Page 1

http://www.

goepel.com

Desktop Transceiver

SFX-TAP4/C

SFX-TAP2/C

Technical Description

Version 0.1

Intelligent Boundary Scan Solutions®

GÖPEL electronic GmbH

Göschwitzer Str. 58/60

D-07745 Jena

Tel.: +49-3641-6896-0

Fax: +49-3641-6896-44

E-Mail: support@goepel.com

Page 2

© 2005 GOEPEL electronic GmbH. All rights reserved.

The software described in this manual as well as the manual itself are supplied under

license and may be used or copied only in accordance with the terms of the license.

The customer may make one copy of the software for safety purposes.

The content of the manual is subject to change without notice and is supplied for

information only.

In case of inaccuracies or errors appearing in this manual,

GOEPEL electronic GmbH assumes no liability or responsibility.

Without the prior written permission of GOEPEL electronic GmbH, no part of this

documentation may be transmitted, reproduced or stored in a retrieval system in

any form or by any means as well as translated into other languages (except as

permitted by the license).

printed: 02.08.2005

Rev.: 07/05

Author: Dietmar Beltz

Page 3

Table of Contents

1 Definition ........................................................................................................................ 5

1.1 Versions of the Desktop Transceiver...................................................................... 5

1.2 Scope of Delivery.................................................................................................... 6

2 Technical Data ............................................................................................................... 6

2.1 General Information ................................................................................................ 6

2.2 Dimensions ............................................................................................................. 6

2.3 Characteristics ........................................................................................................ 6

2.4 ESD / Latch up Strength ......................................................................................... 7

2.5 Current Input ........................................................................................................... 7

3 Device Structure............................................................................................................. 7

3.1 Interfaces ................................................................................................................ 7

3.2 Structure of the Desktop Transceivers SFX-TAP4/C (SFX-TAP2/C) ..................... 7

3.3 AUX Connector ....................................................................................................... 8

3.4 PwrCtrl Connector .................................................................................................. 8

3.5 TAP/PIP Connector ................................................................................................ 8

4 Hardware Components .................................................................................................. 9

4.1 Voltage Supply........................................................................................................ 9

4.2 PIP Complex ........................................................................................................... 9

4.3 Analog IO Signals ................................................................................................... 9

4.4 Digital IO Signals .................................................................................................... 9

4.5 Trigger Signals...................................................................................................... 10

4.6 Output Voltages .................................................................................................... 11

4.6.1 Output Voltages on TAP/PIP Connector: ...................................................... 11

4.6.2 Switch for the function of the PwrCtrl Connector:.......................................... 11

4.7 Boundary Scan Interface ...................................................................................... 12

4.8 Output Driver......................................................................................................... 12

4.8.1 Absolute Maximum Ratings........................................................................... 12

4.8.2 Recommended Operating Conditions ........................................................... 13

4.8.3 Electrical Characteristics ............................................................................... 13

4.9 Input Stage............................................................................................................ 15

5 Software Settings of the Testbus Interface.................................................................. 15

5.1 TCK Frequency..................................................................................................... 15

5.2 TAP Specific Settings ........................................................................................... 17

5.2.1 TIC Type........................................................................................................ 21

5.2.2 Output Voltage............................................................................................... 21

5.2.3 Input Voltage ................................................................................................. 21

5.2.4 Inline Resistor................................................................................................ 22

5.2.5 Pull Down Resistor ........................................................................................ 22

5.2.6 Power Relays ................................................................................................ 22

5.2.7 ADYCS II™.................................................................................................... 22

5.2.8 Testbus Signals on TAP/PIP User Interface ................................................. 25

5.2.9 SCP Controller............................................................................................... 25

6 Appendix ...................................................................................................................... 26

6.1 TAP/PIP : User Interface SFX-TAP4/C ................................................................ 26

6.2 TAP/PIP : User Interface SFX-TAP2/C ................................................................ 27

7 Order Information ......................................................................................................... 28

8 References................................................................................................................... 28

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 3

Page 4

Page 5

1 Definition

The Desktop Transceiver SFX-TAP4/C (SFX-TAP2/C) is a Hardware product of the company

GÖPEL electronic GmbH and belongs to the product group Boundary Scan test tools. It can

only be operated together with the „SYSTEM CASCON“ and „POLARIS“ [1] software or a

respective dynamic link library (DLL) of version 4.2.1 or higher from GÖPEL electronic.

The SFX-TAP4/C (SFX-TAP2/C) is a Desktop Transceiver. In combination Host Controller

connected via a SFX cable, it forms a highly flexible Boundary Scan test system with:

• 4 (2) independent voltage and impedance programmable TAP’s

• ADYCS™ (Active Delay Compensation)

• Fast In System Programming (ISP)

• 32 Bit PIP (Parallel Interface Port)

• Trigger Signals (C-Bus)

• SCP-TAP on SFX-TAP2/C

• 2 analog I/O

• 4 (2) Power outputs, relay-connectable

1.1 Versions of the Desktop Transceiver

There are two versions available. Despite of their identical body structure, the performance is

different:

- Desktop Transceiver SFX-TAP2/C --> Compact Transceiver with 2TAP and one SCP-TAP

- Desktop Transceiver SFX-TAP4/C --> Compact Transceiver with 4TAP

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 5

Page 6

1.2 Scope of Delivery

• SFX-TAP2/C or SFX-TAP4/C

• Power supply 5.0 V / 2.4 A

• SFX Cable

• this manual

2 Technical Data

2.1 General Information

The Desktop Transceiver SFX-TAP4/C (SFX-TAP2/C) forms together with the Host Controller a

Boundary Test System that allows versatile kind of connections the Unit-Under-Test (UUTs).

The following device properties allow maximum flexibility of the interface to the UUT:

• voltage-programmable Testbus interface in the range of 1.8V-4.5V, inputs (TDI

signals) in the range of 0V-3.0V

• 3-array impedance programming of the Testbus interface

• ADYCS™ (Active Delay Compensation)

• voltage-programmable 32 Bit Parallel Interface Port (PIP) in the range of 1.8V- 4.5V

• relay output (5V) or a logic signal at each TAP(2 or 4) on connector PwrCtrl for UUT

power control

• 2 analog I/O with 10 Bit resolution, (AD and DA converter on 2 pins of the AUX

connector)

• 3 digital I/O on AUX connector

• SFX/LS interface

• Trigger lines (2 output, 1 input) on AUX and on TAP/PIP connector

• SCP-TAP on SFX-TAP2/C

2.2 Dimensions

The Desktop Transceiver SFX-TAP4/C (SFX-TAP2/C) has following dimensions:

(L x W x H) 152 mm x 102.5 x 22 mm

2.3 Characteristics

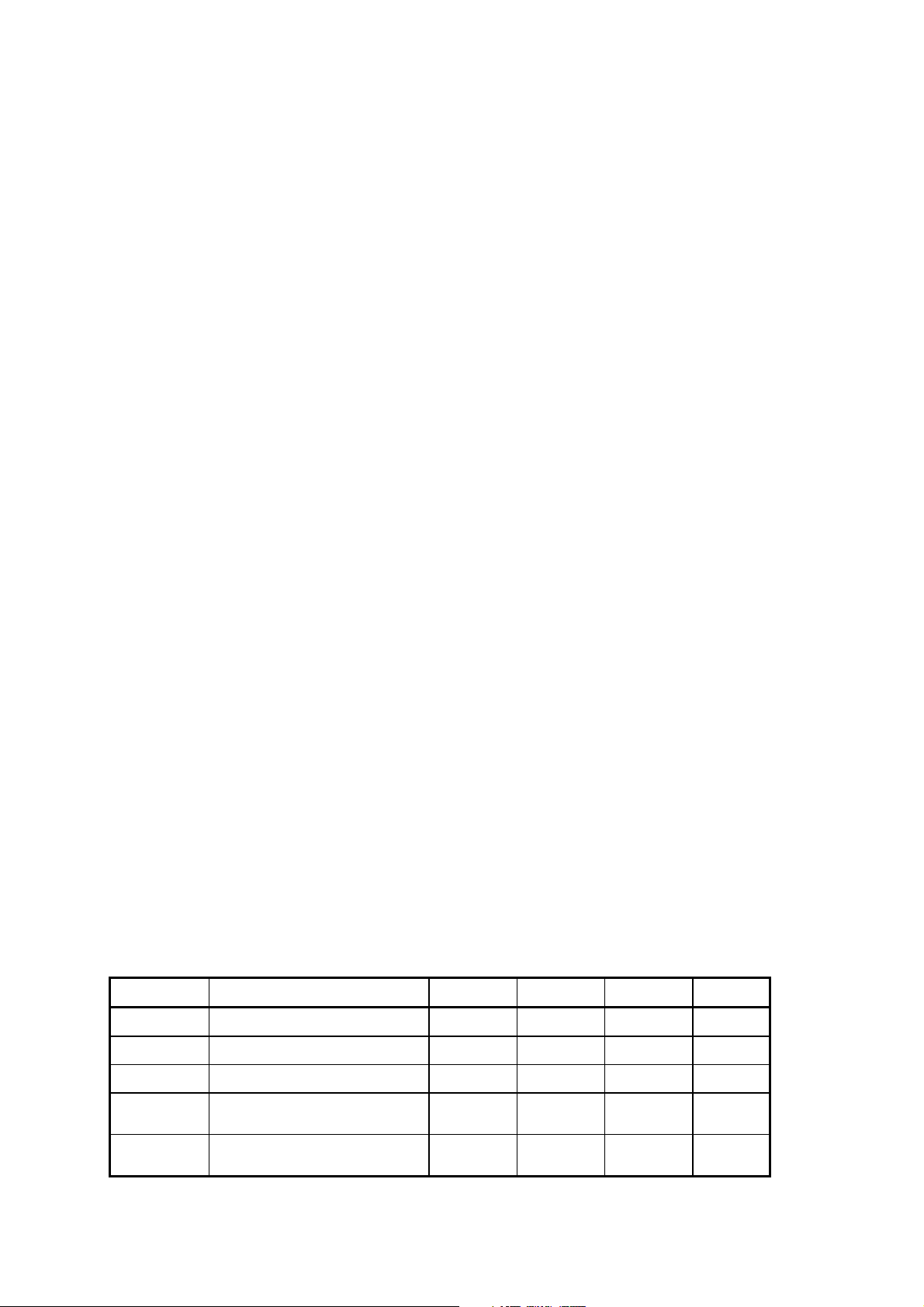

Symbol Name Min. Typical Max. Unit

VDD Operating Voltage 4.75 5.0 5.25 V

T

Storage temperature -40 125 °C

stg

Ta Operating temperature 0 35 °C

6 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Relative storage humidity, not

condensing

Relative operating humidity,

not condensing

10 90 %

20 85 %

Page 7

2.4 ESD / Latch up Strength

All pins of the output drivers have an ESD strength of >1500V and a Latch up Strength of ±100

mA.

2.5 Current Input

The quiescent current is 700 mA.

The current input during operation depends on output driver loads, clock frequency as well as

the load of the power supply pins at connector.

3 Device Structure

3.1 Interfaces

Controller interface

SFX/LS interface

Testbus IEEE 1149.1 : TAP/PIP connector (68-pole, SCSI)

Parallel I/O interface : TAP/PIP connector (68-pole, SCSI)

C-Bus interface : TAP/PIP connector (68-pole, SCSI)

2 analog I/O : AUX connector

PowerCtrl OUT : PwrCtrl connector

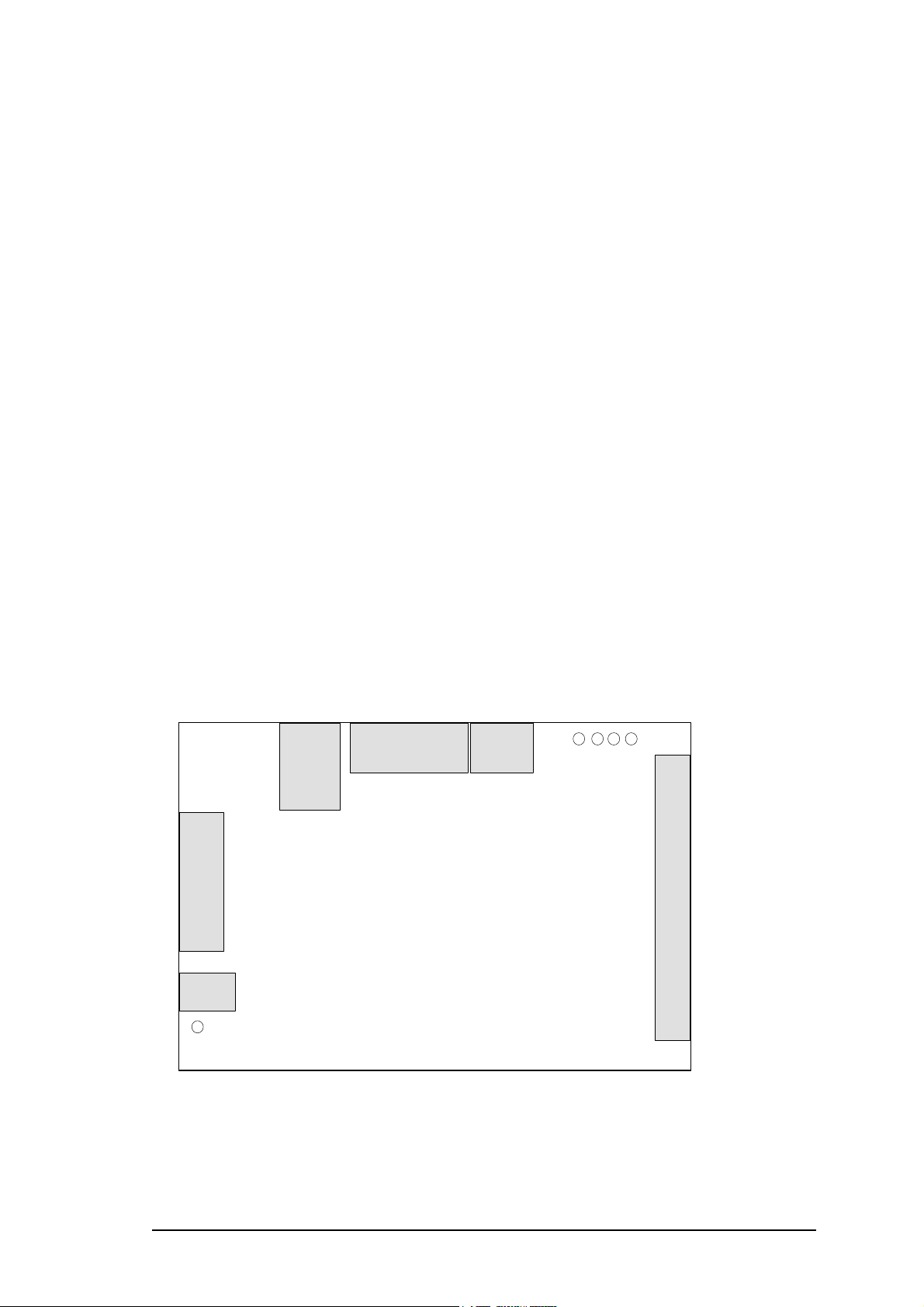

3.2 Structure of the Desktop Transceivers SFX-TAP4/C (SFX-TAP2/C)

AUX

SFX/LS

Controller

PWR

Figure 1: Assignment of the Connector and LED of the Desktop Transceiver SFX-TAP4/C (SFX-TAP2/C)

PwrCtrl

TAP1

TAP2

TAP3

TAP4

TAP/PIP

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 7

Page 8

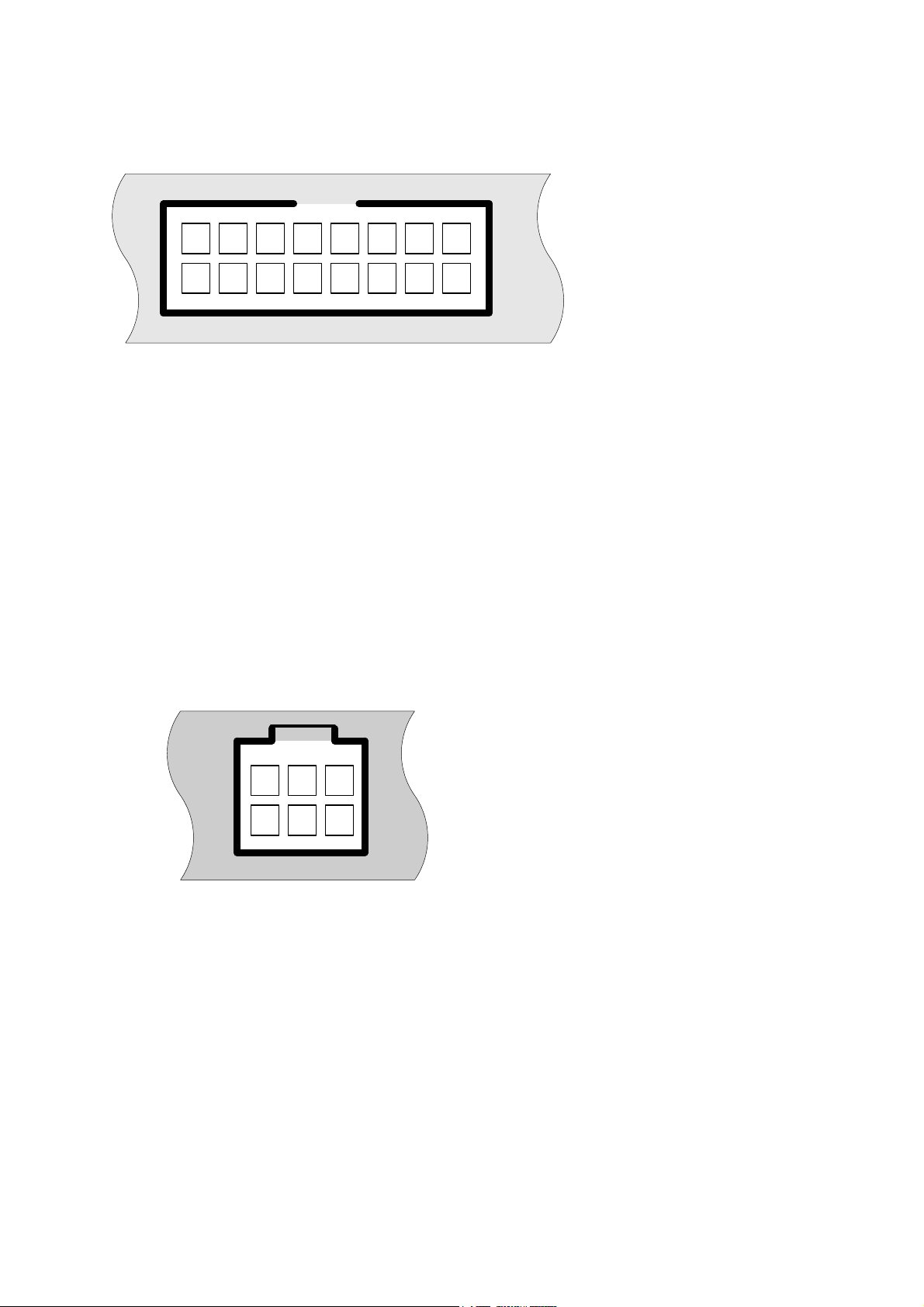

3.3 AUX Connector

35 171113 915

46 281214 1016

Figure 2: AUX connector on the side panel of the Compact Transceiver

Assignment of the AUX connector:

1 TRG0

3 TRG1

5 TRG2

7 D-AUX1

9 D-AUX2

11 D-AUX3

13 A-AUX1

15 A-AUX2

2, 4, 6, 8, 10, 12, 14, 16 GND

3.4 PwrCtrl Connector

35 1

46 2

Figure 3: PwrCtrl connector on the Side panel of the Compact Transceiver

Assignment of the PwrCtrl connector:

1 PWR1

2 PWR2

3 PWR3

4 PWR4

5 GND

6 GND

3.5 TAP/PIP Connector

For assignment see Appendix TAP/PIP – User Interface

8 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Page 9

4 Hardware Components

4.1 Voltage Supply

Die voltage supply of the Desktop Transceiver SFX-TAP4/C (SFX-TAP2/C) is obtained by using

the wall power supply. Connect it to the PWR plug of the Transceiver.

4.2 PIP Complex

Count of I/O: 32

Formatting: 4 x 8, 2 x 16

Input voltage range: 0 V – 5,0 V

Output voltage range: 1.8 – 4.5 V

For the PIP unit, there are no handshake signals available. The user must ensure a safe data

transmission.

The output driver of the PIP‘s are activatable group-wise which means 8 or 16 Bit each can be

in tristate or active mode.

The PIP complex is designed with the same driver circuitries as for TAPs. For further

information refer to chapter 4.8 and [2].

4.3 Analog IO Signals

Analog signals can be provided ore measured on pin 13 and 15 of the AUX connector. Signal

generation and Measuring are based on 10-bit converter technique. The voltage range covers 0

and 4.096 V with a maximum rating of - 0.3 to +5.0 V.

The analog output serves an inline resistor of 1 kOhms.

4.4 Digital IO Signals

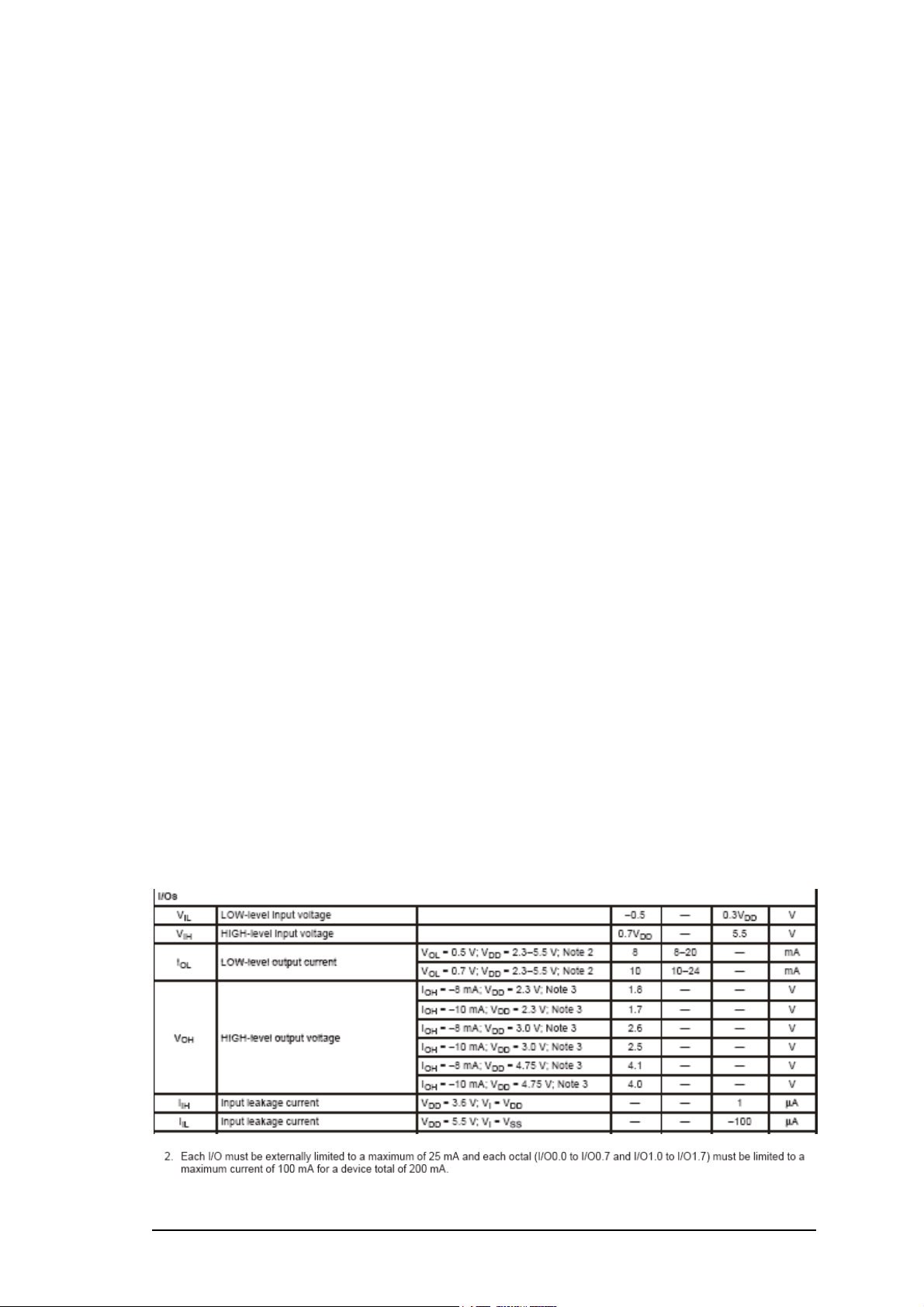

The AUX connector has 3 general purpose digital I/O signals on pins 7, 9, and 11. All of them

have a 22 Ohm in-line resistor. The connected logic IC is PCA9555. Input voltage range is -0.5

V to 6 V, following is the data sheet of that IC type.

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 9

Page 10

The output current must not exceed 25 mA. Input signals < 1.0 V will be seen as LOW, > 2.4 V

as HIGH.

Refer to PCA9555 [3] for further details to signal properties of these digital IO signals.

4.5 Trigger Signals

The signals on the pins 1, 3, and 5 of the AUX connector are trigger signals. TRG0 (pin1) and

TRG1 (pin3) are output signals and TRG2 (pin5) is an input. The voltage limits on all these pins

is -0.3 V to 5.0 V. Load current is limited to 10 mA. Signals < 0.7V are seen a LOW, voltages >

2.0V as HIGH.

Two of the 3 trigger signals are in use: TRG0 and TRG1, TRG2 is reserved.

Capture Update der Daten

TRG0

TRG1

Figure 4: Trigger signals

5

21 3 4

Lines have LVTTL level

io

H and ioL

max. 12 mA

VCC=3.3±0.3V

Symbol Parameter Min Max Unit

1 Time for early update 20 ns

2 Time for late update 20 ns

3 Time to second clock 40 ns

4 unstress clock high time 40 ns

5 Time between update and capture 40 ns

Table: Min. Timing for Trigger signals

10 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Page 11

4.6 Output Voltages

4.6.1 Output Voltages on TAP/PIP Connector:

On TAP/PIP-Connector, two voltages are provided: +5.0V (pin 68) and +3.3V (pin 1). Both are

equipped with self-restoring fuses. This means the voltages are available again after solving the

reason of a possible overcurrent. The nominal value for the fuses is 500 mA.

The pins 1 and 68 of the TAP/PIP connector are not protected against wrong

polarization! The current consumption must not exceed 100 mA.

4.6.2 Switch for the function of the PwrCtrl Connector:

Switch for function of PwrCtrl pin:

1. Switch at left position: - Default setting

Left Position

+5V

PwrCtrlConnector

Figure 5: Switch at left Position and Block Diagram

Is the switch on the left position, 5V / 50 mA is available via relay on PwrCtrl connector. The

relay is active only during the test execution. Condition is the activation of the feature Power

Relay enabled. See chapter software settings.

The pins of the PwrCtrl connector are not protected against short circuit and

wrong polarization! The maximum current consumption must not exceed 50 mA

in the “Left Position” and 50 mA in the “Right Position”.

2. Switch is in Right Position: - Change possible only after open the box.

Right Position

PwrCtrlConnector

GND

Figure 6: Switch in right Position and Block Diagram

Is the switch on the left position, an open collector transistor is activated. The maximum switch

parameters are 50 mA / 20V. The Transistor is active only during the test execution. Condition

is the activation of the feature Power Relay enabled. See chapter software settings.

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 11

Page 12

The pins of the PwrCtrl connector are not protected against short circuit and

wrong polarization! The maximum current consumption must not exceed 100

mA in the “Left Position” and 50 mA in the “Right Position”.

4.7 Boundary Scan Interface

The Desktop Transceiver SFX-TAP4/C (SFX-TAP2/C) allows Boundary Scan Test according to

the Std IEEE 1149.1.

It is not allowed to connect or disconnect the Interface Connector (TAP/PIP

SCSI 68) during power ON state. Otherwise short circuit between output

voltages and GND may happen.

It is recommended to design the Testbus signals as twisted pair with GND.

Note: Connect the TDI line(s) of the Desktop Transceiver SFX-TAP4/C (SFX-TAP2/C) with TDO

lines of the UUT(s). Connect TDO line(s) of the SFX-TAP4/C (SFX-TAP2/C) with the TDI

input(s) of the UUT.

4.8 Output Driver

The output driver for the TAPs is realized by the CION [2] chip. The voltage programming is

done by changing the supply voltage of it. The output current changes over the supply voltage,

see also data sheet [2].

4.8.1 Absolute Maximum Ratings

Supply Voltage I/O Pads (VCC Pads) -0.5V to +5.5V

DC Input Voltage I/O Pads (VI Pads) -0.5V to +5.5V

Output Voltage I/O Pads (VO Pads)

Outputs 3-Stated -0.5V to +5.5V

Outputs active -0.5V to VCC+0.5V

DC Output Source/ Sink Current

I/O Pads (IOH/IOL)

DC VCC or GND Current per Supply Pin

(ICC or GND)

Storage temperature (T

Maximum power dissipation at T

) -65°C to +100°C

STG

= 60°C

A

Table absolute maximum ratings: See [2]

±135mA

±100mA

1.2W

12 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Page 13

4.8.2 Recommended Operating Conditions

Supply Voltage I/O Pads (VCC Pads) +1.8V to +5.0V

DC Input Voltage I/O Pads (VI Pads) -0.2V to +5.0V

Output Voltage I/O Pads (VO Pads)

Outputs 3-Stated 0V to +5.0V

Outputs Active 0V to VCC+0.5V

Output Current in IOH / IOL

Vcc=5.0V

Vcc=3.3V

Vcc=2.5V

Vcc=1.8V

Free Air Operating Temperature (TA) 0°C to +70°C

Input capacity (27°C) 8pF

Output capacity (27°C) 10pF

Table Recommended Operating Conditions: See [2]

±24mA

±24mA

±12mA

±6mA

4.8.3 Electrical Characteristics

Electrical Characteristics (3.6 V < VCC ≤≤≤≤ 5.0 V) für I/O Pins

Symbol Conditions Vcc [V] Min. Max. Unit

VIH 4.0 to 5.0 2.0 V

VIL 4.0 to 5.0 0.8 V

VOH

VOH IOH=-12mA 4.0 2.4 V

VOH IOH=-18mA 5.0 2.4 V

VOH IOH=-24mA 5.0 2.4 V

VOL

VOL IOL=12mA 5.0 0.4 V

VOL IOL=18mA 5.0 0.4 V

VOL IOL=24mA 5.0 0.5 V

Table Electrical Characteristics 1: See [2]

IOH=-100µA

IOL=100µA

5.0 Vcc-0.5 V

5.0 0.2 V

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 13

Page 14

Electrical Characteristics (2.7 V < V

≤≤≤≤ 3.6 V) for I/O Pins

CC

Symbol Conditions Vcc [V] Min. Max. Unit

VIH 2.7 to 3.6 2.0 V

VIL 2.7 to 3.6 0.8 V

VOH

IOH=-100µA

2.7 to 3.6 Vcc-0.2 V

VOH IOH=-12mA 2.7 2.4 V

VOH IOH=-18mA 3.0 2.4 V

VOH IOH=-24mA 3.0 2.4 V

VOL

IOL=100µA

2.7 to 3.6 0.2 V

VOL IOL=12mA 2.7 0.4 V

VOL IOL=18mA 3.0 0.4 V

VOL IOL=24mA 3.0 0.55 V

Table Electrical Characteristics 2: See [2]

Electrical Characteristics (2.3 V ≤≤≤≤ VCC ≤≤≤≤ 2.7 V) for I/O Pins

Symbol Conditions Vcc [V] Min. Max. Unit

VIH 2.3 to 2.7 1.6 V

VIL 2.3 to 2.7 0.7 V

VOH

IOH=-100µA

2.3 to 2.7 Vcc-0.2 V

VOH IOH=-6mA 2.3 2.0 V

VOH IOH=-12mA 2.3 1.8 V

VOH IOH=-18mA 2.3 1.7 V

VOL

IOL=100µA

2.3 to 2.7 0.2 V

VOL IOL=12mA 2.3 0.4 V

VOL IOL=18mA 2.3 0.6 V

Table Electrical Characteristics 3: See [2]

Electrical Characteristics (1.8 V ≤≤≤≤ VCC < 2.3 V) for I/O Pins

Symbol Conditions Vcc [V] Min. Max. Unit

VIH 1.8 to 2.3 0.65xVCC V

VIL 1.8 to 2.3 0.35xVCC V

VOH

IOH=-100µA

1.8 to 2.3 Vcc-0.2 V

VOH IOH=-6mA 1.8 1.3 V

VOL

IOL=100µA

1.8 to 2.3 0.2 V

VOL IOL=6mA 1.8 0.3 V

Table Electrical Characteristics 4: See [2]

V

V

HIGH Level Input Voltage V

IH

HIGH Level Output Voltage V

OH

LOW Level Input Voltage

OL

LOW Level Output Voltage

OL

14 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Page 15

4.9 Input Stage

The input stage consists of a High-Speed comparator. Following operating conditions are

recommended:

VCC 5.0 V

Programmable Threshold 0.0 to 3.0 V

Max. Input Voltage Range -0.3 V to 5.5 V

5 Software Settings of the Testbus Interface

5.1 TCK Frequency

The effective test speed is defined by software access time and frequency of TCK. The TCK

frequency can be freely programmed in the range of 500 Hz ... 20/50/80 MHz. Thee maximum

TCK frequency is given by the SCANFLEX controller type.

Controller Type Max. TCK

[MHz]

A

B

C

Die TCK frequency is generated following this formula: x*(12MHz+n*0.25MHz)/2

Frequency

Range

1

2

3

4

The values of m, n, and x are regarding the set TCK frequency calculated by software SYSTEM

CASCON/ POLARIS and limited by the controller type.

The TCK frequency is set as follow:

Move the mouse cursor to OPTIONS / UUT. Select the index card Testbus. Type-in the wanted

frequency. Red colour indicates a wrong parameter.

Min.

[MHz]

50 80 0.5 2% 0 112

12.0 50.0 0.25 2% 0 0...152

6 12.0 0.125 2% 1 0...47

0.0005 6 0.25/2m 2% 2..15 0..47

20

50

80

Max.

[MHz]

Resolution

[MHz]

Tolerance Value

for m

Value

for m

m

Value

for x

2

1

1

1

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 15

Page 16

Valid parameters (black) are accepted here even in cases outside the controller

specific range as they are depending on the setting of the UUT.

All settings in this index card don’t have any impact to SCANFLEX products.

Voltages and delay values are defined in a further entry field.

Figure 7: TCK Setting

16 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Page 17

5.2 TAP Specific Settings

The system SCANFLEX supports up to 8 independent TAPs. The SFX-TAP2(4)/C supports two

or four TAPs respectively. Each TAP can be configured in its properties individually. These are

the TAP specific settings:

• Aktivierung der TAPs

• Testbus output and Input voltages

• Inline resistor for outputs

• Pull down resistor for inputs

• activation of the power relay

• ADYCS II ™ - the UUT-TCK-TDO delay

The TAP specific settings are made as follow:

First go to View / Tester Configuration. Alternatively, you may use the icon. The purpose

is to create a configuration for a given hardware constellation. In cases, no Tester

Configuration is existing yet, it must be created. For this, press Configuration in the left panel.

Press the button ‚new’ in the right panel. Type in the name of the new configuration. In this case

use SFX_TAP4. Confirm with OK.

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 17

Page 18

Figure 8: Define a new Configuration

Now select the just defined configuration.

On the right side, select SFX Contoller in the group Modul types. Press button Insert.

Figure 9: Insert Controller

Select SFX_controller in the left panel.

Press the button Auto detect on the right.

18 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Page 19

Figure 10: Auto Detection

The result of successful detection is shown in the right panel. The recognized SCANFLEX

hardware is inserted under SFX-HS (SFX-LS1 and SFX-LS2).

In our example, a SFX-TAp4 has been recognized which appears as SFX_TAP_splitter_4_1 in

the left panel. Again, select the recognized hardware and after pressing the Enable button it is

activated for the current UUT.

Figure 11: Enable der Configuration

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 19

Page 20

As a result of successful enable, you can see in the right panel a further register named Project

Parameters. There, all current parameters are displayed. They can be modified there by Edit.

Figure 12: Overview of project parameters

The TAP settings can be changed by selecting the register TAP. The next figure shows the TAP

specific parameters.

Figure 13: Entry Mask for TAP Parameter

20 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Page 21

Since in the example one SFX-TAP4 is connected with the SCANFLEX controller, four sub

registers appear in the register TAP, one per TAP. This allows TAP related definition of the

values.

Moving the mouse cursor to an entry area and waiting 1 sec, the allowed value

range is displayed. Wrong Parameters are displayed in red and automatic

limitation to minimum / maximum are set for those.

Parameters shown in figure 13 are default. They are chosen for each new

configuration. All parameters max be changed by the user.

For more information about configuration refer to SYSTEM CASCON documentation [1].

5.2.1 TIC Type

Using the scrollbar Type (see figure 13), you can select the TIC type. Type 01 must be selected

for operation.

For de-activation, select None. It removes a TAP from the configuration without deleting it from

the SFX-TAPx. For this purpose, it is switched off and no other values can be defined.

5.2.2 Output Voltage

The output voltage can be defined within following limits:

Parameter Min.

[V]

Output Voltage

The voltage entry is set in DH (see figure 13). The applicable output driver is given by the

defined voltage. More information can be found in chapter 4.8.

1.8 4.5 0.05 3.3 0.1

Max.

[V]

Resolution

[V]

Default

[V]

Accuracy

[V]

5.2.3 Input Voltage

The Input voltage is applicable within following limits:

Parameter Min.

[V]

Input voltage

The voltage entry is set in EH (see figure 13). It is a HIGH threshold. Voltages above will be

understood as logic High, otherwise Low.

0.0 3.0 0.05 1.0 0.1

Max.

[V]

Resolution

[V]

Default

[V]

Accuracy

[V]

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 21

Page 22

5.2.4 Inline Resistor

The Inline resistors are applied to all TAP outputs (TCK, TMS, TDO and /TRST) with the same

value. Following values can be selected (see figure 13):

• Tristate --> the driver stays in tristate mode during test execution

• 33Ω

• 22Ω (default)

• 15Ω

These resistors form with possibly existing resistors on the UUT voltage divider

and can affect the operation. Those cases can be compensated by increasing the

output voltage.

5.2.5 Pull Down Resistor

The Pull Down resistor affects the TDI input only. The following values can be set:

• Open --> no Pull down

• 1kΩ (default)

• 330Ω

• 220Ω

5.2.6 Power Relays

The Power Relays is activated by the Checkbox Power relay (see figure 14). With activation, all

power relays are controlled to the on-state with execution start. The following delay parameter

ensures stable relay contact position and power-up of the UUT before the test itself starts. Since

the delay time can be defined per TAP individually, the largest time determines the starting time

of the test when using more than one TAP. After finishing the test, the relays return to the off

state. For further information about Power Relays refer to chapter 4.6.

5.2.7 ADYCS II™

ADYCS™ (Active Delay Compensation) allows data transmission along the TAP cable

independent from the distance to UUT. The UUT and cable design determine the maximum

TCK frequency. The Feature ADYCS™ II is supported by all types of SCANFLEX controllers.

For correct setting, notify the time delay of the UUT. Enter the value in Delay below EH, see

figure 13. Delay corresponds to t

(∆t) is entered in the text field TCK TDO delay delta. That value is global for all TAPs.

For better understanding see the timing diagram in figure 14.

in figure 14. The inaccuracy / tolerance of the time delay

delay

22 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Page 23

T

TCK

TCK

t

delay

TDO

TDO mit ∆t

+ ∆t + ∆t- ∆t - ∆t

f

= 1 / T

TCK

Figure 14: Timing diagram for UUT TCK-TDO delay

TCK

t

delay

The delay time Delay (t

) to be entered is the elapsing time between falling TCK edge on the

delay

TAP/PIP connector of the SFX-TAP4 (SFX-TAP2) until arriving the UUT’s TDO response on the

same connector.

Note, Delay (t

) covers both, time delay of the UUT and cable.

delay

TCK TDO delay delta (∆t) is the tolerance of the time delay. The higher the wanted TCK

frequency is, the more precise ∆t has to be. The software calculates the TCK frequency

following this formula:

F

<= 1 / (4 x (∆∆∆∆t + 2 ns))

TCK

Maximum values of TCK TDO delay delta (∆t), in order to get a particular TCK frequency:

• TCK 20 MHz --> max TCK TDO delay delta = 10 ns

• TCK 30 MHz --> max TCK TDO delay delta = 6 ns

• TCK 50 MHz --> max TCK TDO delay delta = 3 ns

• TCK 80 MHz --> max TCK TDO delay delta = 1 ns

Figure 14 shows a window defined by +∆t and - ∆t. Within this window the TDO is expected.

Due to the nature of Boundary Scan a rising edge must appear only after that window. The

timing difference must be in the minimum as the window itself in order to get an independence

from the time delay.

The conclusion is: The SW has to reduce the TCK frequency depending on ∆t.

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 23

Page 24

Example:

Target frequency: 30 MHz

Tolerance: 8 ns

Software setting: 25 MHz (1 / (4 x (8 ns + 2 ns)) = 25 MHz)

The typical time delay value fort he cable is about 5 ns / m. Multiply this by to

because of the to and from signal propagation.

Example 1:

Hardware configuration: Scan Trainer II (GOEPEL) as UUT plus 50 cm flat cable to controller:

Cable delay + UUT delay = 2 x 2.5 ns + 10 ns = 15 ns

The UUT delay was theoretically calculated and proved by measuring: 10 ns.

Note: Measure the UUT delay:

- set the TCK frequency <= 1 MHz in SYSTEM CASCON

- scope channel 1 to TDO of the UUT

- scope channel 2 to TCK of the UUT

- trigger the scope with channel 1 (no matter which edge)

The t

is the time between falling edege of the TCK and a change of TDO

delay

TCK

t

delay

TDO

Figure 15: Measure the UUT TCK-TDO delay

24 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Page 25

5.2.8 Testbus Signals on TAP/PIP User Interface

All Testbus signals are provided on the connector TAP/PIP (SCSI68) (see TAP/PIP User

interface).

5.2.9 SCP Controller

The Desktop Transceiver SFX-TAP2/C allows the control of „SCP Modules“. These modules

typically provide additional BScan test resources in order to increase the test coverage of a

board. Typical application is testing through edge connectors.

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 25

Page 26

6 Appendix

6.1 TAP/PIP : User Interface SFX-TAP4/C

GND

PIP 4.6

PIP 4.4

PIP 4.2

PIP 4.0

PIP 3.6

PIP 3.4

PIP 3.2

PIP 3.0

GND

PIP 2.6

PIP 2.4

PIP 2.2

PIP 2.0

PIP 1.6

PIP 1.4

PIP 1.2

PIP 1.0

D-AUX3

TRG0

TRG1

RSV

TDI3

TCK3

GND

TDI4

TDI2

TCK2

GND

TCK4

TDI1

TCK1

/TRST

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

9

8

7

6

5

3

2

1+ 3.3V

43

42

41

40

39

38

37

36

35

+ 5.0V

PIP 4.7

PIP 4.5

PIP 4.3

PIP 4.1

PIP 3.7

PIP 3.5

PIP 3.3

PIP 3.1

GND

PIP 2.7

PIP 2.5

PIP 2.3

PIP 2.1

PIP 1.7

PIP 1.5

PIP 1.3

PIP 1.1

GND

GND

GND

GND

GND

TDO3

TMS3

D-AUX2

D-AUX1

TDO2

TMS2

TDO4

TMS44

TDO1

TMS1

GND

Figure 16: Pin assignment User Interface TAP/PIP connector for SFX-TAP4/C

26 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Page 27

6.2 TAP/PIP : User Interface SFX-TAP2/C

GND

PIP 4.6

PIP 4.4

PIP 4.2

PIP 4.0

PIP 3.6

PIP 3.4

PIP 3.2

PIP 3.0

GND

PIP 2.6

PIP 2.4

PIP 2.2

PIP 2.0

PIP 1.6

PIP 1.4

PIP 1.2

PIP 1.0

D-AUX3

TRG0

TRG1

RSV

SCP-TDI

SCP-TCK

GND

RSV

TDI2

TCK2

GND

RSV

TDI1

TCK1

/TRST

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

9

8

7

6

5

3

2

1+ 3.3V

43

42

41

40

39

38

37

36

35

+ 5.0V

PIP 4.7

PIP 4.5

PIP 4.3

PIP 4.1

PIP 3.7

PIP 3.5

PIP 3.3

PIP 3.1

GND

PIP 2.7

PIP 2.5

PIP 2.3

PIP 2.1

PIP 1.7

PIP 1.5

PIP 1.3

PIP 1.1

GND

GND

GND

GND

GND

SCP-TDO

SCP-TMS

D-AUX2

D-AUX1

TDO2

TMS2

RSV

RSV4

TDO1

TMS1

GND

Figure 17: Pin assignment User Interface TAP/PIP connector for SFX-TAP2/C

Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description 27

Page 28

7 Order Information

Desktop Transceiver SFX-TAP4/C STT-010

Desktop Transceiver SFX-TAP2/C STT-011

8 References

[1] - User Manual „SYSTEM CASCON“, GÖPEL electronic GmbH - 2005

[2] - CION: Configurable I/O Network, V1.4, Data Sheet GOEPEL electronic GmbH 2002

[3]..- PCA9555 Product data sheet, Supersedes the data of 2004 Jul 27, Philips

Semiconductors, 2004 Sep 30

28 Desktop Transceiver SFX-TAP4_2/C, V0.1, Technical Description

Loading...

Loading...