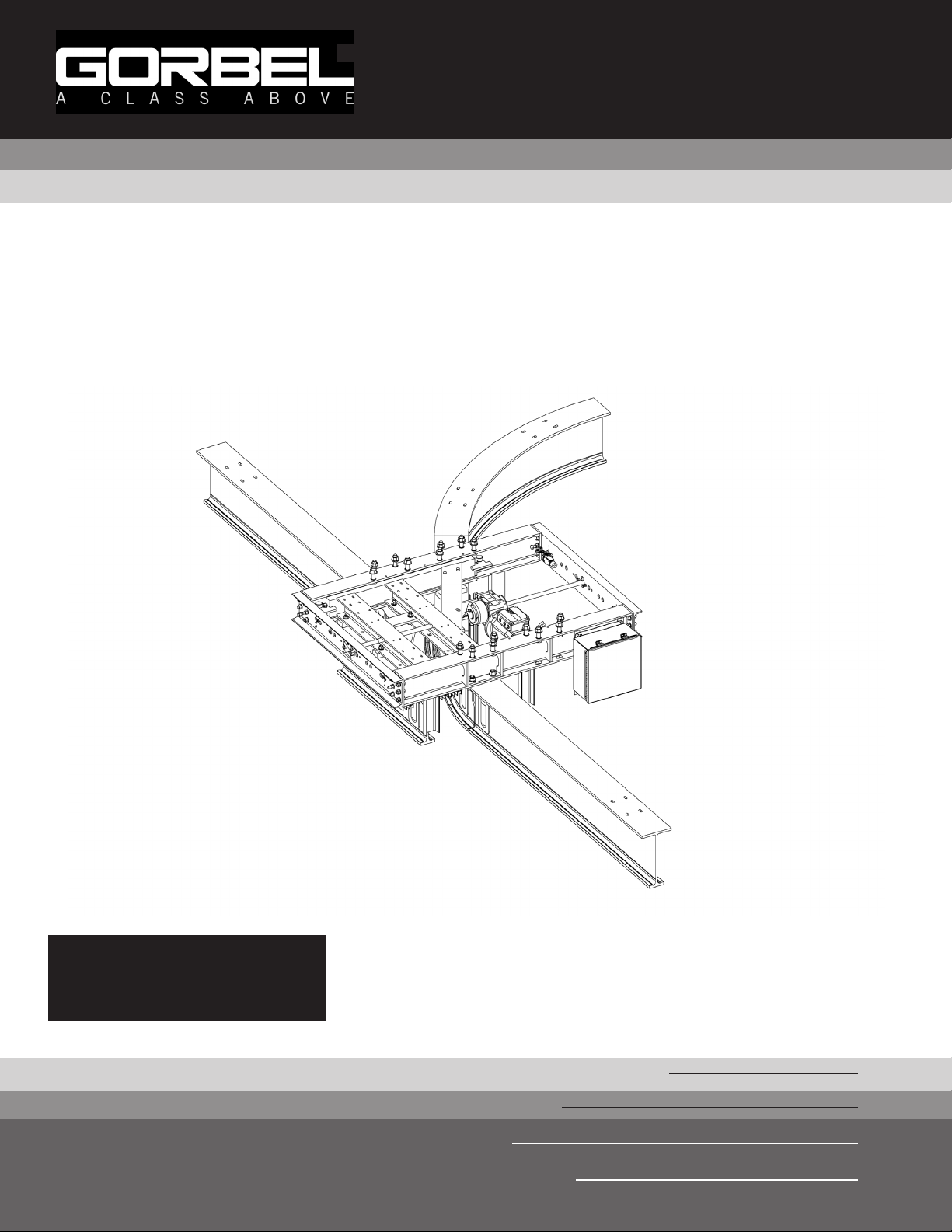

GORBEL Tarca I Series Installation, Operation & Maintenance Manual

®

Installation, Operation,

& Maintenance Manual

IMPORTANT!

DO NOT DESTROY

Issued: 11/2018

Revised: 03/2019

Tarca® Switch

Gorbel® Customer Order No. / Serial No.

Gorbel® Dealer

Date

Month

I Series

Year

THIS PAGE INTENTIONALLY LEFT BLANK.

11/2018

TABLE OF CONTENTS

Introduction ............................................................................................................................ 1

Models and Options .............................................................................................................. 2

Installation

Step 1 - Pre-assembly ................................................................................................................ 3

Step 2 - Attachment and Hole Layout ..........................................................................................4

Step 3 - Mounting .........................................................................................................................5

Step 4 - SAFPOWRBAR® Wiring (Option) ..................................................................................6

Step 5 - Control Wiring (Option) ..................................................................................................7

Step 6 - Motorized Operator (Option) ...................................................................................... 8-9

Limit Switch Adjustment ............................................................................................. 8-9

Step 7 - Pneumatic Operator (Option) .......................................................................................10

Step 8 - Manual Operator (Option) ............................................................................................10

Appendix A - Beam End Prep Diagrams .................................................................. 11-14

Appendix B - Wiring Diagrams.................................................................................. 15-18

Crane Operator / Start Up Instructions ............................................................................... 19

General Safety Requirements ............................................................................................. 19

Limited Warranty ................................................................................................................. 20

Inspection and Maintenance Schedule .......................................................................... 21-24

Questions? Concerns? Comments? Please call (800) 821-0086

11/2018

THIS PAGE INTENTIONALLY LEFT BLANK.

11/2018

INTRODUCTION

Thank you for choosing Gorbel® to solve your material handling needs. The innovative design and heavy-duty

construction of the Gorbel® product will provide a superior quality product that will offer years of long term value.

The hoist weight allowance is 15% of the crane’s capacity (for example, a crane rated for 6000 pounds, allows for a

6000-pound live load plus 900 pounds for the weight of the hoist). There is also an allowance of 15% of the crane

capacity for impact caused by hoist use. Gorbel® products will provide many years of dependable service by

following the installation and maintenance procedures described herein.

Gorbel® products are shipped in various stages of assembly and are installed under varying circumstances. As a

result, a complete guide with descriptions covering all variations is not possible. The following instructions are only to

be used as a general guide. Attention should be paid to the warnings and safety suggestions posted in this manual

and on the equipment.

Dimensions contained in this installation manual are for reference only and may differ for your particular

application.

Normal safety precautions: These include, but are not limited to:

• Checking for obstructions in travel

• Checking that all bolts and threaded rods are tight and have lock washers where applicable

• Making sure that end stops are in place and functional (i.e. stopping rolling equipment from exiting rail)

• Making sure that festooning cannot be snagged or pinched, whether it is electric or pneumatic

• For additional safety precautions, see page 19.

WARNING

Please read entire manual prior to starting installation.

WARNING

Gorbel Inc. assumes no responsibility for adequacy or integrity of the mounting surfaces or the structure that the

crane may be mounted to. Gorbel Inc. will not be liable for any loss, injury or damage to persons or property, nor

for damages of any kind, resulting from the failure or defective operation of any materials not supplied directly by

Gorbel Inc. Bracing systems, if used, must be approved by a local professional engineer.

WARNING

Before installing any crane system, it is critical you determine that your building will safely support the loads.

WARNING

Equipment described herein is not designed for, and should not be used for, lifting, supporting or transporting

humans. Failure to comply with any one of the limitations noted herein can result in serious bodily injury and/or

property damage. Check State and Local regulations for any additional requirements.

WARNING

Crane cannot be utilized as a ground: A separate ground conductor is required. For example, systems with 3 phase

power require three conductors plus one ground conductor.

WARNING

Reference the American Institute of Steel Construction (AISC) Manual of Steel Construction Specification

for Structural Joints using ASTM A325 or A490 Bolts, Installation, Pretensioned Joints, Calibrated Wrench

Pretensioning for the proper procedures to follow when using any torque tightening method.

11/2018

1

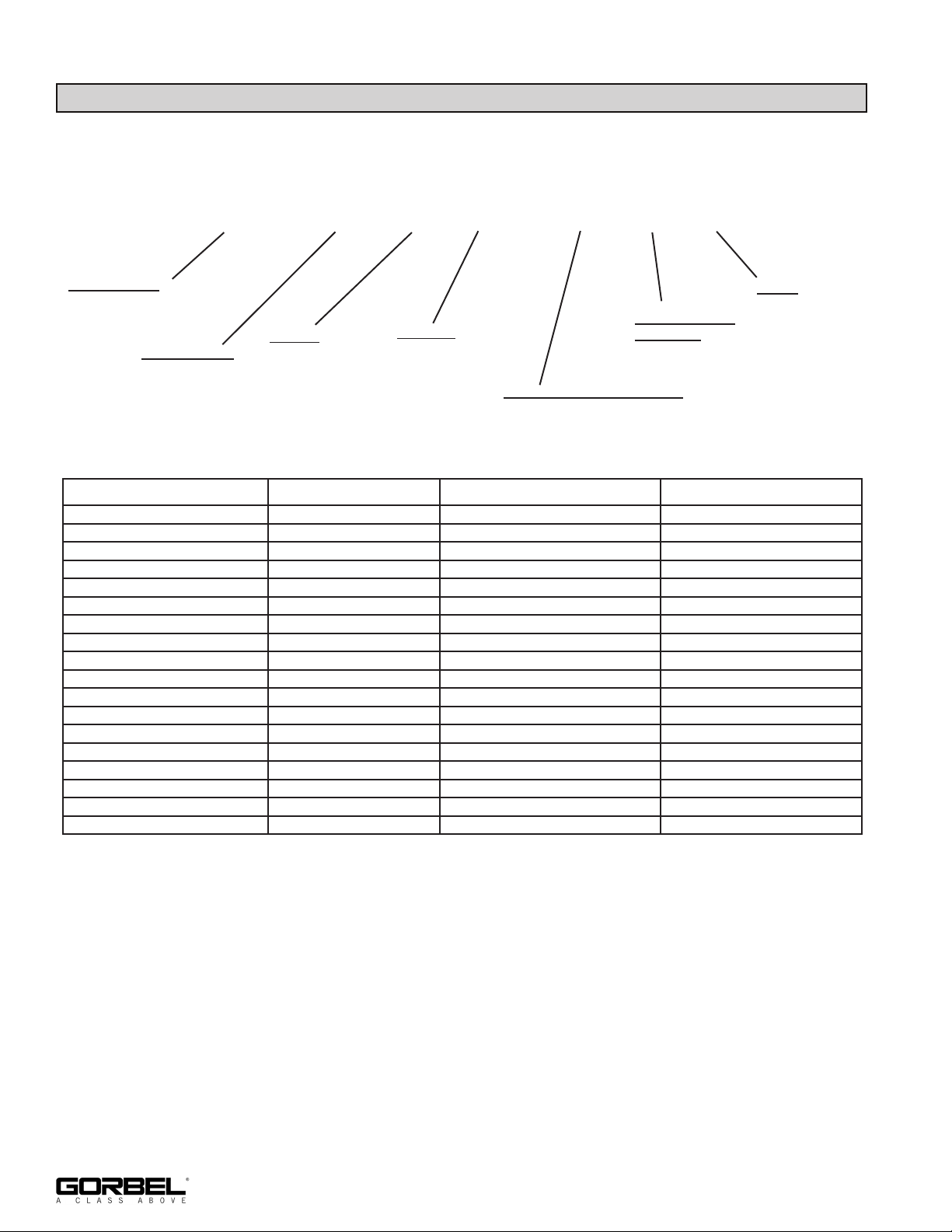

MODELS AND OPTIONS

Part Number:

PT.SWITCH.KIT - I -

5000 - R - M - 460 - H - 4 - G

Track Series:

See Runway Section of

Sales Manual

Switch Style:

L = Left-Hand

R = Right-Hand

Y = Wye

T = 3-Way

Power:

H = Manual

M = Motorized

P = Pneumatic

Voltage:

208, 230, 460, 575

SAFPOWRBAR® Position:

N = None

H = High

L = Low

SAFPOWRBAR

Quantity:

0, 4

SWITCH STYLE POWER VOLTAGE SAFPOWRBAR®

Left/Right Hand Manual None None

Left/Right Hand Manual None High/Low

Left/Right Hand Motorized 208/230 or 460/575 None

Left/Right Hand Motorized 208/230 or 460/575 High/Low

Left/Right Hand Pneumatic 208/230 or 460/575 None

Left/Right Hand Pneumatic 208/230 or 460/575 High/Low

Wye Manual None None

Wye Manual None High/Low

Wye Motorized 208/230 or 460/575 None

Wye Motorized 208/230 or 460/575 High/Low

Wye Pneumatic 208/230 or 460/575 None

Wye Pneumatic 208/230 or 460/575 High/Low

3-Way Manual None None

3-Way Manual None High/Low

3-Way Motorized 208/230 or 460/575 None

3-Way Motorized 208/230 or 460/575 High/Low

3-Way Pneumatic 208/230 or 460/575 None

3-Way Pneumatic 208/230 or 460/575 High/Low

Paint:

G = Gray Green

B = Blue

Y = Yellow

O = Orange

S = Special

N = None

2

11/2018

NOTE: It is recommended to install switch(es) first and align monorails to them.

STEP 1 - INSTALLATION

• It is recommended to install switch(es) first and align monorails to them.

• Read entire installation manual before you begin installing your switch.

• Study all instructions and drawings provided in this manual.

• Verify receipt of all materials in good condition. Check all hole punchings, beam dimensions

and suspension fittings prior to installation.

• Check packing list to make sure correct quantity of parts is included. Any missing items

should be noted and reported to a Gorbel® dealer.

• Tools and materials typically needed to assemble switch are as follows:

• Wrench/socket • Square

• Torque wrench • Tape measure

• Leveling tools • Ladders/man lifts

• Shims • Lifting device

• Standard switch throw is 11”. DO NOT ADJUST.

11/2018

3

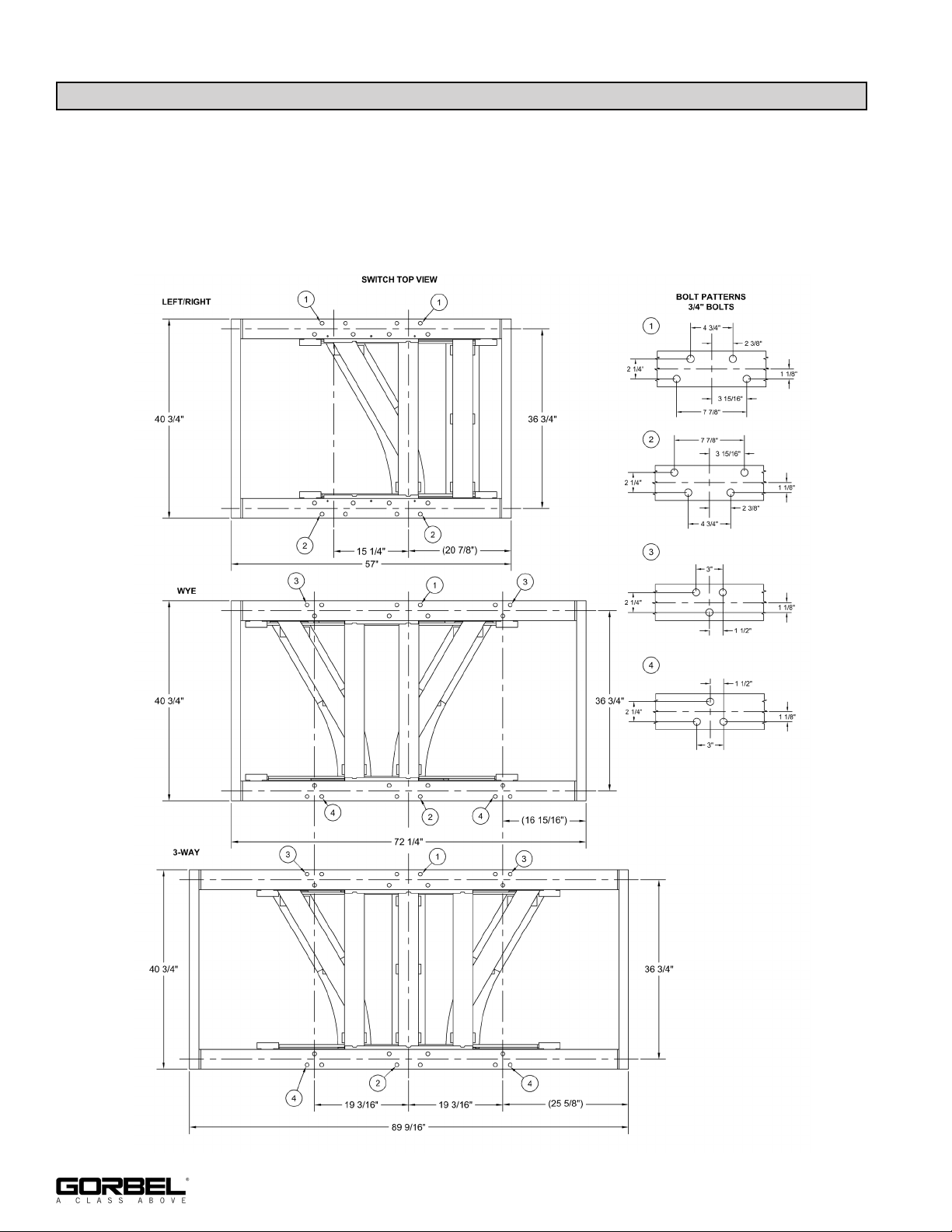

STEP 2 - ATTACHMENT AND HOLE LAYOUT

2.1 Attachment to support structure via 3/4” Grade A325 bolts. 3” long bolts are included.

Hardened washers and Anco lock-nuts are included and must be used. Maximum 1-3/8”

structural member thickness.

2.2 Layout and drill holes in support structures 13/16” nominal. 15/16” maximum hole diameter

per AISC.

Diagram 2A. Switch support detail.

4

11/2018

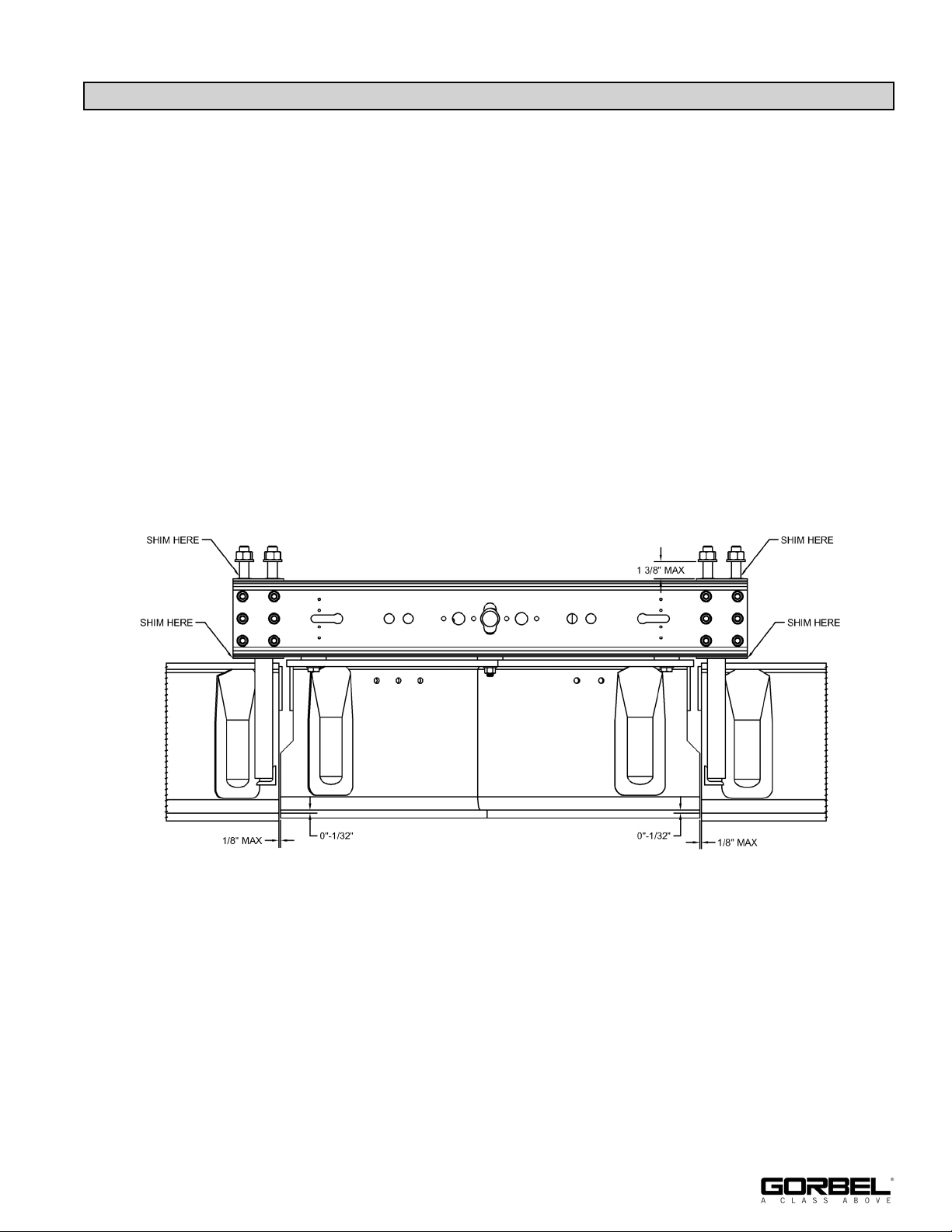

STEP 3 - MOUNTING

3.1 Shim frame to level the underside of the outer frame to prevent racking/twisting (shims

included).

3.2 Verify frame is square by checking diagonals.

3.3 Torque frame attachment hardware to 260 lb ft, Turn-of-Nut method is acceptable

3.4 If beams are not factory prepped, e

nd prep incoming beams. Additional parts required from

factory (see Appendix A on pages 11-14 for detail).

3.5 Use provided 3/4” A325 bolts, washers and nuts to loosely assemble monorail beam to

switch. Do not tighten yet.

3.6 Shim inlet and outlet beams 0” to 1/32” lower than switch track.

3.7 Set gap between inlets and switch track is 1/8” maximum. Ensure that beam ends do not

rub or bind as they pass each other.

3.8 Once beam is positioned, tighten beam attachment hardware. Torque to 260 lb ft. Turn-of

Nut method is acceptable.

Diagram 3A. Shim detail.

OUTLETINLET

11/2018

5

Loading...

Loading...