GORBEL Tether Track Installation, Operation & Maintenance Manual

®

Installation, Operation,

& Maintenance Manual

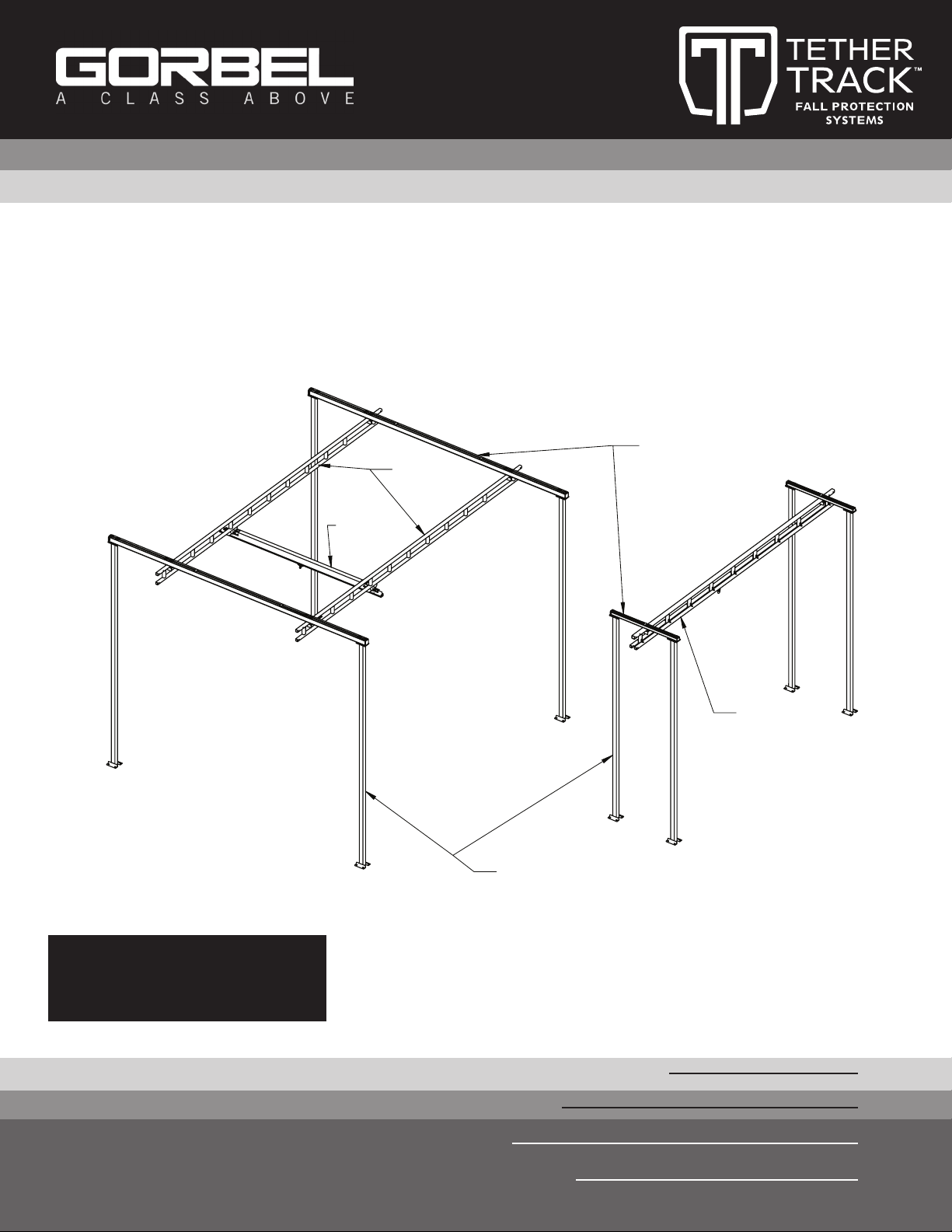

HEADER WELDMENTS

RUNWAYS

IMPORTANT!

DO NOT DESTROY

BRIDGE

MONORAIL

COLUMN WELDMENTS

Tether Track®

Free Standing

Rigid Rail Anchor Systems

Distributed by Engineered Fall Protection

Sales@EngineeredFallProtection.com

www.EngineeredFallProtection.com

Tel: (314) 492-4422

Gorbel® Customer Order No. / Serial No.

Gorbel® Dealer

Date

Month

Year

TABLE OF CONTENTS

Introduction ................................................................................................... 1

Application .................................................................................................... 1

Warnings ...................................................................................................... 2

Restrictions ................................................................................................... 3

Definition of Terms ....................................................................................... 3

Installation

Step 1 - Pre-assembly ...............................................................................................4

Step 2 - Column Weldment Installation ..................................................................... 5

Step 3 - Header Weldment Installation ......................................................................6

Step 4 - Runway Installation ...................................................................................7-8

Step 5 - Bridge and End Truck Installation ...........................................................9-10

Step 6 - Trolley Installation ...................................................................................... 10

Step 7 - Final Steps ................................................................................................. 11

Sway Bracing Guidelines ........................................................................... 11

Labels ......................................................................................................... 12

Authorized Person Instructions .................................................................. 13

General Operational Suggestions .............................................................. 14

Limited Warranty ........................................................................................ 15

Inspection and Maintenance Schedule ..................................................16-18

INTRODUCTION

Thank you for choosing Gorbel® Tether Track® Free Standing Rigid Rail Anchor Systems to solve your

fall protection needs. The innovative design and heavy-duty construction of the Gorbel® Tether Track®

Anchor Systems will provide a superior quality product that will offer years of long term value. Gorbel®

Tether Track® Anchor Systems have been optimally designed and tested to provide the ultimate solution

for fall arrest systems. When properly applied, configured and installed under the supervision of a

qualified person, Tether Track® Rigid Rail Anchor Systems will allow the ultimate in user mobility by

providing a mobile rigid anchorage for the attachment of a lanyard or self-retracting lanyard (SRL). This

reliable performance combined with an ANSI approved Managed Fall Protection Program gives the user

the utmost safety assurance and encourages further safe work practices.

Tether Track® Rigid Rail Anchor Systems are designed using ANSI guidelines and comply with all OSHA

requirements for a fall arrest anchorage system. Tether Track® Free Standing Rigid Rail Anchor Systems

are designed to be statically proof tested up to 110% of the maximum arresting force (MAF). When loaded

through proof testing or during a fall event, the Tether Track® Rigid Rail Anchor Systems will not incur

any visual permanent deformation and may be placed back into service after performing the inspection

requirements detailed in this manual. All engineered Tether Track® Rigid Rail Anchor Systems comply with

OSHA’s required safety factor of 2 and are

Track® Anchor Systems will provide many years of dependable service by following the installation and

maintenance procedures described herein.

designed in accordance with ANSI Z359.6. Gorbel® Tether

APPLICATION

A Gorbel® Tether Track® Free Standing Monorail Anchor System is the best choice for providing

coverage to a narrow rectangular fall zone when an existing support structure is unavailable or

inadequate. The rigid, self-tracking, overhead trolley anchorage, combined with the use of a “Class A”

Self Retracting Lanyard, provides the best solution to minimize fall distance when fall clearance height is

restrictive.

Note: Specify Class A requirement at time of quote, standard design is for 900 pounds MAF.

A Gorbel® Tether Track® Bridge System offers the best solution to a wide rectangular fall zone.

Combined with an SRL, this system allows for user mobility in 3 dimensions. A low inertia bridge

(standard lengths to 18’) glides effortlessly on runways, keeping both the anchorage trolley and bridge

directly above the user. No other systems eliminates swing falls as well as a Gorbel® Tether Track®

Bridge Rigid Rail Anchorage System.

This product meets all applicable OSHA and ANSI standards for fall protection.

Dimensions contained in this installation manual are for reference only and may differ for your

particular application. Please refer to the enclosed General Arrangement Drawing for actual

dimensions.

Normal safety precautions: These include, but are not limited to:

• Checking for obstructions in the fall clearance zone

• Coordinating fall hazard activities with assigned rescue personnel

• Making sure that end stops are in place

• Making sure that the trolley and bridge freely move

For additional safety precautions, see page 13.

9/18 Rev C

1

WARNINGS

1. Do not throw away these instructions.

2. A minimum of a 6”-think reinforced concrete floor is required. Gorbel, Inc. assumes no

responsibility for adequacy or integrity of the mounting surface.

3. Only competent erection personnel familiar with standard fabrication practices should be

employed to assemble these anchor systems. Gorbel is not responsible for the quality of

workmanship employed in the installation of an anchor system according to these

instructions. Contact Gorbel Inc. at 600 Fishers Run, P.O. Box 593, Fishers, New York

14453-0593, 800-821-0086, for additional information if necessary.

4. Read and understand this manual before using equipment.

5. This manual should be read and understood in its entirety, and used as part of a training

program as required by OSHA or any state and local regulatory agency.

6. This and any other included instructions must be provided to the users of this equipment. The

user must understand the proper equipment use and limitations.

7. The Tether Track® Anchor System is only to be used as part of a complete fall protection

system. The buyer or user is responsible for the safety and compatibility of the complete

system.

8. Any component replacement, addition or change to the anchor system or the complete

system requires evaluation by a qualified person.

9. Any fall event can result in injuries. The proper use of this equipment can substantially reduce

an injury. For maximum safety, the worker must be trained in the proper use of this

equipment and all of the components of the fall arrest system.

10. Before each use, the equipment shall be inspected as outlined in the inspection section of

this manual.

11.

The rated capacity, the rated maximum arresting force and the rated number of workers of the

Tether Track® Anchor System must not be exceeded.

12. The maximum arresting force rating of the lanyard or SRL connected to the Tether Track® Anchor

System shall not exceed the rating of the Tether Track® Anchor System.

13. A managed fall protection program which includes a rescue plan is required for the safe use

of this equipment. A worker suspended from this system can lose vital blood flow to the brain

as blood pools in the legs. This is referred to as suspension trauma.

14. Reference the American Institute of Steel Construction (AISC) Manual of Steel Construction,

Specification for Structural Joints using ASTM A325 or A490 Bolts (section 8.d.2) for the

proper procedures to follow when using any torque tightening method.

15. Do not field modify the Tether Track® Free Standing Rigid Rail Anchor System in any way.

Any modifications without the written consent of Gorbel Inc. will void warranty.

16. Gorbel has ensured the compatibility of Tether Track® ONLY with a Gorbel® approved

connector (fall arrest trolley). It is the responsibility of the dealer or end user to ensure proper

design, function and compatibility of any trolley used with Tether Track® that has not been

validated by Gorbel for a fall arrest application.

17. Failure to follow these instructions can result in serious injury or death.

18. Support assemblies are designed to AISC (American Institute of Steel Construction)

specifications. If no movement of the support assembly is required, additional bracing (not

included) to the building steel structure is recommended.

2

9/18 Rev C

RESTRICTIONS

1. The Tether Track® Anchor System shall be used as part of a complete active fall arrest system. Gorbel is not

responsible for the installation of, or additional equipment added to the system. The Tether Track® Anchor

System is manufactured by Gorbel in accordance with OSHA and ANSI Z359.1 and Z359.6 requirements using

a minimum design factor of two. All components are designed in accordance with AISC and Aluminum

Association guidelines.

2. The end user shall be responsible to make sure that the complete fall arrest system shall be designed, installed,

and used under the supervision of a qualified person in accordance with applicable OSHA regulations and ANSI

Z359 Fall Protection Code voluntary consensus standard in addition to any state and local jurisdiction

regulations and/or requirements.

3. It is the responsibility of the user to determine the suitability of this equipment and any attachments prior to each

use. A certified inspection shall be performed by a qualified person at least once per year.

4. Lanyards or self retracting lifelines (SRL) to be used with the Tether Track® Anchor System shall have a

maximum arresting force (MAF) of 900 lbs. or less.

5. Customer chosen lanyards or SRLs shall minimize freefall distance.

6. It is the responsibility of the end user to verify that the mounting height of this Tether Track® Anchor System will

provide adequate fall clearance when used with the customer chosen lanyard or SRL and harness.

7. Each trolley shall have no more than one person attached.

8. Bridges and trolleys are designed to freely move. To prevent a swing fall and the lengthening of the free fall

distance, the user shall verify the bridge and trolley maintains the closest possible distance to the user whenever

he or she changes position.

9. The fall clearance zone shall be free of dangerous obstructions and electrical hazards.

10. The Tether Track® Anchor System is intended only for indoor use.

11. The Tether Track® Anchor System shall be installed per the general arrangement drawing without deviation or

modification.

12. This system is not designed to be used as a crane. Gorbel accepts no responsibility for use of the Tether

Track® Anchor System other than for its intended use.

DEFINITION OF TERMS

AUTHORIZED PERSON - ANSI defines an authorized person as “a person assigned by the employer to perform

duties at a location where the person will be exposed to a fall hazard”.

COMPLETE FALL ARREST SYSTEM - A complete fall arrest system consists of three main components:

A) Engineered Anchor System - Gorbel’s Tether Track® has been engineered to provide the

maximum safety possible. This system allows for the greatest worker mobility through Gorbel’s

ergonomic enclosed track design. It provides minimal fall distance and obstruction impact by

keeping the anchor point overhead and rigid.

B) Body Support - Only a full body harness is allowed for fall arrest systems. Proper fitting and

wearing of this harness is critical so that it can evenly dissipate the fall arrest forces to the

strongest body parts.

C)

is recommended. This provides maximum mobility and minimum fall distance. An energy absorbing

lanyard may also be used. These components have a maximum arresting force rating. Gorbel’s

standard Tether Track® design is based on a maximum arresting force of 900 lbs. or less.

FALL CLEARANCE ZONE - The space below the person where there is a potential to fall. This space must remain

clear of obstructions to prevent injury from contact with any objects during a fall event.

LEADING EDGE - The edge of the working surface that a person could fall off. This edge, if located parallel with the

Tether Track® Monorail, may restrict the lifeline from reaching a vertical orientation and cause off-vertical

(horizontal) loading of the anchorage system. Avoid sharp leading edges or use lifelines designed to withstand a

sharp leading edge fall event.

QUALIFIED PERSON - ANSI defines a qualified person as “A person with a recognized degree or

professional certificate and with extensive knowledge, training and experience in the fall protection and rescue field

who is capable of designing, analyzing, evaluating and specifying fall protection and rescue systems...”

Connecting Means - This is the link between the anchor and body support. A self-retracting lifeline

9/18 Rev C

3

INSTALLATION

STEP 1 - PRE-ASSEMBLY

TIP: Packing list can be found in a plastic pocket attached to the hardware box: General

Arrangement Drawing and additional inserts can be found enclosed in this installation

manual.

TIP: Recommended guidelines to help you determine anchor bolt size are supplied below

(anchor bolts are not included).

1.1 Read entire installation manual before you begin installing your Tether Track® Anchor

System.

1.2 Check packing list to make sure correct quantity of parts is included.

1.3 Tools and materials (by others) typically needed to assemble crane are as follows:

• Mallet • Torque wrench (able to torque up to 95 ft.-lbs.)

• Chalk line • Tape measure

• Hand tools • L

• Shop brush • Leveling tools

• Steel shims • Lifting device to lift heavy runways, bridges, headers

• Large square •

• Drill

adders/man lifts (transit, laser level, water level, etc.)

Anchor bolts (by others, see 1.4 for guidelines in

determining size)

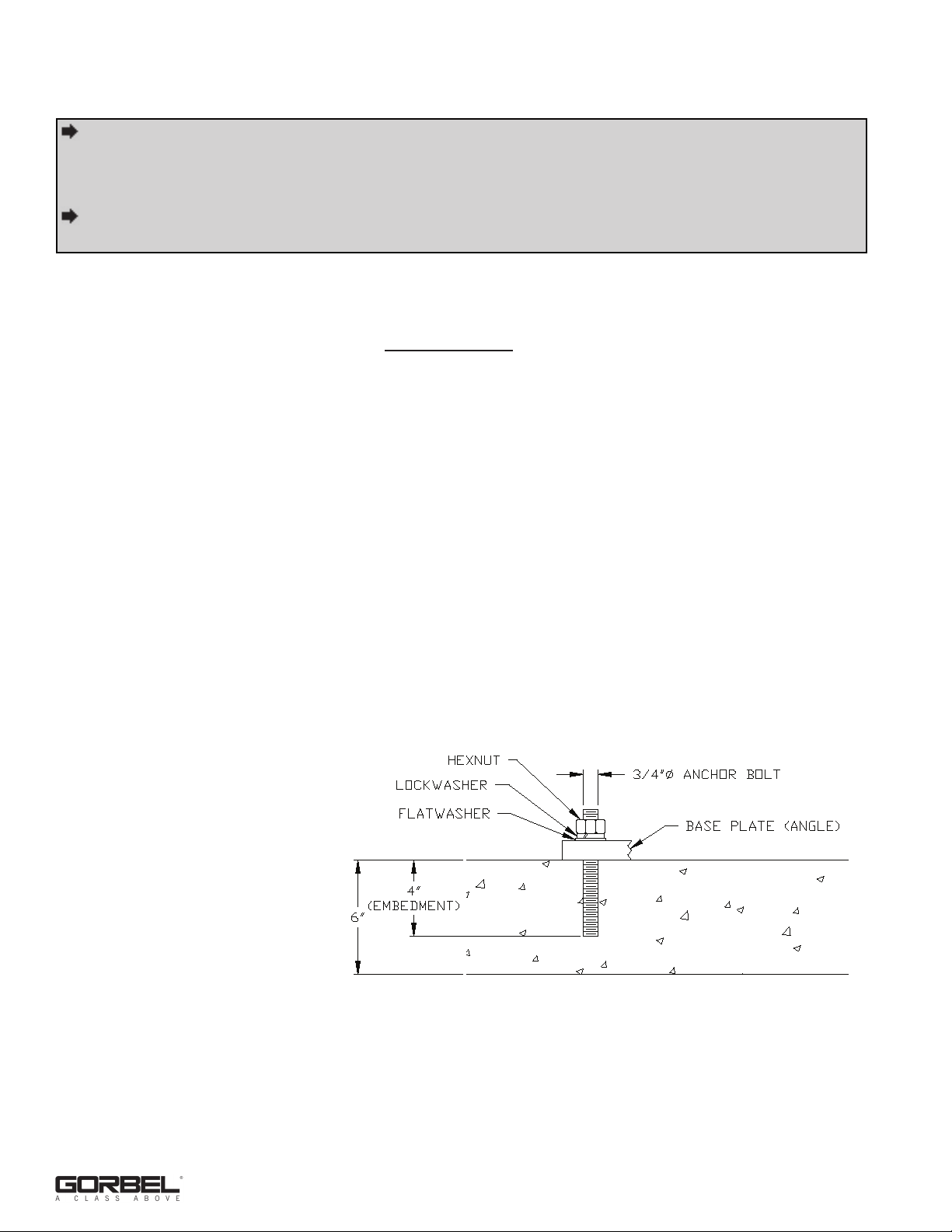

1.4 Recommended guidelines for post-installed anchor bolts:

Note: In addition to the anchor bolt load requirements stated on the quote form, a

minimum 6” thick reinforced concrete floor with a supporting area that is four times

greater than the base plate area and is free of cracks, seams, expansion joints,

and walls is required. Foundation requirements are based on a concrete

compressive strength of 3000# per square inch.

Anchor bolts shall:

• have an ICC-ES listing

demonstrating

suitability for the

application.

• be installed in

accordance with the

manufacturer’s

instructions and

requirements.

Note: Chemical (epoxy)

anchor bolts are recommended.

Diagram 1A Typical anchor bolt embedment.

Note: Hole size may exceed anchor bolt manufacturer’s recommendations. If base plate

hole diameter is greater than bolt diameter plus 1/4”, refer to AISC Design Guide 1

for minimum washer size and thickness recommendations.

4

9/18 Rev C

Loading...

Loading...