Goodway REAM-A-MATIC Series, REAM-A-MATIC RAM-4X, REAM-A-MATIC RAM-4, REAM-A-MATIC RAM-PTC Operating & Maintenance Instructions

Underwriters Laboratories Inc.

®

®

C US

TUBE CLEANING MACHINES

REAM-A-MATIC

RAM-4/RAM-4X/RAM-PTC

OPERATING & MAINTENANCE

INSTRUCTIONS

$1.00

®

®

Effective date – September 1, 2002

MADE IN U.S.A.

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-21

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-28

RAM-4 and RAM-4X Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

RAM-PTC Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SAVE THESE INSTRUCTIONS

CONSERVE ESTAS INSTRUCCIONES

INSTRUCTIONS D’UTILISATION ET DE MAINTENANCE

BETRIEBSANLEITUNG BITTE AUFBEWAHREN

Goodway reserves the right to improve products.

Contact the factory for the latest configuration and uses.

© Copyright 2004 Goodway Technologies Corporation, Stamford, CT, U.S.A.

Goodway is a Trademark of Per K. Reichborn.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electric tools, basic safety precautions should always be

followed to reduce the risk of fire, electric shock and personal injury, including the

following:

1. Read all instructions before using.

2. Keep this manual with the machine at all times.

3. Do not operate without eye protection.

4. Select proper size cleaning tool.

5. Unplug the power cord when servicing the unit or leaving the unit unattended.

6. Turn off all controls before unplugging the power cord.

7. When unplugging the power cord, grasp the plug – not the cord.

8. Do not use the machine if it has a damaged cord or plug.

9. If the machine does not operate properly or has been damaged, return it to fac

tory for service.

10. Do not use the unit in an environment or on objects that are above 175°F (79°C).

11. Do not handle the base unit or plug with wet hands.

12. Do not use unit with combustible fluids or where combustible fluids or fumes

may be present.

13. Keep objects, loose clothing, hair and body parts away from openings and mov

ing parts.

14. Keep unit clean.

15. Do not roll the machine over the power cord, pull the cord, close the door on

the cord or pull the cord around sharp corners. Keep the cord away from hot

surfaces.

16. Do not operate unit when fatigued or under the influence of alcohol or drugs.

17. Do not over reach or stand on unstable support. Keep good footing and bal

ance at all times.

18. Follow maintenance instructions in manual.

19. Stay alert – watch what you are doing.

20. Use only GOODWAY recommended attachments.

21. Save these instructions.

-

-

-

1

WARNING: Keep clear of moving parts. Make sure moving parts will not catch on

anything before beginning the job. This unit is to be used only by trained operators.

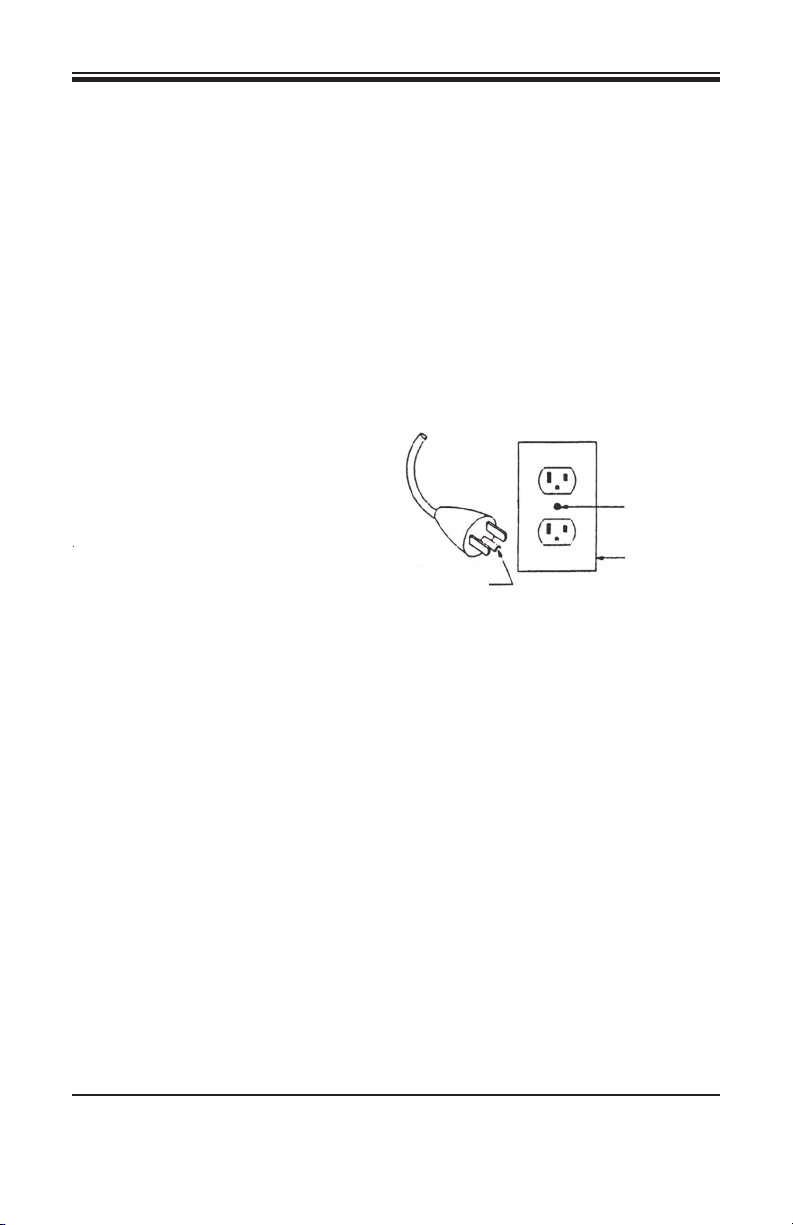

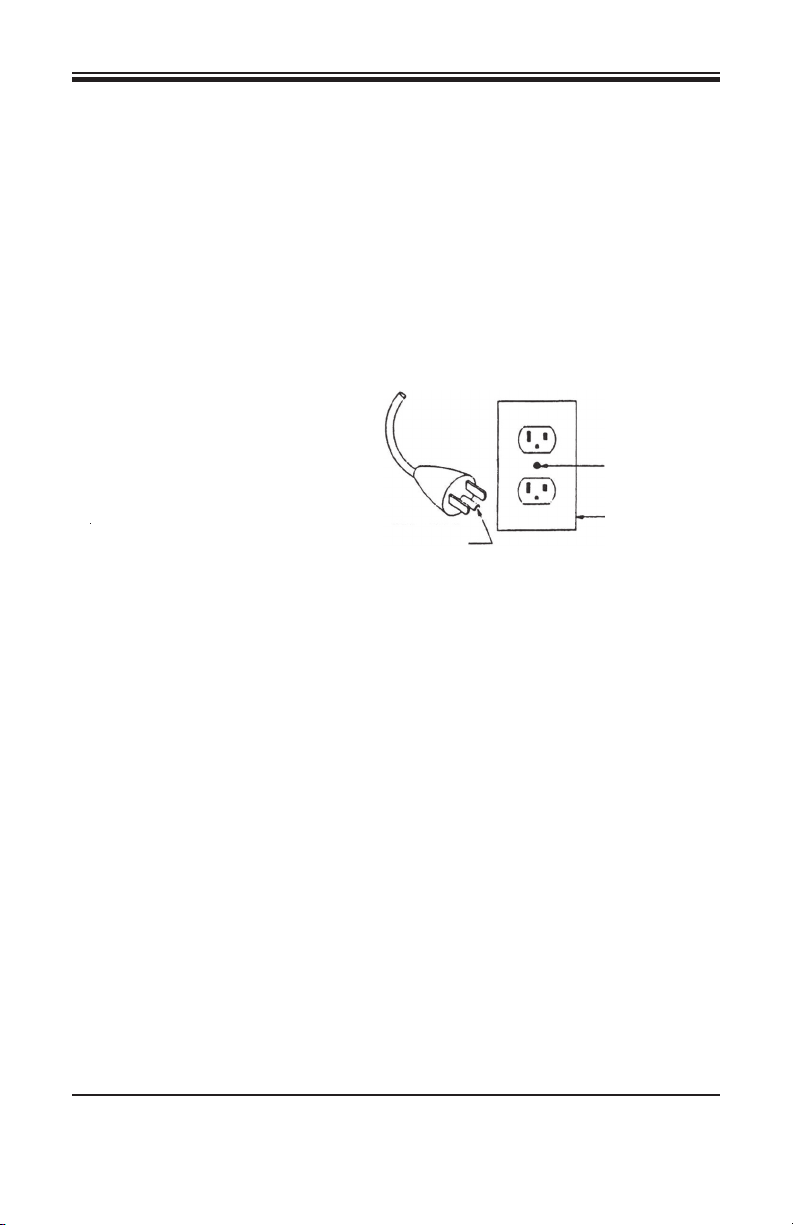

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction or break down, grounding

provides a path of least resistance for electric current to reduce the risk of electric

shock. This product is equipped with a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in accordance with all local codes

and ordinances. The green (or green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or green and yellow) wire to a live

terminal. This product has a plug that looks like that shown here.

DANGER: Improper connection of the

equipment-grounding conductor can

result in a risk of electrocution. Check

with a qualified electrician or service

personnel if you are in doubt as to whether

the outlet is properly grounded.

DO NOT USE ANY TYPE OF ADAPTOR

WITH THIS PRODUCT.

GROUNDING

PIN

METAL SCREW

COVER OF

GROUNDED

OUTLET BOX

The RAM-4, RAM-4X and RAM-PTC are provided with a ground fault circuit

interrupter (GFCI) built into the power supply cord. This device provides

additional protection from the risk of electric shock. Should replacement of

the plug or cord become necessary, use only identical replacement parts that

include GFCI protection.

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding-type plugs and

3-pole cord connectors that accept the plug from the product. Use only extension

cords that are intended for outdoor use. Use only extension cords having an

electrical rating not less then the rating of the product. Do not use damaged

extension cords. Examine extension cord before using and replace if damaged.

When using an extension cord, be sure to use one heavy enough to carry the

current the product will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. The table below shows the correct size

to use depending on cord length and nameplate amperage rating. If in doubt, use

the next heavier gage. The smaller the gage number, the heavier the cord.

2

Minimum Gage of Extension Cords

Ampere

Rating Volts 0-25' (0-7.6m) 26'-50' (7.9-15.3m) 51'-100' (15.6-30.5m) 101'-150' (30.8-45.8m)

8-13 A 120 V 18 16 14 12

4-6.5 A 220 V 18 18 18 16

Do not abuse extension cord and do not yank on any cord disconnect. Keep cord

away from heat and sharp edges. Always disconnect the extension cord from the

receptacle before disconnecting the product from the extension cord.

WARNING: To reduce the risk of electrocution, keep all connections dry and off

the ground. Do not touch plug with wet hands.

THE REAM-A-MATIC – HOW IT WORKS

The Ream-A-Matic uses a flexible shaft, which is available in different lengths

and diameters to fit the size of the tube to be cleaned. As the shaft rotates

inside its watertight nylon casing, the unit feeds water through the casing to the

cleaning tool. While the operator feeds the rotating shaft assembly through the

tube, the water flow flushes out deposits as they are loosened. A solenoid valve

automatically activates the water flow only when the machine is running.

Three models of the Ream-A-Matic are described in this manual: RAM-4,

RAM-4X and RAM-PTC.

The RAM-4 with a 1/2 HP (0.4 kW) motor is designed for cleaning tubes and pipes

1

/4"-1" (6.4-25.4mm) I.D. It is a compact, self-contained, roll-anywhere unit which

permits operation in tight quarters.

The RAM-4X is a heavy-duty version of the RAM-4, equipped with a 1 HP

(0.75 kW) electric motor, it is designed for cleaning tubes over 1" (25.4mm) I.D.

It requires a 1/2" (12.7mm) heavy-duty flexible shaft. The RAM-4X can also be

used for dry applications.

The RAM-PTC Port-A-Ram is a lightweight Ream-A-Matic machine that can

be hand carried, making it ideal for personnel who will use the equipment in

multiple locations. It operates essentially the same as the RAM-4 and performs

the same job. The Port-A-Ram is direct drive so it rotates the cleaning tool at

1,700 rpm.

ASSEMBLY – RAM-4 AND RAM-4X

1. Place the Ream-A-Matic machine on bench or floor with the front

louvered side down.

3

2. Insert the two large plastic thumbscrews through slotted holes in the handle

bar and fasten loosely into the tapped holes in the middle of each side of the

machine.

3. Push the connecting bar up against the drive unit so that the dolly bar is tight

against the bottom of the drive unit.

4. Tighten the two thumbscrews, and turn the machine upright.

CONNECTING FLEXIBLE SHAFTS – ALL MODELS

1. Select the proper size flexible shaft (GTC-701, GTC-702, GTC-703, GTC-704,

GTC-720, GTC-721) for tube diameter and length to be cleaned.

Note:

2. Insert square end of flexible shaft into the square in the drive shaft of the

3. Tighten large nut securely, making sure O-Ring (P/N 805) is in place.

The heavy-duty 1/2" (12.7mm) diameter flexible shaft (GTC-720, 721)

should be used for the RAM-4X machine [O.D. of outer casing is 3/4" (19.1mm)

and 0.955" (24.3mm) respectively].

machine. The shaft may have to be turned slightly for alignment.

OPERATION

CAUTION: Do not operate the Ream-A-Matic without eye protection.

WET APPLICATION – ALL MODELS

1. Connect water hose to water inlet. Water supply should be clean

(use screen washer) to avoid clogging orifice in solenoid valve.

Consult the Goodway catalog for heavy-duty water supply hose.

2. Open water supply line. DO NOT RUN DRY. Solenoid on drive unit will allow

water to flow through the flexible shaft assembly only when the machine is

running.

3. Plug electric cord into an outlet in accordance with voltage and amperage

of the nameplate.

4. Tip the machine over on its back side so that flexible shaft is parallel to floor.

(RAM-4 and RAM-4X).

5. Remove footswitch from tool storage compartment, and position switch in

a convenient position for the operator.

4

6. Select proper size cleaning tool and thread onto end of flexible shaft. Never

use a tool larger than I.D. of tube.

Note: Brush and buffing tools for tubes 7/16"-1" (11.1-25.4mm) I.D. are available

with quick connect couplings.

Note: Most tubes are rolled at tube sheet. Always measure I.D. beyond roll

or consult manufacturer’s manual for tube O.D. and gauge.

7. Locate shaft locator on the outside of the flexible shaft (GTC-701, GTC-702,

GTC-703, GTC-704 and GTC-720 only) in a position so that when the shaft is

fully inserted in the tube, only half the cleaning tool extends outside the other

end of the tube. (GTC-721, GTC-721G and GTC-821 can be marked with a

tape).

8. When necessary, the drive unit can be used separately from the dolly by

removing the two plastic thumbscrews. (RAM-4 and RAM-4X).

9. Uncoil flexible shaft completely and feed it into the tube. DO NOT FORCE

SHAFT DOWN TUBE. Allow machine to do the work. If resistance is felt, back

off 2"-3" (51-76mm) and feed shaft again until it goes easily. If

resistance is too great, use a smaller cleaning tool.

10. For easiest operation, if possible, insert shaft into tube and allow to remain

there for several hours before starting in order to remove loops from flexible

shaft.

DRY APPLICATION – RAM-4X ONLY

The RAM-4X may be adapted for use without water flush. Follow steps 3 through

10 only under “OPERATION – WET APPLICATION”.

Note: Specially designed flexible shaft (GTC-721) for dry application must be

used.

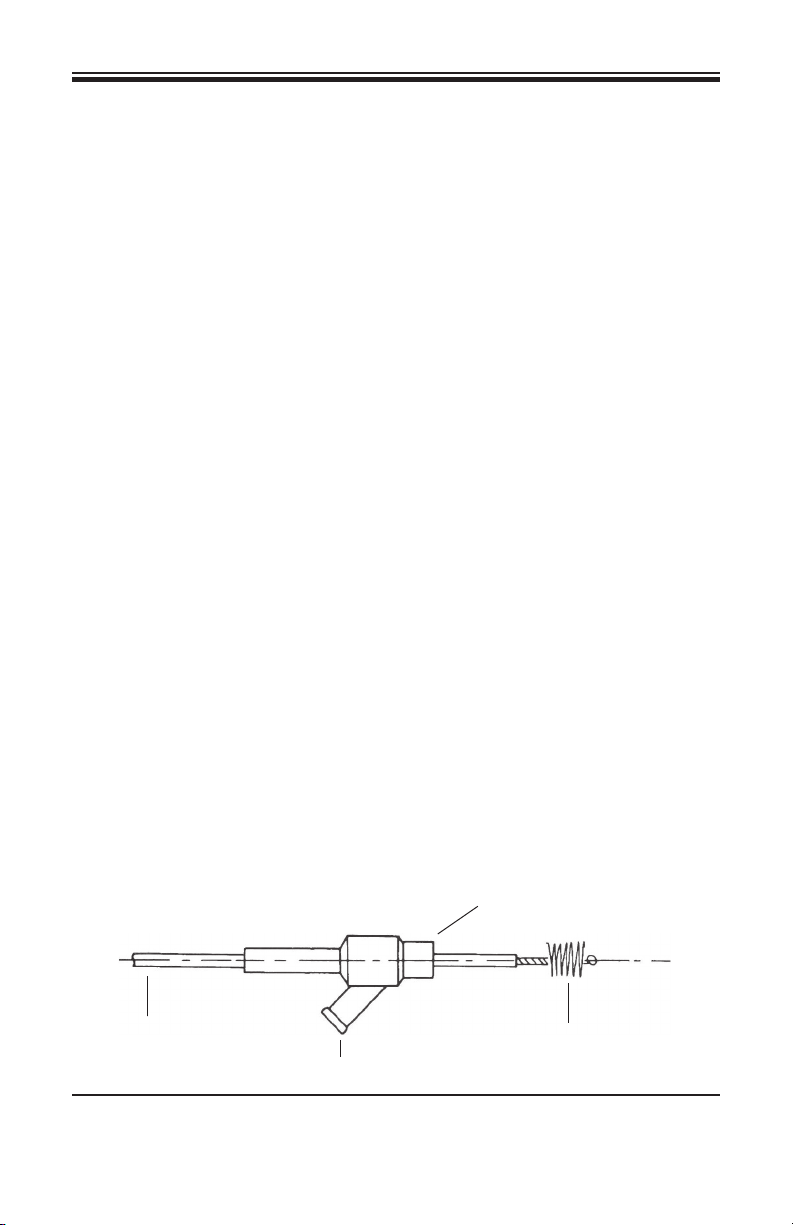

1. VACUUM PICK-UP: Use GTC-DPA assembly as shown below. Extension tube

nozzle (BFN-152S) can be ordered according

to the size of the tube to be cleaned.

Flexible Shaft (GTC-721)

Connect to RAM

Connect to Vacuum

Tube Nozzle (BFN-152S)

Inserted into Tube to be Cleaned

Cleaning Tool

5

2. AIR FLUSH: Compressed air may be used instead of water flush for removal of

deposit simply by connecting an air supply line to the water inlet of the machine.

CAUTIONS

1. The RAM-4X is designed to be used either wet or dry – not both. It is

equipped with a water seal. If used dry, the water seal will no longer

prevent water leakage.

2. Minimum operating radius of flexible shaft is 18" (460mm). However, it

is recommended that the shaft be kept as free from loops as possible.

This is especially critical nearest the drive unit.

3. Do not allow water to freeze in unit.

STORAGE – ALL MODELS

Disconnect water supply line. Disconnect the flexible shaft and drain water

to prevent rusting of shaft. Do not store machine where residual water in

machine may freeze. Refer to Flexible Shaft manual for flexible shaft storage.

USING THE RAM-4 WITH THE OPTIONAL

TWO-DIRECTION FOOTSWITCH

When cleaning internally enhanced tubes, it is sometimes desirable to use a

brush that rotates in both directions. The RAM-6 is best for this application.

However, every RAM-4 is wired for two-direction rotation and only requires

the two-direction footswitch to convert the standard machine.

INSTALLING THE TWO-DIRECTION FOOTSWITCH

1. Disconnect the standard footswitch from the air switch, located inside the

tool box, by pulling the tubing off of the barbed fitting. Be careful not to snap

off the barbed fitting. It is possible to pry the tubing off using the blade of a

small screwdriver but great care must be taken not to break the barb.

2. Connect the twin hose from the two-direction footswitch to the two air

switches located inside the tool box. The air switches are labeled

“FORWARD” and “REVERSE.” When the brush is rotating clockwise when

viewed from behind, the machine is in the “FORWARD” direction. The twin

tubing can be connected to the air switches either way as long as you know

which side of the footswitch activates which air switch.

6

3. Should it become necessary to reconnect the standard footswitch to the

RAM-4, be sure to connect the tubing from the footswitch to the air switch

marked “FORWARD.”

CLEANING INTERNALLY ENHANCED TUBES

1. Select the proper size brush and thread it onto the flexible shaft until it is

hand tight. Hold the shaft coupling with pliers and tighten the jam nut

against the shaft coupling with a wrench. This will prevent the brush from

unthreading when in the reversed direction. USE ONLY BRUSHES WHEN

CLEANING INTERNALLY ENHANCED TUBES.

Note: Use of quick connect brushes eliminates the need for wrenches and

plyers – see the Goodway catalog.

2. Position the shaft locator on the outside of the flexible shaft so that when

the shaft is fully inserted into the tube, the entire bristle portion of the brush

extends outside the tube. The bristles must clear the tube before the brush

can be reversed. Care must be taken not to allow the exposed part of the

flexible shaft to extend beyond the tube end to prevent the wires from being

cut by the sharp end of the tube.

3. The design of the brush and the spiral in the tube cause the brush to move

through the tube with very little assistance from the operator. Depress the

“FORWARD” side of the footswitch to enter the tube. To prevent undue strain

on the flexible shaft, do not change in/out direction or rotation direction until

the brush leaves the opposite end of the tube. Allow rotation to stop before

depressing the “REVERSE” side of the footswitch to exit the tube. The motor

must stop before it can reverse.

Note:

Although the RAM-4 can be used to clean internally enhanced tubes,

the RAM-6 is best for this application as it will allow the brush bristles into

the grooves better. The fixed speed of the RAM-4 requires a fast feed rate,

(the speed of the shaft going into the tube). If the feed rate is not met, the

bristles jump over the grooves leaving them fouled.

CLEANING TOOLS

Consult the Goodway catalog for available cleaning tools and recommended

uses.

7

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

ADVERTENCIA: Cuando se utilicen herramientas eléctricas, siempre se deberán

tomar precauciones para reducir el riesgo de incendios, sacudidas

eléctricas y lesiones personales, incluyendo las siguientes:

1. Lea todas las instrucciones antes de la utilización.

2. Mantenga este manual junto a la máquina en todo momento.

3. No haga funcionar la máquina sin protección para los ojos.

4. Escoja la herramienta limpiadora del tamaño apropiado.

5. Desenchufe el cordón de la corriente cuando esté haciéndole mantenimiento

a la unidad o cuando está dejando la unidad sin atención.

6. Apague todos los controles antes de conectar el cordón de la corriente.

7. Cuando desconecte el cordón de la corriente, jale el enchufe – no el cordón.

8. No opere esta máquina si tiene el cordón de corriente o el enchufe dañado.

9. Si la máquina no funciona correctamente o ha sufrido daños, devuélvala a

la fábrica para su reparación.

10. No use esta unidad en ambientes o en objetos con mas de 175°F (79°C) de

temperatura.

11. No maneje la base de la unidad ni la conecte con las manos mojadas.

12. No use esta unidad con combustibles líquidos o donde haya presencia de humos

combustibles.

13. Mantenga objetos, ropas flojas, cabello y partes del cuerpo lejos de las aberturas

y las piezas móviles.

14. Conserve la unidad bien limpia.

15. No ruede la máquina sobre el cordón de la corriente, jale el cordón, cierre la puerta

sobre el cordón o jale el cordón sobre superficies cortantes. Mantenga el cordón

lejos de superficies calientes.

16. No haga funcionar la unidad cuando esté cansado o bajo los efectos de alcohol

o drogas.

17. No se extienda en exceso ni permanezca de pie sobre objetos inestables.

Mantenga los pies bien asentados y un buen equilibrio en todo momento.

18. Siga las instrucciones de mantenimiento que se dan en el manual.

19. Manténgase alerta y observe siempre lo que está haciendo.

20. Use sólo aditamentos Goodway recomendados.

21. Conserve estas instrucciones.

8

ADVERTENCIA: Mantengase fuera del alcance de partes móviles. Asegúrese que las

partes móviles no se enreden en cualquier cosa antes de empezar el trabajo. Esta unidad

solo debe ser usada por personal que ha sido entrenado en su uso.

INSTRUCCIONES DE TOMA DE TIERRA

Este producto debe tener una conexión a tierra. En caso de que se descomponga o

tenga alguna falla de funcionamiento, la toma de tierra proporciona una trayectoria de

menor resistencia para la corriente eléctrica, de modo que se reduzcan los riesgos de

descargas eléctricas. Este producto va equipado con un cable que tiene un conductor

de puesta a tierra del equipo y una clavija de masa. Esta última se deberá insertar en una

toma apropiada que esté bien instalada y conectada a tierra de conformidad con todos

los códigos y reglamentos locales.

PELIGRO: Una conexión incorrecta del

conductor de puesta a tierra del equipo

puede dar como resultado que haya

riesgos de electrocución. Si tiene dudas

respecto a si la toma de corriente tiene

una conexión adecuada a tierra,

consulte al personal de mantenimiento

o a un electricista competente.

ALAMBRE DE

CONEXIÓN

A TIERRA

NO USE CON ESTE PRODUCTO NINGÚN TIPO DE ADAPTADOR.

Los modelos RAM-4, RAM-4X Y RAM-PTC vienen equipados con un circuito de interruptor

de falla de conexión a tierra (GFCI) dentro del cordón de alimentación de corriente. Este

dispositivo provee protección adicional contra el riesgo de choque eléctrico. Si fuera

necesario reemplazar el enchufe o el cordón, reemplácelo solamente con partes idénticas que tengan la protección GFCI.

TORNILLO DE METAL

CUBIERTA DEL

TOMACORRIENTE CON

CONEXIÓN A TIERRA

CABLES DE EXTENSIÓN

Use sólo cables de extensión de tres conductores, que tengan enchufes de toma de tierra

de tres contactos y conectores de tres puntas que acepten el enchufe del producto.

Utilice sólo cables de extensión para uso en exteriores. Estos últimos se identifican

mediante una inscripción que dice: “Aceptable para uso con aparatos exteriores.

Almacénese al interior cuando no se esté utilizando”. No utilice cables de extensión

dañados. Examine el cable de extensión antes de usarlo y reemplácelo si está dañado.

Cuando emplee un cable de extensión, asegúrese de que sea suficientemente fuerte

para llevar la corriente que consumirá el producto. Un cable de tamaño demasiado

pequeño provocará una caída de voltaje que dará como resultado pérdida de potencia

y recalentamiento. En la tabla que sigue se muestra el tamaño correcto que se deberá

usar, dependiendo de la longitud del cable y el valor nominal de amperaje de la placa de

indicaciones. Si tiene dudas, use el tamaño mayor que sigue. Cuanto más pequeño sea

el número de calibre, tanto más pesado será el cable.

9

Loading...

Loading...