Goodway GPW-1200, GPW-1000, GPW-1000-P, GPW-250, GPW-2003 Operating & Maintenance Instructions

...

OPERATING & MAINTENANCE

INSTRUCTIONS

$1.00

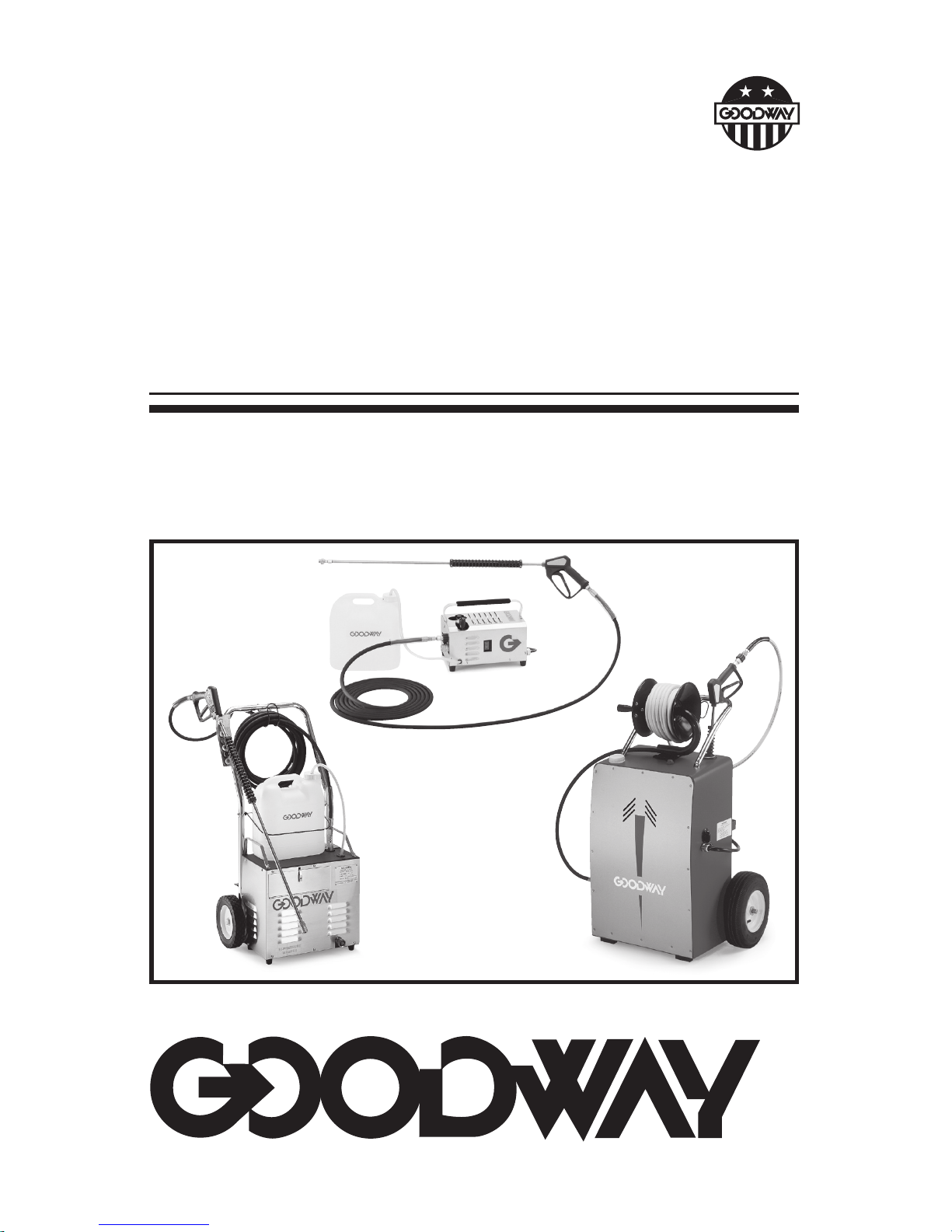

PRESSURE

WASHERS

GPW-1200 • GPW-1000 • GPW-1000-P

GPW-2003 • GPW-2502

®

Effective date – June 1, 2004

MADE IN U.S.A.

© Copyright 2004 Goodway Technologies Corporation, Stamford, CT, U.S.A.

Goodway is a Trademark of Per K. Reichborn.

Goodway reserves the right to improve products.

Contact the factory for the latest configuration and uses.

SAVE THESE INSTRUCTIONS

1

IMPORTANT SAFETY INSTRUCTIONS

To prevent operator injury and damage to the equipment, please read and observe the

following basic safety precautions:

1. Read all the instructions before using the product.

2. To reduce the risk of injury, close supervision is necessary when the

product is used near children.

3. Know how to stop the product and bleed pressures quickly. Be thoroughly

familiar with the controls.

4. Stay alert – watch what you are doing!

5. Do not operate the product when fatigued or under the influence of

alcohol or drugs.

6. Keep operation area clear of all persons.

7. Do not overreach or stand on unstable support. Keep good footing and

balance at all times.

8. Follow the maintenance instructions specified in the manual.

9. Check with your local water utility to see if a backflow preventer is

required.

WARNING: Risk of Injection or Severe Injury – Keep Clear of Nozzle – Do Not

Direct Discharge Stream at Humans or Animal – This Product Is to be Used Only

by Trained Operators.

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction or break down,

grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This product is equipped with a cord having an

equipment-grounding conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER: Improper connection of the equipment-grounding conductor can

result in a risk of electrocution. Check with a qualified electrician or service

personnel if you are in doubt as to whether the outlet is properly grounded.

DO NOT USE ANY TYPE OF ADAPTOR WITH THIS PRODUCT.

2

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION:

GPW-1200/GPW-1000/GPW-2003/2502

These pressure washers are provided with a ground fault circuit interrupter

(GFCI) built into the power supply cord. This device provides additional

protection from the risk of electric shock. Should replacement of the plug

or cord become necessary, use only identical replacement parts that include

GFCI protection. (GPW-2003-3 and GPW-2502-3 three phase units do not have

GFCI and must be connected to one).

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding-type plugs

and 3-pole cord connectors that accept the plug from the product. Use only

extension cords that are intended for outdoor use. These extension cords are

identified by a marking, “Acceptable for use with outdoor appliances; store

indoors while not in use.” Use only extension cords having an electrical rating

not less than the rating of the product. Do not use damaged extension cords.

Examine extension cord before using and replace if damaged.

Do not abuse extension cord and do not yank on any cord disconnect. Keep

cord away from heat and sharp edges. Always disconnect the extension cord

from the receptacle before disconnecting the product from the extension cord.

WARNING: To reduce the risk of electrocution, keep all connections dry and off

the ground. Do not touch plug with wet hands.

CAUTIONS: GPW-1200/GPW-1000/GPW-1000-P

1. When machine is shut down, a small amount of water is left in pump

and plumbing; therefore, THE MACHINE MUST NOT BE STORED UNDER

FREEZING CONDITIONS. If necessary, a small amount of antifreeze may

be pumped through the system if machine is left in cold storage.

2. Do not run pump dry.

3. When pump is running without spraying, the bypass valve allows the

water to circulate around the pump. This condition will gradually elevate the

temperature of the water through friction, and overheating will

damage the pump seals. Therefore, THE PUMP MUST BE ALLOWED

TO RUN MORE THAN 10 MINUTES WITHOUT SPRAYING.

3

4. The Goodway GPW-1000 and GPW-1000P may be used with warm water

supply at a maximum of 180°F (82°C), and the GPW-1200 at a maximum of

140°F (60°C) to improve cleaning. IF WARM WATER SUPPLY IS USED, THE

TIME IN NO. 3 SHOULD BE REDUCED FURTHER.

5. Since the high pressure spray is very powerful, DO NOT AIM AT OR SPRAY

HUMANS OR ANIMALS.

6. Do not operate without eye protection.

CAUTIONS: GPW-2003/GPW-2502

1. Avoid exposing the machine to freezing temperatures as the pump can be

severely damaged if water is allowed to freeze in it. If the unit must be exposed to freezing, run pump dry approximately 10 seconds to drain the pump.

2. Do not run the pump dry.

3. The GPW-2003 and GPW-2502 may be connected to a warm water

supply at a maximum of 160°F (71°C) to improve cleaning action. (See

“MAINTENANCE” for further information regarding warm water operation).

4. Since the high pressure spray is very powerful, DO NOT AIM AT OR SPRAY

HUMANS OR ANIMALS.

5. Do not operate without eye protection.

6. The GPW-2003 and GPW-2502 can only be run in the vertical position.

7. To avoid inadvertent operation, turn power off when the unit is not used for

an extended period of time or when the unit's operator departs the area.

ASSEMBLY INSTRUCTIONS: GPW-1200

The GPW-1200 comes virtually ready to use. Final assembly requires only

the connection of the gun/wand and high pressure hose using the quick

disconnect fitting. Insert the dip tube into the chemical container.

ASSEMBLY INSTRUCTIONS: GPW-1000

1. Place power unit on bench or floor with louvers down. Place dolly

assembly on back and insert the two plastic thumbscrews through the

tapped holes on the back of the power unit.

4

2. Turn the machine upright and connect the end of the high pressure hose to

the quick disconnect fitting on the top of the machine.

3. Assemble water connection fitting in front bottom edge of cover and

carefully thread onto nipple (P/N 1004). Tighten securely.

4. Place chemical container (if used) on top of unit inside the retaining bail and

place dip tube inside container. Make sure dip tube strainer is attached to

dip tube.

ASSEMBLY INSTRUCTIONS: GPW-1000-P

1. Place power unit on bench or floor with louvers down. Place dolly assembly

on back and insert the two thumbscrews through the tapped holes on the

back of the power unit.

2. Assemble water connection fitting in front bottom edge of cover and

carefully thread onto nipple (P/N 1004). Tighten securely.

3. Place chemical container (if used) on top of unit inside the retaining bail and

place dip tube inside container. Make sure dip tube strainer is attached to

dip tube.

4. Connect the high pressure hose to the quick disconnect fitting on the top of

the machine. Connect air hoses to valves (P/N 1060) – either air hose can be

connected to either valve.

ASSEMBLY INSTRUCTIONS: GPW-2003/GPW-2502

1. Remove the unit from the packing material and inspect for damage.

2. Ensure there is sufficient oil in the pump by inspecting the window on

the back of the unit.. Oil level should be in the middle of the window.

DO NOT OVERFILL!

3. Connect the end of the high pressure hose to the fitting on the side of

the machine.

OPERATING INSTRUCTIONS: GPW-1200

1. Connect water hose capable of delivering a minimum of 1.8 GPM

(6.8 LPM) to inlet and turn on faucet. Consult the Goodway catalog for

heavy-duty water supply hose. DO NOT RUN PUMP DRY.

Loading...

Loading...