goodnature X-6, EG-260 Owner's Manual

COMMERCIAL COLD

PRESS JUICER

OWNER’S MANUAL

CONFORMS TO UL STD 763,

CERTIFIED TO CSA STD C22.2 #195

CONFORMS TO CE, IEC TESTED

SERIAL #

R05

Introduction

WARNING : To limit risk of personal i njury and mater ial damage, all users mus t read these ins tructions

in their entirety a nd follow them strictly.

MACHINE SPECIFICATIONS

X-6 Press | 1HP | 220VAC | 8.12 Amp | Single Phase

EG-260 Grinder | 2HP | 220Vac | 5.6 Amp | Single Phase

Capacity per Hour:

JUICE: 40-100 GAL. / 150-380 L.

Dimensions (H” x W” x D”):

WITH HOPPER AND GRINDER:

77” x 59” x 62”

196cm x 150cm x 158cm

WITH HOPPER, WITHOUT GRINDER:

57” x 59” x 59”

145cm x 150cm x 150cm

WITHOUT HOPPER OR GRINDER:

46” x 59” x 46”

117cm x 150cm x 117cm

Total Weight:

1000 lb.

454 KG

Pressure:

CAPABLE OF 12 TONS TOTAL

FORCE ON PRODUCE

GOODNATURE X-6 COMMERCIAL COLD PRESS JUICER

OWNER’S MANUAL

02

35

Table of Contents

SECTION 1

SECTION 2

SECTION 2.1

SECTION 2.2

SECTION 3

SECTION 3.1

SECTION 3.2

SECTION 4

SECTION 4.1

SECTION 4.2

SECTION 4.3

SECTION 4.4

SECTION 4.5

SECTION 5

Safet y Precautions

Unpacking

Unpacking

Enclosed Parts List

Machine Diagrams

X-6 Press Diagrams

EG-260 Grinder Diagrams

Installation and Setup

Installation

Electrical Diagram

Setup - Rack Straps

Setup - Press Bags

Setup - Bag Keepers

Operation

PAGE 05

PAGE 07

PAGE 07

PAGE 07

PAGE 09

PAGE 09

PAGE 10

PAGE 11

PAGE 11

PAGE 12

PAGE 13

PAGE 14

PAGE 15

PAGE 17

SECTION 5.1

SECTION 5.2

SECTION 5.3

SECTION 5.4

SECTION 5.5

SECTION 6

SECTION 6.1

SECTION 6.2

SECTION 7

Grinder Operation

Changing Grinder Disc

Press Operation

Adjusting Press Speed

Adjusting Hydraulic Pressure

Cleaning

Machine Cleaning

Bag Cleaning

Maintenance

GOODNATURE X-6 COMMERCIAL COLD PRESS JUICER

OWNER’S MANUAL

PAGE 17

PAGE 19

PAGE 20

PAGE 22

PAGE 24

PAGE 25

PAGE 25

PAGE 27

PAGE 28

03

35

Table of Contents

SECTION 8

SECTION 9

SECTION 9.1

SECTION 9.2

SECTION 9.3

SECTION 9.4

Troubleshooting

Useful Information

Replacement Parts List

Improving Yield

Warranty

Contact Information

PAGE 30

PAGE 31

PAGE 31

PAGE 33

PAGE 34

PAGE 34

GOODNATURE X-6 COMMERCIAL COLD PRESS JUICER

OWNER’S MANUAL

04

35

Section 1: Safety Precautions

DANGER : This machine is not intended for use by persons (including child ren) with reduced phy sical,

sensor y, or mental capabilities, or la ck of experience a nd knowledge, unle ss they have been g iven super vision

or instr uction concerni ng use of the machine by a person responsible for their safe ty.

DANGER : Never place hands, ar ms, or any foreig n items into the grinder hopper, grinder chute, or g rinder

housing du ring operation. Persona l injury including lacer ations and amputat ions, or damage to the ma chine

can occur.

DANGER : Never place any b ody part bet ween the platens whi le the machine is on . Failure to follow t his

instr uction could resu lt in serious person al injury due to crushin g.

WARNING : Power must be supplied to the X-6 and EG-260 b y a licensed electricia n. Failure to do so m ay

result in s erious persona l injury due to electr ic shock or dama ge to the machine.

WARNING : Be aware of all pi nch points and moving parts a nd take precautions to keep loose cloth ing,

hair, or forei gn objects away from them to avoid p ersonal injury and da mage to the machine.

WARNING : Disconnect a ll power before per forming maintena nce to avoid risk of ser ious electric shock.

WARNING : Always check with your loca l health depar tment regardi ng procedures re quired to ensure proper

cleaning and sanit ation in order to avoid serious foodborne ill ness to consumer s.

For the US: http ://ww w. fda.gov/Food/default .htm

WARNING : Discontinue use immediately and have machine ser viced if any c omponents are dam aged or

malf unctioning to avoid risk of p ersonal injury and da mage to the machine.

WARNING : Disconnect a ll power before moving the machine. Avoid damagi ng the power supply cord du ring

movement and use cautionar y steps to avoid tipping.

WARNING : Electrica l and mechanic al repairs a re not to be carr ied out by the operator unless

authoriz ed to do so.

GOODNATURE X-6 COMMERCIAL COLD PRESS JUICER

OWNER’S MANUAL

05

35

Section 1: Safety Precautions

WARNING : Operator sha ll not interfere w ith interlock device .

WARNING : Operator should not use unaut horized means of gain ing access to parts of the ma chine which are

not normally accessible.

WARNING : Operator should en sure plug is visible f rom points of acces s.

WARNING : Operator should en sure the surrounding a rea is free of debris and sl ipping ha zards to

pr event i njury.

WARNING : In the event of an acc ident or breakdown , all power supply should be dis connected fr om source

and Goodnature customer ser vice should be cont acted for suppor t.

CAUTION: Sa fety glass es must be worn at al l times during operation of the E G-260 Grinder. Machine can be

run at a ver y high speed; splatter and projectile s causing eye da mage and irr itation is possible.

CAUTION: Bla des on the grinder disc are very s harp. Use caution when chan ging the disc t o avoid personal

injury including lacerations.

NOTICE: T he X- 6 Press is only to be used in conjunction w ith the EG-260 Gr inder. Do not mount any other

equipment to t he X- 6 Press.

NOTICE: Noise levels exceed 80 de cibels. Protec tive ear equipment should be worn to prevent i nju ry.

NOTICE: R elieve pressure from hy draulic syst em by cycling the d irectional c ontrol lever prior to ser vicing.

GOODNATURE X-6 COMMERCIAL COLD PRESS JUICER

OWNER’S MANUAL

06

35

Section 2: Unpacking

2.1 UNPACKING

This equipment underwent strict quality control and was carefully inspected mechanically and electrically before

shipment. It should be physically free of marks or scratches and in good electrical order upon delivery. Inspect for

physical damage, electrical damage, and any loose or bare wires.

If any items are damaged due to shipping, contact the freight carrier within 15 days of receiving your shipment.

There is an enclosed parts list below. Inspect a ll enclosed parts carefully and make sure no par ts are missing. If

any parts a re missing or damaged please contact Goodnature Products at 1-800-875-3381.

After unpacking a nd before running, it is importa nt to check that one of the fasteners had become loose during

shipping. Check all nuts, bolts, and screws to make sure everything is tight.

2.2 ENCLOSED PARTS LIST

PART #

19224-R01

14064

14010

14279

14054

18581

19568

12339

20486

11153

11154

11512

11513

PART NAME

Press Rack Assembly

Rack Strap

Press Bag Set (medium weave)

Juice Tray & Hopper Tri-Cla mps

Juice Tray Clamp Gasket

Juice Tray Hose Adapter

Pomace Scoop

Cake Separator

Bag Keepers

Juice Tray Hose

Juice Tray Hose Clamp

Hopper Drain End Cap

Hopper Drain Gasket

QTY

5

4

1

2

1

1

1

1

2

5’

1

1

1

DESCRIPTION

Plastic ridged racks with strap hooks

White straps with holes

White cloth bag set

Stainless steel clamp with tightening screw

Black buna rubber clamp gasket

Stainless steel adapter for hose attachment

Stainless steel paddle with scraper end

Plastic paddle

Rubber cords (3’ long)

Clear, vinyl 1” diameter tube

3/4” x 1-3/4” hose clamp

Solid end cap, 1-1/2”

Black buna rubber clamp gasket

GOODNATURE X-6 COMMERCIAL COLD PRESS JUICER

OWNER’S MANUAL

07

35

Section 2: Unpacking

2.2 ENCLOSED PARTS LIST - CONTINUED

IF PURCHASED, ENCLOSED PARTS FOR EG-260 GRINDER:

PART #

11127

11128

11130

19103

11810

12566

13967

19351

19664

13778

15438

PART NAME

Grinder Disc 3/16”

Grinder Disc 1/4”

Grinder Disc 1/2”

Grinder Disc Backing Plate

Screws for Backing Plate

Grinder Shredder plate Knob

Shredder plate Knob Washer

Hopper Chute

Hopper Gasket

Hopper Knobs

Product Feeder

QTY

1

1

1

1

8

1

1

1

1

4

1

DESCRIPTION

Metal g rinder disc with small holes

Metal g rinder disc with medium holes

Metal g rinder disc with large holes

White plastic disc with raised spokes

Stainless steel PHMS 10-32 x 3/4 screws

Triangular stainless steel knob for disc

Stainless steel washer for shredder plate knob

26” Sta inless steel tube with square base

White U-shaped gasket with four holes in the corners

Black plastic knobs

Round stainless steel paddle with handle

GOODNATURE X-6 COMMERCIAL COLD PRESS JUICER

OWNER’S MANUAL

08

35

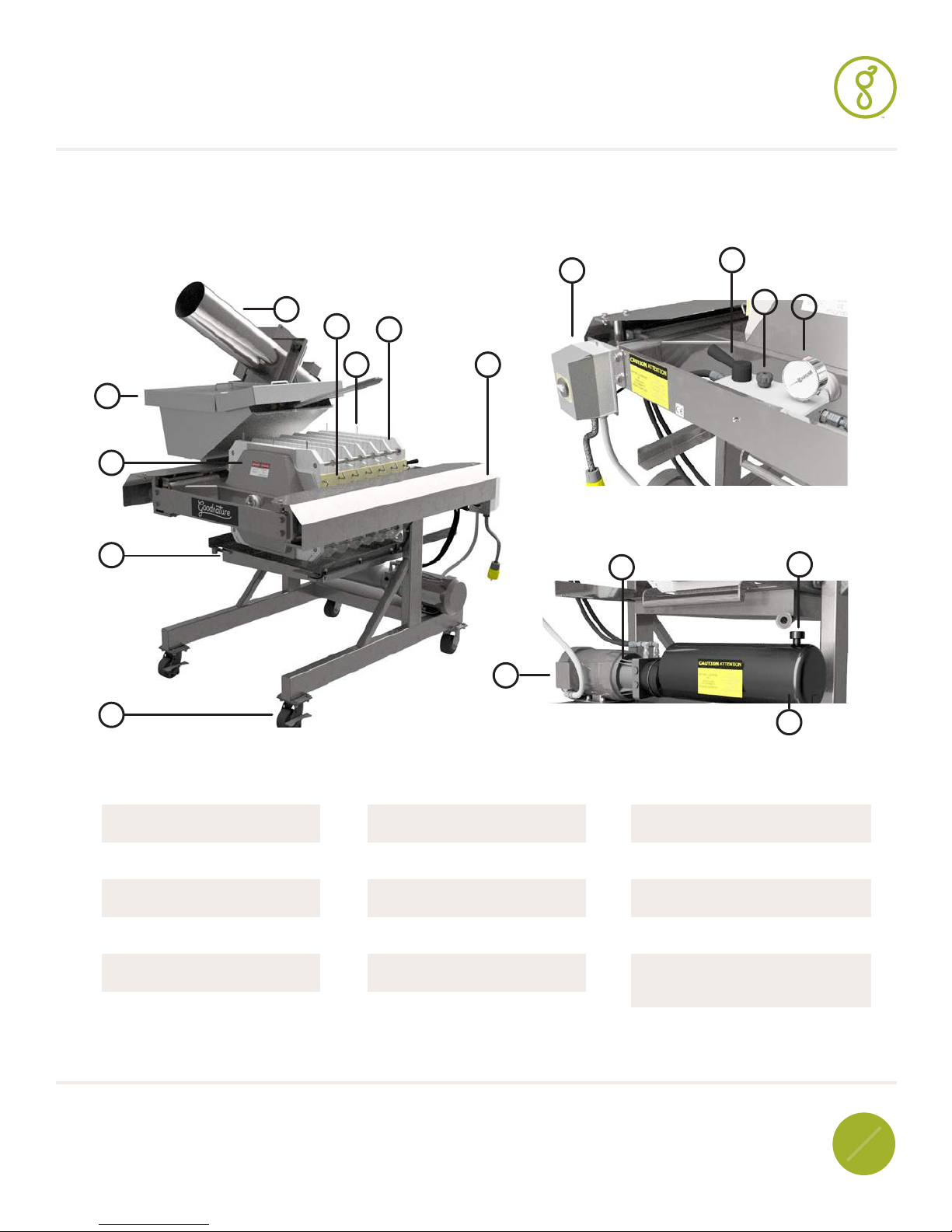

Section 3: Machine Diagrams

3.1 X-6 PRESS DIAGRAMS

12

11

10

17

9

4

3

5 6

1

2

Fig 1.2: Switch and Valve Assembly

7

14

16

13

8

Fig 1.1: X-6 Press

Pomace Hopper

1

Moving Platen

2

Press Racks

3

Rack Strap

4

Bag Pin

5

Safety Guard

6

Juice Tray

7

Casters

8

Start/Stop Switch box

9

Pressure Gauge

10

Flow Control Valve

11

Directional Control Lever

12

GOODNATURE X-6 COMMERCIAL COLD PRESS JUICER

OWNER’S MANUAL

Fig 1.3: Hydraulic Assembly

Motor for Hydraulic Power Unit

13

Hydraulic Pump Assembly

14

Hydraulic Reservoir

15

Reservoir Breather Cap

16

EG-260 Grinder

17

(Add-on Item)

15

09

35

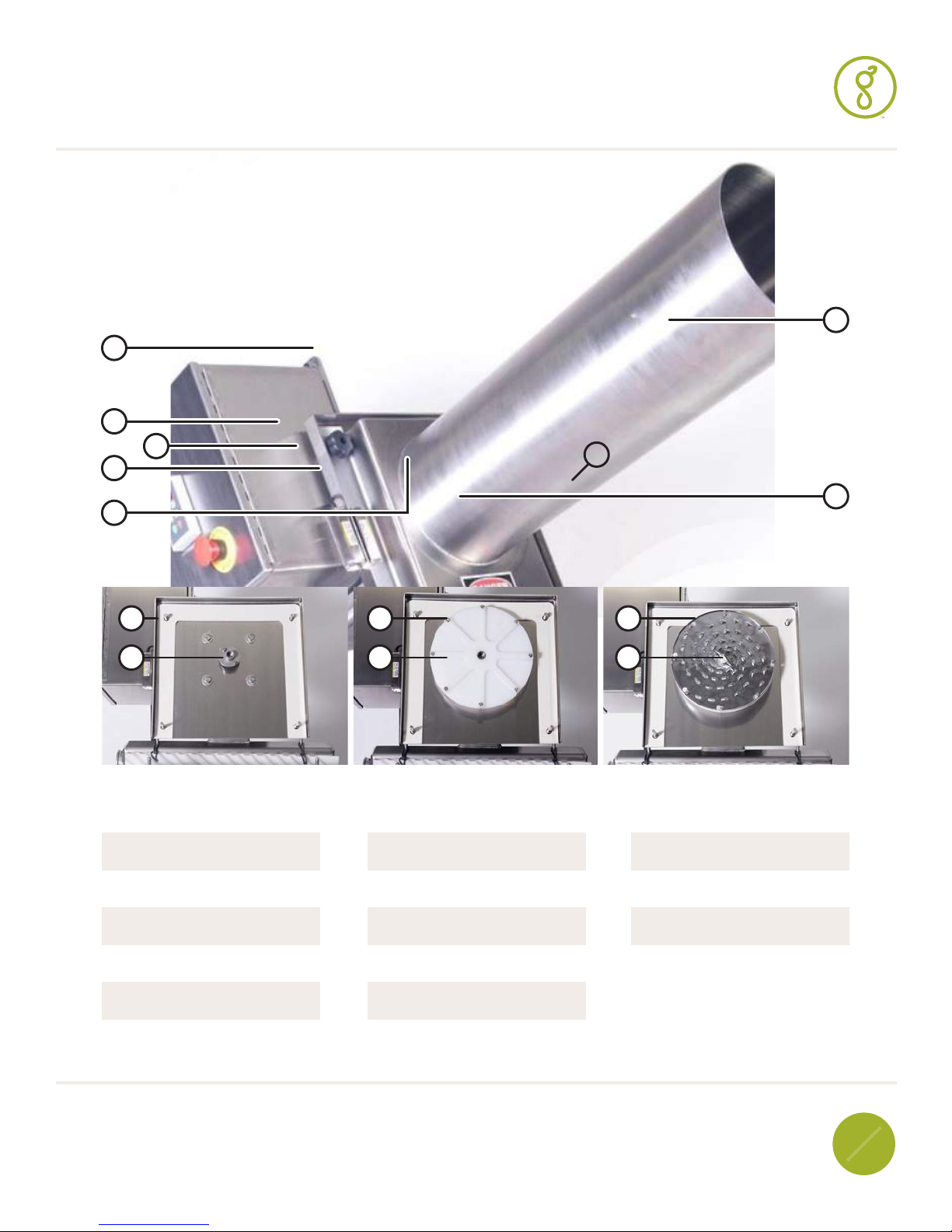

Section 3: Machine Diagrams

3.2 EG-260 GRINDER DIAGRAMS

Fig 2.1: EG-260 Grinder

1

6

7

8

5

4

2

3

9 11 13

10 12 14

Fig 2.2 Fig 2.3 Fig 2.4

Electrical Box

1

Hopper

2

Hopper Knobs

3

Grinder Stems

4

Safety Interlock Switch

5

Power Disconnect Switch

6

Keypad

7

Emergency Stop

8

Hopper Gasket

9

Drive Hub

10

Retaining Screw

11

Grinder Disc Backing Plate

12

Grinder Disc

13

Shredder Plate Knob

14

GOODNATURE X-6 COMMERCIAL COLD PRESS JUICER

OWNER’S MANUAL

10

35

Section 4: Installation and Setup

4.1 INSTALLATION

WARNING : Power must be supplied to the X-6 and EG-260 b y a licensed electricia n. Failure to do so m ay

result in s erious persona l injury due to electr ic shock or dama ge to the machine.

Inspect for physical damage, electrica l damage, or any loose or bare wires. Make sure there are no loose nuts, bolts,

or any other fasteners.

Check for proper voltage before connecting any power to the machine.

Standard electrical supply for the X-6 and EG-260 is 1Ph 220V 50/60Hz.

Place a properly grounded electrica l outlet close enough to the press so the cord from the motor will reach it

without the use of an extension cord. This outlet should be on a dedicated circuit protected by a 20 Amp breaker.

The grinder should be on a dedicated circuit separate from the press with a 20 Amp breaker.

GOODNATURE X-6 COMMERCIAL COLD PRESS JUICER

OWNER’S MANUAL

11

35

Loading...

Loading...