Page 1

•

gorenJe

gorenje

OGB 30-200

SEDDN9

Page 2

Dear buyer, we

thank

you

for

purchase

of

our

product. I

Prior

to

installation and

first

use

of

the electric

water

heater, please carefully read

these instructions.

THIS APPLIANCE IS NOT INTENDED FOR USE BY PERSONS (INCLUDING CHILDREN)

WITH REDUCED PHYSICAL, SENSORY

OR

MENTAL CAPABILITIES, OR

LACK

OF

EXPERIANCE

AND

KNOWLEDGE, UNLESS THEY HAVE BEEN GIVEN SUPERVISION

OR INSTRUCTION CONCERNING USE OF

THEAPPLIANCE

BY

PERSON RESPONSIBLE

FOR THEIR

SAFETY.

CHILDREN

SHOULD

BE SUPERVISED TO ENSURE THAT THEY

DO

NOT PLAY WITH

THE APPLIANCE.

This

water

heater

has

been

manufactured

in

compliance

with

the

relevant

standards

and

tested

by

the

relevant

authorities

as

indicated

by

the

Safety

Certificate

and

the

Electromagnetic

Compatibility

Certificate.

The

technical

characteristics

of

the

product

are

listed

on

the

label

affixed

between

the

inlet

and

outlet

pipes.

The

installation

must

be carried

out

by

qualified

staff.

All

repairs

and

maintenance

work

within

the

water

heater, e.g.

lime

removal

or

inspection/replacement

of

the

protective

anticorrosion

anode, must

be

carried

out

by

the

authorised

maintenance

service

provider.

BUILDING-IN

The

water

heater

shall

be built-in

as

close

as

possible

to

the

outlets.

When

installing

the

water

heater

in a

room

with bathtub

or

shower,

take

into

account

requirements

defined

in

IEC

Standard

60364- 7-701

(VDE

0100,

Part

701

).

It

has

to

be

fitted

to

the

wall

using

appropriate

rag

bolts

with

minimum

diameter

of

8 mm.

The

wall

with

feeble

charging

ability

must

be on

the

spot

where

the

water

heater

shall

be

hanged

suitably

reinforced.

The

water

heater

may

be fixed upon the wall only vertically.

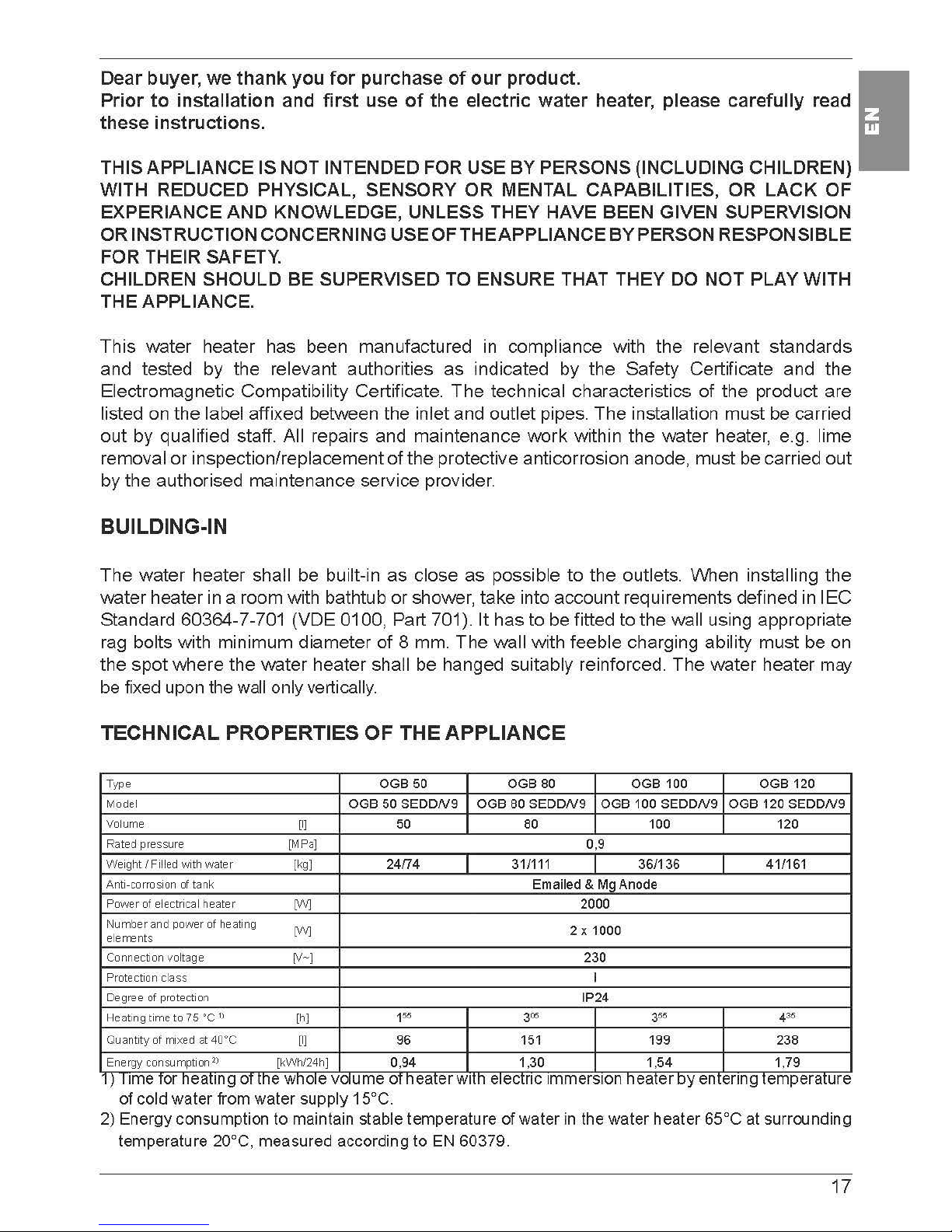

TECHNICAL PROPERTIES OF THE APPLIANCE

Type

OGB50 OGB80

OGB

100

OGB

120

Model

OGB

50

SEDDN9

OGB

80

SEDDN9

OGB

100

SEDDN9

OGB

120

SEDDN9

Volume

[I]

50

80

100 120

Ra

ted pressure [

MPa

] 0,9

Weight I Fi

lled IMth wat

er

[kg]

24/74

31/111

36/1

36

41/161

Anti.corrosion of

tank

Emailed

& Mg

Anode

Power of electrical heat

er

['N]

2000

Nu

mber

and

pow

er of heating

['N] 2 x

1000

el

ements

Connection

vol

tage

[V

-J

230

Protecti

on

cla

ss

I

Degree

of protection

IP24

Heating

time to

75

°( 1) [h]

1"

3"' 3" 4"

Quantity of rrixed at 40°C

[I

]

96

151

199

238

Energy

consumpt

ion2) [kWhl24h]

0,94

1,30

1,

54

1,

79

1) lime

Tor

neat1ng

oT

me

wno1e

volume orneater

w1m

e1ectnc

1mmers1on

neater oy entering temperature

of cold water from water supply 15°C.

2) Energy consumption to maintain stable temperature of water

in

the water heater 65°C

at

surrounding

temperature

20°C, measured according to

EN

60379.

17

Page 3

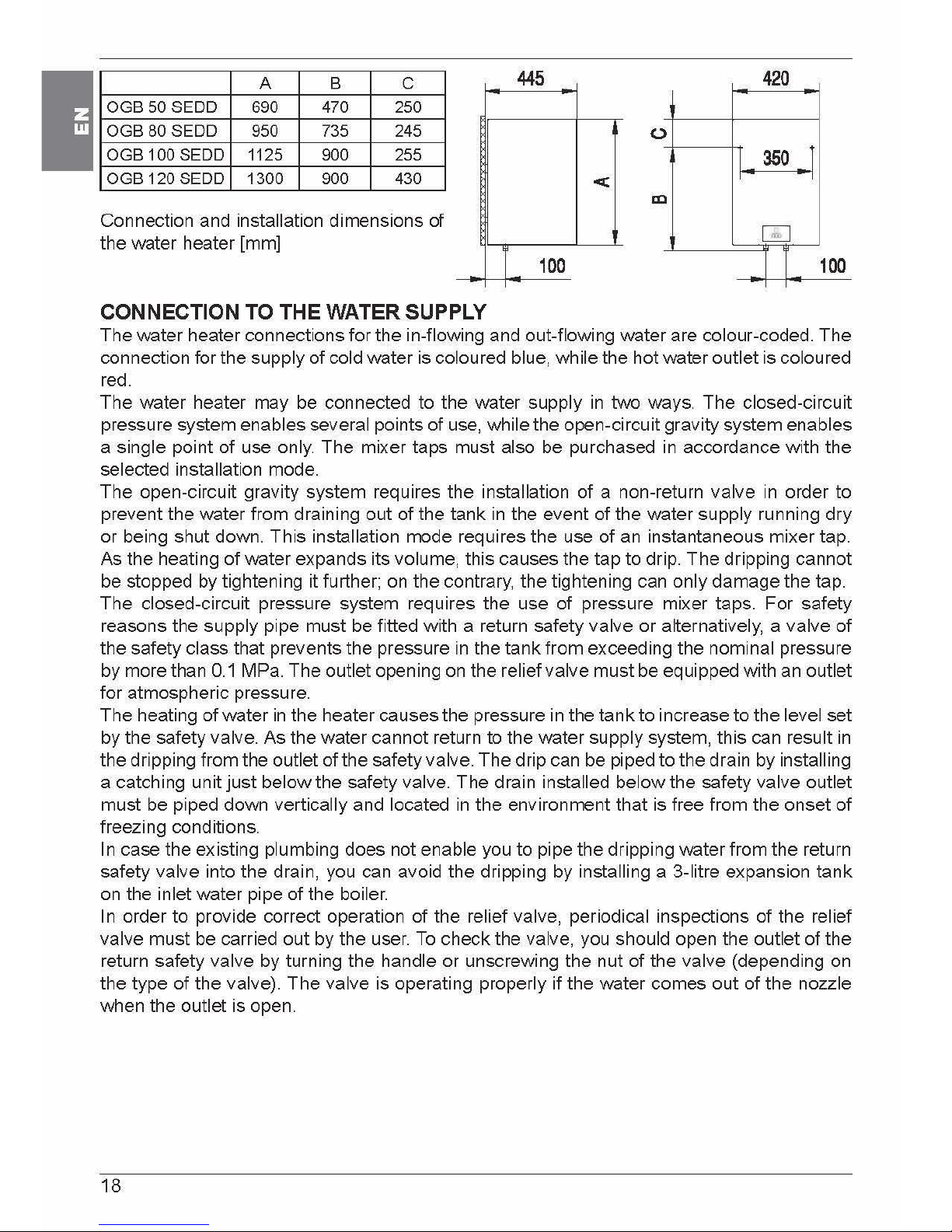

A B c

OGB

50

SEDD 690 470 250

OGB

80

SEDD 950 735 245

OGB 100 SEDD 1125 900 255

OGB 120 SEDD 1300 900 430

Connection and installation dimensions of

the

water heater [mm]

CONNECTION TO THE WATER SUPPLY

445

420

(.)

I

350

r

<

I I

GJ

r

100

I I

100

I I I

The

water heater connections for the in-flowing and out-flowing water are colour-coded. The

connection for the

supply of cold water is coloured blue, while the hot water outlet is coloured

red.

The

water heater may be connected to

the

water supply

in

two

ways. The closed-circuit

pressure system enables several points

of

use, while the open-circuit gravity system enables

a single point

of

use only. The mixer taps must also be purchased in accordance with the

selected installation mode.

The

open-circuit gravity system requires

the

installation of a non-return valve

in

order to

prevent the water from draining out

of

the

tank

in the event

of

the water supply running

dry

or being shut down.

This

installation mode requires

the

use

of

an instantaneous mixer tap.

As

the

heating of water expands its volume, this causes the tap to drip.

The

dripping cannot

be stopped

by

tightening it further; on

the

contrary,

the

tightening can only damage

the

tap.

The

closed-circuit pressure system requires

the

use of pressure mixer taps. For safety

reasons the

supply pipe must be fitted with a return safety valve

or

alternatively, a valve

of

the

safety class that prevents

the

pressure

in

the

tank

from exceeding the nominal pressure

by more than

0.1

MPa. The outlet opening on the relief valve must be equipped with an outlet

for atmospheric pressure.

The

heating

of

water

in

the

heater causes the pressure

in

the

tank

to increase

to

the level set

by the safety

valve.

As

the water cannot return to

the

water supply system, this can result

in

the

dripping from the outlet of

the

safety valve.

The

drip can be piped

to

the drain by installing

a catching unit just

below

the safety valve.

The

drain installed below

the

safety valve outlet

must be piped down vertically and located

in

the

environment

that

is free from

the

onset

of

freezing conditions.

In case the existing plumbing does not enable you to pipe

the

dripping water from the return

safety

valve into the drain, you can avoid the dripping by installing a 3-litre expansion

tank

on the inlet water pipe

of

the boiler.

In

order to provide correct operation of

the

relief valve, periodical inspections of

the

relief

valve

must be carried

out

by the user.

To

check the valve, you should open the outlet

of

the

return safety

valve by turning the handle

or

unscrewing

the

nut

of

the

valve (depending on

the

type of the valve).

The

valve is operating properly if the water comes

out

of the nozzle

when the outlet is open.

18

Page 4

~T~--\

\ \

~

7 2 3 6 4 5

Closed (pressure) system

Legend:

1 - Safety

valve

2 - Test valve

3 - Non-return valve

4 - Pressure reduction valve

5 - Closing valve

Open

(non-pressure) system

6 - Checking fitting

7 -

Funnel with outlet connection

H -

Cold water

T - Hot water

Between the water heater and return safety valve no closing valve may be built-in

because with it the function of return safety valve wou

Id

be impeded.

The water heater may be connected to the water network

in

the house without reduction

valve if the pressure

in

the network is lower than 0.5 MPa

(5

bar). If the pressure exceeds

0.5 MPa (5 bar), a reduction valve must be installed. Prior

to

the electric connection the

water heater must

obligatorily be filled with water. By first filling the tap for the hot water upon

the mixing tap must be opened. When the heater is

filled with water, the water starts

to

run

through the

outlet pipe of the mixing tap.

CONNECTION OF THE WATER HEATER

TO

THE ELECTRIC NETWORK

Before connecting to power supply network, install a power supply cord

in

the water heater,

with a min. diameter of 1,5 mm

2

(H05VV-F 3G 1,5 mm

2

).

For it the protection plate must be

removed from the water heater.

The connection of water heater

to

the electric network must be performed according to

standards for

electric installation. Install a disconnect switch (separating all poles from the

power

supply network) between the water heater and the permanent power connection,

in

compliance with

the

national regulations.

19

I

Page 5

Legend:

1 -

Electronic thermostat

2 -

Bipolar thermal fuse

2 - Electric heater

5 - Connection

terminal

L - Live conductor

N -

Neutral conductor

...L

.

-=-

- Earthing conductor

~

NL

L

___

_J

L _

_J

Electric installation

CAUTION: Prior to each reach

in

the inner of the water heater it must absolutely

be

disconnected from the electric network!

OPERATION AND MAINTENANCE

After connecting to water and power supply, the heater is prepared for use.

The water heater features

an

that enables

of

water temperature of

in

water heater tank. The

electronic regulator allows manual adjustment of temperature

in

range from 35°C to 75°C,

settings

to

cost saving operation mode and temperature adjustment

to

prevent freezing.

Electronic regulator display shows the current temperature

of

water

in

water heater.

OPERATION CONTROL:

The heater is switched ON and OFF by pressing the

~

key for 2s.

Continue pressing the

@ key and select the three operating modes:

-

~protection

against freezing (factory water temperature set

to

7°C)

e cost saving operation (factory set

to

55°C)

-

~optional

manual setting of temperature in the range from 35°C

to

75°C (increments

of

1oq

20

Page 6

Protection

3lainst

freezing: I

- Use the

~

key and select the

~operating

mode (yellow control lamp

under~

1s

on)

The

regulator

1s

set

to

temperature 7°C - shown

on

the display

Cost saving operating mode:

- Use the @ key and select

thee

operating mode (yellow control lamp under e is on)

- The regulator is set

to

temperature

55°C

- shown

on

the display

Manual temperature setting:

- Use the @ key and select

the~

operating mode (yellow control lamp

under~

is

on).

- The

display always shows the last setting

of

the water temperature; except on first turn

on

of

appliance when factory setting

35°C

is displayed.

- Use the @

or

@ key

to

select

new

temperature. By pressing the key you increase/

decrease the temperature by

1°C. Holding the key will speed up the process.

- After required temperature is

set

display flashes for 3 seconds and then shows the current

temperature again.

-

In

case of interruptions

in

power supply, the appliance resumes operating with the settings

adjusted before the interruption.

INQICATION·

Control lamps:

- Heating element operation

&:

Green control lamp:

the heating element is

on

- the lamp is

on

the heating element is off - the lamp is off

Mg

anode

©=i:;I:

Red control lamp:

the lamp is off - anode

is

active

the

lamp is on - anode may be worn out

Warning! When the water heater is

out

of

use for longer

period

of

time, the signal lamp

may

indicate that the

Mg

anode is worn

out

in

spite

of

the fact that the Mg anode

is still active. In this case open the

hot

water tap (fresh

water flow into water heater).

If

the signal lamp switches

off, the w

ater

heater operation is

not

impaired.

If

not

, call

the nearest authorized service provider

Water heater operation: Yellow control lamps:

protection against freezing - the lamp is

on

or

cost saving temperature setting - the lamp is on

or

manual

setting-

the lamp is on

21

Page 7

LED display:

Water temperature

of

in the heater.

from

0°C to 75°C

When set, display

of

the adjusted temperature: (flashing

from

0°C to

75°C)

Error indication:

display

E1

- failure

of

the

electronic regulator sensor (the

heating

element

doesn't

operate)

display

E2

- failure

of

the

thermometer

sensor (water heater

operates)

display E3 - failure

of

both sensors (water heater doesn't

operate)

display

E4-

low

temperature, freezing (water heater doesn't

operate)

display

E5

- overheating

(temperature>

100°C) - (failure

of

electronic regulator)

VVhen

the

water

heater is not in use

for

longer periods

of

time, it should be protected

from

freezing

by

setting the temperature

to"*".

Do

not

disconnect the power.

Thus

the temperature

of

water

is

maintained

at

about

10°C. Should you choose

to

disconnect the power, the

water

heater should be

thoroughly

drained before the

onset

of

freezing conditions.

Water

is

discharged from heater

via

the inlet pipe. To this purpose, a special fitting (T-fitting)

must

be

mounted between

the

relief valve and the heater inlet pipe, or a discharge tap.

The

heater

can be discharged directly through

the

relief valve,

by

rotating

the

handle or

the

rotating

valve

cap

to

same position

as

for checking the operation. Before discharge,

make

sure

the

heater is disconnected

from

the

power

supply

, open the hot

water

on

the

connected

mixer tap. After discharging through the

inlet pipe,

there

is still

some

water

left

in

the

water

heater.

The

remaining water

will

be discharged after removing the heating flange, through

the

heating flange opening.

The

external parts

of

the water heater

may

be cleaned with a mild detergent solution. Do not

use

solvents and abrasives.

Regular preventive maintenance inspections ensure faultless performance and long

life

of

your heater.

The

first

of

these

inspections should be carried

out

by

the authorised

maintenance service provider

about

two

years

from

installation

in

order

to

inspect the

wear

of

the protective anticorrosion anode and remove the lime coating and sediment

as

required.

The

lime coating and sediment on the

walls

of

the

tank

and on

the

heating

element

is a product

of

quality, puantity and temperature

of

water

flowing through the

water

heater.

The

maintenance service provider shall also issue a condition report and recommend the

approximate date

of

the

next inspection.

Never

try

to repair

any

possible faults

of

the

water

heater by yourself, but inform

about it the nearest authorised service workshop.

22

Page 8

Gorenje

Loading...

Loading...