Page 1

AC

OM-03604-OM14

December 28, 1990

Rev. E 07‐19‐12

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

D SERIES PUMP

MODEL

3D-E1.5 1P

3D-E1.5 3P

THE GORMAN‐RUPP COMPANY D MANSFIELD, OHIO

www.grpumps.com

GORMAN‐RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

e1990 The Gorman‐Rupp Company

3D-X1.5 1P

3D-X1.5 3P

Page 2

Register your new

Gorman‐Rupp pump online at

www.grpumps.com

Valid serial number and e‐mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman‐Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

Page 3

TABLE OF CONTENTS

INTRODUCTION PAGE I - 1...................................................

SAFETY ‐ SECTION A PAGE A - 1.............................................

INSTALLATION - SECTION B PAGE B - 1.....................................

Pump Dimensions PAGE B - 1........................................................

PREINSTALLATION INSPECTION PAGE B - 1...............................................

POSITIONING PUMP PAGE B - 2..........................................................

Lifting PAGE B - 2....................................................................

Mounting PAGE B - 2................................................................

SUCTION AND DISCHARGE PIPING PAGE B - 2............................................

Materials PAGE B - 2.................................................................

Line Configuration PAGE B - 2.........................................................

Fixed, Rigid Piping PAGE B - 2........................................................

Gauges PAGE B - 3..................................................................

SUCTION LINES PAGE B - 3..............................................................

Fittings PAGE B - 4..................................................................

Strainers PAGE B - 4.................................................................

Sealing PAGE B - 4..................................................................

DISCHARGE LINES PAGE B - 4...........................................................

Siphoning PAGE B - 4................................................................

Valves PAGE B - 4...................................................................

ALIGNMENT PAGE B - 4.................................................................

ELECTRICAL CONNECTIONS PAGE B - 5..................................................

OPERATION - SECTION C PAGE C - 1.......................................

STARTING PAGE C - 1...................................................................

OPERATION PAGE C - 1.................................................................

Priming PAGE C - 1..................................................................

OPERATION CHECKS PAGE C - 1.........................................................

Gearbox Check PAGE C - 1...........................................................

Leakage Check PAGE C - 1...........................................................

Strainer Check PAGE C - 1............................................................

Accumulator Chamber Check PAGE C - 1..............................................

STOPPING PAGE C - 2...................................................................

Cold Weather Preservation PAGE C - 2.................................................

GEARBOX TEMPERATURE CHECK PAGE C - 2.............................................

TROUBLESHOOTING - SECTION D PAGE D - 1...............................

PUMP MAINTENANCE AND REPAIR ‐ SECTION E PAGE E - 1..................

STANDARD PERFORMANCE CHART PAGE E - 1...........................................

PARTS LISTS:

Pump Model PAGE E - 3.............................................................

Diaphragm Pot Assembly PAGE E - 5..................................................

Plunger Rod Assembly PAGE E - 7....................................................

Gearbox Assembly PAGE E - 9........................................................

i

Page 4

TABLE OF CONTENTS

(continued)

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E - 10...........................

Suction And Discharge Check Valve Removal PAGE E - 10...............................

Diaphragm Removal PAGE E - 10......................................................

Plunger Rod Removal And Disassembly PAGE E - 11....................................

Gearbox Removal And Disassembly PAGE E - 11........................................

Gearbox Reassembly And Installation PAGE E - 13......................................

Plunger Rod Reassembly And Installation PAGE E - 14...................................

Diaphragm Installation PAGE E - 15....................................................

Suction And Discharge Check Valve Installation PAGE E - 15.............................

LUBRICATION PAGE E - 15...............................................................

Plunger Rod Assembly PAGE E - 15...................................................

Gearbox PAGE E - 16................................................................

ii

Page 5

D SERIES

INTRODUCTION

Thank You for purchasing a Gorman‐Rupp pump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

This Installation, Operation, and Maintenance

manual is designed to help you achieve the best

performance and longest life from your Gorman‐

Rupp pump.

This is a D Series, positive displacement pump,

utilizing a single‐action diaphragm to produce a

straight‐through flow of liquid. The pump is flex‐

coupled to a 1.5 HP electric motor. It is ideally

suited to industrial and contractor's applications

since it will handle liquids ranging from clear water

to construction‐site muck. The basic material of

construction for wetted parts is aluminum, with

neoprene flap valves and a DuraBlue 1000t dia

phragm.

If there are any questions regarding the pump or

its application which are not covered in this man

ual or in other literature accompanying this unit,

please contact your Gorman‐Rupp distributor, or:

OM-03604

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure re

quired and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

The Gorman‐Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-1217

Phone: (419) 755-1011

or:

Gorman‐Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631-2870

The following are used to alert maintenance per

sonnel to procedures which require special atten

tion, to those which could damage equipment, and

to those which could be dangerous to personnel:

Hazards or unsafe practices which COULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possi

ble damage which could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation,and

maintenance, or which clarify a procedure.

PAGE I - 1INTRODUCTION

Page 6

D SERIES

SAFETY ‐ SECTION A

This information applies to D Series

electric motor driven diaphragm

pumps. Refer to the manual accompa

nying the motor before attempting to

begin operation.

Before attempting to open or service the

pump:

1. Familiarize yourself with this man

ual.

2. Lock out and tag out incoming

power to the motor to ensure that

the pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Drain the pump.

This pump is designed to handle non‐

volatile non‐flammable liquids contain

ing specified entrained solids. Do not

attempt to pump volatile, corrosive, or

flammable liquids which may damage

the pump or endanger personnel as a

result of pump failure.

After the pump has been installed, block

the wheels and secure the pump to pre

vent creeping. Make certain that the

pump and all piping or hose connec

tions are tight, properly supported and

secure before operation.

OM-03604

All electrical connections must be in ac

cordance with the National Electric

Code. If there is a conflict between in

structions provided and N.E.C. specifi

cations, N.E.C. specifications shall take

precedence. All electrical equipment

supplied with this pump was in confor

mance with N.E.C. requirements in ef

fect on the date of manufacture. Failure

to follow applicable specifications, or

substitution of electrical parts not sup

plied or approved by the manufacturer,

can result in severe injury or death.

Do not operate the pump without the ec

centric and coupling guards in place

over the rotating parts. Exposed rotat

ing parts can catch clothing, fingers, or

tools, causing severe injury to person

nel.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Obtain the services of a

qualified electrician to make all electri

cal connections. Make certain the pump

and motor are properly grounded; never

use gas pipe as an electrical ground. Be

sure that the incoming power matches

the voltage and phase of the motor be

fore making motor connections. Do not

run the pump if the voltage is not within

limits.

PAGE A - 1SAFETY

Page 7

Do not install and operate a non‐explo

sion proof motor in an explosive atmo

sphere. Install, connect, and operate

the motor in accordance with The Na

tional Electric Code and all local codes.

If there is a conflict between the instruc

tions in the manual accompanying the

unit and The National Electric Code or

the applicable local code, The National

or local code shall take precedence.

D SERIESOM-03604

Never install a positive shut‐off valve in the

discharge line; discharge restrictions will

cause excessive friction loss resulting in

overloading and destruction of pump and

drive components. It is strongly recom

mended that unless absolutely necessary,

no positive shut‐off valve be installed in the

suction line; excessive restriction will

cause incomplete filling of the diaphragm

chamber and result in shortened dia

phragm life.

PAGE A - 2 SAFETY

Page 8

D SERIES OM-03604

INSTALLATION - SECTION B

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section offers only general recommendations and

practices required to inspect, position, and ar

range the pump and piping.

OUTLINE DRAWING

For further assistance, contact your Gorman‐Rupp

distributor or the Gorman‐Rupp Company.

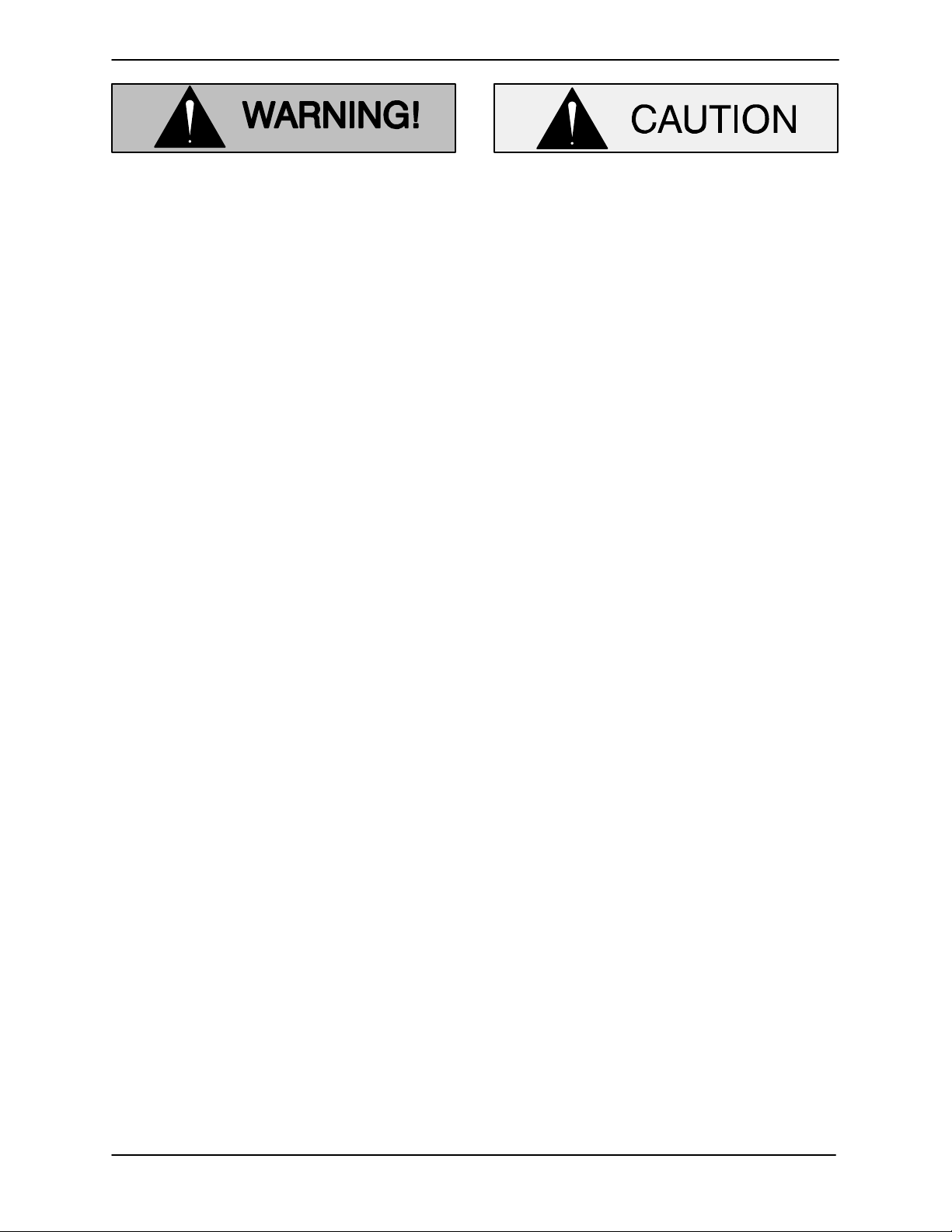

Pump Dimensions

See Figure 1 for the approximate physical dimen

sions of this pump.

Figure 1. Pump Model 3D‐E/X1.5 All Voltages

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be

fore shipment from the factory. Before installation,

inspect the pump for damage which may have oc

curred during shipment. Check as follows:

a. Inspect the pump for cracks, dents, damaged

threads, and other obvious damage.

b. Check for and tighten loose attaching hard

ware. Since gaskets tend to shrink after dry

ing, check for loose hardware at mating sur

faces.

c. Carefully read all tags, decals, and markings

on the pump assembly, and perform all duties

indicated.

d. Check levels and lubricate as necessary. Re

fer to LUBRICATION in the MAINTENANCE

AND REPAIR section of this manual and per

form duties as instructed.

e. If the pump and motor have been stored for

more than 12 months, some of the compo

nents or lubricants may have exceeded their

maximum shelf life. These must be inspected

PAGE B - 1INSTALLATION

Page 9

OM-03604 D SERIES

or replaced to ensure maximum pump serv

ice.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman‐Rupp distributor or the factory to deter

mine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

POSITIONING PUMP

Do not install and operate a non‐explo

sion proof motor in an explosive atmo

sphere.

Lifting

After the pump has been positioned, block the

wheels and secure the pump to prevent creeping.

SUCTION AND DISCHARGE PIPING

Pump performance is adversely effected by in

creased suction lift, discharge elevation, and fric

tion losses. See Page E‐1 to be sure your overall

application allows the pump to operate within the

safe operation range.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatible with the liquid being pumped. If hose is

used in suction lines, it must be the rigid‐wall, rein

forced type to prevent collapse under suction. Us

ing piping couplings in suction lines is not recom

mended.

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer‐installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

The pump assembly can be seriously

damaged if the cables or chains used to lift

and move the unit are improperly wrapped

around the pump.

Mounting

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mount

ing is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibra

tion.

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make mini

mum use of elbows and fittings, which substan

tially increase friction loss. If elbows are necessary,

use the long‐radius type to minimize friction loss.

Never pull a line into place by tightening connec

tions at the pump. Lines near the pump must be in

dependently supported to avoid strain on the

pump which could cause excessive vibration and

increased diaphragm and gear train wear. If hose‐

type lines are used, they should have adequate

support to secure them when filled with liquid and

under pressure.

Fixed, Rigid Piping

This pump is equipped with an integral suction ac

cumulator chamber which promotes an efficient

flow of liquid and acts as an air cushion against

shock. Since the air in this chamber will leak away

during pump operation, the air must be replen

ished periodically. To introduce air into the cham

ber, stop the pump and remove the suction accu

mulator plug and integral gasket; this will break

PAGE B - 2 INSTALLATION

Page 10

D SERIES OM-03604

prime and allow the liquid in the chamber to drain

away through the suction line.

If the pump is mounted in a system with fixed, rigid

piping, it is recommended that a flexible connec

tion be installed at or near the suction and dis

charge ports to absorb shock which would other

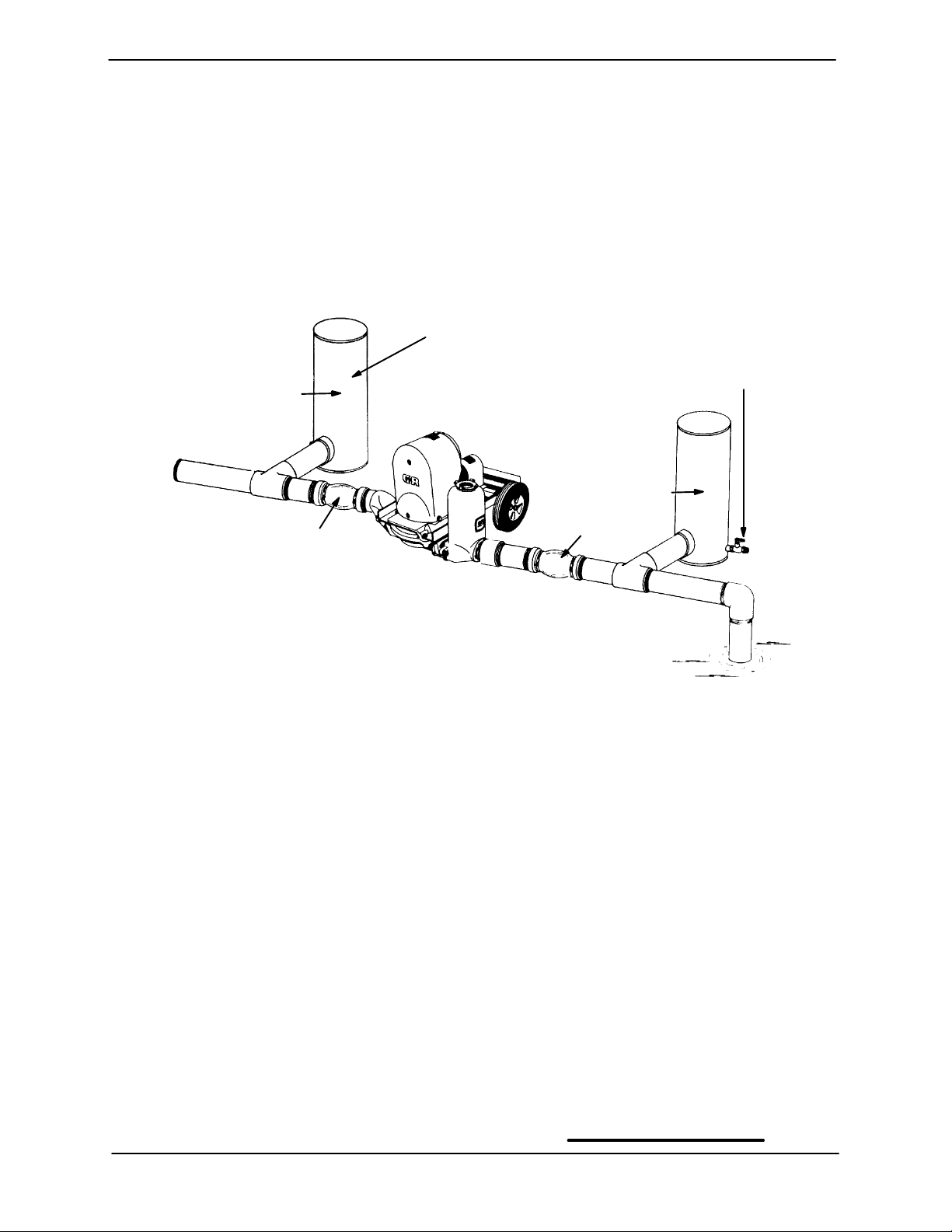

AIR CHAMBERS

(18 TO 24 INCH LENGTHS OF

6 TO 8 INCH DIAMETER PIPE

WITH WELDED CAPS)

DISCHARGE

CHAMBER

DISCHARGE

FLEXIBLE JOINT

wise be transmitted through the drive train and

greatly accelerate pump wear.

In a fixed piping installation, properly sized surge

suppressors must be installed in both suction and

discharge lines. If commercial surge suppressors

are not readily available, air chambers may be fab

ricated from pipe as shown in Figure 2.

1/2‐INCH VALVE FOR

RECHARGING AIR

CHAMBER WITH

COMPRESSED AIR

(ALSO ON DISCHARGE

CHAMBER)

SUCTION

CHAMBER

FLEXIBLE JOINT

NOTE: INSTALL AIR CHAMBERS OFF FLOW LINE TEES

TO AVOID SURFACE TURBULENCE WITHIN CHAMBERS.

Figure 2. Fixed Piping Installation

Note that the air chambers have not been installed

directly in the flow line, but have been installed off

tees to avoid turbulence within the chambers. The

air chambers are fitted with valves to permit intro

duction of small amounts of compressed air to fur

ther dampen shock; this compressed air will leak

away during operation, and should be replaced

from time to time. If the suction chamber floods,

open the suction chamber valve to break prime

and allow the liquid in chamber to drain through

the suction line.

Gauges

If discharge pressure and vacuum suction gauges

are desired, drill and tap the suction and discharge

lines not less than 18 inches (457,2 mm) from the

suction and discharge ports and install the lines.

SUCTION

Installation closer to the pump may result in erratic

readings.

SUCTION LINES

To avoid air pockets which could affect pump prim

ing, the suction line must be as short and direct as

possible. When operation involves a suction lift, the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

NOTE

Maximum pump performance is realized at suction

lifts of 5 feet (1,5 m) or less. Use the shortest possi

ble length of suction hose or piping; lengths of 25

feet (7,6 m) or longer will reduce the capacity of the

pump.

PAGE B - 3INSTALLATION

Page 11

OM-03604 D SERIES

It is strongly recommended that no positive shut‐

off valve be installed in the suction line; excessive

restrictions will cause incomplete filling of the dia

phragm chamber and result in short diaphragm

life.

Fittings

Suction lines should be the same size as the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be in

stalled with the flat part of the reducers uppermost

to avoid creating air pockets. The suction line

should not be restricted more than 1 inch below the

nominal suction size.

The use of pipe couplings in the suction line is not

recommended.

DISCHARGE LINES

The discharge line must be the same size

as, or larger than, the suction line. Never in

stall or operate the pump with a discharge

line smaller than the suction; a restricted

discharge line will cause excessive friction

loss resulting in overloading and destruc

tion of pump and drive components.

Siphoning

Do not terminate the discharge line at a level lower

than that of the liquid being pumped unless a si

phon breaker is used in the line. Otherwise, a si

phoning action causing damage to the pump

could result.

Strainers

If a strainer is furnished with the pump, be certain

to use it; any spherical solids which pass through a

strainer furnished with the pump will also pass

through the pump itself.

If a strainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

three or four times the cross section of the suction

line, and that the openings will not permit passage

of solids larger than the solids handling capability

of the pump.

This pump is designed to handle up to 2‐1/4 inch

(57,2 mm) diameter spherical solids.

Sealing

Valves

The pump is provided with integral suction and dis

charge check valves.

Never install a positive shut‐off valve in the

discharge line; discharge restrictions will

cause excessive friction loss resulting in

overloading and destruction of pump and

drive components. It is strongly recom

mended that unless absolutely necessary,

no positive shut‐off valve be installed in the

suction line; excessive restriction will

cause incomplete filling of the diaphragm

chamber and result in shortened dia

phragm life.

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an air

tight seal. Follow the sealant manufacturer's rec

ommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

PAGE B - 4 INSTALLATION

ALIGNMENT

The alignment of the pump and motor is critical for

trouble‐free mechanical operation. The motor and

pump must be mounted so that their shafts are

aligned with and parallel to each other. The pump

and motor were aligned and secured at the factory,

Page 12

D SERIES OM-03604

but fastening hardware may have loosened during

shipment. It is imperative that alignment be

checked after the pump and piping are installed,

and before operation. Adjustments may be made

by loosening the securing hardware and shifting or

shimming components as required.

To check coupling alignment, use a feeler gauge or

taper gauge between the coupling halves every

_

. The coupling is in alignment when the hubs

90

are the same distance apart at all points.

To check parallel adjustment, lay a straightedge

across both coupling halves at the top, bottom,

and side. When the straightedge rests evenly on

both halves of the coupling, the coupling is in hori

zontal parallel alignment. If the coupling is

misaligned, use a feeler gauge between the cou

pling and the straightedge to measure the amount

of misalignment.

matches the pump motor requirements stamped

on the motor nameplate.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Obtain the services of a qu

alified electrician to make all electrical

connections. Make certain the pump

and motor are properly grounded; never

use gas pipe as an electrical ground. Be

sure that the incoming power matches

the voltage and phase of the motor be

fore making motor connections. Do not

run the pump if the voltage is not within

limits.

Do not operate the pump without the ec

centric and coupling guards in place

over the rotating parts. Exposed rotat

ing parts can catch clothing, fingers, or

tools, causing severe injury to person

nel.

ELECTRICAL CONNECTIONS

Before connecting the motor to the incoming

power, check that the electrical service available

Motor Data

MODEL

3D-E1.5

VOLTAGE PHASE HP Hz RPM THERMAL

115/230

230/460

1

3

Do not install and operate a non‐explo

sion proof motor in an explosive atmo

sphere. Install, connect, and operate

the motor in accordance with The Na

tional Electric Code and all local codes.

If there is a conflict between the instruc

tions in the manual accompanying the

unit and The National Electric Code or

the applicable local code, The National

or local code shall take precedence.

Refer to the following motor data before making

electrical connections.

OVERLOAD

1.5

1.5

60

60

1800

1800 N/A

N/A

3D-X1.5

115/230

230/460

1

3

1.5

1.5

60

60

1800

1800 YES

YES

PAGE B - 5INSTALLATION

Page 13

D SERIES

OM-03604

OPERATION - SECTION C

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and

decals attached to the pump.

This pump is designed to handle non‐

volatile non‐flammable liquids contain

ing specified entrained solids. Do not

attempt to pump volatile, corrosive, or

flammable liquids which may damage

the pump or endanger personnel as a

result of pump failure.

After the pump has been installed, block

the wheels and secure the pump to pre

vent creeping. Make certain that the

pump and all piping or hose connec

tions are tight, properly supported and

secure before operation.

Pump application will affect its performance, espe

cially discharge velocities. Consult the Gorman‐

Rupp factory for actual performance levels for the

pump.

striction will cause incomplete filling of the

diaphragm chamber and result in short

ened diaphragm life. No positive shut‐off

valve should be installed in the discharge

line.

STARTING

Consult the operations manual furnished with the

motor before starting the pump. Open any valves

installed in the suction line and start the pump.

OPERATION

The pump is designed to operate at ap

proximately 60 cycles per minute through

a gearbox with a 30.36:1 ratio at a maxi

mum input speed of 1800 RPM. Make cer

tain that the electric motor installed does

not exceed this RPM. Operation at higher

RPM can cause pump components to be

damaged or destroyed.

Priming

Install the pump and piping as described in IN

STALLATION. Make sure that the piping connec

tions are tight, and that the pump is securely

mounted. Check that components are properly lu

bricated (see LUBRICATION in MAINTENANCE

AND REPAIR).

Make certain that any positive shut‐off

valve installed in the suction line is open

before operating the pump; excessive re

OPERATION PAGE C - 1

The pump may not prime immediately because the

suction line must first fill with liquid. If the pump fails

to prime within five minutes, stop the engine and

check the suction line for leaks.

OPERATION CHECKS

Gearbox Check

Check that the gearbox is properly lubricated (see

LUBRICATION in MAINTENANCE AND RE

PAIR).

Page 14

OM-03604 D SERIES

Leakage Check

No leakage should be visible at pump mating sur

faces, connections or fittings. Keep all line connec

tions and fittings tight to maintain maximum pump

efficiency.

Strainer Check

If a suction strainer has been installed, check and

clean it as necessary. It should be cleaned if pump

flow begins to drop. If a vacuum suction gauge has

been installed, monitor and record the readings

regularly to detect strainer blockage.

Accumulator Chamber Check

Check periodically to ensure that there is sufficient

air in the integral suction accumulator chamber.

Replenish as required (see Fixed, Rigid Piping in

Section B for details).

Cold Weather Preservation

The primary construction materials of this

pump are aluminum, with neoprene flap

valves and a DuraBlue 1000t diaphragm.

Do not attempt to clean or flush this pump

with any liquid which would attack pump

fittings or components. Avoid cleaning

with cleaning solvent.

In below freezing conditions, drain the water from

the pump and the lines when the pump is not in op

eration. Also, clean out any solids by flushing with a

hose.

GEARBOX TEMPERATURE CHECK

The gearbox runs higher than ambient tempera

tures because of heat generated by friction. Tem

peratures of approximately 200_F (93_C) are con

sidered normal, and can operate intermittently at

250_F (121_C).

Checking gearbox temperatures by hand is inac

curate. Place a contact‐type thermometer against

the housing and record this temperature for future

reference.

STOPPING

After stopping the pump, lock out and tag out in

coming power to the motor to ensure that the

pump will remain inoperative.

If the pump will be idle for more than a few hours, or

if it has been pumping liquids containing a large

amount of solids, flush it with clean water.

A sudden increase in gearbox temperature is a

warning that the bearings are at the point of failing.

Make certain that the bearing lubricant is of the

proper viscosity and at the correct level (see LU

BRICATION in Section E). Bearing overheating

can also be caused by shaft misalignment and/or

excessive vibration.

When pumps are first started, the bearings may

seem to run at temperatures above normal. Con

tinued operation should bring the temperatures

down to normal levels.

OPERATIONPAGE C - 2

Page 15

D SERIES OM-03604

TROUBLESHOOTING - SECTION D

Review all SAFETY information in Section A.

Before attempting to open or service

the pump:

1. Familiarize yourself with this man

ual.

2. Lock out and tag out incoming

power to ensure that the pump will

remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Drain the pump.

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PUMP FAILS TO

PRIME

PUMP STOPS OR

FAILS TO DELIVER

RATED FLOW OR

PRESSURE

Air leak in suction line. Correct leak.

Lining of suction hose collapsed. Replace suction hose.

Integral suction or discharge check Clean valves, check that flange nuts

valve clogged, binding, or not seating are tight.

properly.

Cracked or broken diaphragm. Replace diaphragm.

Diaphragm not securely in place. Secure diaphragm.

Strainer clogged. Check strainer and clean if necessary.

Air leak in suction line. Correct leak.

Suction intake not properly submerged. Check installation.

Lining of suction hose collapsed. Replace suction hose.

Cracked or broken diaphragm. Replace diaphragm.

Diaphragm not securely in place. Secure diaphragm.

Strainer clogged. Check strainer and clean if necessary.

Integral suction or discharge check Clean valves, check that flange nuts

valve clogged, binding, or not seating are tight.

properly.

TROUBLESHOOTING PAGE D - 1

Page 16

OM-03604 D SERIES

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PUMP REQUIRES

TOO MUCH

POWER

PUMP CLOGS

FREQUENTLY

EXCESSIVE NOISE

BEARINGS RUN

TOO HOT

Liquid solution too thick. Dilute if possible.

Integral discharge check valve clogged Clean valve.

or binding.

Bearings in motor or gearbox Check bearings.

worn or binding.

Integral suction or discharge check Clean valves, check that flange nuts

valve clogged, binding, or not seating are tight.

properly.

Liquid solution too thick. Dilute if possible.

Pump, gearbox, or motor not Check and tighten mounting bolts.

securely mounted.

Gearbox or motor not properly See LUBRICATION in MAINTE‐

lubricated. NANCE AND REPAIR.

Bearing temperature is high, but within Check bearing temperature regularly

limits. to monitor any increase.

Low or incorrect lubricant. Check for proper type and level of

lubricant.

Drive misaligned. Align drive properly.

TROUBLESHOOTINGPAGE D - 2

Page 17

D SERIES OM-03604

PUMP MAINTENANCE AND REPAIR ‐ SECTION E

MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK

OPERATING PERFORMANCE.

IN GALLONS PER MINUTE AT 60 STROKES PER MINUTE

STATIC

LIFT

IN FEET

5786766 68

10 73 64 66 62

20 64 59 65 59

IN LITERS PER MINUTE AT 60 STROKES PER MINUTE

STATIC

LIFT

IN METERS

1,5 295,2 253,6 249,8 257,4

3,0 276,3 242,2 249,8 234,7

4,6 257,4 227,1 242,2 223,3

6,1 242,2 223,3 246,0 223,3

51015 20

1,5 3,0 4,6 6,1

STATIC DISCHARGE HEAD IN FEET

5964606815

5660565625

STATIC DISCHARGE HEAD IN METERS

7,6 212,0 212,0 227,1 212,0

STANDARD PERFORMANCE TEST DATA FOR 3D ELECTRIC MOTOR DRIVEN PUMP

Based on 70_F (21_C) clear water at sea level

with minimum suction lift, using 3 inch (7,62 cm)

suction hose and 4 inch (10,16 cm) non‐collapsible

discharge hose. Since pump installations are sel

dom identical, your performance may be differ

ence due to such factors as viscosity, specific grav

MAINTENANCE & REPAIR PAGE E - 1

ity, elevation, temperature, and impeller trim.

If your pump serial number is followed by an “N”,

your pump is NOT a standard production model.

Contact the Gorman‐Rupp Company to verify per

formance or part numbers.

Page 18

PARTS PAGE

D SERIESOM-03604

SECTION DRAWING

Figure 1. 3D Electric Motor Driven Pump

MAINTENANCE & REPAIRPAGE E - 2

Page 19

D SERIES OM-03604

PARTS LIST

Pump Model 3D‐E1.5 1P And 3D-E1.5 3P

Bill of Material Issue 14 (From S/N 883504 up

Pump Model 3D‐X1.5 1P And 3D-X1.5 3P

Bill of Material Issue 14 (From S/N 883504 up)

If your pump serial number is followed by an “N”, your pump is NOT a standard production model. Contact

the Gorman‐Rupp Company to verify part numbers.

ITEM

PART NAME PART

NO.

NUMBER

MAT'L

CODE

QTY ITEM

NO.

PART NAME PART

NUMBER

MAT'L

CODE

QTY

1 ECCENTRIC GUARD 38861-501 23200 1

2 NYLOCK CAPSCREW BT0403 15991 1

3 WASHER S157 --- 1

4 FLAT WASHER K04 15991 1

5 LUBRICATION DECAL 38817-066 --- 1

6 SNAP RING 5385 --- 1

7 GUARD WARNING DECAL 38816-063 --- 1

8 GEAR BOX ASSY 8981 --- 1

9 COUPLING GUARD 34613-005 15020 1

10 GUARD WARNING DECAL 38816-063 --- 1

11 3/4” COUPLING HALF 24355-035 --- 1

12 7/8” COUPLING HALF 24355-037 --- 1

13 SPIDER 24355-262 --- 1

14 KEY N0304 15990 1

15 HEX HD CAPSCREW B0504 15991 4

16 FLANGED HEX NUT 21765-312 --- 4

17 U‐BOLT 5495 15991 2

18 FLANGED HEX NUT 21765-314 --- 4

19 AXLE 4607AD 15990 1

20 SPACE WASHER 5382 15990 4

21 HAIRCLIP PIN 21183-010 --- 4

22 HEX HD CAPSCREW B0403 15991 2

23 FLANGED HEX NUT 21765-310 --- 2

24 BASE 13583 24000 1

25 HEX HD CAPSCREW B0608 15991 5

26 FLANGED HEX NUT 21765-314 --- 5

27 PLUNGER ROD ASSY 5685 --- 1

28 DRAW BAR 5438 15990 1

29 U-BOLT 5495 15991 2

30 FLANGED HEX NUT 21765-314 --- 4

31 SUCTION STICKER 6588AG --- 1

32 FLAT WASHER K08 15991 4

33 HEX NUT D08 15991 4

34 HEX HD CAPSCREW B0811 15991 4

35 DIAPHRAGM POT ASSY 46475-701 --- 1

36 DIAPHRAGM RING 13582 13010 1

37 PNEUMATIC WHEEL S752 --- 2

38 DISCHARGE STICKER 6588BJ --- 1

39 HEX HD CAPSCREW B0604 15991 2

40 LOCKWASHER J06 15991 2

41 HEX HD CAPSCREW B0402 1/2 15991 2

42 T TYPE LOCKWASHER AK04 15991 2

43 FLAT WASHER K04 15991 2

44 MOTOR X1.5 HP 1P 28274-040 --- 1

MOTOR X1.5 HP 3P 28274-442 --- 1

MOTOR E1.5 HP 1P 28214-040 --- 1

MOTOR E1.5 HP 3P 28214-440 --- 1

45 WARNING DECAL 2613FF --- 1

46 WARNING DECAL 2613FE --- 1

NOT SHOWN:

NAME PLATE 2613BP 13990 1

DRIVE SCREW BM#04-03 15990 4

STRAINER 4917 24001 1

TRADEMARK DECAL 38812-049 --- 1

OPTIONAL:

STATIONARY BASE 8283 24000 1

INDICATES PARTS RECOMMENDED FOR STOCK

MAINTENANCE & REPAIR PAGE E - 3

Page 20

SECTION DRAWING

D SERIESOM-03604

Figure 2. 46475-701 Diaphragm Pot Assembly

MAINTENANCE & REPAIRPAGE E - 4

Page 21

D SERIES OM-03604

PARTS LIST

46475-701 Diaphragm Pot Assembly

ITEM

NO.

1 DISCHARGE FLANGE 5658 13040 1

2 STUD C0810 15991 2

3 HEX NUT D08 15991 2

4 FLAT WASHER KE08 15991 2

5 RD HD MACHINE SCREW X0404 17090 2

6 LOCKWASHER J04 15991 2

7 RD HD MACHINE SCREW X0404 17090 2

8 LOCKWASHER J04 15991 2

9 PLUG AND GASKET S519A --- 1

10 SUCTION STUB 5376 13010 1

11 RED PIPE BUSHING AP4832 11999 1

12 STUD C0810 15991 2

13 FLAT WASHER K07 15991 2

14 HEX NUT D08 15991 2

15 VALVE SEAT 5374 10010 1

16 GASKET 5374G 19100 1

17 DIAPHRAGM POT DRAIN PLUG P06 11990 1

18 DIAPHRAGM POT 5375 13010 1

19 GASKET 5374G 19100 1

20 STUD C0809 15991 2

21 FLAT WASHER K07 15991 2

22 HEX NUT D08 15991 2

23 DISCHARGE FLANGE 5377 13040 1

24 GASKET 5374G 19100 1

25 VALVE SEAT 5374 10010 1

26 FLAP VALVE ASSY 46413-013 --- 1

27 -VALVE WEIGHT 5428 15990 1

28 -RD HD MACHINE SCREW X0403 17090 4

29 -LOCKWASHER J04 17090 4

30 -VALVE WEIGHT 5426 15990 1

31 -FLAP VALVE 5427 19100 1

PART NAME

PART

NUMBER

MAT'L

CODE

QTY

INDICATES PARTS RECOMMENDED FOR STOCK

MAINTENANCE & REPAIR PAGE E - 5

Page 22

SECTION DRAWING

D SERIESOM-03604

Figure 3. STANDARD 5685 AND OPTIONAL 5685B Plunger Rod Assembly

MAINTENANCE & REPAIRPAGE E - 6

Page 23

D SERIES OM-03604

PARTS LIST

5685 Standard Plunger Rod Assembly And

5685B Optional Plunger Rod Assembly

ITEM

NO.

1 ECCENTRIC CAP 5373 13010 1

2 ECCENTRIC BEARING 5610 14000 1

3 T‐TYPE LOCK WASHER AK12 15991 1

4 JAM NUT AT12 15991 1

5 SPRING WASHER 5384 15991 1

6 SPRING 5398 16081 1

7 FLAT WASHER K20 15991 1

8 DIAPHRAGM PLATE 5381 10010 1

9 DIAPHRAGM (5685) 26844-041 --- 1

10 DIAPHRAGM PLATE ASSY 5394 --- 1

11 -DIAPHRAGM PLATE NOT AVAILABLE 1

12 -STUD NOT AVAILABLE 3

13 HEX NUT D08 15991 3

14 HEX HEAD CAPSCREW 21612-577 --- 1

15 LUBE FITTING S191 --- 1

16 LUBE FITTING S191 --- 1

INDICATES PARTS RECOMMENDED FOR STOCK

PART NAME

DIAPHRAGM (5685B) S1042 --- 1

PART

NUMBER

MAT'L

CODE

QTY

MAINTENANCE & REPAIR PAGE E - 7

Page 24

SECTION DRAWING

D SERIESOM-03604

Figure 4. 8981 Gearbox Assembly

MAINTENANCE & REPAIRPAGE E - 8

Page 25

D SERIES OM-03604

PARTS LIST

8981 Gearbox Assembly

ITEM

PART NAME PART

NO.

NUMBER

MAT'L

CODE

QTY ITEM

NO.

PART NAME PART

NUMBER

MAT'L

CODE

QTY

1 GEAR HOUSING 5367 13010 1

2 SPACER SLEEVE S952 --- 1

3 HEX HD CAPSCREW B1004 15991 1

4 BEARING S702 --- 1

4A BEARING S702 --- 1

5 SPACER WASHER 5395 15990 1

HOUSING GSKT 5367G 18000 1

6

7 COVER PLATE 5396 13010 1

8 HEX HD CAPSCREW B0403 15991 7

9 LOCKWASHER J04 15991 9

10 HEX HD CAPSCREW B0407 15991 2

11 GEAR 5334 16060 1

12 HARDENED KEY 31811-040 15990 1

13 SNAP RING S1004 --- 1

14 GASKET S825 --- 1

15 INTERNAL GEAR S823 --- 1

16 BEARING HOUSING 5918 13010 1

17 STR DOWEL PIN AA0405 15990 2

18 PINION BRG BUSH S824 --- 1

19 WASHER 2M 15990 3

INDICATES PARTS RECOMMENDED FOR STOCK

20 KEY N0304 15990 1

21 OIL SEAL ASSY 14408 --- 1

22 -OIL SEAL ADAPTER 14407 15000 1

23 -OIL SEAL 25227-355 --- 1

24 SNAP RING S269 --- 1

25 BALL BEARING S1044 --- 1

25A BALL BEARING S1044 --- 1

26 DRIVE PINION 5917 16070 1

27 SLEEVE 5922 15070 1

28 WASHER 5921 15990 1

29 OIL CUP S617 --- 1

30 SPACER WASHER 5382 15991 1

31 PINION 5333 16020 1

32 BEARING S703 --- 1

33 ECCENTRIC CAM 5378A 10080 1

34 ADJ SHIM SET 13103A 15990 1

35 DRIVE SHAFT 5397 15020 1

36 HARDENED KEY 31811-040 15990 1

37 SNAP RING S700 --- 1

38 WASHER 6531 18040 1

MAINTENANCE & REPAIR PAGE E - 9

Page 26

D SERIESOM-03604

PUMP DISASSEMBLY AND REASSEMBLY

Review all SAFETY information in Section A.

Follow the instructions on all tags, label and de

cals attached to the pump.

This pump requires little service due to its rugged,

minimum‐maintenance design. However, if it be

comes necessary to inspect or replace the wearing

parts, follow these instructions which are keyed to

the sectional views (see Figures 1, 2, 3 and 4) and

the accompanying parts lists.

Before attempting to service the pump, lock out

and tag out incoming power to the motor to ensure

that it will remain inoperative. Close all valves in the

suction and discharge lines.

Suction And Discharge Check Valve Removal

(Figure 2)

To service the suction and discharge check valves,

remove the suction and discharge piping.

To service the suction check valve assembly (26),

remove the suction accumulator (10) by removing

the hardware (13 and 14) securing it to the dia

phragm pot (18). Remove the hardware (7 and 8)

securing the valve seat (15) and check valve as

sembly to the diaphragm pot. Pull the check valve

assembly from the suction port.

To service the discharge check valve assembly

(26), loosen the hardware (3 and 4) and remove the

assembled discharge flange (1), valve seat (25)

and check valve assembly. Remove the gasket

(24).

Remove the hardware (5 and 6) securing the valve

seat and discharge check valve assembly to the

discharge elbow.

For motor disassembly and repair, consult the lit

erature supplied with the motor, or contact your lo

cal motor representative.

Most service functions may be performed without

separating the pump and gearbox from the motor.

If major repair is required, the pump, gearbox and

motor must be disconnected.

Before attempting to open or service the

pump:

1. Familiarize yourself with this man

ual.

2. Lock out and tag out incoming

power to the motor to ensure that

the pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Drain the pump.

Before attempting to service the pump, drain the

pump by removing the drain plug (18, Figure 2).

Clean and reinstall the drain plug.

To remove the discharge flange (23), loosen the

hardware (21 and 22) securing the flange to the di

aphragm pot. Remove the gasket (19).

The suction and discharge check valve assemblies

are identical parts and operate in the same direc

tion. For removal and/or replacement, remove the

hardware (28 and 29) securing the check valve

weights (27 and 30) to the check valve (31). Inspect

and replace parts as required.

If no further disassembly is required, see Suction

And Discharge Check Valve Installation.

Diaphragm Removal

(Figure 1)

To remove the diaphragm (9, Figure 3), disengage

the hardware (32, 33 and 34) and remove the dia

phragm pot assembly (35). Inspect the diaphragm

ring (36) for wear or damage. If replacement is re

quired, the gearbox assembly (8) must be re

moved.

(Figure 3)

Remove the nuts (13). Separate the lower dia

phragm plate assembly (10) from the diaphragm

(9) and the upper diaphragm plate (8). Inspect the

diaphragm and replace a required.

MAINTENANCE & REPAIRPAGE E - 10

Page 27

OM-03604D SERIES

If no further disassembly is required, see Dia

phragm Installation.

Plunger Rod Removal And Disassembly

(Figure 1)

With the diaphragm pot assembly and diaphragm

removed, disengage the hardware (2, 3, 4, 41, 42

and 43) and remove the eccentric guard (1).

Removing the snap ring (6) and slide the plunger

rod assembly (27) off the eccentric cam (33, Figure

4).

(Figure 3)

Use a socket wrench to hold the plunger rod (14)

securely and unscrew the eccentric cap (1). Re

move the T‐type lockwasher (3), jam nut (4), spring

washer (5) and spring (6). Remove the flat washer

(7) and slide the plunger rod out of the upper dia

phragm plate (8).

Inspect the eccentric bearing (2) for excessive

wear. If replacement is necessary, use a suitable

tool to cut the bearing and remove it from the ec

centric cap. Be careful not to damage the eccen

tric cap.

ring for wear or damage and replace as necessary.

It is not necessary to remove the drawbar (28) from

the diaphragm ring unless replacement is re

quired. Disengage the hardware (30) from the U‐

bolts (29) to remove the drawbar.

Disengage the hardware (22 and 23) and remove

the coupling guard (9). Loosen the attaching hard

ware, separate the coupling halves (11 and 12)

and remove the spider (13). Remove the gearbox

assembly, and slide the coupling half off the pinion

drive shaft (26, Figure 4).

(Figure 4)

Before attempting to disassemble the gearbox as

sembly, drain the lubricant by removing the oil cup

(29) and turning the gearbox on its side. Clean and

reinstall the oil cup.

Remove the two lower and the five upper pieces of

hardware (8, 9 and 10) securing the cover plate (7)

to the gear housing (1). Pull the bearing housing

(16) and cover plate from the pinion shaft (31) and

gear (15). Remove the gasket (6) and clean the

mating surfaces. Replace the gasket as necessary.

Remove the remaining two pieces of hardware (9

and 10) and separate the cover plate from the bear

ing housing. Remove the gasket (14) and clean the

mating surfaces. Replace the gasket as necessary.

Gearbox Removal And Disassembly

(Figure 1)

When properly operated and maintained, the gear

box assembly (8) should not require disassembly.

Disassemble the gearbox only when there is evi

dence of wear or damage.

Shaft and bearing disassembly in the field

is not recommended. These operations

should be performed only in a properly

equipped shop by qualified personnel.

Support the diaphragm ring (36) with wooden

blocks. Disengage the hardware (25 and 26) se

curing the gearbox to the diaphragm ring, and re

move the diaphragm ring. Inspect the diaphragm

To disassemble the pinion drive shaft components,

remove the key (20) and pry the oil seal assembly

(21) from the bearing housing. Press the oil seal

(23) from the seal adaptor (22).

Remove the washer (19) and slide the assembled

pinion drive shaft (26), bearings (25 and 25A) and

sleeve (27) from the bearing housing.

After removing the shaft and bearings, clean and

inspect the bearings in place as follows.

To prevent damage during removal from

the shaft, it is recommended that bearings

be cleaned and inspected in place. It is

strongly recommended that the bearings

be replaced any time the shaft and bear

ings are removed.

MAINTENANCE & REPAIR PAGE E - 11

Page 28

D SERIESOM-03604

Clean the bearing housing, shaft and all compo

nent parts (except the bearings) with a soft cloth

soaked in cleaning solvent. Inspect the parts for

wear or damage and replace as necessary.

Most cleaning solvents are toxic and

flammable. Use them only in a well‐ven

tilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent contain

ers.

Clean the bearings thoroughly in fresh cleaning

solvent. Dry the bearings with filtered compressed

air and coat with light oil.

Bearings must be kept free of all dirt and

foreign material. Failure to do so will great

ly shorten bearing life. Do not spin dry

bearings. This may scratch the balls or

races and cause premature bearing fail

ure.

other tool to pry the bushing from the bearing

housing.

Slide the pinion shaft (31) and gear (15) out of the

pinion bearing (32). Remove the spacer washer

(30).

Inspect the pinion shaft and gear for wear or bro

ken teeth. If replacement is required, use an harbor

(or hydraulic) press to remove the shaft from the

gear.

Use an arbor (or hydraulic) press to remove the

pinion bearing from the gear housing.

NOTE

It is not necessary to remove the drive shaft (35),

drive gear (11), shaft bearings (4 and 4A) or eccen

tric cam (33) unless wear or damage is obvious. In

spect the parts, and if replacement is necessary,

proceed as follows.

Remove the snap ring (37) from the drive shaft. Us

ing a bearing puller, remove the eccentric cam and

key (36) from the drive shaft. Remove the eccentric

cam shim set (34) and washer (38). Tie and tag the

shims or measure and record their thickness for

ease of reassembly.

Slide the drive shaft and gear out of the gear hous

ing. Slide the spacer washer (5) off the drive shaft.

Rotate the bearings by hand to check for rough

ness or binding and inspect the bearing balls. If ro

tation is rough or the bearing balls are discolored,

replace the bearings.

The bearing tolerances provide a tight press fit

onto the shaft and a snug slip fit into the bearing

housing. Replace the bearings, shaft, or bearing

housing if the proper bearing fit is not achieved.

Inspect the sleeve (27) and replace as necessary.

If bearing and sleeve replacement is required, re

move the snap ring (24). Using a bearing puller, re

move the outboard bearing (25) from the drive pin

ion. Remove the sleeve and pull the inboard bear

ing (25A) from the shaft. Remove the washer (28)

from the shaft.

Inspect the pinion bushing (18) for excessive wear.

If replacement is required, use a screwdriver or

Remove the snap ring (13). Use an arbor (or hy

draulic) press to remove the gear (11) and key (12)

from the shaft.

To remove the drive shaft bearings (4 and 4A), the

spacer sleeve (2) must be coiled into a smaller di

ameter to allow passage through the I.D. of the

bearings.

NOTE

After the spacer sleeve in compressed, it will be

permanently damaged and require replacement.

To remove the spacer sleeve, remove the caps

crew (3) and use a pointed tool to rotated the perfo

rated steel sleeve until the seam is visible through

the tapped holed. Apply pressure on one side of

the seam until one edge overlaps the other. Reach

though the I.D. of the bearings and continue to coil

the spacer sleeve until is can be removed. Reinstall

the capscrew (3).

MAINTENANCE & REPAIRPAGE E - 12

Page 29

OM-03604D SERIES

Use an arbor (or hydraulic) press to remove the

bearings (4 and 4A) from the gear housing..

It is not necessary to remove the locating pins (17)

from the gear housing unless they are bent or dam

aged. If replacement is required, press the pins

from the housing.

Gearbox Reassembly And Installation

(Figure 4)

Inspect the shafts (26, 31 and 35) for distortion,

nicks or scratches. Dress small nicks and burrs

with a fine file or emery cloth. Replace the shaft if

defective.

NOTE

Do not heat the needle bearings (4, 4A and 32).

These bearings are designed to be pressed into the

gear housing, not onto the shafts.

tinuous motion, to prevent the bearings from cool

ing and sticking on the shaft.

Use caution when handling hot bear

ings to prevent burns.

After the bearings have been installed and allowed

to cool, check to ensure that they have not moved

out of position in shrinking. If movement has oc

curred, use a suitably sized sleeve and a press to

reposition the bearings.

If heating the bearings is not practical, use a suit

ably sized sleeve and an arbor (or hydraulic) press

to install the bearings on the shaft.

When installing the bearings onto the

shaft, never press or hit against the outer

race, balls, or ball cage. Press only on the

inner race.

To prevent damage during removal from

the shaft (26), it is recommended that the

bearings (25 and 25A) be cleaned and in

spected in place. It is strongly recom

mended that the bearings be replaced any

time the shaft and and bearings are re

moved.

The bearings may be heated to ease installation.

An induction heater, hot oil bath, electric oven, or

hot plate may be used to heat the bearings. Bear

ings should never be heated with a direct flame or

directly on a hot plate.

NOTE

If a hot oil bath is used to heat the bearings, both the

oil and the container must be absolutely clean. If

the oil has been previously used, it must be thor

oughly filtered.

Heat the bearings to a uniform temperature no

higher than 250_F (120_C) and slide the bearings

onto the shaft (26), one at a time, until they are fully

seated. This should be done quickly, in one con

If removed, install the snap ring (28) in the groove

on the pinion drive shaft (26). Install the bearing

(25A) on the pinion drive shaft against the snap

ring. Install the sleeve (27). Install the bearing (25)

onto the pinion drive shaft until squarely seated

against the sleeve. Secure the bearing with the

snap ring (24). Wrap the shaft and bearings in a

clean cloth until reassembly in the bearing hous

ing.

Install the bearing (4A) in the gear housing until it is

flush with the outer machined face of the housing.

Install a new spacer sleeve (2) through the open

bearing bore, then press the bearing (4) into the

bore until it is flush with the inner machined face on

the housing.

When installing the bearings into the bear

ing bore, push against the outer race. Nev

er hit the balls or ball cage.

Install the gear key (12) in the keyway in the drive

shaft (35). Press the drive gear (11) onto the drive

MAINTENANCE & REPAIR PAGE E - 13

Page 30

D SERIESOM-03604

shaft and secure it with the snap ring (13). Be sure

the drive gear seats against the snap ring.

Install the washer (5) onto the drive shaft and slide

the assembled drive shaft and gear through the

bearings in the gear housing. Install the same

thickness of shims (34) as previously removed. In

stall the washer (38) and drive shaft key (36). Press

the eccentric cam (33) onto the shaft and secure

with the snap ring (37).

Press the pinion bearing (32) into the gear housing

until the closed end is flush with the outer face of

the bore.

Press the internal gear (15) onto the pinion shaft

until it seats squarely against the pinion shoulder.

Position the spacer washer (30) in the gear hous

ing and slide the pinion shaft through the washer

and into the pinion bearing.

Press the pinion bushing (18) into the bearing

housing until fully seated.

Slide the assembled pinion drive shaft and bear

ings (25, 25A and 26) into the bearing housing (16)

until the bearing (25A) is fully seated against the

bore shoulder.

Press the oil seal (23) into the adaptor (22) with the

lip positioned as shown in Figure 4. The outer face

of the oil seal should be just flush with the face of

the adaptor.

Secure the cover plate and bearing housing to the

gear housing with the remaining attaching hard

ware (8, 9 and 10).

NOTE

The two longer capscrews (10) must be installed in

the two lower holes in the gear housing.

Install the drive key (20) in the drive pinion.

(Figure 1)

Install the coupling half (12) on the drive pinion (26,

Figure 4).

Secure the gearbox assembly (8) to the diaphragm

ring (36) with the hardware (25 and 26). Connect

the coupling halves and check alignment as de

scribed in Section B.

Secure the coupling guard (9) to the base with

hardware (22 and 23).

Lubricate the gearbox as described in LUBRICA

TION.

Plunger Rod Reassembly And Installation

(Figure 3)

If the eccentric bearing (2) was removed, clean the

bore of the eccentric cap (1) with a cloth soaked in

cleaning solvent.

Install the washer (19) in the bearing housing.

Press the oil seal assembly (21) into the bearing

housing until fully seated. Be careful not to roll or

damage the oil seal lip on the pinion keyway.

Install the housing gasket (6) and secure the cover

plate (7) to the bearing housing with two of the

capscrews and lockwashers (8 and 9).

If the locating pins (17) were removed, press new

pins into the gear housing (1). Install the gasket

(14) and position the bearing housing (16) over the

internal gear (15) and against the cover plate so

that the locating pins align with the holes in the cov

er plate. Be sure the teeth on the drive pinion (26)

mesh with those on the internal gear (15). Tap

against the bearing housing with a soft‐faced mal

let or wood block until the pinion bushing (18) fully

engages the pinion shaft (31).

Most cleaning solvents are toxic and

flammable. Use them only in a well‐ven

tilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent contain

ers.

Use a suitably sized dowel and an arbor (or hy

draulic) press to install a new eccentric bearing (2)

into the eccentric cap until fully seated.

Slide the plunger rod (14) through the upper dia

phragm plate (8). Install the flat washer (7), spring

(6), spring washer (5) and jam nut (4). Compress

the spring to the dimension shown in Figure 3 by

tightening the jam nut.

MAINTENANCE & REPAIRPAGE E - 14

Page 31

OM-03604D SERIES

Install the T‐type lockwasher (3). Apply `Loctite No.

242 Threadlocker' or equivalent compound on the

plunger rod threads and screw the eccentric cap

on until tight.

NOTE

The lubrication fitting (15) in the diaphragm plate

must face the same direction as the lubrication fit

ting (16) in the eccentric cap.

Lubricate the eccentric bearing (2) with a thin coat

ing of No.2 lithium base grease.

Diaphragm Installation

(Figure 3)

Position the diaphragm (9) on the upper dia

phragm plate, making sure the lip is properly

seated. Slide the studs (12) in the lower diaphragm

plate (11) through the holes in the upper plate and

secure with the nuts (13).

(Figure 1)

Install the plunger rod assembly (21) onto the ec

centric cam (33, Figure 4) and secure with the snap

ring (6).

(19). Secure the flange to the diaphragm pot with

the hardware (21 and 22).

Subassemble the valve seat (25) and discharge

check valve (26) to the discharge elbow (1) with the

weights positioned as shown in Figure 2. Secure

with the hardware (3 and 4).

Clean the mating surfaces of the valve seat and dis

charge flange (23). Install the gasket (24) and se

cure the outboard discharge flange, check valve,

and seat to the inboard discharge flange with the

hardware (5 and 6).

Check the operation of the check valve to ensure

proper seating and free movement.

Clean the mating surfaces of the valve seat (5) and

suction accumulator (10). Position the suction

check valve, valve seat (15) and gasket (16)

against the diaphragm pot (19) with the weights

positioned as shown in Figure 2. Secure with the

hardware (7 and 8).

Check the operation of the check valve to ensure

proper seating and free movement.

Secure the suction accumulator (10) to the dia

phragm pot with the hardware (13 and 14).

Connect the suction and discharge piping as de

scribed in INSTALLATION, Section B.

Install the eccentric guard (1) and secure it with the

hardware (2, 3, 4, 41, 42 and 43).

Lubricate the plunger rod assembly as described

in LUBRICATION, Section E.

Secure the diaphragm pot assembly (35) to the di

aphragm ring (36) with the hardware (32, 33 and

34).

Suction And Discharge Check Valve

Installation

(Figure 2)

Inspect the check valve components and replace

as required. Subassemble the check valve weights

(27 and 30) and check valves (31) with the hard

ware (28 and 29).

If the inboard discharge flange (23) was removed,

clean the mating surfaces and install the gasket

Refer to OPERATION, Section C before starting

the pump.

LUBRICATION

Plunger Rod Assembly

(Figure 3)

The eccentric bearing should be lubricated

thoroughly after each 8 hours of operation.

Failure to do so may cause the bearing to

overheat and fail.

Before attempting to lubricate the plunger rod as

sembly, rotate the eccentric cam until the grease

fittings (15 and 16) can be accessed through the

holes in the eccentric guard (1, Figure 1).

MAINTENANCE & REPAIR PAGE E - 15

Page 32

D SERIESOM-03604

Use a grease gun to apply No. 2 lithium base

grease to the upper lubrication fitting until grease

escapes from the eccentric cap. Lubricate the low

er fitting until grease escapes from the top of the

upper diaphragm plate inside the spring.

Gearbox

(Figure 4)

The gearbox was fully lubricated when shipped

from the factory. Change the oil in a new gearbox at

operating temperature after 100 hours of operation

or four weeks, whichever comes first. To drain the

oil, remove the oil cup (29) and position the pump

and gearbox on its side. After draining, reinstall the

oil cup and flush the case thoroughly with a light oil.

Remove the oil cup and drain the flushing oil. Rein

stall the oil cup.

To lubricate the gearbox, add SAE No. 30 non‐de

tergent oil through the oil cup (29) until the oil level

stabilizes at the middle of the oil cup. Check the oil

regularly and maintain it at this level.

Monitor the condition of the bearing lubri

cant regularly for evidence of rust or mois

ture condensation. This is especially im

portant in areas where variable hot and

cold temperatures are common.

MAINTENANCE & REPAIRPAGE E - 16

Page 33

For U.S. and International Warranty Information,

Please Visit www.grpumps.com/warranty

or call:

U.S.: 419-755-1280

International: +1-419-755-1352

For Canadian Warranty Information,

Please Visit www.grcanada.com/warranty

or call:

519-631-2870

THE GORMAN‐RUPP COMPANY D MANSFIELD, OHIO

GORMAN‐RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA

Loading...

Loading...