Page 1

ACE

OM---01216---OE08

March 18, 2002

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

0SERIESPUMP

MODEL

04B3---F4L

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST.THOMAS, ONTARIO, CANADA Printed in U.S.A.

ECopyright by the Gorman-Rupp Company

Page 2

The engine exhaust from this

product contains chemicals

known to the State ofCaliforniato

cause cancer, birth defects or

other reproductive harm.

Page 3

TABLE OF CONTENTS

INTRODUCTION PAGE I --- 1.................................................

SAFETY - SECTION A PAGE A --- 1............................................

IN S TA LLATIO N --- SE C TION B PA G E B --- 1....................................

Pump Dimensions PAGE B --- 1.....................................................

PREINSTALLATION INSPECTION PAGE B --- 1............................................

Battery Specifications And Installation PAGE B --- 2....................................

POSITIONING PUMP PA GE B --- 2.......................................................

Lifting PA GE B --- 2.................................................................

Alignment PA GE B --- 2.............................................................

Mounting PA GE B --- 2.............................................................

SUCTION AND DISCHARGE PIPING PAGE B --- 3.........................................

Materials PA GE B --- 3..............................................................

Line Configuration PAGE B --- 3......................................................

Connections to Pump PAGE B --- 3..................................................

Gauges PA GE B --- 3...............................................................

SUCTION LINES PAGE B --- 3...........................................................

Fittings PA GE B --- 3...............................................................

Strainers PA GE B --- 3..............................................................

Sealing PAGE B --- 3...............................................................

Suction Line Positioning PAGE B --- 4................................................

FLOAT SWITCHES PA GE B --- 4.........................................................

Installation PA GE B --- 4............................................................

DISCHARGE LINES PA GE B --- 5........................................................

Siphoning PAGE B --- 5.............................................................

Valves PA GE B --- 5................................................................

OP E R AT ION --- SEC T ION C PA G E C --- 1......................................

PRIMING PA GE C --- 1.................................................................

STARTING PA GE C --- 1................................................................

Manual Starting PAGE C --- 2........................................................

Automatic Starting PAGE C --- 2.....................................................

OPERATION PA GE C --- 3..............................................................

Lin es W ith a Bypa ss PA GE C --- 3....................................................

Lines Without a Bypass PAGE C --- 3.................................................

Leakage PAGE C --- 3..............................................................

Liquid Temperature And Overheating PAGE C --- 3.....................................

Strainer Check PAGE C --- 3.........................................................

Pump Vacuum Check PAGE C --- 3..................................................

STOPPING PA GE C --- 4................................................................

Manual Stopping PAGE C --- 4.......................................................

Automatic Stopping PAGE C --- 4....................................................

Safety Shutdown System PAGE C --- 4...............................................

OPERATIONINEXTREMEHEAT PAGEC---4............................................

BEARING TEMPERATURE CHECK PAGE C --- 5..........................................

Cold Weather Preservation PAGE C --- 5..............................................

i

Page 4

TABLE OF CONTENTS

(continued)

TROU BLESH OOT I NG --- SE CTIO N D PA G E D --- 1..............................

PREVENTIVE MAINTENANCE PAGE D --- 3...............................................

PUMP MAINTENANCE AND REPAIR - SECTION E PAGE E --- 1.................

STANDARD PERFORMANCE CURVE PAGE E --- 1........................................

PARTS LISTS:

Pump Model PA GE E --- 3..........................................................

Pump End Assembly PAGE E --- 5...................................................

Drive Assembly PAGE E --- 6........................................................

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E --- 7.........................

Pump Disassembly PAGE E --- 7.....................................................

Impeller Removal P AGE E --- 8......................................................

Seal Removal and Disassembly PAGE E --- 8..........................................

Separating Intermediate and D rive Assembly From Engine PAGE E --- 8..................

Shaft and Bearing Removal and Disassembly PAGE E --- 8.............................

Shaft and Bearing Reassembly and Installation PAGE E --- 9............................

Securing Intermediate and Drive Assembly To Engine PAGE E --- 11......................

Seal Reassembly and Installation P AGE E - -- 11........................................

Impeller Installation P AGE E - -- 13.....................................................

Pump Reassembly PAGE E --- 13.....................................................

Final Pump Assembly PAGE E --- 14..................................................

LUBRICATION PA GE E --- 14.............................................................

Seal Assembly PAGE E --- 14.........................................................

Engine PA GE E --- 14................................................................

ii

Page 5

0SERIES

OM--01216

INTRODUCTION

This Installation, Operation, and Maintenance

manual is designed to help you achieve the best

performance and longest life from your GormanRupp pump.

Thispumpisan 0Series,closedimpeller,self-priming centrifugal model, designed with straigh-in

suction, without a suction check valve. It is designed tohandleclearliquids containingspecified

entrained solids. The basic material of constructionforwettedparts isgray iron,withbronzeimpeller and gray iron wear rings.

The pump is close-coupledtoa four cylinder Deutz

dieselengine, modelF4L912D. Refer tothemanual accompanying the engine before installing or

operating the pump.

If there are any questions regarding t he pump or

its application which are not covered in this manual or in other literature accompanying this unit,

please contact your Gorman-Rupp distributor, or

write:

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901--1217

or

Gorman-Rupp of Canada Limited

70 Burwell Ro ad

St. Thomas, Ontario N5P 3R7

equipment must be installed and operated ac-

cording to all national, local and industry stan dards.

The following are used to alert maintenance personnel toprocedureswhich require specialattention, tothosewhichcoulddamage equipment, and

to those which could be dangerous to personnel:

Immediate hazards whichWILL result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULDresult in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

For information or technical assistance on the engine, contact the engine manufacturer’s local

dealer or representative.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed instructions and precautions for every aspect of

each specific application. Therefore, it is the responsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operator safety norpumpintegrity are compromised by the installation. Pumps and related

HazardsorunsafepracticeswhichCOULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possible damagewhich could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation,and

maintenance, or which clarify a procedure.

PAGE I -- 1INTRODUCTION

Page 6

0SERIES

OM--01216

SAFETY - SECTION A

This information applies to 0 Series engine driven pumps. Refer to the manual

accompanying the engine before attempting to begin operation.

Because pump installations are seldom

identical, this manual cannot possibly

provide detailed instructions and precautions for each specific application.

Therefore, it is the owner/installer’s responsibility to ensure that applications

not addressed in this manual are performed only after establishing that neither operator safety nor pump integrity

are compromised by the installation.

Beforeattemptingto openorservicethe

pump:

1. Familiarize yourself with this man ual.

2. Switch off the engine ignition and

disconnect the positive battery

cable. Take precautions to ensure

that the pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

vent injury during automatic operation.

Disconnect the positive battery cable

before performing any maintenance.

Failuretodosomayresultinserious

personal injury.

This pump is designed to handle clear

liquids containing specified entrained

solids.Donotattempttopumpvolatile,

flammable or corrosive materials, or

any liquids which may damage the

pumporendange r personnelas a result

of pump failure.

Use lifting and moving equipment in

good repair and with adequate capacity

toprevent injuriestopersonnelordamage to equipment. Suction and discharge hoses and piping must be removed from the pump before lifting.

Afterthepumphasbeen installed,make

certain that the pump and all piping or

hose connections are tight, properly

supportedandsecurebeforeoperation.

Ifthe pump is equipped with the optional automatic starting system, it is subject to automatic restart. Keep hands

and clothing away from the unit to pre-

Do not operate the pump against a

closeddischarge valve for longperiods

oftime.Ifoperatedagainstacloseddischarge valve, pump components will

deteriorate, and the liquid could come

to a boil, build pressure, and cause the

pump casing to rupture or explode.

PAGE A -- 1SAFETY

Page 7

0SERIESOM--01216

Do not remove plates, covers, gauges,

pipe plugs, or fittings from an overheated pump. Vaporpressure withinthe

pump can cause parts being disengagedtobe ejectedwithgreat force.Allow the pump to cool before servicing.

Do not operate an i n ternal combustion

engine in an explosive atmosphere.

When operating internal combustion

engines in an enclosed area, make ce rtain that exhaust fumes are piped to the

outside. These fumes contain carbon

monoxide, a deadly gas that is colorless, tasteless, and odorless.

Fuel used by internal combustion engines presents an extreme explosion

and fire hazard. Make certain that all

fuel lines are securely connected and

free of leaks. Never refuel a hot or running engine. Avoid overfilling the fuel

tank.Alwaysusethe correcttype offuel.

Never tamper with the governor to gain

more power. The governor establishes

safe operating limits that should not be

exceeded. The maximum continuous

operating speed for this pump is 2400

RPM.

PAGE A -- 2

SAFETY

Page 8

0SERIES OM--01216

INSTALLATION --- SECTION B

Review all SAFETY information in Section A.

Since pump installations are seldom identical,this

section offers only general recommendations and

practices required to inspect, position, and arrange the pump and piping.

Most of the information pertains to a standard

staticlift application where the pump ispositioned

above the free level of liquid to be pumped.

If installed ina flooded suction application where

the liquid is supplied to the pump under pressure,

some of the information such as mounting, line

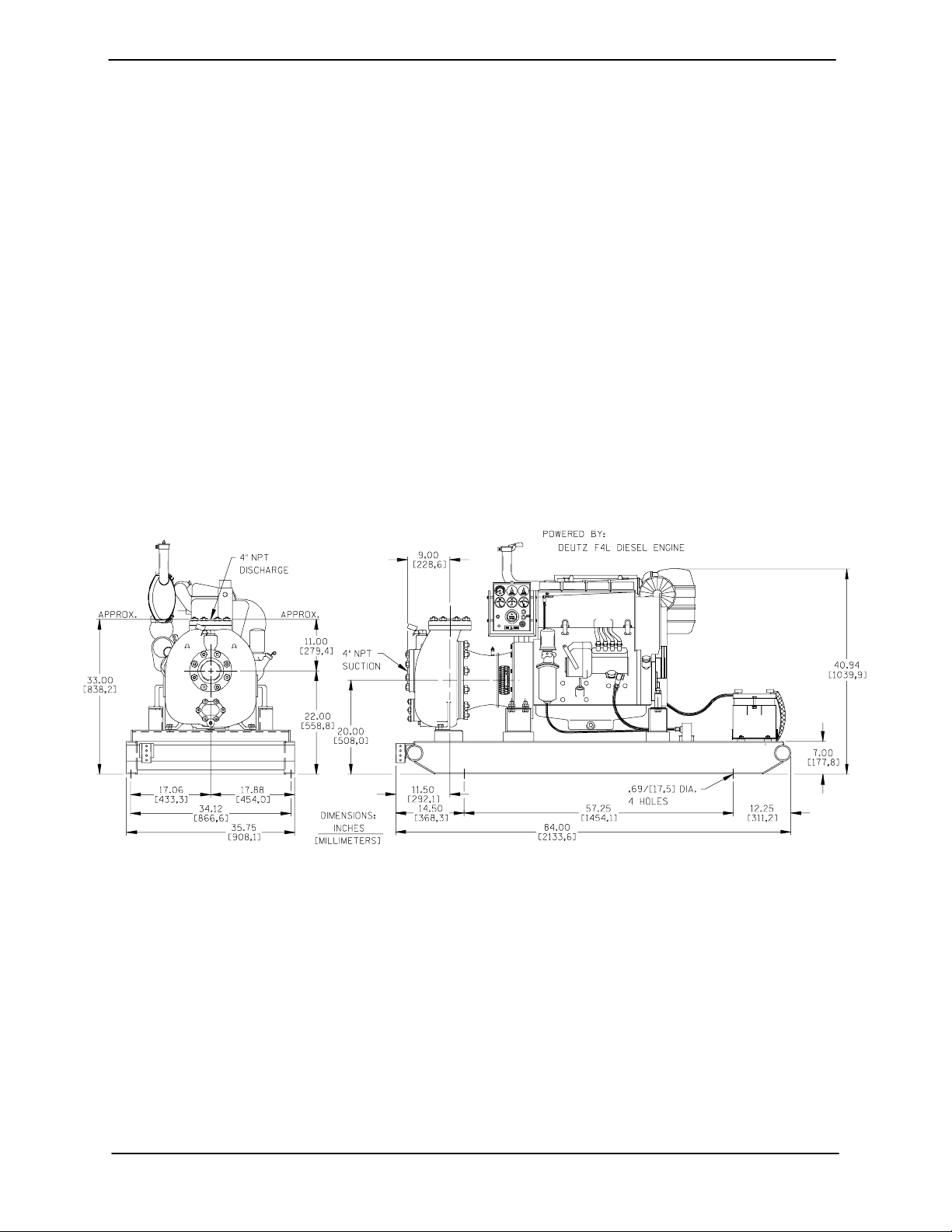

OUTLINE DRAWING

configuration, and priming must be tailored to the

specific application. Since the pressure supplied

to the pump is critical to performance and safety,

besuretolimitthe incomingpressureto50%ofthe

maximum permissible operating pressure a s

shown on the pump performance curve.

Forfurtherassistance, contact yourGorman-Rupp

distributor or the Gorman-Rupp Company.

Pump Dimensions

SeeFigure1fortheapproximatephysicaldimensionsofthispump.

Figure 1. Pump Model 04B3--F4L

PREINSTALLATION INSPECTION

Thepump assemblywas inspectedandtested beforeshipment from the factory. Before installation,

inspect the pump for damage which may haveoc curred during shipment. Check as follows:

a. Inspect the pump and engine for cracks,

dents, damaged threads, and other obvious

damage.

b. Check for and tighten loose attaching hard-

ware. Since gaskets tend to shrink after drying, check for loose hardware at mating surfaces.

c. Carefully read all tags, decals, and markings

onthepumpassembly,and performallduties

indicated.

d. Check levels and lubricate as necessary. Re-

fer to LUBRICATION in the MAINTENANCE

PAGE B -- 1INSTALLATION

Page 9

OM--01216 0SERIES

AND REPAIR section of thismanualandper-

form duties as instructed.

e. If the pump and engine have been stored for

more than 12 months, some of the components or lubricants may have exceeded their

maximumshelflife.These mustbeinspected

or replaced to ensure maximum pump service.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to determinethe repair or updating policy. Donotput the

pump into service until appropriate action has

been taken.

Battery Specifications And Installation

Unlessotherw ise specified on the pump order,the

engine battery wa s not included with the unit. Refer to the following specifications when selecting a

battery.

age to equipment. Suction and discharge hoses and piping must be removed from the pump before lifting.

Lifting

Use lifting equipment with a capacity of at least

7,650 pounds (3540 kg.). The pump weighs approximately1,560pounds (708kg.), notincluding

the weight of any customer installed options.Customerinstalledequipmentsuchas suctionanddischargepipingmustbe removedbefore attempting

to lift.

Thepumpassemblycanbeseriously

damagedifthecablesorchainsused tolift

andmovetheunitare improperlywrapped

around the pump.

Alignment

Table 1. Battery Specifications

Voltage

12 Volts

Cold

Crank

Amps

@0

_ F

960 ---975

Reserve

Capacity

@80

_ F

(Minutes)

365

Amp/

Rating

175

Hr.

Approx.

Overall

Dims.

(Inches)

20.5L

x

8.75W

x

9.75H

Refer tothe information accompanyingthe battery

and/or electrolytesolutionfor activationandcharging instructions.

Beforeinstalling thebattery,cleanthe positive and

negative cable connectors, and the battery terminals. Secure the battery by tightening the

holddown brackets. The terminals and clamps

maybecoated with petroleumjellyto retard corrosion. Connect and tighten the positive cable first,

then the negative cable.

POSITIONING PUMP

Use lifting and moving equipment in

good repair and with adequate capacity

toprevent injuriestopersonnelordam-

Thealignmentofthe pumpendand enginearecritical for trouble-free performance. During repair of

thepumpend, refertoSecuring Intermediateand

Drive Assembly to Engine in MAINTENANCE

AND REPAIR, Section E for Details.

Mounting

Locatethepump inanaccessibleplaceascloseas

practicalto the liquidbeingpumped. Levelmounting is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibration.

If the pump has been mounted on a moveable

base,makecertainthebaseisstationarybysetting

the brakeandblocking thewheelsbefore attempting to operate the pump.

To ensure sufficient lubrication and fuel supply to

the engine, do not position the pump and engine

morethan 15_ off horizontal for continuousoperation. The pump and engine may be positioned up

to 30_ off horizontal for intermittent operation

only;however,the enginemanufacturershouldbe

consulted for continuous operation at angles

greater than 15_.

PAGE B -- 2 INSTALLATION

Page 10

0SERIES OM--01216

SUCTION AND DISCHARGE PIPING

Pump performance is adversely effected by increased suction lift, discharge elevation, and friction losses. Contact the factory to be sure your

overall application allows pump to operate within

thesafeoperationrange.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatiblewiththe liquidbeingpumped. Ifhoseis

used in suction lines, it must be therigid-wall, reinforcedtype to prevent collapseunder suction.Using piping couplings in suction lines is not recommended.

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make minimum use of elbows and fittings, which substantiallyincreasefriction loss.If elbowsarenecessary,

use the long-radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it exactlywith the pump port. Never pulla pipe lineinto

place by tightening the flange bolts and/or couplings.

Lines near the pump must be independently supported to avoid strain on the pump which could

cause excessive vibration, decreased bearing life,

and increased shaft and seal wear. If hose-type

linesare used,they shouldhaveadequatesupport

to secure them when filled with liquid and under

pressure.

Gauges

Most pumps are drilled and tapped for installing

discharge pressure and vacuum suction gauges.

If these gauges are desired for pumps that a re not

tapped, drill and tap the suction and discharge

lines not less than 18 inches from the suction and

discharge ports and install the lines. Installation

closer to the pump may result in erratic readings.

SUCTION LINES

Toavoidair pocketswhichcould affectpump priming, thes uction line must be as short and direct as

possible.Whenoperationinvolvesasuctionlift,the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

Fittings

Suction lines should be the same size as the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be installedwith the flat part of the reducers uppermost

to avoid creating air pockets. Valves are not normally used in suction lines, but if a valve is used,

install it with the stem horizontal to avoid air pockets.

Strainers

If a strainer is furnished with the pump, be certain

touse it;any sphericalsolidswhichpassthrougha

strainer furnished with the pump will also pass

through the pump itself.

If a strainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

three or four times the cross section of the suction

line,and that the openings willnot permit passage

of solids larger than the solids handling capability

of the pump.

Thispump isdesignedtohandle up to 1/2-inchdiameter spherical solids.

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an airtight seal. Follow the sealant manufacturer’s recommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

Suction Lines In Sumps

If a single suction line is installed in a sump, it

should be positioned away from the wall of the

sumpata distance equal to1 1/2 times the diameter of the suction line.

PAGE B -- 3INSTALLATION

Page 11

OM--01216 0SERIES

If there is a liquid flow from an open pipe into the

sump, the flow should be kept away from the suctioninlet because theinflowwillcarryair downinto

the sump, and air entering the suction line will reduce pump efficiency.

Ifitis necessary to positioninflowclose to the suctioninlet, installa bafflebetween theinflowandthe

suctioninlet at a distance 1-1/2 times the diameter

of the suction pipe. The baffle will allow entrained

air to escape from the liquid before it is drawn into

the suction inlet.

If two suction lines are installed in a single sump,

theflow pathsmay interact,reducing theefficiency

of one or both pumps. To avoid this, position the

suction inlets so that they are separated by a distance equal to at least 3 times the diameter of the

suction pipe.

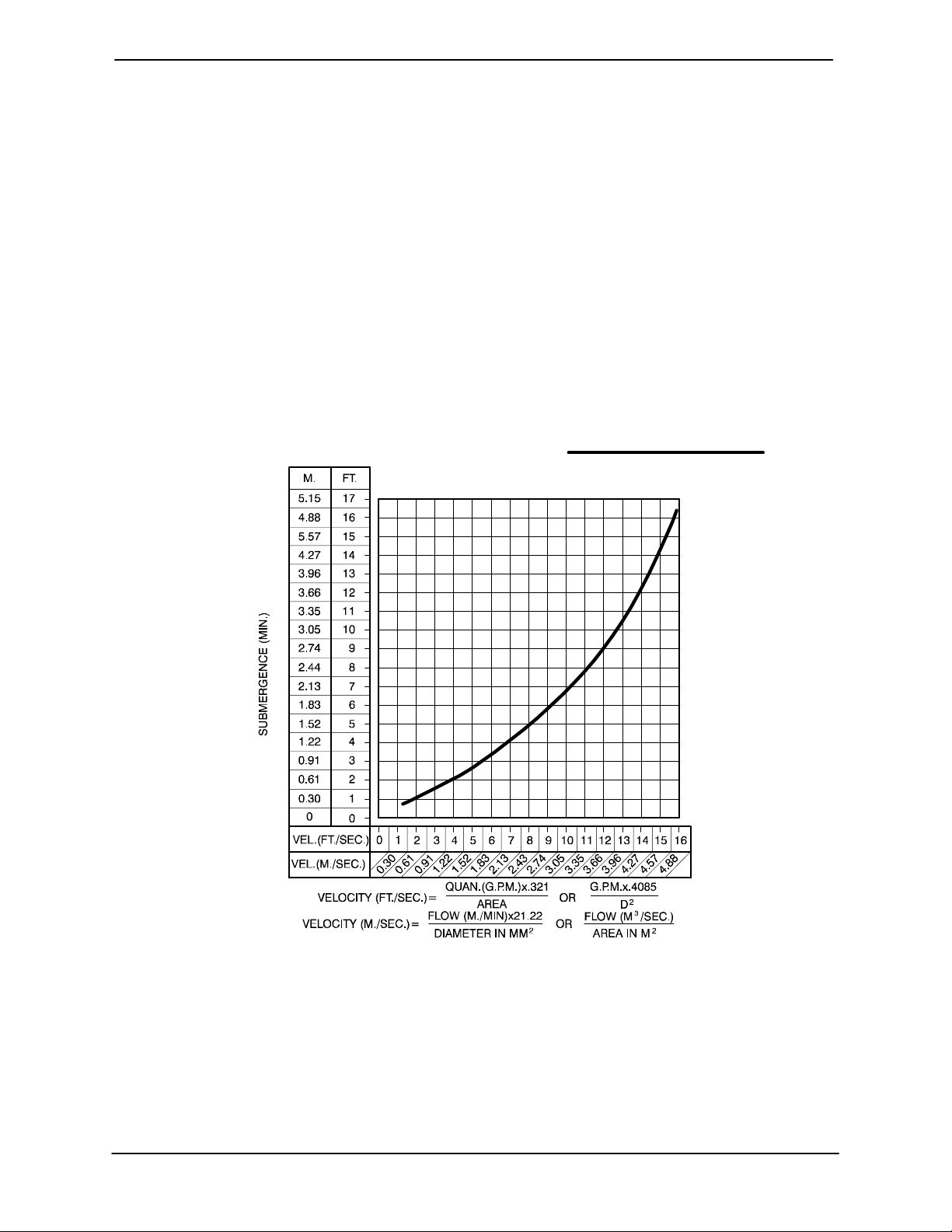

Suction Line Positioning

The depth of submergence of the suction line is

critical toefficient pump operation. Figure 2 shows

recommended minimum submergence vs. veloc-

ity.

NOTE

The pipe submergence required may be reduced

by installing a standard pipe increaserfitting at the

endof the suctionline. The largeropening size will

reduce the inlet velocity. Calculate the required

submergence using the following formula based

on the increased opening size (area or diameter).

Figure 2. Recommended Minimum Suction Line Submergence vs. Velocity

FLOAT SWITCHES

Installation

The standard pump is not furnished with a means

to automatically regulate liquid level. However, if

the unit is equipped with the optional auto-start

control system, the pump can be conformed to

PAGE B -- 4 INSTALLATION

start a nd stop as the liquid level in the wet well or

sump risesand falls. Theautostartoptionemploys

eitherasingle ordoublefloatswitch system,where

a bulb raises or lowers (floats) with the liquid level,

thus activating an enclosed miniature switch. The

floats are equipped with a socket type connector

that plugs into a matching receptacle on the auto start control box.

Page 12

0SERIES OM--01216

Standard floatsare equipped with 50 feet(15,2m)

of cable.

When installing the floats, note the following:

a. Be sure to provide sufficient room in the wet

well or sump so that floats do not get obstructedordrawn intothesuctionline.Ifaflexible suction hose is used, it may be extended

tolayalongthebottomofthe wetwellorsump

and the float can be attached to the hose

abovethe point where it bends along the bottom. Direct the suction line toward the flow,

and the float(s) away fromthe flow.If a standpipe is available, attach the float switch cable

to the standpipe in the sump at the approximatedesiredliquidlevel.

ENGINE

CONTROL

BOX

ON

(Emptying)

OFF

(Filling)

OPERATING

CABLE

TETHER

RANGE

(See Table Below)

POINT

OFF

(Emptying)

1.25” Pipe

(Not Furnished)

ON

(Filling)

b. In a single floatsystem, the cablecan be teth-

ered to the suction line or standpipeapproximately 6 inches (152 mm) above the float.

This setting allows approximately 9 inches

(229 mm) of liquid rise between pump start/

stop.The start/stopintervalmay beincreased

by extending the float end of the cable. The

liquid level in the sump will increase approximately8 inches (203mm) between start/stop

intervals for every 6 inches (152 mm) of cable

increase.

c. If a double float switch system is used, posi -

tion the “Start” float at the desired high water

level in the sump, and the “Stop” float at the

desired low water level in the pump.

d. Refer to Figure 3 for additional float switch

data.

3.0

(0.9)

2.5

(.76)

2.0

(0.6)

1.5

(.46)

1.0

(0.3)

0.5

(.15)

1.0

(0.3)

APPROXIMATEFREECORDLENGTHINFT.(M)

2.0

(0.6)

3.0

(0.9)

4.0

(1.2)

Figure 3. Float Switch Data

DISCHARGE LINES

Siphoning

Donot terminate the discharge lineat a level lower

than that of the liquid being pumped unless a siphon breaker is used in the line. Otherwise, a siphoning action causing damage to the pump

could result.

Valves

If a throttlingvalve is desired in the discharge line,

useavalveaslargeasthelargestpipetominimize

friction losses. Never install a throttling valve in a

suction line.

Withhighdischarge heads,itis recommendedthat

a t hrottling valve and a system check valve be installed in the discharge line to protect the pump

from excessive shock pressure and reverse rotation when it is stopped.

Iftheapplicationinvolvesa highdischarge

head, gradually close the discharge

throttling valve before stopping the pump.

Bypass Lines

If a system check valve is used due to high discharge head, it may be necessary to vent trapped

PAGE B -- 5INSTALLATION

Page 13

OM--01216 0SERIES

airfromthetop ofthepump duringtheprimingprocess.This maybeaccomplishedby installingabypass line from the top of the pump, back to the

source of the liquid. The end of the bypass line

must be submerged. The line must be large

enough to prevent clogging, but not so large as to

affect pump discharge capacity.

PAGE B -- 6 INSTALLATION

Page 14

0SERIES

OM--01216

OPERATION --- SECTION C

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and

decals attached to the pump.

Do not operate an i n ternal combustion

engine in an explosive atmosphere.

When operating internal combustion

engines in an enclosed area, make ce rtain that exhaust fumes are piped to the

outside. These fumes contain carbon

monoxide, a deadly gas that is colorless, tasteless, and odorless.

This pump is designed to handle clear

liquids containing specified entrained

solids.Donotattempttopumpvolatile,

corrosive, or flammable materials, or

any liquids which may damage the

pumporendange r personnelas a result

of pump failure.

PRIMING

Install the pump and piping as described in INSTALLATION. Make sure that the piping connec-

tions are tight, and that the pump is securely

mounted. Check that the pump is properly lubricated (see LUBRICATION in MAINTENANCE

AND REPAIR).

notprimewhen dry.Extended operationof

a dry pump willdestroythesealassembly.

Add liquid to the pump casing w hen:

1. The pump is being put into service for the

first time.

2. Thepump has notbeenusedfora considerable length of time.

3. The liquid in the pump casing has evaporated.

When installed in a flooded suction application,

simply open the system valves and permit the incoming liquid to evacuate the air. After the pump

and piping system have completely filled, evacuate any remaining air pockets in the pump or suctionlineby looseningpipeplugoropeningbleeder

valves.

Once the pump casing has been filled, the pump

will prime and reprime as necessary.

After filling the pump casing, reinstall

and tighten the fill plug. Do not attempt

to operate the pump unless all connecting piping is securely installed. Otherwise, liquid in the pump forced out under pressure could cause injury to personnel.

Tofill the pump, remove the pump casing fill cover

or fill plug in the top of the casing, and add clean

liquid until the casing is filled. Replace the fillcover

or fill plug before operating the pump.

This pump is self priming, but the pump should

never be operated unless there is liquid in the

pump casing.

STARTING

Ifthe pump is equipped with the optional automatic starting system, it is sub-

Never operate this pump unless there is

liquid in the pump casing. The pump will

OPERATION PAGE C -- 1

ject to automatic restart. Keep hands

and clothing away from the unit to pre-

Page 15

OM--01216 0SERIES

vent injury during automatic operation.

Disconnect the positive battery cable

before performing any maintenance.

Failuretodosomayresultinserious

personal injury.

Consult the operations manual furnished with the

engine.

Manual Starting

On initial start-up, set the engine speed at the halfthrottleposition.Turnthe keyswitch on the control

boxto the “START”positionuntil the enginestarts.

Release the key and the switch will return to the

“RUN” position.

After the engine starts and the unit is fully primed,

adjust the engine RPM until the desired flow rateis

achieved.

Pump speed and operating condition

points must be within the continuous performance range shown on the curve on

page E-1.

the keyswitch in the “AUTO START” position by

pressing thewhite“MAN”button onthecontrol.The

“Single Lightning Bolt” light on the control will illuminate in conjunction with an audible alarm before

the unit starts. The unit can then be stopped manually by pressing the “OFF/SET” button.

In the auto-start mode, the “SingleLightningBolt”

light will illuminate in conjunction with an audible

alarm when the liquid level in the sump or wet well

rises and activates the float(s). The light will blink

and the alarm will sound for approximately 8 seconds before the unit starts.

Whentheliquidlevelinthesumpor wetwell issufficiently pumped down, the unit will automatically

shut down.

NOTE

If the keyswitch is moved to the “OFF” position

while in the auto-start mode, the engine will stop.

However, the auto-start process will continue as

soonas thekeyswitch is moved backtothe “AUTO

START” position. Tocancel the auto-start process,

press the “OFF/SET” button.

Automatic Starting

If the unit is equipped with the optional autostart

control system, install the float(s) as described in

INSTALLATION, Section B.

Followtheprocedures outlined formanual starting

and throttle adjustment, then turn the key to the

“AUTO START” position.

NOTE

For securitypurposes, thekey canbe removedwith

the switch in the “AUTO START” position.

Press and hold the white “AUTO” button on the

controlpanel untilthered “AUTO”lightilluminates.

The auto-start system is now armed.

NOTE

The unit can continue to be started manually with

Thecontrolpanelisequipped with high oiltemperature, lowoil pressure, V-beltand start failure(3 attempts)safetyshutdowns. Ifanyoftheseproblems

occur,the red “Double LightningBolt”lightwillilluminate to indicate a system fault. When the problemis corrected,pressthe“OFF/SET”buttontoreset the control.

NOTE

The “OFF/SET” button has dual functionality when

in program mode. If necessary, consult the factory

for details on programming functions.

The unit can be started manually with the keyswitch in the “AUTO START” position by pressing

the white “MAN” button. The “Single Lightning

Bolt” light will illuminatein conjunction with an audible alarm before the unit starts.

Stop the unit manually bypressing the “OFF/SET”

button.

OPERATIONPAGE C -- 2

Page 16

0SERIES

OM--01216

OPERATION

Lines With a Bypass

Close the discharge throttling valve (if so

equipped) so that the pump will not have to prime

against the weight of the liquid in the discharge

line. Air from the suction line will be discharged

throughthe bypassline backto thew et wellduring

the priming cycle. When the pump is fully primed

andliquidisflowingsteadilyfromthebypassline,

open the discharge throttling valve. Liquid will then

continueto circulate through the bypass linewhile

the pump is in operation.

Lines Without a Bypass

Open all valves in the discharge line and start the

power source. Priming is indicated by a positive

reading on the discharge pressure gauge or by a

quieteroperation. The pump maynot primeimmediately because the suction line must first fill w ith

liquid. If the pump fails toprimewithin fiveminutes,

stop it and check the suction line for leaks.

Afterthepump hasbeen primed,partiallyclosethe

discharge line throttling valve in order to fill the line

slowly and guard against excessive shock pressure which could damage pipe ends, gaskets,

sprinkler heads, and any other fixtures connected

to the line. When the discharge line is completely

filled,adjustthethrottlingvalve tothe requiredflow

rate.

boil, build pressure, and cause the pump to rupture or explode. If overheating occurs, stop the

pump and allow it to cool before servicing it. Refill

the pump casing with cool liquid.

Do not remove plates, covers, gauges,

pipe plugs, or fittings from an overheated pump. Vaporpressure withinthe

pump can cause parts being disengagedtobe ejectedwithgreat force.Allow the pump to cool before servicing.

Strainer Check

If a suction strainer has been shipped with the

pump or installed by the user, check the strainer

regularly, and clean it as necessary. The strainer

shouldalsobe checkedifpumpflowratebeginsto

drop. If a vacuum suction gauge has been installed, monitor and record the readings regularly

to detect strainer blockage.

Never introduce air or steam pressure into the

pump casingor piping to removea blockage.This

could result in personal injury or damage to the

equipment. If backflushing is absolutely necessary,liquid pressuremustbe limited to50% oft he

maximum permissible operating pressure. Since

this pump is fitted with a Gorman-Rupp double

grease lubricated seal, the maximum incoming

pressure must be reduced to 10 p.s.i.

Leakage

No leakage should be visibleat pump mating surfaces, or at pump connections or fittings. Keep all

lineconnectionsand fittingstight tomaintain maximum pump efficiency.

Liquid Temperature And Overheating

The maximum liquid temperature for this pump is

160_ F(71_C).Donotapplyitata higher operating

temperature.

Overheating can occur if operated with the valves

in the suction or discharge lines closed. Operating

against closed valves could bring the liquid to a

OPERATION PAGE C -- 3

Pump Vacuum Check

Withthe pump inoperative,installa vacuumgauge

in the system, using pipe dope on the threads.

Block the suction lineandstart thepump. At operating speed the pump should pull a vacuum of 20

inches (508,0 mm) or more of mercury. If it does

not, check for air leaks in the seal, gask et, or discharge valve.

Openthe suctionline,andread thevacuum gauge

with the pump primed and at operation speed.

Shut offthe pump. The vacuumgaugereading will

immediately drop proportionate to static suction

lift,andshouldthenstabilize.Ifthevacuumreading

falls off rapidly after stabilization, an air leak exists.

Page 17

OM--01216 0SERIES

Before checking for the source of the leak, check

the point of installation of the vacuum gauge.

STOPPING

Manual Stopping

In the manual mode, reduce the throttle speed

slowly, and allow the engine to idle briefly before

switching the HAND-OFF-AUTO switch to ‘OFF’.

If the application involves a high discharge

head, gradually close the discharge

throttling valve before stopping the pump.

Afterstoppingthe pump,switchoffthe engineignition and disconnect the positive battery cable to

ensure that the pump will remain inoperative.

Automatic Stopping

In the automatic mode, the pump will stop when

the liquid in the wet well or sump lowers and activatesthe“Off” floatswitch(s).Thepump willrestart

automatically when the liquid rises and activates

the “On” float switch(s).

Safety Shutdown System

The unit is equipped with a safety system to automaticallyshut down the engine under certain conditions. The engine will automatically shut down:

1. If the engine exceeds its safe operating temperature.

2. If the engine oil pressure drops below design

limits.

3. Iftheenginefailstostartwithinapre-setperiod of time.

Shouldany oft he safety featurescausethe engine

toshut down,the cause must bedeterminedand

correctedbeforeputtingtheunitback intoservice.

The engine will not restart until the HAND-OFFAUTOswitch has been returned to the ‘OFF’ position for at least 10 seconds.

Allsafetyshutdown features are pre-set at the factory for optimum performance and safety; do not

attempt to adjust these settings.

Neverdisconnectanyofthe safetyshutdown features; this will void the warran-

and could result in serious damage to

ty

theuni t and/orinjuryto personnel.Safety shutdown features are pre-set at the

factory; do not

attempt to adjust any of

the settings. Determine the cause of

shutdown before putting the unit back

into service. Consult the factory for additional information.

OPERATIONINEXTREMEHEAT

The safety shutdown system will automatically

stop the unit if engine operating temperature exceeds design limits. If engine over-temperature

shutdown occurs, allow the unit to cool before restarting.

If engine overheating continues, check the engine

lubricant level and viscosity. Consult the engine

operation manual for the recommended lubricant

for operation in extreme heat.

If the unit is equipped with the optional auto-start

control,the float(s)may need to be adjusted to allow shorter run and longer coolingperiods, ifpossible.

4. If the engine speed exceeds the safe operating range.

5. Iftheenginefanbeltbreaks.

Lights onthe control panelwillindicatewhich ofthe

safety features has caused the engine to shut

down.

Ifthe pump is equipped with the optional automatic starting system, it is subject to automatic restart. Keep hands

and clothing away from the unit to prevent injury during automatic operation.

Disconnect the battery before perform-

OPERATIONPAGE C -- 4

Page 18

0SERIES

OM--01216

ing any maintenance. Failure to do so

may result in serious personal injury.

BEARING TEMPERATURE CHECK

Bearingsnormallyrun at highert han ambient temperatures because of heat generated by friction.

Temperatures up to 160_F(71_C) are considered

normalforbearings, andthey canoperatesafelyto

at least 180_F(82_C).

Checkingbearingtemperatures byhand isinaccurate. Bearing temperatures can be measured accurately by placing a contact-type thermometer

against the housing. Record this temperature for

future reference.

A sudden increase in bearing temperatures is a

warning that the bearings are at the pointoffailing

to operate properly.Make certain that the bearing

lubricant is of the proper viscosity and at the correct level (see LUBRICATION in Section E). Bear-

ing overheating can also be caused by shaft

misalignment and/or excessive vibration.

When pumps are first started, the bearings may

seem to run at temperatures above normal. Con tinued operation should bring the temperatures

down to normal levels.

Cold Weather Preservation

In below freezing conditions, drain the pump to

preventdamagefrom freezing. Also,clean outany

solids by flushing w ith a hose. Operate the pump

for approximatelyone minute; this willremove any

remaining liquid that could freeze the pump rotating parts. If the pump will be idle for more than a

few hours, or if it has been pumping liquids containing a large amount of solids, drain the pump,

and flush it thoroughly with clean water .T oprevent

large solids from clogging the drain port and preventing the pump from completely draining, insert

a rod or stiff wire in the drain port, and agitate the

liquid during the draining process. Clean out any

remaining solids by flushing with a hose.

OPERATION PAGE C -- 5

Page 19

0SERIES

OM--01216

TROUBLESHOOTING --- SECTION D

Review all SAFETY information in Section A.

Beforeattemptingto openorservicethe

pump:

1. Familiarize yourself with this man ual.

2. Set the HAND-OFF-AUTO switch to

‘OFF’, and disconnect the positive

battery cable to ensure that the

pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

Ifthe pump is equipped with the optional automatic starting system, it is subject to automatic restart. Keep hands

and clothing away from the unit to prevent injury during automatic operation.

Disconnect the positive battery cable

before performing any maintenance.

Failuretodosomayresultinserious

personal injury.

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PUMP FAILS TO

PRIME

PUMP STOPS OR

FAILS TO DELIVER

RATED FLOW OR

PRESSURE

Not enough liquid in casing. Add liquid to casing. See PRIMING.

Suction check valve contaminated Clean or replace check valve.

or damaged.

Air leak in suction line. Correct leak.

Lining of suction hose collapsed. Replace suction hose.

Leaking or worn seal or pump gasket. Check pump vacuum. Replace

leakingorwornsealorgasket.

Suction lift or discharge head too high. Check piping installation and

install bypass line if needed. See

INSTALLATION.

Strainer clogged. Check strainer and clean if

necessary.

Suction check valve or foot valve Clean valve.

clogged or binding.

Air leak in suction line. Correct leak.

Lining of suction hose collapsed. Replace suction hose.

Leaking or worn seal or pump gasket. Check pump vacuum. Replace

leakingorwornsealorgasket.

Strainer clogged. Check strainer and clean if

necessary.

TROUBLESHOOTING PAGE D -- 1

Page 20

OM--01216

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

0SERIES

PUMP STOPS OR

FAILS TO DELIVER

RATED FLOW OR

PRESSURE (cont.)

PUMP REQUIRES

TOO MUCH

POWER

PUMP CLOGS

FREQUENTLY

Suction intake not submerged at Check installation and correct

proper level or sump too small. submergence as needed.

Impellerorotherwearingpartsworn Replacewornordamagedparts.

or damaged. Check that impeller is properly

centered and rotates freely.

Impeller clogged. Free impeller of debris.

Pump speed too s low. Check engine output; consult

engine operation manual.

Suction lift or discharge head too high. Check piping installation and

install bypass line if needed. See

INSTALLATION.

Pump speed too high. Check engine output.

Discharge head too low. Adjust discharge valve.

Liquid solution too thick. Dilute if possible.

Bearing(s) frozen. Disassemble pump and check

bearing(s).

Liquid solution too thick. Dilute if possible.

Discharge flow too slow. Open discharge valve fully to in---

crease flow rate, and run power

source at maximum governed

speed.

EXCESSIVE NOISE

BEARINGS RUN

TOO HOT

Discharge line clogged or restricted; Check discharge lines; straighten

hose kinked. hose.

Suction check valve or foot valve Clean valve.

clogged or binding.

Cavitation in pump. Reduce suction lift and/or friction

losses in suction line. Record

vacuum and pressure gauge

readings and consult local

representative or factory.

Pumping entrained air. Locate and eliminate source of air

bubble.

Pump or drive not securely mounted. Secure mounting hardware.

Impeller clogged or damaged. Clean out debris; replace damaged

parts.

Bearing temperature is high, but Check bearing temperature regu---

within limits. larly to monitor any increase.

Loworincorrectlubricant Checkforpropertypeandlevel

of lubricant.

Suction and discharge lines not Check piping installation for proper

properly supported. support.

Drive misaligned. Align drive properly.

TROUBLESHOOTINGPAGE D -- 2

Page 21

0SERIES

OM--01216

PREVENTIVE MAINTENANCE

Sincepump applicationsareseldomidentical,and

pump wear is directly affected by such things as

the abrasive qualities, pressure and temperature

oftheliquidbeingpumped, thissection isintended

only to provide general recommendations and

practices for preventive maintenance. Regardless

of the application however,following a routine preventive maintenance schedule will help assure

trouble-free performance and long life from your

Gorman-Rupp pump. For specific questions concerning your application, contact your GormanRupp distributor or the Gorman-Rupp Company.

Record keeping is an essential component of a

good preventive maintenance program. Changes

in suction and discharge gauge readings (if so

equipped) between regularly scheduled inspections can indicate problems that can be corrected

before system damage or catastrophic failure occurs.The appearanceof wearingpartsshouldalso

bedocumented ateach inspectionfor comparison

as well. Also, if records indicate that a certain part

(such as the seal) fails at approximately the same

duty cycle, the part can be checked and replaced

beforefailureoccurs,reducing unscheduleddown

time.

For new applications, a first inspection of wearing

partsat250 hourswillgiveinsightintothewearrate

foryourparticularapplication.Subsequentinspections should be performed at the intervals shown

on the chart below. Critical applications should be

inspected more frequently.

Preventive Maintenance Schedule

Service Interval*

Item

General Condition (Temperature, Unusual

Noises or Vibrations, Cracks, Leaks,

Loose Hardware, Etc.) I

Pump Performance (Gauges, Speed, Flow) I

Bearing Lubrication I R

Seal Lubrication (And Packing Adjustment,

If So Equipped) I R

V-Belts (If So Equipped) I

Air Release Valve Plunger Rod (If So Equipped) I C

Front Impeller Clearance (Wear Plate) I

Rear Impeller Clearance (Seal Plate) I

Check Valve I

Pressure Relief Valve (If So Equipped) C

Pump and Driver Alignment I

Shaft Deflection I

Bearings I

Bearing Housing I

Piping I

Driver Lubrication --- See Mfgr’s Literature

Daily Weekly Monthly Semi-

Annually

Annually

Legend:

I = Inspect, Clean, Adjust, Repair or Replace as Necessary

C= Clean

R= Replace

* Service interval based on an intermittent duty cycle equal to approximately 4000 hours annually.

Adjust schedule as required for lower or higher duty cycles or extreme operating conditions.

TROUBLESHOOTING PAGE D -- 3

Page 22

0SERIES OM--01216

PUMP MAINTENANCE AND REPAIR - SECTION E

MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK

OPERATING PERFORMANCE.

STANDARD PERFORMANCE FOR PUMP MODEL 04B3--F4L

Based on 70_ F(21_ C) clear water at sea level

with minimumsuction lift.Since pump installations

areseldomidentical,yourperformancemaybe difference due to such factors as viscosity, specific

gravity, elevation, temperature, and impeller trim.

Never tamper with the governor to gain

more power. The governor establishes

If your pump serial number is followed by an “N”,

your pump is NOT astandardproductionmodel.

Contact the Gorman-Rupp Company to verifyperformance or part numbers.

MAINTENANCE & REPAIR PAGE E -- 1

safe operating limits that should not be

exceeded. The maximum continuous

operating speed for this pump is 2400

RPM.

Page 23

SECTION DRAWING

0SERIESOM-- 01216

Figure 1. 04B3---F4L Pump Model Assembly

MAINTENANCE & REPAIRPAGE E -- 2

Page 24

0SERIES OM--01216

PARTS LIST

Pump Model 04B3---F4L

(From S/N 1242057 Up)

Ifyourpump serialnumber is followedby an “N”,your pumpis NOT a standard production model. Contact

the Gorman-Rupp Company to verify part numbers.

ITEM

NO.

10 FUEL RETURN LINE 14294 24030 1

11 MUFFLER GUARD ASSY 42331---031 --- ------ 1

12 DEUTZ F4L 912D ENG 29217---043 --- --- --- 1

13 CAUTION DECAL 38816---169 --- - -- --- 1

14 BAT T E RY B O X A S S Y GR P 40 --- 08 C --- --- --- 1

15 ---HEX HD CAPSCREW B0607 15991 2

16 ---FLAT WASHER K06 15991 2

17 ---HEX NUT W/FLANGE 21765---314 --- ------ 2

18 ---GRND CABLE ASSY 47311---064 --- --- --- 1

19 ---BATT BOX LID ASSY 42113---012 24150 1

20

21 ---BATTERY TAG 38818- --506 ------ --- 1

22 ---BATTERY BOX ASSY 42431---030 24150 1

23 ---STUD MOUNT 24631---006 --- --- --- 4

24 ---FLANGED HEX NUT 21765---314 --- ------ 8

25 ---T TYPE LOCKWASHER BL06 15991 1

26 POS CABLE ASSY 47311---114 ------ --- 1

27 HEX HD CAPSCREW B1017 15991 2

28 LOCKWASHER J10 15991 2

29 HEX NUT D10 15991 2

30 OIL DRAIN ASSY 46342---007 --- - -- --- 1

PART NAME PART

NUMBER

1 P U MP E N D A S S Y 04B3 --- (SA E 4/ 1 0) --- --- --- 1

2 CONTROL PANEL 48122---501 --- --- --- 1

3 EXHAUST ELBOW 31912---023 15990 1

4 WEATHER CAP S1331 --- ------ 1

5 FUEL RETURN LINE 11308F ------ --- 1

6 HOSE CLAMP 26518---641 --- -- ---- 2

7 HOSE BARB FITTING 26523---443 --- ------ 1

8 MALE CONNECTOR 26523---382 ------ --- 1

9 REDUCER ELBOW Q0402 11999 1

---12V BATTERY SEE OPTION LIST REF

MAT’L

CODE

QTY ITEM

NO.

31 HOSE INLET ASSY 46341---796 ------ --- 1

32 MALE CONNECTOR S1447 --- ------ 1

33 HEX HD CAPSCREW B1007 15991 4

34 LOCKWASHER J10 15991 4

35 HEX NUT D10 15991 4

36 FUEL TANK AND 46711---041 ------ --- 1

37 ---FUEL TANK ASSY 46711---042 ------ --- 1

38 ---FLANGED HEX NUT 21765---314 --- ------ 6

39 ---CARRIAGE BOLT AB0604 15991 6

40 ---FLAT WASHER K06 15991 6

41 ---TANK GRD ASSY 34851---178 15080 1

42 FLANGED HEX NUT 21765---314 --- ------ 10

43 FLAT WASHER K06 15991 10

44 HEX HD CAPSCREW B0604 15991 10

45 COMBINATION BASE 41566- --669 24150 1

46 HEX HD CAPSCREW B1010 15991 2

47 LOCKWASHER J10 15991 2

48 HEX NUT D10 15991 2

NOT SHOWN:

OPTIONAL:

PART NAME PART

NUMBER

GUARD ASSEMBLY

WARNING DECAL 2613FE ------ - -- 1

12V BATTERY 29331---506 --- ------ 1

WHEEL KIT GRP30---248F --- ------ 1

PRESSURE GAUGE 48312---012 --- --- --- 1

REPAIR MUFFLER 42331- --048 ------ --- 1

GUARD ASSEMBLY

MAT’L

CODE

QTY

INDICATES PARTSRECOMMENDEDFOR STOCK

MAINTENANCE & REPAIR PAGE E -- 3

Page 25

SECTION DRAWING

0SERIESOM-- 01216

Figure 2. 04B3---(SAE 4/10) Pump End Assembly

MAINTENANCE & REPAIRPAGE E -- 4

Page 26

0SERIES OM--01216

PARTS LIST

04B3---(SAE 4/10) Pump End Assembly

ITEM

NO.

10 RD HD MACH SCREW X0404 15991 2

11

12 LU B E F IT TING S1 91 --- --- --- 1

13 PIPE NIPPLE T0410 15079 1

14 PIPE COUPLING AE04 15079 1

15 CAP PLUG 25141---151 --- - -- --- 1

16 ALLEN HD SETSCREW GA0403 15990 1

17

18

19

20 INTERMEDIATE GUARD 42381---504 --- ------ 2

21 BEARING RET NUT 4329 10010 1

22 SPACER 13886 15990 1

23 RET AIN I N G R ING S2 1 5 --- --- --- 1

PART NAME PART

1 PUMP CASING 4820C 10010 1

2

IMPELLER 4803D 14000 1

SEAL ASSY 25271---207 --- ------ 1

3

4 DISCHARGE STICKER 6588BJ ------ --- 1

5 STUD C1010 15991 8

6 HEX NUT D10 15991 8

7

WEAR RING 3765A 10010 1

8 DISCHARGE FLANGE 1756 10010 1

9

DISCH FLANGE GASKET 1676GB 20000 1

BALL BEARING 23423---472 --- -- ---- 1

IMP ADJ SHIM SET 37J 17090 REF

SHAFT KEY N0607 15990 1

IMPELLER SHAFT 38517---517 1706H 1

NUMBER

MAT’L

CODE

QTY ITEM

NO.

24 RET AIN I N G R ING S2 1 5 --- --- --- 1

25 INTERMEDIATE 7765D 10010 1

26

27 STUD C1010 15991 12

28 HEX NUT D10 15991 12

29 SEAL PLATE 5792 10010 1

30

31

32 NAME PLATE 38818---018 13990 1

33 DRIVE SCREW BM#04---03 17000 4

34 PIPE PLUG P06 15079 1

35 STUD C0807 15991 6

36 HEX NUT D08 15991 6

37 COVER PLATE 4822 10010 1

38

39

40 SUCTION FLANGE 1756 10010 1

41 HEX HD CAPSCREW B1005S 15991 1

42 T TYPE LOCKWASHER AK10 15991 1

43 IMPELLER WASHER 5718 15990 1

44 HEX HD CAPSCREW C1010 15991 8

45 HEX NUT D10 115991 8

46 DISCHARGE STICKER 6588AG --- --- --- 1

47 FILL PLUG ASSY 48271---065 --- ------ 1

PART NAME PART

NUMBER

WEAR RING 6902 10010 1

PUMP CASING GASKET 4820G 20000 1

IMPELLER KEY N0408 15990 1

COVER PLATE GASKET 4822G 20000 1

SUCT FLANGE GASKET 1676GB 20000 1

MAT’L

CODE

QTY

INDICATES PARTSRECOMMENDEDFOR STOCK

MAINTENANCE & REPAIR PAGE E -- 5

Page 27

SECTION DRAWING

0SERIESOM-- 01216

Figure 3. 04B3---(SAE 4/10) Drive Assembly

PARTS LIST

ITEM

NO.

1 PILOT BUSHING ASSY 44144---003 ------ --- 1

2 COUPLING KIT 48112---001 --------- 1

3 ---BUSHING 24131---345 ------ --- 1

4 ---COUPLING ASSEMBLY 44165---011 --------- 1

5 ---LOCKWASHER 21171---536 --------- 8

6 ---SOCKET HD CAPSCREW 22644---220 --------- 8

7 HEX HD CAPSCREW 22645---164 --------- 12

8 LOCKWASHER 21171---511 --------- 12

PART NAME

PART

NUMBER

MAT’L

CODE

MAINTENANCE & REPAIRPAGE E -- 6

QTY

Page 28

OM--012160SERIES

PUMP AND SEAL DISASSEMBLY

AND REASSEMBLY

Review all SAFETY information in Section A.

Followtheinstructionson all tags,labeland de cals attached to the pump.

This pump requires little service due to its rugged,

minimum-maintenance design. However, if it becomesnecessarytoinspect orreplacethe wearing

parts, followthese instructionswhichare keyed to

thesectionalviews(seeFigures 1,2 and3) andthe

accompanying parts lists.

As described on the following pages, this manual

willalert personnel toknown procedures which require special attention, to those which could dam age equipment, and to those which could be dangerousto personnel. However,this manualcannot

possibly anticipate and provide detailed precautions for every situation that might occur during

maintenanceof theunit. Therefore,itis theresponsibilityof the owner/maintenance personnel to ensure that only safe, established maintenance proceduresare used, andthat anyproceduresnot addressedinthismanualareperformedonlyafterestablishingthat neitherpersonal safetynorpump integrity are compromised by such practices.

Before attempting to service the pump, switch off

theengineignitionanddisconnect thepositivebatterycabletoensure thatthe pumpwill remaininoperative. Close all valves in the suction and dis charge lines.

Forengine disassembly and repair, consult the literature supplied with the engine, or contact your

local engine representative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

Pump Disassembly

(Figure 2)

Beforeattemptingtoservicethepump, removethe

pump casing drain plug (34) and drain the pump.

Clean and reinstall the drain plug.

To service the wear ring (7), impeller (2), seal assembly (3), or seal plate (29), the pump casing (1)

mustbe separatedfromthebase andintermediate

(25).

Remove the suction and discharge lines. See Figure1,andremovethehardware(46, 47and 48)securing the casing to the base (45). Remove the

nuts(28)and useasuitablehoistand slingtoseparatethe pumpcasingandgasket(30)fromtheseal

plate and intermediate.

Use lifting and moving equipment in

good repair and with adequate capacity

toprevent injuriestopersonnelordamage to equipment. Suction and discharge hoses and piping must be removed from the pump before lifting.

Tieand tagany levelingshims usedunder the casing feet to ease reassembly.

Beforeattemptingto openorservicethe

pump:

1. Familiarize yourself with this man ual.

2. Switch off the engine ignition and

disconnect the positive battery

cable to ensure that the pump will

remain inoperative.

MAINTENANCE & REPAIR PAGE E -- 7

Inspect the wear ring (7) for excessive wear or

scoring.The wear ring issecured in the pumpcasing by a press fit. If replacement is required, use a

small bit to drill two holes through the ring horizontally, 180_ apart. Use a saw or chisel to complete

the cuts through the ring, and remove it from the

pump casing. Use caution not to damage the

pump casing bore when removing the wear ring.

Page 29

Use caution not to damage the pump casing bore when removing the wear ring.

0SERIESOM--01216

(Figure 3)

Support the intermediate using a hoist and sling,

and remove the hardware (7 and 8) securing it to

theenginebellhousing.Separatetheassemblies

by pulling the intermediate straight away from the

engine.

Impeller Removal

(Figure 2)

To remove the impeller (2), disengage the hardware(41,42 and 43).Install3/8---16UNCby 4-inch

longcapscrews inthetapped holesin the impeller.

Use thecapscrewsanda suitablepuller toremove

the impeller from the shaft. Use caution when removingthe impeller;tension on the sealspring will

be released as the impeller is removed. Retain the

impeller key (31).

Remove the impelleradjusting shims (17). Tie and

tag the shims or measure and record their thickness for ease of reassembly.

Seal Removal and Disassembly

(Figures 2 and 5)

Removethe spring. Apply oilto the shaft and work

it up under the rubber bellows. Slide the rotating

portionofthesealofftheshaft.

Remove the round head machinescrews (10) and

slide the seal plate and stationary element off the

impeller shaft as a unit. Press the stationary seal

element and O-ring out of the seal plate from the

back side.

Inspect the wear ring (26) for excessive wear or

damage. If replacement is required, use a suitable

puller to remove it from the seal plate.

As the assemblies separate, the flexible portionof

the couplingassembly(4) will remain on the shaft.

Toremovethe couplingfromt he shaft,unscrew the

two allen head setscrews from the bushing (3).

Screw one ofthe setscrews into the puller holeon

the circumference of the bushing. As the coupling

and bushing separate, remove the bushing, and

slide the coupling off the shaft. Remove the shaft

key (18, Figure 2).

It is not necessary to remove the outer ring of the

coupling from the engine flywheel unless the couplingmust be replaced. To removethe ring, disengage the hardware (5 and 6) securing it to the flywheel.

Inspect t he pilot bushing (1) for excessive wear. If

replacement is required, it can be easily removed

from the engine flywheel by making a hydraulic

ramfroma piece ofsteel bars tock. Turnthe ramto

a diameter of 0.983 inch (25 mm).

Whenperforming the following procedure,

grease can be ejected with great force.

Wear safety glasses or goggles to prevent

injury.

Completelypack the bore of the pilotbushingwith

grease. Insert theendof the ram intothe I.D.of the

bushing. Strike the ram sharply with a hammer,

compressing the grease, and forcing the bushing

out of the flywheel. Use additional grease as required, and continue to strike the ram until the

bushing is completely free.

Separating Intermediate and Drive Assembly

From Engine

(Figure 2)

To service the shaft (19), bearing (11) or drive assembly, the intermediate (25) must be separated

from the engine.

Shaft and Bearing Removal and Disassembly

(Figure 2)

When the pump is properly operated and maintained, the shaft and bearing should not require

disassembly. Disassemble the shaft and bearing

only when there is evidence of wear or damage.

MAINTENANCE & REPAIRPAGE E -- 8

Page 30

Shaft and bearing disassembly in the field

is not recommended. These operations

should be performed only in a properly

equipped shop by qualified personnel.

After separating the intermediatefrom the engine,

loosen the allen head setscrew (16) and unscrew

thebearing retainernut (21) fromtheintermediate.

NOTE

There are no provisions for draining the grease

fromtheintermediatecavity.Placea drip pan under

theintermediatebeforeremovingtheshaftand

bearing.

OM--012160SERIES

Cleanthebearingthoroughlyinfreshcleaningsolvent. Dry the bearing with filtered compressed air

and coat with light oil.

Thebearingmustbekeptfreeofalldirtand

foreign material. Failure to do so willgreatly shorten bearing life. Do not spin dry

bearings. This may scratch the balls or

races and cause premature bearing failure.

Rotatethe bearingbyhand tocheck forroughness

or binding and inspect the bearing balls. If rotation

is rough or the bearing balls are discolored, replace the bearing.

Place a block of wood against the impeller end of

the shaft (19) and tap the shaft, spacer (22) and

bearing (11) from the bearing bore.

Afterremoving theshaftand bearing, cleanandinspect the bearing in place as follows.

To prevent damage during removal from

theshaft, it is recommendedthat thebearing be cleaned and inspected in place.It

isstrongly recommended that thebearing

bereplacedany time theshaftandbearing

are removed.

Clean the intermediate, s haft and all component

parts (except the bearing) with a soft cloths oaked

in cleaning solvent. Inspect t he parts for wear or

damage and replace as necessary.

Most cleaning solvents are toxic and

flammable. Use them only in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solventcontainers.

The bearing tolerances provide a tight press fit

ontothe shaft and a snug slipfit into the intermediate. Replace the bearing, shaft, or intermediate if

the proper bearing fit is not achieved.

Remove the inboard bearing retaining ring (24)

andusing anarbor (orhydraulic)press removethe

bearing (11) from the shaft. It is not necessary to

remove the outboard bearing retaining ring (23)

from the shaft unless replacement is required. Remove the bearing spacer (22).

Shaftand Bearing Reassembly and Installation

Clean and inspect the bearing as indicated in

Shaft and Bearing Removal and Disassembly.

To prevent damage during removal from

theshaft, it is recommendedthat thebearing be cleaned and inspected in place.It

isstrongly recommended that thebearing

be replaced any time the shaft and and

bearings are removed.

Inspect the shaft for distortion, nicks or scratches

ordamage. D ress small nicks and burrswith a fine

file or emery cloth. Replace the shaft if defective.

Installthe outboard bearing retaining ring (23) if it

was removed. Replace the bearing spacer (22).

MAINTENANCE & REPAIR PAGE E -- 9

Page 31

0SERIESOM--01216

NOTE

If ahot oil bathis used to heat thebearing, boththe

oil and the container must be absolutely clean. If

the oil has been previously used, it must be thor-

oughly filtered.

Thebearing maybe heatedto ease installation.An

induction heater, hot oil bath, electric oven, or hot

plate may be used to heat the bearing. Bearings

should never be heated with a direct flame or directly on a hot plate.

NOTE

Positionthebearing ontheshaftas indicated inFigure 4.

BALL LOADING

DIRECTIONOF

THRUST

GROOVE POSITIONED

AWAY FROM

LOADING

GROOVE

IMPELLER

Heat the bearing to a uniform temperature no

higher than 250_F (120_C), and slide the bearing

ontothe shaft until fullyseated against the bearing

spacer. This should be done quickly, in one continuous motion, to prevent the bearing from cooling and sticking on the shaft.

Use caution when handling hot bear ings to prevent burns.

BALL LOADING

DIRECTIONOF

THRUST

GROOVE POSITIONED

TOWARD

LOADING

GROOVE

IMPELLER

INSTALLATION OF NEW DEPARTURE OR

BCA/FEDERAL MOGAL 5300W SERIES BEARINGS

(OPEN OR ENCLOSED IMPELLERS)

Figure 4. Bearing Positioning

After the bearing has been installed and allowed to

cool, check to ensure that it has not moved in

shrinking. If movement has occurred, use a suitable sized sleeve and a press to reposition the

bearing.

Ifheatingthebearingis notpractical,usea suitable

sizedsleeveandan arbor(orhydraulic)press toinstall the bearing on the shaft.

When installing the bearing on the shaft,

never press or hit against the outer race,

balls, or ball cage. Press only on the inner

race.

Packthe bearing by hand with No. 0 lithiumbased

grease until the bearing balls are thoroughly lubri-

INSTALLATIONOF MRC/SKF5300M OR

FAFNIR 5300W SERIES BEARINGS

(OPEN OR ENCLOSED IMPELLERS)

cated. Secure the bearing on the shaft with the inboard bearing retaining ring (24).

Slide the shaft and assembled bearing into the intermediate bore from the drive end until the bearing seats squarely against the bore shoulder.

When installing the shaft and bearing into

the bearing bore, push against the outer

race. Never hit the balls or ball cage.

Installthe spacer(22)in theintermediate. Packthe

intermediate w ith 2/3 lb. (0.3 kg.) of No. 0 lithium

based grease (approximately 1/3 full).

Screw the bearing retaining nut (21) into the intermediate and check the shaft endplay. Adjust the

bearing retaining nut to establish the correct

MAINTENANCE & REPAIRPAGE E -- 10

Page 32

OM--012160SERIES

endplay,and secure the bearingretaining nutwith

the setscrew (16).

NOTE

Impellershaftendplayshouldbe between.002and

.010inch(0,05mmto0,25mm). Adjustthebearing

retaining nut to obtain the correct endplay.

Securing Intermediate and Drive Assembly To

Engine

(Figure 3)

Ifremoved,apply a thincoating of‘Never-Seez’(or

equivalent) lubricant to the inside diameter of the

replacement pilot bushing (1) and press it into the

flywheel until fully seated.

Install the shaft key (18, Figure 2) in the shaft keyway.Position the flexible portion ofthecouplingassembly (4) on the shaft as shown in Figure 3.

NOTE

Theflexible portion ofthe coupling mustbeproperly positioned on the shaft. The heads of the capscrews in the center of the coupling must be posi-

tioned toward the pump end of the shaft.

Align the keyway in the bushing (3) with the shaft

key, and slide it onto the shaft to the dimension

showninFigure3.

without pre-loading the bearing or pilot

bushing.

Rotate the flexible portion of the coupling until the

tappedholesforthetwosetscrewsalign withthose

in the bushing, and install the setscrews.

With the flexible portion of the coupling and the

bushing properly positioned on the shaft, tighten

the two setscrews in an alternatingsequence until

thebushing andcouplingare fullysecured.Torque

thesetscrewsto175in.lbs.(2m.kg.).

If the complete coupling assembly is being replaced, apply ‘ Loctite Retaining Compound No.

242’ or equivalent compound to the threads of the

hardware(5and 6),andsecure theouterringofthe

coupling to the engine flywheel by torquing the

hardwareto45ft.lbs.(540in.lbs.or6,2m.kg.).

Using a suitable lifting device, position the assembled intermediate and flexible portion of the

couplingso thecouplingseatsinsidetheouterring

attached to the engine flywheel.

NOTE

Toeaseinstallation,lightlylubricatetherubberportion of the coupling with a non-petroleum based

lubricant suchasvegetableoilor glycerin,ora silicon-based lubricant such as“WD40”or equivalent.

Donot usepetroleum-basedlubricants,oranyother substance which may soften or otherwise damage the rubber.

Secure the intermediate to the engine bellhousing

with the previously removed hardware (7 and 8).

Make certain that the flexible portion of the

coupling is mounted as shown in Figure 3.

Seal Reassembly and Installation

(Figures 2 and 5)

Thisis critical. If the coupling is not prop-

erly positioned on the shaft, the coupling

Cleanthe seal cavityandshaft witha clothsoaked

in fresh cleaning solvent.

parts may not fully engage, or a pre-load

condition can cause premature bearing

failure.

The flexible portion of the coupling, shaft

key and bushing must be positioned on

theshaft to thedimension shown inFigure

3. This will allow the two portions of the

coupling to fullyengage when the intermediate is secured to the engine bellhousing,

MAINTENANCE & REPAIR PAGE E -- 11

Most cleaning solvents are toxic and

flammable. Use them only in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solventcontainers.

Page 33

0SERIESOM--01216

The sealis not normallyreused because wear patterns on the finished faces cannot be realigned

during reassembly. This could result in premature

failure.Ifnecessary toreuse anoldsealinanemergency, carefully w ash all metallic parts in fresh

cleaning solvent and allow to dry thoroughly .

Handlethe seal parts with extreme care to prevent

damage. Be careful not to contaminate precision

finished faces; even fingerprints on the faces can

shortenseallife.Ifnecessary,cleanthefaceswitha

non-oilbased solvent and a clean, lint-free tissue.

Wipe lightly in a concentric pattern to avoid

scratching the faces.

SPRING

RETAINER

IMPELLER

SHAFT

KEY

Inspect the seal components for wear, scoring,

grooves,and otherdamage that mightcauseleakage.Ifany componentsareworn,replacethe complete seal; never mix old and new seal parts.

If a replacement seal is being used, remove it from

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter.

To ease installation of the seal, lubricate the bellows and O-rings with water or a very small

amount of light lubricating oil, and apply a drop of

lightlubricatingoilonthe finishedfaces.Assemble

thesealasfollows,(seeFigure5).

SEAL PLATE

O-RING

IMPELLER

SHAFT

BELLOWS

IMPELLER

SHIMS

DRIVE BAND

Figure 5. 25271--207 Seal Assembly

This seal is not designed for operation at

temperatures above 160_F(71_C). Do not

use at higher operating temperatures.

STATIONARY

SEAT

ROTATING

ELEMENT

plate untilit seatssquarelyagainst the bore shoulder.

Laythe seal plate (29)on a flat surface with the impeller side facing up. If the wear ring (26) was removed, press the replacement ring into the seal

The wear ring must seat squarely in the

seal plate bore or binding and/or excessive wear will result.

MAINTENANCE & REPAIRPAGE E -- 12

Page 34

OM--012160SERIES

Subassemble the O-ring onto the stationary element and use even pressure to press this subassembly into the seal plate until it seats squarely

against the shoulder bore

Carefully slide the assembled seal plate and stationarysealelement overtheshaft.Securetheseal

plate to the intermediate w ith the round head machine screws (10).

NOTE

It is recommended that a tapered sleeve be installedover the endof theimpellershaft to easeinstallation of the rotating seal components.

Subassemble the rotating element into theretainer

and bellows. Lubricate the I.D. of the bellows with

water,and slidethis subassemblyoverthetapered

CD

sleeve and onto the shaft until the polished faces

contact. Install the seal spring.

Impeller Installation

(Figure 2)

Inspect the impeller, and replace it if cracked or

badly worn.

Formaximum pump efficiency,the impellershould

be centered within the volute scroll.

To verify the impeller positioning, measure the

pump casing and impeller as shown in Figure 6.

Usethese measurementstocalculatetherequired

impeller location (dimension E). Add orremoveimpelleradjusting shims (17) untildimension E isobtained.

B

2

AB

B

+

A

2

Figure 6. Centering Impeller Within Volute Scroll

Installthe correct thickness of impellershims, and

install the impeller key (31) in the shaft keyway.

Align the impeller keyway with the key, and slide

the impeller onto the shaft until fully seated. M ake

sure theseal s pring seats squarely over the shoulder on the back of the impeller.

NOTE

After the impeller has been properly positioned,

check for free rotation. Correct any scraping binding before further reassembly.

D

2

E

Step 2Step 1 Step 3

---

D

+

C

2

Pump Reassembly

(Figure 2)

If removed at disassembly, press the replacement

wear ring (7) into the pump casing until it seats

squarely against the shoulder bore.

=

E

The wear ring must seat squarely in the

When the impeller is properlypositioned, secure it

with the hardware (41, 42 and 43).

MAINTENANCE & REPAIR PAGE E -- 13

casing bore or binding and/or excessive

wear will result.

Page 35

0SERIESOM--01216

Install the casing gasket (30) and secure the casingto the seal plateand intermediatewith the nuts

(28). See Figure 1, reinstall any leveling shims under the casing mountingfeet, and secure the casing to the base (45) with the previously removed

hardware (46, 47 and 48).

Final Pump Assembly