User's Manual

Introduction

Z-Wave Roller Shutter Controller is an ideal for the remotely electric

motor controller. It is used to control the motors of rollers, shades,

blinds, venetian blinds and similar sun shade, which are single phase

AC powered. The module can be controlled either through a Z-Wave

network or through the wall switch, and measures power

consumption of motor.

Z-Wave Roller Shutter needs to motor calibration before use, please

refer to CONFIGURATION command class parameter 0x01. Z-Wave

Roller Shutter’s positioning calibration does not apply to m otor

without obstacle detection, using this fu nction may cause

unpredictable problems, please make sure your motor has obstacle

detection function before positioning calibration.

Package Contents

■ Z-Wave Roller Shutter Controller x1

■ User Manual x1

Command Class

Device Information

GENERIC_TYPE_SWITCH_MULTILEVEL

SPECIFIC_TYPE_CLASS_C_MOTOR_CONTROL

z-wave protocol Command Class Node Info

COMMAND_CLASS_ZWAVEPLUS_INFO_V2

COMMAND_CLASS_VERSION_V3

COMMAND_CLASS_MANUFACTURER_SPECIFIC_V2

COMMAND_CLASS_DEVICE_RESET_LOCALLY_V1

COMMAND_CLASS_POWERLEVEL_V1

COMMAND_CLASS_SWITCH_MULTILEVEL_V3

COMMAND_CLASS_CONFIGURATION_V1

COMMAND_CLASS_ASSOCIATION_V2

COMMAND_CLASS_ASSOCIATION_GRP_INFO_V1

COMMAND_CLASS_SWITCH_BINARY_V1

COMMAND_CLASS_METER_V3

COMMAND_CLASS_FIRMWARE_UPDATE_MD_V4

COMMAND_CLASS_SUPERVISION_V1

COMMAND_CLASS_Transport_Service_V2

COMMAND_CLASS_SECURITY_V1

COMMAND_CLASS_SECURITY_2_V1

The Below listed Command Class are all supported the S

ecurity S2

COMMAND_CLASS_VERSION_V3

COMMAND_CLASS_MANUFACTURER_SPECIFIC_V2

COMMAND_CLASS_DEVICE_RESET_LOCALLY_V1

COMMAND_CLASS_POWERLEVEL_V1

COMMAND_CLASS_SWITCH_MULTILEVEL_V3

COMMAND_CLASS_CONFIGURATION_V1

COMMAND_CLASS_ASSOCIATION_V2

COMMAND_CLASS_ASSOCIATION_GRP_INFO_V1

COMMAND_CLASS_SWITCH_BINARY_V1

COMMAND_CLASS_METER_V3

COMMAND_CLASS_FIRMWARE_UPDATE_MD_V4

COMMAND_CLASS_SUPERVISION_V1

Detailed description of each command class

【ZWAVEPLUS INFO command class】

The Z-Wave Plus Info Get Command is used to get additional

information of the Z-Wave Plus device in question.

【VERSION command class】

The user can enquire the version of the unit using VERSION_GET

command. It will return VERSION_REPORT Command. Version

Report Command:

[Command Class Version, Version Report, Z-Wav e Library Type, ZWave Protocol Version, Z-Wave Protocol Sub Version, Application

Version, Application Sub Version]

【MANUFACTURER SPECIFIC command class】

The user can use the Manufacturer Specific Get Command to request

manufacturer specific information from another node.

Manufacturer Specific Report Command:

[Command Class Manufacturer Specific, Manufacturer ID 1,

Manufacturer ID 2, Product Type ID 1, Product Type ID 2, Product ID

1, Product ID 2]

【DEVICE RESET LOCALLY command class】

The Dev ice Res et Locally Command Class is used to notify central

controllers that a Z-Wave device is resetting its network specific

parameters.

【POWERLEVEL command class】

The Power level Command Class defines RF transmit power

controlling commands useful when installing or testing a network.

The commands make it possible for supporting controllers to set/get

the RF transmit power level of a node and test specific links between

nodes with a specific RF transmit power level.

【BASIC command class】

Control the roller shutter to be opened or closed after receiving the

BASIC_SET command.

To be opened:

[Command Class Multilevel, Multilevel Set, Value = 0xFF]

To be closed:

[Command Class Multilevel, Multilevel Set, Value= 0x00]

To be the percentage of full opened position:

[Command Class Multilevel, Multilevel Set, Value = 0x01~0x63]

【SWITCH MULTILEVEL command class】

Control the roller shutter to be opened, closed, stopped or be the

percentage of full opened position after receiving the SWITCH

MULTILEVEL command.

To be opened:

[Command Class Multilevel, Multilevel Set, Value = 0xFF]

To be closed:

[Command Class Multilevel, Multilevel Set, Value= 0x00]

To be the percentage of full opened position:

[Command Class Multilevel, Multilevel Set, Value = 0x01~0x63]

To be stopped:

[Command Class Multilevel,

SWITCH_MULTILEVEL_STOP_LEVEL_CHANGE]

【CONFIGURATION command class】

This class is used for setting certain vendor specific configuration

variables. See the following table for configuration variables:

Parameter

Name

Size

(byte)

Range

Default

value

Description

1

(0x01)

Positioni

ng

Calibratio

n

1

0 - 1 0 0: Disable

1: Executing

calibration

2

(0x02)

External

switch

Protectio

n

1

0 - 1 0 0: Enable external

switch

1: Disable external

switch

3

(0x03)

When

the door

is

opened,

set the

delay

time for

automati

c closing.

2

0 32767

0

0: Disable automatic

closing

1 - 32767: The door

will be closed

automatically in 1 32767sec

4

(0x04)

When

the door

is open,

set the

delay

time for

automati

c

notificati

on.

2

0 32767

0

0: Disable automatic

notification

1 - 32767: The

notification will be

sent automatically in

1 - 32767sec

5

(0x05)

Set the

operatio

n mode

1

0 - 1 0 0: Roller Shutter

1: Venetian

(up/down and slate

rotation)

6

(0x06)

Set the

angle of

blinds

1

0 - 6 0 Angles of blinds

0:0∘

1:30∘

2:60∘

3:90∘

4:120∘

5:150∘

6:180∘

7

(0x07)

Set the

slats

turning

time

1

0 - 127

15

(1.5sec

)

0:Disable.

1 - 127: 0.1 - 12.7 sec

8

(0x08)

Set the

delay

time to

start the

motor up

to the

blade

1

0 - 127 0 0:No offset time

1 - 127: 0.1 - 12.7 sec

9

(0x09)

Set the

delay

time to

start the

motor

down to

the blade

1

0 - 127 0 0:No offset time

1 - 127: 0.1 – 12.7 sec

10

Set the 1 0 - 100 0 0:Disabled

(0x0A)

power

changed

percenta

ge to

send the

power

report

1 - 100: 1% - 100%

11

(0x0B)

Set the

time

interval

of

reporting

watts in

seconds

2

0,

60 32767

300

sec

0:Disable

60 - 32767:

60 - 32767sec

12

(0x0C)

Set the

time

interval

of

reporting

KWH in

seconds

2

0,

60 32767

3600

0:Disable

60 - 32767:

60 - 32767sec

【ASSOCIATION command class】

The device can be set 1 auto-report ID in Group 1.

The device sends an unsolicited command to the configured

destinations when triggered by an event.

Group1:"Lifeline" :

【ASSOCIATION GRP INFO command class】

The purpose of the Association Group Information (AGI) Command

Class is to allow a device to report the capabilities of each

association group supported by the device.

【SWITCH_BINARY command class】

Control the roller shutter to be opened or closed after receiving the

SWITCH BINARY command.

To be opened:

[Command Class SWITCH_BINARY, Set Value = 0xFF]

To be closed:

[Command Class SWITCH_BINARY, Set Value = 0x00]

【METER command class】

The Meter Command C lass is intended for Z-Wave enabled devices

capable of reporting energy measurements in addition to any main

functionality or features e.g. an appliance module rep orting the

current consumption of the connected load. The Meter command

class not support V1&V2 version. And it will take about 3 seconds to

show the meter report on the request sending device.

【FIRMWARE UPDATE META DATA command class】

Support OTA (On-The-Air) firmware update function.

【COMMAND_CLASS_SECURITY_V1】

【COMMAND_CLASS_SECURITY_2_V1】

This device is a security enabled Z-Wave Plus product that is able to

use encrypted Z-Wave Plus messag es to communicate to other

security enabled Z-Wave Plus products.

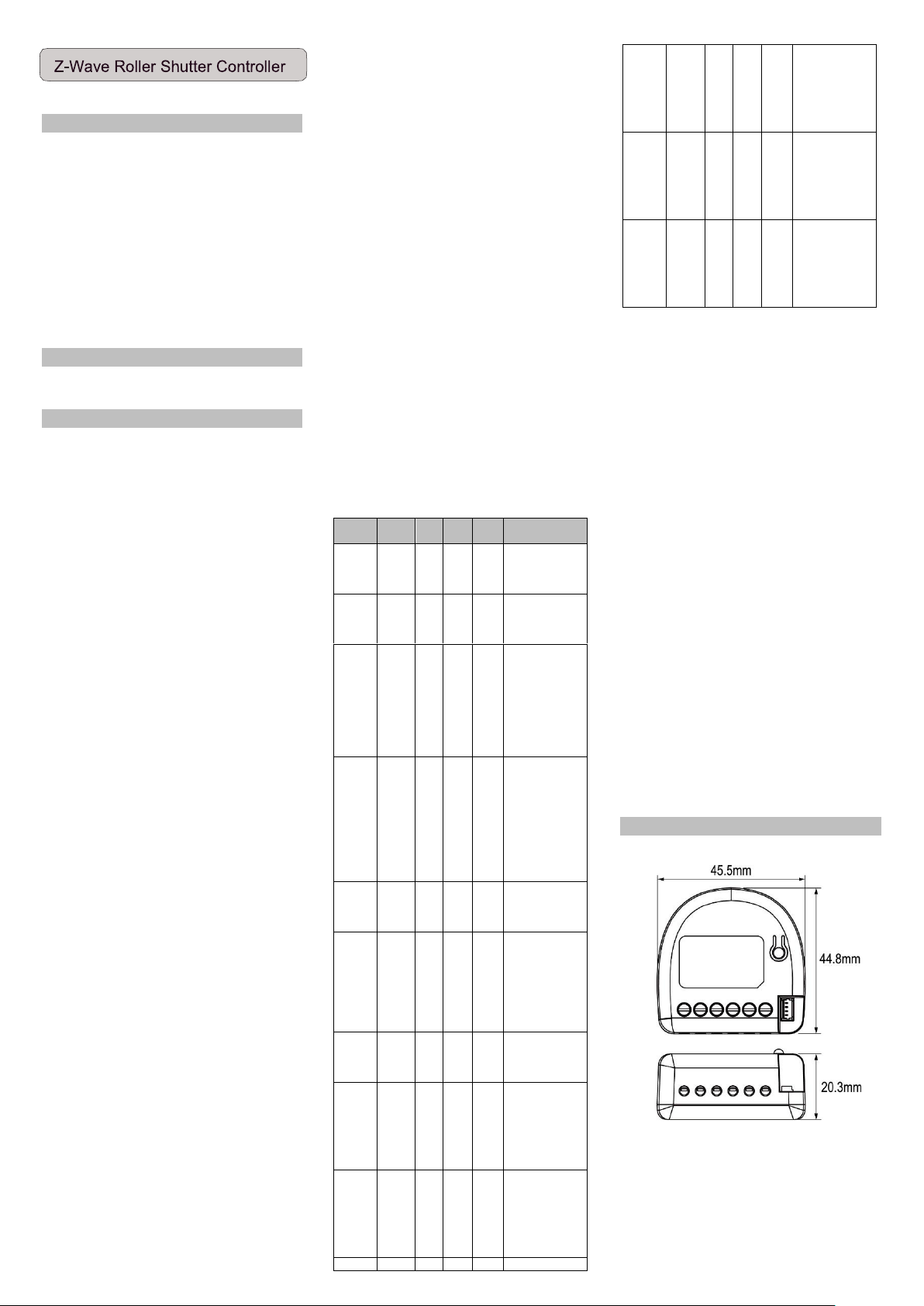

Product Overview

Product Dimensions

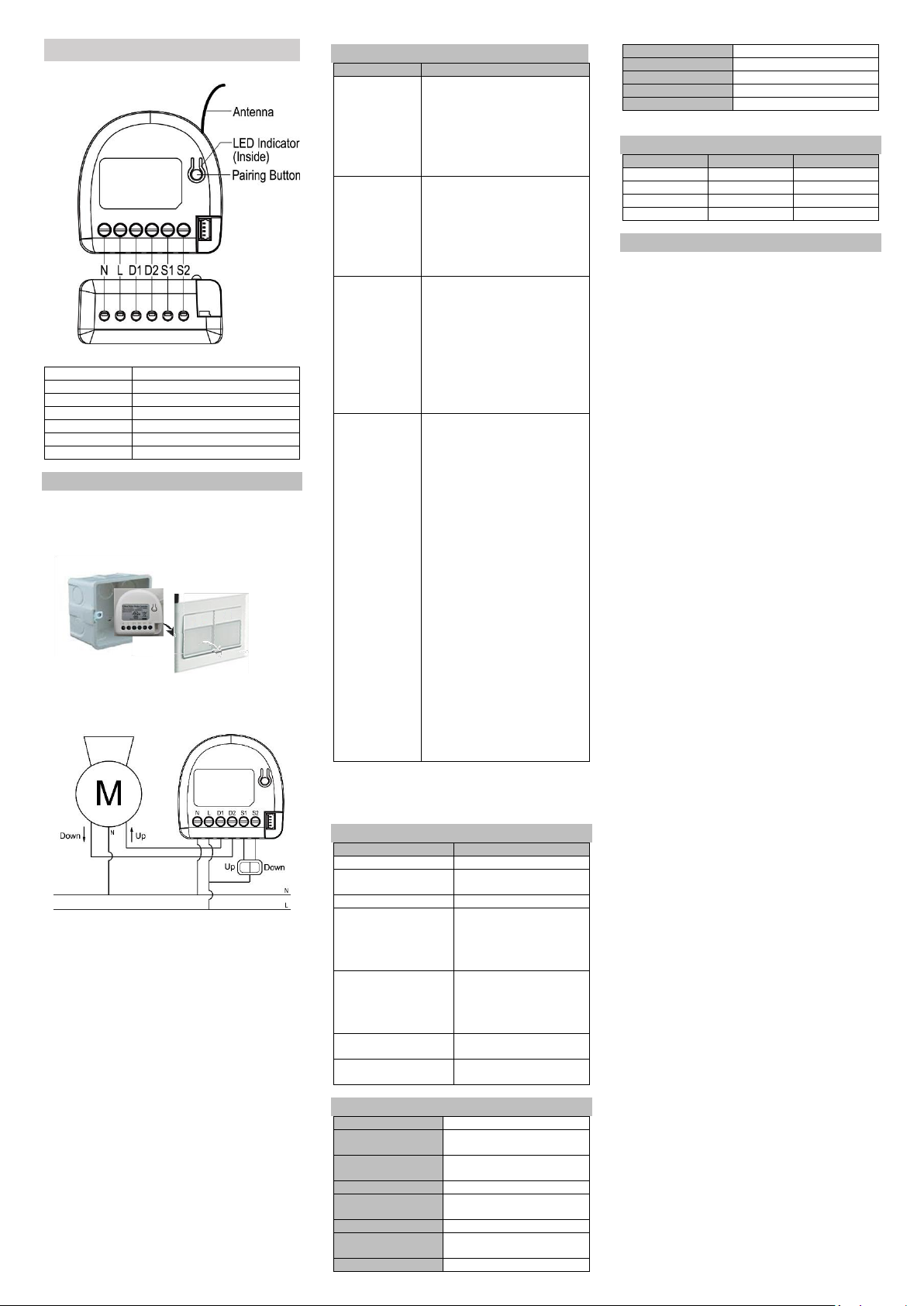

Application Diagram

Main Diagram

- Notes for the Diagram

N

Neutral lead

L

Live lead

D1

Output for motor UP

D2

Output for motor DOWN

S1

Input for switch/push button UP

S2

Input for switch/push button DOWN

Pairing Button

Include/ Exclude/ Reset Button

Device Installation

1. Before installation make sure the voltage supply is disconnected.

2. Put the device into a small box (such as wall box or small plastic

box and etc.) near the motor to avoid direct exposure danger in

the air and to the water.

3. Connect the motor of Roller Shutter and Switch in accordance

with the wiring diagram presented on Fig. 1 (roller blinds,

venetian blinds).

Figure 1. Roller Shutter wiring diagram

4. Locate the antenna far from metal elements (as far as possible)

5. Do not shorten the antenna.

6. Turn on the power supply keeping the necessary safety

precautions.

7. Include the module into the Z-Wave network, please refer to the

"Operation" section for “Inclusion” operating instructions.

8. Executing the positioning calibration process, please refer to the

"Operation" section for “Positioning calibration” operating

instructions.

CAUTION!

! Read this manual before attempting to install the device! Failure

to observe recommendations included in this manual may be

dangerous or cause a violation of the law. The manufacturer will

not be held responsible for any loss or damage resulting from not

following the instructions of operating manual.

! Any maintenance work on controlled devices may be performed

only after the power supply has been disconnected.

! Do not connect the module to loads exceeding recommended

values. Connect the module only in accordance with the diagram

presented in the manual. Improper connections may be

dangerous.

Operation

Function

Operation

Add for Inclusion

1. Put the Z-Wave Controller into

inclusion mode, and press the pairing

button 3 times in 2 seconds to include

the module.

2. Put the Z-Wave Controller into

inclusion mode, and press the “external

swtich1” or “external swtich2” 3 times

in 2 seconds to include the module.

Remove for

Exclusion

1. Put the Z-Wave Controller into

exclusion mode, and press the pairing

button 3 times in 2 seconds to exclude

the device.

2. Put the Z-Wave Controller into

inclusion mode, and press the “external

swtich1” or “external swtich2” 3 times

in 2 seconds to include the module.

Reset

1. Press the pairing button 3 times in 2

seconds and press and hold the pairing

button for more than 5 seconds at the

3rd time.

2. The module is excluded and restores to

factory default setting.

3. Then the module will be in auto-

inclusion mode for 2 minutes.

Please use this procedure only when the

network primary controller is missing or

otherwise inoperable.

Positioning

calibration

Positioning calibration is a process during

which a Roller Shutter learns the position

of the limit switches and a motor

characteristic. Calibration is mandatory in

order for the Roller Shutter to correctly

recognize a roller blind position. The

procedure consists of an automatic, full

movement between the limit switches

(up, down, and up again).

There are three kinds of positioning

calibration operation as follows:

1. Parameter Setting: Parameter 1(0x01),

Size 1(byte), Value 1.

2. Pairing Button: Press and hold the

button for 6 to 10 seconds, release the

button (less than 2 seconds), and then

click the button (less than 2 seconds)

3. External Switch: Use the same external

switch (S1 or S2), turn on and off 3

times. Turn ON =>OFF => ON=> OFF=>

ON=> OFF (Turn ON: lasts 3 to10

seconds), Turn OFF: less than 2

seconds)

Note: If an emergency is encountered

during the positioning calibration process,

please click the external switch, the

pairing button, or the APP to abort the

positioning calibration processes.

Notice: Including a node ID allocated by Z-WaveTM Controller

means “Add” or “Inclusion”. Excluding a node ID allocated by Z WaveTM Controller means “Remove” or “Exclusion”.

LED Indicator

LED Signal

Status

LED OFF

Power OFF

Red & Green blinking by

turns

Power ON (No node ID)

Solid Green

Power ON (Included)

Green blinking twice per

second for 3 seconds

(1) Inclusion process success

(2) Exclusion process success

(3) Parameter setting success

(4) Positioning calibration

success

Red blinking twice per

second for 3 seconds

(1) Inclusion process failed

(2) Exclusion process failed

(3) Parameter setting failed

(4) Positioning calibration

failed

Green blinking twice per

second for 2 minutes

Auto Inclusion Mode

Red blinking twice per

second

Overload Protection

Specification

Wireless Type

Z-Wave Plus

Frequency

EU: 868.4 MHz

US: 916.0 MHz

Operating Distance

up to 100m outdoors ;

up to 30m indoors

Power Supply

110 -230 VAC ±10% 50 / 60 Hz

Rated load current of AC

output (resistive load)

2 @ 5A (230 VAC)

Rated power of Motor

Motor under 170W

Power measurement

accuracy

P = 0-40 W, ± 2 W; P > 40 W, ±3%

Electricity Consumption

<0.5W

LED

Red /Green LED*1

Switching

Relay x 2

Data Rate

100 kbps

Operation temperature

-10°C ~ 40°C

Dimensions (L x W x H)

45.5 x 44.8 x 20.3 mm

*Specification is subject to change without prior notice.

External Switch Operation

S1

S2

Motor Action

Turn OFF

Turn OFF

STOP

Turn ON

Turn OFF

UP

Turn OFF

Turn ON

DOWN

Turn ON

Turn ON

STOP

Regulatory Compliance

CE Caution

Electromagnetic compatibility and Radio spectrum Matters (ERM);

Short Range Devices (SRD); Radio equipment to be used in the 25

MHz to 1,000 MHz frequency range with power levels ranging up to

500 mW; Part 2: Harmon ized EN covering essential requirements

under article 3.2 of the R&TTE Directive.

FCC Caution

This device complies with Part 15 of the FCC rules standard.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including

interference that may cause undesired operation.

Any changes or modifications not expressly approved by the party

responsible for compliance could void the authority to operate

equipment. This device and its antenna must not be co-located or

operating in conjunction with any other antenna or transmitter. This

equipment complies with FCC radiation exposure limits set forth for

an uncontrolled environment. This equipment should be installed

and operated with minimum distance 20cm between the radiator &

your body. This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used i n acc ordance with the

instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the

following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for

help.

WEEE Information

For EU (European Union) member users: According to the WEEE

(Waste electrical and electronic equipment) Directive, do not

dispose of this product as household waste or commercial waste.

Waste electrical and electronic equipment should be appropriately

collected and recycled as required by practices established for your

country.

For information on recycling of this product, please contact your

local authorities, your household waste disposal service or the shop

where you purchased the product.

Z-Wave Plus

This product can be included and operated in any Z-Wave network

with other Z-Wave certified devices from other manufacturers

and/or other applications. All non-battery operated nodes within

the network will act as repeaters regardless of vendor to increase

reliability of the network.

This device must be used in conjunction with a Security Enabled ZWave Controller in order to fully utilize all implemented functions.

Security S2

Security S2 is supported with the Au thenticated and

UnAuthenticated levels of security. The Authenticated level requires

the user to enter the PIN code or QR code printed on the box of the

Roller Shutter. The UnAuthenticated level does not require the PIN

code. Both security levels will encrypt nearly all communication

using AES-128 encryption to ensure reliable and secure

communication.

SmartStart

Sigma Designs technology makes installation easy and secure. Simply

install Roller Shutter into a wall and it will autom atically attempt to

join the Z-Wave network. During the inclusion process, your home

automation system will ask for a PIN code or to scan a QR code. The

pin code is printed on the back of Roller Shutter along with the QR

code. Simply enter the PIN code or scan the QR code with a

compatible device. Each QR code is unique for every device.

SmartStart uses the latest Security S2 encryption technology for all

radio communication. It is completely backwa rds compatible with

non-SmartStart systems if your home automation system doesn’t

support it yet.

Ex:

WARNING: Important safety instructions.

It is important for the safety of persons to follow these instructions.

Save these instructions.

- Important safety instructions. Follow all instructions, since

incorrect installation can lead to severe injury

- All wiring interconnecting with this controller is non-isolated

hazardous live parts.

- The appliance is not to be used by persons (including children)

with reduced physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they have been given

supervision or instruction.

- Frequently examine the installation for imbalance and signs of

wear or damage to cables and springs.

- Do not use if repair or adjustment is necessary.

- Do not allow children to play with fixed controls. Keep remote

controls away from children.

- The drive shall be disconnected from its p ower source during

cleaning, maintenance and when replacing parts.

- Indoor use only.

- Never install independent switch for each S1 and S2, to

prevent the activation on D1 and D2 at the same time.

- Material used only for the 16 AWG copper wires and the

suggested strip length is 4.5 ~ 5 mm.

- Equipment shall not be interconnected with the output of

another power source.

- High Voltage - Disconnect power supply before servicing.

- Risk of Electric Shock - More than one disconnect switch may

be required to de-energize the device before servicing.

Loading...

Loading...