Page 1

COD. 04037CEGOA (04037CEIT) - 22.01.2009

Istruzioni per il montaggio e

avvertenze per la manutenzione

G34AX1-236650 - G64AX1-236625

G640AX1-236636 - G760AX1-236651

G960AX1-234640

Manuale istruzioni

G34AX1-236650 - G64AX1-236625

G640AX1-236636 - G760AX1-236651

G960AX1-234640

Page 2

2

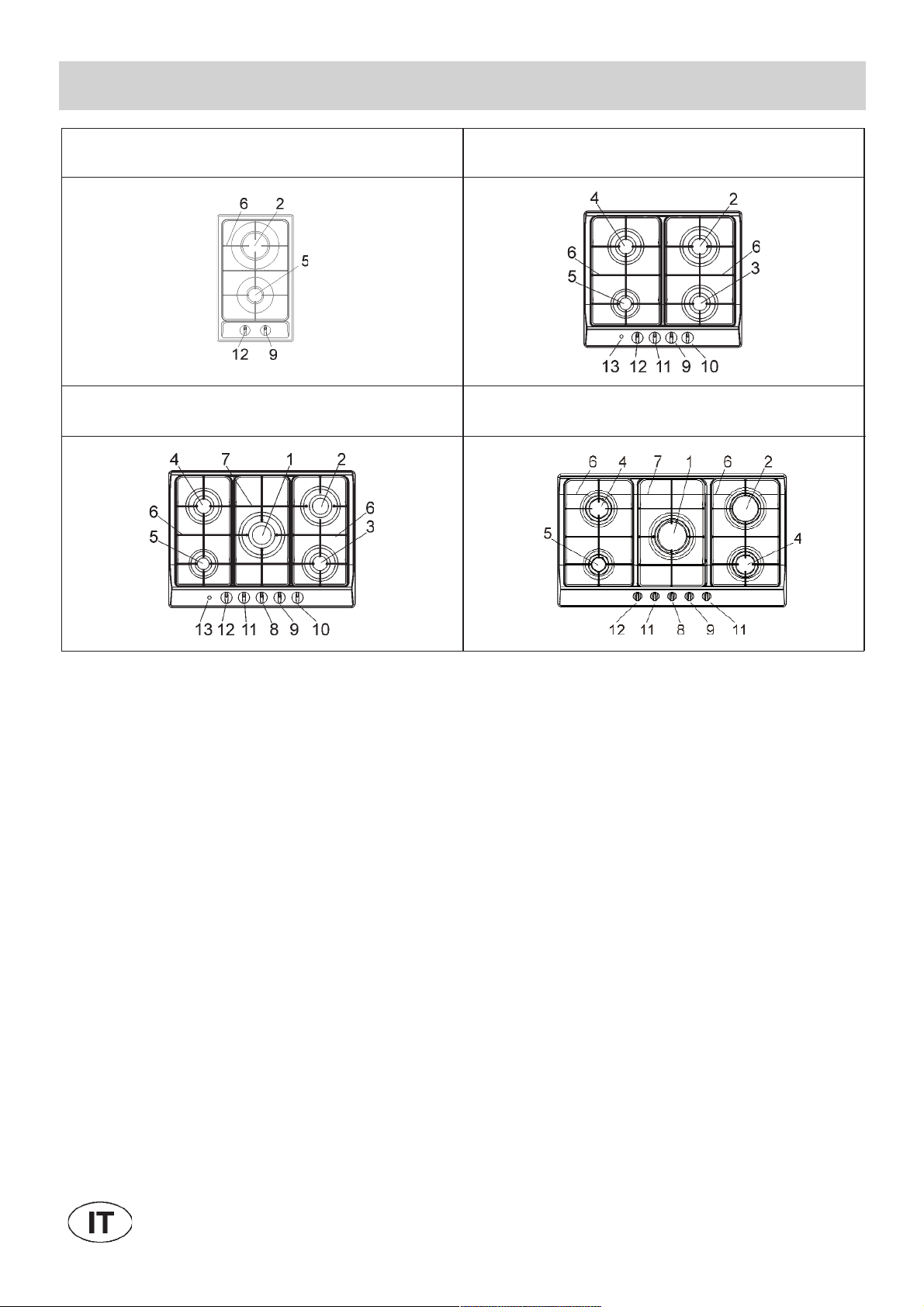

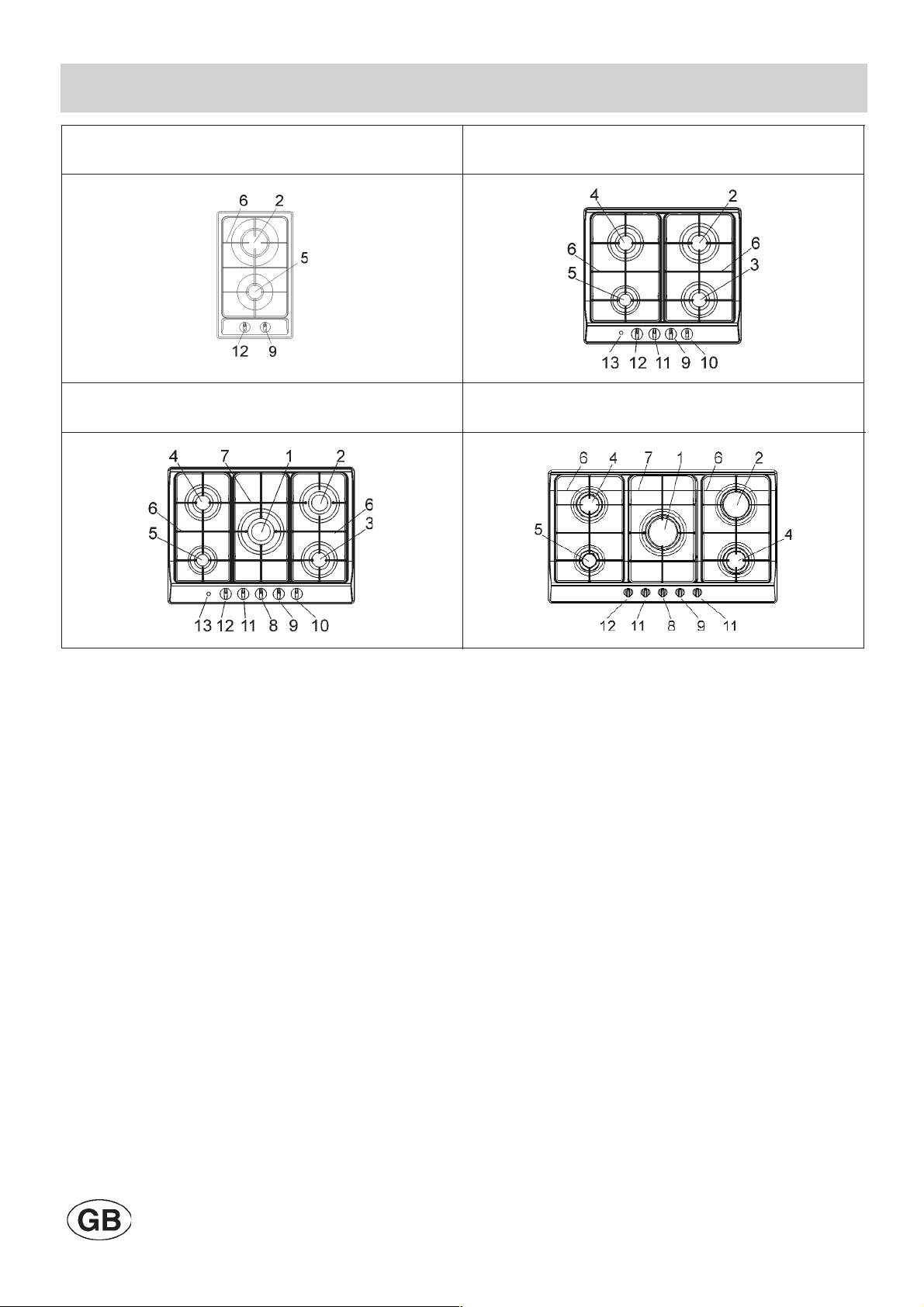

DESCRIZIONE PIANI DI COTTURA

1 Bruciatore tripla corona di 3100 W

2 Bruciatore rapido di 2800 W

3 Bruciatore semirapido anteriore destro di 1400 W

4 Bruciatore semirapido posteriore sinistro di 1750 W

5 Bruciatore ausiliario di 1000 W

6 Griglia in acciaio smaltato 2 fuochi

7 Griglia in acciaio centrale

8 Manopola comando bruciatore n° 1

9 Manopola comando bruciatore n° 2

10 Manopola comando bruciatore n° 3

11 Manopola comando bruciatore n° 4

12 Manopola comando bruciatore n° 5

13 Pulsante accensione elettrica

Attenzione: questo apparecchio è stato concepito per uso domestico, in ambienti domestici e da

parte di soggetti privati.

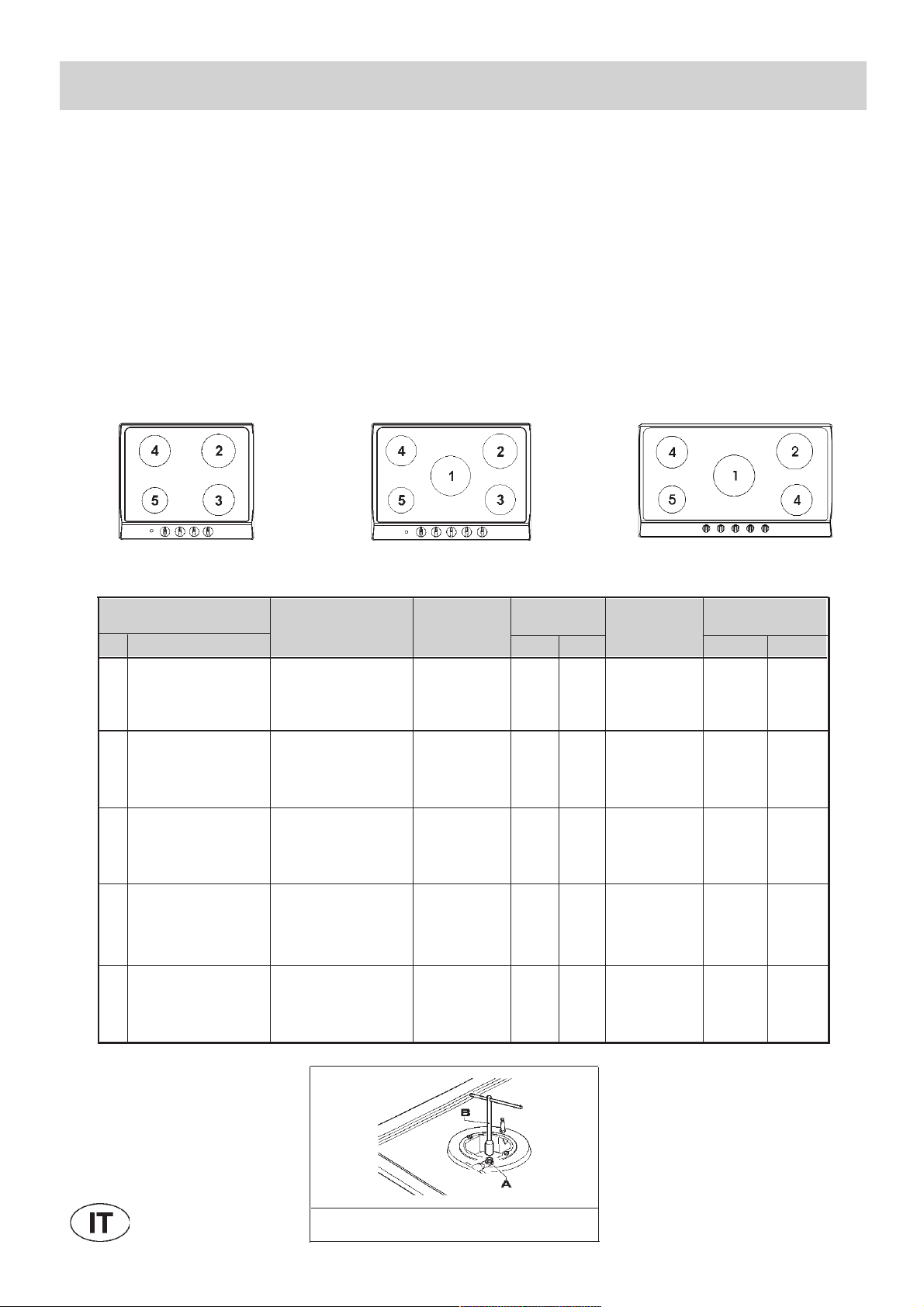

MOD.: G34AX1-236650

MOD.: G64AX1-236625 - G640AX1-236636

MOD.: G760AX1-236651

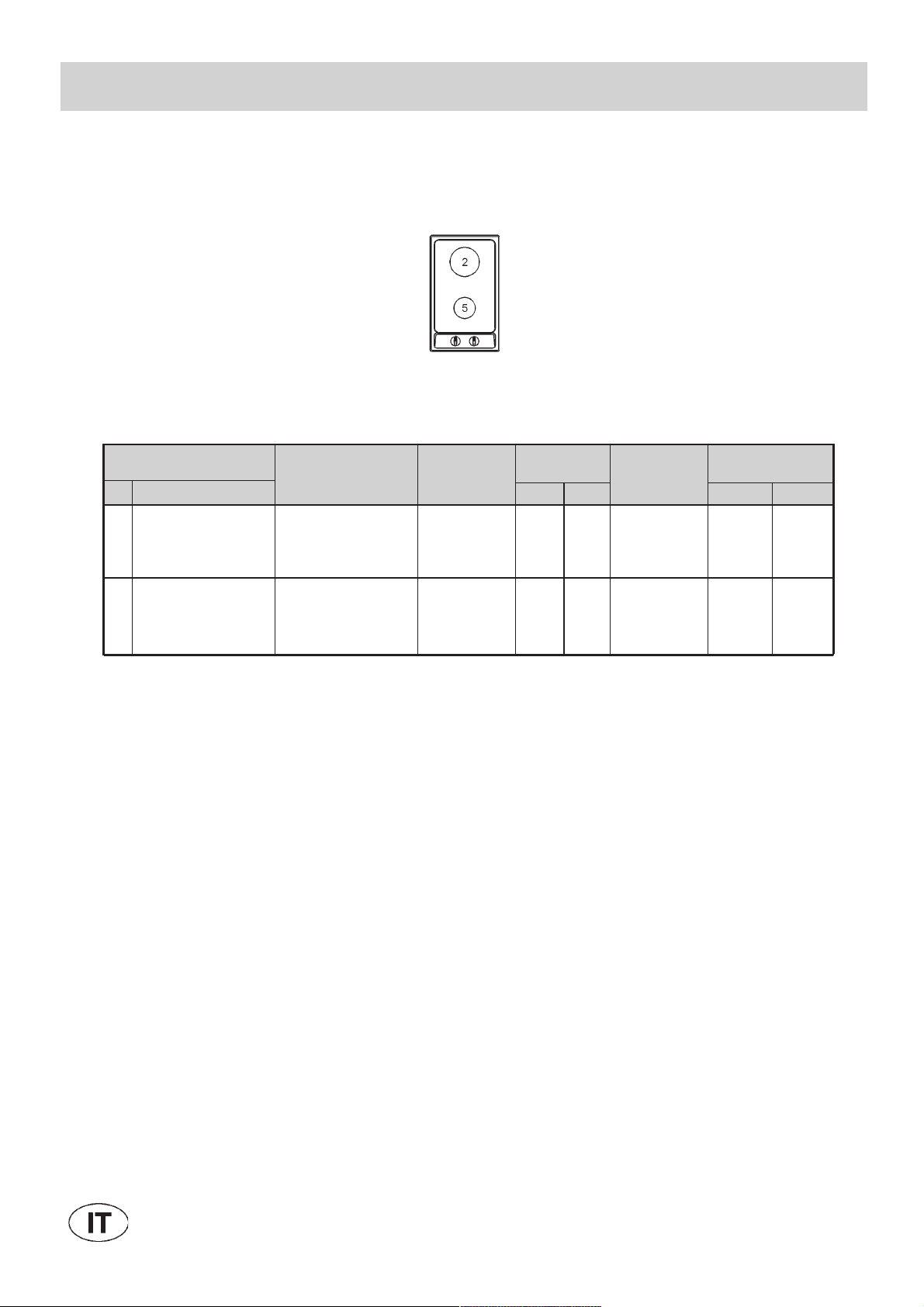

MOD.: G960AX1-234640

Page 3

1) BRUCIATORI

Sul frontalino è serigrafato sopra ad ogni manopola

uno schema in cui è indicato a quale bruciatore la

manopola stessa si riferisce. Dopo aver aperto il

rubinetto della rete gas o della bombola gas,

accendere i bruciatori come più sotto descritto:

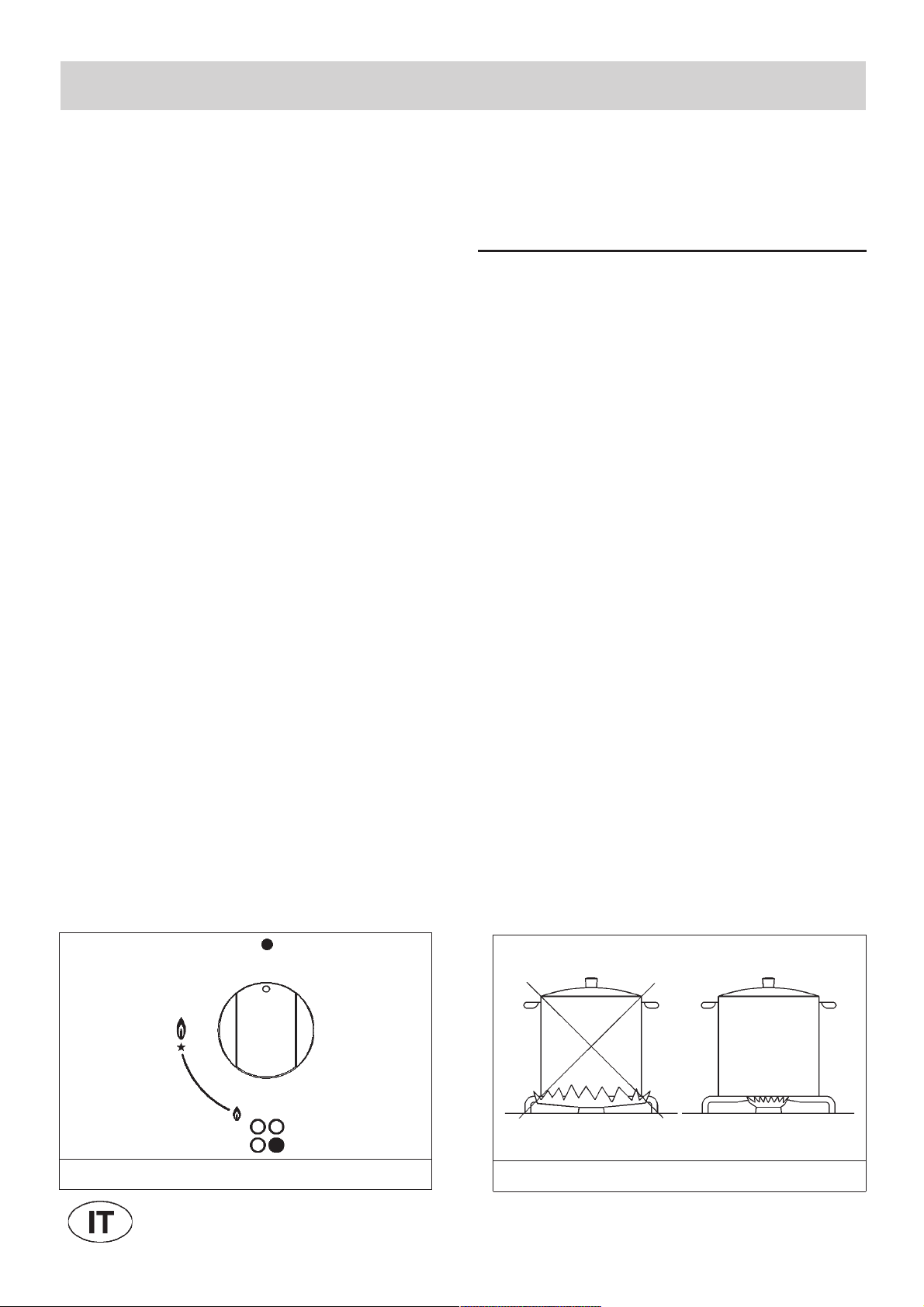

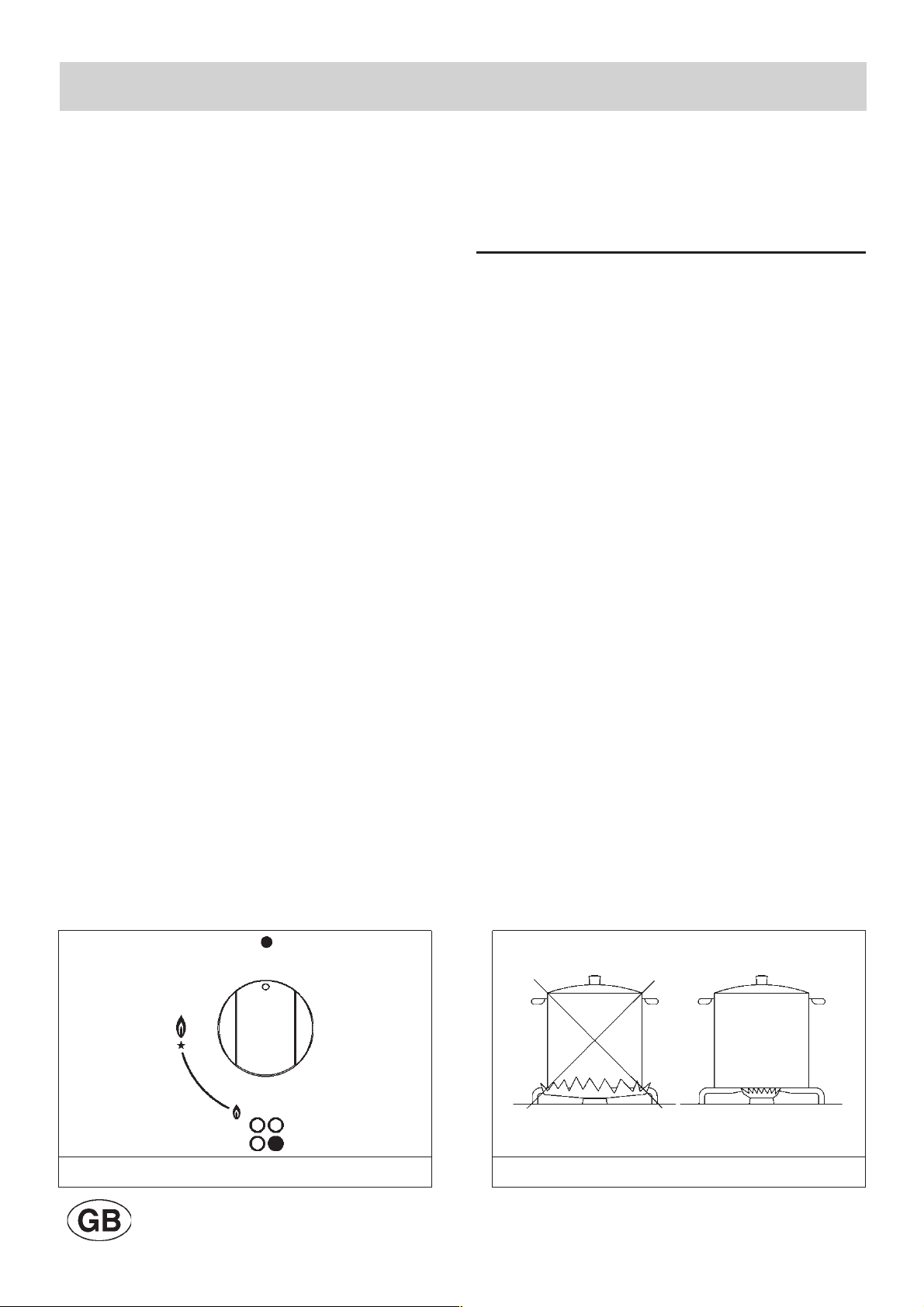

- accensione manuale

Premere e ruotare in senso antiorario la manopola

corrispondente al bruciatore da usarsi, portarla sulla

posizione di Massimo (fiamma grande fig. 1) ed

accostare un fiammifero acceso al bruciatore.

- Accensione elettrica

Premere e ruotare in senso antiorario la manopola

corrispondente al bruciatore da usarsi, portarla sulla

posizione di Massimo (fiamma grande fig. 1) quindi

premere e rilasciare il pulsante d’accensione “E”.

- Accensione elettrica automatica

Premere e ruotare in senso antiorario la manopola

corrispondente al bruciatore da usarsi, portarla sulla

posizione di Massimo (fiamma grande fig. 1) quindi

premere la manopola a fondo.

- Accensione bruciatori dotati di termocoppia di

sicurezza

Con i bruciatori dotati di termocoppia di sicurezza,

si deve ruotare in senso antiorario la manopola

corrispondente al bruciatore da usarsi, portarla sulla

posizione di Massimo (fiamma grande fig. 1) sino

ad avvertire un piccolo fermo quindi premere la

manopola e ripetere le operazioni indicate

precedentemente.

Ad accensione avvenuta mantenere premuta la

manopola per circa 10 secondi.

Come usare i bruciatori

Per ottenere il massimo rendimento con il minimo

consumo di gas è utile ricordare quanto sotto

specificato:

- utilizzare per ciascun bruciatore pentole adeguate

(vedi la tabella seguente e la fig. 2).

- Quando si è giunti all’ebollizione portare la manopola

in posizione di Minimo (fiamma piccola fig. 1).

- Usare sempre pentole con coperchio.

- Utilizzare solamente recipienti a fondo piatto.

Bruciatori Potenze W Ø Pentole cm

Tripla corona 3100 24 ÷ 26

Rapido 2800 20 ÷ 22

Semirapido ant. dx 1400 16 ÷ 18

Semirapido post. sx 1750 16 ÷ 18

Ausiliario 1000 10 ÷ 14

AVVERTENZE:

- l’accensione dei bruciatori con termocoppie di

sicurezza può avvernire solamente quando la

manopola è sulla posizione di Massimo

(fiamma grande fig. 1).

- Mancando l’energia elettrica è possibile

accendere i bruciatori con i fiammiferi.

- Durante l’uso dei bruciatori non lasciare

incustodito l’apparecchio e fare attenzione che

i bambini non siano nelle vicinanze. In

particolare assicurarsi che le maniglie delle

pentole siano posizionate in modo corretto e

sorvegliare le cotture di cibi che utilizzano olii

e grassi in quanto facilmente infiammabili.

- L’uso di questo apparecchio non é consentito

a persone (incluso i bambini) dalle ridotte

capacità fisiche e mentali, o carenti di

esperienza nell’uso di apparecchiature

elettriche, a meno che non siano

supervisionati o istruiti da parte di persone

adulte e responsabili per la loro sicurezza. I

bambini devono essere controllati per

assicurarsi che non giochino con

l’apparecchio.

- Non utilizzare spray in prossimità

dell’apparecchio quando è in funzione.

- Se il piano di cottura è dotato di un coperchio,

prima di aprirlo, eliminare tutti i residui

d’alimenti traboccati sulla sua superficie. Se

l’apparecchio verrà dotato di un coperchio in

vetro, questo può scoppiare quando viene

scaldato. Spegnere e lasciare raffreddare tutti i

bruciatori prima di chiudere il coperchio.

- Si sconsiglia l’utilizzo di recipienti che escano

dai bordi del piano.

FIG. 1

FIG. 2

USO

3

Page 4

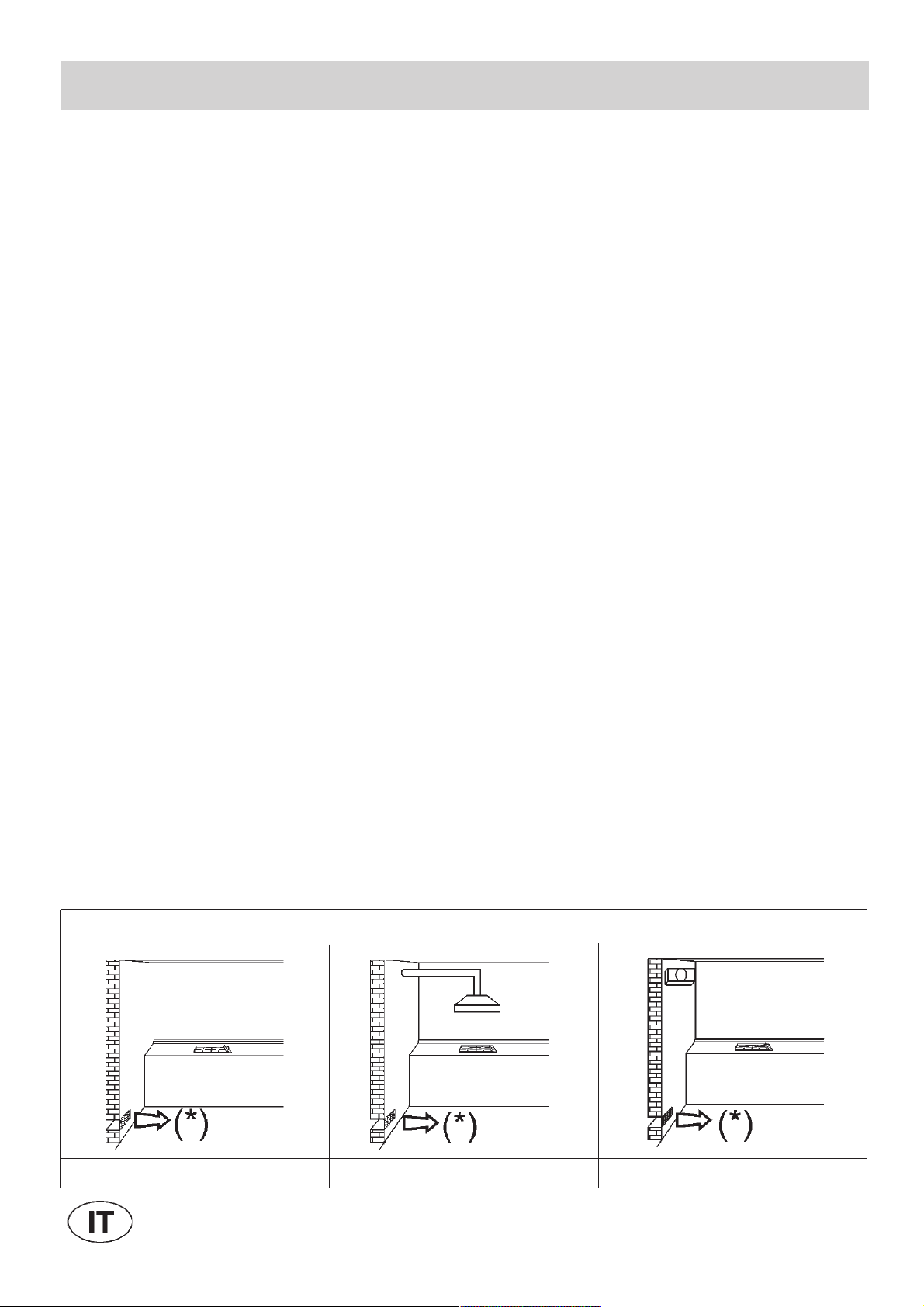

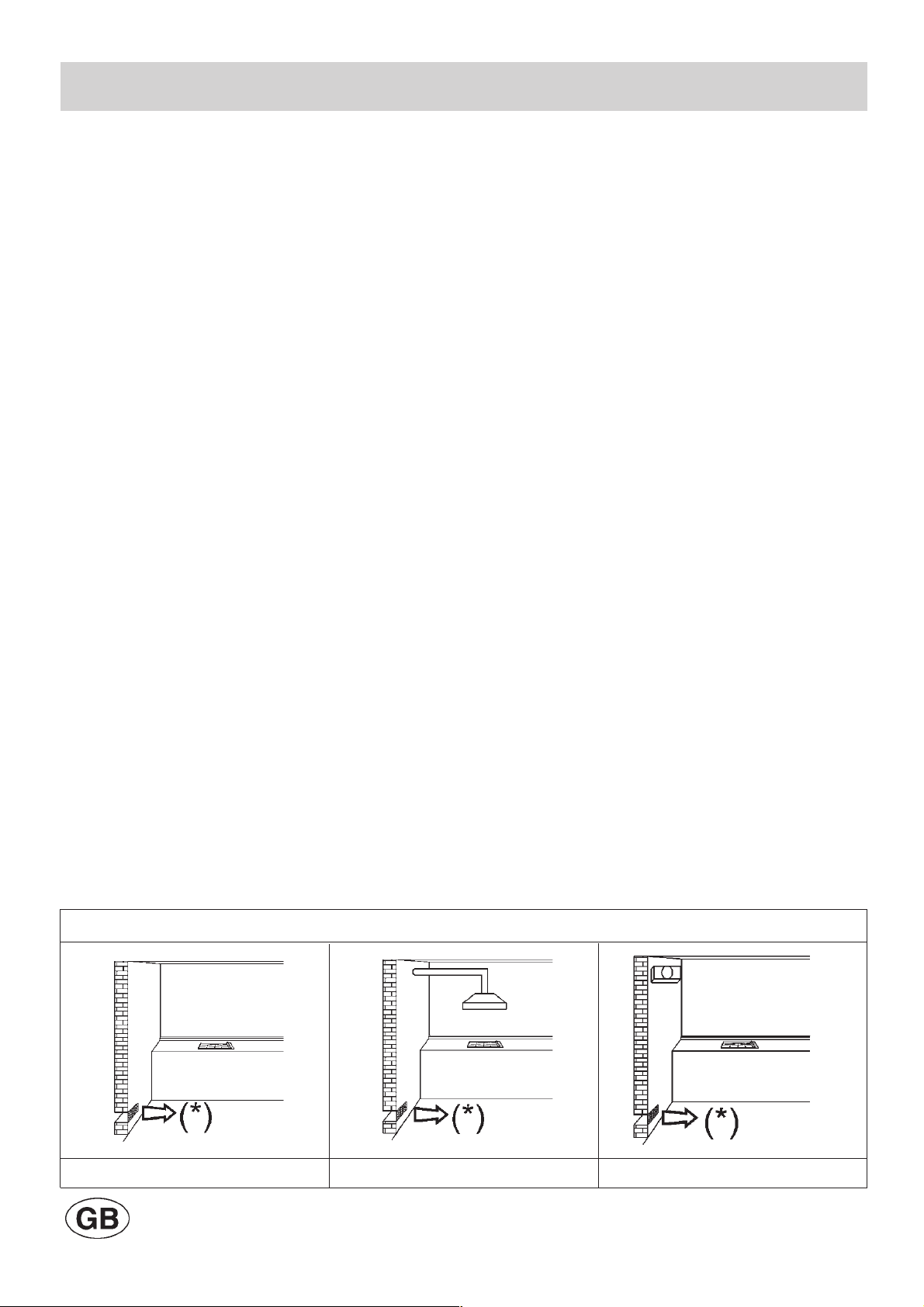

Note:

l’utilizzo di un apparecchio di cottura a gas produce calore ed umidità nel locale in cui è installato.

Necessita pertanto assicurare una buona aerazione del locale mantenendo sgombre le aperture

della ventilazione naturale (fig. 3) ed attivando il dispositivo meccanico di aerazione (cappa di

aspirazione o elettroventilatore fig. 4 e fig. 5).

Un utilizzo intensivo e prolungato dell’apparecchio, può necessitare di una aerazione

supplementare, per esempio l’apertura di una finestra, oppure un’aerazione più efficace aumentando

la potenza dell’aspirazione meccanica se esiste.

FIG. 3 FIG. 4 FIG. 5

(*) ENTRATA ARIA: VEDI CAPITOLO INSTALLAZIONE (PARAGRAFI 5 E 6)

USO

4

Page 5

ATTENZIONE:

prima di effettuare qualsiasi operazione di pulizia,

disinserire l’apparecchio dalla rete d’alimentazione

gas ed elettrica.

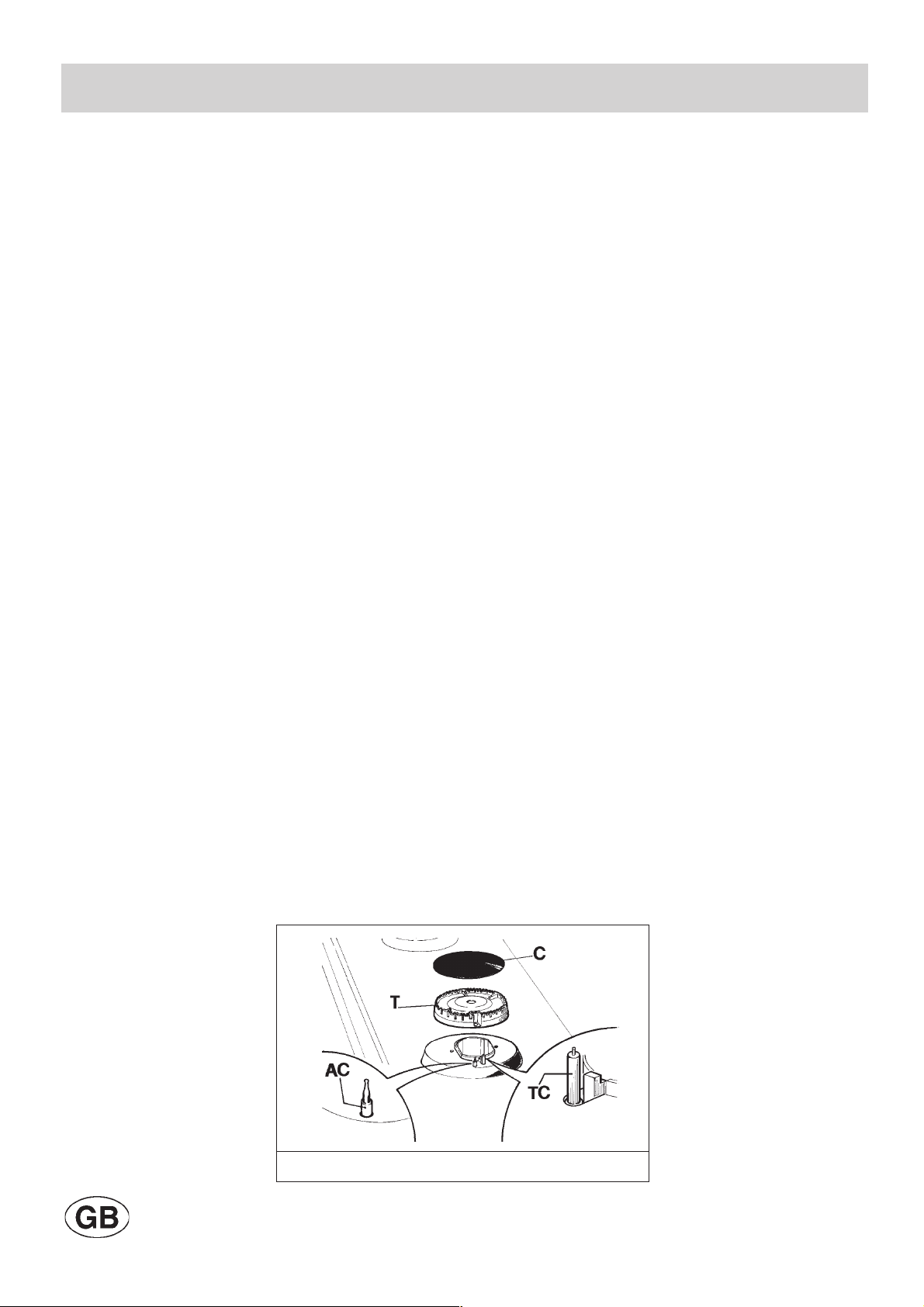

2) PIANO LAVORO

Se si vuole mantenere la superficie del piano lucente, è molto

importante lavarla dopo ogni utilizzo con acqua saponata

tiepida, risciacquarla ed asciugarla. Allo stesso modo devono

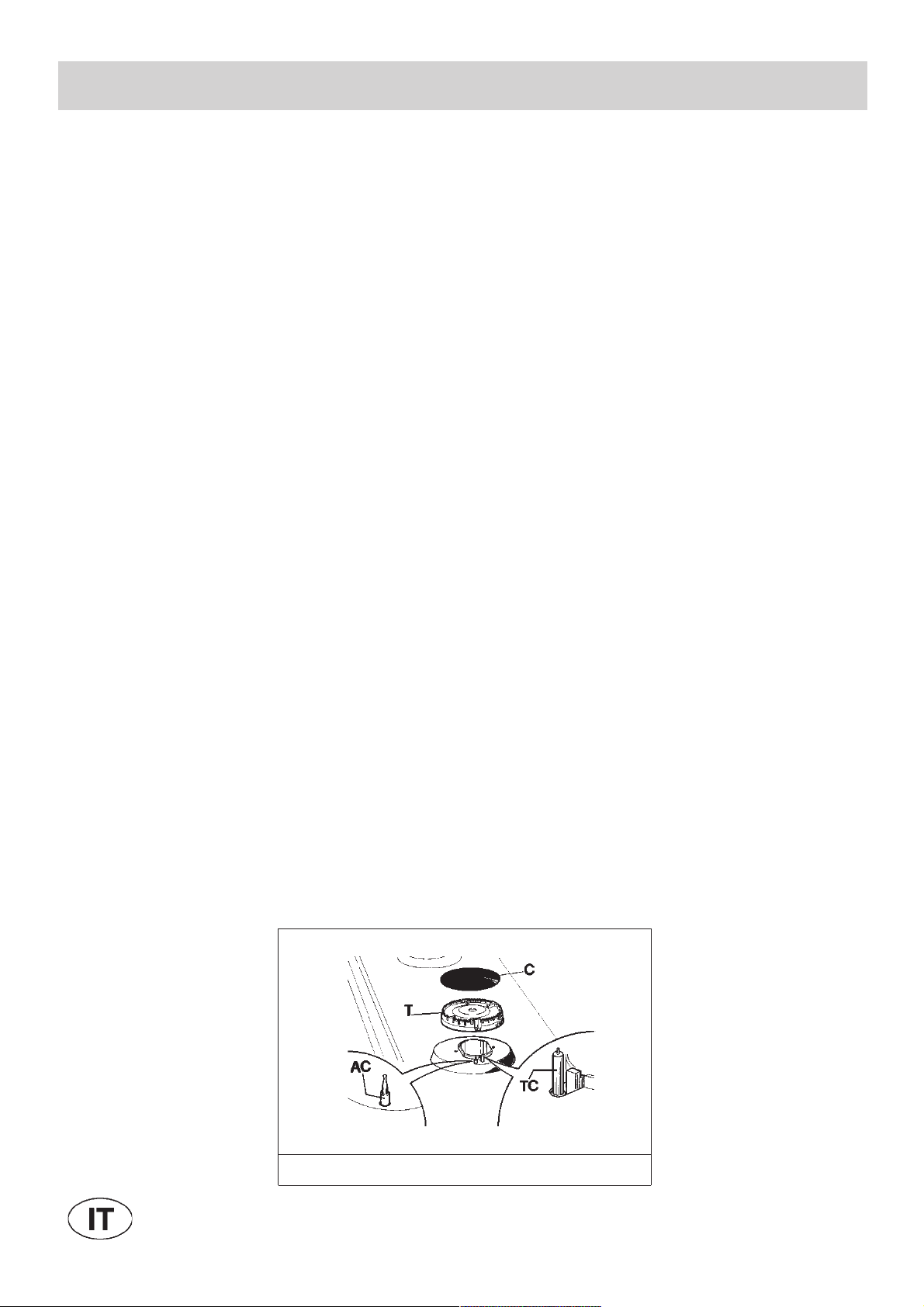

essere lavati le griglie smaltate, i coperchietti smaltati “C” e le

teste bruciatori “T” (vedi fig. 6).

La pulizia deve essere eseguita quando il piano ed i componenti

non sono caldi e non si devono utilizzare spugnette metalliche,

abrasivi in polvere o spray corrosivi.Non permettere che aceto,

caffè, latte, acqua salina e succo di limone o di pomodoro

rimangano per lungo tempo a contatto delle superfici.

AVVERTENZE:

nel rimontare i componenti si prega di attenersi alle

sottonotate raccomandazioni:

- verificare che le fessurazioni delle teste bruciatori

“T” (fig. 6) non siano otturate da corpi estranei.

-

Assicurarsi che il coperchietto smaltato “C” (fig. 6)

sia posizionato correttamente sulla testa bruciatore.

Questa condizione può ritenersi soddisfatta quando

il coperchietto posizionato sulla testa risulti

perfettamente stabile.

- La posizione esatta della griglia è definita dagli

angoli arrotondati da posizionare verso il bordo

laterale del piano.

- Se la manovra di apertura e chiusura di qualche

rubinetto è difficoltosa, non forzare, ma richiedere

con urgenza l’intervento dell’assistenza tecnica.

- Non usare getti di vapore per la pulizia

dell’apparecchio.

FIG. 6

USO

5

Page 6

NOTIZIE TECNICHE DEDICATE AI

SIGNORI INSTALLATORI

L’installazione, tutte le regolazioni, le

trasformazioni e le manutenzioni elencate in

questa parte devono essere eseguite

esclusivamente da personale qualificato (legge

n° 46 e D.P.R. 447).

Una errata installazione può causare danni a

persone, animali o cose, nei confronti dei quali

il costruttore non può essere considerato

responsabile.

I dispositivi di sicurezza o di regolazione

automatica degli apparecchi durante la vita

dell’impianto potranno essere modificati

solamente dal costruttore o dal fornitore

debitamente autorizzato.

3) INSERIMENTO PIANO

Dopo aver tolto l’imballo esterno e gli imballi interni

delle varie parti mobili, assicurarsi dell’integrità del

piano. In caso di dubbio non utilizzare l’apparecchio

e rivolgersi a personale qualificato.

Gli elementi dell’imballaggio (cartone, sacchetti,

polistirolo espanso, chiodi...) non devono

essere lasciati alla portata dei bambini in quanto

potenziali fonti di pericolo.

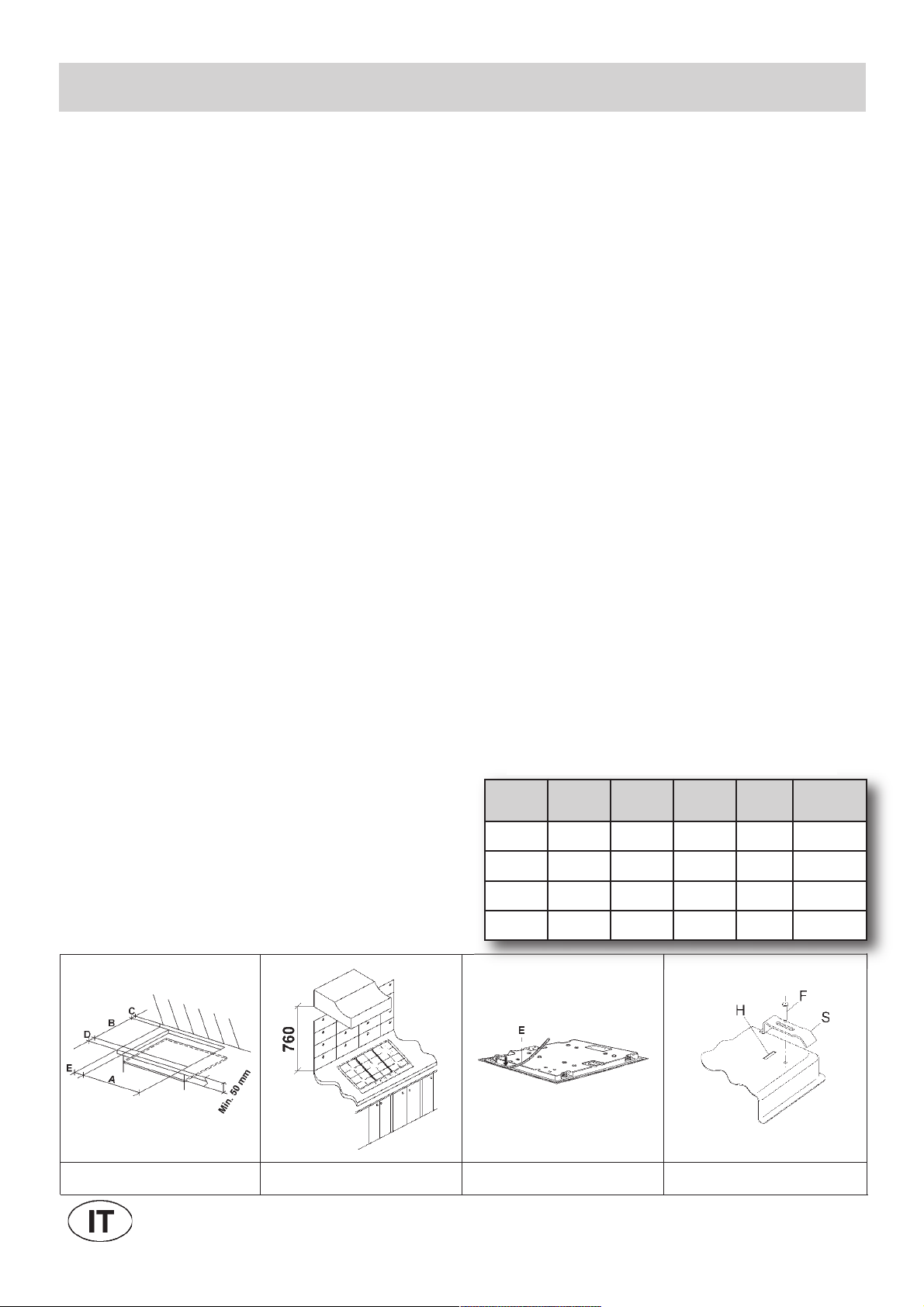

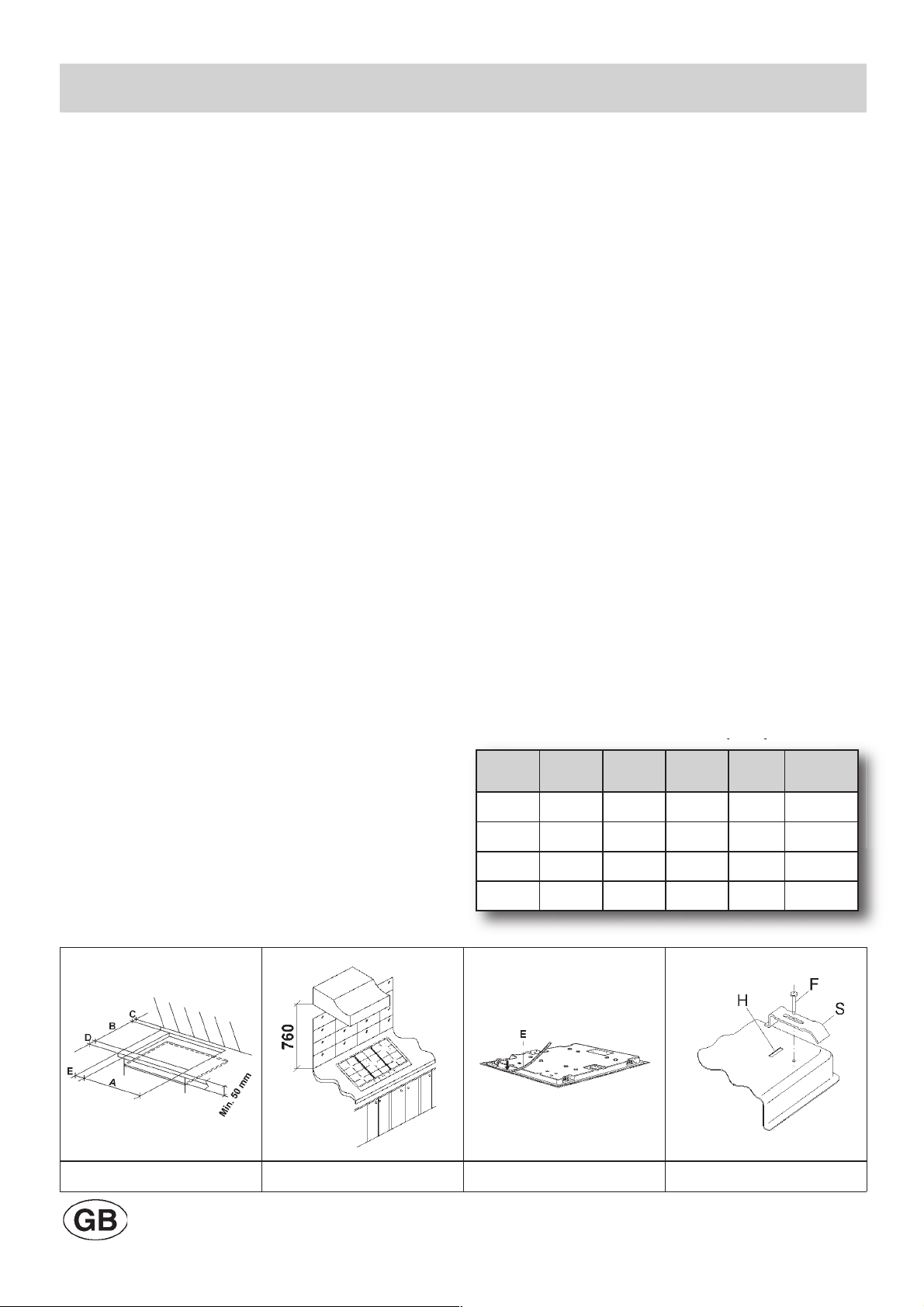

Si deve praticare nel piano del mobile componibile

una apertura per l’incasso delle dimensioni

espresse in mm indicate nella fig. 7, curando che

siano rispettate le distanze critiche tra il piano, le

pareti laterali, la parete posteriore e quella superiore

(vedi fig. 7 e 8).

L’apparecchio deve classificarsi in classe 3 ed è

pertanto soggetto a tutte le prescrizioni previste

dalle norme per tali apparecchi.

4) FISSAGGIO DEL PIANO

Il piano è corredato di una speciale guarnizione al

fine di evitare qualsiasi infiltrazione di liquido nel

mobile. Per applicare correttamente questa

guarnizione, si prega di attenersi scrupolosamente

a quanto specificato più sotto:

- staccare le striscie della guarnizione dal loro

supporto curando che la protezione trasparente

rimanga attaccata alla guarnizione stessa.

- Rovesciare il piano e posizionare correttamente la

guarnizione “E” (fig. 9) sotto il bordo del piano, in

modo che il lato esterno della guarnizione stessa

combaci perfettamente con il bordo perimetrale

esterno del piano. Le estremità delle striscie

devono combaciare senza sormontarsi.

- Fare aderire al piano la guarnizione in modo

uniforme e sicuro, pressandola con le dita, quindi,

togliere la striscia di carta protettiva della

guarnizione e posizionare il piano nel foro

praticato sul mobile.

- Bloccarlo con le apposite staffette “S”, avendo cura

di infilare la parte sporgente nella feritoia “H” ricavata

sul fondo e avvitando la vite “F” fino a che la staffetta

“S” non blocchi sul top (vedi fig. 10).

- Al fine di evitare possibili contatti accidentali con la

superficie della scatola del piano surriscaldata durante il

funzionamento dello stesso, necessita applicare una

separazione in legno bloccata da viti ad una distanza

minima di 50 mm dal top (fig. 7).

FIG. 7

FIG. 8 FIG. 9

FIG. 10

USO

6

A B C D E

2F (30) 285 485 57.5 57.5 100 min.

4F (60) 553 473 67.5 59.5 175 min.

5F (70) 553 473 67.5 59.5 175 min.

5F (90) 833 475 62.5 62.5 73.5 min.

MISURE DA RISPETTARE (in mm)

Page 7

IMPORTANTI PRESCRIZIONI

D’INSTALLAZIONE

Si segnala all’installatore che le eventuali pareti

laterali non devono superare in altezza il piano di

cottura. Inoltre la parete posteriore e le superfici

adiacenti e circostanti al piano devono resistere ad

una sovratemperatura di 65K.

Il collante che unisce il laminato plastico al mobile,

deve resistere a temperature non inferiori a 150° C per

evitare lo scollaggio del rivestimento stesso.

L’installazione dell’apparecchio deve essere conforme a

quanto prescritto dalle norme UNI 7129 e 7131.

Questo apparecchio non è collegato ad un

dispositivo d’evacuazione dei prodotti della

combustione. Esso deve pertanto essere collegato

conformemente alle regole d’installazione più sopra

menzionate. Particolare attenzione si dovrà prestare

alle sottonotate disposizioni applicabili in materia di

ventilazione e di aerazione.

5) VENTILAZIONE LOCALI

E’ indispensabile che il locale dove viene installato

l’apparecchio sia permanentemente ventilato per

garantire un corretto funzionamento dello stesso. La

quantità d’aria necessaria è quella richiesta dalla

regolare combustione del gas e dalla ventilazione del

locale il cui volume non potrà essere inferiore a 20 m3.

L’afflusso naturale dell’aria deve avvenire per via diretta

attraverso aperture permanenti praticate sulle pareti del

locale da ventilare che danno verso l’esterno con una

sezione minima di 100 cm2(vedi fig. 3). Queste aperture

devono essere realizzate in modo che non possano

essere ostruite.

E’ consentita anche la ventilazione indiretta mediante

prelievo dell’aria da locali attigui a quello da ventilare,

rispettando tassativamente quanto prescritto dalle norme

UNI 7129 e 7131.

ATTENZIONE: se i bruciatori del piano lavoro sono

privi della termocoppia di sicurezza, l’apertura di

ventilazione deve avere una sezione minima di

200 cm2.

6) UBICAZIONE ED AERAZIONE

Gli apparecchi di cottura a gas devono sempre

scaricare i prodotti della combustione a mezzo cappe

collegate a camini, a canne fumarie o direttamente

all’esterno (vedi fig. 4). In caso non esista la

possibilità di applicazione della cappa, è tollerato

l’utilizzo di un ventilatore installato su finestra o su

parete affacciata all’esterno, da mettere in funzione

contemporaneamente all’apparecchio (vedi fig. 5),

purché siano tassativamente rispettate le disposizioni

riguardanti la ventilazione elencate nelle norme

UNI 7129 e 7131.

7) ALLACCIAMENTO GAS

Prima di collegare l’apparecchio accertarsi che i dati

dell’etichetta segnaletica applicata nella parte

inferiore del cassone siano compatibili a quelli della

rete di distribuzione gas.

Un’etichetta stampata di questo libretto ed una

applicata sulla parte inferiore del cassone, indica le

condizioni di regolazione dell’apparecchio: tipo di

gas e la pressione d’esercizio.

Quando il gas viene distribuito a mezzo

canalizzazione, l’apparecchio deve essere allacciato

all’impianto di adduzione gas:

o con tubo metallico rigido d’acciaio a norme UNI

8863, le cui giunzioni devono essere realizzate

mediante raccordi filettati conformemente alla norma

UNI EN 10226.

o Con tubo di rame a norma UNI 6507 serie B, le cui

giunzioni devono essere realizzate mediante raccordi a

tenuta meccanica a norma UNI 8050.

o Con tubo flessibile di acciaio inossidabile a parete

continua, secondo la norma UNI-EN 14800, con

estensione massima di 2 metri e guarnizioni di tenuta

conformi alla norma UNI 9264. Questo tubo deve

essere installato in maniera che non possa venire in

contatto con parti mobili del modulo d’incasso (per

esempio cassetti) e non deve attraversare vani che

possono venire stipati.

Quando il gas viene erogato direttamente da una

bombola, l’apparecchio, alimentato con un regolatore di

pressione conforme alla norma UNI-EN 12864, deve

essere allacciato:

o con tubo di rame a norma UNI 6507 serie B, le cui

giunzioni devono essere realizzate mediante raccordi a

tenuta meccanica a norma UNI 8050.

o Con tubi flessibili di acciaio inossidabile a parete

continua, secondo la norma UNI-EN 14800, con

estensione massima di 2 metri e guarnizioni di tenuta

conformi a norma UNI 9264. Questo tubo deve essere

installato in maniera che non possa venire in contatto

con parti mobili del modulo d’incasso (per esempio

cassetti) e non deve attraversare vani che possono

venire stipati. Si consiglia di applicare sul tubo flessibile

lo speciale adattatore, facilmente reperibile sul

mercato, per facilitare il collegamento con il

portagomma del regolatore di pressione montato sulla

bombola.

Ad allacciamento ultimato verificate la perfetta tenuta

utilizzando una soluzione saponosa e mai una fiamma.

AVVERTENZE:

si rammenta che il raccordo di entrata gas

dell’apparecchio è filettato 1/2” gas conico maschio

a norme UNI EN 10226.

L’apparecchio è conforme alle prescrizioni delle

sottonotate Direttive Europee:

CEE 90/396 + 93/68 relative alla sicurezza gas.

USO

7

Page 8

8

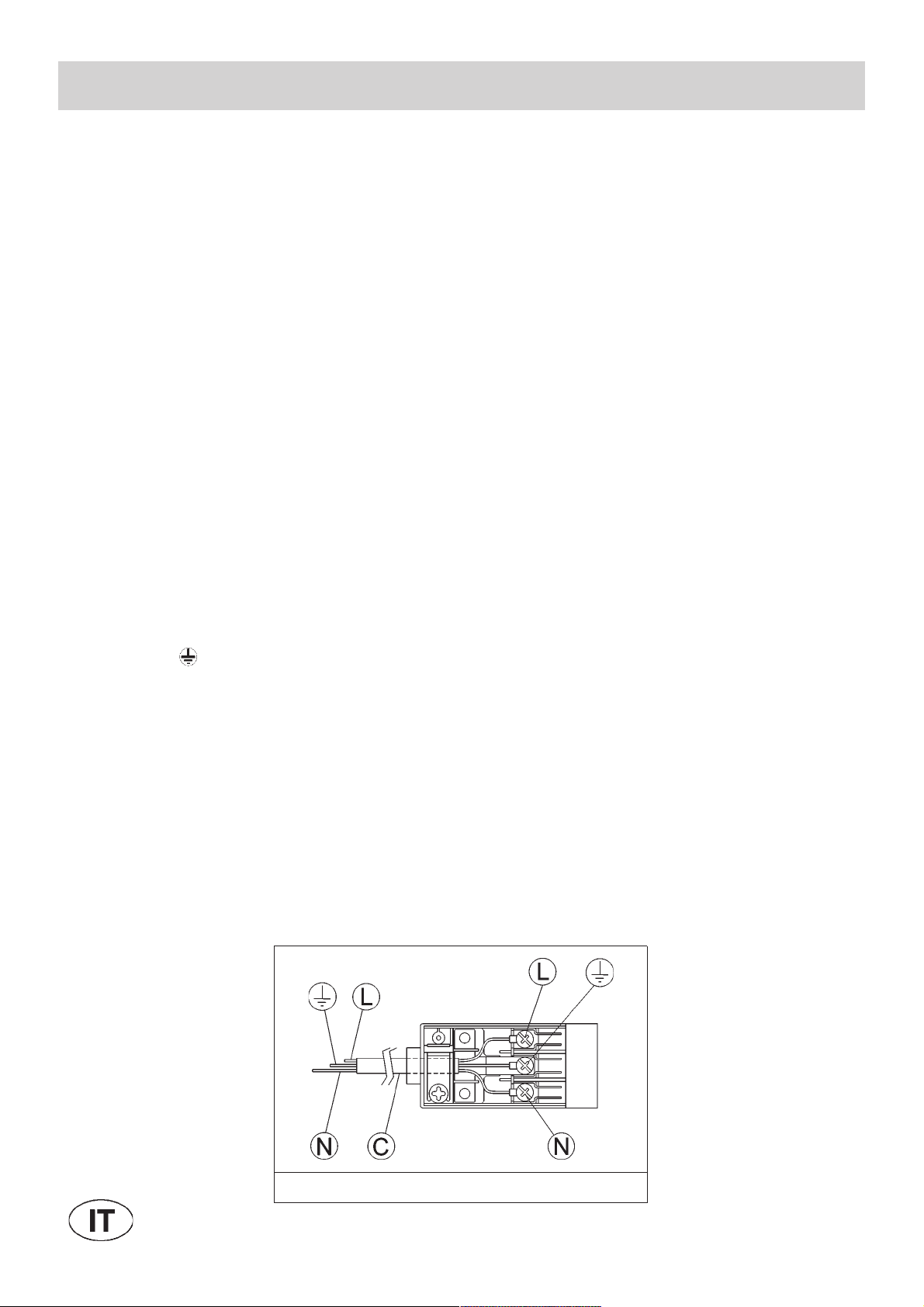

8) ALLACCIAMENTO ELETTRICO

Il collegamento elettrico deve essere eseguito in

conformità con le norme e le disposizioni di

legge in vigore.

Prima di effettuare l’allacciamento, verificare che:

- la portata elettrica dell’impianto e delle prese di

corrente siano adeguate alla potenza massima

dell’apparecchio (vedi etichetta segnaletica

applicata nella parte inferiore del cassone).

- La presa o l’impianto sia munito di un efficace

collegamento a terra secondo le norme e le

disposizioni di legge attualmente in vigore. Si

declina ogni responsabilità per l’inosservanza di

queste disposizioni.

Quando il collegamento alla rete

d’alimentazione è effettuato tramite presa:

- applicare al cavo d’alimentazione “C” se

sprovvisto (vedi fig. 11) una spina normalizzata

adatta al carico indicato sull’etichetta segnaletica.

Allacciare i cavetti secondo lo schema della fig. 11

avendo cura di rispettare le sottonotate

rispondenze:

lettera L (fase) = cavetto colore marrone;

lettera N (neutro) = cavetto colore blu;

simbolo terra = cavetto colore verde-giallo.

-Il cavo d’alimentazione deve essere posizionato in

modo che non raggiunga in nessun punto una

sovratemperatura di 65K.

- Non utilizzare per il collegamento riduzioni,

adattatori o derivatori in quanto potrebbero

provocare falsi contatti con conseguenti pericolosi

surriscaldamenti.

- Ad incasso avvenuto la presa deve essere

accessibile.

Quando il collegamento è effettuato

direttamente alla rete elettrica:

- interporre tra l’apparecchio e la rete un interruttore

onnipolare, dimensionato al carico

dell’apparecchio, con apertura minima fra i contatti

di 3 mm.

- Ricordare che il cavo di terra non deve essere

interrotto dall’interruttore.

- In alternativa, il collegamento elettrico può essere

anche protetto con un interruttore differenziale ad

alta sensibilità.

Si raccomanda vivamente di fissare l’apposito

cavetto di terra colorato verde-giallo ad un efficiente

impianto di terra.

AVVERTENZE:

si segnala all’installatore che l’apparecchio è di

tipo Y. Inoltre le pareti e le superfici adiacenti e

circostanti al piano devono resistere ad una

sovratemperatura di 65K.

Tutti i nostri apparecchi sono progettati e

costruiti secondo le norme europee

EN 60 335-1, EN 60 335-2-6 e EN 60 335-2-102

più relativi emendamenti.

L’apparecchio è conforme alle prescrizioni delle

Direttive Europee:

- CEE 2004/108/CE relative alla compatibilità

elettromagnetica.

- CEE 2006/95 relative alla sicurezza elettrica.

INSTALLAZIONE

FIG. 11

Page 9

9

REGOLAZIONI

Prima di eseguire qualsiasi regolazione togliere

corrente all’apparecchio.

Al termine delle regolazioni o preregolazioni, le

eventuali sigillature devono essere ripristinate

dal tecnico.

La regolazione dell’aria primaria sui nostri

bruciatori non è necessaria.

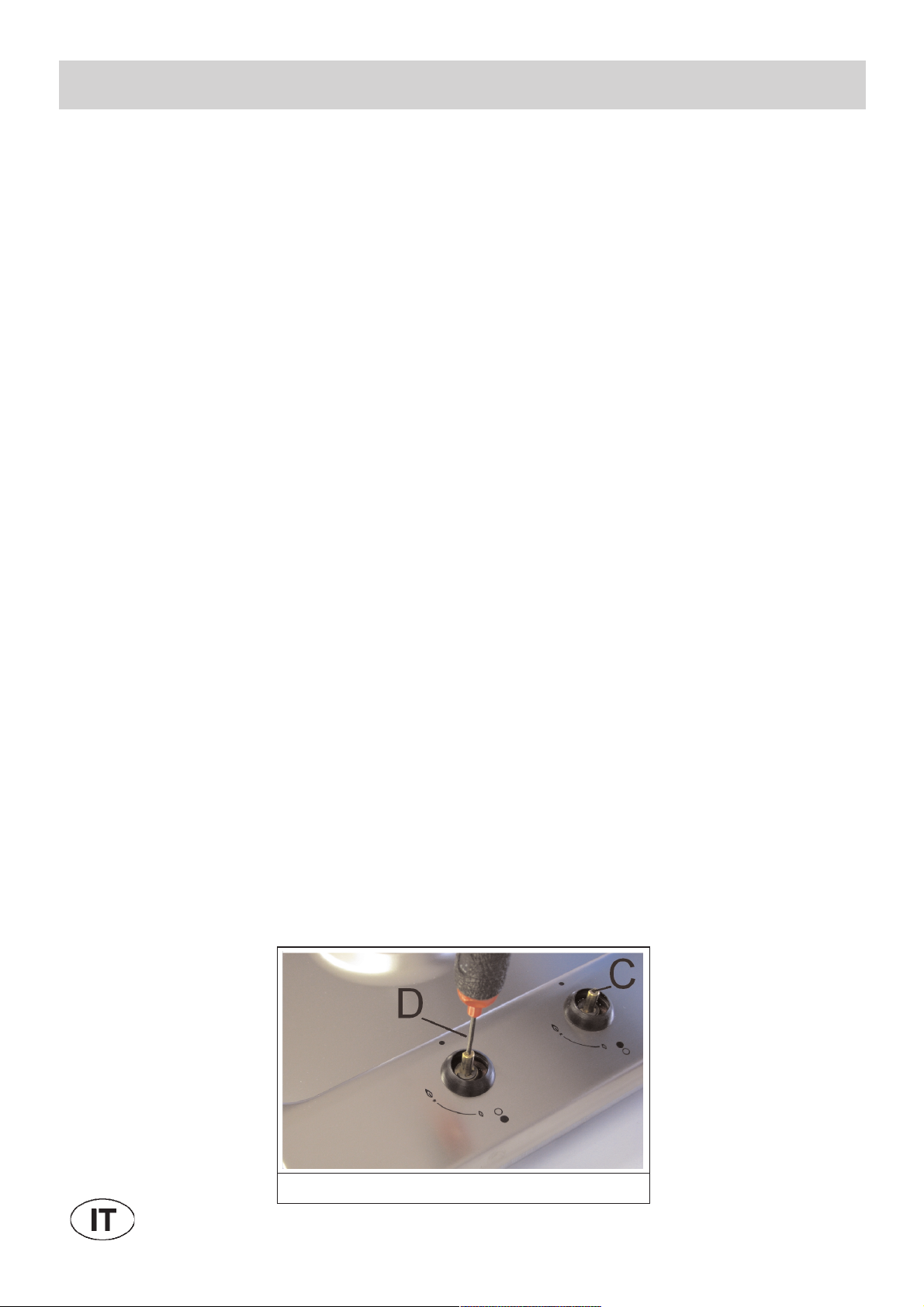

9) RUBINETTI

Regolazione del “Minimo”:

- accendere il bruciatore e mettere la manopola sulla

posizione di “Minimo“ (fiamma piccola fig. 1).

- Togliere la manopola (fig. 12) del rubinetto fissata

per semplice pressione sull’astina dello stesso.

- Introdurre un piccolo cacciavite “D” nel foro “C”

(fig. 12) e girare a destra o a sinistra la vite di

strozzamento fino a che la fiamma del bruciatore

sia regolata convenientemente al “ Minimo”.

Assicurarsi che passando velocemente dalla

posizione di “Massimo” alla posizione di “Minimo” la

fiamma non si spenga.

Resta inteso che la regolazione suddetta va

eseguita soltanto con bruciatori funzionanti a

G20, mentre con bruciatori funzionanti a G30 o

G31 la vite deve essere bloccata a fondo

(ruotando in senso orario).

FIG. 12

Page 10

10) SOSTITUZIONE UGELLI

I bruciatori sono adattabili ai diversi gas montando

gli ugelli corrispondenti al gas d’utilizzazione. Per

fare questo è necessario togliere le teste dei

bruciatori e con una chiave diritta “B”, svitare l’ugello

“A” (vedi fig. 13) e sostituirlo con un ugello

corrispondente al gas d’utilizzazione.

Si consiglia di bloccare energicamente l’ugello.

Dopo aver eseguito le suddette sostituzioni, il

tecnico dovrà procedere alla regolazione dei

bruciatori come descritto nel paragrafo 9,

sigillare gli eventuali organi di regolazione o

preregolazione ed applicare sull’apparecchio, in

sostituzione di quella esistente, l’etichetta

corrispondente alla nuova regolazione gas

effettuata sull’apparecchio. Questa etichetta è

contenuta nella busta degli ugelli di ricambio.

La busta contenente gli iniettori e le etichette

può essere inclusa nella dotazione o disponibile

c/o il centro assistenza autorizzato.

Per comodità dell’installatore riportiamo più sotto

una tabella con le portate, le portate termiche dei

bruciatori, il diametro degli ugelli e la pressione di

esercizio per i vari gas.

DISPOSIZIONE DEI BRUCIATORI

FIG. 13

TABELLA

1 TRIPLA CORONA

G 30 - BUTANO 28 - 30 225 90 1400 3100

G 31 - PROPANO 37 222 90 1400 3100

G 20 - NATURALE 20 295 121 Y 1400 3100

2 RAPIDO

G 30 - BUTANO 28 - 30 204 83 800 2800

G 31 - PROPANO 37 200 83 800 2800

G 20 - NATURALE 20 267 117 S 800 2800

BRUCIATORI

N°

DENOMINAZIONE

GAS

PRESSIONE

DI ESERCIZIO

PORTATA

TERMICA

DIAMETRO

UGELLO

PORTATA

TERMICA (W)

mbar g/h l/h 1/100 mm Min. Max.

4 SEMIRAPIDO

G 30 - BUTANO 28 - 30 127 65 500 1750

POST. SX

G 31 - PROPANO 37 125 65 500 1750

G 20 - NATURALE 20 167 97 Z 500 1750

5 AUSILIARIO

G 30 - BUTANO 28 - 30 73 50 400 1000

G 31 - PROPANO 37 71 50 400 1000

G 20 - NATURALE 20 95 72 X 400 1000

3 SEMIRAPIDO

G 30 - BUTANO 28 - 30 102 58 500 1400

ANT. DX

G 31 - PROPANO 37 100 58 500 1400

G 20 - NATURALE 20 133 85 Y 500 1400

USO

10

Page 11

11

TRASFORMAZIONI

DISPOSIZIONE DEI BRUCIATORI

TABELLA

2 RAPIDO

G 30 - BUTANO 28 - 30 218 85 750 3000

G 31 - PROPANO 37 200 85 750 3000

G 20 - NATURALE 20 267 115 Y 750 3000

BRUCIATORI

N°

DENOMINAZIONE

GAS

PRESSIONE

DI ESERCIZIO

PORTATA

TERMICA

DIAMETRO

UGELLO

PORTATA

TERMICA (W)

mbar g/h l/h 1/100 mm Min. Max.

5 AUSILIARIO

G 30 - BUTANO 28 - 30 73 50 400 1000

G 31 - PROPANO 37 71 50 400 1000

G 20 - NATURALE 20 95 72 X 400 1000

Page 12

MANUTENZIONE

Prima d’effettuare qualsiasi operazione di

manutenzione, disinserire l’apparecchio dalla

rete d’alimentazione gas ed elettrica.

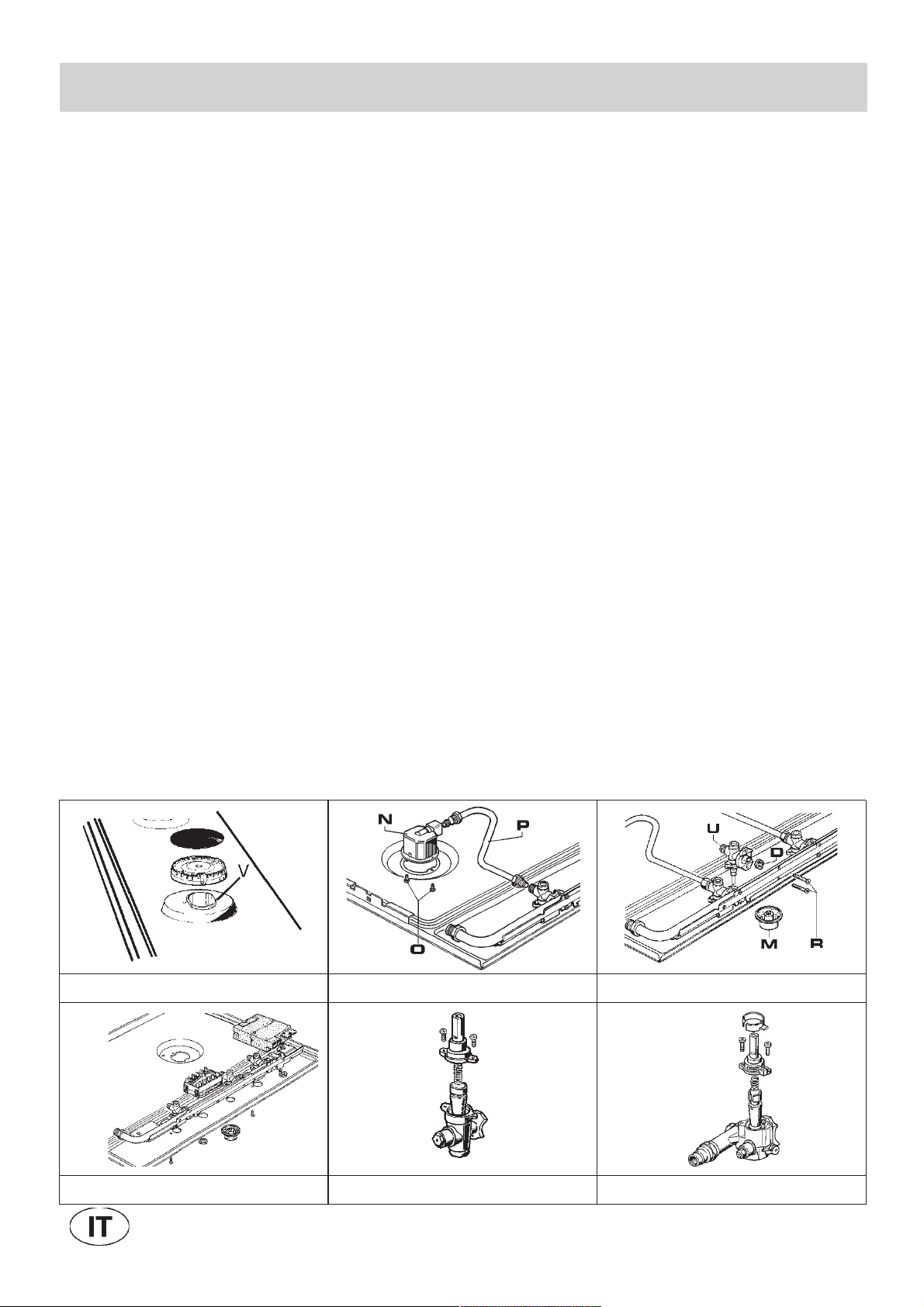

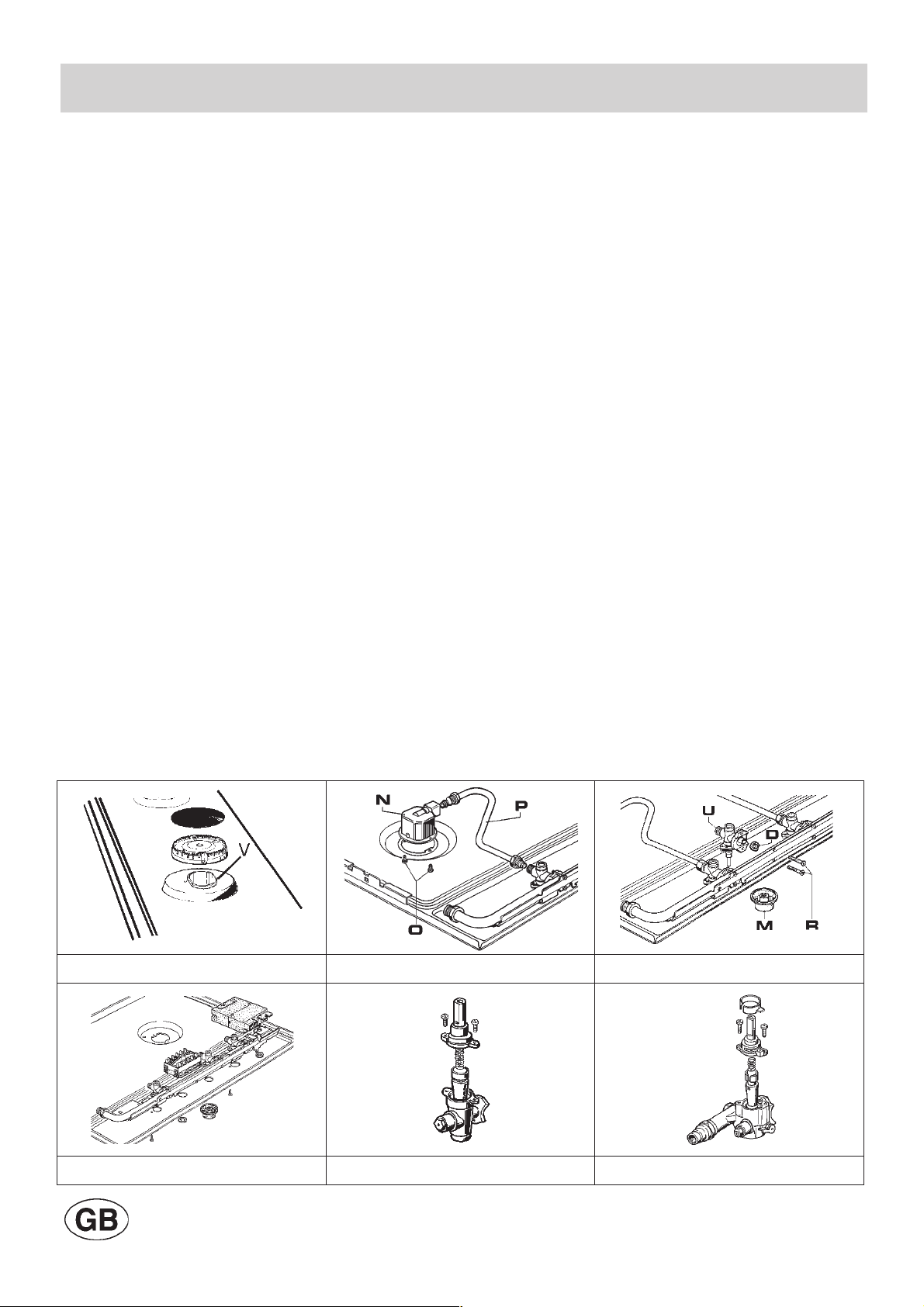

11) SOSTITUZIONE DEI COMPONENTI

Per sostituire i componenti alloggiati all’interno

dell’apparecchio bisogna togliere le griglie ed i

corpi bruciatore dalla parte superiore del piano di

lavoro. Quindi rimuovere le viti “V” di fissaggio dei

bruciatori (fig. 14) e le manopole comando fissate

per semplice pressione, in modo da poter sfilare il

piano di lavoro.

Dopo aver eseguito le operazioni indicate sopra, si

possono sostituire i bruciatori (fig. 15), i rubinetti (fig. 16)

ed i componenti elettrici (fig. 17).

Si consiglia di cambiare la guarnizione “D” tutte le

volte che si sostituisce un rubinetto, al fine di

assicurare una perfetta tenuta tra il corpo e la rampa.

Ingrassaggio dei rubinetti (vedi fig. 18 - 19)

Se la manovra di un rubinetto diventa dura, senza

aspettare altro tempo bisogna ingrassarlo

seguendo le sottonotate istruzioni:

- smontare il corpo rubinetto.

- Pulire il cono ed il suo alloggiamento con uno

straccio imbevuto di diluente.

- Ingrassare leggermente il cono con l’apposito

grasso.

- Introdurre il cono, manovrarlo più volte, estrarlo di

nuovo, togliere il grasso superfluo e assicurarsi

che i passaggi del gas non siano otturati.

- Rimontare tutti i pezzi nell’ordine inverso dello

smontaggio.

- Il controllo della tenuta deve essere effettuato con

l’ausilio di acqua saponata; l’uso di una fiamma

è vietato.

Per facilitare il lavoro del manutentore riportiamo,

nella pagina successiva, una tabella con i tipi e le

sezioni dei cavi d’alimentazione e la potenza dei

componenti elettrici.

FIG. 17 FIG. 18 FIG. 19

FIG. 14 FIG. 15 FIG. 16

12

Page 13

MANUTENZIONE

Piano a gas H05 RR - F Sezione 3 x 0.75 mm

2

TIPO DI PIANO TIPO DI CAVO

ALIMENTAZIONE

MONOFASE

TIPI E SEZIONI DEI CAVI DI ALIMENTAZIONE

ATTENZIONE!!!

Nel caso di sostituzione del cavo di alimentazione, l’installatore dovrà tenere il conduttore di terra

più lungo rispetto ai conduttori di fase (vedi fig. 20) ed inoltre dovrà rispettare le avvertenze indicate

nel paragrafo 8.

FIG. 20

13

Page 14

DATI TECNICI RIPORTATI SULL’ETICHETTA

SEGNALETICA

4 FUOCHI (60)

CATEGORIA = II

2H3+

G 30 - BUTANO = 28 - 30 mbar

G 31 - PROPANO = 37 mbar

G 20 - NATURALE = 20 mbar

Σ Qn Gas Naturale = 6.95 kW

Σ Qn GPL = 505 g/h

TENSIONE = 220 - 240 V

~

FREQUENZA = 50/60 Hz

2 FUOCHI (30)

CATEGORIA = II

2H3+

G 30 - BUTANO = 28 - 30 mbar

G 31 - PROPANO = 37 mbar

G 20 - NATURALE = 20 mbar

Σ Qn Gas Naturale = 4 kW

Σ Qn GPL = 291 g/h

TENSIONE = 220 - 240 V

~

FREQUENZA = 50/60 Hz

5 FUOCHI (70)

CATEGORIA = II

2H3+

G 30 - BUTANO = 28 - 30 mbar

G 31 - PROPANO = 37 mbar

G 20 - NATURALE = 20 mbar

Σ Qn Gas Naturale = 10.05 kW

Σ Qn GPL = 731 g/h

TENSIONE = 220 - 240 V

~

FREQUENZA = 50/60 Hz

5 FUOCHI (90)

CATEGORIA = II

2H3+

G 30 - BUTANO = 28 - 30 mbar

G 31 - PROPANO = 37 mbar

G 20 - NATURALE = 20 mbar

Σ Qn Gas Naturale = 10.40 kW

Σ Qn GPL = 756 g/h

TENSIONE = 220 - 240 V

~

FREQUENZA = 50/60 Hz

14

Page 15

DATI TECNICI DELLA REGOLAZIONE GAS

DELL’APPARECCHIO

15

Page 16

Questa apparecchiatura, prima di lasciare la fabbrica, è stata collaudata e messa a punto da personale

esperto e specializzato, in modo da garantire i migliori risultati di funzionamento.

I ricambi originali si trovano solo presso i nostri Centri di assistenza Tecnica e negozi autorizzati.

Ogni riparazione, o messa a punto che si rendesse in seguito necessaria deve essere fatta con la

massima cura ed attenzione da personale qualificato.

Per questo motivo raccomandiamo di rivolgerVi sempre al Concessionario che ha effettuato la vendita od

al nostro Centro di Assistenza più vicino specificando la marca, il modello, il numero di serie ed il tipo di

inconveniente dell’apparecchiatura in Vostro possesso. I dati relativi sono stampigliati sull’etichetta

segnaletica applicata sulla parte inferiore dell’apparecchio e sull’etichetta applicata alla scatola imballo.

Queste informazioni permettono all’assistente tecnico di munirsi degli adeguati pezzi di ricambio e

garantire di conseguenza un intervento tempestivo e mirato. Si consiglia di riportare più sotto tali dati in

modo da averli sempre a portata di mano:

MARCA: ............................................................................

MODELLO: ........................................................................

SERIE: ...............................................................................

ASSISTENZA TECNICA E RICAMBI

INFORMAZIONE AGLI UTENTI

Ai sensi dell'art. 13 del Decreto Legislativo 25 luglio 2005, n. 151 "Attuazione delle Direttive

2002/95/CE, 2002/96/CE e 2003/108/CE, relative alla riduzione dell'uso di sostanze pericolose nelle

apparecchiature elettriche ed elettroniche, nonché allo smaltimento dei rifiuti".

Il simbolo del cassonetto barrato riportato sull'apparecchiatura o sulla sua confezione indica che il

prodotto alla fine della propria vita utile deve essere raccolto separatamente dagli altri rifiuti. L'utente

dovrà, pertanto, conferire l'apparecchiatura giunta a fine vita agli idonei centri di raccolta differenziata dei

rifiuti elettronici ed elettrotecnici, oppure riconsegnarla al rivenditore al momento dell'acquisto di una

nuova apparecchiatura di tipo equivalente, in ragione di uno a uno. L'adeguata raccolta differenziata per

l'avvio successivo dell'apparecchiatura dismessa al riciclaggio, al trattamento e allo smaltimento

ambientalmente compatibile contribuisce ad evitare possibili effetti negativi sull'ambiente e sulla salute e

favorisce il reimpiego e/o riciclo dei materiali di cui è composta l'apparecchiatura. Lo smaltimento abusivo

del prodotto da parte dell'utente comporta l'applicazione delle sanzioni amministrative previste dalla

normativa vigente.

16

Page 17

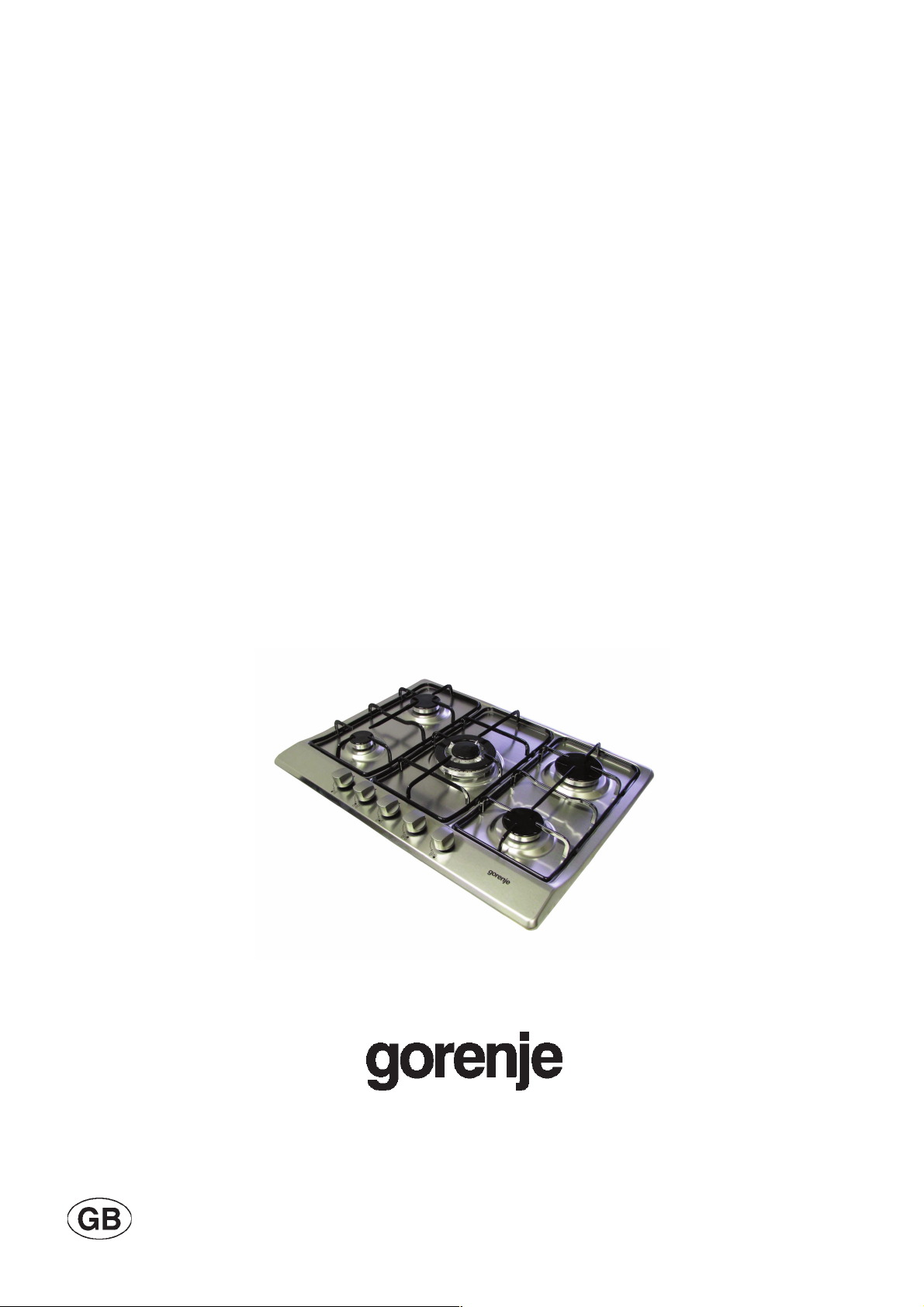

Instructions for the installation

and advice for the maintenance

G34AX1-236650 - G64AX1-236625

G640AX1-236636 - G760AX1-236651

G960AX1-234640

Instructions Manual

G34AX1-236650 - G64AX1-236625

G640AX1-236636 - G760AX1-236651

G960AX1-234640

COD. 04037CEGOA (04037CEGB) - 22.01.2009

Page 18

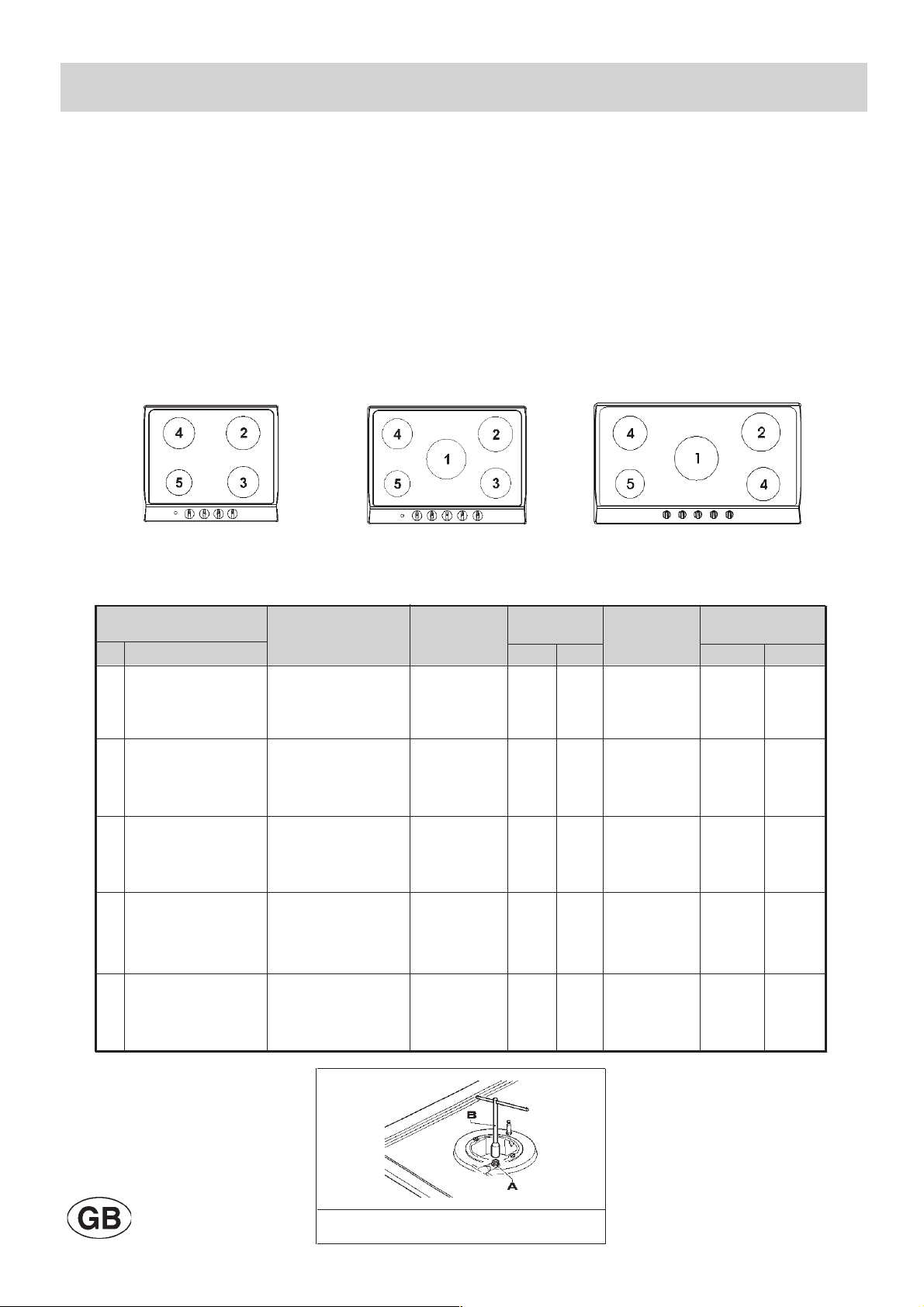

DESCRIPTION OF THE HOT PLATES

1 Ultra rapid gas burner of 3100 W

2 Rapid gas burner of 2800 W

3 Semirapid gas burner right front of 1400 W

4 Semirapid gas burner left back of 1750 W

5 Auxiliary gas burner of 1000 W

6 Enamelled steel pan support 2F

7 Central enamelled steel pan support

8 Burner n° 1 control knob

9 Burner n° 2 control knob

10 Burner n° 3 control knob

11 Burner n° 4 control knob

12 Burner n° 5 control knob

13 Electric ignition button

Attention: this appliance has been manufactured for domestic use only and it employment by

private person.

TYPE: G34AX1-236650

TYPES: MOD.: G64AX1-236625 - G640AX1-236636

TYPE: G760AX1-236651

TYPE: G960AX1-234640

18

Page 19

1) BURNERS

A diagram is screen-printed above each knob on

the front panel. This diagram indicates to which

burner the knob in question corresponds. After

having opened the gas mains or gas bottle tap, light

the burners as described below:

- Manual ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1), then

place a lighted match near the burner.

- Electrical ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1), then

depress and release the ignition button “E”.

- Automatic electrical ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1), then

depress the knob.

- Lighting burners equipped with flame failure

device

The knobs of burners equipped with flame failure

device must be turned in an anticlockwise direction

until they reach the full on position (large flame fig. 1)

and come to a stop. Now depress the knob in

question and repeat the previously indicated

operations.

Keep the knob depressed for about 10 seconds

once the burner has ignited.

HOW TO USE THE BURNERS

Bear in mind the following indications in order to

achieve maximum efficiency with the least possible

gas consumption:

- Use adequate pans for each burner (consult the

following table and fig. 2).

- When the pan comes to the boil, set the knob to

the reduced rate position (small flame fig. 1).

- Always place a lid on the pans.

- Use only pan with a flat bottom.

Burners Power ratings Pan Ø in cm

Ultra rapid 3100 24 ÷ 26

Rapid 2800 20 ÷ 22

Semirapid right front 1400 16 ÷ 18

Semirapid left back 1750 16 ÷ 18

Auxiliary 1000 10 ÷ 14

WARNINGS:

- burners with flame failure device may only be

ignited when the relative knob has been set to

the Full on position (large flame fig. 1).

- Matches can be used to ignite the burners in a

blackout.

- Never leave the appliance unattended when

the burners are being used. Make sure there

are no children in the near vicinity. Particularly

make sure that the pan handles are correctly

positioned and keep a chek on foods requiring

oil and grease to cook since these products

can easily catch fire.

- The machine must not be used by people

(including children) with impaired mental or

physical capacities, or without experience of

using electrical devices, unless supervised or

instructed by an expert adult responsible for

their care and safety. Children should not be

allowed to play with the equipment.

- Never use aerosols near the appliance when it

is operating.

- If the built-in hot plate has a lid, any spilt food

should be immediately removed from this

before it is opened. If the appliance has a glass

lid, this could shatter when the hot plate

becomes hot. Always switch off all the burners

before closing the lid.

- Containers wider than the unit are

recommended.

USE

FIG. 1 FIG. 2

19

Page 20

USE

Notes:

Use of a gas cooking appliance produces heat and moisture in the room in which it is installed.

The room must therefore be well ventilated by keeping the natural air vents clear (fig. 3) and by

activating the mechanical aeration device (suction hood or electric fan fig. 4 and fig. 5).

Intensive and lengthy use of the appliance may require additional ventilation. This can be

achieved by opening a window or by increasing the power of the mechanical exhausting system if

installed.

FIG. 3 FIG. 4 FIG. 5

(*) AIR INLET: SEE INSTALLATION CHAPTER (PARAGRAPHS 5 AND 6)

20

Page 21

CLEANING

IMPORTANT:

Always disconnect the appliance from the gas

and electricity mains before carrying out any

cleaning operation.

2) HOT PLATE

Periodically wash the hot plate, the enamelled stell

pan support, the enamelled burner caps “C” and

the burner heads “T” (see fig. 6) with lukewarm

soapy water. Following this, all parts should be

thoroughly rinsed and dried. Never wash them

while they are still warm and never use abrasive

powders. Do not allow vinegar, coffee, milk, salted

water, lemon or tomato juice from remaining in

contact with the enamelled surfaces for long

periods of time.

WARNINGS:

Comply with the following instructions, before

remounting the parts:

- Check that burner head slots “T” (fig. 6) have

not become clogged by foreign bodies.

- Check that enamelled burner cap “C”(fig. 6)

have correctly positioned on the burner head.

It must be steady.

- The exact position of the pan support is

established by the rounded corners, which

should be set towards the side edge of the

hot plate.

- Do not force the taps if they are difficult open

or close. Contact the technical assistance

service for repairs.

- Don’t use steam jets for the equipment

cleaning.

FIG. 6

21

Page 22

INSTALLATION

TECHNICAL INFORMATION FOR THE

INSTALLER

Installation, adjustments of controls and

maintenance must only be carried out by a

qualified engineer.

Incorrect installation may cause damage to

persons, animals or property for which the

Manufacturer shall not be considered

responsible.

During the life of the system, the automatic

safety or regulating devices on the appliance

may only be modified by the manufacturer or by

his duly authorized dealer.

3) INSTALLING THE HOT PLATE

Check that the appliance is in a good condition after

having removed the outer packaging and internal

wrappings from around the various loose parts. In

case of doubt, do not use the appliance and contact

qualified personnel.

Never leave the packaging materials (cardboard,

bags, polystyrene foam, nails, etc.) within

children’s reach since they could become

potential sources of danger.

The measurements of the opening made in the top

of the modular cabinet and into which the hot plate

will be installed are indicated in either fig. 7. Always

comply with the measurements given for the hole

into which the appliance will be recessed (see

fig. 7 and 8).

The appliance belongs to class 3 and is

therefore subject to all the provisions

established by the provisions governing such

appliances.

4) FIXING THE HOT PLATE

The hot plate has a special seal which prevents

liquid from getting into the cabinet. Strictly comply

with the following instructions in order to correctly

apply this seal:

- Detach the seals from their backing, checking that

the transparent protection still adheres to the seal

itself.

- Overturn the hot plate and correctly position seal

“E” (fig. 9) under the edge of the hot plate itself, so

that the outer side of the seal perfectly matches

the outer edge of the hot plate. The ends of the

strips must fit together without overlapping.

- Evenly and securely fix the seal to the hot plate,

pressing into place with the fingers and remove

the strip of protective paper from the seal and set

the plate into the hole made in the cabinet.

- Fix the hob with the proper brackets “S” and fit the

prominent part into the porthole “H” on the bottom;

turn the screw “F” until the bracket “S” stick on the

top (fig. 10).

- In order to avoid accidental touch with the

overheating bottom of the hob, during the working,

is necessary to put a wooden insert, fixed by

screws, at a minimum distance of 50 mm from the

top (see fig. 7).

FIG. 7 FIG. 8 FIG. 9

FIG. 10

COMPLY WITH THE

DIMENSIONS

(mm)

A B C D E

2F (30) 285 485 57.5 57.5 100 min.

4F (60) 553 473 67.5 59.5 175 min.

5F (70) 553 473 67.5 59.5 175 min.

5F (90) 833 475 62.5 62.5 73.5 min.

22

Page 23

IMPORTANT INSTALLATION

SPECIFICATIONS

The installer should note that the appliance that side

walls should be no higher than the hot plate itself.

Furthermore, the rear wall, the surfaces surrounding

and adjacent to the appliance must be able to withstand

an overtemperature of 65K.

The adhesive used to stick the plastic laminate to the

cabinet must be able to withstand a temperature of not

less than 150° C otherwise the laminate could come

unstuck.

The appliance must be installed in compliance with the

provisions in force.

This appliance is not connected to a device able to

dispose of the combustion fumes. It must therefore be

connected in compliance with the above mentioned

installation standards. Particular care should be paid to

the following provisions governing ventilation and

aeration.

5) ROOM VENTILATION

It is essential to ensure that the room in which the

appliance is installed is permanently ventilated in order

to allow the appliance itself to operate correctly. the

necessary amount of air is that required for regular gas

combustion and ventilation of the relative room, the

volume of which must not be less than 20 m

3

. Air must

naturally flow through permanent openings in the walls

of the room in question. These openings must vent the

fumes outdoors and their section must be at least 100

cm2 (see fig. 3). Construction of the openings must

ensure that the openings themselves may never be

blocked. Indirect ventilation by air drawn from an

adjacent room is also permitted, in strict compliance

with the provisions in force.

CAUTION: if the burners of the cooking top are

without safety thermocouple, the ventilation outlet

must have a minimum 200 cm² section.

6) LOCATION AND AERATION

Gas cooking appliances must always dispose of their

combustion fumes through hoods. These must be

connected to flues, chimneys or straight outside. If it is

not possible to install a hood, an electric fan can be

installed on a window or on a wall facing outside (see

fig. 4). This must be activated at the same time as the

appliance (see fig. 5), so long as the specifications in the

provisions in force are strictly complied with.

7) GAS CONNECTION

Before connecting the appliance, check that the values

on the data label affixed to the underside of the hot plate

correspond to those of the gas and electricity mains in

the home.

A label on the appliance indicates the regulating

conditions: type of gas and working pressure. Gas

connection must comply with the pertinent standards

and provisions in force.

When gas is supplied through ducts, the appliance must

be connected to the gas supply system:

o with a rigid steel pipe. The joints of this pipe must consist

of threaded fittings conforming to the standards.

o With copper pipe. The joints of this pipe must consist of

unions with mechanical seals.

o With seamless flexible stainless steel pipe. The length of

this pipe must be 2 meters at most and the seals must

comply with the standards.

When the gas is supplied by a bottle, the appliance must

be fuelled by a pressure governor conforming to the

provisions in force and must be connected:

o with a copper pipe. The joints of this pipe must consist of

unions with mechanical seals.

o With seamless flexible stainless steel pipe. The length of

this pipe must be 2 meters at most and the seals must

comply with the standards. It is advisable to apply the

special adapter to the flexible pipe. This is easily available

from the shops and facilitates connection with the hose

nipple of the pressure governor on the bottle.

o With rubber hose pipe in compliance with standards. The

diameter of this hose pipe must be 8 mm and its length

must be no less than 400 mm and no more than 1500

mm. It must be firmly fixed to the hose nipple by means of

the safety clamp specified by standards.

At the connection end, verify the gasproof using a soap solution,

never a flame.

WARNINGS:

Remember that the gas inlet union on the

appliance is a 1/2" gas parallel male type in

compliance with EN 10226 standards.

Installation of stainless steel pipe and rubber hose

pipe must ensure that it is never able to touch

mobile parts of the built-in cabinet (eg. drawers).

Furthermore, it must not pass through

compartments that could be used for storage

purposes.

When using a rubber hose pipe, it is essential to

comply with the following instructions:

- no part of the pipe must be able to touch parts

the temperature of which exceeds 65K.

- The pipe must not be pulled or twisted, throttled

or tughtly bent.

- It must not come into contact with sharp edges or

corners.

- It must be easy to inspect the entire pipe length in

order to check its state of wear.

- The pipe must be replaced within the date

stamped on the pipe itself.

- The appliance complies with the provisions of the

following EEC Directives:

90/396 + 93/68 regarding gas safety.

INSTALLATION

23

Page 24

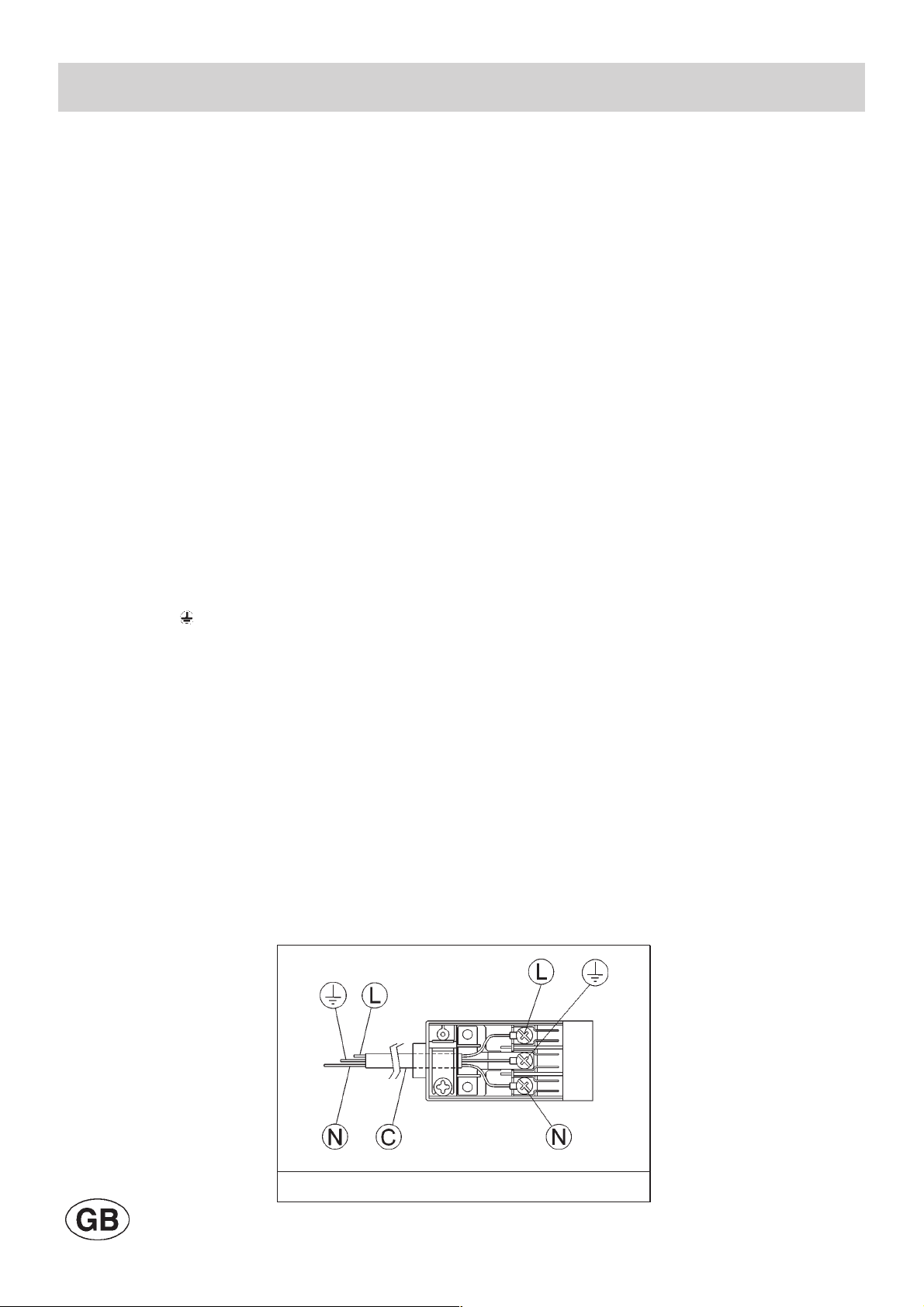

8) ELECTRICAL CONNECTION

The electrical connections of the appliance

must be carried out in compliance with the

provisions and standards in force.

Before connecting the appliance, check that:

- The electrical capacity of the mains supply and

current sockets suit the maximum power rating of

the appliance (consult the data label applied to the

underside of the hot plate).

- The socket or system has an efficient earth

connection in compliance with the provisions and

standards in force. The manufacturer declines all

responsibility for failing to comply with these

provisions.

When the appliance is connected to the

electricity main by a socket:

- Fit a standard plug suited to the load indicated on

the data label to the cable.

- Fit the wires following figure n.11, taking care of

respecting the following correspondences:

letter L (live) = brown wire;

letter N (neutral) = blue wire;

earth symbol = green - yellow wire

- The power supply cable must be positioned so

that no part of it is able to reach an

overtemperature of 65K.

- Never use reductions, adapters of shunts for

connection since these could create false contacts

and lead to dangerous overheating.

- The outlet must be accessible after the built-in.

When the appliance is connected straight to the

electricity main:

- Install an omnipolar circuit-breaker between the

appliance and the electricity main. This circuitbreaker should be sized according to the load

rating of the appliance and possess a minimum 3

mm gap between its contacts.

- Remember that the earth wire must not be

interrupted by the circuit-breaker.

- Alternatively, the electrical connection may also be

protected by a high sensitivity differential circuitbreaker.

You are strongly advised to fix the relative yellowgreen earth wire to an efficient earthing system.

WARNINGS:

All our appliances are designed and

manufactured in compliance with European

standards EN 60 335-1, EN 60 335-2-6 and

EN 60 335-2-102 plus the relative amendments.

The appliance complies with the provisions of

the following EEC Directives:

- CEE 2004/108/CE regarding to electromagnetic

compatibility.

- CEE 2006/95 regarding electrical safety.

INSTALLATION

FIG. 11

24

Page 25

ADJUSTMENTS

Always disconnect the appliance from the

electricity main before making any adjustments.

All seals must be replaced by the technician at

the end of any adjustments or regulations.

Our burners do not require primary air

adjustment.

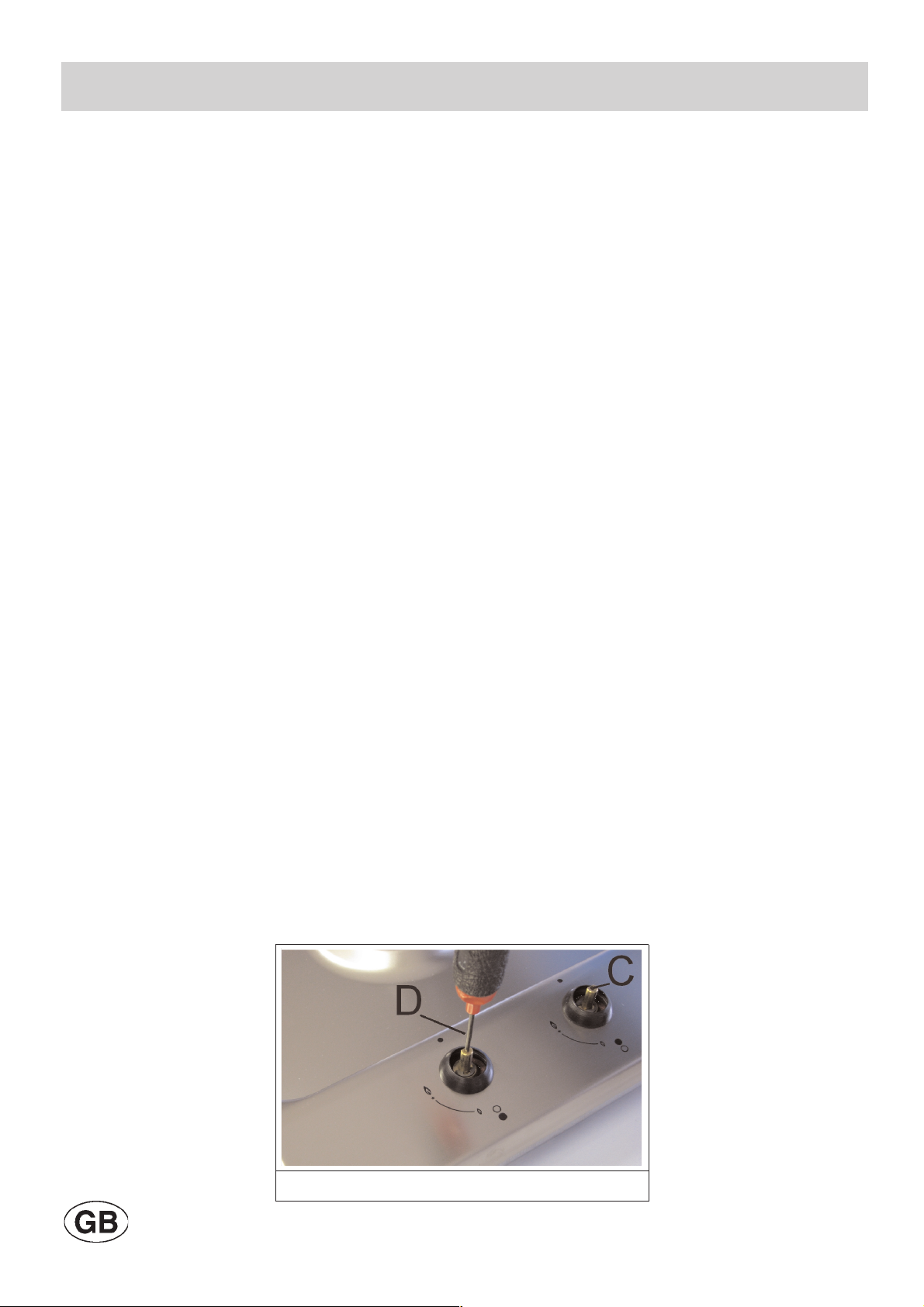

9) TAPS

“Reduced rate” adjustment

- Switch on the burner and turn the relative knob to

the “Reduced rate” position (small flame fig.1).

- Remove knob (fig. 12) of the tap, which is simply

pressed on to its rod.

- Insert a small screwdriver “D” into hole “C” (fig. 12)

and turn the throttle screw to the right or left until

the burner flame has been adequately regulated to

the “Reduced rate” position.

Check that the flame does not go out when the

knob is sharply switched from the “Full on” to the

“Reduced rate” position.

It is understood that only burners operating

with G20 gas should be subjected to the above

mentioned adjustments. The screw must be

fully locked when the burners operate with G30

or G31 gas (turn clockwise).

25

FIG. 12

Page 26

10) REPLACING THE INJECTORS

The burners can be adapted to different types of

gas by mounting injectors suited to the type of gas

in question. To do this, first remove the burner tops

using a wrench “B”. Now unscrew injector “A” (see

fig. 13) and fit a injector corresponding to the

utilized type of gas in its place.

It is advisable to strongly tighten the injector in

place.

After the injectors have been replaced, the

burners must be regulated as explained in

paragraphs 9. The technician must reset any

seals on the regulating or pre-regulating devices.

The envelope with the injectors and the labels can

be included in the kit, or at disposal to the

authorized customer Service Centre.

For the sake of convenience, the nominal rate table

also lists the heat inputs of the burners, the

diameter of the injectors and the working pressures

of the various types of gas.

BURNER ARRANGEMENT ON THE HOT PLATE

CONVERSIONS

TABLE

1 ULTRA RAPID

G 30 - BUTANE 28 - 30 225 90 1400 3100

G 31 - PROPANE 37 222 90 1400 3100

G 20 - NATURAL 20 295 121 Y 1400 3100

2 RAPID

G 30 - BUTANE 28 - 30 204 83 800 2800

G 31 - PROPANE 37 200 83 800 2800

G 20 - NATURAL 20 267 117 S 800 2800

BURNERS

N°

DESCRIPTION

GAS

NORMAL

PRESSURE

NORMAL

RATE

INJECTOR

DIAMETER

NOMINAL HEAT

INPUT (W)

mbar g/h l/h 1/100 mm Min. Max.

4 SEMIRAPID

G 30 - BUTANE 28 - 30 127 65 500 1750

LEFT BACK

G 31 - PROPANE 37 125 65 500 1750

G 20 - NATURAL 20 167 97 Z 500 1750

5 AUXILIARY

G 30 - BUTANE 28 - 30 73 50 400 1000

G 31 - PROPANE 37 71 50 400 1000

G 20 - NATURAL 20 95 72 X 400 1000

3 SEMIRAPID

G 30 - BUTANE 28 - 30 102 58 500 1400

RIGHT FRONT

G 31 - PROPANE 37 100 58 500 1400

G 20 - NATURAL 20 133 85 Y 500 1400

FIG. 13

26

Page 27

CONVERSIONS

BURNER ARRANGEMENT ON THE HOT PLATE

TABLE

2 RAPID

G 30 - BUTANE 28 - 30 218 85 750 3000

G 31 - PROPANE 37 200 85 750 3000

G 20 - NATURAL 20 267 115 Y 750 3000

BURNERS

N°

DESCRIPTION

GAS

NORMAL

PRESSURE

NORMAL

RATE

INJECTOR

DIAMETER

NOMINAL HEAT

INPUT (W)

mbar g/h l/h 1/100 mm Min. Max.

5 AUXILIARY

G 30 - BUTANE 28 - 30 73 50 400 1000

G 31 - PROPANE 37 71 50 400 1000

G 20 - NATURAL 20 95 72 X 400 1000

27

Page 28

SERVICING

Always disconnect the appliance from the

electricity and gas mains before proceeding

with any servicing operation.

11) REPLACING HOT PLATE PARTS

When parts housed within the hot plate need

replacing, it is first necessary to remove the hot

plate itself from the cabinet, to overturn it, unscrew

screws “V” and to remove part (see fig. 14).

After having carried out the above listed operations,

the burners (fig. 15), taps (fig. 16) and electrical

components can all be replaced (fig. 17).

It is advisable to change seal “D” whenever a tap is

replaced to ensure a perfect tightness.

Greasing the taps (see fig. 18 - 19)

If a tap becomes stiff to operate, it must be

immediately greased in compliance with the

following instructions:

- Remove the tap.

- Clean the cone and its housing using a cloth

soaked in diluent.

- Lightly spread the cone with the relative grease.

- Fit the cone back in place, operate it several times

and then remove it again. Eliminate any excess

grease and check that the gas ducts have not

become clogged.

- Fit all parts back in place, complying with the

demounting order in reverse.

- The tight closure test must be done using a foamy

liquid.

To facilitate the servicing technician’s task, here is a

chart with the types and sections of the powering

cables and the ratings of the electrical components.

FIG. 17 FIG. 18 FIG. 19

FIG. 14 FIG. 15 FIG. 16

28

Page 29

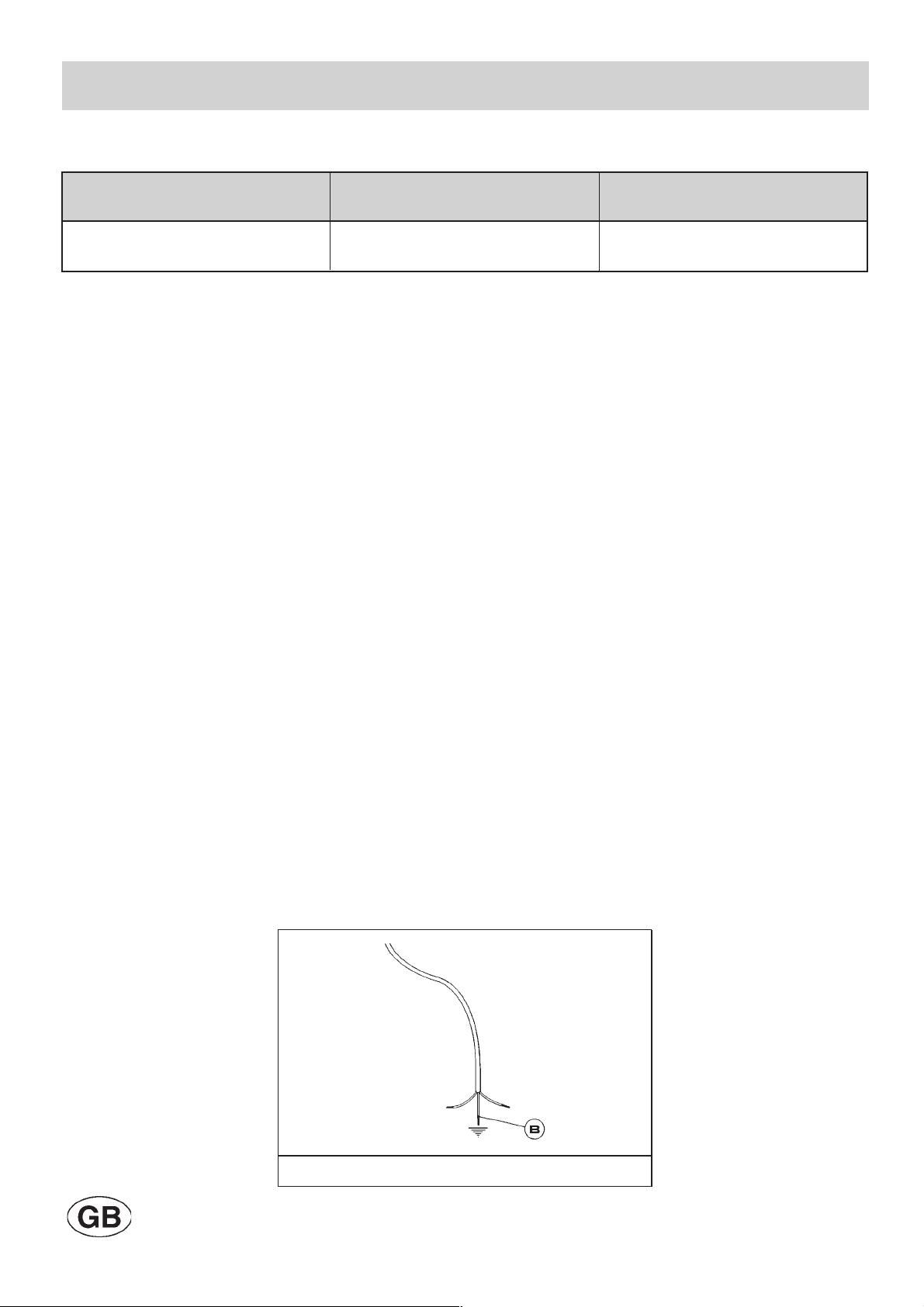

SERVICING

CABLE TYPES AND SECTIONS

Gas hot plate H05 RR - F Section 3 x 0.75 mm

2

TYPE OF TYPE OF SINGLE - PHASE

HOT PLATE CABLE POWER SUPPLY

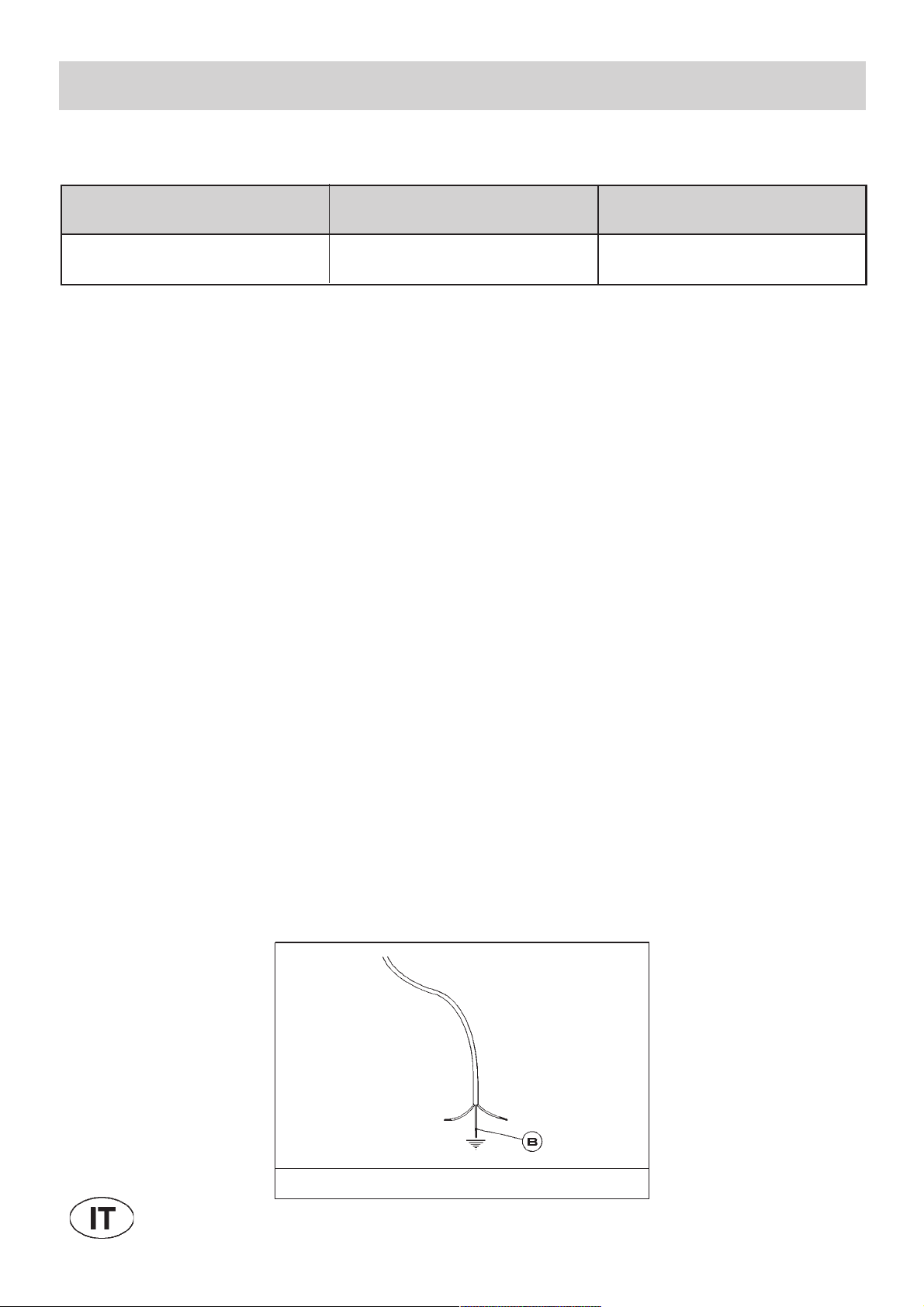

ATTENTION!!!

If the power supply cable is replaced, the installer should leave the ground wire longer than the

phase conductors (fig. 20) and comply with the recommendations given in paragraph 8.

FIG. 20

29

Page 30

4 BURNERS (60)

CATEGORY: II

2H3+

BUTANE = 28 - 30 mbar

PROPANE = 37 mbar

NATURAL = 20 mbar

Σ Qn Gas Natural = 6.95 kW

Σ Qn LPG = 505 g/h

VOLTAGE = 220 - 240 V ~

FREQUENCY = 50/60 Hz

TECHNICAL DATA ON THE DATA LABEL

5 BURNERS (70)

CATEGORY: II

2H3+

BUTANE = 28 - 30 mbar

PROPANE = 37 mbar

NATURAL = 20 mbar

Σ Qn Gas Natural = 10.05 kW

Σ Qn LPG = 731 g/h

VOLTAGE = 220 - 240 V ~

FREQUENCY = 50/60 Hz

2 BURNERS (30)

CATEGORY: II

2H3+

BUTANE = 28 - 30 mbar

PROPANE = 37 mbar

NATURAL = 20 mbar

Σ Qn Gas Natural = 4 kW

Σ Qn LPG = 291 g/h

VOLTAGE = 220 - 240 V ~

FREQUENCY = 50/60 Hz

5 BURNERS (90)

CATEGORY: II

2H3+

BUTANE = 28 - 30 mbar

PROPANE = 37 mbar

NATURAL = 20 mbar

Σ Qn Gas Natural = 10.40 kW

Σ Qn LPG = 756 g/h

VOLTAGE = 220 - 240 V ~

FREQUENCY = 50/60 Hz

30

Page 31

TECHNICAL DATA FOR THE APPLIANCE GAS

REGULATION

31

Page 32

32

Before leaving the factory, this appliance will have been tested and regulated by expert and specialized

personnel in order to guarantee the best performances.

Any repairs or adjustments which may be subsequently required may only be carried out by qualified

personnel with the utmost care and attention.

For this reason, always contact your Dealer or our nearest After Sales Service Center whenever repairs

or adjustments are required, specifying the type of fault and the model of the appliance in your

possession.

Please also note that genuine spare parts are only available from our After Sales Service Centers and

authorized retail outlets.

The above data are printed on the data label put on the inferior part of the appliance and on the packing

label.

The above informations give to the technical assistant the possibility to get fit spare parts and a heavensent intervention. We suggest to fill the table below.

MARK: ........................................................................

MODEL: ......................................................................

SERIES: ......................................................................

TECHNICAL ASSISTANCE AND SPARE PARTS

This appliance is marked according to the European directive 2002/96/EC on Waste Electrical and

Electronic Equipment (WEEE).

This guideline is the frame of a European-wide validity of return and recycling on Waste Electrical and

Electronic Equipment.

Page 33

COD. 04037CEGOA (04037CESK) - 22.01.2009

Inštrukcie pre inštaláciu

a radi pre údržbu

G34AX1-236650 - G64AX1-236625

G640AX1-236636 - G760AX1-236651

G960AX1-234640

Návod obsluhu

G34AX1-236650 - G64AX1-236625

G640AX1-236636 - G760AX1-236651

G960AX1-234640

Page 34

POPIS VARNÝCH DOSIEK

TYPY: G34AX1-236650

TYPY: G64AX1-236625 - G640AX1-236636

TYPY: G760AX1-236651

TYP.: G960AX1-234640

1 Horák veľmi rýchly 3100 W

2 Horák rýchly 2800 W

3 Horák polorýchly snížené 1400 W

4 Horák polochýchly 1750 W

5 Horák doplnkový 1000 W

6 Rošt zo smaltovej ocele pre dva horáky

7 Centrálny rošt zo smaltovanej ocele

8 Ovládač k horáku č. 1

9 Ovládač k horáku č. 2

10 Ovládač k horáku č. 3

11 Ovládač k horáku č. 4

12 Ovládač k horáku č. 5

13 Tlačidlo elektrického zapaľovania

Pozor: toto zariadenie bolo vyvinuté na používanie v domácom prostredí.

34

Page 35

1) HORÁKY

Na čelnej maske je nad každým ovládacím

gombíkom vytlačená schéma, z ktorej je zrejmé

ktorý horák sa príslušným gombíkom ovláda. Po

otvorení ventilu prívodu plynu na plynovom

potrubí alebo na plynovej bombe, zapáliť horáky

podľa nasledovných inštrukcií:

- ručné zapálenie

Zatlačiť ovládaci gombík príslušného horáku a

otáčať ním v protismere hodinových ručičiek až do

polohy Max (silný plameň, obr. 1). Priložiť horiacu

zápalku ku horáku.

- Elektrické zapálenie

Zatlačiť ovládaci gombík príslušného horáku a

otáčať ním v protismere hodinových ručičiek až do

polohy Max (silný plameň, obr. 1). Zatlačiť a hneď

pustiť tlačidlo zapaľovania „E“.

- Elektrické automatické zapaľovanie

Zatlačiť ovládaci gombík príslušného horáku a

otáčať ním v protismere hodinových ručičiek až do

polohy Max (silný plameň, obr. 1). Zatlačiť

ovládací krúžok až na doraz.

- Zapaľovanie horákovvy bavených

bezpečnostným termočlánkom

Pri horákoch vybavených bezpečnostným

termočlánkom otáčať príslušným ovládacím

gombíkom v protismere hodinových ručičiek do

polohy Max (silný plameň, obr. 1) až kým necítiť

jemný odpor. Vtedy zatlačiť ovládaci gombík a

zopakovať kroky opísané vyššie.

Po zapálení držať ovládací krúžok stlačený ešte

asi 10 sekúnd.

AKO POUŽÍVAŤ HORÁKY

Pre dosiahnutie maximálneho výkonu pri

minimálnej spotrebe plynu je užitočné zapamätať

si nasledujúce kroky:

- pre každý horák používať správne hrnce (viď

tabuľku a vyobrazenie č. 2).

- Po dosiahnutí varu otočiť ovládacím gombíkom

do polohy Min (slabý plameň, obr. 1).

- Vždy používať hrnce s pokrievkou.

- Používajte panvice s rovným dnom.

Horáky výkon W Priemer

nádoby v cm

veľmi rýchly 3100 24 ÷ 26

rýchly 2800 20 ÷ 22

polorýchly predný pravý 1400 1 6 ÷ 18

polochýchly zadný ľavý 1750 16 ÷ 18

doplnkový 1000 10 ÷ 14

UPOZORNENIA:

- horáky vybavené bezpečnostným

termočlánkom možno zapaľovať iba vtedy,

keď je ovládaci gombík v polohe Max (silný

plameň, obr. 1).

- Ak bol prerušený prívod elektrickej energie, je

možné horáky zapáliť pomocou zápaliek.

- Počas používania horákov nenechávať

zariadenie bez dozoru a nepúšťať deti do jeho

blízkosti. Zvlášť sa ubezpečiť o tom, že sú

rúčky hrncov v správnej polohe a dohliadať

na prípravu jedál s použitím olejov alebo

tukov, nakoľko tieto sú ľahko zápalné.

- Nie je dovolené používať túto techniku ľuďom

(vrátane detí) s obmedzenými fyzickými či

mentálnymi schopnosťami alebo s

nedostatočnými vedomosťami o používaní

elektrických prístrojov, okrem prípadov, ak

pracujú pod dozorom alebo boli poučení

dospelými ľuďmi, zodpovednými za ich

bezpečnosť. Deti musia byť pod dohľadom

pre ubezpečenie sa, že sa nehrajú s

technikou.

- Nepoužívať spreje v blízkosti zapálených

horákov.

- Pokiaľ je varná doska vybavená krytom,

odstraňte pred je otvorením z jeho povrchu

všetky zbytky potravín. Pokiaľ je tento kryt zo

skla, dbajte pred jeho sklopením na to, aby

horáky boli vychladnuté. Horúce horáky môžu

spôsobiť prasknutie skleného krytu.

- Neodporúča sa používať nádoby, ktoré

prečnievajú za okraje povrchu varnej plochy.

POUŽÍVANIE

OBR. 2OBR. 1

35

Page 36

POUŽÍVANIE

POZNÁMKY:

používaním zariadenia pre varenie na plyne vzniká v miestnosti kde je toto umiestnené, teplo a

vlhko. Preto je potrebné zabezpečiť dobré vetranie priestorov. Je dôležité udržiavať otvory pre

prirodzenú ventiláciu (obr. 3) voľné a používať mechanické prístroje vetrania (digestor alebo

elektrický ventilátor, obr. 4. a 5.).

Intenzívnejšie a dlhšie trvajúce používanie zariadenia môže vyžadovať takisto lepšie vetranie,

napríklad otvorením okna alebo zvýšením výkonu mechanického odsávania, ak je toto k

dispozícii.

OBR. 3

OBR. 4

OBR. 5

(*) PRÍVOD VZDUCH: VID. KAPITOLA INŠTALÁCIE (PARAGRAF 5 A 6)

36

Page 37

37

ČISTENIE

OBR. 6

POZOR:

predtým ako pristúpite k akémukoľvek čisteniu, odpojte zariadenie od elektrickej siete a

plynového potrubia.

2) PRACOVNÁ PLOCHA

Pracovná plocha, rošty zo smaltovanej ocele, smaltované kryty „C“ a hlavy horákov „T“ (viď obr. 6) musia

byť pravidelne umývané vlažnou vodou so saponátom, následne opláchnuté a dobre vysušené.

Neumývať smaltované povrchy keď sú ešte veľmi horúce a nikdy nepoužívať brúsne prášky. Nedovoliť

aby ocot, káva, mlieko, slaná voda, šťava z citróna alebo paradajok zostávali dlho v styku so

smaltovanými povrchmi.

UPOZORNENIA:

je žiadúce aby boli pri zakladaní jednotlivých častí späť na ich pôvodné miesto rešpektované

nasledovné odporúčania:

- presvedčiť sa že hlavy horákov sedia správne vo svojich sedlách a že štrbiny nie sú upchaté

cudzími telesami.

- Presvedčiť sa že smaltované kryty „C“ (viď obr. 6) sú umiestnené správne na hlavách horákov. To

je vtedy, keď kryty na hlavách pevne sedia.

- Správna poloha roštu je daná zaoblenými rohmi, ktoré majú smerovať k bočným stranám.

- Ak je obsluha pri otváraní alebo zatváraní niektorého z ventilov ťažká, nepreťažovať, urýchlene

vyžiadať zásah technického servisu.

- Nepoužívajte na čistenie spotrebiča horúcu paru.

Page 38

38

INŠTALÁCIA

OBR. 7

OBR. 8 OBR. 9

OBR. 10

TECHNICKÉ INFORMÁCIE URČENÉ

INŠTALATÉROM

Inštaláciu, všetky nastavenia, zmeny a údržby

opisované v tejto časti, musia vykonávať

výlučne kvalifikovaný pracovníci.

Nesprávna inštalácia môže spôsobiť škody na

ľuďoch, zvieratách a veciach, za čo nemôže

byť zodpovedný výrobca.

Bezpečnostné prvky alebo prvky

automatického nastavenia zariadení môžu byť

počas životnosti zariadenia zmenené iba

výrobcom, alebo dodávateľom s náležitým

splnomocneným.

3) MONTÁŽ VARNEJ DOSKY

Po odstránení vonkajšieho obalu a iných obalov

rôznych menších častí sa treba presvedčiť o

kompletnosti zariadenia. V prípade pochybností

zariadenie nepoužiť a obrátiť sa na odborných

pracovníkov.

Obalové časti (kartón, sáčky, voľný

polystyrén, klince...) napatria do rúk deťom,

keďže sú možnými zdrojmi úrazu.

Do pracovnej plochy sektorového nábytku treba

vyrezať otvor pre vloženie zariadenia, podľa

rozmerov na obr. 7, a presvedčiť sa že budú

dodržané kritické rozmery priestoru, do ktorého

má byť zariadenie nainštalované (viď obr. 7 - 8).

Zariadenie je zaradené do 3 triedy a podlieha

preto všetkým predpisom vyplývajúcim z

noriem pre takéto zariadenia.

4) UPEVNENIE VARNEJ DOSKY

Varná doska je vybavená špeciálnym tesnením

pre zabránenie prenikaniu tekutiny do nábytku.

Pre správne založenie tohto tesnenia je dôležité

podrobne dodržať nasledovné kroky:

- odlepiť prúžky tesnenia od ich podkladu, dbajúc

o to, aby priesvitná ochranná páska ostala

prilepená na samotnom tesnení.

- Obrátiť dosku a umiestniť tesnenie „E“ (obr. 9)

správne pod okraj dosky tak, aby vonkajšia

strana tesnenia dôkladne priľahla k obvodovému

okraju dosky. Konce prúžkov musia priliehať bez

toho, aby presahovali von.

- Prilepiť tesnenie bezpečne k doske, stláčajúc ho

prstami. Potom odlepiť ochrannú pásku z

tesnenia a umiestniť dosku do otvoru v nábytku.

- Zablokovať dosku protichodnými svorkami „S“,

vsadiť opatrne ich vyčnievajúce časti do otvoru

„H“ a priskrutkovať skrutkou „F“ až do pozície,

kde sa svorka „S“ dotkne hornej časti (obr. 10).

- Případná stěna (levá nebo pravá), která výškově

přesahuje pracovní desku, musí být od otvoru

vzdálena minimálně tak, jak je uvedeno ve

sloupci tabulky.

- Aby sa zabránilo nebezpečným kontaktom s

krytom dosky, rozpáleným počas jej používania,

je nevyhnutné priskrutkovať drevenú oddeľujúcu

policu, vo vzdialenosti 50 mm od vrchu (obr. 7).

ZÁVÄZNÉ MIERY

(v mm)

A B C D E

2F (30) 285 485 57.5 57.5 100 min.

4F (60) 553 473 67.5 59.5 175 min.

5F (70) 553 473 67.5 59.5 175 min.

5F (90) 833 475 62.5 62.5 73.5 min.

Page 39

39

INŠTALÁCIA

POKYNY DOLEŽITÉ PRE

INŠTALÁCIU

Oznamuje sa inštalatérom že prípadné bočné

steny nemôžu prevyšovať varičovú dosku.

Okrem toho zadná stena a okolité povrchy

priľahlé k doske musia odolať teplote vyššej

ako 65K.

Lepidlo ktoré spája plastickú fóliu s nábytkom,

musí odolať teplote min. 150º C aby nedošlo k

odlepeniu samotného plastického poťahu.

Inštalácia zariadenia musí byť v súlade s

predpismi noriem.

Toto zariadenie nie je pripojené na prístroj

odčerpávajúci splodiny horenia. Napriek tomu

musí byť zapojené podľa hore uvedených

predpisov pre inštaláciu. Zvláštnu pozornosť

treba venovať nasledovným opatreniam,

týkajúcich sa prúdenia vzduchu a vetrania.

5) PRÚDENIE VZDUCHU V MIESTNOSTI

Pre správnu funkciu zariadenia je nevyhnutné, aby

bolo v miestnosti kde je toto umiestnené,

zabezpečené stále prúdenie vzduchu. Potrebné

množstvo vzduchu je závislé od riadneho horenia

plynu a od prúdenia vzduchu v miestnosti. Objem

vzduchu v miestnosti musí byť minimálne 20 m

3

.

Prirodzené prúdenie vzduchu musí byť

zabezpečené priamou cestou cez stále otvory v

stenách smerujúce do von, s minimálnym

prierezom 100 cm

2

(viď obr. 3). Tieto otvory musia

byť umiestnené tak, aby nedošlo k ich upchatiu.

Povolená je aj nepriama ventilácia ku ktorej

dochádza prelievaním vzduchu z priľahlých

miestností do miestnosti kde je umiestnená

varičová doska, za prísneho dodržiavania

predpisov noriem STN.

Pozor:

Pokiaľ nie sú horáky na pracovnej doske

vybavené termopoistkami, musí mať otvor

ventilácie rozlohu aspoň 200m

2

.

6) UMIESTNENIE A VETRANIE

Plynové varné dosky musia mať vždy

zabezpečené odsávanie splodín horenia pomocou

odsávačov napojených na komíny, dymových

kanálov alebo priamo do von (viď obr. 4). Ak nie je

možné nainštalovať odsávač (digestor), toleruje sa

aj použitie ventilátora namontovaného na okne

alebo obvodovej stene, ktorý sa zapne súčasne so

zariadením (viď obr. 5). Musia pritom byť

zodpovedne dodržané nariadenia týkajúce sa

ventilácie, ktoré sú opísané v normách STN.

7) PRIPOJENIE PLYNU

Pred pripojením zariadenia je potrebné uistiť

sa že informácie na štítku, ktorý sa nachádza

na zadnej strane krytu, sú zlučiteľné s

informáciami týkajúcimi sa siete rozvodu

plynu.

Štítok vytlačený tejto príručky a ďalší prilepený

na zadnej strane krytu, obsahujú podmienky

nastavenia zariadenia: typ plynu a

prevádzkový tlak.

Ak je plyn distribuovaný prostredníctvom

centrálneho rozvodu, zariadenie musí byť

pripojené na prívod plynu:

o pevnou oceľovou trúbkou podľa normy. Spoje

musia byť realizované prostredníctvom závitových

spojok, podľa normy. Je prípustné použiť tesniace

materiály ako konope s vhodným tmelom, alebo

teflónovú pásku.

o Medenou trúbkou podľa normy. Spoje musia byť

realizované prostredníctvom spojok s

mechanickou upchávkou podľa normy.

o Pružnou hadicou z nehrdzavejúcej ocele podľa

normy, s maximálnym natiahnutím 2 metre a

hermetickým tesnením podľa normy. Táto hadica

musí byť nainštalovaná tak, aby sa nedostala do

styku s pohyblivými časťami nábytku (ako napr.

zásuvky) a nesmie prechádzať prázdnymi

miestami, ktoré môžu byť niečím zaplnené.

Keď je plyn dodávaný priamo z bomby,

zariadenie ktoré je napájané prostredníctvom

regulátora tlaku podľa normy, musí byť pripojené:

o medenou trúbkou podľa normy. Spoje musia byť

realizované prostredníctvom spojok s

mechanickou upchávkou podľa normy.

o Pružnou hadicou z nehrdzavejúcej ocele podľa

normy, s maximálnym natiahnutím 2 metre a

hermetickým tesnením podľa normy. Táto hadica

musí byť nainštalovaná tak, aby sa nedostala do

styku s pohyblivými časťami nábytku (ako napr.

šuflíky) a nesmie prechádzať prázdnymi miestami,

ktoré môžu byť niečím zaplnené. Odporúča sa

pripevniť na ohybnú hadicu špeciálny adaptér,

ľahko dostupný v obchodoch, aby sa uľahčilo

pripájanie na koncovku regulátora tlaku, ktorý je

namontovaný na bombe.

Po pripojení zariadenia skontrolovať dokonalosť

tesnenia pomocou mydlového roztoku, nikdy nie

pomocou plameňa.

UPOZORNENIA:

- pripomína sa že spoj vstupu plynu na

zariadení je závitový 1/2" kuželovitý závitník

podľa noriem EN 10226.

- Zariadenie je v súlade s predpismi

doleuvedených Európskych Nariadení:

- CEE 90/396 + 93/68 týkajúce sa bezpečnosti

plynu.

Page 40

40

8) ELEKTRICKÉ PRIPOJENIE

Elektrické pripojenie musí byť realizované v

súlade s normami a nariadeniami platných

zákonov.

Pred samotným pripojením sa uistiť že:

- elektrická kapacita rozvodu a zásuviek je

primeraná maximálnemu výkonu zariadenia (viď

štítok na zadnej strane krytu).

- Zástrčky a inštalácia sú vybavené účinným

uzemnením podľa noriem a nariadení platných

zákonov. Odmieta sa akákoľvek zodpovednosť za

nedodržanie týchto nariadení.

Ak je pripojenie do siete realizované

prostredníctvom zásuvky:

- na napájací kábel „C“, pokiaľ tam už nie je, (viď

obr. 11) primontovať normalizovanú zástrčku

vhodnú pre zaťaženie vyznačené na štítku.

- Pripojiť káble podľa schémy na obr. 11, dbajúc o

to, aby boli dodržané nasledovné údaje:

písmeno L (fáza) = kábel hnedej farby;

Písmeno N (nulový vodič) = kábel modrej farby;

Symbol (zem) = kábel zeleno-žltej farby.

- Napájací kábel musí byť umiestnený tak, aby v

žiadnom mieste nedosiahol teplotu nad 65K.

- Pre pripojenie nepoužívať redukcie, adaptéry

alebo bočníky, nakoľko by mohli vyvolať falošné

kontakty s následnými nebezpečnými

prehriatiami.

- Zástrčka musí byť dostupná aj po zabudovaní

spotrebiča.

Ak je pripojenie realizované priamo do

elektrickej siete:

- vložiť medzi zariadenie a sieť vypínač,

dimenzovaný na záťaž zariadenia, s minimálnym

odskokom medzi kontaktmi 3 mm.

- Pamätať že uzemňovací kábel nemôže byť

prerušený vypínačom.

- Alternatívne môže byť elektrické pripojenie

chránené aj diferenčným vypínačom vysokej

citlivosti.

Zásadne sa odporúča pripojiť uzemňujúci kábel

zeleno-žltej farby na účinné uzemňujúce zariadenie.

UPOZORNENIA:

oznamuje sa inštalatérom že kombinované

zariadenie je typu Y. Okrem toho zadné steny a

okolité plochy priľahlé k doske musia zniesť

teplotu väčšiu ako 65K.

Všetky naše zariadenia sú projektované a

konštruované podľa európskych noriem

EN 60 335-1, EN 60 335-2-6 a EN 60 335-2-102

plus príslušné pozmeňovacie návrhy.

Zariadenie je v súlade s predpismi Európskych

Smerníc:

- CEE 2004/108/CE týkajúcich sa

elektromagnetickej prípustnosti.

- CEE 2006/95 týkajúcich sa elektrickej

bezpečnosti.

INSTALACE

OBR. 11

Page 41

41

NASTAVENIA

Pred vykonaním akéhokoľvek nastavenia odpojiť zariadenie od elektrického prúdu.

Po ukončení nastavení alebo prestavení musí technik obnoviť prípadné plomby.

Nastavenie primárneho vzduchu na našich horákoch nie je nutné.

9) VENTILY

Nastavenia „Minima“:

- zapáliť horák a nastaviť ovládacie koliesko do polohy „Minimum“ (slabý plameň, obr. 1).

- Stiahnuť ovládacie koliesko (obr. 12), z ventilu. Je nasadené na jeho oske slabým tlakom.

- Vložiť do otvoru „C“ malý skrutkovač „D“ (obr. 12) a otáčať škrtiacou skrutkou doprava alebo doľava až

kým nie je plameň horáku vhodne nastavený na „Minimum“.

Uistiť sa že pri rýchlom pootočení kolieskom z „Maxima“ do „Minima“ plameň nezhasne.

Je dohodnuté že horeuvedené nastavenie sa vykonáva iba na horákoch fungujúcich na zemný G20,

na horákoch fungujúcich na bután G30 alebo propán G31 však musí byť skrutka dotiahnutá na

doraz (otáčajúc v smere hodinových ručičiek).

OBR. 12

Page 42

42

USPORIADANIE HORÁKOV

TABUĽKA

OBR. 13

POLORÝCHLY

PREDNÝ

PRAVÝ

HORÁKY

č

TYP

PLYN

mbar

TEPLOTNÝ

PRIETOK

g/h

l/h

PRIEMER

TRYSKY

1/100 mm

TEPLOTNÝ

PRIETOK W

min. max.

1

3

2

G 30 - BUTÁN

G 31 - PROPÁN

G 20 - ZEMNÝ

VEĽMI

RÝCHLY

RÝCHLY

30

30

20

225

222

295

204

200

267

102

100

133

90

90

121 Y

83

83

117 S

58

58

85 Y

1400

1400

1400

800

800

800

500

500

500

3100

3100

3100

2800

2800

2800

1400

1400

1400

4

127

125

167

65

65

97 Z

500

500

500

1750

1750

1750

5

DOPLNKOVÝ

73

71

95

50

50

72 X

400

400

400

1000

1000

1000

PRETLAK

30

30

20

30

30

20

30

30

20

30

30

20

10) VÝMENA TRYSIEK

Horáky možno prispôsobiť rôznym druhom plynov,

namontovaním trysiek vhodných pre používaný

plyn. K tomu je treba sňať hlavy horákov a

pomocou priameho kľúča „B“ odkrútiť trysku „A“

(viď obr. 13) a vymeniť ju za trysku vhodnú pre

používaný plyn. Odporúča sa trysku energicky

dotiahnuť.

Po opísanej výmene musí technik nastaviť

horáky tak ako je to naznačené v kapitole 9,

zaplombovať nastavované alebo prestavované

časti a nalepiť na zariadenie, namiesto starého

štítku štítok nový, zodpovedajúci novým

nastaveniam plynu vykonaným na zariadení.

Tento štítok sa nachádza v obálke náhradných

trysiek. Obálka s tryskami a štítkami môže byť

priamo vo výbave, inak je k dispozícii v

autorizovanom servisnom centre.

Pre uľahčenie práce inštalatérom uvádzame

nasledovnú tabuľku s výmerami, teplotnými

prietokmi horákov, priemermi trysiek a

prevádzkovými tlakmi pre rôzne druhy plynov.

POLOCHÝCHLY

ZADNÝ ĽAVÝ

VÝMENY

G 30 - BUTÁN

G 31 - PROPÁN

G 20 - ZEMNÝ

G 30 - BUTÁN

G 31 - PROPÁN

G 20 - ZEMNÝ

G 30 - BUTÁN

G 31 - PROPÁN

G 20 - ZEMNÝ

G 30 - BUTÁN

G 31 - PROPÁN

G 20 - ZEMNÝ

Page 43

43

VÝMENY

USPORIADANIE HORÁKOV

TABUĽKA

HORÁKY

č

TYP

PLYN

mbar

TEPLOTNÝ

PRIETOK

g/h

l/h

PRIEMER

TRYSKY

1/100 mm

TEPLOTNÝ

PRIETOK W

min. max.

2

RÝCHLY

218

200

267

85

85

115 Y

750

750

750

3000

3000

3000

5

DOPLNKOVÝ

73

71

95

50

50

72 X

400

400

400

1000

1000

1000

PRETLAK

30

30

20

30

30

20

G 30 - BUTÁN

G 31 - PROPÁN

G 20 - ZEMNÝ

G 30 - BUTÁN

G 31 - PROPÁN

G 20 - ZEMNÝ

Page 44

44

ÚDRŽBA

OBR. 17 OBR. 18 OBR. 19

OBR. 14 OBR. 15 OBR. 16

Pred pristúpením k akejkoľvek údržbe, odpojiť

zariadenie od elektrického napájania a prívodu

plynu.

11) VÝMENA DIELOV

Pre výmenu náhradných dielov vo vnútri dosky ,je

treba odstrániť rošt a hlavy horákov z hornej časti

dosky a nastaviť závity “V“ tak, aby zafixovali

horáky (obr. 14) a ovládače nastaviť do takej

polohy, aby bolo možné odstrániť pracovnú dosku.

Po prevedení vyššie uvedených úkonov je možné

vymeniť horáky (obr. 15) ventily (obr. 16) a

elektrické časti (obr. 17).

Odporúča sa vymeniť tesnenie „D“ vždy keď sa

vymieňa jeden z ventilov, kvôli dosiahnutiu

dokonalého tesnenia medzi telom a rampou.

Mazanie ventilov (viď obr. 18 – 19)

Ak je ovládanie ventilu ťažké, je potrebné ho

bezodkladne namazať podľa nasledovných

krokov:

- odmontovať teleso ventilu.