Gorenje GBFU 50-150EDD/V9 User Manual

GBFU 50-150EDD/V9

16

Dear buyer, we thank you for purchase of our product.

PRIOR TO INSTALLATION AND FIRST USE OF THE ELECTRIC WATER HEATER,

PLEASE CAREFULLY READ THESE INSTRUCTIONS.

This water heater has been manufactured in compliance with the relevant standards

and tested by the relevant authorities as indicated by the Safety Certificate and the

Electromagnetic Compatibility Certificate. The technical characteristics of the product are

listed on the label affixed between the inlet and outlet pipes. The installation must be carried

out by qualified staff. All repairs and maintenance work within the water heater, e.g. lime

removal or inspection/replacement of the protective anti-corrosion anode, must be carried

out by the authorised service provider.

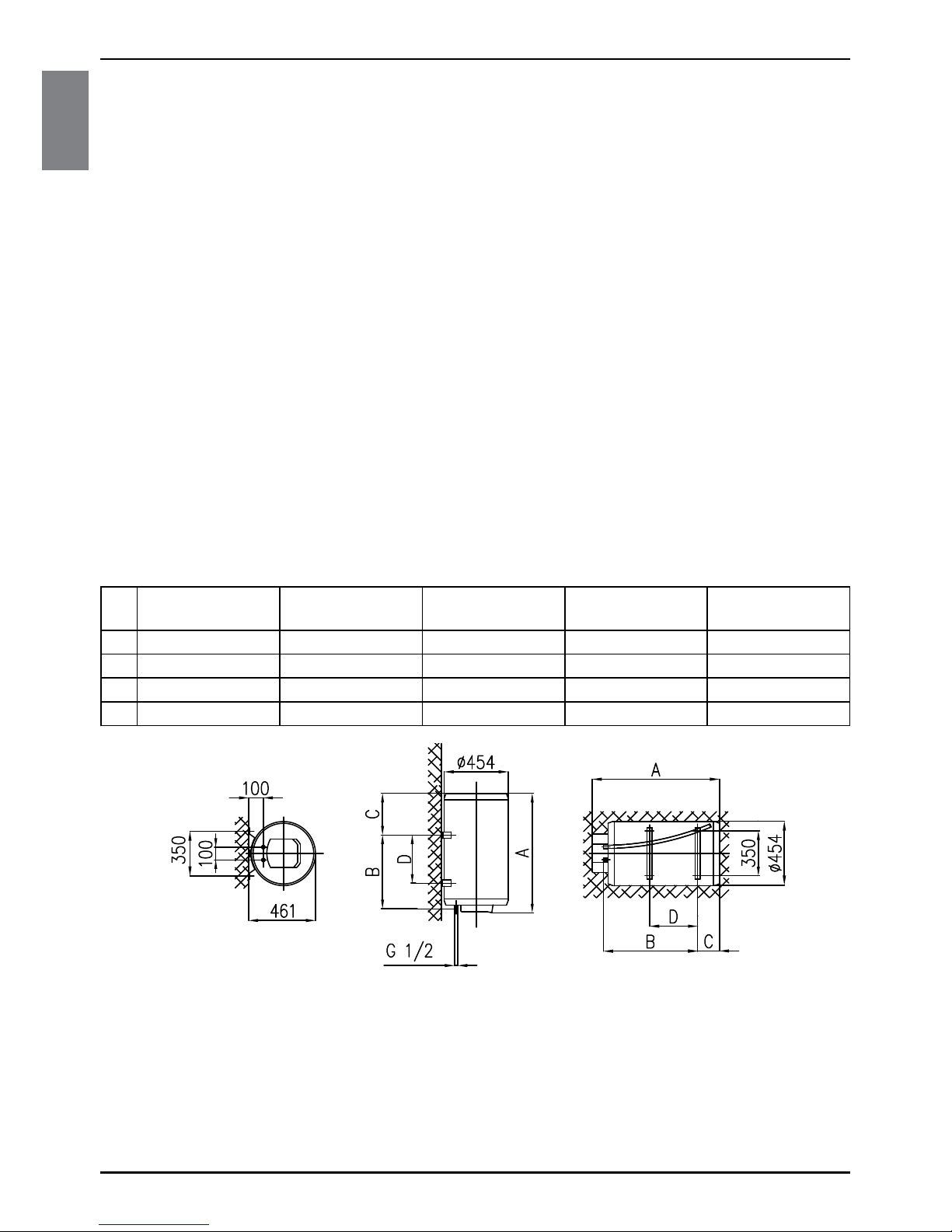

BUILDING-IN

The water heater shall be built-in as close as possible to the outlets. When installing the

water heater in a room with bathtub or shower, take into account requirements defined in IEC

Standard 60364-7-701 (VDE 0100, Part 701). It has to be fitted to the wall using appropriate

rag bolts with minimum diameter of 8 mm. The wall with feeble charging ability must be

on the spot where the water heater shall be hanged suitably reinforced. Due to universal

construction of the water heater it can be fixed vertically on the wall or horizontally on the

wall (output pipes must be on the left).

GBFU 50EDD/V9

GBFU 80 EDD/V9GBFU 100 EDD/V9GBFU 120 EDD/V9GBFU 150 EDD/

V9

A 583 803 948 1103 1318

B 365 565 715 865 1065

C 185 205 200 205 220

D 145 345 495 645 845

Connection and installation dimensions of the water heater [mm]

GB

17

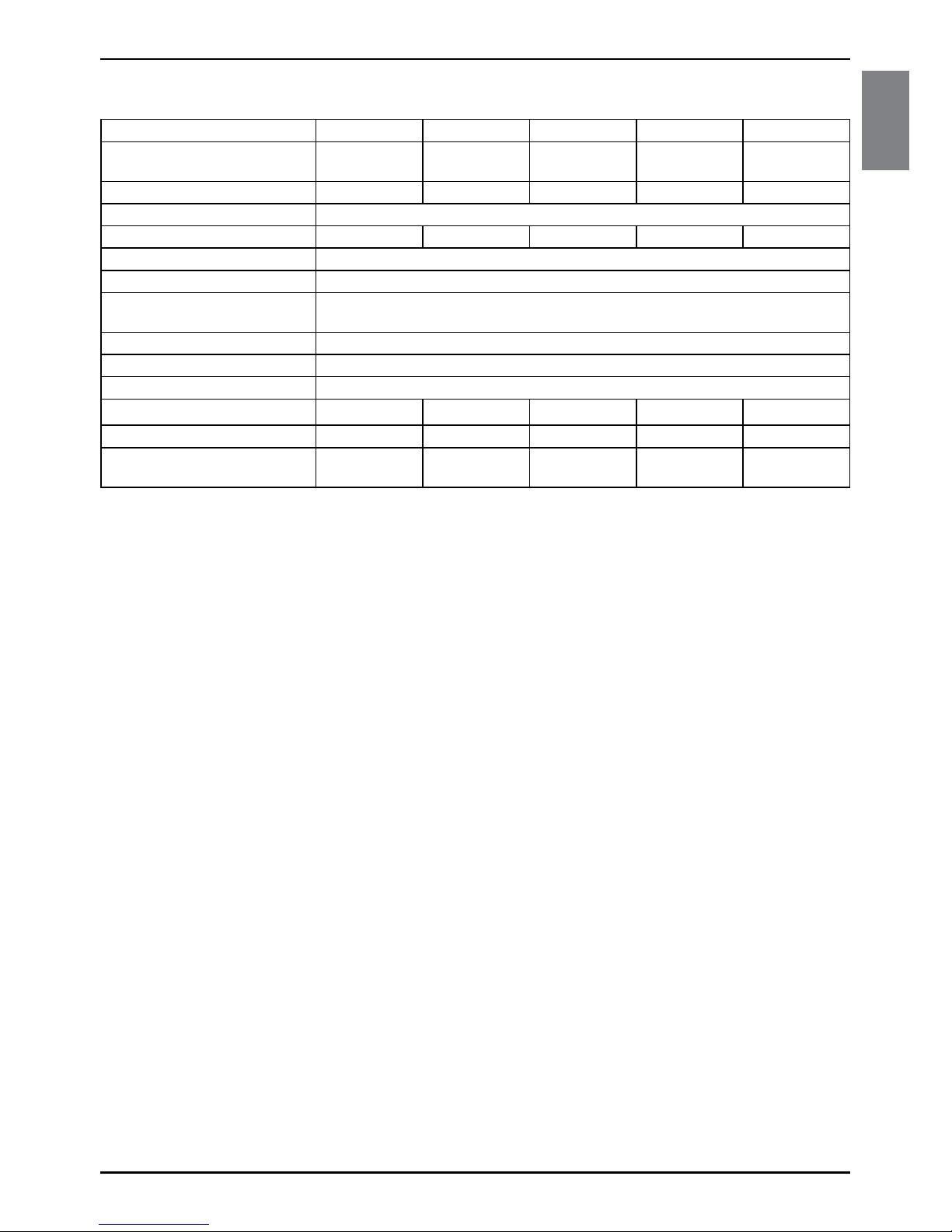

TECHNICAL PROPERTIES OF THE APPLIANCE

Type GB 50 GB 80 GB 100 GB 120 GB 150

Model

GBFU 50

EDD/V9

GBFU 80

EDD/V9

GBFU 100

EDD/V9

GBFU 120

EDD/V9

GBFU E150

EDD/V9

Volume [ l ] 50 80 100 120 150

Rated pressure [ MPa ] 0,9

Weight / Filled with water [ kg ] 24/74 30/110 34/134 38/158 44/194

Anti-corrosion of tank Enamelled / Mg anode

Connected power [ W ] 2000

Number and power of heating

elements [ W ]

2 x 1000

Voltage [ V~ ] 230

Protection class I

Degree of protection IP 25

Heating time to 75 °C

1)

[ h ] 1

55

3

05

3

55

4

35

5

45

Quantity of mixed at 40°C [ l ] 96/80 151/130 199/174 238/210 296/260

Energy consumption

2)

[kWh/24h]

1,32/1,45 1,85/2,10 2,20/2,45 2,60/2,90 3,20/3,60

1) Time for heating of the whole volume of heater with electric immersion heater by entering temperature of cold water

from water supply 15°C.

2) Energy consumption to maintain stable temperature of water in the water heater 65°C at surrounding temperature

20°C, measured according to EN 60379.

CONNECTION TO THE WATER SUPPLY

The water heater connections for the in-flowing and out-flowing water are colour-coded. The

connection for the supply of cold water is coloured blue, while the hot water outlet is coloured

red.

The water heater may be connected to the water supply in two ways. The closed-circuit

pressure system enables several points of use, while the open-circuit gravity system enables

a single point of use only. The mixer taps must also be purchased in accordance with the

selected installation mode.

The open-circuit gravity system requires the installation of a non-return valve in order to

prevent the water from draining out of the tank in the event of the water supply running dry

or being shut down. This installation mode requires the use of an instantaneous mixer tap.

As the heating of water expands its volume, this causes the tap to drip. The dripping cannot

be stopped by tightening it further; on the contrary, the tightening can only damage the tap.

The closed-circuit pressure system requires the use of pressure mixer taps. For safety

reasons the supply pipe must be fitted with a return safety valve or alternatively, a valve of

the safety class that prevents the pressure in the tank from exceeding the nominal pressure

by more than 0.1 MPa. The outlet opening on the relief valve must be equipped with an outlet

for atmospheric pressure.

The heating of water in the heater causes the pressure in the tank to increase to the level set

by the safety valve. As the water cannot return to the water supply system, this can result in

the dripping from the outlet of the safety valve. The drip can be piped to the drain by installing

a catching unit just below the safety valve. The drain installed below the safety valve outlet

must be piped down vertically and located in the environment that is free from the onset of

freezing conditions.

GB

Loading...

Loading...