Gordic Environment AB

P.O Box 11, SE 280 22 Vittsjö, Sweden

Installation Manual

PellX 20 kW Pellets Burner

Eng. Edition 1.0 2004, Nov.

1

1 INFORMATION ...................................................................................................................2

1.1 INTRODUCTION ..................................................................................................................2

1.2 TECHNICAL DATA. DIMENSIONS ........................................................................................3

1.3 DELIVERY CHECK ..............................................................................................................4

2 INSTALLATION ..................................................................................................................5

2.1 PRECAUTIONS ....................................................................................................................5

Boiler..................................................................................................................................6

Chimney..............................................................................................................................6

2.2 MOUNTING ........................................................................................................................8

General...............................................................................................................................8

Burner installation..............................................................................................................9

Pellet storage......................................................................................................................9

Feed screw installation.....................................................................................................10

Installation of the control box ..........................................................................................11

Connection of temperature sensor....................................................................................13

Draft regulator .................................................................................................................14

2.3 ELECTRICAL INSTALLATION.............................................................................................15

Mains supply.....................................................................................................................15

Connections inside the burner..........................................................................................16

2.4 SETTINGS.........................................................................................................................17

Control box functions .......................................................................................................17

Description. Control box adjustments..............................................................................18

First start/adjustment during operation...........................................................................20

Modifications/Adaptions...................................................................................................22

Eng. Edition 1.0 2004, Nov.

2

1 Information

1.1 Introduction

This installation manual is a supplement to the Operation and Maintenance

Manual, which is supplied with the PellX burner.

The manual presumes general knowledge regarding installation of pellets

burners and boilers, which are suitable for being fitted with a pellets burner. In

case that you are not acquainted with the burner or if there are any other unclear

questions, please contact the authorized PellX dealer for more detailed

information.

This burner is different from earlier versions. The electronic control system is

completely new and the design is improved in many other respects. To get to

know the function of the burner, we recommend you to study the Operation and

Maintenance Manual carefully.

Used symbols

Warnings and safety regulations

This sign is used to draw your attention to instructions especially important from

the safety point of view. Non-compliance may cause serious damage to the

equipment and be a risk to yourself and the safety of other people.

Eng. Edition 1.0 2004, Nov.

3

1.2 Technical data. Dimensions

Heat output, max. ___________________ approx. 20 kW

Heat output, min. ___________________ approx. 13 kW

Output levels ___________________ 65 %, 100 %

Combustion efficiency ___________ approx. 95 %

Combustion air consumption ___________ approx. 30 – 40 m

3

/h

Weight ___________________________ approx. 13 kg

Power supply _________________ 230 V 50 Hz

Power consumption (ignition)__________ 400 W

Power consumption (operation)_________ 40 W

Fuel ___________________________ Wood pellets: ∅ 6 or ∅ 8 mm

max. length 30 mm

Dimensions (outside the boiler):

Depth __________________________ 300 mm

Width _________________________ 225 mm

Total height ______________________ 520 mm

Dimensions, combustion chamber tube in the boiler:

Length _________________________ 205 mm

Diameter _______________________ 155 mm

Recommended exhaust gas values:

CO

2

___________________________ 10 – 13 %

CO ___________________________ < 300 ppm

Recommended exhaust gas temperature _ 180 ±20ºC

(Measured directly after the boiler)

Eng. Edition 1.0 2004, Nov.

4

1.3 Delivery check

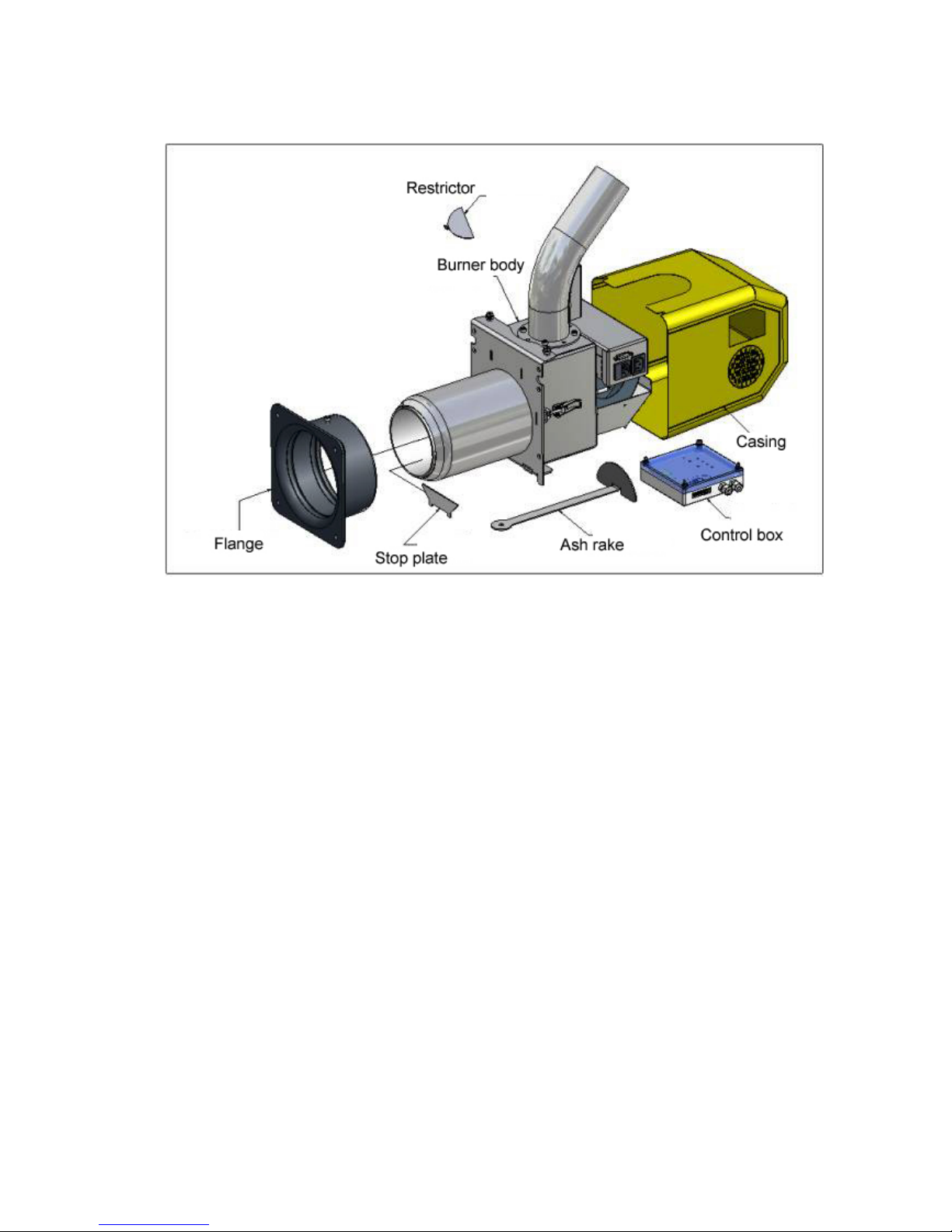

The standard delivery includes the above shown equipment.

(Sealing cord, 2 pcs. and stop screw, 1 pc. belong to the mounting flange).

The following items are also included in the box:

• Operation and Maintenance Manual

• Short m aintenance instruction (A4 poster)

• Plastic tubing (blue pellets tubing)

• Hose adapter between plastic tubing and flame trap pipe

• Hose clamps, 2 pcs. (for the plastic tubing)

• Suspendor (straps for the feed screw)

• Signal cable, 3 m (15-poles D-Sub cable)

• Mains cable, 2.5 m (for m ains supply to the burner)

• Net cable, 2.5 m (for connection between burner and feed screw)

• Tem perature sensor, 2 or 5 m (temp.sensor start/stop, for connection to the

control box)

If a PellX feed screw is included in the delivery, the motor will be packed in the

box, while the tubing/screw, 1.7 or 2.3 m, is in a separate package.

A flat mounting plate, 350 x 350 mm, is available as option. If ordered, it will be

packed in the box.

Eng. Edition 1.0 2004, Nov.

5

2 Installation

2.1 Precautions

Before selling a PellX burner, the dealer has to be sure that all conditions

necessary for creating a functional installation are fulfilled. If extra

modifications have to be carried out, information must be given before selling

the burner.

Always check the local regulations for new/changed installations with the

housing committee in the municipality, where the installation is to be made. A

permit might be required. Also contact the local chimney sweep.

The boiler room, where the pellets burner is to be installed, the chimney and

other auxiliary equipment must comply with the current fire protection

regulations and local standards. The boiler room must be provided with an open

air inlet valve with a free area corresponding to the chimney cross sectional area.

A warm air boiler may not take warm air from the boiler room.

The burner installation shall be carried out by an authorized installation

contractor in accordance with the instructions in the PellX Installation Manual

and according to local regulations. Electrical authorization is required for the

electrical installation. Final inspection, function control and adjustment of the

installation are to be carried out by a person with PellX authorization.

Eng. Edition 1.0 2004, Nov.

6

Boiler

Check the condition of the boiler to avoid that unexpected operational troubles

will occur in the future.

Exhaust valves, if any, shall be fully open. All doors and exhaust connections on

the boiler shall be tight.

It is important that the fire place is big enough, so that the flame will not be in

contact with water-cooled walls. The burner’s capacity must conform to the size

of the boiler. The fireplace, where the burner is mounted, must be dimensioned

for the output of the burner. In so called combi-boilers, the fireplaces for oil and

wood can be dimensioned for different maximum output. There must be enough

space for the ash. The exhaust channels must be wide enough not to be easily

plugged with ash.

The distance between the upper edge of the pellets burner’s combustion

chamber tube and the fireplace roof must be at least 50 mm. As general the

distance between the front edge of the burner and the rear fireplace wall should

be 300 mm, which however can often be reduced to 200 mm. The important

thing is that the flames from the combustion chamber tube never reach the boiler

wall. The minimum distance to the bottom of the fireplace depends on the boiler

design. There must be enough space for the quantity of ash that is created during

at least one week use in wintertime.

The directions above are general for most installations. If you are not familiar

with the boiler type in question or not sure about any other detail, please contact

the authorized PellX dealer for more information. In some cases smaller

modifications of e.g. the boiler might be required for a proper function of the

installation.

Chimney

We recommend you to have the local sweep make an inspection and give advice

and instructions about measurements, which might be necessary for the chimney

and the exhaust pipe connections.

The following has to be considered before and after operation start of the plant:

• The burner is adjusted to a chimney draft of 15-20 Pa. If the depression is

too much, a draft regulator has to be fitted. As a draft regulator is an

advantage also in other respects, we recommend it also in cases of normal

depression; see the chapter Draft regulator under 2.2 Mounting.

Eng. Edition 1.0 2004, Nov.

7

• Check the exhaust gas tem perature. Directly after the boiler it should be 160

to 200ºC. Too low temperature will cause condensation and lead to

corrosion and freezing damage. Too high temperature can damage the

chimney and is also uneconomical.

• Condensation in the chimney must be attended to. First check and adjust the

temperature. The exhaust gas temperature shall be at least 80 ºC measured

one meter down from the top of the chimney. A draft regulator is effective

while it is ventilating the chimney but if that does not help, a steel tube

insert should be mounted in the chimney.

Eng. Edition 1.0 2004, Nov.

8

2.2 Mounting

General

The PellX burner is intended for horizontal installation with a mounting flange

on one of the boiler doors. When the burner is fitted in a door it is quick and

easy to remove the ash. Some doors can be too small to allow opening when a

pellets burner is fitted. In such cases the burner can be moved backwards in the

mounting flange until it is possible to open the door. Alternatively the burner

can be taken out from the flange during the removal of ash.

The oil burner door is often the most suitable place in combi-boilers. If the ash

space is too small, the door for putting in wood is an alternative. Contact your

PellX dealer for more detailed information about the boiler; suitable mounting,

modifications needed, etc.

If the standard flange can not be used, a flat mounting plate is available as

option. Adjust and fasten the plate to the boiler, seal with insulation cement.

Fasten the burner body with screws in the holes in the plate, seal with Ø10 mm

sealing cord. The ash removal is described under Cleaning of the space between

mantle and combustion chamber tube in the Operation and Maintenance

Manual.

It is forbidden to tamper with the safety devices or disable their function. See the

Operation and Maintenance Manual.

The burner is adapted for pellets feeding from a standard PellX screw 1.7 or 2.3

m long and with the feed pipe inclining between 40 and 50º. Feed screws of

other manufacture can be used, consult your PellX dealer. Larger types of feed

screws are not suitable for direct feed to the burner, but must be equipped with

an intermediate hopper. A non-standard screw of more than 1.6 Amp. must be

connected via a separate relay.

Eng. Edition 1.0 2004, Nov.

9

Burner installation

Decide where the burner is to be mounted in the boiler. Consider the lateral

position – if possible the door should be able to open with the burner installed.

It may be needed to turn the door around to be able to open it with mounted

burner.

Mark and drill holes for the mounting flange in the door. Put a layer of

insulation cement or high temperature silicone on the flange’s sealing surfaces

towards the door. Mount the flange with screws and nuts, stainless steel 8.8 (not

included). Make sure that the stop screw on the flange is easily accessible.

Mount the burner in the mounting flange. Pull the burner at least so far that the

mantle cone passes the inner sealing cord. Fix the burner with the stop screw but

not too hard; the mantle can be deformed or the screw can be broken.

Insulate the flange and the mantle with mineral wool. An extra covering plate,

with holes for the flange stop screw, is a practical complement, which also

functions as a distance so that the burner is always mounted in the right position.

Insert the stop plate in the combustion chamber tube and mount the burner

casing.

Check that all doors and valves are tight to avoid unintentional air inlet. Exhaust

gas valve, if any, must be fully open. This is especially important if the chimney

is narrow or generates bad draft for any other reason. There is otherwise a risk of

smoke leakage during combustion start, especially if the burner is not correctly

adjusted.

Pellet storage

Your PellX dealer can offer several storage alternatives, from 300 lit. minihoppers to large storage tanks for truck replenishment. Installation instructions

are supplied from the respective producer. Alternatively the storage can be selfmade, but in this case the PellX dealer or manufacturer take no responsibility.

Eng. Edition 1.0 2004, Nov.

10

Feed screw installation

(For PellX feed screws, 1.7 and 2.3 m.)

Check that the screw turns easily in the screw tube. Put the blue pellet tubing on

the angular outlet pipe of the feed screw and fasten it with hose clamps. Mount

the adapter with clamps on the other end of the tubing.

Mount the screw tube in the storage hopper. The screw inlet shall be positioned

at least 100 mm from the bottom and 150 mm from the nearest storage wall and

the inclination to the ground plane between 40° and 50°. Adjust the position of

the screw so that the hose adapter can be pressed into the flame trap tube and so

that the tube has an unbroken slope without being stretched or deformed. The

tube may not be cut to less than 500 mm plus the length for fitting.

The feed screw must be well anchored so that it does not work its way into the

storage hopper. Fasten the screw without deforming the pipe. Most storage

hoppers on the market (intermediate types, week-size types, etc.) are provided

with a connection sleeve that fastens the tube perfectly. Balance the tube by

hanging it with the enclosed suspendor. Put a suitable hook or loop in the roof

and stretch the suspendor between that point and the fixing hole in the end of the

screw tube. Do not stretch too much; the tube may bend.

Mount the screw motor onto the feed screw driver. The M8 bolt with its distance

tube shall stick into the motor plate and lock the motor, which prevents it from

rotating. Ensure that the stop screw fits into the groove on the motor shaft and

tighten the screw.

Connect the supply cable to the socket on the burner.

Independant of manufacture or type of feed screw, it shall not be

possible to come in contact with any moving parts of the screw during

operation. Dependant on each individual installation, it can be

necessary with a safety switch and/or an emergency stop and also a

safety guard. The installation should be secure for children and

animals.

Eng. Edition 1.0 2004, Nov.

11

Installation of the control box

The separate control box is to be mounted onto a wall or a cool part of the

boiler. Max. allowed temperature 40ºC.

Decide the position for the control box. Check that the cable to the temperature

sensor (2 or 5 m) reaches the insert on the boiler or the accumulator tank. Also

check that the signal cable (3 m) reaches the socket on the burner.

Remove the transparent cover from the control box. Mark the fixing points and

fasten the box in at least two (diagonally positioned) of the four screw holes. If

you place the box onto the boiler, be careful not to damage the boiler.

The screws are not supplied.

Dismantle the front panel, which is held by two screws. You have now access to

the electronics and the terminal.

Connections to control box terminal:

1, 2 Alarm relay (max. 1A, 24 V)

3, 4 Temperature sensor, boiler

5 - 12 Not used

Connect the temperature sensor to the terminals 3 and 4 in the control box. The

cable to the temperature sensor may not be clamped or bundled together with

230 V cables.

An external alarm device can be connected to the terminals 1 and 2 (e.g. GSM

alarm connected to your cell phone or to an alarm lamp). The alarm relay may

not be charged with more than 24 V, 1A. Heavier load requires an external

relay.

Signal cable Connection

cable temp.senso

r

Bridge for Hole for mounting

low effect Circuit board

Figure 2.1 Control box without front panel

1 2 3 4 5 6 7………12

Eng. Edition 1.0 2004, Nov.

12

Reinstall the front panel and the cover.

Connect the control box to the socket on the burner with the signal cable. The

socket is positioned above the mains inlet on the burner (No. 1, fig. 2.2) and at

the left of the bottom of the control box (fig. 2.1). Fasten the stop screws in both

ends of the cable. Do not disconnect or connect the cable when the burner is

mains supplied 230 V.

1. Signal cable connection

15-poles D-sub with straight coupling.

2. Mains supply (230V) with fuse (S).

(L) phase, (PE) earth and (N) zero.

3. Feed screw mains socket (230 V)

The burner is as standard delivered with 3 m signal cable. Consult the authorized

PellX dealer if you need a longer cable. There is a maximum limit allowed for

the length of the cable.

Connection in the signal cable:

1-2: Circuit board feed 12 Vac

3-4: Flame sensor

5: Control signal for ash screw

6: Control signal for ignition element

7: Control signal for combustion fan

8: Control signal for feed screw

14-15: 3.3 Vdc from circuit board

L

PE

N

2 3

1

S

Fig. 2.2 Socket on the burner.

Eng. Edition 1.0 2004, Nov.

13

Connection of temperature sensor

(Temperature sensor boiler temp.)

The enclosed sensor for the boiler temperature shall be placed in an insert. It can

be fixed directly to the pressure tank plate on the hot water section of the boiler

with 2-component epoxy glue, if there is no other way. It should be placed as far

away as possible from the hot water tank.

If water heater or shunt valve is fitted in the boiler, the burner must be controlled

by the boiler temperature and the temperature sensor shall be fitted on the boiler.

If water heater or shunt valve is fitted in an accumulator tank, the temperature

sensor can be fitted on the accumulator tank in order to get longer operation time

and less starts and stops. If the temperature sensor is placed on the accumulator

tank, there must be a loading circuit with capacity to cool down the boiler, so

that the boiler temperature does not exceed 95°C before the tank has reached the

temperature-setting (80°C is recommended) and the burner is shut down.

Do not place the temperature sensor too near the bottom of the tank as that will

make it more difficult for the loading circuit to cool down the boiler to a

sufficient level. In doubtful cases, fit the temperature sensor on the boiler and

make the following test: Heat the boiler and the tanks up to a boiler temperature

of 95°C and check the tank temperatures. This test will help to find out where to

place the sensor, and, if at all suitable, to place it on the accumulator tank.

If the boiler is connected to a tank with direct circulation, the boiler temperature,

to avoid corrosion in the boiler, may not fall below 60°C before the burner

starts.

Eng. Edition 1.0 2004, Nov.

14

Draft regulator

Approx. 1.8 – 2.0 m³ air per kW burner efficiency are needed for complete

combustion of the solid fuel. Example: A 20 kW pellets burner needs approx. 40

m³ air per hour to give optimal efficiency.

A 10-12 m high chimney can evacuate 200-250 m³/h in cold weather if it has an

area of a ½ stone x 1/1 stone (325 cm²). When this air volume passes through

the burner, the efficiency is very much reduced due to the high speed of the gas

flow through the boiler. Also the exhaust gas temperature will be too high. The

pellets consumption can increase by 40-50 % at low outside temperatures,

sometimes more if very windy.

The pellets burner requires a constant depression in the chimney, not exceeding

15-20 Pa for optimal operation. The relation between air quantity and fuel

quantity (set during the installation at a certain condition) will then be correct.

This is of great importance to achieve good combustion with the minimum

possible disturbances. Combustion without draft stabilizing continually varies

the draft, dependant on variations in the wind and weather.

The draft regulator capacity must be sufficient to be able to balance depression

in the chimney which is greater than 15 – 20 Pa. If the draft regulator is underdimensioned it can fasten in the open position and the regulation function

disappears.

Eng. Edition 1.0 2004, Nov.

15

2.3 Electrical installation

Mains supply

The cable for mains supply must be installed by an authorized electrician. The

cable is connected to the mains, 230 V, 50 Hz, via the boiler’s overheat

protection and the safety switch on the door, if any. The connection is carried

out so that the overheat protection for the boiler and the burner switches off the

phase wire (L). A separate overheat protection must be installed if not provided

in the boiler.

The wires in the supplied mains cable are marked as follows:

• Phase (L) Brown wire

• Zero (N) Blue wire

• Earth Yellow/green wire

This marking complies with the mains supply connection shown in figure 2.2.

Old safety switches and overheat protections can cause malfunctions and should

be replaced. If an old overheat protection is considered to be satisfactory, the

electrician has to make sure that it is correctly connected, i.e. it switches off the

phase wire (L). The overheat protection sensor shall be placed in an insert or in

the best position on the boiler for good temperature scanning.

Electrical cables and signal cables to the control box may not be in contact with

surfaces with a temperature above 70

o

C. If the door is not provided with a safety

switch, the mains cable must be installed so that the burner can not be turned

around or removed from the boiler without disconnecting the mains cable. It is

thus suitable to fix the mains cable with clamps on the opening side of the fire

place door.

The mains connection on the side of the burner must be easy accessible to allow

easy break of the voltage when carrying out cleaning and maintenance or if a

serious malfunction is detected.

It is forbidden to connect the burner mains supply directly to a wall

socket as then there will be no protection against overheat of the

Eng. Edition 1.0 2004, Nov.

16

Connections inside the burner

All internal connections are installed from

the factory. Split type terminals simplify the

service. Pull slightly backwards to remove

them from the triac unit. The cables shall be

fixed in pairs with straps.

Internal connections:

1 - 2: Flame sensor

3 – 4: Overheat protection, flame

trap pipe

5 – 6: Ash screw (option)

7 – 8: Combustion fan

9 – 10: Ignition element

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

Fig. 2.3 Wiring diagram.

Burner internal terminal.

Eng. Edition 1.0 2004, Nov.

17

2.4 Settings

Control box functions

Function switch, level 0-9:

(dT, ”delta t”, is the temperature difference between start and stop of the burner.

Set switch-off temperature (boiler temp.) – dT = burner start temperature)

Level 0 Operation, dT 10

o

C. Level 5 Boiler temperature setting

Level 1 Operation, dT 15 oC. Level 6 Low fan setting

Level 2 Operation, dT 20 oC. Level 7 High fan setting

Level 3 Operation, dT 25 oC. Level 8 Feed quantity, operation.

Level 4 Vacant Level 9 Feed quantity, start.

Display with 10 lights in pile;

Standby/Start, Effect H(igh) and

Effect L(ow).

Indicator light; Larm(Alarm)/Test, red.

Indicator li

g

ht; On, green.

Test button.

Funkt/Function witch 0-9

Pann Temp/Boiler temp.

setting (switch off temp.)

Operating switch on/off.

Inställning fläkt i lågeffektområdet.

Inställning fläkt i högeffektområdet.

Inställning pelletsmängd, Startdos.

Inställning pelletsmängd, Driftdos.

Display with 10 diodes;

Standby/Start, Effect H (high) and

Effect L (low). Indicator diode; Larm

(Alarm)/Test, red. Indicator diode; On,

g

reen.

Test button.

Funkt/Function switch 0-9

Pann Temp/Boiler temp.

setting (switch off temp.)

Operating switch on/off.

Settings:

Fläkt L. Fan at low effect level

Fläkt H. Fan at high effect level

Startdos. Pellets feed quantity at start

Driftdos. Pellets feed quantity during

operation

Eng. Edition 1.0 2004, Nov.

18

Control box adjustments

Turn the function switch to desired position – turn on the operating switch –

press the test button. (Green diode on flashes, red diode Larm/Test is

illuminated during the test interval and a number of green diode on the display

are switched on).

All settings, except dT, can be changed during operation (without support by

indications from the LED’s).

Specified voltage values are for 230 V supply and by use of a ” true RMSvoltmeter”. Less qualified voltmeters can show deviations of several tens of

volts measuring triac-regulated voltage.

Adjustment of fuel quantity during operation

• Put the switch in position 8, the operating switch in position on and press the

test button. The screw motor starts and runs the operational portion during 6

minutes, meanwhile the red diode (Larm/Test) is illuminated and the set

value will be shown on the display with the number of illuminated diodes.

Set the potentiometer at desired operational portion, the number of

illuminated diodes will follow the setting. Put the operating switch in

position off when the adjustment is finished.

Adjustment of fuel quantity at start

• Put the switch in position 9, the operating switch in position on and press the

test button. The screw motor starts and runs a start portion, the red diode

(Larm/Test) is illuminated and the set value is shown on the display with the

number of illuminated diodes. Set the potentiometer at desired start portion,

the number of illuminated diodes will follow the setting. Put the operating

switch in position off when the adjustment is finished.

Adjustment of fan for high effect level

The adjustment range for the high effect level is approx. 175-230 V measured

with a ”true RMS” voltmeter at the fan connections.

• Put the switch in position 7, the operating switch in position on and press the

test button. The screw motor starts and runs a start portion, the red diode

(Larm/Test) is illuminated and the set value is shown on the display with the

number of illuminated diodes. Set the potentiometer at desired fan speed, the

number of illuminated diodes will follow the setting. Put the operating switch

in position off when the adjustment is finished.

Eng. Edition 1.0 2004, Nov.

19

Adjustment of fan for low effect level

The adjustment range for the low effect level is approx. 155-190 V measured

with a ”true RMS” voltmeter.

• Put the switch in position 6, the operating switch in position on and press the

test button. The screw motor starts and runs a start portion, the red diode

(Larm/Test) is illuminated and the set value is shown on the display with the

number of illuminated diodes. Set the potentiometer at desired fan speed, the

number of illuminated diodes will follow the setting. Put the operating switch

in position off when the adjustment is finished.

Adjustment of boiler temperature

(shut-off temperature)

• Put the switch in position 5, the operating switch in position on and press the

test button. The number of diodes, which are illuminated, is proportional to

the position of the boiler temperature potentiometer, which corresponds to

approx. 55-85

o

C.

Adjustment of dT

”delta t” (temperature distance between start and stop in the burner programme)

• To change dT, shut off the operatig switch on the control box. Turn the

switch to desired dT (0, 1, 2, 3). Switch on the operating switch.

Changing dT 10° to 15°, 20° or 25° (from level 0 to 1, 2 or 3 on the switch) increases the

distance between start and stop by 5° for each value. The boiler’s preset end temperature (the

boiler temperature) does not change.

Eng. Edition 1.0 2004, Nov.

20

First start/adjustment during operation

The burner is not factory adjusted. It has to be adjusted at the first start. We

suggest that a preliminary adjustment is carried out at the first start, which make

the burner function satisfactory. After operation in normal mode for one or two

weeks, the final adjustment can be carried out.

When carrying out a preliminary adjustment and control of the function, the

combustion quality can be evaluated by visual inspection of the flame size and

colour. A few minutes after start, the flame should be yellow/white. A dark

yellow flame means that the burner gets too much fuel or an insufficient volume

of air. A white flame means too much air or an insufficient amount of fuel. It is

quite normal if the colour of the flame varies a bit between white and yellow.

Grey or black smoke from the chimney is also an indication of insufficient air.

White smoke mainly consists of water vapour and is normal at low outside

temperatures. If the boiler was earlier wood fired, the smoke may be dark and

has a strong smell caused by tar that is burnt away from the walls in the boiler

and the chimney. This may go on for about a week.

Adjustment of air volume and fuel quantity

1. Fill the feed screw with pellets before connecting it to the burner. See

description in the Operation and Maintenance Manual.

2. Set the start portion (quantity of pellets at ignition) with the knob on the

control box. Turn clockwise to increase the quantity. Approx. 2-3 dl (150-200 g)

is a normal portion. Always check the start portion when changing setting or

fuel type. Too large start portion may temporarily cause grey/black, bad

smelling smoke 5-10 minutes after start. If the start portion is too small, it will

not be possible to ignite the burner at all, or two or three attempts are needed.

The start portion may also burn out before the burner reaches the operational

mode.

If the ignition fails, do not open the fire place door until the

combustion chamber is totally ventilated! Wait at least 10 minutes

after the 3rd starting attempt and be careful .

Be very careful when opening the fire place door or inspection eye

during operation. Keep your face at a safe distance and be

prepared to close the door quickly.

Eng. Edition 1.0 2004, Nov.

21

3. Recommended operational portion for the high effect level is 4 - 5.5 kg /h

(20-27.5 kW supply) for pellets with an energy content of approx. 5 kWh/kg.

This means, with a standard screw, that 2-4 diode segments are illuminated on

the control box. Which setting to be chosen within this interval depends on the

type of boiler, in which the burner is installed and also on the energy level

required for the house. Ask your PellX dealer for advice.

The operational portion is adjusted by the lower positioned knob. Turn

clockwise to increase the quantity. Always check the operational portion when

changing the setting or the type of fuel.

4. Set the air volume (fan). To achieve high total efficiency and positive

operating economy, it is important to adjust the air volume correctly. A smoke

gas device must be used for optimal adjustment. If you are not familiar how to

adjust the air in relation to the adjusted start portion, set the air volume at

maximum for both high and low effects before the first start.

The fine adjustment of the burner is to be carried out when the boiler has

reached the normal operating temperature (at least 60

o

C) and the burner has run

in the high effect operating position for at least 15 minutes and also minimum 5

minutes after it has turned to the low effect position.

Recommended content of CO2 is an average of 10-13 % of the high effect

position and a few percentages less for the low effect position.

The CO content should be a mean value below 300 ppm.

Even when possible to adjust the burner with low CO at higher CO2, it should be

considered that a margin of a few percentages might be needed to take care of

normal variations caused by fuel, draft conditions and accumulated ash in the

burner pipe.

5. Wait for the burner to operate in the low effect position at least 5 minutes (5

segments are illuminated on the display), adjust the air volume in the same

manner as when setting the high effect position but use the upper knob. The

flame will be much smaller than at the high effect position.

Eng. Edition 1.0 2004, Nov.

22

Modifications/Adaptions

Modification of boiler

The boiler may need to be modified. It might for instance be necessary to

remove baffle plates or turbulators in the smoke channels. Ask your PellX dealer

for advice.

Disconnect the low effect position

The burner is normally used with two effect levels (high and low), but the low

effect level may easily be disconnected by an adjustment of the circuit board. A

big and effective boiler that produces exhaust gas temperatures exceeding

approx. 180ºC should only operate on high effect to avoid condensation

problems in the chimney. Exception: Chimneys with an insert tube can be

considered more corrosion resistant. Ask your PellX dealer for advice.

Open the control box and remove the front panel. For disconnection of the low

effect position, remove the bridge in the left upper corner of the circuit board

(see figure 2.1).

Mount the restrictor in the flame trap pipe

The burner might drop a considerable amount of non-burnt pellets in the

fireplace. The supplied restrictor should in such case be installed in the flame

trap pipe. Drill a Ø 4.5 mm hole in the pipe, opposite to the overheat protection,

48 mm up from the flange. Bend the restrictor approx. 45º and fasten it with

sheet metal screws ST 3.5x 9.5 or thread the restrictor and use M4 bolts. Adjust

the bending of the restrictor to restrict but not stop the pellets feed.

Loading...

Loading...