goodnature AA-375R, AA-475R, AA-575R Owner's Manual

Flash Pasteurizer

All Models

OWNER’S MANUAL

Serial # ____________

1

BEGIN READING HERE

IMPORTANT WARNING: To limit electric shocks, personal inju-

ry or material damage due to misuse, please read these instructions carefully and follow them strictly. The operation manual

should be kept within easy access for all users and read completely by all first time users of the machine.

Machine Specicaons

Model Voltage Amperage

Flow Rate

Hold Time 30 Seconds

Dimensions

Table of Contents

Secon Content Page Secon Content Page

Secon 1. Safety Precauons . . . . . . . . . 3 Secon 5. Cleaning . . . . . . . . . . . . . . . . 21

5-1. Machine cleaning . . . . . . . . 21

Secon 2. Unpacking . . . . . . . . . . . . . . . . . 4

2-1. Unpacking . . . . . . . . . . . . . . . . 4 Secon 6. Maintenance . . . . . . . . . . . . 22

2-2. Parts list . . .. . . . . . . . . 4 6-1. Maintenance 22

Secon 3. Installaon . . . . . . . . . . . . . . . . . 5-7 Secon 7. Useful Informaon . . . . . . . 23-27

3-1 Installaon 5-7 7-1. Replacement parts list . . . . 23

7-2. Reference 24

Secon 4. Operang Instrucons . . . . . . . 8-20 7-3. Troubleshoong 25-27

4-1. Operaon.. . . . . . . . . . . . . . . . . . 8-12

4-2. Adjusng Pump Speed 13-14 .

4-3. Adjusng Boiler Temperature 15

4-4. Pressure Dierenal System 16

4-5. Chart Recorder Programming 17-19

4-6. Thermometer Calibraon 20

2

SECTION 1: Safety Precautions

IMPORTANT WARNING: To limit electric shocks, per-

sonal injury or material damage due to misuse, please

read these instructions carefully and follow them strictly.

The operation manual should be kept within easy access

for all users and read completely by all first time users of

the machine.

1-1 Safety Precautions

SAFETY GLASSES must be worn at all times during operation, cleaning, and

servicing of the machine.

Never wear loose fitting clothing that can get caught on any moving parts.

Long hair must be worn up and tied back or in a hat or hair net.

Never insert any foreign items into the Pasteurizer that weren’t supplied by the

manufacturer and described in this manual.

Always disconnect power before cleaning or servicing this machine.

If any components are damaged or are malfunctioning, discontinue use immedi-

ately and get the machine serviced.

3

SECTION 2: Unpacking

2-1 Unpacking

Unpacking Equipment

The equipment has been packaged to reduce the chance of damage during shipment.

After unloading the pomace pump from the common carrier, remove the crate, banding

and shrink wrap to expose the pump for inspection.

Inspection

This equipment was carefully inspected both mechanically and electrically before

shipment. It should be physically free of marks or scratches and in perfect electrical order

upon receipt. The equipment should be inspected for physical damage. Also, the

equipment should be inspected for loose or bare wires. If there are any damaged items

due to shipping, contact the freight carrier. If any parts are missing, please call our

Customer Service Department at (716)855-3325.

Locating the Pasteurizer

The pasteurizer should be in an area with ample room with easy access to all four

sides of the machine.

The location should also be warm enough to prevent freezing from occurring. Freezing

will cause significant problems.

The unit should be in close proximity of the tank holding the raw product and the tank

that will be receiving the pasteurized product.

The unit should be in close proximity to a fresh water supply, fuel source for the boiler,

and electrical supply.

A floor drain in the same room as the machine will provide an outlet for accepting

water used to rinse and clean this equipment.

4

SECTION 3: Installation

IMPORTANT WARNING: All electrical connections

should be made by a licensed professional in accordance

with state and local codes.

3-1. Installation

Check for proper voltage before connecting any power to the machine.

The voltage and amperage of the power supply depends on the specifications

provided by the customer. Information should be written in on page 2 of this

manual. Can also be found on the serial sticker located on the electric box of

your machine. For help finding this information call Goodnature customer

service. 716-855-3325.

After unpacking and before running, it is important to check that no fasteners

became loose during shipping. Check all nuts, bolts, and screws to make sure

everything is tight.

Some components of your machine were removed at the factory to prevent

damage during transport.

These parts will be in separate boxes with a red tag attached indicating where it

belongs. Match the corresponding letters on the parts to the letters on the

machine.

Attach each part by hand tightening any nuts, bolts or clamps. Once all parts

are connected go back and tighten further with the appropriate tool.

Pump feed: raw product can also be pumped into the machine. It is important

to note that the in-feed level control on the pasteurizer does not shut the pump

on and off, it operates the air actuated butterfly valve only. When choosing a

pump, select a pump that is the same as or greater than the anticipated

pasteurization flow rate or if your pump is oversized install a flow control valve

in the line. An undersized pump will cause plate exchanger fouling. Install hose

or stainless tube between raw product tank, pump, and the inlet of the feed

control valve. Make sure that the portion of this line between the pump and

valve is run above the highest possible product level in the raw tank to prevent

5

SECTION 3: Installation

IMPORTANT WARNING: All electrical connections

should be made by a licensed professional in accordance

with state and local codes.

3-1. Installation

Pasteurized product outlet (standard): install a flexible hose from the

pasteurized product outlet on the back of the unit that can reach the following:

pasteurized product tank, raw product tank, and to a suitable drain. This hose

should be rated to withstand temperatures up to 190°F (87.8°C) and be chemical

resistant. At start up hose will be placed in the pasteurized product tank. When

flushing the system the hose should be directed to a drain. During cleaning, this

hose should be connected to a spray ball in the raw product tank.

Pasteurized product outlet (with cooling section): the pasteurized product

outlet is located on the front of the machine just above the balance tank. Flexible

hose or stainless tube must be run straight up from product outlet at least 2

inches (5 cm) above the plate packs to ensure that all piping fills completely.

From that point, use flexible hose as mentioned in the previous paragraph.

Pasteurized product outlet (hot-fill): the divert valve will be the product outlet

for a machine designed to hot fill product.

Filling Boiler System: to fill boiler system first make sure that all pipe fittings

are tight and the valves on the pasteurizer heating section are open. You may

decide to install a valve on the welded coupler next to the reducing valve on

the top of the 40 gallon (151.4 L) storage tank to help air removal for filling.

Open the air bleeder on top of the air scoop. Open cold water supply valve and

lift rapid fill lever, reducing valve to an upright position. Continue filling the

entire system until all air is removed and the system pressure is correct. Adjust

pressure if necessary. Place rapid fill lever back into horizontal position for

normal automatic operation and close water supply valve to prevent cold water

from entering an overheated boiler.

6

SECTION 3: Installation

IMPORTANT WARNING: All electrical connections

should be made by a licensed professional in accordance

with state and local codes.

3-1. Installation

Cooling section (optional): if your unit is equipped with a cooling section it is

the plate pack closest to the electrical enclosure.

Cold water as cooling medium: attach a cold water supply line with a valve

to the lower of the two galvanized fittings on the front of the machine. This

valve is necessary to control exiting product temperature. Run a line from the

higher fitting to drain or collect this water in a tank for other use.

Glycol chiller as cooling medium: place supply line from the chiller to the

lower of the two galvanized fittings. Place the return line to the upper fitting.

Place valves on both fittings for the purpose of servicing chiller or pasteurizer.

Please note: the flow direction of the product through the cooling section is

from top to bottom. Consequently the flow direction of the cooling medium has

to be from bottom to top.

Filler recycling valve: if you are planning on operating the pasteurizer directly

into a filler, then a filler recycling valve is recommended. Place the recycling

valve at the filler reservoir and plumb a line back to the pasteurizer's balance

tank. Connect the recycling valve to a level control in the filler reservoir. This is

so that if the reservoir becomes full the flow is directed back to the pasteurizer

to prevent from having to shut the pasteurizer off (which is not recommended).

7

SECTION 4: Operation

4-1. Operation

Always start machine with water. If you start the machine with product in it,

the first 10-20 gallons (38-76 L) of product will come out of the machine too hot

and fouling of the plates will occur.

Product containing large amounts of sediment has to be allowed to settle out

or be filtered before going through the pasteurizer

If your unit is equipped with a cooling section, never adjust chiller unit

temperature below 33°F (0.55°C) or freezing of the product will occur.

If while pasteurizing you experience large temperature fluctuations or unit is

diverting, adjust pump speed or adjust boiler target temperature. See

"adjusting pump speed" or "adjusting boiler temperature" sections.

Never adjust pump speed above or below the rated capacity of your machine

during pasteurization. See table below for these rates. Your machine was

factory set for the minimum and maximum. It can be operated anywhere in between those two settings.

Machine type Minimum flow Maximum flow

180 2.2 gpm (8.3 L) 3 gpm (11.4 L)

600 4.4gpm (16.7 L) 10 gpm (37.9 L)

900 8.5 gpm (32.2 L) 15 gpm (56.8 L)

1200 15 gpm (56.8 L) 20 gpm (75.7 L)

8

SECTION 4: Operation

4-1. Operation

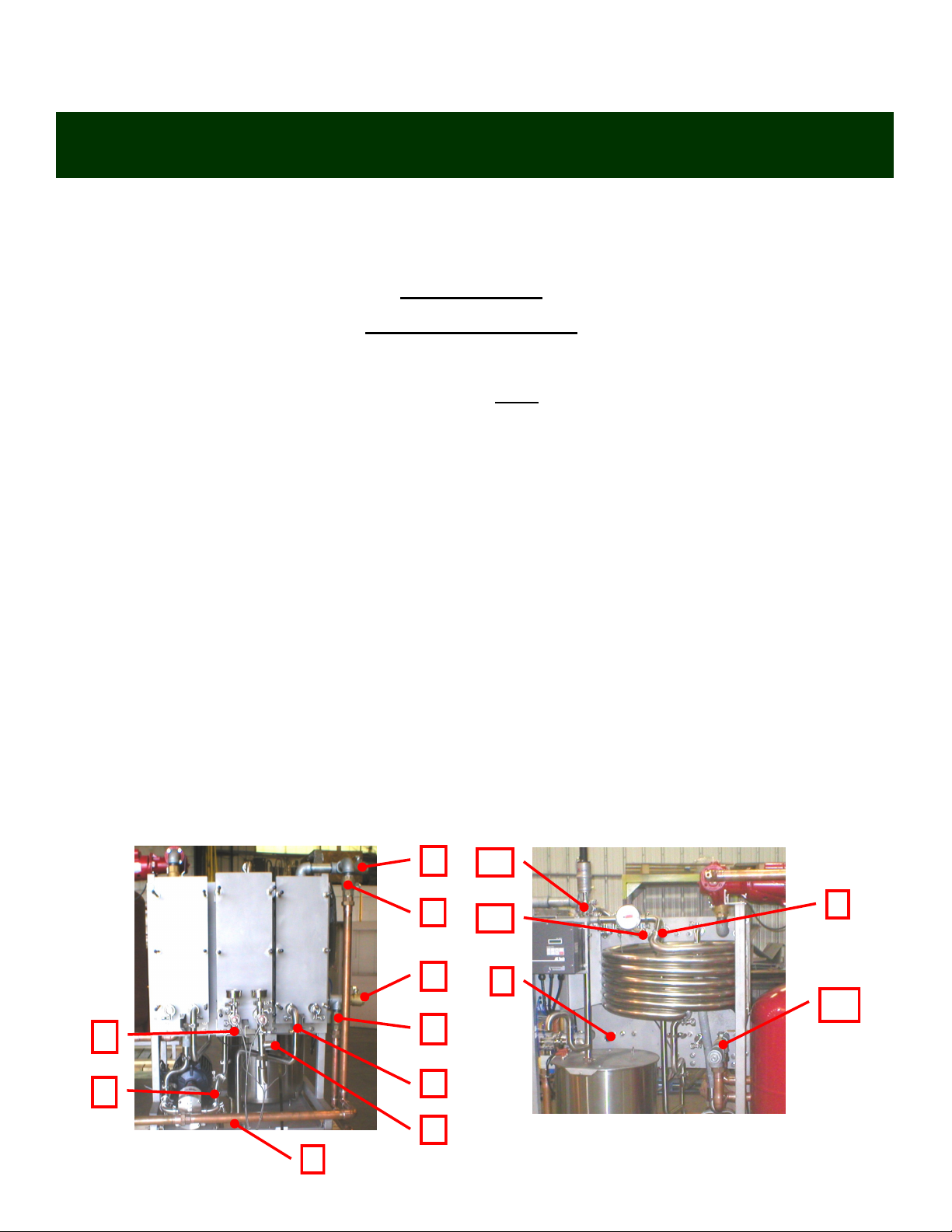

1. PNP144DUAL users complete step #7 only.

2. Connect provided hose from booster pump #1 in to the raw side of the re-

generation plate pack on the back of the machine #2 in figure 1.

3. Connect provided manifold from the raw product exit of regen #8 in figure 2

to inlet of the timing pump #3 in figure 1.

4. Attach manifold from exit of regen #5 in to inlet of cooling #4.

5. Close valves labeled #1 and open valves labeled #6.

Set-up for HTST

Dual purpose units only

6. Open valve labeled #10.

7. Install manifold between divert valve #11 and pasteurized side of regen

#12.

8. Remove hose from between #9 in figure 2 and #3 in figure 1.

9. Finished product will exit the machine at location #9.

2

Figure 1

6

7

6

7

11

12

9

Figure 2

8

10

3

4

5

1

9

Loading...

Loading...