Page 1

Digital oil control valve

Instruction Manual

WARNING:

Read carefully and understand all INSTRUCTIONS before operating. Failure to follow the safety

rules and other basic safety precautions may result in serious personal injury.

Save these instructions in a safe place and on hand so that they can be read when required.

Keep these instructions to assist in future servicing.

REV 12/05/16

Page 2

GENERAL SAFETY REGULATIONS

WARNING: The warnings, cautions, and instructions

discussed in this instruction manual cannot cover all

possible conditions or situations that could occur. It

must be understood by the operator that common

sense and caution are factors that cannot be built into

this product, but must be supplied by the operator.

1. Keep the work area clean and dry. Damp or wet work areas can result in

injury.

2. Keep children away from work area. Do not allow children to handle this

product.

3. Use the right tool for the job. Do not attempt to force small equipment to do

the work of larger industrial equipment. There are certain applications for

which this equipment was designed. It will do the job better and more safely

at the capacity for which it was intended. Do not modify this equipment, and

do not use this equipment for a purpose for which it Was not intended.

4. Check for damaged parts. Before using this product, carefully check that it

will operate properly and perform its intended function. Check for damaged

parts and any other conditions that may affect the operation of this product.

Replace damaged or worn parts immediately.

5. Do not overreach. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etc.

6. DO NOT use the equipment when tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating this

equipment may result in serious personal injury

Page 3

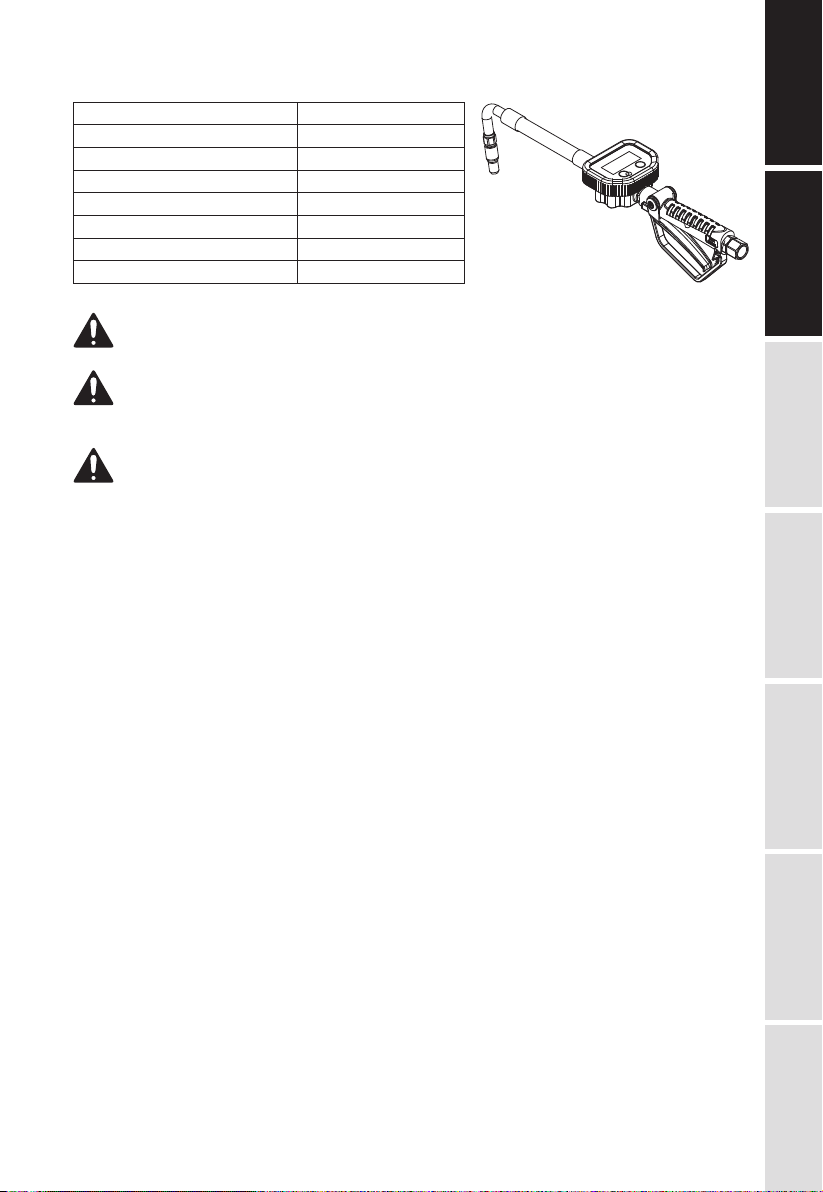

TECHNICAL DETAILS

Item No.

Inlet

Configure

Flow Rate

Operating Pressure Range

Max Operation Temperature

Accuracy

Battery

This manual contains important warnings and information.

Read and keep for reference.

Warning Symbol

This symbol alerts you to the possibility of serious injury or death if you do not follow the

instructions.

Caution Symbol

This symbol alerts you to the possibility of damage to or destruction of

equipment if you do not follow the instructions.

18123521G

1/2” BSP / NPT

Flexible nozzle, auto tip

1-35L/min / 0.3~9.2gpm

0.5-100bar / 7-1500psi

60°C / 140°F

±0.5%

ER14250 3.6V

SAFETY PRECAUTIONS

EQUIPMENT MISUSE HAZARD

1. This equipment is for professional use only.

2. Read all instruction manuals, tags, and labels before operating the equipment.

3. Use the equipment only for its intended purpose. If you are not sure, call your distributor.

4. Do not alter or modify this equipment.

5. Check equipment daily. Repair or replace worn or damaged parts immediately.

6. Do not exceed the maximum working pressure of the lowest rated system component. This

equipment has a 1500psi (10Mpa, 100bar) maximum working pressure.

7. Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

8. Route hose away from traffic areas, sharp edges, moving parts, and hot surfaces.

9. Do not lift pressurized equipment.

10. Comply with all application local, state, and national fire, electrical, and safety regulations.

INJECTION HAZARD

Spray from the valve, leaks or ruptured components can inject fluid into your body and cause

extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on

the skin can also cause serious injury.

1. Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate

medical attention.

2. Do not point the valve at anyone or at any part of the body.

3. Do not put your hand or fingers over the grease fitting coupler.

4. Do not stop or deflect leaks with your hand, body, glove or rag.

5. Tighten all fluid connections before operating the equipment.

6. Check the hose, tubes, and couplings daily. Replace worn or damaged parts immediately.

Do not repair high pressure couplings; you must replace the entire hose.

DETAILS

TECHNICAL

SAFETY

PRECAUTIONS

INSTALLATIONOPERATION

TROUBLE

SHOOTING GUIDE

LIMITED

WARRANTY

E1

EXPLODED AND

PARTS LIST

Page 4

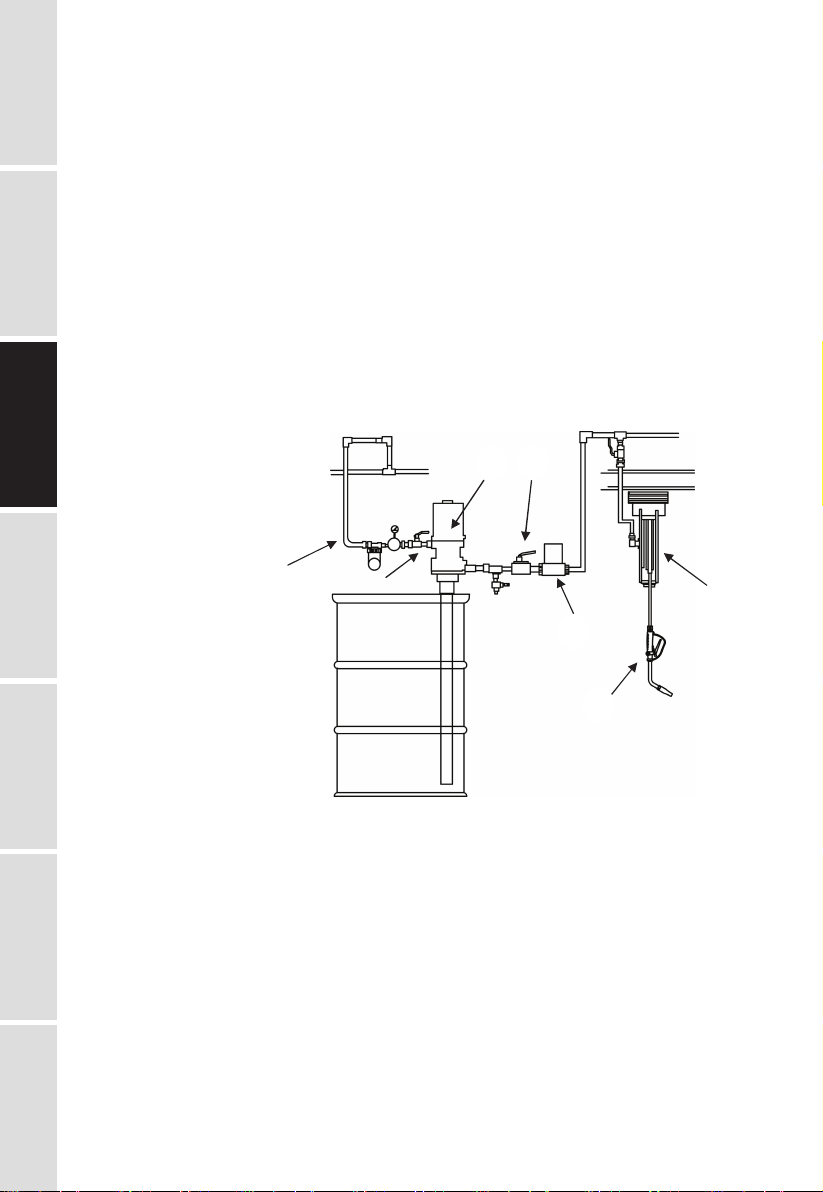

INSTALLATION

7

Typical Installation

DETAILS

Fig. 1 shows a typical installation.

TECHNICAL

The installation shown in Fig. 1 is only a guide. The components shown are typical; however, it

is not a complete system design. Contact your distributor for assistance in designing a system

to suit your particular needs.

Pre-Installation Procedure

1. Relieve the pressure.

To reduce the risk of serious injury whenever you are instructed to relieve pressure, always

SAFETY

follow the pressure relief procedure on page 3.

1. Close the fluid shut-off valve (Item 4 in Fig.1)

PRECAUTIONS

2. Ground the hose and reel or console. Do not use PTFE tape on the pipe joints; it may cause

a loss of ground across the pipe joint.

Installation Procedure

If this is a new installation, or if the oil in the lines is contaminated, flush the lines before you

install the dispense valve.

1: Air inlet

2: Air shut-off valve

INSTALLATIONOPERATION

3: Oil pump

4: Fluid shut-off valve

5: Meter

6: Hose reel

7: Control valve

TROUBLE

SHOOTING GUIDE

NEW INSTALLATION

1. Relieve the pressure

To reduce the risk of serious injury whenever you are instructed to relieve pressure, always

follow the pressure relief procedure on page 3.

2. Close the fluid shut-off valve at each dispense position.

3. Make sure the main fluid outlet valve at the pump is closed, the air pressure to the pump

LIMITED

EXPLODED AND

motor is adjusted, and the air valve is open. Slowly open main fluid valve.

4. Place the hose end (with no dispense valve connected) into a container for waste oil. Secure

WARRANTY

the hose in the container so it will not come out during flushing. If you have multiple dispense

positions, first flush the dispense position farthest from the pump, and work your way toward

the pump.

5. Slowly open the shut-off valve at the dispense position. Flush out a sufficient amount of oil to

ensure that the entire system is clean, and close the valve.

6. Repeat step 5 at all other dispense positions.

E2

PARTS LIST

Fig. 1

Page 5

1: Trigger

1

2: Nozzle

3: Tip

4: Swivel nut

Fig. 2

Remark: If you want to adjust the angle of the nozzle, you can loose the #4 swivel nut, then

turn thenozzle to your desired position and tighten the nut.

Existing Installation

1. Relieve the pressure

To reduce the risk of serious injury whenever you are instructed to relieve pressure, always

follow the pressure relief procedure on page 3.

2. Loosen and disconnect the hose from the old dispense valve (the one that you are replacing)

3. Thread the extension into the outlet of the dispense valve, and tighten firmly. NOTE: Do not

over tighten the extension tube assembly by using the nozzle adapter to hand turn the

nozzle. For rigid extensions, thread the extension in at least three full turns, position the

extension for proper alignment, and tighten the sealing nut. The PTFE seal on the sealing

nut must face the valve housing.

4. Apply thread sealant to the male threads of the hose fitting, thread the hose fitting into the

swivel, and tighten firmly.

5. Thread the new nozzle or nozzle adapter onto the extension, and tighten firmly.

6. Open all dispense position shut-off valves, and start the pump to pressurize the system. See

the Operation section for proper operation.

7. For metered dispense valves, to ensure dispensing accuracy, purge all air from the fluid

lines and dispense valves before you use them.

Grounding

Proper grounding is an essential part of maintaining a safe system.

To reduce the risk of static sparking, ground all system components per local and national

electrical codes.

Refer to the user manuals for the pump and other system components to ground the following:

- Pump: Follow manufacture’s recommendations.

- Air and Fluid hoses: Use only grounded hoses.

- Air compressor: Follow manufacture’s recommendations

- Fluid supply container: Follow your local code.

- To maintain grounding continuity when flushing or relieving pressure, always hold a metal part

of the valve firmly to the side of a grounded metal pail, then trigger the valve.

DETAILS

TECHNICAL

SAFETY

PRECAUTIONS

INSTALLATIONOPERATION

TROUBLE

SHOOTING GUIDE

OPERATION

CAUTION

- Never operate the meter with the plastic cover removed. The cover protects the meter from

damage due to impact. Meters are factory sealed to keep moisture and dirt out.

- To prevent line contamination, which can cause equipment malfunction or damaged, flush the

lines before you install this equipment in the system.

LIMITED

E3

EXPLODED AND

WARRANTY

PARTS LIST

Page 6

Display and Button Usage

DETAILS

TECHNICAL

AREA 1: FOR LAST DISPENSE CYCLE AREA 2: FOR MEASUREMENT UNITS

AREA 4: FOR BATTERY

AREA 3: FOR ACCUMULATED

TOTAL

CAPACITY

Notes: It will flashing when

battery voltage less than 3.3V;

SAFETY

PRECAUTIONS

Menu: MOVING THE NUMBERS FOR

ADJUSTING THE CALIBRATION AND

CHOOSING THE UNITS

Reset: CHOOSING THE UNITS AND SETTING

CORRECTION FACTOR

To Activate the Digital Display

Press the RESET key pad to clear the meter before starting a new dispense cycle. This is the

best way to activate the meter, because it also clears the quantity of the last dispense cycle.

The digital display can also be activated by pressing the MENU key pad or by running fluid

through the meter.

INSTALLATIONOPERATION

Calibrating Automatically

- Press Reset key for 1 second and Area 1 shows .000 L;

- Keep running fluid through the meter until the fluid running out of the certain measuring

cylinder. The display will show certain value as *.**L, press the Menu key for 3 seconds. The

meter will enter instrument calibration mode and Area 1 shows 00*.**L;

- Press Menu key to move the flashing digital, press Reset key to choose number, enter the

fluid volume and press Menu key again for 3 seconds, then exit the calibration mode. The

calibration settled

Show Current Correction Factor

- Press Menu key and Reset key together. The display will show the correction factor, which

can be reset

Reset The Resettlement Total

- Press Menu key for 10 seconds, the accumulated total will be reset to be “0”

TROUBLE

To Change the Measurement Units (L / GAL/ PT / QT meter only)

- Move the flashing display to Area 2 by pressing Menu key, then press Menu key to choose

SHOOTING GUIDE

measurement unit

- Press Menu key over 3 seconds to exit the setting mode

CAUTION

- To be sure the proper amount of fluid is dispensed, always use the same measurement unit

for a particular fluid. Units should be changed only by authorized employees.

- To Verify the Accuracy of an Digital Meter

LIMITED

WARRANTY

- Use a clean, calibrated container. If using a single container, be sure to clean it after each

dispense.

- Have pump air pressure at the lowest possible setting for dispensing fluid.

- Put the tip of the nozzle at the bottom of the calibrated container.

- If the tip of the dispense valve does not reach the bottom of the calibrated container, use a

length of plastic tubing over the tip of the nozzle to ensure liquid enters the container from the

bottom.

E4

PARTS LIST

EXPLODED AND

Page 7

- Trigger the gun slowly so the fluid immediately covers the tip of the dispense valve.

Pressure Relief Procedure

Pressurized Equipment Hazard

The equipment stays pressurized Fluid under high pressure can be injected through the skin

and cause serious injury. To reduce the risk of an injury from injection, splashing fluid, or

moving parts, follow the pressure relief procedure whenever you:

- Are instructed to relieve pressure,

- Check, clean or service any of the system equipment,

- Install or clean the nozzle.

1. Turn off the power supply to the pump.

2. Trigger the valve into a waste container to relieve pressure.

3. Open any bleed-type master air valves and fluid drain valves in the system.

4. Leave the drain valve open until you are ready to pressurize the system.

If you suspect that the dispensing valve, extension, or nozzle is clogged or that pressure has

not been fully relieved after following the steps above, very slowly loosen a fitting on the fluid

line to relieve pressure gradually, then loosen it completely, then clear the clog.

To reduce the risk of a serious bodily injury, including fluid injection, never exceed the

maximum working pressure of the valve you are using or of the lowest rated component in your

system.

Dispensing Procedure

Note: Before you begin, make sure you understand how to unlock the trigger.

1. Pull the trigger toward the valve body to open the valve and begin dispensing.

2. Lock the valve open by keeping the trigger squeezed and depressing the trigger lock button.

Then release the trigger, releasing your forefinger from the trigger lock last.

3. Pull the trigger toward the valve body to release the trigger lock. The trigger lock

disengages. Release the trigger to stop dispensing.

DETAILS

TECHNICAL

SAFETY

PRECAUTIONS

INSTALLATIONOPERATION

TROUBLE

LIMITED

E5

EXPLODED AND

SHOOTING GUIDE

WARRANTY

PARTS LIST

Page 8

TROUBLE SHOOTING GUIDE

Relieve the pressure before you check or repair the dispensing valve. Be sure all other valves

DETAILS

and controls and the pump are operating properly.

TECHNICAL

To reduce the risk of serious injury whenever you are instructed to relieve pressure, always

follow the pressure relief procedure on page 3.

Problem

Slow or no fluid flow

Oil leaks from swivel

SAFETY

PRECAUTIONS

Oil drips from nozzle

Valve leaks

INSTALLATIONOPERATION

Leakage from meter

No Display

TROUBLE

SHOOTING GUIDE

Wrong Reading

Problem

Filter is clogged, or pump pressure is low,

or shut-off valve is not fully open, or

foreign materialis jammed in the

metering element.

Swivel is loose

O-ring is worn or damaged

Nozzle is damaged or obstructed

O-rings or valve seat are worn or damaged

O-ring damaged

Loosing Battery

Battery out of power

correction coefficient error

Solution

1. Relief the pressure.

2. Loose swivel fitting, clean or replace the filter.

3. If the problem remains, contact your

distributor for repair or replacement.

Torque the swivel

If the problem remains, contact your distributor

for repair or replacement

Replace the o-ring.

If the problem remains, contact your distributor

for repair or replacement

Inspect the nozzle for damage or obstructions,

and replace if damaged

If the problem remains, contact your distributor

for repair or replacement

Replace the o-rings and/or the valve seat.

If the problem remains, contact your distributor

for repair or replacement

1. Get the meter off from the dispense system

2. Take off the protector

3. Loosing four the socket head cap screws on

the cover of the meter

4. Loosing eight the hex bolts on the bottom of

the meter

5. Take off the seat

6. Check the o-ring, replacing the o-ring if it is

damaged

7. After replacing the o-ring, assemble the meter

and fix it back to the dispense system

1. Get the meter off from the dispense system

2. Take off the protector

3. Take off the labels sticks on the bottom of the

meter

4. Loosing the five socket head cap screws on

the bottom of the meter

5. Take off the seat

6. Check the battery, replacing the battery if it is

out of power

7. After replacing the battery, assemble the

meter and fix it back to the dispense system

Reset the correction factor (follow the

instructions on Page 6)

LIMITED WARRANTY

LIMITED

1. The manufacturer warrantees this product against defects in material and craftsmanship, for

WARRANTY

a period of five years from date of purchase, but not including wearing parts.

2. Manufacturer’s liability is limited to replacement or repair of defective material within the

warranty period, when returned freight prepaid to the distributor or their designated service

depot.

3. The warranty does not cover damage caused by accident, misuse or faulty installation.

4. The product must be installed and maintained in compliance with the instructions.

E6

PARTS LIST

EXPLODED AND

Page 9

EXPLODED AND PARTS LIST

3-4

3-6

3-19

3-8

3-21

3-20

3-3

3-9

3-18

3-14

3-7

4

1-5

DETAILS

TECHNICAL

1-10

1-11

1-121-9

1-13

1-1

1-14

SAFETY

1-2 1-82

1-3

PRECAUTIONS

3-5

3-2

3-16

3-13

3-12

3-11

3-17

3-15

3-1

3-10

1-4

1-7

1-6

INSTALLATIONOPERATION

TROUBLE

SHOOTING GUIDE

LIMITED

WARRANTY

E7

EXPLODED AND

PARTS LIST

Page 10

Part No.

1-1

DETAILS

TECHNICAL

SAFETY

1-2

1-3

1-4

1-5*

1-6

1-7*

1-8

1-9

1-10*

PRECAUTIONS

1-11

1-12

1-13*

2

3-1*

3-2

3-3

INSTALLATIONOPERATION

3-4

Item No.4 description:

Part No.

MH10001

MH10002

MT10001

MT10002

MT10003

Description

Swivel

Handle

Trigger lock

Trigger

O-ring

Screw

Washer, flat

Cam

Rod

Seat

Washer

Spring

Filter

Adapter

O-ring

Meter Holder

Meter Cover

Rubber Protector

Description

Rigid nozzle

Flexible nozzle

Manual tip

Auto tip

Semi-auto tip

Q’ty

1

1

1

1

2

2

2

1

1

1

1

1

1

1

1

1

1

1

Part No.

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-13*

3-14

3-15

3-16

3-17

3-18

3-19*

3-20*

3-21

4

Description

Main Circuit Board

Front Label

Screw

Screw

O-ring

Seat

Battery cover

Spring

Battery

Screw

Shaft

Oval Gear

Magnetic Rod

Bolt

Waterproof protector

Seal washer

Washer

Nozzle with tip

Q’ty

1

1

4

4

1

1

11

1

1

2

2

2

2

8

2

4

4

1

Wearing parts:

Part No.

1-5*

TROUBLE

LIMITED

1-7*

1-10*

1-13*

SHOOTING GUIDE

3-1*

WARRANTY

E8

PARTS LIST

EXPLODED AND

Description

O-ring

Washer, flat

Seat

Filter

O-ring

Q’ty

2

2

1

1

1

Part No.

3-9*

3-13*

3-19*

3-20*

Description

O-ring

Battery

Waterproof protector

Seal washer

Q’ty

1

1

2

4

Page 11

Page 12

Goodyear (and winged foot design) and Blimp are trademarks of The Goodyear Tire &

Rubber Company used under license by Intradin (Shanghai) Machinery Co., Ltd. China.

Copyright 2016 The Goodyear Tire & Rubber Company.

Size: 145x210mm REV 12/05/16 2.09.05.30.686157克铜版纸

Loading...

Loading...