Page 1

Pure Sine Inverter

GPSW-150

GPSW-300

________________________________________________

Owner’s Manual

Page 2

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

Table of Contents

Introduction 2

Specifications 3

Name and Main Function 5

Installation 9

Operation 12

Operating Limits 14

Troubleshooting 15

Maintenance 15

Disclaimer of Liability and Warranty 16

1.0 Introduction

The Go Power!

AC power and can be used in a wide range of applications including remote

homes, RVs, sailboats, powerboats, laptops, cell phone chargers, and even

gaming equipment. The inverters operate most televisions, VCRs, personal

computers, small appliances, and cab charge cordless tools such as drills,

sanders and grinders, mixers, and blenders.

An inverter must have a greater power rating than the load to which it is providing

power. To get the most out of the inverter, ensure it is installed and used

correctly. Please read the instructions in this manual before installing and using

the inverters.

TM

SW150 and SW300 Sine Wave Inverters convert DC power to

2

Page 3

Pure Sine Wave Inverter

A

GPSW-150

GPSW-300

___________________________________________________________

2.0 Specifications

2.1 GPSW-150 W Inverter

SPECIFICATIONS*

Continuous Output Power 150 W

Surge Rating 260 W

Output Waveform Pure Sine Wave <3% THD

Output Voltage

Input Voltage 10.5 – 15 VDC 21.0-30.0

Efficiency 80-90%

No Load Current Draw / Powersave 0.20 A 0.15 A

Protection

Low Battery Alarm

Low Battery Shut-Down

Operating Temperature Range

Storage Temperature Range

Cooling Thermostatically Controlled Fan

C Receptacle Dual GFCI

Remote Port Option Yes

Dimensions (L x W x H) in mm 200 x 132 x 72

Dimensions (L x W x H) in

inches

Weight 2.7 kg / 5.9 lbs

Warranty 2 Year

Inverter Install Kits

UPC 8-39085-00057-1 8-39085-00135-6

± 5%

115 VAC RMS

± 2%

10.5 V

± 2%

10.5 V 21.0 V

GPSW-150 (12V)

Overload, Short Circuit, Reverse Polarity (Fuse),

Over/Under Input Voltage, Over Temperature

0 - 40ºC / 32ºF - 104ºF

-30ºC - 70ºC / -22ºF - 158ºF

8 x 5.3 x 2.9

Auto Utility Adapter

Battery Ring Terminal Connection

GPSW-150 (24V)

21.0 V

3

Page 4

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

2.2 GPSW-300 W Inverter

SPECIFICATIONS*

Continuous Output Power 300 W

Surge Rating 450 W

Output Waveform Pure Sine Wave <3% THD

Output Voltage

Input Voltage 10.5 – 15 VDC 21.0-30.0

Efficiency 80-90%

No Load Current Draw / Powersave 0.26 A 0.23 A

Protection

Low Battery Alarm

Low Battery Shut-Down

Operating Temperature Range

Storage Temperature Range -30ºC - 70ºC / -22ºF - 158ºF

Cooling Thermostatically Controlled Fan

AC Receptacle Dual GFCI

Remote Port Option Yes

Dimensions (L x W x H) in mm 237 x 155 x 72

Dimensions (L x W x H) in inches 9.3 x 6.1 x 2.8

Weight 2.7 kg / 5.9 lbs

Warranty 2 Year

± 5%

115 VAC RMS

± 2%

10.5 V

± 2%

10.5 V 21.0 V

GPSW-300 (12V)

Overload, Short Circuit, Reverse Polarity (Fuse),

Over/Under Input Voltage, Over Temperature

0 - 40ºC / 32ºF - 104ºF

GPSW-300 (24V)

21.0 V

Inverter Install Kits Anderson Lug Terminals

UPC 8-39085-00004-5 8-39085-00060-1

4

Page 5

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

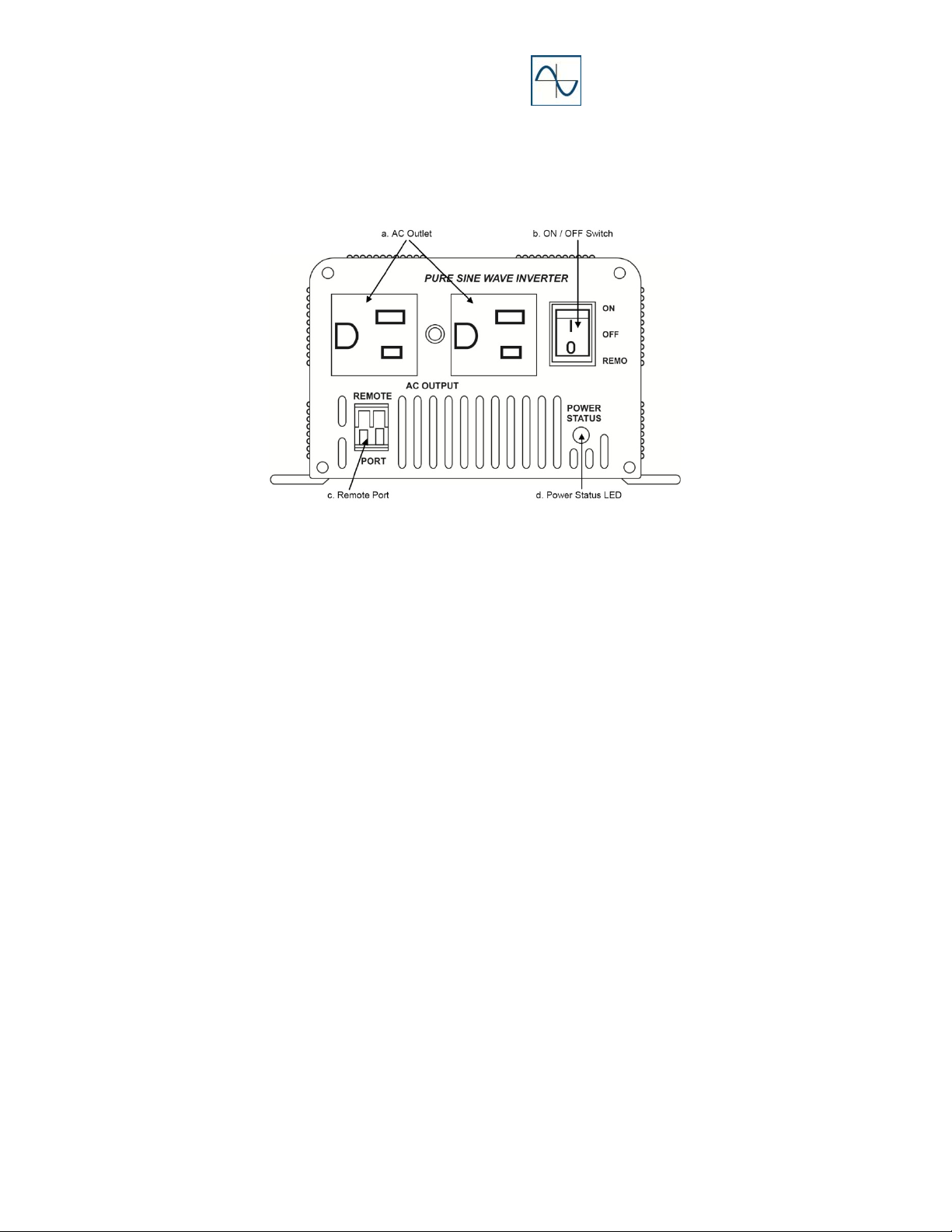

3.0 Name and Main Function

3.1 GPSW-150

Front View

a.

b.

c.

d.

Solid Green: AC power OK

Fast Red Blink: Over voltage protection (OVP)

Slow Red Blink: Under voltage protection (UVP)

Intermittent Red

Solid Red: Overload protection (OLP)

AC outlet:

Outlet sockets available: North America (NEMA 5-15R)

ON / OFF switch:

Power ON/OFF switch, leave in the OFF position during installation.

Remote port:

Allows customer to connect 2 wire switch to use as ON/OFF remote.

Ex. Toggle switch or light switch.

Power status LED:

The LED display indicates the power status of the inverter; see section

0 5.2 Power

Blink:

Status for more information.

Over temperature protection (OTP)

5

Page 6

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

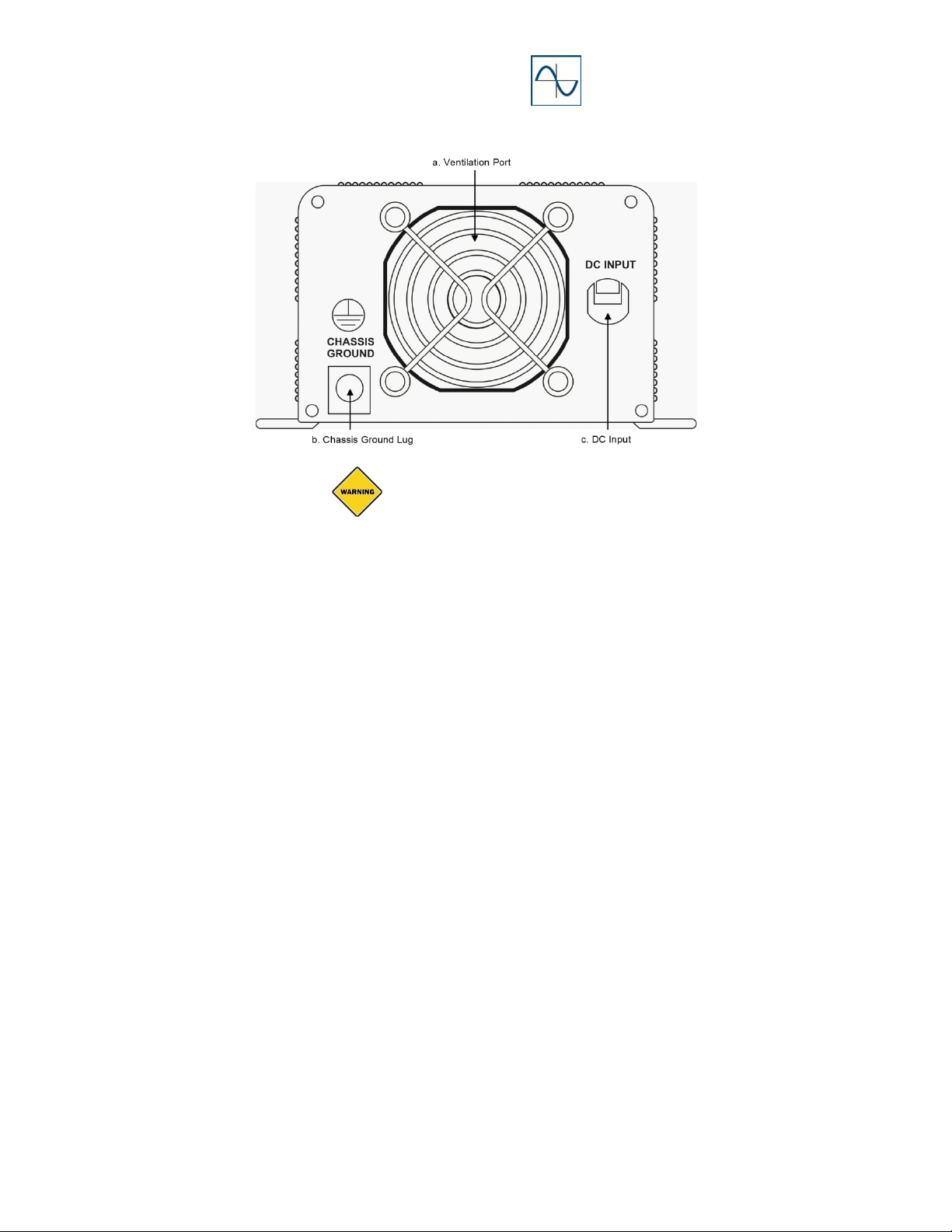

3.1.2 Rear View GPSW-150

Operation of the inverter without a proper ground

connection may result in an electrical safety hazard.

a.

b.

c.

Ventilation port:

Do not obstruct, allow at least 1 inch (2.54 cm) for air flow.

Connect the chassis ground to the vehicle chassis using a #8 AWG

wire.

DC Input:

Included: 3 foot (0.91 m) cable with automobile DC plug.

Use the DC input terminal to connect to a battery or other power

source: black is negative (–), red is positive (+). A reverse polarity

connection will blow the internal fuse and may permanently damage the

inverter. Observe the DC Input rating.

6

Page 7

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

3.2 GPSW-300

Front View

a.

b.

c.

d.

Solid Green: AC power OK

Fast Red Blink: Over voltage protection (OVP)

Slow Red Blink: Under voltage protection (UVP)

Intermittent Red

Solid Red: Overload protection (OLP)

ON / OFF switch:

Power ON/OFF switch, leave in the OFF position during installation.

AC outlet:

Outlet sockets available: North America (GFCI).

Remote port:

Allows customer to connect 2 wire switch to use as ON/OFF remote.

Ex. Toggle switch or light switch.

Power status LED:

The LED display indicates the power status of the inverter; see section

0 5.2 Power

Blink:

Status for more information.

Over temperature protection (OTP)

7

Page 8

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

Rear View

Operation of the inverter without a proper ground

connection may result in an electrical safety hazard.

a.

b.

c.

Ventilation port:

Do not obstruct, allow at least 1 inch (2.54 cm) for air flow.

Connect the chassis ground to the vehicle chassis using a #8 AWG

wire.

DC Input:

Included: 4 foot (1.22 m) cable with Anderson Power Pole connectors.

Use the battery terminals to connect to battery or other power source:

black is negative

(–), red is positive (+). A reverse polarity connection will blow the

internal fuse and may permanently damage the inverter. Observe the

DC Input rating.

8

Page 9

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

4.0 Installation

4.1 Where to Install

The inverter should be installed in a location that meets the following

requirements:

Do not connect the inverter and another AC source (generator

or utility power) to the AC wiring or AC loads at the same

time. Doing so will destroy the inverter and void the warranty,

regardless whether the inverter is switched on or off. If you

are using more than one AC source for the AC wiring or AC

loads, it is highly recommended that you install an automatic

transfer switch (GP-TS), available from Go Power!

a) Dry - Do not allow water to drip or splash on the inverter.

b) Cool - Ambient air temperature should be between 32 and 104 °F (0 and 40

°C); the cooler the better.

c) Ventilated - Allow at least 2 inches (5.08 cm) of clearance around the

inverter for air flow. Ensure the ventilation openings on the rear and bottom

of the unit are not obstructed.

d) Safe - Do not install the inverter in the same compartment as batteries or in

any compartment capable of igniting flammable liquids such as gasoline.

e) The inverter location should not exceed 10 feet (3.05 m) of the batteries.

TM

4.2 Installation and testing

The following procedure describes how to install and test the GPSW150 and

GPSW300 inverters.

1. Unpack and inspect your Go Power!

switch is in the OFF position.

2. Connect power:

GPSW150:

Attach the automobile DC plug to a DC socket; go to step 7.

Ensure there is circuit protection on the DC socket; see section 0 4.3

. If the DC plug is removed showing the negative and positive wires,

Cables

go to step 3.

GPSW300: Plug in the Anderson Power Pole connectors; go to step 3.

3. Securely connect the negative cable (black) to the negative terminal of the

battery.

TM

Inverter. Ensure that the power

9

Page 10

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

Loose connections result in excessive voltage drop and

may cause overheated wires and melted insulatio n.

A reverse polarity connection will blow a fuse in the

inverter and may permanently damage the inverter.

Damage caused by reverse polarity connection is not

covered by the warranty.

4. Before proceeding further, carefully check to ensure that the cable connects

from the negative DC input of the inverter to the negative terminal of the

battery.

You may observe a spark when you make the positive

connection since current may flow to charge capacitors

in the inverter. Do not make this connection in the

presence of flammable fumes, as explosion or fire may

result.

5. Install the recommended inverter fuse in the positive lead; see section 4.3

Cables. The fuse should be located as close to the battery as possible.

Ensure all connections are tight and secure.

6. Securely connect the positive cable (red) to the positive terminal of the

battery.

7. Set the power switch to the ON position. Check the indicator LED on the

front panel of the inverter to ensure that it is green.

8. Set the inverter switch to the OFF position. The indicator light may blink

and the internal alarm may sound momentarily. This is normal. Plug the

test load into the AC receptacle on the front panel of the inverter.

9. Set the inverter switch to the ON position and turn on the test load; the

inverter should supply power to the load. If you plan to measure the output

voltage of the inverter, a true RMS meter must be used for accurate

readings.

10

Page 11

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

4.3 Cables

4.3.1 GPSW150 – 12 V / 24 V

Use the included 3 feet (0.91 m) of #14 AWG wire and automobile DC plug.

When used in conjunction with an automobile DC socket, ensure the DC socket

fuse in the automobile fuse box is rated to the inverter load.

For example:

100 W = 10 A fuse

150 W = 15 A fuse

If the DC automobile plug is removed and/or the inverter is not attached to a

battery via an automobile fuse box, attach a 20 A fuse in line with the positive

conductor as close to the battery as possible. Extending the included cables may

result in excessive voltage drop. Increase the overall cable gauge to the next

larger standard size for every 3 feet (0.91 m) extended and do not exceed 10 feet

(3.05 m) total inverter cable length.

For example: 10 feet (3.05 m) cable = 10 gauge wire

4.3.2 GPSW300 – 12 V / 24 V

Use the included 4 feet (1.22 m) of #10 AWG wire and Anderson Power Pole

connectors.

Attach a 40 A or 20 A when using 24 volt version fuse in line with the positive

conductor as close to the battery as possible. Extending the included cables may

result in excessive voltage drop. Increase overall cable gauge to the next larger

standard size for every 3 feet (0.91 m) extended and do not exceed 10 feet (3.05

m) total inverter cable length.

For example: 10 feet (3.05 m) cable = 6 gauge wire

4.4 Grounding

The inverter has a chassis ground lug on the rear panel allowing you to connect

the chassis of the inverter to ground. The ground terminals in the AC outlets on

the front panel of the inverter are internally connected to the chassis ground. If

available, the chassis ground lug should be connected to a grounding point,

which will vary depending on where the inverter is installed. In a vehicle, connect

the chassis ground to the chassis of the vehicle. In a boat, connect the chassis

ground lug to the boat's grounding system. In a fixed location, connect the

chassis ground lug to an earth ground.

The neutral (common) conductor of the inverter AC output circuit is connected

(bonded) to the chassis ground inside the inverter. Therefore, when the chassis

is connected to a ground, the neutral conductor is also grounded. These

grounding connections conform to national electrical code requirements which

state that separately derived AC sources (such as inverters and generators) have

their neutral tied (bonded) to ground in the same way that the neutral conductor

11

Page 12

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

from the utility line is tied (bonded) to ground in the AC breaker panel of a

non-mobile dwelling.

Important:

As per the national electrical code, electrical panels in mobile applications must

not have a bonded neutral. If the inverter is supplying power to equipment or a

panel where the neutral and ground are connected (bonded), a ground loop will

occur. If a ground loop occurs on inverters with GFCI outlets, the GFCI outlet will

trip and output power from the inverter will be cut off. If your GFCI repeatedly

needs to be reset, this indicates a ground loop somewhere in your system. In this

case, please have a qualified service technician inspect your electrical system or

equipment.

The negative DC input of the inverter is connected to the

chassis. Do not install the inverter in a positive ground

DC system. A positive ground DC system has the

positive terminal of the battery connected to the chassis

of the vehicle or to the grounding point.

5.0 Operation

To operate the inverter, turn it on using the ON / OFF switch on the front panel.

The inverter is now ready to deliver AC power to your loads. If you are operating

several loads from the inverter, turn on the inverter, and then turn on each load

separately. This will ensure that the inverter does not have to deliver the

starting-currents for all the loads at once.

5.1 Operating On / Off Switch

The ON / OFF switch turns the control circuit in the inverter ON and OFF. It does

not disconnect power from the inverter.

When the switch is in the OFF position, the inverter draws no current from the

battery. When the switch is in the ON position, but with no load, the inverter

draws approximately 0.20 A from the battery.

5.2 Power Status

The power status LED indicates the operating state of the inverter. If the LED is

green, then the inverter is in operational mode and producing approximately 115

V AC. If the LED is red or flashing red, then the inverter is in fault mode and there

is no AC output.

12

Page 13

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

Table 1: Inverter Power States

State LED Description

Over voltage

protection

Under voltage

protection

Over temperature

protection

Overload

protection

Red LED blinking

fast

Red LED blinking

slowly

Red LED blinking

intermittently

Red LED solid Overload protection indicates that the inverter

Over voltage protection indicates that the

inverter has shut itself down because its input

voltage is over:

12 V: 15.0 ~ 16.0 V DC

24 V: 30.0 ~ 32.0 V DC

Under voltage protection indicates that the

inverter has shut itself down because its input

voltage is lower than:

12 V: 10.0 ~ 10.5 V DC

24 V: 20.0 ~ 21.0 V DC

Over temperature protection indicates that the

inverter has shut itself down because it has

become overheated.

The inverter may overheat if it has been

operated at power levels above its rating or if

it has been installed in a location which does

not allow it to properly dissipate heat. The

inverter automatically restarts once it has

cooled down.

has shut itself down because its output circuit

has been short circuited or drastically

overloaded.

Switch the ON / OFF switch to OFF, correct

the fault condition, and then switch the ON /

OFF switch back to ON.

5.3 Resetting Faults

Any of the inverter protection faults can be re-set by turning the inverter off for 5

seconds and then turning the inverter on again. The GPSW150 and GPSW300

inverters can also re-set any protection faults using the optional remote on/off

switch (2 wire switch supplied by customer) to turn the inverter off and then on

again.

5.4 Remote

A user supplied remote option is available for both the GPSW150 and GPSW300

inverters. When the ON / OFF switch is moved to the remote setting, the inverter

13

Page 14

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

becomes operational only when a connection is made between the two terminals

of the remote input. A switch may be placed between the two terminals and the

inverter can then be turned off using the switch. A ⅛” (3.0 mm) precision

screwdriver is recommended for tightening the two terminals. It is recommended

that a #18 gauge wire no longer than 150 feet (45.72 m) (terminal to terminal) is

used for this application.

Never connect live AC or DC conductors to the remote

terminals.

6.0 Operating limits

6.1 Power output

Some induction motors used in refrigerators, freezers, pumps, and other motoroperated equipment require very high surge currents to start. The inverter may

not be able to start some of these motors even though their rated current draw is

within the power rating of inverter. Televisions and computer monitors may surge

up to four times their rated power on startup, which may result in the inverter

showing an overload fault.

6.2 Input voltage

The inverter operates at the following input voltage ranges:

12 V: 10.5 to 15.0 V

24 V: 21.0 to 30.0 V

The inverter shuts down if the input voltage drops below:

12 V: 10.5 V

24 V: 21.0 V

This protects your battery from being over discharged.

The inverter also shuts down if the input voltage exceeds:

12 V: 15.0 V

24 V: 30.0 V

This protects the inverter against excessive input voltage. Although the inverter

incorporates protection against over voltage, it may still be damaged if the input

voltage is allowed to exceed:

12 V: 16.0 V

24 V: 35.0 V

14

Page 15

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

7.0 Troubleshooting

7.1 Television interference

Operation of the inverter can interfere with television reception on some

channels. If this situation occurs, the following steps may help to alleviate the

problem.

Ensure that the chassis ground lug on the back of the inverter is

securely connected to the ground system of your vehicle, boat, or home.

Do not operate high power loads with the inverter while watching

television.

Make sure that the antenna feeding your television provides an

adequate ("snow free") signal and that you are using a good quality

cable between the antenna and the TV.

Move the television as far away from the inverter as possible.

Keep the cables between the battery and the inverter as short as

possible and twist them together with about 2 to 3 twists per foot. This

minimizes radiated interference from the cables.

7.2 Troubleshooting guide

Table 2: Common Problems

Problem and Symptoms

No output voltage, red

LED blinking fast

Possible

Cause

High input

voltage

Solution

Ensure that inverter is

connected to a 12 V / 24 V

battery. Check the regulation

of charging system.

No output voltage, red

LED blinking slowly

No output voltage, load in

excess of 150 W, red LED

blinking intermittently

No output voltage, load

less than 150 W, red LED

blinking intermittently

No output voltage, red

LED solid

Poor DC wiring,

poor battery

condition

Thermal

shutdown

Thermal

shutdown

Overload Reduce the load.

Use the proper cable and

make secure connections.

Use a new battery.

Allow the inverter to cool off.

Reduce the load if continuous

operation required.

Improve ventilation; ensure

that the inverter ventilation

openings are not obstructed.

Reduce the ambient

temperature.

15

Page 16

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

Problem and Symptoms

No output voltage, red

LED blinking slowly

Possible

Cause

Low input

voltage

Inverter

switched off

No power to

inverter

Solution

Recharge the battery.

Check the connections and

cable.

Turn the inverter ON.

Check wiring to the inverter.

No output voltage,

previous solutions are not

working

No output voltage,

overload indicator ON

Car lighter fuse

open

Internal fuse

open

Reverse DC

polarity

Short circuit or

wiring error

Replace the fuse.

Have a qualified service

technician check and replace.

Have a qualified service

technician check and replace

fuse.

Observe correct polarity.

Check the AC wiring for a

short circuit or improper

polarity (hot and neutral

reversed).

8.0 Maintenance

Clean the exterior of the unit periodically with a damp cloth to prevent

accumulation of dust and dirt and check all connections between the battery and

inverter.

9.0 Disclaimer of Liability & Warranty

Go Power!TM provides the following limited 2 year warranty (“Warranty”) coverage

as applicable to the purchaser (“Purchaser”) of the Go Power!

(“Product”) directly from Go Power!TM The following constitutes the terms and

conditions of that limited warranty.

TM

branded product

9.1.1 What the Go Power! Warranty Covers and for How Long

Subject to the exclusions and claim procedure set out below, Go Power!TM

warrants for a period of 2 years from the date of purchase at the point-of-sale to

the original end-user customer (“Sale Date”), that the Go Power!TM Product

provides coverage as follows:

16

Page 17

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

For the period ending 2 years from the Sale Date, Go Power!

Power!TM’s discretion, repair or replace the Product which fails to meet the

Product Specifications due to a defect in materials or workmanship or apply

credit towards the purchase of new Go Power!TM Product.

To exercise this right, the Purchaser shall ship, at its own expense, and return

the Product to Go Power! according to the return instructions detailed below, and

Go Power!

of charge, or offer credit towards the purchase of new Product.

Go Power!TM shall be entitled, at its discretion, to use new and/or reconditioned

parts in performing warranty repair or providing a replacement Product. Go

Power!TM also reserves the right to use parts or Product of original or improved

design in any repair or replacement. All replaced Product and/or any parts

removed from repaired Products become the property of Go Power!

If Go Power!

continue to apply and remain in effect for the balance of the warranty period

calculated from the Sale Date (and not the repair or replacement date).

If Go Power!

then the warranty in effect and applicable to the new Product shall apply to the

new Product.

TM

will, repair or replace the Product and return it to the Purchaser free

TM

chooses to repair or replace a Product, the above warranty will

TM

chooses to offer a credit towards the purchase of new Product,

TM

will, at Go

TM

9.1.2 What the Go Power! Warranty Does Not Cover

Go Power!TM’s Warranty does not provide coverage for the following which are

expressly excluded from the above warranty:

Failure due to normal wear and tear of the Product.

Failure caused by separate computer software supplied with or

associated with a Go Power!

TM

Product.

Failure due to fire, water, neglect, improper installation, generalized

corrosion, biological infestations, or input voltages that create operating

conditions beyond the maximum or minimum listed in the Go Power!

specifications including lightning strikes.

Products which have been altered other than by Go Power!

authorized by Go Power!

TM

TM

or

Products that have their original identification (trademark, serial number)

markings defaced altered or removed.

Products utilized as a component part of a product expressly warranted

by another manufacturer.

Operation or storage of the Product outside the specification ranges,

and/or alteration or deployment of Go Power!

TM

Products other than in

TM

17

Page 18

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

accordance with any published or provided user, storage or

maintenance requirements.

Failure that is in any way attributable to the improper use, storage,

maintenance, installation or placement of the Go Power!

TM

Product.

Failure caused by abuse, misuse, abnormal use, or use in violation of

any applicable standard, code or instructions for use in installations,

including, but not limited to, those contained in the National Electrical

Code, the Standards for Safety of Underwriters Laboratory, Inc.,

Standards for the International Electrotechnical Commission, Standards

for the American National Standards Institute, or the Canadian

Standards Association.

Failure due to acts of God.

9.1.3 Restrictions and Limitations to Go Power!’s Warranty

This Warranty is not transferable and only applies to the Purchaser.

Go Power!

implementation of recommendations made by Go Power!

authorized distributors concerning the use, design or application of Go

Power! Products

The end-user who purchases the Product assumes all responsibility and

liability for loss or damage resulting from the handling or use of Go

Power!TM Products.

Go Power!

negligence, or any other legal theory, for loss, damage or injury arising

directly or indirectly from or in relation to the use of the Go Power!

Product shall in no event exceed the purchase price of the Go Power!TM

Product which gave rise to the claim. IN NO EVENT SHALL GO POWER!

BE LIABLE FOR PUNITIVE, SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES WHETHER FORSEEABLE OR NOT INCLUDING BUT NOT

LIMITED TO LOSS OF PROFITS OR REVENUES, LOSS OF USE OF GOODS,

OR LOSS OF BARGAIN.

The Warranty set out above is the sole warranty granted by Go

Power!

representations or warranties shall be of any effect and Go Power!TM

makes no further warranties, express or implied concerning the Go

Power!

where permitted by applicable law, hereby expressly waives any

statutory or implied warranty that the Go Power!TM Product shall be

merchantable or fit for a particular purpose.

TM

does not warrant the results obtained from the

TM

's liability on any claim, whether in warranty, contract,

TM

or its

TM

with respect to the Product. No oral understanding,

TM

Products other than the Warranty set out above. The Buyer,

TM

TM

18

Page 19

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

9.2 Warranty Return Procedure

Visit www.gpelectric.com to read the “frequently asked questions” section of

our website to troubleshoot the problem. If trouble persists:

1. Call your Go Power!™ Technical Support team (1-866-247-6527).

2. Return defective product to place of purchase.

9.2.1 End Users

Contact your sales representative or Dealer and discuss the problem. Often the

sales representative can troubleshoot common scenarios. If applicable, warranty

will be handled between the End User and the Dealer. Go Power!

accept returned items from an End User as a last resort. If you are unable to

contact the Dealer, or the Dealer refuses to provide service, please contact Go

TM

Power!

directly.

TM

will only

9.2.2 Dealers

Dealers will handle warranty either through their supplier or Go Power!TM if they

qualify as a Purchaser.

9.2.3 Units bought directly from Go Power!

The Purchaser will return the product, freight prepaid, to Go Power!TM You must

obtain a Return Material Authorization (RMA) number from Go Power!

returning a product. The RMA number MUST be clearly indicated on the outside

of the box.

Items received without an RMA number will be refused.

TM

before

9.2.3 Additional Information

Unless approved by Go Power!TM management, all product shipped collect to Go

TM

Power!

Test items or items that are not under warranty, or units that are not defective,

will be charged a minimum bench charge of ($50.00 US) plus taxes and shipping.

A 15% restocking charge will be applied on goods returned and accepted as

“new” stock.

will be refused.

9.4 Out of Warranty Items

Go Power!TM electronic products are non-repairable, Go Power!! does not

perform repairs on its products nor does it contract out those repairs to a third

party. Go Power!

its electronic products.

TM

does not supply schematics or replacement parts for any of

19

Page 20

Pure Sine Wave Inverter

GPSW-150

GPSW-300

___________________________________________________________

© 2011 GO POWER!™ By Carmanah Technologies

www.gpelectric.com

MOBI_MAN_GPSW-150-300_vF_Dec2011

20

Loading...

Loading...