Goodwe GW1500-SS, GW2000-SS, GW4600-SS, GW3000-SS, GW4000-SS User Manual

...

User Manual

GOODWE SS SERIES

Ver 02

已发行

Table of Contents

1 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01

2 Safety . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 02

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

3.1 Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . 04

3.2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

3.3 Equipment Installation . . . . . . . . . . . . . . . . . . . . . 06

3.4 Electrical Connection . . . . . . . . . . . . . . . . . . . . . 10

3.5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4 System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1 Operating Panel . . . . . . . . .. . . . . . . . . . . . . . . . . . 35

4.2 Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.3 LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.4 Error Messages . . . . . . . . . . .. . . . . . . . . . . . . . . . . 45

4.5 ID Reset . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . 47

5 Technical Parameters . . . . . . . . . . . . . . . . . . . . . . . . 48

GW1500-SS GW2000-SS GW3000-SS . . . . . . . . . . . 48

GW4000-SS GW4600-SS . . . . . . . . . . . .. . . . . . . . . . . 51

GW3600S-UK/DK . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6 Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7 Warranty . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . 58

7.1 Warranty Period . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.2 Warranty Card . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.3 Warranty Conditions . . . . . . . . . . . . . . . . . . . . . . 58

7.4 Scope of Warranty . . . . . . . . . . . .. . . . . . . . . . . . . 59

8 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Notes:

The images and diagrams in this manual are for guidance

only. Please refer to the actual product.

已发行

1

1 Symbols

Caution! - Failure to observe a warning

indicated in this manual may result injury.

Danger of high voltage and electric shock!

Danger of hot surface!

Product should not be disposed as household

waste.

This side up; the package must always be

transported, handled and stored in such a way

that the arrows always point upwards.

Components of the product can be recycled.

Fragile; the package/product should be handled

carefully and never be tipped over or slung.

No more than six (6) identical packages may be

stacked on each other.

Keep dry; the package/product must be

protected from excessive humidity and must be

stored under cover.

CE Mark

Residual voltage exists in the inverter; before

commencing any maintenance, at least 5

minutes must be allowed for the capacitor in the

inverter to fully discharge.

已发行

2

Units:

2 Safety

The SS series inverter of Jiangsu GoodWe Power Supply

Technology Co. Ltd. ( hereinafter referred to as GoodWe )

strictly conforms to related safety rules in design and test.

Safety regulations relevant to the location shall be followed

during installation, commissioning, operation and maintenance.

Improper operation may cause serious injury, electric shock

and/or damage to equipment and property.

` Installation, maintenance and connection of inverters must

be performed by qualified personnel, in compliance with

local electrical standards, regulations and the requirements

of local power authorities and/or companies.

` To avoid electric shock, DC input and AC output of the

inverter must be terminated at least 5 minutes before

performing any installation or maintenance.

已发行

3

` The temperature of some parts of the inverter may exceed

60Ԩ during operation. To avoid being burnt, do not touch

the inverter during operation. Let it cool before touching it.

` Ensure children are kept away from inverters.

` Do not open the front cover of the inverter. Apart from

performing work at the wiring terminal (as instructed in this

manual), touching or changing components without

authorization may cause injury to people, damage to

inverters and annulment of the warranty.

` Static electricity may damage electronic components.

Appropriate methods must be adopted to prevent such

damage to the inverter; otherwise the inverter may be

damaged and the warranty annulled.

` Ensure the output voltage of the proposed PV array is lower

than the maximum rated input voltage of the inverter,

otherwise the inverter may be damaged and the warranty

annulled.

已发行

4

3 Installation

3.1 Mounting Instruction

A For optimal performance, the inverter must be located

where the ambient temperature is less than 45 °C.

B For convenience in maintenance and in checking the LCD

display, install the inverter at eye level.

C Inverters should NOT be installed near flammable and/or

explosive items. Any electro-magnetic equipment should

be kept away from the installation site.

D The product label and warning symbol must be clearly

visible after installation.

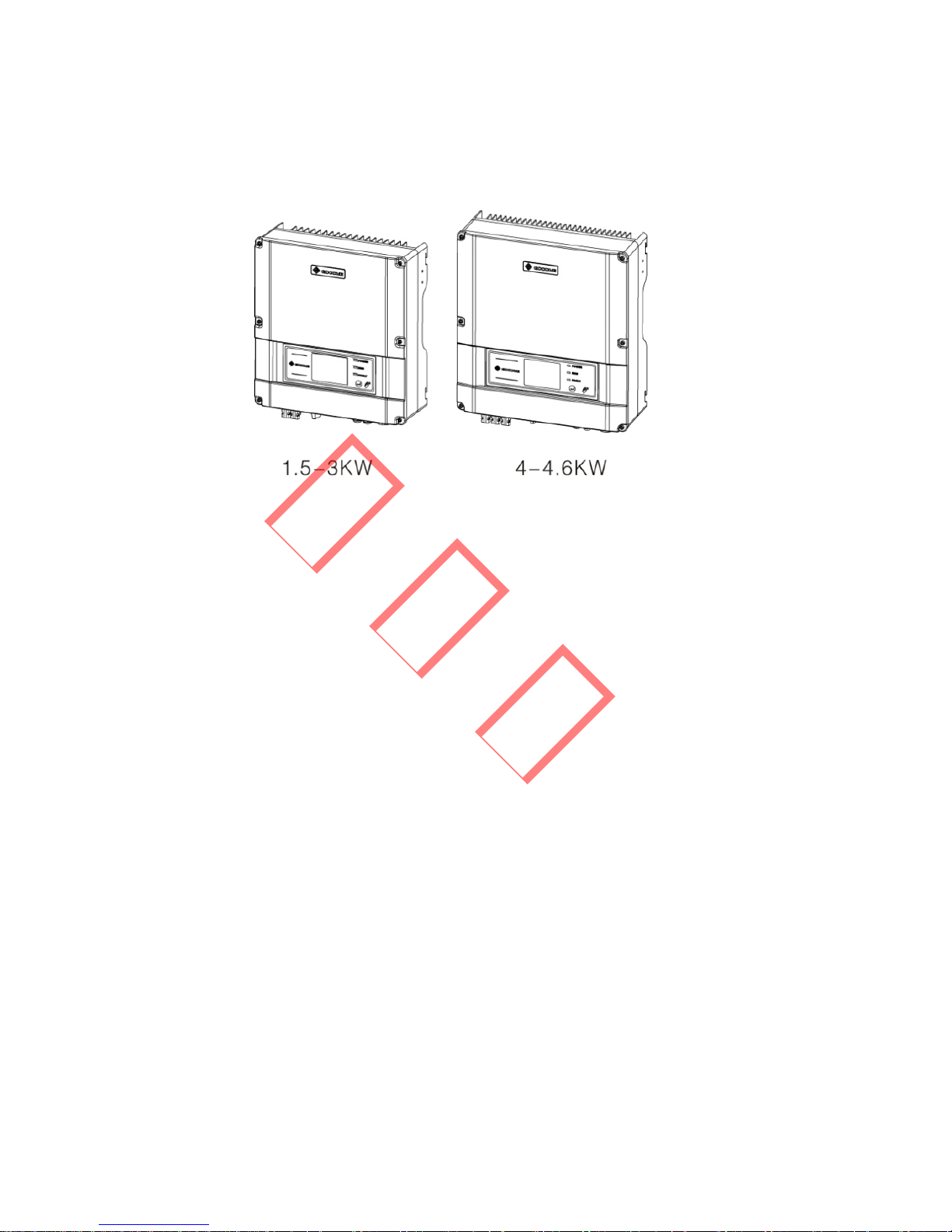

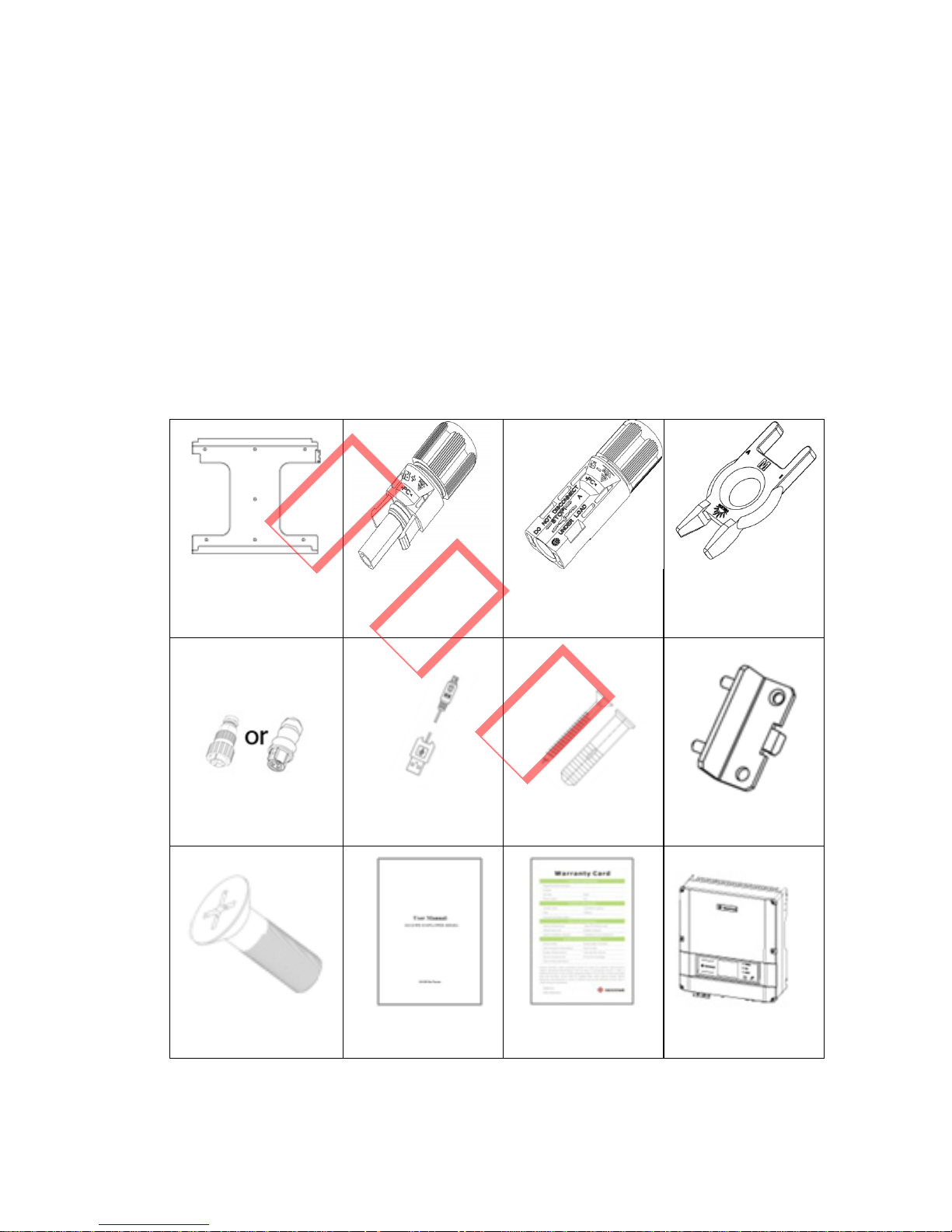

3.2 Unpacking

When you receive the GoodWe inverter, please check for

external damage to the inverter and any accessories. Please

also check that the following are included:

Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Wall-mounted bracket . . . . . . . . . . . . . . . . . . . . . . . . . 1

Lock Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Positive DC Plug (GW1500-SS) . . . . . . . . . . . . . . . . . . 1

Negative DC Plug (GW1500-SS) . . . . . . . . . . . . . . . . . 1

Positive DC Plug (GW2000-SS / GW3000-SS) . . . . . . . 2

Negative DC Plug (GW2000-SS / GW3000-SS) . . . . . . 2

Positive DC Plug (GW3600S-UK/DK) . . . . . . . . . . . . . 3

Negative DC Plug (GW3600S-UK/DK) . . . . . . . . . . . . 3

Positive DC Plug (GW4000-SS / GW4600-SS) . . . . . . . 3

已发行

5

Negative DC Plug (GW4000-SS / GW4600-SS) . . . . . . 3

Unlock Tool for DC Plug . . . . . . . . . . . . . . . . . . . . . . . 1

AC Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

USB Data Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Expansion Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Flat Head Screw for Lock Plate and RS485 Cover . . . . . . 5

User Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warranty Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Wall-mounted

Bracket

Positive DC Plug

Negative DC Plug

Unlock Tool for DC

Plug

AC Plug

USB Data Cable

Expansion Bolt

Lock Plate

Flat Head Screw

User Manual

Warranty Card

Inverter

已发行

6

3.3 Equipment Installation

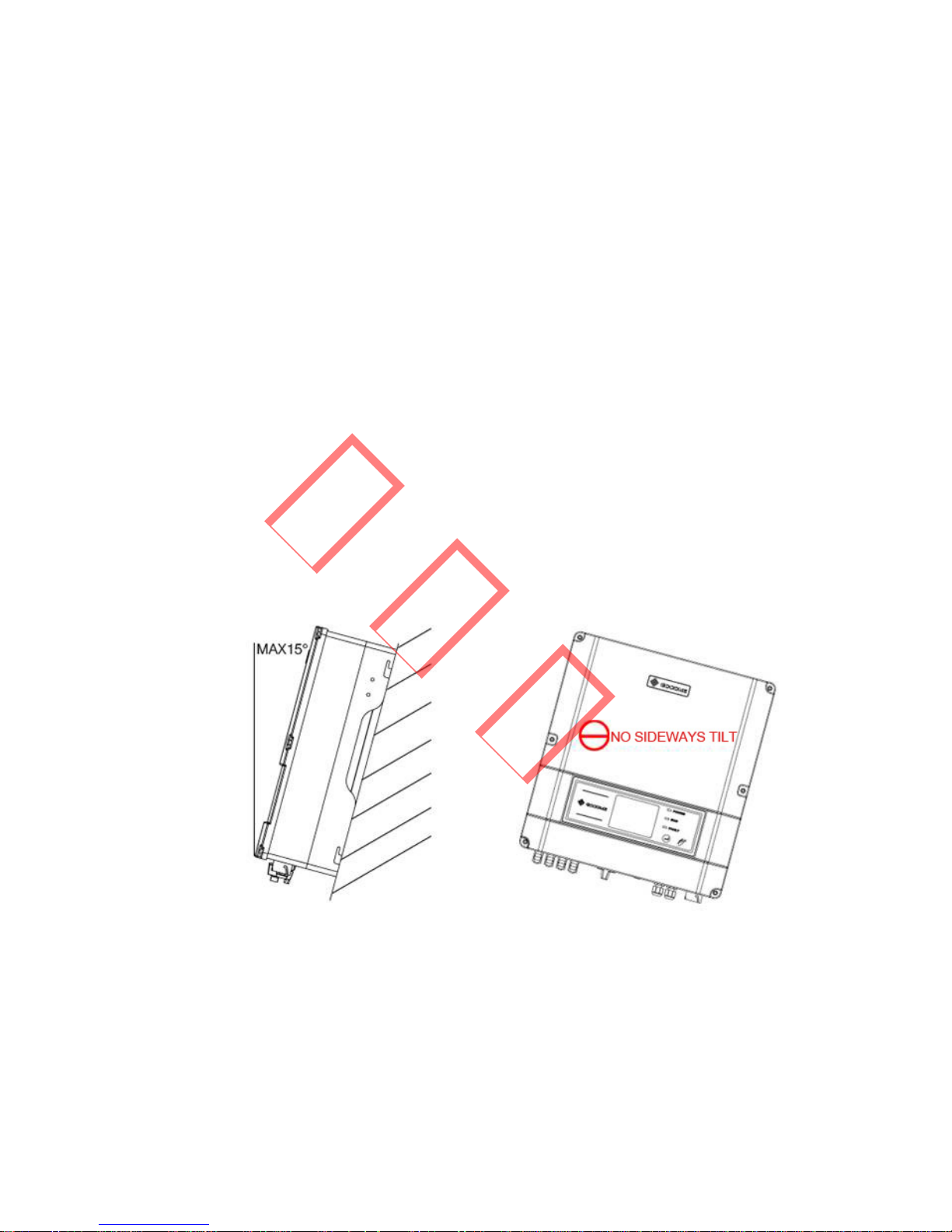

3.3.1 Selecting the installation position

The following must be considered when selecting the best

location for an inverter:

` The mount and installation method must be suitable for the

inverter's weight and dimensions.

` The location must be well ventilated and sheltered from

direct sunlight.

` Install vertically or tilted backward by max 15°. The device

cannot be installed with a sideways tilt. The connection area

must point downwards.

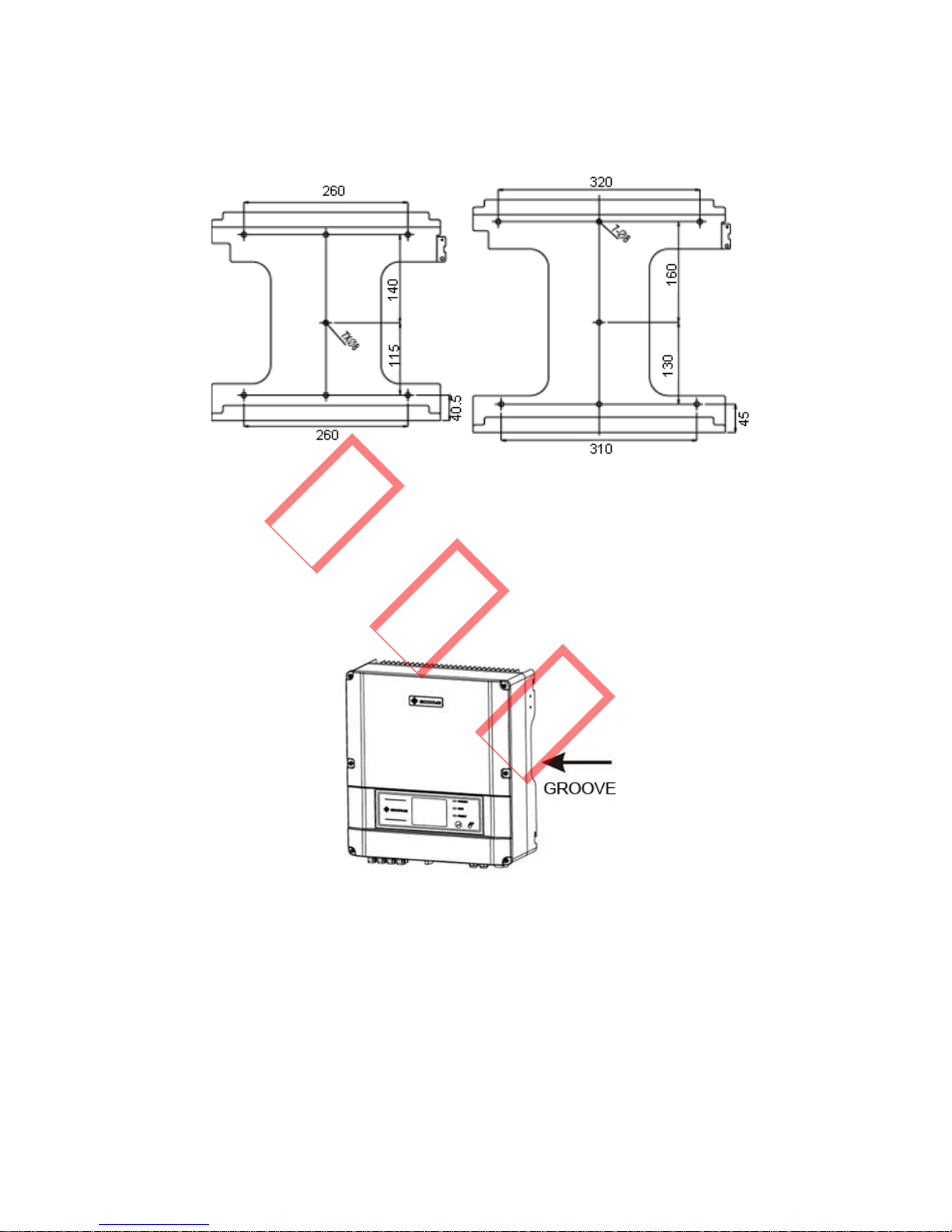

Figure 3.3.1-1

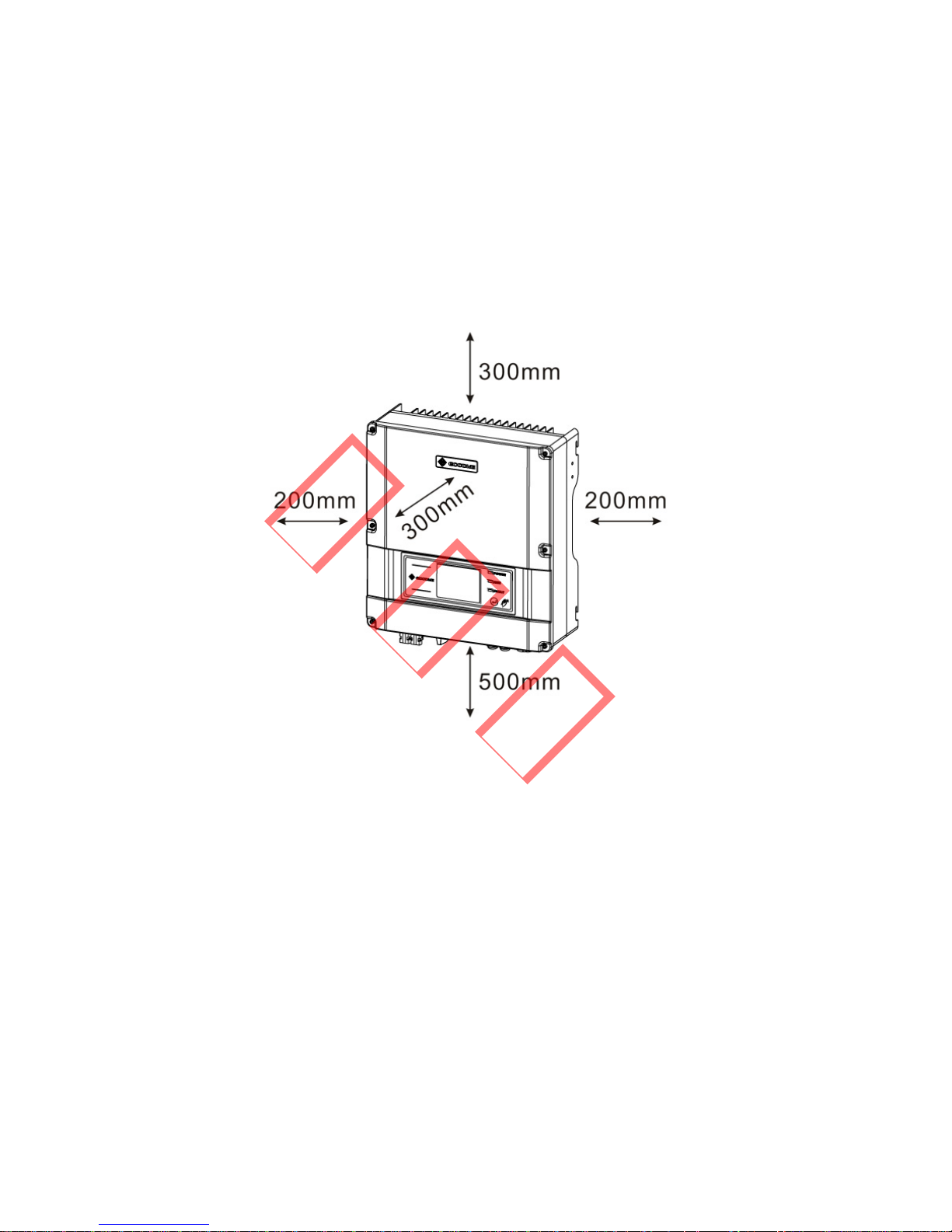

` To allow dissipation of heat, and for convenience of

dismantling, clearances around the inverter must be at least:

已发行

7

Upward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300mm

Downward . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500mm

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300mm

Both sides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200mm

Figure 3.3.1-2

3.3.2 Mounting Procedure

A Use the wall-mounted bracket as a template and drill 7

holes on the wall, 10 mm in diameter and 80 mm deep.

已发行

8

Figure 3.3.2-1

B Fix the wall mounting bracket on the wall using the

expansion bolts in the accessories bag.

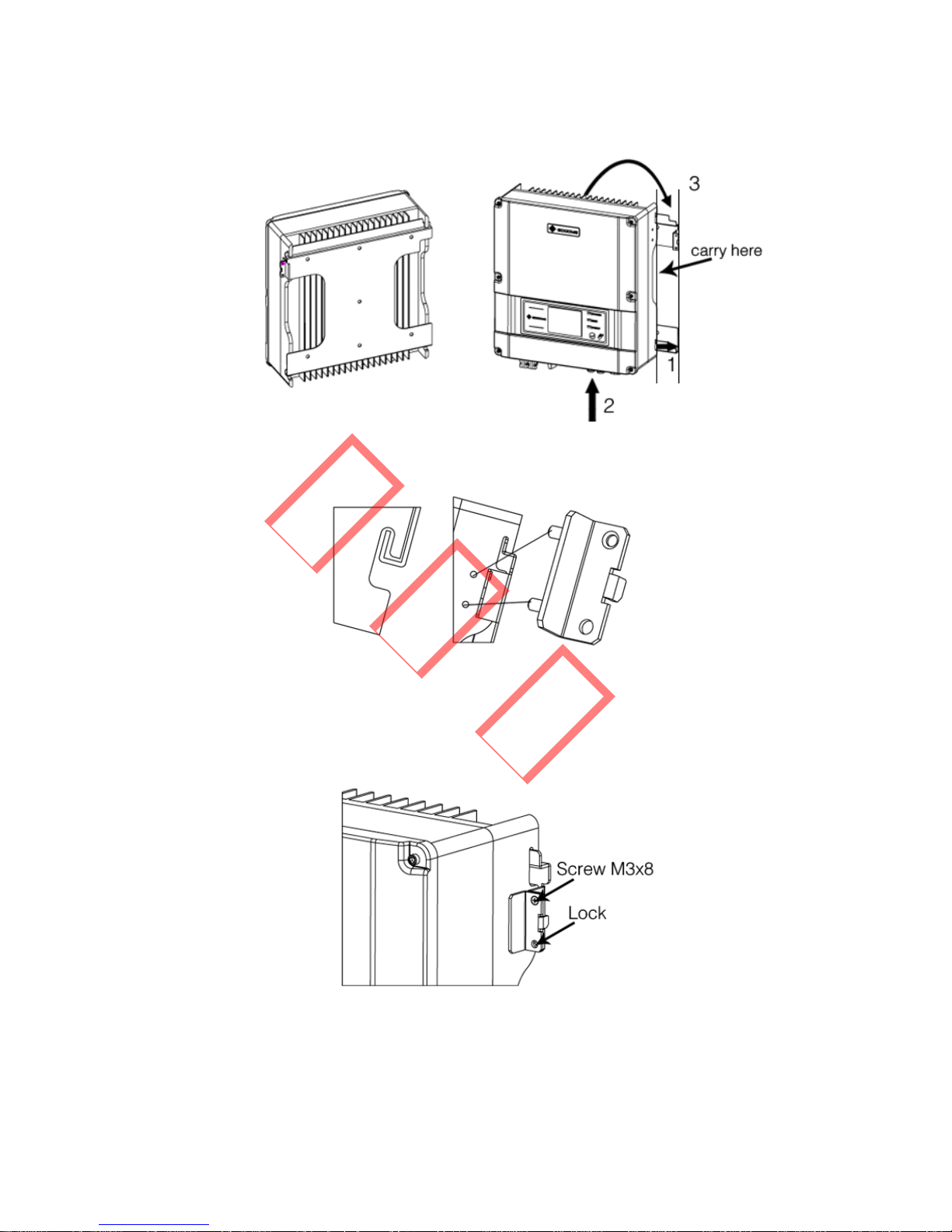

C Hold the inverter by the groove on the heat sink.

Figure 3.3.2-2

D Place the inverter on the wall-mounted bracket (as

illustrated below).

已发行

9

Figure 3.3.2-3 Figure 3.3.2-4

Figure 3.3.2-5

E Insert the lock plate pegs into the two holes in the heat-sink,

then fix the inverter with a padlock and screw M3x8.

Figure 3.3.2-6

已发行

10

3.4 Electrical Connection

Connections must be made in compliance with local

regulations and the requirements of local power

authorities/companies.

In accordance with VDE0126-1-1/A1, the inverter incorporates

a Residual Current Monitoring Unit (RCMU) which monitors

residual current from the solar module to the grid side of the

inverter. The inverter can automatically differentiate between

fault current and normal capacitive leakage currents.

3.4.1 Connection to grid (AC side Connection)

A Check the grid (utility) voltage and frequency at the

connection point of the inverter. It should be 230VAC (or

220VAC), 50/60Hz, and single phase.

B Disconnect the breaker or fuse between the PV-inverter

and the utility.

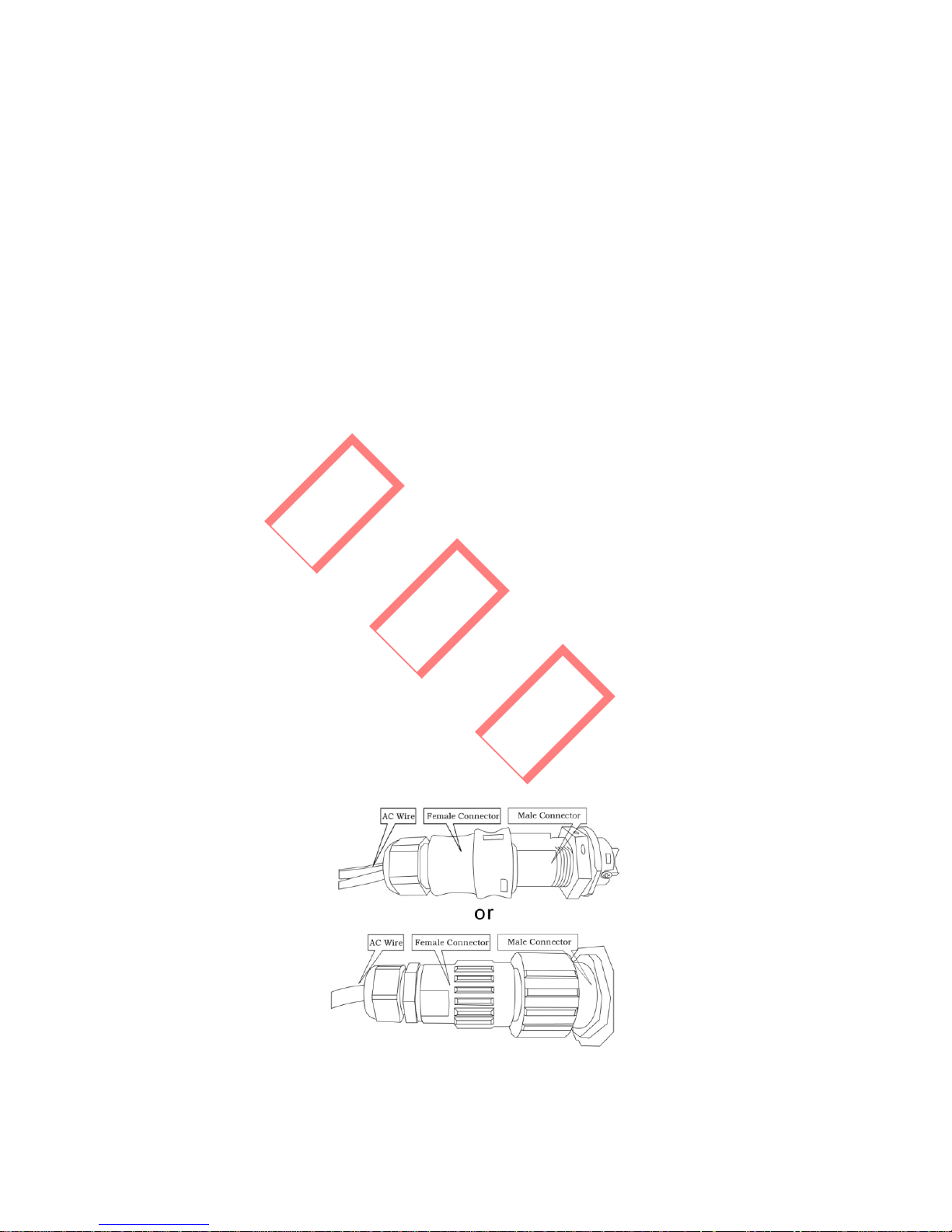

C Connect the inverter to the grid as follows:

` Switch off the AC breaker.

` Disassemble the female connector of the AC wire

connector and connect the AC wires to the connection

socket as indicated.

Figure 3.4.1-1

已发行

11

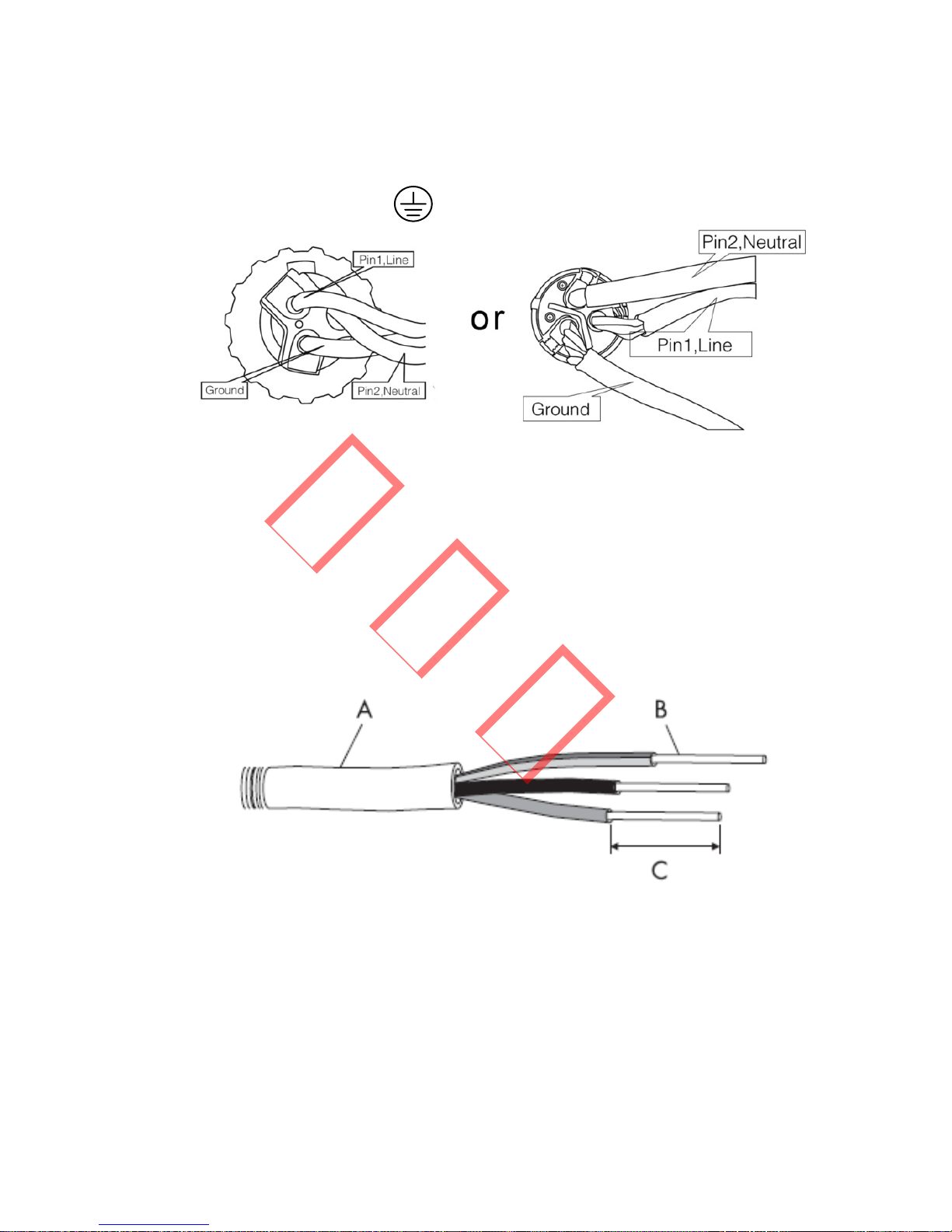

` Insert Line wire to Pin 1, Neutral wire to Pin 2 and

Ground wire to Pin

Figure 3.4.1-2

` After fastening all screws, reassemble the female

connector of the AC wire connector.

` Connect the female connector of the AC wire

connector to the male connector on the inverter.

D Specifications of the AC wires:

Figure 3.4.1-3

已发行

12

Depicted Size

A External diameter of the wire 12mm-25mm

B Sectional area of conducting materials Max.6mm2

C Length of bare wire Approx.10mm

E AC output connection

Tighten the screw with a screw driver until the head of the

screw is inside the connector. Otherwise the wire could be

loose.

Figure 3.4.1-4

3.4.2 DC side connection

A Make sure the maximum open circuit voltage (Voc) of

each PV string does not exceed the inverter’s input voltage

Vmax under any condition.

B Use Amphenol or Multi-contact connectors for the PV

array terminals.

C Connect the positive and negative terminals of the PV

panel to corresponding terminals on the inverter. The DC

terminal on each inverter can bear 20A DC current.

已发行

13

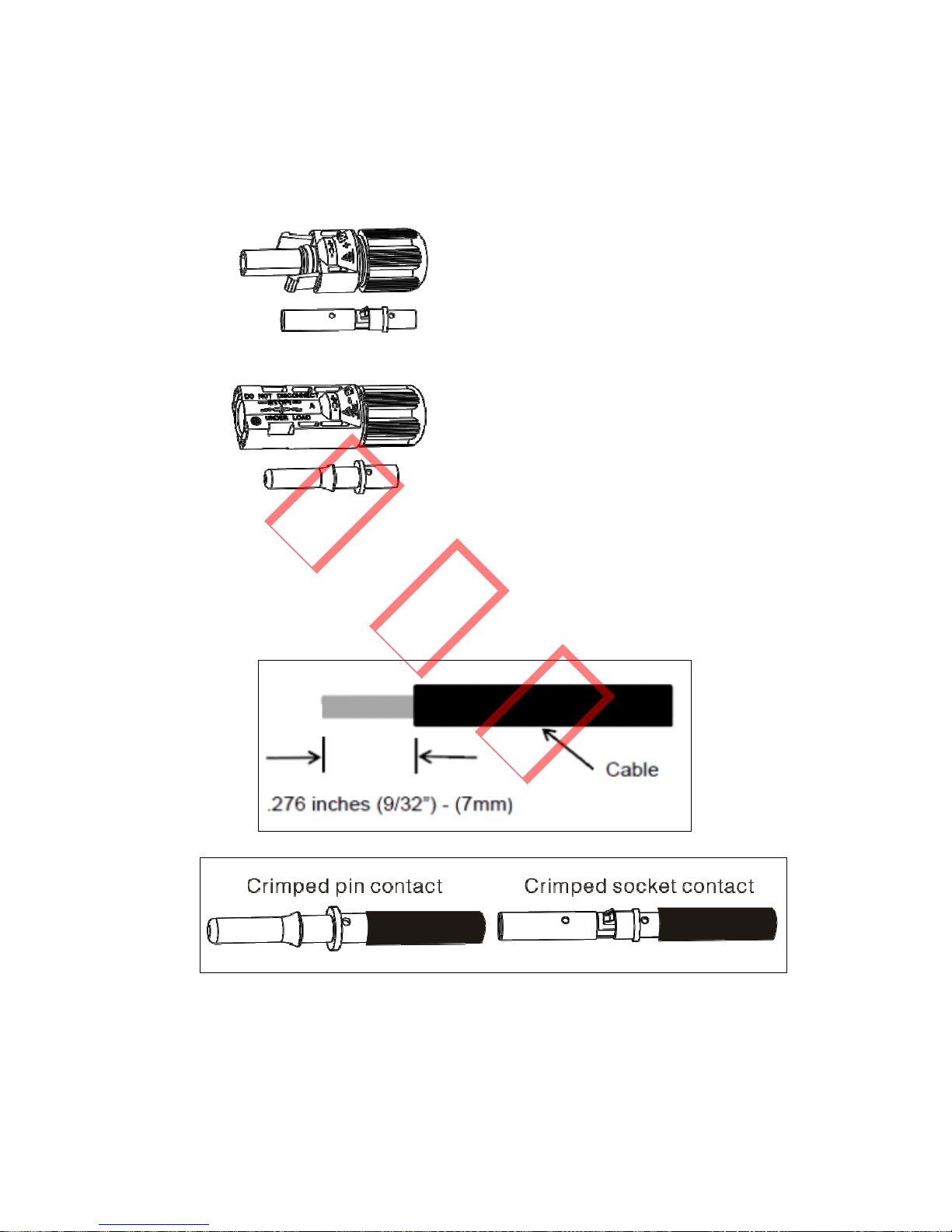

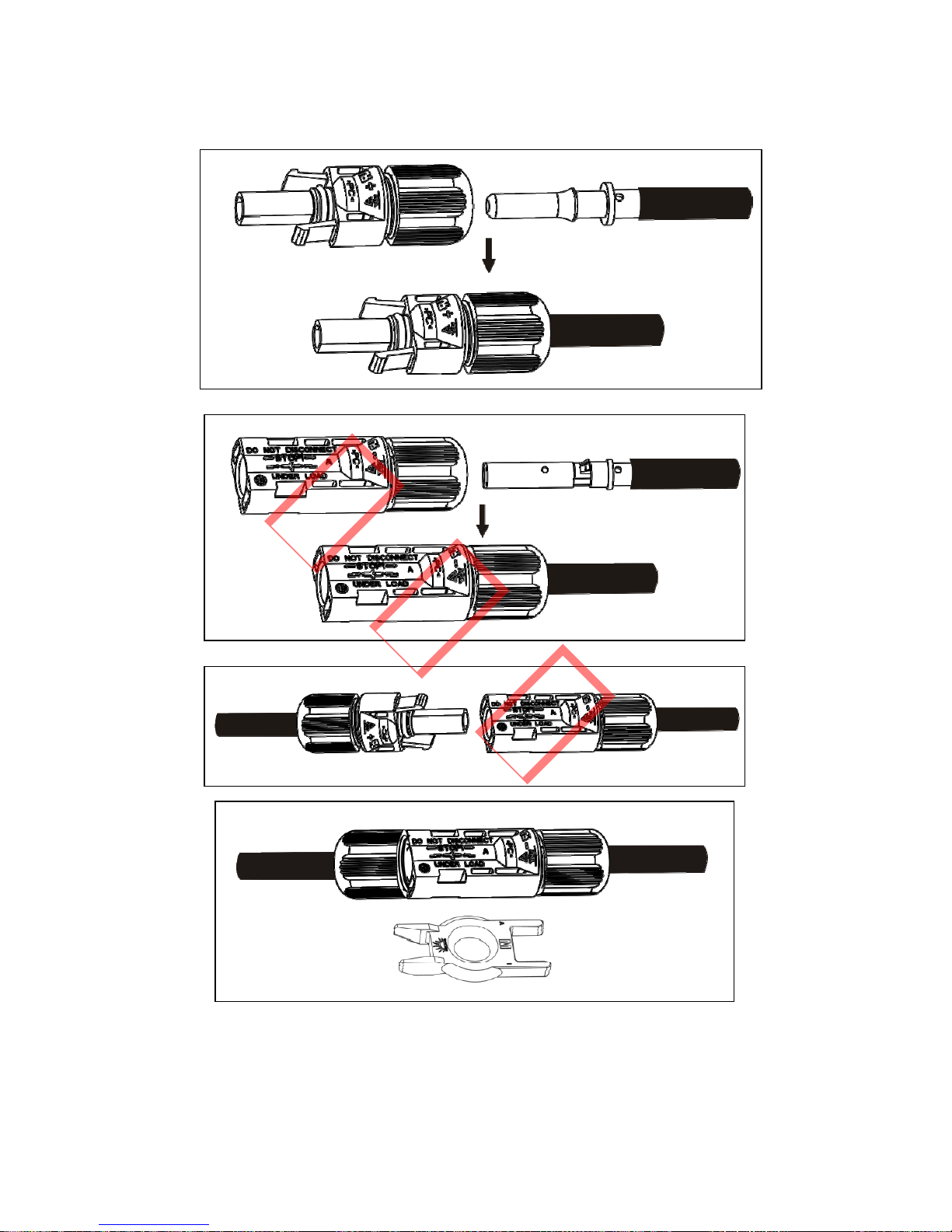

If using Amphenol connectors for the PV array terminals,

install as follows.

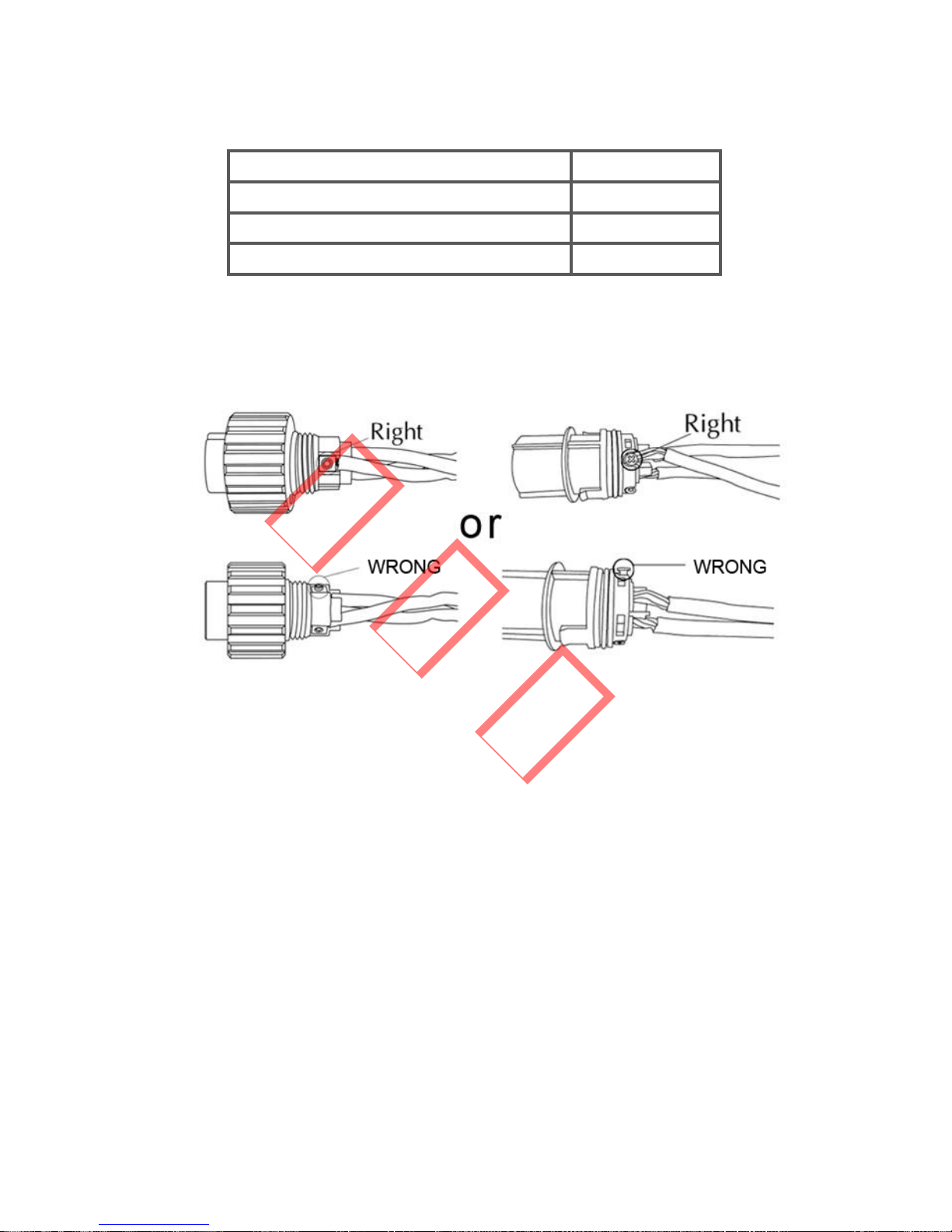

Female side connector (PV+) Male side connector (PV-)

Connectors must be installed as a pair, and each cable stripped

and installed as shown below.

已发行

14

Figure 3.4.2-1 Separated by Ring tool

已发行

15

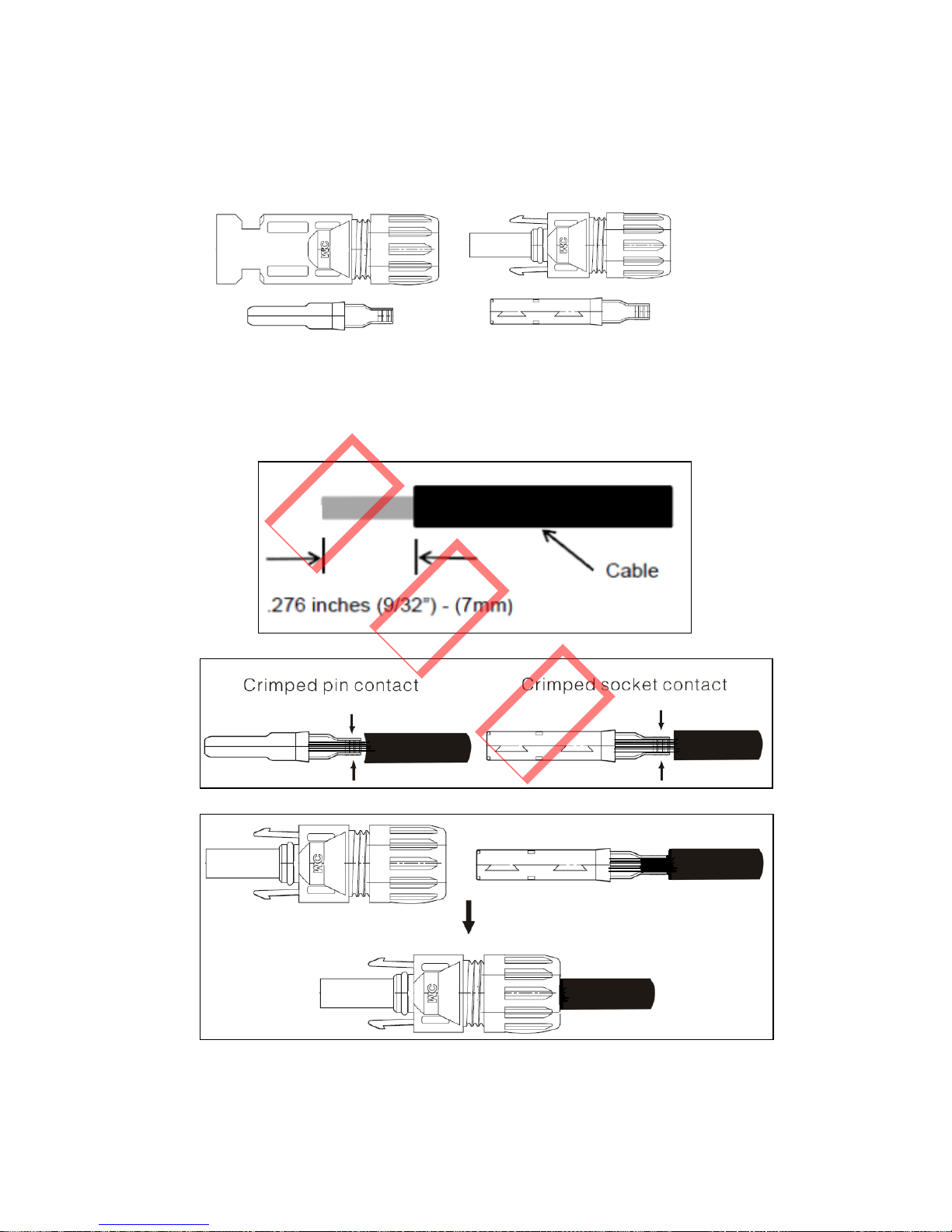

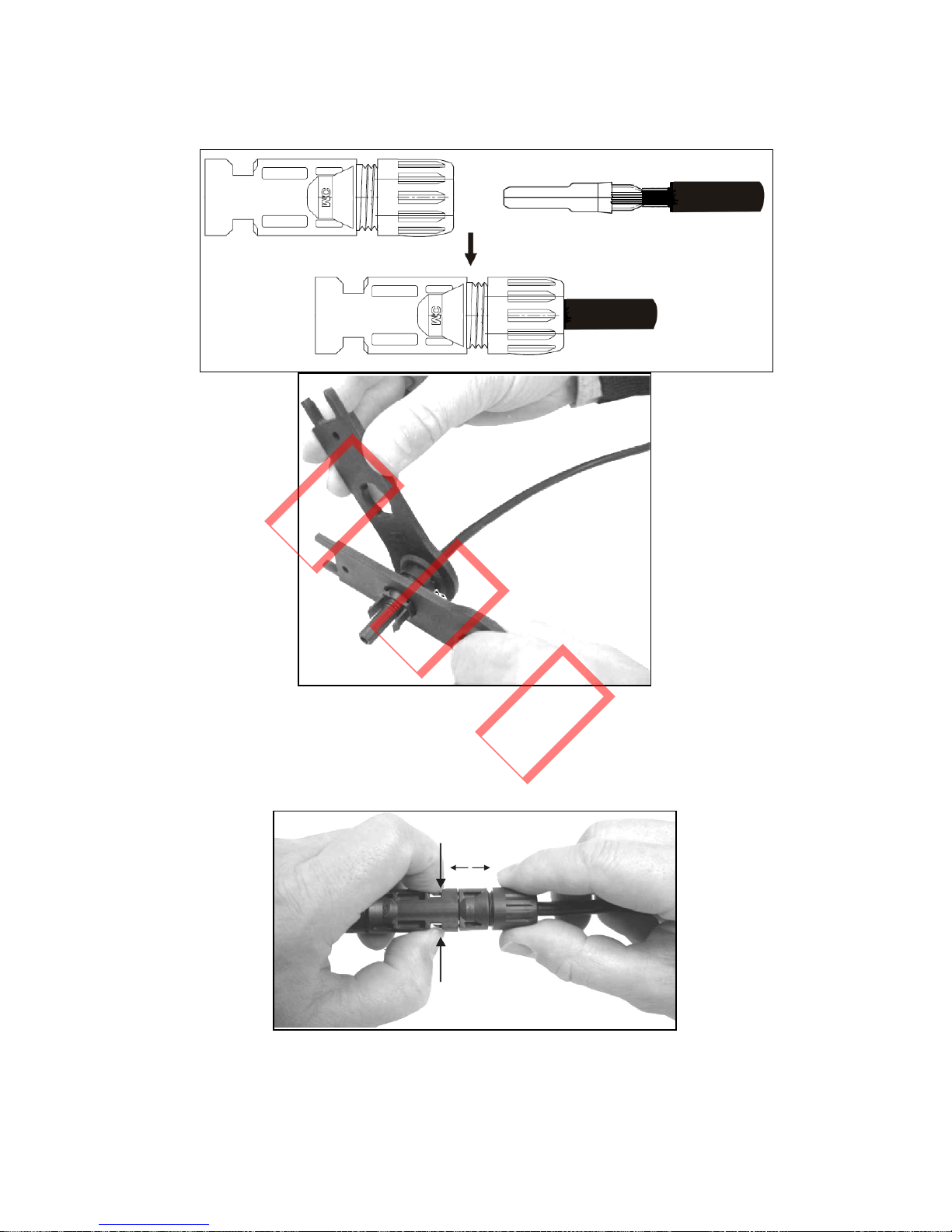

If using Multi-contact connectors for the PV array terminals,

install as follows.

Female side connector (PV+) Male side connector (PV-)

Connectors must be installed as a pair, and each cable stripped

and installed as shown below.

已发行

16

Figure 3.4.2-6

Tighten the screw connection. Then the terminal can be

connected to the inverter side.

Figure 3.4.2-7

已发行

17

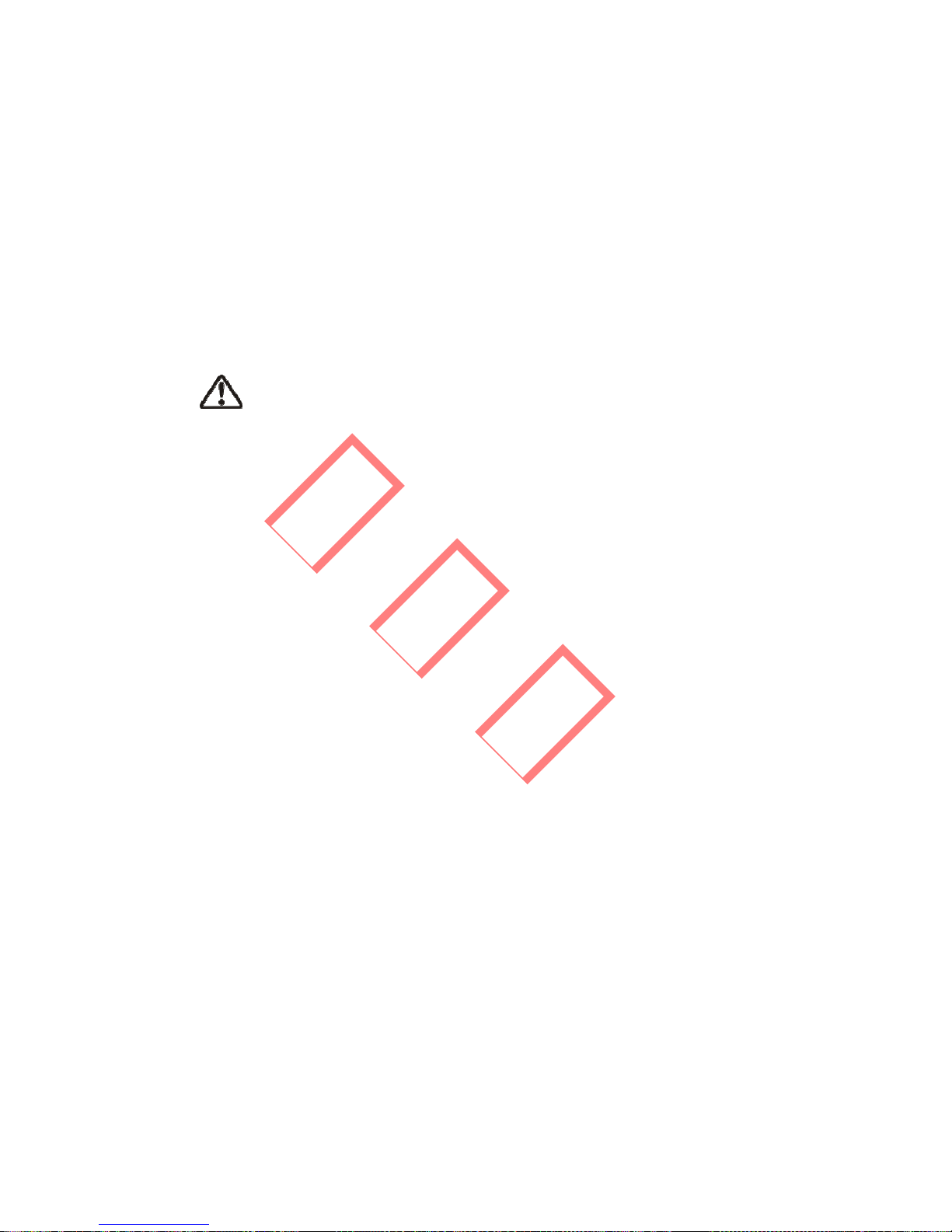

Compress the two snap-in springs by hand and release

Where the inverter is equipped with a DC switch, ensure the

switch is in the "OFF" position before connecting the inverter

to PV panels. Switch to "ON" after completing the connection.

Caution:

` Before connecting the PV panels, ensure the plug

connectors have the correct polarity. Incorrect polarity could

permanently damage the unit.

` Checks the short-circuit current of the PV string. The total

short-circuit current of must not exceed the inverter’s

maximum DC current.

` High voltage exists when the PV panel is exposed to the sun.

Secure the terminal connection and, to avoid electric shock,

do NOT touch any exposed components.

3.4.3 RS485 Communication

An RS485 interface is used for multipoint communication. The

EzLogger can monitor and communicate with 50 inverters at

the same time; however the cable length should not exceed

1000 m. The diagram below shows a typical inverter

connection through the RS485 interface.

已发行

Loading...

Loading...