Page 1

Solar Controller

GP-PWM-30

Owner’s Manual

1

© 2012 Carmanah Technologies Corporation

September 2012

Page 2

Solar Controller

GP-PWM-30

______________________________________________________________________

© 2012 Carmanah Technologies Corporation

September 2012

2

Page 3

Solar Controller

______________________________________________________________________

GP-PWM-30

CONTENTS

1.0 Installation Overview 4

1.1 Introduction 4

1.2 Specifications 5

2.0 Warnings 6

3.0 Tools and Materials Needed 7

4.0 Choosing a Location 7

5.0 Installation Instructions 8

6.0 Operating Instructions 10

7.0 Frequently Asked Questions (FAQs) 15

8.0 Troubleshooting Problems 16

8.1 Problems with the Display 16

8.2 Problems with Voltage 17

8.3 Problems with Current 17

9.0 Limited Warranty 19

9.1 Repair and Return Information 19

10.0 Glossary 20

11.0 Installation Template 21

12.0 Wiring Diagram 23

© 2012 Carmanah Technologies Corporation

September 2012

3

Page 4

Solar Controller

______________________________________________________________________

GP-PWM-30

1.0 Installation Overview

1.1 Introduction

A Charge Controller is an essential component of your photovoltaic (PV)

system. The Controller maintains the life of the battery by protecting it

from overcharging. When your battery has reached a 100% state of

charge, the Controller prevents overcharging by limiting the current

flowing into the batteries from your solar array.

The GP-PWM-30 is a 12 volt flush mounted photovoltaic (PV) charge

controller rated for a continuous solar current input of 30 amps. The GPPWM-30 uses pulse width modulation technology and a unique four

stage charging system and optional equalize setting to charge and

protect your battery bank. The GP-PWM-30 features an LCD digital

display that shows solar array charge current, system battery voltage

and battery capacity.

© 2012 Carmanah Technologies Corporation

September 2012

4

Page 5

______________________________________________________________________

Description

Value

Dimensions (H x W x D):

107 x 190 x 35 mm

4.25 x 7.5 x 1.38 in

Weight: 172 grams

6 oz

Maximum Wire Gauge: #6 AWG

Warranty: 5 years

PWM Charging

3 Battery Charging profiles

4 Stage Charging

Monthly Equalize option

Displays Charging Current,

Battery Voltage and Battery

State of Charge

Reverse Polarity protected

Temperature Compensated

RoHS Compliant,

environmentally safe

Accepts over 400 Watts of

solar at 12 volts

Nominal System Voltage

12V

Max. Solar Array Current

30 amps

Battery Voltage Range

6V – 15.5V

Max. Solar Voltage

28V

Operating Consumption

Display Consumption

6mA

10mA

Absorption Voltage

14.1/14.4V

(25°C / 77°F), 1 - 2h / Day

Float Voltage

13.7 (25°C / 77°F)

Equalization Voltage

14.8V (25°C / 77°F),

2h / 28 Day or V < 12.1

Temperature

Compensation

- 4mV/cell*K

Operating Temperature

Display Operating

Temperature

- 40 to 85°C / - 40 to 185°F

- 20 to 55°C / - 4 to 131°F

Humidity

99% N.C.

Protection

Battery Reverse Polarity,

Solar Array Reverse Polarity,

Over Temperature, PV Short

Circuit, Over Current

The total rated Maximum Power Current (Imp) of the PV

input should not exceed 30 Amps.

The GP-PWM-30 will limit PV current above 30 Amps.

Although the GP-PWM-30 will accept PV current greater

than 30 Amps for a short duration, damage may occur if the

GP-PWM-30 operates continuously with greater than 30

Amps of PV input.

1.2 Specifications

Solar Controller

GP-PWM-30

© 2012 Carmanah Technologies Corporation

5

September 2012

Page 6

Solar Controller

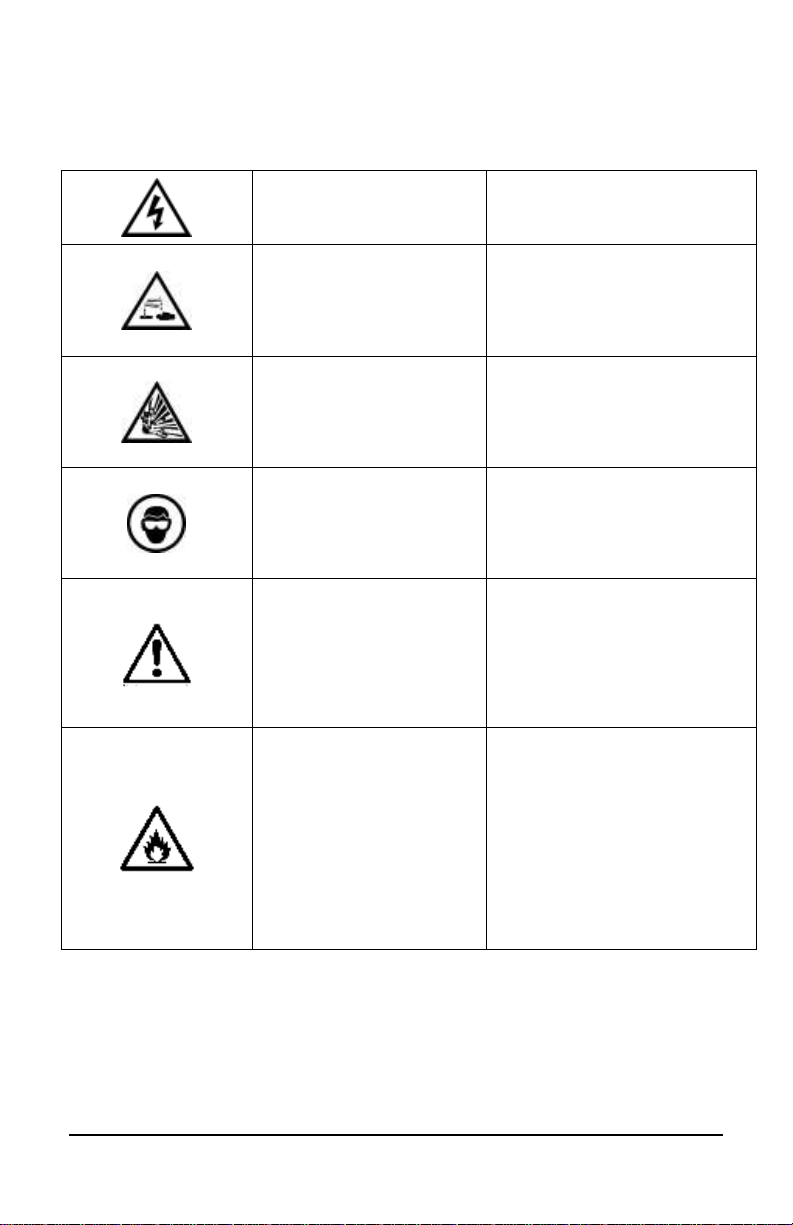

Disconnect all power

sources

Electricity can be very dangerous.

Installation should be performed

only by a licensed electrician or

qualified personnel.

Battery and wiring

safety

Observe all safety precautions of

the battery manufacturer when

handling or working around

batteries. When charging, batteries

produce hydrogen gas, which is

highly explosive.

Wiring connections

Ensure all connections are tight

and secure. Loose connections

may generate sparks and heat. Be

sure to check connections one

week after installation to ensure

they are still tight.

Work safely

Wear protective eyewear and

appropriate clothing during

installation. Use extreme caution

when working with electricity and

when handling and working around

batteries.

Observe correct

polarity

Reverse polarity of the battery

terminals will cause the controller

to give a warning tone. Reverse

connection of the array will not

cause an alarm but the controller

will not function. Failure to correct

this fault could damage the

controller.

Do not exceed the

GP-PWM-30 Amp

current and max

voltage ratings

The current rating of the solar

system is the sum of the Maximum

Power Current (Imp) of the solar

PV strings in parallel. The resulting

system Imp current is not to

exceed 30A. The voltage of the

array is the rated open circuit

voltage (Voc) of the PV array and

is not to exceed 28V. If your solar

system exceeds these ratings,

contact your dealer for a suitable

controller alternative.

______________________________________________________________________

GP-PWM-30

2.0 Warnings

6

© 2012 Carmanah Technologies Corporation

September 2012

Page 7

Solar Controller

If the GP-PWM-30 Controller was purchased with a Go

Power! RV Solar Power Kit then UV resistant wire is

included. For instructions regarding the Go Power! RV

Solar Power Kit installation, please refer to the

Installation Guide provided with the Kit.

Drill with 3/32” and 3/8 bits

UV Wire (Solar Array to

GP-PWM-30)*

Keyhole or Jigsaw

Battery Wire (GP-PWM-

30 to Battery)*

Phillips Screwdriver

Wire Cutters

Pencil or Marking Implement

Wire Strippers

Torque wrench (optional)

Electrical Tape

______________________________________________________________________

GP-PWM-30

3.0 Tools and Materials Needed

4.0 Choosing a Location

The GP-PWM-30 is designed to be mounted flush against a wall, out of

the way but easily visible.

The GP-PWM-30 should be:

mounted as close to the battery as possible.

mounted on a vertical surface to optimize cooling of the unit.

indoors, protected from the weather.

In a RV, the most common controller location is above the refrigerator.

The wire from the solar array most commonly enters the RV through the

fridge vent on the roof. PV connections should connect directly to the

controller. Positive and negative battery connections must connect

directly from the controller to the batteries. Use of a positive or negative

distribution bus is allowed between the controller and battery as long as

it is properly sized, electrically safe and an adequate wire size is

maintained.

© 2012 Carmanah Technologies Corporation

7

September 2012

Page 8

Solar Controller

50 Watt

#14 Wire Gauge

80 Watt

#12 Wire Gauge

95 Watt

#10 Wire Gauge

110 Watt

#10 Wire Gauge

125 Watt

#10 Wire Gauge

160 Watt

#10 Wire Gauge

240 Watt

#10 Wire Gauge

Terminal Screw Torque

16 inch pounds (1.8N.m)

______________________________________________________________________

GP-PWM-30

5.0 Installation Instructions

1. Prepare for mounting. Use the template provided at the end of

the manual to mark the four mounting holes and the “cutting line

for flush mounting.”

2. Complete the installation of the solar modules. If this GPPWM-30 was purchased as part of a Go Power! Solar Power Kit,

follow the Installation Guide provided. Otherwise, follow

manufacturer’s instructions for solar module mounting and

wiring.

3. Select wire type and gauge. If this GP-PWM-30 was

purchased as part of a Go Power! Solar Power Kit, appropriate

wire type, gauge, and length is provided. Please continue to

Section 6, “Operating Instructions.” If the GP-PWM-30 was

purchased separately, follow the instructions included here.

Wire type is recommended to be a stranded copper UV resistant wire.

Wire fatigue and the likelihood of a loose connection are greatly reduced

in stranded wire compared to solid wire. Wire gauge should be able to

sustain rated current as well as minimizing voltage drop.

Suggested Minimum Wire Gauge

(Cable length 25 ft max. from solar array to battery bank)

IMPORTANT: Identify the polarity (positive and negative) on the

cable used for the battery and solar module. Use colored wires or

mark the wire ends with tags. Although the GP-PWM-30 is

protected, a reverse polarity contact may damage the unit.

8

© 2012 Carmanah Technologies Corporation

September 2012

Page 9

Solar Controller

______________________________________________________________________

GP-PWM-30

4. Wiring the GP-PWM-30. Wire the GP-PWM-30 according to the

wiring schematic in Section 11. Run wires from the solar array

and the batteries to the location of the GP-PWM-30. Keep the

solar array covered with an opaque material until all wiring is

completed.

Torque all terminal screws to 16 inch pounds (1.8N.m)

Connect the battery wiring to the controller first and then connect

the battery wiring to the battery.

IMPORTANT: Always use appropriate circuit protection on any

conductor attached to a battery.

With battery power attached, the controller should power up and

display information. Connect the solar wiring to the controller and

remove the opaque material from the solar array. The negative

solar array and battery wiring must be connected directly to the

controller for proper operation. Do not connect the negative solar

array or negative battery controller wiring to the chassis of the

vehicle.

5. Mounting the GP-PWM-30. Mount the GP-PWM-30 to the wall

using the included four mounting screws.

IMPORTANT: You must set the battery type on the GP-PWM-30

before you begin to use the controller. If the battery type is not

selected, the GP-PWM-30 will only flash 3 dashes (---) on the screen

and will not operate correctly. See section 6.0 for instructions on

setting battery type.

Congratulations, your GP-PWM-30 should now be operational. If the

battery power is low and the solar array is producing power, your battery

should begin to charge.

6. Re-torque:

After 30 days of operation, re-torque all terminal screws to

ensure the wires are properly secured to the controller.

© 2012 Carmanah Technologies Corporation

September 2012

9

Page 10

Solar Controller

______________________________________________________________________

GP-PWM-30

6.0 Operating Instructions

Power Up

When the GP-PWM-30 is

connected to the battery, the

GP-PWM-30 will go into Power

Up mode.

Icons Displayed: Three

horizontal dashes

Setting the Battery Type / Charging Profile

Set the Battery Type / Charging

Profile by holding down the B

Button for 5 seconds. When the

display begins blinking you may

set the Battery Type by toggling

through the Charging Profile

numbers 1, 2 or 3 by pressing

the B Button.

10

© 2012 Carmanah Technologies Corporation

September 2012

Page 11

Solar Controller

______________________________________________________________________

GP-PWM-30

Refer to the Battery Charge

Profile Chart on the following

page for details on each

profile.

Confirm the Battery Type /

Charging Profile selection by

pressing the A Button.

Depending on the battery voltage when the GP-PWM-30 Power Up

occurs, the GP-PWM-30 may do a Boost Charge or quickly go into Float

Charge. The Charging Profile selected will commence the following day

after a Power Up.

© 2012 Carmanah Technologies Corporation

September 2012

11

Page 12

Solar Controller

Battery Type

FLOODED

AGM

GEL

Charging Profile #

1 2 3

Float Charge @ 25°C:

13.7V

Bulk/Absorption Charge @ 25°C:

Applied for 1h each morning

14.4V

14.1V

Boost Charge

Applied for 2 hours if the battery voltage drops

below 12.3 volts.

14.4V

14.1V

Equalization Charge

Applied for 2 hours every 28 days and if the

battery voltage drops below 12.1 volts.

14.8V

N/A

N/A

The Boost Charge will occur in addition to the Bulk Charge. The Equalization Charge will

occur in addition to the Boost Charge.

If a charging cycle is unable to complete in a single day, it will continue the following day.

The terms FLOODED, AGM and GEL are generic battery designations. Choose the

charging profile that works best with your battery manufacturer’s recommendations.

______________________________________________________________________

GP-PWM-30

Battery Charge Profile Chart

Auto Equalize: The GP-PWM-30 has an automatic equalize feature that

will charge and recondition your batteries once a month at a higher

voltage to ensure that any excess sulfation is removed. This feature is

recommended for Flooded batteries only. Check with your battery

manufacturer.

NOTE: This feature is only available for Charging Profile 1.

© 2012 Carmanah Technologies Corporation

September 2012

12

Page 13

Solar Controller

______________________________________________________________________

GP-PWM-30

Viewing the Controller

display information

To toggle between State of

Charge (SOC), Battery

Voltage and PV Charging

Current, press the B Button.

The battery state of charge is

shown as a percentage.

Icons Displayed: Battery,

Percent Symbol

Push the B Button to show

the battery voltage.

Icons Displayed: Battery,

Volt Symbol (V)

Push the B Button to show

the PV charging current. The

GP-PWM-30 will begin to limit the current as the battery reaches a full

charge.

Icons Displayed: Sun, Battery, Current Symbol (A)

NOTE:

Non-volatile memory: Any settings made on the GP-PWM-30 will be

saved even when the power has been disconnected from the controller.

© 2012 Carmanah Technologies Corporation

September 2012

13

Page 14

Solar Controller

______________________________________________________________________

GP-PWM-30

Errors

Over Voltage

If the GP-PWM-30 experiences

a battery over voltage (15.5V),

the controller will stop operating

and the display will begin to

flash. The controller will resume

operating when the error is

cleared.

Icons Displayed: Battery, Volt Symbol, Lightning Bolt

Low Voltage

If the GP-PWM-30 experiences

the battery state of charge

reaching zero, a lightning bolt

symbol will begin to flash in the

lower right corner of the display.

The controller will continue

operating. The controller will

only stop operating if the

voltage drops below 6 volts.

Icons Displayed: Battery, Percent Symbol, Lightning Bolt

14

© 2012 Carmanah Technologies Corporation

September 2012

Page 15

Solar Controller

______________________________________________________________________

GP-PWM-30

7.0 Frequently Asked Questions

(FAQs)

Before a problem is suspected with the system, read this section. There

are numerous events that may appear as problems but are in fact

perfectly normal.

It seems like my flooded batteries are losing water over time.

Flooded batteries may need to have distilled water added periodically to

replace fluid loss during charging. Excessive water loss during a short

period of time indicates the possibility of overcharging or aging batteries.

When charging, my flooded batteries are emitting gas.

During charging, hydrogen gas is generated within the battery. The gas

bubbles stir the battery acid allowing it to receive a more full state of

charge. Ensure they are in a well ventilated space.

My voltmeter shows a different reading than the GP-PWM-30 display

The meter value on the GP-PWM-30 display is an approximate reading

intended for indication purposes only. There is an approximate 0.1 volt

inherent error present that may be accentuated when compared with

readings from another voltmeter.

There may be a slight difference between the battery voltage displayed

on the GP-PWM-30 display and the battery voltage measured at the

battery terminals. When troubleshooting using a voltmeter, check both

the battery voltage at the GP-PWM-30 battery terminals and battery

voltage at the battery terminals. If a difference of more than 0.5 volts is

noted, this indicates a large voltage drop possibly caused by loose

connections, long wire runs, small wire gauge, faulty wiring, a faulty

voltmeter or all the above. Consult the Suggested Minimum Wire Gauge

chart in Section 5 for wiring suggestions and check all connections.

15

© 2012 Carmanah Technologies Corporation

September 2012

Page 16

Solar Controller

______________________________________________________________________

GP-PWM-30

8.0 Troubleshooting Problems

How to read this section

Troubleshooting Problems is split into three sub-sections, grouped by

symptoms involving key components. Components considered irrelevant

in a diagnosis are denoted ‘Not Applicable’ (N/A). A multimeter or

voltmeter may be required for some procedures listed.

It is imperative all electrical precautions stated in the Warning Section

and outlined in the Installation Section are followed. Even if it appears

the system is not functioning, it should be treated as a fully functioning

system generating live power.

8.1 Problems with the Display

Display Reading: Blank

Time of Day: Daytime/Nighttime

Possible Cause:

(1) Battery or fuse connection and/or solar array connection (Daytime only).

(2) Battery or fuse connection (Nighttime only).

How to tell:

(1) & (2) Check the voltage at the controller battery terminals with a voltmeter and compare

with a voltage reading at the battery terminals.

If there is no voltage reading at the controller battery terminals, the problem is in the wiring

between the battery and the controller. If the battery voltage is lower than 6 volts the

controller will not function.

For the solar array, repeat steps 1 and 2 substituting all battery terminals with solar array

terminals.

Remedy:

(1) & (2) Check all connections from the controller to the battery including checking for

correct wire polarity. Check that all connections are clean, tight, and secure. Ensure the

battery voltage is above 6 volts.

16

© 2012 Carmanah Technologies Corporation

September 2012

Page 17

Solar Controller

______________________________________________________________________

GP-PWM-30

8.2 Problems with Voltage

Voltage Reading: Inaccurate

Time of Day: Daytime/Nighttime

Possible Cause:

(1) Excessive voltage drop from batteries to controller due to loose connections, small wire

gauge or both.

How to tell:

(1) Check the voltage at the controller battery terminals with a voltmeter and compare with

the voltage reading at the battery terminals. If there is a voltage discrepancy of more

than 0.5 V, there is an excessive voltage drop.

Remedy:

(1) Check all connections from the controller to the battery including checking for correct

wire polarity. Check that all connections are clean, tight, and secure. Shorten the

distance from the controller to battery or obtain larger gauge wire. It is also possible to

double up the existing gauge wire (i.e. two wire runs) to simulate a larger gauge wire.

8.3 Problems with Current

Current Reading: 0 A

Time of Day: Daytime, clear sunny skies

Possible Cause:

(1) Current is being limited below 1 Amp as per normal operation.

(2) Poor connection between solar array and controller.

How to tell:

(1) The State of Charge (SOC) screen is close to 100% and the Sun and Battery icon are

present with an arrow between.

(2) With the solar array in sunlight, check the voltage at the controller solar array terminals

with a voltmeter. If there is no reading at the controller solar array terminals, the

problem is somewhere in the wiring from the solar array to the controller.

Remedy:

(2) Check all connections from the controller to the array including checking for correct wire

polarity. Check that all connections are clean, tight, and secure.

Continue with the solutions below for additional help on low current readings.

17

© 2012 Carmanah Technologies Corporation

September 2012

Page 18

Solar Controller

______________________________________________________________________

GP-PWM-30

Current Reading: Less than expected

Time of Day: Daytime, clear sunny skies

Possible Cause:

(1) Current is being limited below 1 Amp as per normal operation.

(2) Incorrect series/parallel configuration and/or wiring connections and/or wire gauge.

(3) Dirty or shaded module or lack of sun.

(4) Blown diode in solar module when two or more modules are connected in parallel.

How to tell:

(1) Battery State of Charge screen is close to 100% and the Sun and Battery icon are

present with an arrow in between.

(2) Check that the modules and batteries are configured correctly. Check all wiring

connections.

(3) Modules look dirty, overhead object is shading modules or it is an overcast day in which

a shadow cannot be cast. Note: Avoid any shading no matter how small. An object as

small as a broomstick held across the solar module may cause the power output to be

cut to almost nil. Overcast days may also cut the power output of the module to

almost nil.

(4) Disconnect one or both array wires from the controller. Take a voltage reading between

the positive and negative array wire. A single 12 volt module should have an open

circuit voltage between 17 and 22 volts. If you have more than one solar module, you

will need to conduct this test between the positive and negative terminals of each

module junction box with either the positive or negative wires disconnected from the

terminal.

Remedy:

(2) Reconnect in correct configuration. Tighten all connections. Check wire gauge and

length of wire run. Refer to Suggested Minimum Wire Gauge in Section 5.

(3) Clean modules, clear obstruction or wait for conditions to clear.

(4) If the open circuit voltage of a non-connected 12 volt module is lower than the

manufacturer’s specifications, the module may be faulty. Check for blown diodes in

the solar module junction box, which may be shorting the power output of module.

18

© 2012 Carmanah Technologies Corporation

September 2012

Page 19

Solar Controller

______________________________________________________________________

GP-PWM-30

9.0 Limited Warranty

1. Carmanah warrants the GP-PWM-30 for a period of five (5)

years from the date of shipment from its factory. This warranty is

valid against defects in materials and workmanship for the five

(5) year warranty period. It is not valid against defects resulting

from, but not limited to:

Misuse and/or abuse, neglect or accident

Exceeding the unit’s design limits

Improper installation, including, but not limited to, improper

environmental protection and improper hook-up

Acts of God, including lightning, floods, earthquakes, fire,

and high winds

Damage in handling, including damage encountered during

shipment

2. This warranty shall be considered void if the warranted product is

in any way opened or altered. The warranty will be void if any

eyelet, rivets, or other fasteners used to seal the unit are

removed or altered, or if the unit’s serial number is in any way

removed, altered, replaced, defaced, or rendered illegible.

9.1 Repair and Return Information

Visit www.gpelectric.com to read the “frequently asked questions” section of

our website to troubleshoot the problem. If trouble persists:

1. Call your Go Power!™ Technical Support team (1-866-247-6527).

2. Return defective product to place of purchase

© 2012 Carmanah Technologies Corporation

September 2012

19

Page 20

Solar Controller

______________________________________________________________________

GP-PWM-30

10.0 Glossary

Ampere: A unit of electrical current. Designates the number of electrons flowing per

second through a conductive material.

Array: One or more photovoltaic (PV) modules electrically connected to produce a single

electrical output.

Battery: Two or more electrochemical cells connected to provide energy storage.

May be used to designate one cell. PV system batteries may be “sealed” or “wet acid”.

Charge Controller: The PV system component that controls the battery’s state of charge.

It may also provide other system control functions. Also referred to as a controller.

Charge Rate: The current applied to a battery to restore its energy capacity. The battery

manufacturer will usually have a recommended charge rate for their product. The rate is

typically 10 –20 percent of the amp hour capacity at the 20-hour rate.

Current: DC or Direct Current is the type of electron flow provided by a battery or solar

cell, which flows in one direction. The unit for current is ampere or amp for short and

designated by the letter A.

Deep Cycle Battery: Batteries that are designed to discharge as much as 80% of their

capacity as opposed to engine-starting or “shallow cycle” batteries which are designed for

heavy cranking but will not stand up to repeated deep discharges.

Equalization: The process that equalizes the specific gravity of all the cells in a battery by

means of a controlled overcharge that breaks down sulfation on the battery plates. Most

inverter/chargers and some charge controllers are equipped with this feature.

Maximum Power: Also referred to as peak power. The point of a solar array, panel or

module output where the product of “Imp” and “Vmp” (“Pmax”, measured in watts) is

maximized. The points used to calculate Pmax are Imp (current @ max power) and Vmp

(voltage @ max power).

Solar Module: A number of solar cells electrically connected, and protected from the

environment usually by an aluminum frame covered with a pane of glass. A module is selfcontained and not sub dividable, therefore providing a single electrical output.

Open-Circuit Voltage (Voc): Refers to a photovoltaic device’s voltage potential when it is

disconnected from the rest of the PV system.

Parallel Connection: Electrical connection where the positive terminals of a number of

devices are connected together, as are their negative terminals. The output voltage is

usually limited to the device with the lowest voltage, and the total current is the sum of the

current of all the devices.

Photovoltaic (PV): Capable of producing a voltage when exposed to radiant energy,

especially light.

Sealed Batteries: Electrolyte will not spill out and gassing is kept to a minimum. A sealed

battery is maintenance free and may be installed in several orientations. GEL and AGM are

two common types of sealed batteries.

20

© 2012 Carmanah Technologies Corporation

September 2012

Page 21

Solar Controller

______________________________________________________________________

Series Connection: Electrical connection where the positive terminal of one device is

attached to the negative terminal of the next in a series string; in this connection, the string

voltage is the sum of the device voltages and the string current is limited to the current of

the least productive device in the string.

Short-Circuit Current (Isc): Refers to a photovoltaic device’s current output when the

positive terminal is directly connected to the negative terminal.

State of Charge (SOC): The percentage of energy in a battery referenced to its nominal

full capacity.

Sulfation: The formation of lead sulfate crystals on the plates of a lead-acid battery.

Normally used to refer to large sulfate crystals, rather than small crystals formed in normal

battery operation. The plates of a battery will sulfate if left in a partially charged state,

causing reduced battery capacity and shortening the life of the battery. If caught in time,

equalization will remove the buildup of sulfation.

Voltage: The electrical potential between two points. Voltage is analogous to water

pressure in that it pushes the electrons or current through a conductor. The unit for voltage

is volt and designated by the letter V.

Wet Acid or Flooded Batteries: The most common type of PV battery. Battery caps may

be removed to expose the electrolyte liquid inside the battery. Need proper ventilation due

to gassing and may need to be topped up with distilled water at regular intervals.

GP-PWM-30

11.0 Installation Template

(see next page)

Please see supplement page (attached)

21

© 2012 Carmanah Technologies Corporation

September 2012

Page 22

Solar Controller

______________________________________________________________________

GP-PWM-30

22

© 2012 Carmanah Technologies Corporation

September 2012

Page 23

Solar Controller

______________________________________________________________________

GP-PWM-30

12.0 Wiring Diagram

23

© 2012 Carmanah Technologies Corporation

September 2012

Page 24

© 2012 GO POWER!™ By Carmanah Technologies

MOBI_MAN_GP-PWM-30_vB

www.gpelectric.com

Loading...

Loading...