GORBEL Free Standing PIVOT PRO, Wall Mounted PIVOT PRO Installation, Operation & Maintenance Manual

®

Installation, Operation,

& Maintenance Manual

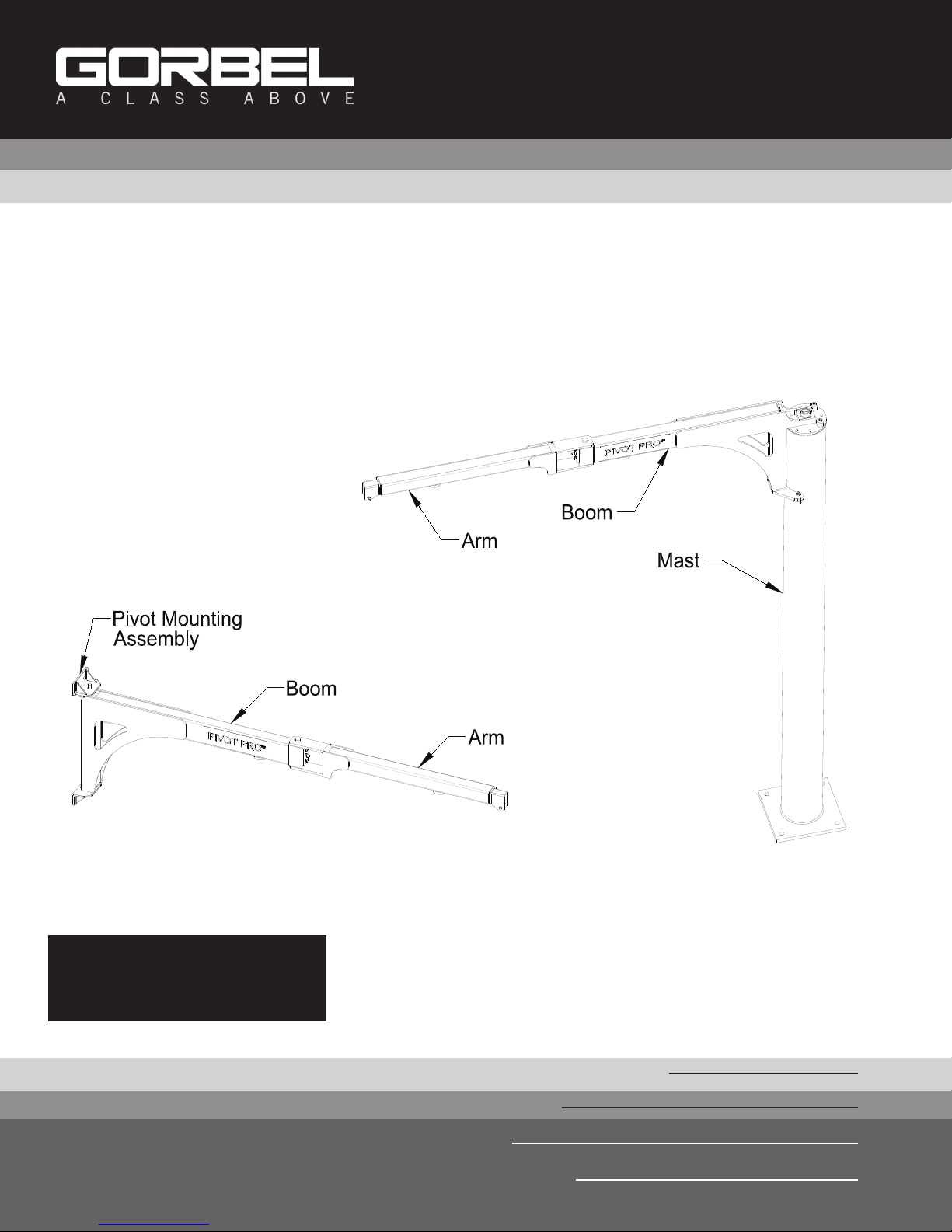

Wall Mounted PIVOT PRO®

IMPORTANT!

DO NOT DESTROY

Free Standing PIVOT PRO®

PIVOT PRO®

Articulating Jib Crane

Gorbel® Customer Order No. / Serial No.

®

Dealer

Gorbel

Date

Month

Year

TABLE OF CONTENTS

Introduction ................................................................................................... 1

Crane Operator Instructions ......................................................................... 2

Safe Operating Guidelines ........................................................................... 3

Installation

Step 1 - Pre-assembly ............................................................................................4-5

Step 2 - PIVOT PRO® (Wall/Column Mounted) Boom Installation ........................6-7

Step 3 - PIVOT PRO® (Free Standing) Mast Installation ......................................8-9

Step 4 - PIVOT PRO® (Free Standing) Boom Installation .................................10-11

Step 5 - Vacuum Hose Installation .......................................................................... 12

Step 6 - Accessories (Optional) Installation .......................................................13-15

Step 7 - Final Steps ................................................................................................. 16

Limited Warranty ........................................................................................ 17

Inspection and Maintenance Schedule ...................................................... 18

Questions? Concerns? Comments? Please call (800) 821-0086 (US and Canada) or

(585) 924-6262 (outside US).

INTRODUCTION

Thank you for choosing a Gorbel® PIVOT PRO® Light Duty Articulating Jib Crane to solve your material handling

needs. The innovative design and heavy duty construction of a Gorbel® PIVOT PRO® will provide a superior quality

product that will offer years of long term value. The Gorbel® PIVOT PRO® jib crane is pre-engineered for vacuum

lift operation. The lift tube weight allowance is 40 pounds (for example, a jib crane rated for 150 pounds allows for a

150 pound live weight plus 40 pounds for the weight of the lift tube). There is also an allowance of 50% of the crane

capacity for impact caused by vacuum use. A Gorbel® PIVOT PRO® will provide many years of dependable service by following the installation and maintenance procedures described herein.

Dimensions contained in this installation manual are for reference only and may differ for your particular

application. Please refer to the enclosed General Arrangement Drawing for actual dimensions.

Normal safety precautions: These include, but are not limited to:

• Checking for obstructions in crane rotation

• Checking that all bolts are tight and have lock washers

• Making sure that rotation limits are in place

• Making sure that vacuum hose or festooning cannot be snagged or pinched.

For additional safety precautions see pages 2 & 3.

WARNING

Only qualified personnel familiar with standard fabrication practices should be employed to assemble these cranes

because of the necessity of properly interpreting these instructions. Gorbel is not responsible for the quality of workmanship employed in the installation of a crane according to these instructions. Contact Gorbel, Inc., at 600 Fishers

Run, P.O. Box 593, Fishers, New York 14453-0593, 1-800-821-0086, for additional information if

necessary.

WARNING

Equipment described herein is not designed for, and should not be used for lifting, supporting or transporting

humans. Failure to comply with any one of the limitations noted herein can result in serious bodily injury and/or

property damage. Check Federal, State and Local regulations for any additional requirements.

WARNING

Consult a qualified structural engineer to determine if your support structure is adequate to support the loads

generated by thrust and pull (wall/column mounted), or anchor bolt force, overturning moment, or axial load (free

standing) of your crane.

WARNING

Crane cannot be utilized as a ground: A separate ground wire is required. For example, systems with 3 phase

power require 3 conductors plus one ground wire.

WARNING

Reference American Institute of Steel Construction (AISC) Manual of Steel Construction, Specifications and Codes,

Specification for Structural Joints using ASTM A325 or A490 Bolts for proper procedures to follow when using any

torque tightening method.

WARNING

Do not field modify crane in any way. Any modifications without the written consent of Gorbel, Inc., will void

warranty.

9/18

1

CRANE OPERATOR INSTRUCTIONS

Overhead cranes and jib cranes generally handle materials over working areas where there are personnel. Therefore, it is important for the Crane Operator to be

instructed in the use of the crane and to understand the severe consequences of careless operation. It is not intended that these suggestions take precedence over

existing plant safety rules and regulations or OSHA regulations. However, a thorough study of the following information should provide a better understanding of safe

operation and afford a greater margin of safety for people and machinery on the plant floor. It must be recognized that these are suggestions for the Crane Operator’s

use. It is the responsibility of the owner to make personnel aware of all federal, state and local rules and codes, and to make certain operators are properly trained.

Qualifications

Crane operation, to be safe and efficient, requires skill: the exercise of extreme care and good judgment, alertness and concentration, and rigid adherence to proven

safety rules and practices as outlined in applicable and current ANSI and OSHA safety standards. In general practice, no person should be permitted to operate a

crane:

• Who cannot speak the appropriate language or read and understand the printed instructions.

• Who is not of legal age to operate this type of equipment.

• Whose hearing or eyesight is impaired (unless suitably corrected with good depth perception).

• Who may be suffering from heart or other ailments which might interfere with the operator’s safe performance.

• Unless the operator has carefully read and studied this operation manual.

• Unless the operator has been properly instructed.

• Unless the operator has demonstrated his instructions through practical operation.

• Unless the operator is familiar with hitching equipment and safe hitching equipment practices.

Handling the Jib Boom Motion

Before using the boom of the jib crane, the operator should be sure the hook or lift tube is high enough to clear any obstruction. Before a load is handled by the

crane, the jib boom should be brought into position so that it is directly over the load. Start the jib boom slowly and bring it up to speed gradually. Approaching the

place where it is desired to stop the jib, reduce the boom speed.

Handling the Hoist or Vacuum LIfter Motion

Refer to the lifting equipment’s operating instructions.

GENERAL SUGGESTIONS

Know Your Crane

Crane operators should be familiar with the principal parts of a crane and have a thorough knowledge of crane control functions and movements. The crane operator

should be required to know the location and proper operation of the main conductor disconnecting means for all power to the attachments on the crane.

Responsibility

Each crane operator should be held directly responsible for the safe operation of the crane. Whenever there is any doubt as to SAFETY, the crane operator should

stop the crane and refuse to handle loads until: (1) safety has been assured or (2) the operator has been ordered to proceed by the supervisor, who then assumes all

responsibility for the SAFETY of the lift.

Do not permit ANYONE to ride on the hook, lift tube, or load.

Inspection

Test the crane movement and any attachments on the crane at the beginning of each shift. Whenever the operator finds anything wrong or apparently wrong, the

problem should be reported immediately to the proper supervisor and appropriate corrective action taken.

Operating Suggestions

One measure of a good crane operator is the smoothness of the crane operation. The good crane operator should know and follow these proven suggestions for

safe, efficient crane handling.

1. The crane should be moved smoothly and gradually to avoid abrupt, jerky movements of the load. Slack must be removed from the sling and hoisting ropes

before the load is lifted.

2. Center the crane over the load before starting the hoist or vacuum lifter to avoid swinging the load as the lift is started. Loads should not be swung by the crane

to reach areas not under the crane.

3. Crane-hoisting ropes or lift tubes should be kept vertical. Cranes shall not be used for side pulls.

4. Be sure everyone in the immediate area is clear of the load and aware that a load is being moved.

5. Do not make lifts beyond the rated load capacity of the crane, vacuum lifter, sling chains, rope slings, etc.

6. Make certain that before moving the load, load slings, load chains, or other lifting devices are fully seated in the saddle of the hook with the hook latch closed (if

equipped with hook latch), or verify that the vacuum head is completely sealed on the center of the load surface.

7. Check to be sure that the load and/or bottom block is lifted high enough to clear all obstructions when moving boom.

8. At no time should a load be left suspended and unattended.

9. Do not lift loads with sling hooks hanging loose. If all sling hooks are not needed, they should be properly stored, or use a different sling.

10. All slings or cables should be removed from the crane hooks when not in use (dangling cables or hooks hung in sling rings can inadvertently snag other objects

when the crane is moving).

11. Operators shall not carry loads and/or empty bottom blocks over personnel. Particular additional caution should be practiced when using magnet or vacuum

devices. Loads, or parts of loads, held magnetically could drop. Failure of power to magnets or vacuum devices can result in dropping the load. Extra

precaution should be exercised when handling molten metal in the proximity of personnel.

12. Whenever the operator leaves the crane the following procedure should be followed:

• Raise all hooks to an intermediate position.

• Spot the crane at an approved designated location.

• Place all controls in the “off” position.

• Open the main switch to the “off” position.

• Make visual check before leaving the crane.

13. In case of emergency or during inspection, repairing, cleaning or lubrication, a warning sign or signal should be displayed and the main switch should be locked

in the “off” position. This should be done whether the work is being done by the crane operator or by others.

14. Contact with rotation stops or trolley end stops shall be made with extreme caution. The operator should do so with particular care for the safety of persons

below the crane, and only after making certain that any persons on the other cranes are aware of what is being done.

15. ANY SAFETY FEATURES AND MECHANISMS BUILT-IN OR OTHERWISE PROVIDED WITH THE CRANE BY GORBEL ARE REQUIRED FOR THE SAFE

OPERATION OF THE CRANE. DO NOT, UNDER ANY CIRCUMSTANCES, REMOVE OR OTHERWISE IMPAIR OR DISABLE THE PROPER FUNCTIONING

OF ANY CRANE SAFETY MECHANISMS OR FEATURES BUILT-IN OR OTHERWISE PROVIDED BY GORBEL FOR SAFE OPERATION OF THE CRANE.

ANY REMOVAL, IMPAIRMENT OR DISABLING OF ANY SUCH SAFETY MECHANISMS OR FEATURES OR OTHER USE OR OPERATION OF THE CRANE

WITHOUT THE COMPLETE AND PROPER FUNCTIONING OF ANY SUCH SAFETY MECHANISMS OR FEATURES AUTOMATICALLY AND IMMEDIATELY

VOIDS ANY AND ALL EXPRESS AND IMPLIED WARRANTIES OF ANY KIND OR NATURE.

2

9/18

SAFE HOIST & VACUUM LIFTER OPERATING GUIDELINES

General

There is no one single factor that is more important for minimizing

the possibility of personal injury to the operator and those working in

the area, or damage to property, equipment, or material than being

familiar with the equipment and using Safe Operating Practices.

Hoists and vacuum lifters are designed for lifting and transporting of

material only. Under no circumstances, either during initial installation

or in any other use, should the hoist or vacuum lifter be used for

lifting or transporting personnel.

No operator should be permitted to use the equipment that is not

familiar with its operation, is not physically or mentally fit, or has not

been schooled in safe operating practices. The misuse of hoists or

vacuum lifters can lead to certain hazards which cannot be protected

against by mechanical means; hazards which can only be avoided by

the exercise of intelligence, care, and common sense.

Safe Operating Practices also involve a program of periodic

inspection and preventative maintenance (covered in a separate

section). Part of the operator’s training should be an awareness of

potential malfunctions/hazards requiring adjustments or repairs, and

bringing these to the attention of supervision for corrective action.

Supervision and management also have an important role to play

in any safety program by ensuring that a maintenance schedule is

adhered to, and that the equipment provided for the operators is suitable for the job intended without violation of one or more of the rules

covering safe operating practices and good common sense.

The Safe Operating Practices shown are taken in part from the

following publications:

• American National Standard Institute (ANSI)

• Safety Standards for Cranes, Derricks, Hoists

• ANSI B30.2 - Overhead and Gantry Cranes

• ANSI B30.16 - Overhead Hoists

Do’s and Don’ts (Safe Operation of Hoists & Vacuum Lifters)

The following are Do’s and Don’ts for safe operation of overhead

hoists and vacuum lifters. A few minutes spent reading these rules

can make an operator aware of dangerous practices to avoid and

precautions to take for his own safety and the safety of others.

Frequent examinations and periodic inspections of the equipment as

well as a conscientious observance of safety rules may save lives as

well as time and money.

6. Do not tamper with or adjust any parts of the hoist or vacuum

lifter unless specifically authorized to do so.

7. Do not divert attention from load while operating hoist or vacuum

lifter.

8. Never leave a suspended load unattended.

9. Never operate a hoist or vacuum lifter that has an inherent or

suspected mechanical or electrical defect.

10. Do not jog controls unnecessarily.

11. Do not operate hoist or vacuum lifter if load is not centered under

hoist or lift tube.

12. Do not operate hoist or vacuum lifter if cable chain or lift tube is

twisted, kinked, or damaged.

13. Do not remove or obscure warning labels.

DO’S - HOISTS & VACUUM LIFTERS

1. Read and follow manufacturer’s instruction, installation, and

maintenance manuals. When repairing or maintaining a hoist or

vacuum lifter, use only manufacturer’s recommended parts and

materials.

2. Read and follow all instruction and warning information on or

attached to a hoist or vacuum lifter.

3. Remove the hoist or vacuum lifter from service and thoroughly

inspect and repair, as necessary, if unusual performance or

visual defects (such as peculiar noise, jerky operations, travel in

improper direction, or obviously damaged parts) are noticed.

4. Establish a regular schedule of inspection and maintain records

for all hoists and vacuum lifters.

6. Never lift loads over people, etc.

7. Check for damaged hooks, load cables, and lift tubes.

10. Make sure a load clears neighboring stockpiles, machinery, or

other obstructions when raising, lowering, or traveling the load.

11. Center hoist or lift tube over the load before operating.

12. Avoid swinging of load when pivoting the jib.

14. Pull in a straight line, so that neither hoist body nor lift tube are

angled around an object.

16. Know the hand signals for hoisting, cross travel, and crane travel

if working with cab-operated hoists or cranes. Operators should

accept signals of only those persons authorized to give them.

DON’TS - HOISTS & VACUUM LIFTERS

1. Never lift or transport a load until all personnel are clear and do

not transport the load over personnel.

2. Do not allow any unqualified personnel to operate hoist or

vacuum lifter.

3. Never pick up a load beyond the capacity rating appearing on

the hoist or vacuum lifter. Overloading can be caused by jerking

as well as by static overload.

4. Never carry personnel on the hook, the lift tube, or the load.

5. Do not operate hoist or vacuum lifter if you are not physically fit.

9/18

3

INSTALLATION

STEP 1 - PRE-ASSEMBLY

TIP: Packing list can be found in plastic pocket inside hardware box: General Arrangement

Drawing can be found inserted in this installation manual.

1.1 Read entire manual before installing the PIVOT PRO®.

1.2 Check packing list to ensure no parts have been lost prior to initiating assembly of crane.

1.3 Tools and materials (by others) typically needed to assemble crane:

• Torque wrench • Ladders/man lifts

• Hand tools • Heavy duty drill

• Allen wrenches (1/4”, 3/16”, 3/8”) • Steel shims

• Lifting device to lift heavy masts and booms • Teflon

• Leveling tools (plumb bob, plumb fixture-pg. 9)

• PPRO-FS anchor bolts (by others, Grade 5 or better), refer to page 5 for specifications

• PPRO-WM mounting bolts (by others, Ø 5/8” Grade 5 or better)

• Grout (Non-Shrink Precision Grout for PPRO-FS)

WARNING

Consult a qualified structural engineer to determine that your support structure is adequate to support the

loads generated by thrust and pull (wall mounted) or anchor bolt force, overturning moment, or axial load

(free standing) of your PIVOT PRO®.

®

tape

1.4 Identify crane type:

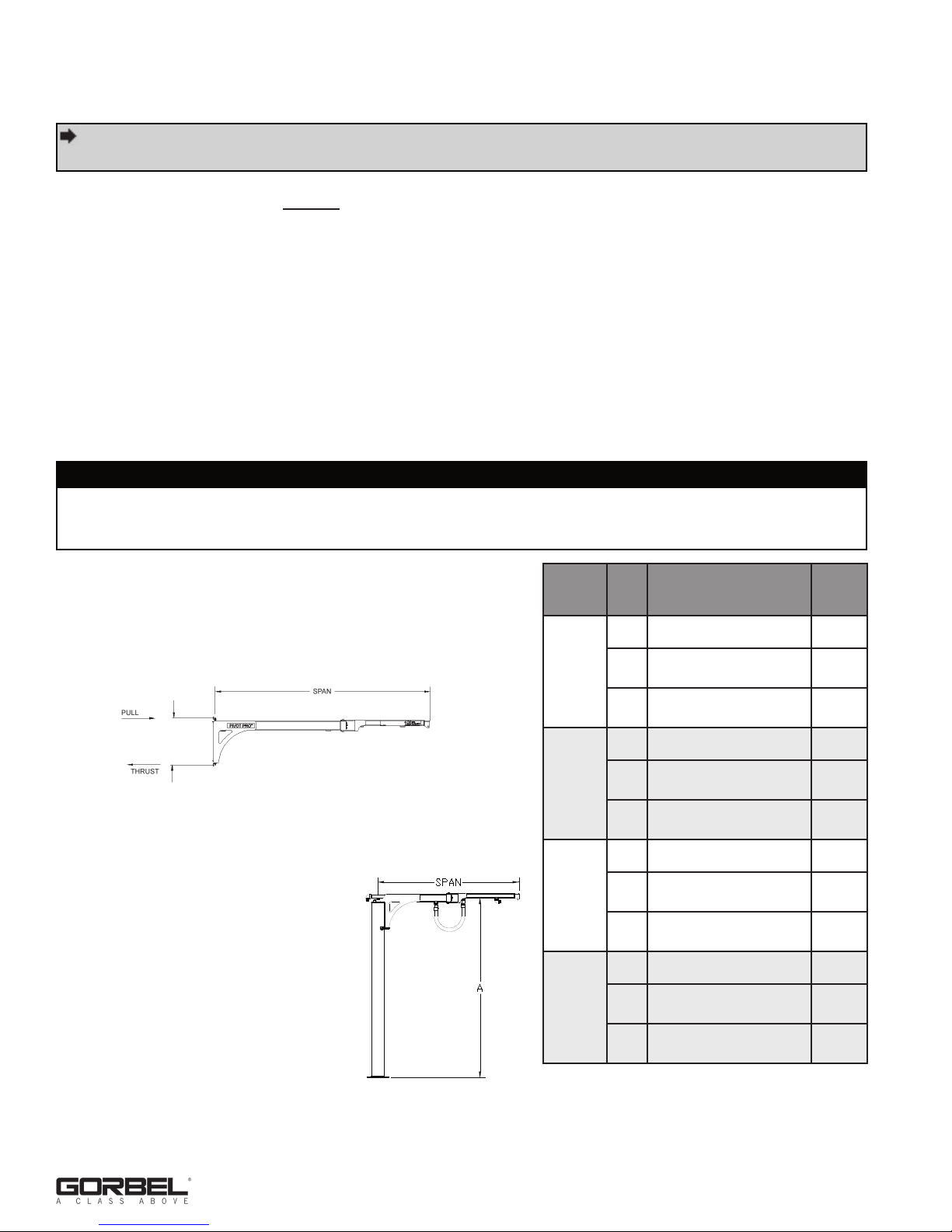

Wall/Column Mounted PIVOT PRO® (diagram 1A)

Refer to Chart 1A to determine thrust and

pull, then proceed to Step 2, page 6.

27.45”

The distance between pivot mounting

bracket centers (B) is 27.45”.

Diagram 1A. Wall/Column Mounted PIVOT PRO®.

Free Standing PIVOT PRO® (diagram 1B)

Refer to Chart 1B, on

page 5, to determine

anchor bolt load. Refer to

Diagram 3B on page 8 to

determine footer width

and depth, then proceed

to Step 3, page 8.

Diagram 1B. Free

Standing PIVOT PRO®.

Capacity Span

8’

50#

10’

12’

8’

75#

10’

12’

8’

100#

10’

12’

8’

150#

10’

12’

Chart 1A. Chart for determining thrust and pull of

Wall Mounted PIVOT PRO®.

Note: This is based on a lift tube or hoist weight of

40 lbs and a 50% impact factor.

Model Number

T =Top hose connection

B= Bottom hose connection

PPRO-WM-50-8-T

PPRO-WM-50-8-B

PPRO-WM-50-10-T

PPRO-WM-50-10-B

PPRO-WM-50-12-T

PPRO-WM-50-12-B

PPRO-WM-75-8-T

PPRO-WM-75-8-B

PPRO-WM-75-10-T

PPRO-WM-75-10-B

PPRO-WM-75-12-T

PPRO-WM-75-12-B

PPRO-WM-100-8-T

PPRO-WM-100-8-B

PPRO-WM-100-10-T

PPRO-WM-100-10-B

PPRO-WM-100-12-T

PPRO-WM-100-12-B

PPRO-WM-150-8-T

PPRO-WM-150-8-B

PPRO-WM-150-10-T

PPRO-WM-150-10-B

PPRO-WM-150-12-T

PPRO-WM-150-12-B

Thrust

& Pull

584#

756#

941#

717#

921#

1139#

849#

1086#

1337#

1114#

1417#

1732#

4

9/18

Loading...

Loading...