19 HEX NUT D04 15991 2

20 DIAPHRAGM RING 6621 13010 1

21 DRAW BAR 5438 15990 1

22 PLUNGER ROD ASSY 6959 --- --- - -- 1

23 LU B FIT TIN G S19 1 --- --- --- 1

24 END CAP 6643 10010 1

25 GEARBOX ASSY 44161---009 --- --- --- 1

26 HEX HD CAPSCREW B1010 15991 4

27 LOCKWASHER J10 15991 4

28 HEX HD CAPSCREW B1211 15991 4

29 LOCKWASHER J12 15991 4

30 HEX NUT D12 15991 4

31 DIAPHRAGM POT ASSY 46475---702 - -------- 1

32 U---BOLT 5495 15991 2

33 HEX NUT D06 15991 4

34 LOCKWASHER J06 15991 4

35 HEX HD CAPSCREW B0402 1/2 15991 2

36 T TYPE LOCK WASHER AK04 15991 2

37 FLAT WASHER K04 15991 2

38 LUBE DECAL 38817---066 --- --- --- 1

39 ECCENTRIC GUARD 38861- --504 23200 1

40 NYLOCK CAP SCREW BT0403 15991 1

41 WA SH ER S1 57 --- --- --- 1

42 FLAT WASHER K04 15991 1

43 GUARD WARNING STKER 38816---063 --------- 1

NOT SHOWN:

NAME PLATE 2613BP 13990 1

DRIVE SCREW BM#04---03 17000 4

STRAINER 4917 24001 1

DISCHARGE STICKER 6588BJ --- --- --- 1

SUCTION STICKER 6588AG --------- 1

INSTRUCTION TAG 38817---031 --------- 1

OPTIONAL:

STATIONARY BASE 8283 24000 1

INDICATES PARTS RECOMMENDED FOR STOCK

MAINTENANCE & REPAIR PAGE E -- 3

Page 18

DISCHARGE

30

29

28

25

27

26

SECTION DRAWING

NOTE:

FLAP VAL VE ASSEMBLY SHOWN IN POSITION ON DISCHARGE SIDE. SUCTION SIDE

TO OPEN IN SAME DIRECTION.

32

37

36

35

34

DSERIESOM--01505

SUCTION

23

22

21

20

24

33

31

2

1

3

1213141516171819

Figure 2. 46475---702 Diaphragm Pot Assembly

MAINTENANCE & REPAIRPAGE E -- 4

,,,,,,

4567891011

Page 19

DSERIES OM--01505

PARTS LIST

46475---702 Diaphragm Pot Assembly

ITEM

NO.

1 DIAPHRAGM POT 6622 13010 1

2 SUCT ACCUMULATOR PLUG AND GASKET S591A --- --- --- 1

3 SUCTION ACCUMULATOR 6625 13010 1

4 REDUCER PIPE BUSHING AP6448 11990 1

5 HEX HD CAPSCREW B0504 15991 2

6 LOCKWASHER J05 15991 2

7 STUD C1013 15991 2

8 FLAT WASHER KE10 15991 2

9 HEX NUT D10 15991 2

10

11 DIAPHRAGM POT DRAIN PLUG P06 11990 1

12

13 STUD C1010 15991 2

14 FLAT WASHER KE10 15991 2

15 HEX NUT D10 15991 2

16 HEX HD CAPSCREW B0504 15991 2

17 LOCKWASHER J05 15991 2

18 DISCHARGE FLANGE 6627 13040 1

19

20 STUD C1013 15991 2

21 FLAT WASHER KE10 15991 2

22 HEX NUT D10 15991 2

23 DISCHARGE ELBOW 6626 13040 1

24 VALVE SEAT 6635 10010 1

25 DISCHARGE FLAP VALVE ASSY 46413---007 --------- 1

26 ---VALVE WEIGHT 6801 15990 1

27

28 ---VALVE WEIGHT 6642 15990 1

29 ---RD HD MACHINE SCREW X0402 1/2 17090 4

30 ---LOCKWASHER J04 17090 4

31 VALVE SEAT 6635 10010 1

32 SUCTION FLAP VALVE ASSY 46413---007 ------ --- 1

33 ---VALVE WEIGHT 6642 15990 1

34 ---VALVE WEIGHT 6801 15990 1

35 ---RD HD MACHINE SCREW X0402 1/2 17090 4

36 ---LOCKWASHER J04 17090 4

37

PART NAME

SUCTION ACCUMULATOR GASKET 6625G 19100 1

DISCHARGE FLANGE GASKET 6625G 19100 1

DISCHARGE ELBOW GASKET 6625G 19100 1

---FLAP VALVE 6925 19100 1

---FLAP VALVE 6925 19100 1

PART

NUMBER

MAT’L

CODE

QTY

INDICATES PARTS RECOMMENDED FOR STOCK

MAINTENANCE & REPAIR PAGE E -- 5

Page 20

13

DSERIESOM--01505

SECTION DRAWING

234

,,

1

5

10

12

8.00 REF

10.78 HOLD

11

Figure 3. 6959 Plunger Rod Assembly

6789

MAINTENANCE & REPAIRPAGE E -- 6

Page 21

DSERIES OM--01505

PARTS LIST

6959 Plunger Rod Assembly

ITEM

NO.

1 BEARING CAP 6560 10010 1

2 ---HEX HD CAPSCREW B0813S 15991 2

3 ---HEX NUT D08S 15991 2

4 ---LOCKWASHER J08 15991 2

5 PLUNGER ROD ASSEMBLY 6633 15990 1

6

7 LUBRICATION FITTING S194 --- --- --- 1

8 DIAPHRAGM PLATE 6629 15990 1

9 DIAPHRAGM PLATE 6628 10010 1

10 HEX NUT D08 15991 4

11 SPRING WASHER 6639 15000 1

12 SPRING 6547 16080 1

13 SPRING RETAINING NUT 6638 11000 1

INDICATES PARTS RECOMMENDED FOR STOCK

PART NAME

DIAPHRAGM S1017 --- --- --- 1

PART

NUMBER

MAT’L

CODE

QTY

MAINTENANCE & REPAIR PAGE E -- 7

Page 22

SECTION DRAWING

DSERIESOM--01505

Figure 4. 44161---009 Gearbox Assembly

MAINTENANCE & REPAIRPAGE E -- 8

Page 23

DSERIES OM--01505

PARTS LIST

44161---009 Gearbox Assembly

ITEM

PART NAME PART

NO.

NUMBER

MAT’L

CODE

QTY ITEM

NO.

PART NAME PART

NUMBER

MAT’L

CODE

QTY

1 GEAR HOUSING 6624 13040 1

2 CR AN KSHAF T B EARIN G S 37 4 --- --- --- 1

CRANKSHAFT GEAR 6641 15060 1

3

4

GEAR HOUSING GSKT 6624G 18000 1

5 AIR VENT FITTING S2162 --------- 1

6 HEX HD CAPSCREW B0803 15991 1

7 GEAR COVER 6623 13010 1

8

CRANKSHAFT GEAR KEY N0605 15990 1

9 CRANKSHAFT BEARING S1080 --------- 1

10 HEX HD CAPSCREW B1004 15991 1

11 FLAT WASHER 21161---442 ------ -- - 1

12 WASHER 6637 15000 1

13

PINION BUSHING S1016 --- ------ 1

14 GEAR COVER PLUG S1053 --- --- --- 1

15 HEX HD CAPSCREW B0504 15991 4

16 LOCKWASHER J05 15991 4

17

DRIVE SHAFT KEY N0304 15990 1

18 DRIVE SHAFT 6631 15010 1

19

OIL SEAL S1012 --- --- --- 1

20 ECCENTRIC HOUSING 6632 10010 1

21

ECC HOUSING GSKT 6632G 18000 1

22 DRAIN PLUG P04 15079 1

23

DRIVE SHAFT BEARING S1044 --- - ----- 2

24 RETAINING R IN G S2 04 --- --- --- 1

25 DRIVE GEAR 6558 16040 1

INDICATES PARTS RECOMMENDED FOR STOCK

26

SNAP RING S1004 --- --- --- 1

27 INTERNAL GEAR S1014 --- --- -- - 1

28 PINION SHAFT 6634 16070 1

29 GEAR HOUSING PLUG S1054 --------- 1

30

PINION SHAFT BUSHING S1015 --- --- --- 1

31 WASHER 6636 15990 1

32

SN AP RI NG S24 4 --- --- --- 1

CRANKSHAFT ROLLER S1011 --- --- --- 1

33

BEARING

34 RETAINING R IN G S44 2 --- --- --- 1

35

CRANKSHAFT 6550 11000 1

36

SNAP RING S1010 --- --- --- 1

37 HEX HD CAPSCREW B0511 15991 5

38 LOCKWASHER J05 15991 5

39 HEX NUT D05 15991 5

40 SHOULDER BOLT S1018 ------ --- 1

41 LOCKWASHER J05 15991 1

42 HEX NUT D05 15991 1

43 HEX HD CAPSCREW B0518 15991 3

44 LOCKWASHER J05 15991 3

45 HEX NUT D05 15991 3

46 O IL CU P S61 7 --- --- --- 1

47 SHOULDER BOLT S1019 ------ --- 1

48 LOCKWASHER J05 15991 1

49 HEX NUT D05 15991 1

MAINTENANCE & REPAIR PAGE E -- 9

Page 24

DSERIESOM--01505

PUMP AND SEAL DISASSEMBLY

AND REASSEMBLY

Review all SAFETY information in Section A.

Followthe instructionsonall tags, label anddecals attached to the pump.

This pump requires littleservice due to its rugged,

minimum-maintenance design. However, if it becomesnecessarytoinspectorreplacethewearing

parts, followthese instructions which are keyed to

the sectional views (see Figures 1, 2, 3 and 4) and

the accompanying parts lists.

Most service functions may be performed without

separating the pump and gearbox from t he motor.

If major repair is required, the pump, gearboxand

motor must be disconnected.

Before attempting to service the pump, shut off incomingpower tothemotorandlockitouttoensure

that it willremain inoperative. Close allvalves in the

suction and discharge lines.

For motor disassembly and repair, consult the literature supplied with the motor,orcontact your local motor representative.

Beforeattempting toopenorservic e the

pump:

1. Familiarize yourself with this manual.

2. Shut off incoming powertothemotorand lock itouttoensurethatthe

pump will remain inoperative.

3. Allowthe pump to completelycool

if overheated.

4. Close the discharge valve (if

used).

5. Drain the pump.

Before attempting to service the pump, drain the

pump by removing the drain plug (11, Figure 2).

Clean and reinstall the drain plug.

Suction And Discharge Check Valve Removal

(Figure 2)

To servicethesuctionand dischargecheck valves,

remove the suction and discharge piping.

To service the suction check valve assembly (32),

removethe suctionaccumulator(3)bydisconnecting the hardware (8 and 9) securing it to the diaphragmpot(1).Removethehardware(5and6)securing the valve seat (31) and check valve assembly to the diaphragm pot. Pull t he check valve assembly from the suction port.

To service the discharge check valve assembly

(25), loosenthe hardware (21 and 22) and remove

theassembledoutboarddischargeelbow(23),

check valve, and seat (24). Remove the gasket

(19).

Remove the hardware (16 and 17) securing the

valve seat (24) and discharge check valveassembly to the discharge elbow.

To remove the inboard dischargeflange (18),loosen the hardware (14 and15) securingthe flangeto

the diaphragm pot. Remove the gasket (12).

Thesuctionand dischargecheckvalveassemblies

are identical parts and operate in the same direction. For removal and/or replacement, remove the

hardware (29, 30, 35 and 36) securing the check

valve weights (26, 28, 33 and 34) to the check

valves (27 and 37). Inspect and replace as required.

If no further disassembly is required, see Suction

And Discharge Check Valve Installation.

Diaphragm Removal

(Figure 1)

To remove the diaphragm (6, Figure 3), disengage

the hardware (28, 29 and 30) and remove the diaphragm pot assembly(31). Inspect thediaphragm

ring (20) for wear or damage. If replacement is required, the gearbox assembly (25) and the eccentric guard (39) must be removed.

(Figure 3)

Remove the nuts (10). Separate the lower diaphragmplateassembly (8) fromthe diaphragm(6)

MAINTENANCE & REPAIRPAGE E -- 10

Page 25

OM--01505DSERIES

andtheupperdiaphragmplate(9).Inspect thediaphragm and replace a required.

If no further disassembly is required, see Dia-

phragm Installation.

Plunger Rod Removal And Disassembly

(Figure 3)

With the diaphragm pot assembly and diaphragm

removed, disengage the hardware (35, 36, 37,40,

41, and 42, Figure 1) and remove the eccentric

guard (39, Figure 1).

Loosen the hardware (2, 3 and 4) and remove the

endcap (24,Figure1). Slidethe bearingcap (1)off

the crankshaft roller bearing (33, Figure 4), and remove the plunger rod assembly.

Useasocketwrench to holdtheplungerrod(5)securely,and unscrew the bearingcap assembly(1).

Unscrewthespringretainingnut(13).Use caution

when unscrewing the retaining nut; tension on the

spring (12) will be released.

Remove the spring (12) and spring washer (11).

Slidetheplungerrod assembly(5)out of theupper

diaphragm plate (9).

Inspect t he component parts for excessive wear

and replace as required.

Gearbox Removal And Disassembly

(Figure 1)

Whenproperlyoperatedand maintained, thegearboxassembly(25)shouldnotrequiredisassembly.

Disassemble the gearbox only when there is evidenceofwearordamage.

Shaft and bearing disassembly in the field

is not recommended. These operations

should be performed only in a properly

equipped shop by qualified personnel.

remove the diaphragm ring. Inspect the diaphragmringforwearordamageandreplaceas

necessary. It is not necessary to remove the drawbar (21) from the diaphragm ring unless replacement is required.Disengage the hardware (33 and

34) from the U-bolts (32) to remove the drawbar.

Disengage the hardware (16, 17, 18 and 19) and

remove the coupling guard (4). Loosen the hardware securing the coupling(1). Separatethe gearbox assemblyfromthe couplingby pullingstraight

away. Remove the shaft key (17, Figure 4).

(Figure 4)

Before attempting to disassemble the gearboxassembly, drain the lubricant by removing the drain

plug(22)andturningthegearboxonitsside.Clean

and reinstall the drain plug.

Removethehardware(15and16)securingtheeccentrichousing(20) and housinggasket (21) tothe

gear cover (7). Pull the complete drive shaft subassembly from the gear cover.

To disassemble the drive shaft subassembly, remove the snap ring (26) and slide the drive gear

(25) off the drive shaft (18). Remove the retaining

ring(24), and press the drive shaft and assembled

bearings (23) out of the eccentric housing. Press

the oil seal (19) from the housing bore. Cover the

shaft and bearing with a clean cloth until ready to

clean and inspect the gearbox components.

Foraccess tothe remaining gearboxdrivecomponents, the gear cover (7) and gear housing gasket

(4)mustbeseparated fromthegearhousing(1)by

removing the t wo close-tolerance s houlder bolts

(40and 47), which act a s pilots to ensure accurate

concentric positioning of the cover, and the remaininghardware(37, 38,39, 41,42, 43,44, 45,48

and 49).

NOTE

The shoulder bolts and capscrews securing the

gearbox cover to the gearbox housing are of different lengths. For ease of reassembly, record the

positions of the shoulder bolts and capscrews at

thetimeofremoval.

Remove the gear housing gasket and clean allthe

mating surfaces.

Support the diaphragm ring (20) with wooden

blocks. Disengage the hardware (26 and 27), and

MAINTENANCE & REPAIR PAGE E -- 11

If the gear cover does not readily separate from the

NOTE

Page 26

DSERIESOM--01505

housing, removethe hardware(10 and11), install a

5/8-11 UNC by 4-inch long capscrew,and jack the

cover from the housing. Removethe jacking screw

and replace the hardware (10 and 11).

Afterthegearcoverhasbeenremoved,inspectthe

pinion shaft bushing (13). If replacement is required, remove the cover plug (14) and press the

pinionshaft bushing(14)fromthe coverbore.Slide

thepinionshaftwasher(12)offthepinionshaft (28)

and tag it for reference during reassembly.

Use a bearing puller to remove the crankshaft

bearing (9) from the crankshaft (35). Remove the

spacer (31).

Install two 5/8-11 UNC capscrews in the tapped

holes in the crankshaft gear (3), and use a gear

pullertoslidethegearoffthecrankshaft.Retainthe

crankshaft gear key (8). Remove the capscrews

from the gear.

Removethe snapring(36)and slide the crankshaft

and crankshaft bearing (2) out of the gearbox

housing.

To disassemble the pinion shaft and components,

slidethe shaft and assembled piniongear (27) out

of the shaft bushing (30). The pinion gear is retained on the shaft by tight friction fit and does not

normally require removal. If removal is required,

press the pinion gear from the shaft.

in cleaning solvent. Inspect the parts for wear or

damage and replace as necessary.

Most cleaning solvents are toxic and

flammable. Use themonly in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solventcontainers.

Clean the bearings thoroughly in fresh cleaning

solvent.Dry the bearings with filteredcompressed

air and coat with light oil.

Bearings must be kept free of all dirt and

foreign material. Failureto do sowillgreatly shorten bearing life. Do not spin dry

bearings. This may scratch the balls or

races and cause premature bearing failure.

Rotate the bearings by hand to check for roughnessorbinding and inspect the bearing balls.If rotation is rough or the bearing balls are discolored,

replace the bearings.

Inspect the pinion shaft bushing and, if replacement is required, remove the plug (29) and press

the bushing from the gear housing bore.

After removing the shafts and bearings, clean a nd

inspect the bearings in place as follows.

To prevent damage during removal from

the shaft, it is recommended that bearings

be cleaned and inspected in place.Itis

strongly recommended that the bearings

be replaced any time the shaft and bearings are removed.

Clean t he gear housing, shaft and all component

parts(exceptthebearings)withasoftclothsoaked

The bearing tolerances provide a tight press fit

onto the shafts and a snug slip fit into the gear

housing. Replace the bearings, shafts, eccentric

housing,or gear housingif the proper bearingfit is

not achieved.

If the bearings require replacement, remove the

bearing retaining ring (34). Remove the bearing

snap ring (32) and use a bearing puller to remove

the bearings (2, 23, and 33).

Gearbox Reassembly And Installation

(Figure 4)

Inspect the shafts (18, 28 and 35) for distortion,

nicks or scratches. Dress small nicks and burrs

with a fine file or emery cloth. Replacethe shafts if

defective.

MAINTENANCE & REPAIRPAGE E -- 12

Page 27

OM--01505DSERIES

To prevent damage during removal from

the shaft, it is recommended that bearings

be cleaned and inspected in place.Itis

strongly recommended that the bearings

be replaced any time the shaft and and

bearings are removed.

The bearings may be heated to ease installation.

An induction heater, hot oil bath, electric oven, or

hotplatemaybeusedtoheatthebearings.Bearings should never be heated with a direct flame or

directly on a hot plate.

NOTE

Ifahotoil bathisused toheatthebearings, both the

oil and the container must be absolutely clean. If

the oil has been previously used, it must be thor-

oughly filtered.

Heat the bearings to a uniform temperature no

higher than250_F(120_C), andslidethebearings

onto the shafts, one at a time, until they are fully

seated. This should be done quickly, in one continuous motion, to prevent the bearings from cooling and sticking on the shaft.

When installing the bearings onto the

shaft, never press or hit against the outer

race, balls, or ball cage. Press only onthe

inner race.

Secure the bearing (2) with the snap ring (36). Secure the crankshaft roller bearing (33) with the

snap ring (32).

Ifremoved,press thepinionshaft bushing (30)into

the gear housing until fully seated.

Use a hydraulicpress toinstallthe piniongear (27)

onto the pinion shaft (28).

NOTE

Thepinion gear is a tight interferencefit on thepinion s haft. To ease installation, the gear may be

heated (and the shaft cooled) to a temperature differentialof350_F (177_C).Ifthegearisheated,use

caution when handling the gear to prevent burns.

Slidethe assembled pinionshaft and gear into the

pinion shaft bushing until fully seated.

Slide the crankshaft and assembled bearing (2)

intothe gearhousingand secure withthesnapring

(36).

Use caution when handling hot bearings to prevent burns.

When installing the shaft and bearings into

the bearing bore, push against the outer

NOTE

The crankshaft bearing (9) must be installed after

the crankshaft gear (3).

Afterthe bearingshave beeninstalled and allowed

to cool,check to ensure that they have notmoved

out of position in shrinking. If movement has occurred, use a suitable sized sleeve and a press to

reposition the bearings.

If heating the bearings is not practical, use a suitablesizedsleeve andan arbor(or hydraulic)press

to install the bearings on the shaft.

MAINTENANCE & REPAIR PAGE E -- 13

race. Never hit the balls or ball cage.

Install the crankshaft gear key (8) in the shaft keyway. Alignthe crankshaft gear teeth with those on

thepinionshaft,andpress the gearontothecrankshaft until fully seated against the shoulder. Install

the spacer (31), and press the bearing (9) ontothe

shaft until fully seated against the spacer.

Tap theend ofthecrankshaft witha soft-facedmallet to ensure that all components are fully seated.

Ifremoved,press thepinionshaft bushing (13)into

the gear cover (7). Slide the pinion shaft washer

(12) onto the pinion shaft (28). Install the gear

Page 28

DSERIESOM--01505

housinggasket (4). Position the gearcover so that

the respective bores slip over the crankshaft bearingandpinionshaft. Tapthecover intoplace with a

soft-faced mallet.

Install the two close-tolerance shoulder bolts (40

and 47) (which act as pilots to ensure accurate

concentric positioning of the cover) through their

respective holes, and secure them with the hardware (41, 42, 48 and 49). Secure the gear cover to

thegearhousingbytighteningtheremaininghardware (37, 38, 39, 43, 44, and 45) evenly.

Installthe gear cover plug (14) and the gear housingplug(29).

Press the drive shaft and assembled bearings into

the eccentric housing (20), and secure with the retaining ring (24).

When installing the shaft and bearings into

the bearing bore, push against the outer

race. Never hit the balls or ball cage.

(Figure 1)

Position the gearbox on the base (7). Position the

diaphragm ring (20) under the base, and secure

thegearboxanddiaphragmringwith the hardware

(26 and 27).

If the drawbar (21) was removed, secure it to the

diaphragmringwith theU-bolts(32) andhardware

(33 and 34).

Reinstall the drive coupling (1), and connect the

halves. Check the coupling alignment as described in ALIGNMENT,SectionB.

Lubricate the gearbox as described in LUBRICA-

TION.

Plunger Rod Reassembly And Installation

(Figure 3)

Slide the plunger rod (5) through the upper diaphragmplate (9). Slidethe spring washer (11) and

spring (12) down over the plunger rod. Install the

springretainingnut (13),andtightenittoobtainthe

dimension shown in Figure 3.

Cleanthebearingcap(1)withaclothsoakedin

cleaning solvent.

Lubricatethe lipof the oilseal(19)withlightoil,and

position it on the drive shaft with the lip positioned

as shown in Figure4. Press the oil seal intothe eccentric housing bore untilthe face of the oil seal is

just flush with the face of the eccentric housing.

Be careful not to roll or cut the lip of the oil seal on

the shaft keyway.

Installthedrivegear(27)onthedriveshaft,andsecure with the snap ring (26).

Clean the mating surface ofthe eccentric housing

andreplace theeccentric housinggasket (21). Position the assembled eccentric housing and drive

shaftinthegearcoverborewiththeword“top”on

the eccentric housing flange facing up. Slide the

housing and drive shaft into the gearbox, making

certain the drive gear teeth fully engage those of

the pinion gear. Secure the eccentric housing to

the gear housing with the hardware (15 and 16).

Install the drive shaft key (17).

Most cleaning solvents are toxic and

flammable. Use themonly in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solventcontainers.

Inspect the bearing cap for wear or damage and

replace if necessary.

NOTE

Thebearingcapconsistsofanupperandlowerhalf

securedwith the hardware (2, 3 and 4). The cap is

machinedasonepiecebeforebeingsplittoensure

concentricityof thebore,andisavailableonlyasan

assembly.

MAINTENANCE & REPAIRPAGE E -- 14

Page 29

OM--01505DSERIES

Screw the bearing cap assembly onto the plunger

rod until fully seated against the spring retaining

nut.

Loosen the hardware (2, 3 and 4), and position the

bearing cap overthe crankshaft rollerbearing (33,

Figure 4). Secure the plunger rod assembly by

tightening the hardware (2, 3 and 4).

Secure the eccentric guard (39, Figure 1) with the

hardware (35, 36, 37, 40, 41, and 42, Figure 1).

Lubricate the plunger rod assembly as described

in LUBRICATION,SectionE.

Diaphragm Installation

(Figure 3)

Position the diaphragm (6) on the upper diaphragm plate (9), making sure the lip is properly

seated. Slide the studs in the lower diaphragm

plate(8) through the holesinthe upper diaphragm

plate, and secure with the nuts (10).

(Figure 1)

Cleanthematingsurfacesofthe valveseatanddischarge flange. Install the gasket (19) and secure

assembleddischarge elbow,check valve,andseat

to the discharge flange with the hardw are (21 and

22).

Check the operation of the check valve to ensure

proper seating and free movement.

Subassemble the suction check valve (32). Clean

the mating surfaces, and position the gasket (10),

check valveassembly,and valve seat (31)against

the diaphragm pot with the weights positioned as

shown in Figure 2. Secure with the hardw a re (5

and 6).

Check the operation of the check valve to ensure

proper seating and free movement.

Secure the suction accumulator (3) to the diaphragm pot with the hardware (8 and 9).

Connect the suction and discharge piping as described in INSTALLATION,SectionB.

Refer to OPERATION, Section C before starting

the pump.

Securethe diaphragm potassembly (31)to the diaphragm ring (20) with the hardware (28, 29 and

30).

SuctionAndDischargeCheckValveInstallation

(Figure 2)

Inspect the check valve components and replace

asrequired.Subassemblethecheckvalveweights

(26, 28, 33 and 34) and check valves (27 and 37)

with the hardware (29, 30, 35 and 36).

If the inboard discharge flange (18) was removed,

clean the mating surfaces and install the gasket

(12). Secure the flange to the diaphragm pot (1)

with the hardware (14 and 15).

Subassemble the valve seat (24) and discharge

check valve (25) to the discharge elbow (23) with

the weights positioned as shown in Figure 2, and

secure with the hardware (16 and 17).

LUBRICATION

Plunger Rod Assembly

(Figure 1)

The crankshaftroller bearing (33, Figure4)

shouldbelubricated thoroughly aftereach

8 hours of operation. Failure to do so may

cause the bearing to overheat and fail.

ApplyNo. 2 lithiumbase grease to the upper lubricationfitting(23)untilgreaseescapesfromtheend

cap (24).

Apply No. 2 lithium base grease tothe lower fitting

(7, Figure 3) until grease escapes from the top of

the upper diaphragm plate inside the spring.

MAINTENANCE & REPAIR PAGE E -- 15

Page 30

Gearbox

(Figure 4)

The gearbox was fully lubricated when shipped

fromthe factory. Check the oil level regularlyat the

oilcup(46),andkeep the oil cup full.Lubricate with

SAE No. 30 non-detergent when lubrication is required. Do not over-lubricate. Over-lubrication can

causethebearingstooverheat,resultinginpremature bearing failure.

Under normal conditions, change the oilaftereach

5000 hours of operation, or at 12 month intervals,

whichever occurs first. Change the oil more frequently if the pump if operated continuously or installed in a dirty or humid environment with rapid

temperature change.

DSERIESOM--01505

Monitor the condition of the bearing lubricantregularly for evidence of rust ormoisture condensation. This is especially important in areas where variable hot and

cold temperatures are common.

When lubricating a dry (or overhauled) gearbox,

add one ounce of ‘Molykote M Gear Guard’ and

‘top off’ with clean oil.

Forcold w eather operation,consultthefactoryora

lubricant supplier for the recommended grade of

oil.

Motor

Refer to the motor manufacturer’ s recommendations or contact your local motor representative.

MAINTENANCE & REPAIRPAGE E -- 16

Page 31

For U.S. and International Warranty Information,

Please Visit www.grpumps.com/warranty

or call:

U.S.: 419−755−1280

International: +1−419−755−1352

For Canadian Warranty Information,

Please Visit www.grcanada.com/warranty

or call:

519−631−2870

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA

Loading...

Loading...