Page 1

TECHNICAL MANUTECHNICAL MANU

TECHNICAL MANU

TECHNICAL MANUTECHNICAL MANU

ALAL

AL

ALAL

GSH 13 SEER - 3 PHASE

Split System Heat Pump

(Shipped Without Refrigerant Charge)

• Refer to Service Manual RS6100004 for installation, operation, and troubleshooting information.

• All safety information must be followed as provided in the Service Manual.

• Refer to the appropriate Parts Catalog for part number information.

• Models listed on page 3.

This manual is to be used by qualified, professionally trained HVAC technicians only. Goodman

does not assume any responsibility for property damage or personal injury due to improper

service procedures or services performed by an unqualified person.

Copyright © 2011 - 2013 Goodman Manufacturing Company, L.P.

RT6212008r5

April 2013

1

Page 2

PRODUCT IDENTIFICATION

The model number is used for positive identification of component parts used in manufacturing. Please use this number

when requesting service or parts information.

G S H 13 036 3 A E

BRAND:

G: Good man

(Standard

Feature Set

Models)

S: G oodman

Deluxe

(High

Feature Set

Models)

V: Value

S: Split Syst em

®

®

PRODUCT

FAMILY:

PRODUCT

TYPE:

C: Condens er R- 22

X: Condenser R-410A

H: Heat Pump R- 22

Z : Heat Pu m p R- 410A

SEER

RATING:

SEER Rating

NOMINAL

CAPACITY:

0 48 : 4 Tons

0 60 : 5 Tons

*MINOR

REVISI O N:

E: Initial Release

w/o refrigerant

*MAJOR

R EVISION:

A: Initial

Release

VOLTAGE:

1: 20 8- 230v/ 1ph/60Hz

3. 20 8- 230v/ 3ph/60Hz

4. 46 0V /3ph/6 0 Hz

03 6: 3 Tons

*Specific models without refrigerant charge (with their major & minor revision l evels)

are listed on the following page.

HIGH VOLTAGE!

WARNING

WARNING

WARNING

WARNING

arising from improper service or service procedures. If

you install or perform service on this unit, you assume

responsibility for any personal injury or property damage

which may result. Many jurisdictions require a license to

install or service heating and air conditioning equipment.

2

Disconnect ALL power before servicing or installing this unit. Multiple power

sources may be present. Failure to do so may cause property damage, personal

injury or death.

Goodman will not be responsible

for any injury or property damage

WARNING

WARNING

individuals meeting the requirements (at a minimum) of

an "entry level technician" as specified by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI). Attempting to install or repair this unit without such background may result in product damage, personal injury or

death.

Installation and repair of this unit

should be performed

ONLY by

Page 3

PRODUCT IDENTIFICATION

The model number is used for positive identification of component parts used in manufacturing. Please use this number

when requesting service or parts information.

GSH130484AC

GSH130603AC

GSH130604AC

GSH130484AD

GSH130484AE

GSH130363AE

GSH130483AE

GSH130363AF

GSH130363AG

GSH130483BA

GSH130483BB

* Indicates minor revision & is not used for order entry or inventory management

WARNING

WARNING

WARNING

WARNING

Serious property damage, personal injury, reduced unit

performance and/or hazardous conditions may result

from the use of such non-approved devices.

The United States Environmental Protection Agency (“EPA”) has issued various regulations regarding the introduction and disposal of refrigerants introduced into this unit. Failure to follow

these regulations may harm the environment and can lead to the imposition of substantial fines.

These regulations may vary by jurisdiction. Should questions arise, contact your local EPA office.

Do not connect or use any device

that is not design certified by

Goodman for use with this unit.

WARNING

WARNING

do not store combustible materials or use gasoline or

other flammable liquids or vapors in the vicinity of this

appliance.

To prevent the risk of property

damage, personal injury, or death,

3

Page 4

PRODUCT DESIGN

These GSH13 SEER heat pump models are shipped with a

nitrogen holding charge only and are available in 3, 4 and 5

ton sizes for 208/230 volt 3 phase applications and for 4 and

5 tons in 460 volt 3 phase.

These units are designed for free air discharge. Air is drawn

through the outdoor coil by a propeller fan, and is discharged

vertically out the top of the unit. No additional restriction

(ductwork) shall be applied.

All units come equipped with suction and liquid valves

designed for connection to refrigerant-type copper. Non-back

seating valves are factory installed to accept the field run

copper.

Systems should be properly sized by heat gain and loss

calculations made according to methods of the Air Conditioning Contractors Association (ACCA) or equivalent. It is

the contractors responsibility to ensure the system has adequate capacity to heat or cool the conditioned space.

GSH13 units use a mix of reciprocating and scroll compressors. There are a number of design characteristics which

are different from the scroll compared to the traditional reciprocating compressor.

Due to their design, Scroll compressors are inherently more

tolerant of liquid refrigerant.

Note: Even though the compressor section of a Scroll compressor is more tolerant of liquid refrigerant, continued

floodback or flooded start conditions may wash oil from the

bearing surfaces causing premature bearing failure.

These Scroll compressors use white oil which is compatible

with 3GS. 3GS oil may be used if additional oil is required.

GSH13 model heat pumps do not use a reversing relay to

energize the reversing valve. The reversing valve is energized

in the cooling cycle through the "O" terminal on the room

thermostat.

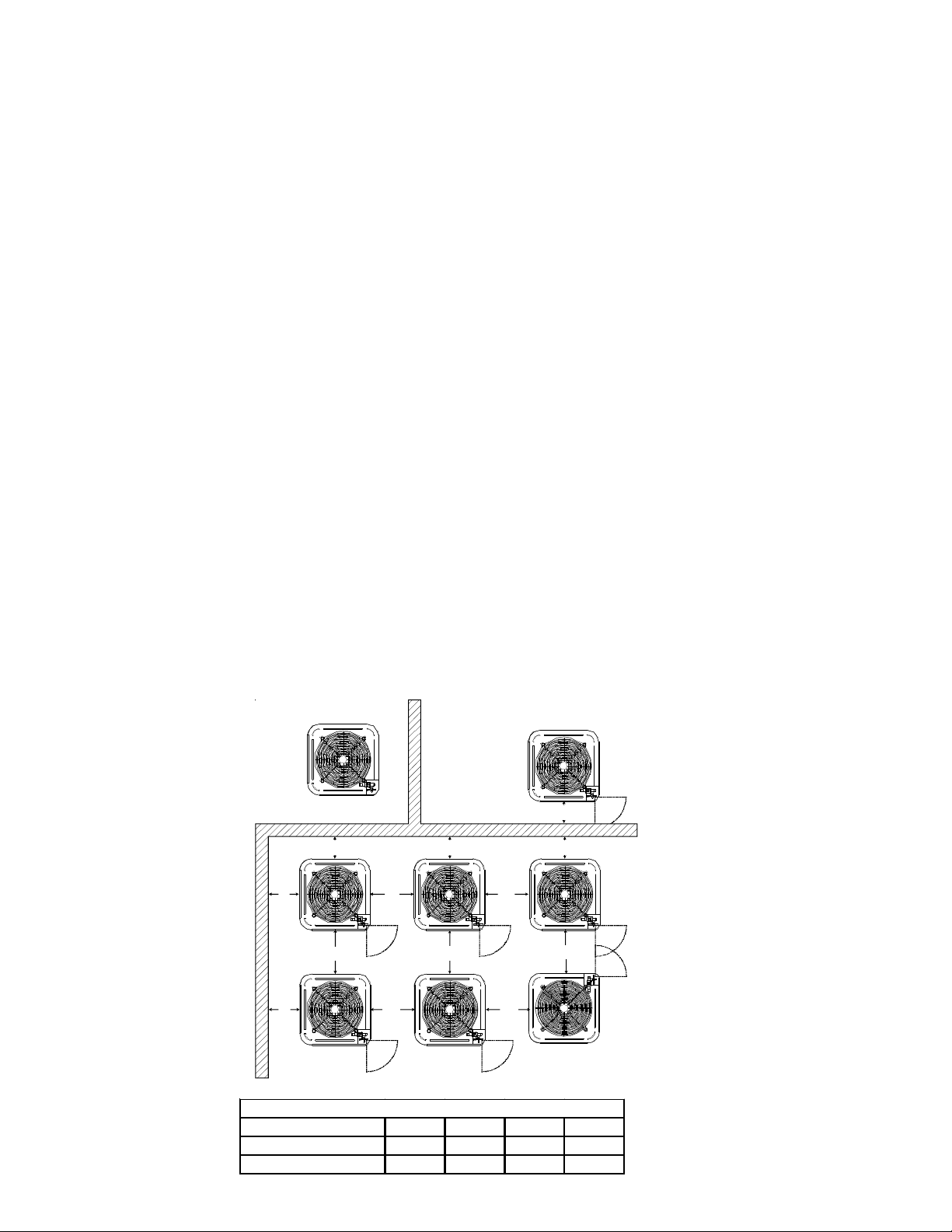

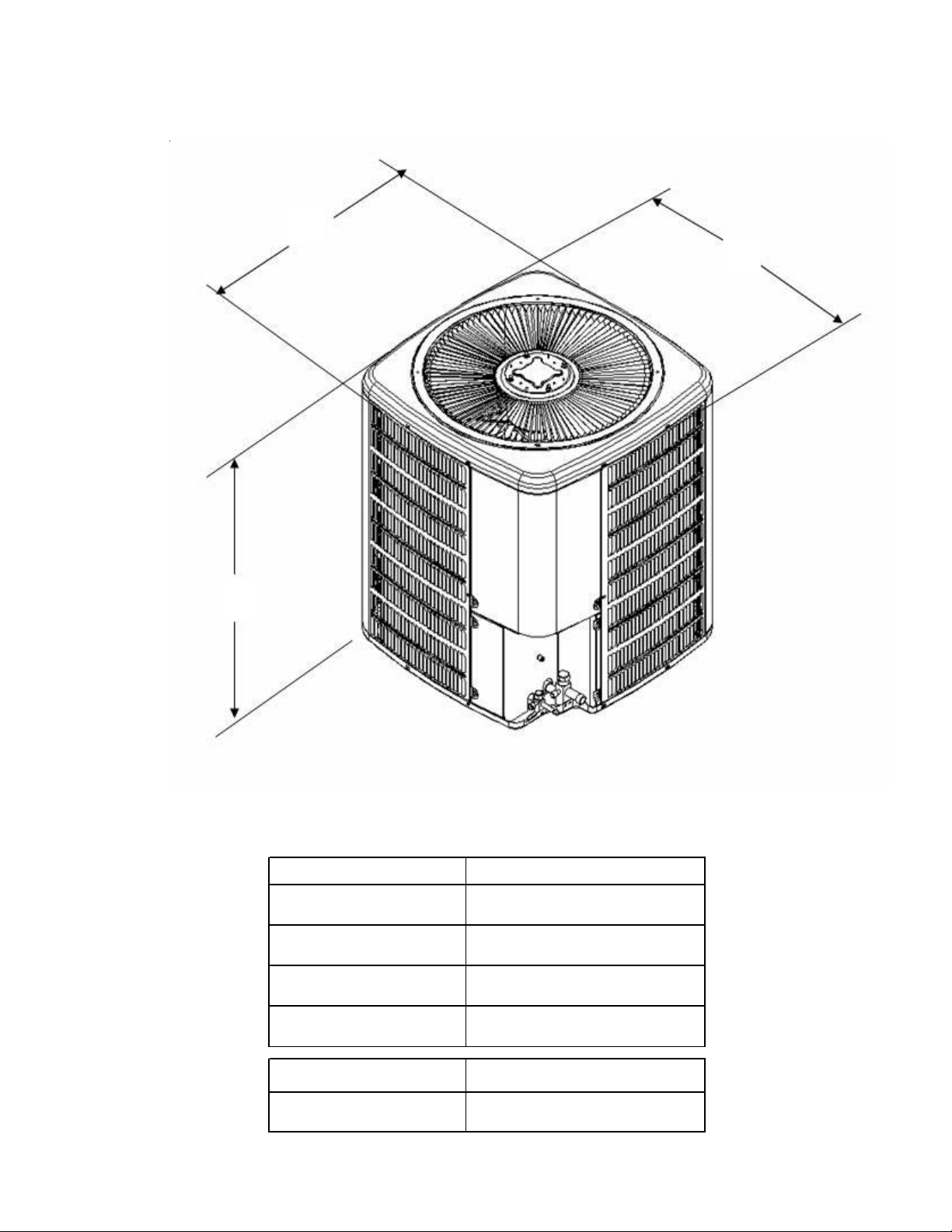

This unit is for outdoor installation only. Refer to minimum

figure for clearances from the sides of the unit to full walls

and other objects.

NOTE: This unit cannot be completely enclosed. At least

one side must be unrestricted.

These clearances will help avoid air recirculation. If installing

two or more units at the same location, allow at least 24

inches between units. If only one side is restricted (for example, against the outside wall of a house), the unit may be

placed as close as 8" to that one wall.

DO NOT locate the unit:

* Directly under a vent termination for a gas appliance.

* Within 3 feet of a clothes drier vent

* Where the refreezing of defrost water would create

a hazard

* Where water may rise into the unit.

NOT

RECOMMENDED

B B B

AA AAA

C

AA

A

Model Type A B C AA

Residential

Li ght Commercial

AA

Minimum Airflow Clearance

10" 10" 18" 20"

12" 12" 18" 24"

AA

C

AA

CC

B

AA

OK!

OK!

OK!

OK!

OK!

OK!

4

Page 5

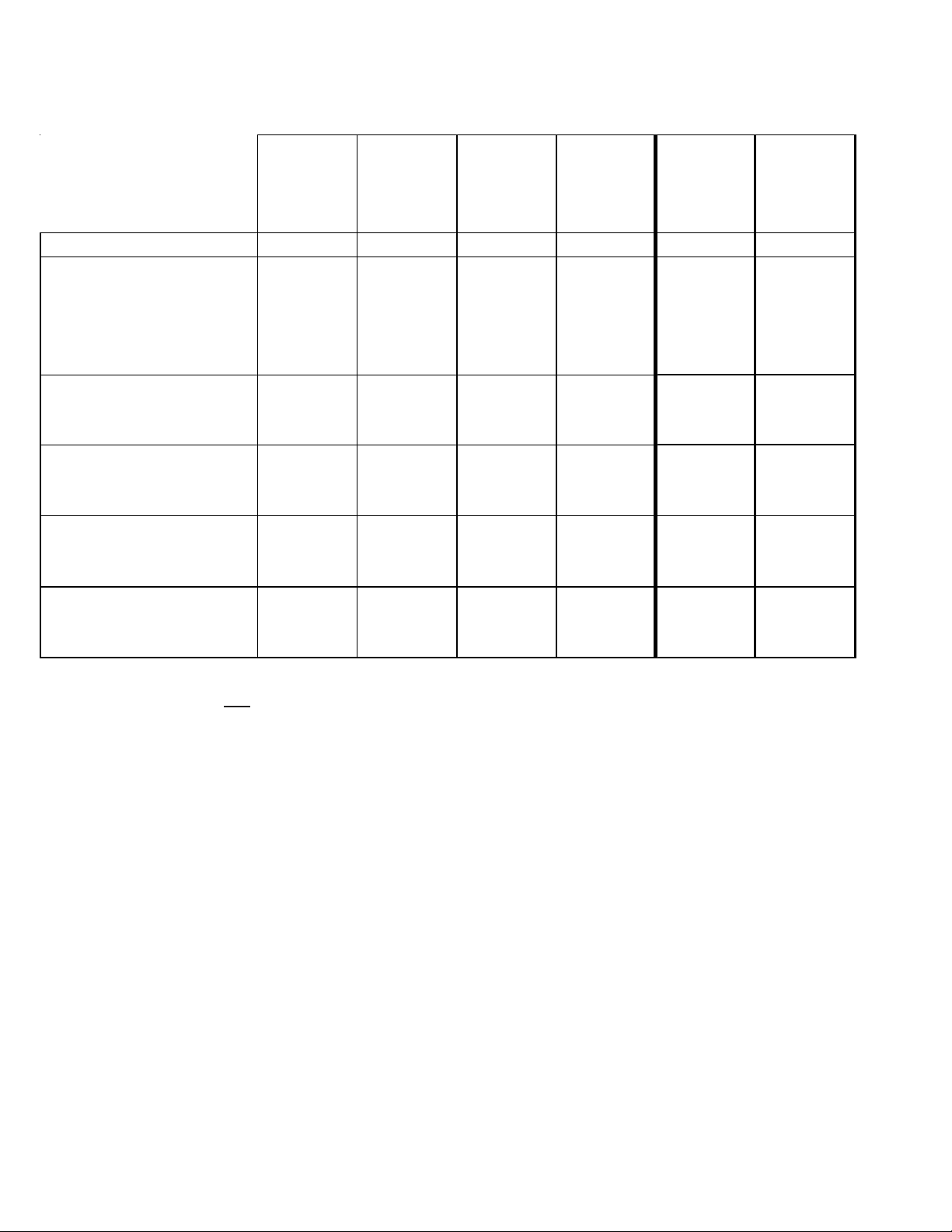

PRODUCT DIMENSIONS

W

D

H

Model Dimensions - W x D x H

GSH130363AE/AF 29 x 29 x 38¼

GSH130483AE 29 x 29 x 34¼

GSH130483B* 29 x 29 x 34¼

GSH130603AC 35½ x 35½ x 34¼

GSH130484AC/AD 29 x 29 x 34¼

GSH130604AC 35½ x 35½ x 34¼

5

Page 6

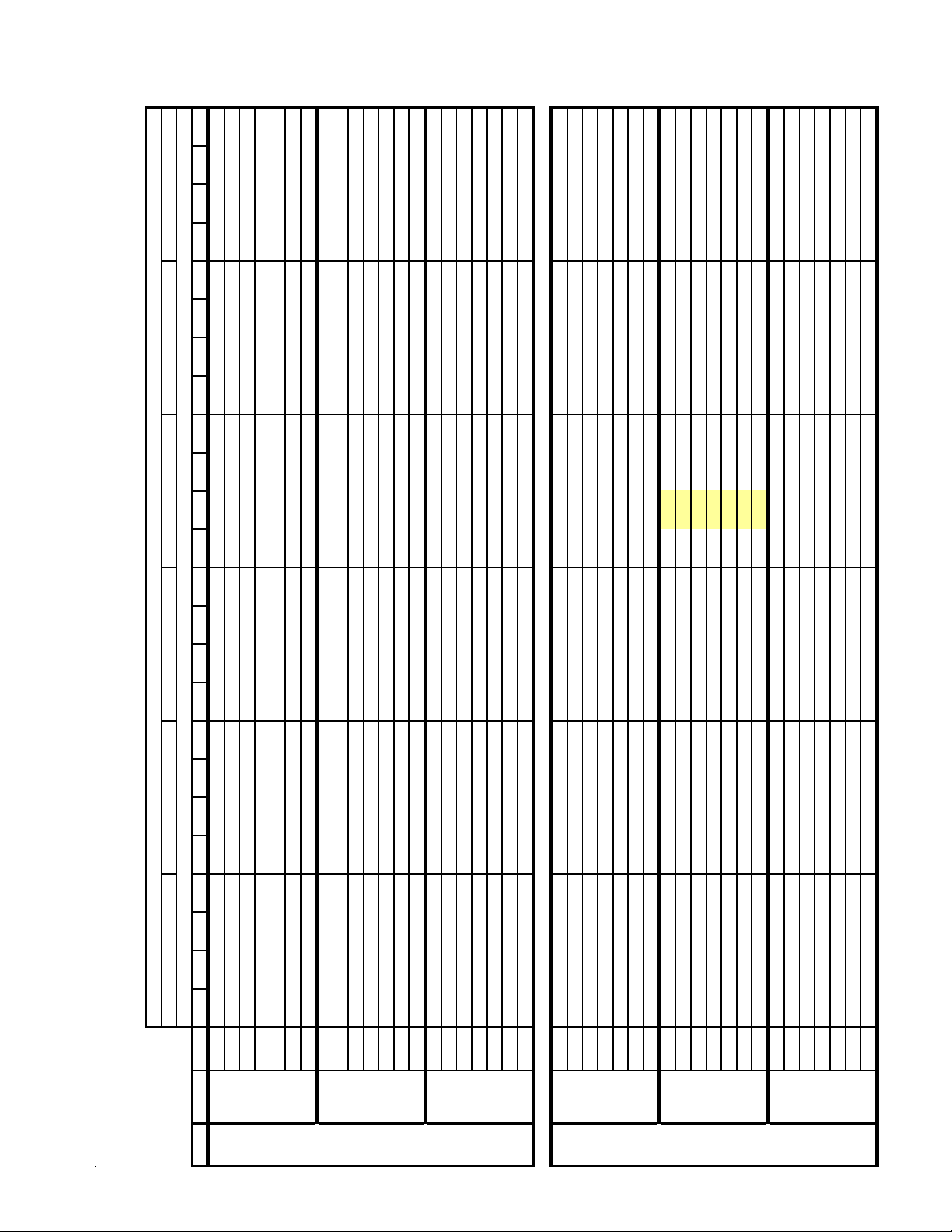

HEAT PUMP SPECIFICATIONS

GSH130[36-60]3*

GSH130[48-60]4*

GSH130363AE

Cooling Capacity, BTUH 35,000 31,400 45,000 55,500 45,000 55,500

Compressor

R.L. Amps 9 .0 9 .9 12.4 17 .3 5.8 6. 7

L.R. Amps 65.5 73.0 88.0 123.0 44.0 49.5

Loss of Cha rge Pressure Swi tch

Open / Close 7 PSIG/25 PSIG 7 PSIG/25 PSIG 7 PSIG/25 PSIG 7 PSIG/25 PSIG 7 PSIG/25 PSIG 7 PSIG/25 PSIG

Condenser Fan Moto r

Horsepower 1/4 1/4 1/4 1/6 1/4 1/6

F.L. Amps 1.5 1.5 1.5 1.1 0.8 0.6

Li qu id Line, Inc hes O.D. 3 /8" 3/8" 3/8" 3/8 " 3/8" 3/8 "

Suctio n L ine, Inches O.D. 7/8 " 7 /8" 7/8" 7/8" 7/8" 7/8"

Refrigerant Ch arge 188 188 223 233 2 23 233

Pow er Su pply 208/2 30- 60-3 208/ 230-60-3 20 8/ 230-60-3 20 8/ 230-60-3 460-60- 3 460-60- 3

Minimum Circuit Ampa city

Maximum Overcu rrent Device

Electrical Conduit Size

Pow er Supply (Inches) 1/2 or 3/4 1/2 or 3/4 1/2 or 3/4 1/2 or 3/4 1/2 or 3/4 1/2 or 3/4

App rox imate Shipping Weight 207 207 225 266 225 266

(1)

(2)

12.7 13.9 17.1 22.7 8.0 9.0

20 20 20 40 15 15

GSH130363AF

GSH130483AE

GSH130603AC

GSH130484AC

GSH130604AC

(1)

Wire size should be determined in accordance with National Electrical Codes. Extensive wire runs will require larger wire sizes.

(2)

Maximum Overcurrent Protection: Must use fuses or HACR-type Circuit Breakers of the same size as noted.

NOTES:

* Always check the S&R plate for electrical data on the unit being installed.

* Installer will need to supply 7/8" to 1 1/8" adapters for suction line connections.

* Unit is charged with refrigerant for 15' of 3/8" liquid line. System charge must be adjusted per Installation Instructions Final Charge Procedure.

* Installation of these units that require a TXV Kit to be installed on the indoor coil: PLEASE NOTE: THE SPECIFIED TXV IS DETERMINED BY THE OUTDOOR UNIT

NOT THE INDOOR COIL

6

Page 7

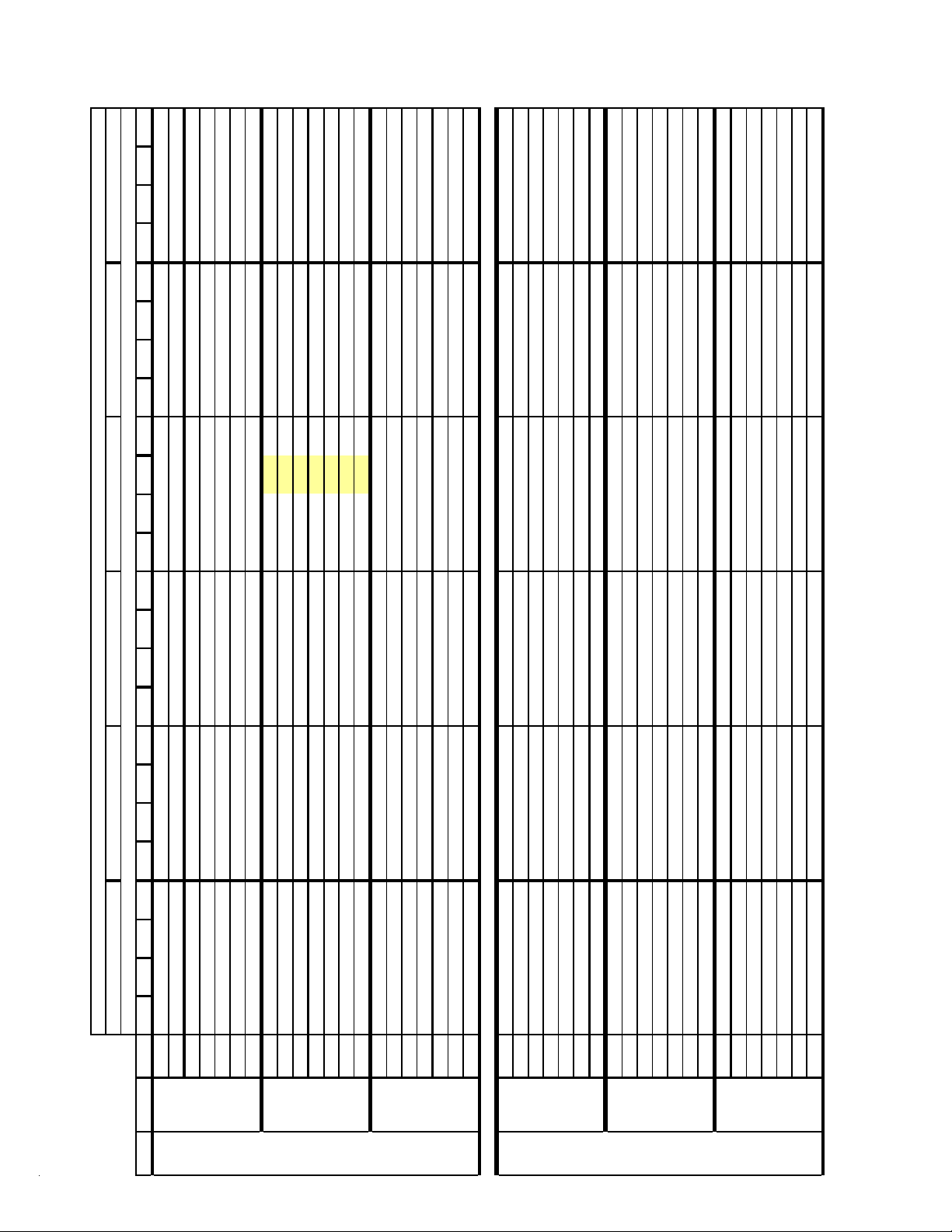

COOLING PERFORMANCE DAT A

COOLING OPERATION

GSH130363AE

82 87 74 79 86 92 77 81 89 95

234 244 232 250 263 275 256 276 291 304

36.2 38.8 30.8 31.7 34.4 36.9 28.6 29.4 31.8 34.2

33.4

35.1 37.7 29.9 30.8 33.3 35.8 27.7 28.5 30.9 33.2

222

32.4

232 242 230 247 261 272 254 273 288 301

32.4 34.8 27.6 28.4 30.8 33.0 25.6 26.3 28.5 30.6

220

29.9

225 235 223 240 253 264 246 265 280 292

75

213

EXPANDED PERFORMANCE DATA

Outdoor Ambient Temperature

Entering Indoor Wet Bulb Temperature

65 75 85 95 105 115

S/T 0.76 0.64 0.44 - 0.79 0.66 0.46 - 0. 81 0.67 0.47 - 0.83 0.70 0.48 - 0.87 0.72 0.50 - 0.87 0 .73 0.51 -

MBh 34.3 35.5 38.9 - 33.5 34.7 38.0 - 32.7 33.9 37.1 - 31.9 33.1 36.2 - 30.3 31. 4 34.4 - 28.1 29.1 31.9 -

HI PR 140 151 160 - 158 170 179 - 179 193 204 - 204 220 232 - 230 247 261 - 254 273 288 -

AMPS 7.7 7.8 8.1 - 8.2 8.4 8.7 - 8.9 9.1 9.4 - 9.5 9.7 10.0 - 10.1 10.3 10.7 - 10.7 10.9 11.3 -

Delta T 17 14 11 - 17 15 11 - 17 15 11 - 17 15 11 - 17 15 11 - 16 14 10 -

S/T 0.73 0.61 0.42 - 0.75 0.63 0.43 - 0. 77 0.64 0.45 - 0.80 0.66 0.46 - 0.83 0.69 0.48 - 0.83 0 .70 0.48 -

MBh 33.3 34.5 37.8 - 32.5 33. 7 36.9 - 31.7 32.9 36.1 - 31.0 32.1 35.2 - 29.4 30.5 33.4 - 27.3 28.3 31.0 -

LO PR 63 67 73 - 67 71 77 - 69 74 81 - 73 77 85 - 76 81 89 - 79 84 92 -

HI PR 139 150 158 - 156 168 177 - 177 191 202 - 202 217 230 - 227 245 258 - 251 270 285 -

AMPS 7.6 7.8 8.0 - 8.2 8.4 8.6 - 8.8 9.0 9.3 - 9. 4 9.6 9.9 - 10.0 10. 2 10. 6 - 10.6 10.8 11.2 -

Delta T 17 15 11 - 18 15 12 - 18 15 12 - 18 15 12 - 18 15 12 - 16 14 11 -

S/T 0.70 0.58 0.40 - 0.72 0.61 0.42 - 0. 74 0.62 0.43 - 0.77 0.64 0.44 - 0.80 0.66 0.46 - 0.80 0 .67 0.46 -

MBh 30.7 31.9 34.9 - 30.0 31. 1 34.1 - 29.3 30.4 33.3 - 28.6 29.6 32.5 - 27.2 28.2 30.8 - 25.2 26.1 28.6 -

LO PR 63 66 73 - 66 70 77 - 69 73 80 - 72 77 84 - 76 80 88 - 78 83 91 -

HI PR 135 145 153 - 151 163 172 - 172 185 196 - 196 211 223 - 220 237 251 - 244 262 277 -

AMPS 7.4 7.6 7.8 - 8.0 8 .1 8.4 - 8.6 8.8 9.1 - 9.2 9.4 9. 7 - 9.7 10.0 10.3 - 10.3 10.5 10.9 -

Delta T 18 15 12 - 18 16 12 - 18 16 12 - 18 16 12 - 18 15 12 - 17 14 11 -

LO PR 61 65 70 - 64 68 74 - 67 71 77 - 70 74 81 - 73 78 85 - 76 81 88 -

S/T 0.860.770.590.380.900.800.610.390.920.820.620.400.950.85 0.64 0.41 0.98 0.88 0.67 0.43 0. 99 0 .89 0.67 0.43

MBh 34.9 35.9 38.9 41.7 34.1 35.1 38.0 40.7 33. 3 34.2 37.1 39.8 32.4

HI PR 142 153 161 168 159 171 181 189 181 195 206 214 206

AMPS 7.7 7.9 8.1 8.4 8.3 8.5 8.8 9.1 9.0 9.2 9.5 9.8 9.6 9.8 10.1 10.5 10.2 10.4 10.8 11.2 10.8 11.0 11.4 11.8

Delta T1918151020181510201815102018 15 10 19 18 15 10 18 17 14 9

LO PR 64 68 74 79 67 72 78 83 70 74 81 87 74 78 85 91 77 82 90 95 80 85 93 99

S/T 0.820.740.560.360.850.760.580.370.880.780.590.380.900.81 0.61 0.39 0.94 0.84 0.64 0.41 0. 95 0 .85 0.64 0.41

MBh 33.9 34.9 37.7 40.5 33.1 34.1 36.9 39.6 32. 3 33.2 36.0 38.6 31.5

Delta T2019151020191511201915112119 15 11 20 19 15 11 19 17 14 10

HI PR 140 151 160 166 158 170 179 187 179 193 204 212 204

AMPS 7.7 7.8 8.1 8.4 8.2 8.4 8.7 9.0 8.9 9.1 9.4 9.8 9.5 9.7 10.0 10.4 10.1 10.3 10.7 11.1 10.7 10.9 11.3 11.7

LO PR 63 67 73 78 67 71 77 83 69 74 81 86 73 77 85 90 76 81 89 94 79 84 92 98

S/T 0.790.710.540.350.820.740.560.360.840.760.570.370.870.78 0.59 0.38 0.91 0.81 0.61 0.39 0. 91 0 .82 0.62 0.40

MBh 31.3 32.2 34.8 37.4 30.5 31.4 34.0 36.5 29. 8 30.7 33.2 35.6 29.1

Delta T2019151121191611211916112119 16 11 21 19 16 11 19 18 15 10

HI PR 136 147 155 161 153 164 174 181 174 187 197 206 198

AMPS 7.5 7.6 7.9 8.1 8.0 8.2 8.5 8.8 8.7 8.9 9.2 9.5 9.3 9.5 9. 8 10.1 9.8 10.1 10.4 10.8 10.4 10.6 11.0 11.4

LO PR 61 65 71 76 65 69 75 80 67 72 78 83 71

1434 KW 2.38 2.43 2.50 - 2.56 2.61 2.69 - 2.71 2.77 2.86 - 2.8 5 2. 91 3.00 - 2.96 3.03 3.12 - 3. 06 3 .13 3.23 -

MOD EL: GSH130363A* / ARUF49-00 *-1* / ARUF36421A*

IDB*Airflow 596367715963677159636771596367715963677159636771

70 1275 KW 2.36 2.41 2.49 - 2.54 2.59 2.67 - 2.69 2.75 2.83 - 2.8 3 2. 89 2.98 - 2.94 3.00 3.10 - 3. 04 3 .11 3.21 -

1116 KW 2.31 2.36 2.43 - 2.48 2.53 2.61 - 2.63 2.68 2.77 - 2.7 6 2. 82 2.91 - 2.87 2.93 3.02 - 2. 97 3 .03 3.13 -

1434 KW 2.40 2.45 2.52 2.60 2.58 2. 63 2.71 2.80 2.73 2.79 2.88 2.97 2.87 2.93 3.03 3.12 2.99 3.05 3.15 3.25 3.09 3.16 3.2 6 3.37

75 1275 KW 2.38 2.43 2.50 2.58 2.56 2. 61 2.69 2.78 2.71 2.77 2.86 2.95 2.85 2.91 3.00 3.10 2.96 3.03 3.13 3.23 3.06 3.13 3.2 3 3.34

1116 KW 2.33 2.38 2.45 2.52 2.50 2. 55 2.63 2.71 2.65 2.70 2.79 2.88 2.78 2.84 2.93 3.02 2.89 2.95 3.05 3.15 2.99 3.05 3.1 5 3.26

Shaded area is ACCA (TVA) conditions IDB: Entering Indoor Dry Bulb Temperature KW=Total system power AMPS=outdoor unit amps (comp.+fan)

High and low pressures are me as ured at the liquid and suction service valves.

7

Page 8

COOLING PERFORMANCE DAT A

COOL ING OPERATION

GSH130363AE

EXPANDED PERFORMANCE DATA

15 22 22 19 15 20 20 18 14

37.4 30.5 31.1 33.3 35.5 28.2 28.8 30.8 32.9

0.57 1.00 0.97 0.79 0.59 1.00 0. 97 0.79 0.59

19

35.0

0.76

O u t door Ambient Temp erature

Entering Indoor Wet Bulb Temperature

91 77 82 90 95 80 85 93 99

244 232 250 264 275 256 276 291 304

3.12 2.99 3.05 3.15 3.25 3.09 3. 16 3.26 3.37

10.5 10.2 10.4 10.8 11.2 10.8 11.0 11.4 11.8

85

234

3.03

10.1

65 75 85 95 105 115

S/T 0.950.890.720.541.000.920.750.561.000.940.770.571.001.000.790.591.001.000.820.621.001.000.830.62

MBh 35.5 36.3 38.8 41.4 34.7 35.4 37.9 40.5 33.8 34.6 37.0 39.5 33.0 33.7 36.1 38.5 31.4 32.1 34.2 36.6 29.1 29.7 31.7 33.9

MODEL: GSH130363A* / ARUF49-00*-1* / ARUF36421A*

IDB*Airflow 596367715963677159636771596367715963677159636771

Delta T222118142221181522211815212218152021181419191713

1434 KW 2.42 2.47 2.54 2.62 2.60 2.65 2.73 2.82 2.76 2.81 2.90 3.00 2.89 2.96 3.05 3.15 3.01 3.08 3.18 3.28 3.12 3.18 3.29 3.39

HI PR 143 154 163 170 161 173 183 190 183 197 208 217 208 224 237 247 234 252 266 278 259 278 294 307

AMPS 7.8 8.0 8.2 8.5 8.4 8.6 8.8 9.2 9.1 9.3 9.6 9.9 9.7 9.9 10.2 10.6 10.3 10.5 10.9 11.3 10.9 11.1 11.5 11.9

S/T 0.90 0.85 0.69 0.52 0.94 0.88 0.72 0.53 0.96 0 .90 0.73 0.55 0.99 0.93

MBh 34.5 35.2 37.6 40.2 33.7 34.4 36.8 39.3 32.9 33.6 35.9 38.4 32.1 32.8

L O PR 64 69 75 80 68 7 2 79 84 71 75 82 87 74 79 86 9 2 78 83 90 96 81 86 94 100

Delta T2222191523221915232219152322

80 1275 KW 2.40 2.45 2.52 2.60 2.58 2.63 2.71 2.80 2.73 2.79 2.88 2.97 2.87 2.93

HI PR 142 153 161 168 159 171 181 189 181 195 206 215 206 222

AMPS 7.7 7.9 8.1 8.4 8.3 8.5 8.8 9.1 9.0 9.2 9.5 9.8 9.6 9.8

L O PR 64 68 74 79 67 7 2 78 83 70 75 81 87 74 78

DT 23 22 19 15 23 22 19 15 23 22 19 15 23 22 19 16 23 22 19 15 21 21 18 14

S/T 0.870.820.670.500.900.850.690.520.930.870.710.530.960.900.730.550.990.930.760.571.000.940.760.57

MBh 31.8 32.5 34.7 37.1 31.1 31.7 33.9 36.3 30.3 31.0 33.1 35.4 29.6 30.2 32.3 34.5 28.1 28.7 30.7 32.8 26.0 26.6 28.4 30.4

HI PR 138 148 156 163 154 166 175 183 176 189 199 208 200 215 227 237 225 242 256 267 249 267 282 295

AMPS 7.5 7.7 7.9 8.2 8.1 8.3 8.5 8.8 8.8 9.0 9.2 9.6 9.3 9.6 9.9 10.2 9.9 10.1 10.5 10.9 10.5 10.7 11.1 11.5

L O PR 62 66 72 77 65 7 0 76 81 68 72 79 84 71 76 83 8 8 75 80 87 93 77 82 90 96

1116 KW 2.35 2.39 2.47 2.54 2.52 2.57 2.65 2.73 2.67 2.73 2.81 2.90 2.80 2.86 2.95 3.05 2.92 2.98 3.07 3.17 3.01 3.08 3.18 3.28

S/T 0.990.960.870.701.000.990.900.731.001.000.920.751.001.000.950.771.001.000.990.801.001.000.990.81

MBh 36.1 36.8 38.6 41.1 35.3 36.0 37.7 40.2 34.4 35.1 36.8 39.2 33.6 34.2 35.9 38.3 31.9 32.5 34.1 36.4 29.6 30.1 31.6 33.7

Delta T232321192323221922232219222222192021221919192017

1434 KW 2.44 2.49 2.56 2.64 2.62 2.67 2.76 2.84 2.78 2.84 2.93 3.02 2.92 2.98 3.08 3.18 3.04 3.10 3.20 3.31 3.14 3.21 3.31 3.42

HI PR 145 156 164 171 162 175 184 192 185 199 210 219 210 226 239 249 237 255 269 280 261 281 297 310

AMPS 7.9 8.0 8.3 8.6 8.5 8.7 8.9 9.2 9.2 9.4 9.7 10.0 9.8 10.0 10.3 10.7 10.4 10.6 11.0 11.4 11.0 11.2 11.6 12.0

S/T 0.950.910.830.670.980.950.860.691.000.970.880.711.001.000.910.731.001.000.940.761.001.000.950.77

MBh 35.1 35.7 37.4 39.9 34.3 34.9 36.6 39.0 33.4 34.1 35.7 38.1 32.6 33.3 34.8 37.2 31.0 31.6 33.1 35.3 28.7 29.3 30.6 32.7

L O PR 65 69 76 80 69 7 3 80 85 71 76 83 88 75 80 87 9 3 79 84 91 97 81 87 94 101

Delta T242422192424232024242320242423202223221921212118

85 1275 KW 2.42 2.47 2.54 2.62 2.60 2.65 2.73 2.82 2.76 2.81 2.90 3.00 2.89 2.96 3.05 3.15 3.01 3.08 3.18 3.28 3.12 3. 18 3.29 3.39

HI PR 143 154 163 170 161 173 183 190 183 197 208 217 208 224 237 247 234 252 266 278 259 278 294 307

AMPS 7.8 8.0 8.2 8.5 8.4 8.6 8.8 9.2 9.1 9.3 9.6 9.9 9.7 9.9 10.2 10.6 10.3 10.5 10.9 11.3 10.9 11.1 11.5 11.9

S/T 0.910.880.800.650.950.910.820.670.970.940.850.691.000.970.870.711.001.000.910.741.001.000.910.74

MBh 32.4 33.0 34.6 36.9 31.6 32.2 33.8 36.0 30.9 31.5 32.9 35.1 30.1 30.7 32.1 34.3 28.6 29.2 30.5 32.6 26.5 27.0 28.3 30.2

L O PR 64 69 75 80 68 7 2 79 84 71 75 82 87 74 79 86 9 2 78 83 90 96 81 86 94 100

Delta T242423202524232025242320252423202424232022222118

1116 KW 2.36 2.41 2.48 2.56 2.54 2.59 2.67 2.75 2.69 2.75 2.83 2.92 2.83 2.89 2.98 3.07 2.94 3.00 3.10 3.20 3.04 3.10 3.20 3.31

HI PR 139 150 158 165 156 168 177 185 177 191 201 210 202 217 229 239 227 244 258 269 251 270 285 298

AMPS 7.6 7.8 8.0 8.3 8.2 8.4 8.6 8.9 8.8 9.0 9.3 9.7 9.4 9.6 9.9 10.3 10.0 10.2 10.6 11.0 10.6 10.8 11.2 11.6

L O PR 62 66 73 77 66 7 0 77 82 69 73 80 85 72 77 84 8 9 76 80 88 93 78 83 91 97

Shaded area is AHRI Rating Conditions IDB: Entering Indoor Dry Bulb Temper ature KW=Tota l system power AMPS=outdoor unit amps (comp.+fan)

High and low p res sures are measured at t he liquid and suction service valve s.

8

Page 9

COOLING PERFORMANCE DAT A

C OOLING OP ERATION

GSH130363AF

EXPANDED PERFORMANCE DATA

15 10 19 17 14 10 17 16 13 9

32.034.327.228.130.432.625.226.028.130.2

0.67 0.43 1.00 0.91 0.69 0.45 1.00 0.92 0.70 0.45

18

29.5

0.88

Outdoor Ambient Temperature

En t er ing Ind oor We t Bulb Te mpera tu re

89 95 80 85 93 99 83 88 96 103

7.2 7.4 7.2 7.4 7.6 7.9 7.6 7.8 8.0 8.3

242253240258273284265285301314

2.89 3.00 2.85 2.92 3.02 3.13 2.96 3.03 3.14 3.25

81

7.0

229

2.79

31.533.826.827.629.932.124.925.627.729.7

29.1

15 10 20 18 15 10 19 17 14 10

0.64 0.41 0.98 0.88 0.66 0.43 0.99 0.88 0.67 0.43

19

0.84

88 94 80 85 92 98 82 88 96 102

7.1 7.4 7.2 7.3 7.6 7.8 7.6 7.7 8.0 8.3

241251238256271282263283299312

2.87 2.98 2.83 2.90 3.01 3.11 2.94 3.01 3.12 3.23

81

6.9

228

2.78

29.131.224.825.527.629.623.023.625.627.5

26.9

16 11 20 19 15 11 19 18 14 10

0.62 0.40 0.94 0.84 0.64 0.41 0.95 0.85 0.64 0.41

19

0.81

86 91 77 82 90 95 80 85 93 99

7.0 7.2 7.0 7.1 7.4 7.6 7.4 7.5 7.8 8.1

233243231249263274255275290303

2.80 2.90 2.76 2.82 2.92 3.03 2.86 2.93 3.03 3.14

78

6.7

221

2.70

65 75 85 95 105 115

DT 16 14 11 - 17 14 11 - 17 14 11 - 17 14 11 - 16 14 11 - 15 13 10 -

S/T 0.79 0.66 0.46 - 0.82 0.68 0.47 - 0.84 0.70 0.49 - 0.87 0.72 0.50 - 0.90 0.75 0 .52 - 0.91 0.76 0.52 -

MBh 30.3 31.4 34.4 - 2 9.6 30.7 33.6 - 28.9 30.0 32.8 - 28.2 29.2 32.0 - 26.8 27.8 30.4 - 24.8 25.7 28.2 -

MODE L: GSH130363A* / ARUF49- 00*-1* / ARUF36421A*

IDB*Airflow 596367715963677159636771596367715963677159636771

HI PR145156165 - 163175185 - 185199 211 - 211227240 - 237255270 - 262282298 -

AMPS 5.5 5.6 5.8 - 5.9 6.0 6.2 - 6.3 6.5 6.7 - 6.8 6.9 7.1 - 7.2 7.3 7.5 - 7.6 7.7 8.0 -

L O PR 66 70 76 - 69 74 81 - 72 77 84 - 7 6 81 88 - 79 8 4 92 - 8 2 87 95 -

1350 KW 2.21 2.26 2.34 - 2.40 2.45 2.54 - 2.56 2.62 2.71 - 2.70 2.77 2.87 - 2.83 2.89 3 .00 - 2.93 3.00 3.11 -

DT 17 15 11 - 17 15 11 - 17 15 11 - 17 15 11 - 17 15 11 - 16 14 11 -

S/T 0.76 0.63 0.44 - 0.78 0.66 0.45 - 0.80 0.67 0.47 - 0.83 0.69 0.48 - 0.86 0.72 0 .50 - 0.87 0.73 0.50 -

MBh 29.9 31.0 33.9 - 2 9.2 30.2 33.1 - 28.5 29.5 32.3 - 27.8 28.8 31.6 - 26.4 27.4 30.0 - 24.5 25.3 27.8 -

HI PR144155164 - 162174184 - 184198 209 - 210226238 - 236254268 - 260280296 -

AMPS 5.4 5.6 5.7 - 5.8 6.0 6.2 - 6.3 6.5 6.7 - 6.7 6.9 7.1 - 7.1 7.3 7.5 - 7.5 7.7 7.9 -

L O PR 65 69 76 - 69 73 80 - 72 76 83 - 7 5 80 87 - 79 8 4 92 - 8 1 87 95 -

70 1217 KW 2.20 2.25 2.33 - 2. 38 2.44 2.52 - 2.54 2.60 2.70 - 2.69 2.75 2.85 - 2.81 2.88 2.98 - 2.91 2.98 3. 09 -

DT 18 15 12 - 18 15 12 - 18 15 12 - 18 16 12 - 18 15 12 - 17 14 11 -

S/T 0.73 0.61 0.42 - 0.76 0.63 0.44 - 0.78 0.65 0.45 - 0.80 0.67 0.46 - 0.83 0.69 0 .48 - 0.84 0.70 0.48 -

MBh 27.6 28.6 31.3 - 2 6.9 27.9 30.6 - 26.3 27.2 29.9 - 25.6 26.6 29.1 - 24.4 25.3 27.7 - 22.6 23.4 25.6 -

HI PR140151159 - 157169178 - 178192 203 - 203219231 - 229246260 - 253272287 -

AMPS 5.3 5.4 5.6 - 5.7 5.8 6.0 - 6.2 6.3 6.5 - 6.5 6.7 6.9 - 6.9 7.1 7.3 - 7.3 7.5 7.7 -

L O PR 63 67 73 - 67 71 78 - 69 74 81 - 7 3 78 85 - 76 8 1 89 - 7 9 84 92 -

1050 KW 2.14 2.19 2.26 - 2.32 2.37 2.46 - 2.48 2.53 2.62 - 2.62 2.68 2.77 - 2.73 2.80 2 .90 - 2.84 2.90 3.01 -

MBh 30.831.734.436.930.131.033.636.029.430.332.835.228.7

S/T 0.900.800.610.390.930.830.630.410.950.850.650.420.99

DT 19 17 14 10 19 18 14 10 19 18 14 10 19

HI PR147158167174165177187195187201213222213

AMPS5.55.65.86.05.96.16.26.56.46.56.77.06.8

L O PR 66 71 77 82 70 75 81 8 7 73 7 7 85 90 76

1350 KW 2.23 2.28 2.36 2.44 2.42 2.47 2.56 2.65 2.58 2.64 2.74 2.83 2.73

MBh 30.431.333.936.329.730.633.135.529.029.832.334.628.3

S/T 0.860.770.580.370.890.800.600.390.910.820.620.400.94

DT 20 18 15 10 20 18 15 10 20 18 15 10 20

HI PR146157166173163176186194186200211220212

AMPS5.55.65.86.05.96.06.26.46.46.56.76.96.8

L O PR 66 70 76 81 70 74 81 8 6 72 7 7 84 89 76

75 1217 KW 2.22 2.27 2.35 2.43 2.40 2.46 2.54 2.63 2.57 2.63 2.72 2.82 2.71

MBh 28.028.931.233.527.428.230.532.826.727.529.832.026.1

S/T 0.830.740.560.360.860.770.580.370.880.790.600.380.91

DT 20 19 15 11 21 19 16 11 21 19 16 11 21

HI PR141152161167159171180188180194205214205

AMPS5.45.55.65.85.85.96.16.36.26.36.56.86.6

L O PR 64 68 74 79 67 72 78 8 3 70 7 5 81 87 74

1050 KW 2.16 2.21 2.28 2.36 2.34 2.39 2.48 2.56 2.50 2.56 2.65 2.74 2.64

Shaded area is ACCA (T VA) cond i tions IDB: Enteri ng I ndoor Dry Bulb Temperature KW=T otal system power AMPS=outdo or unit amp s (comp. +fan)

High an d l ow pressu res ar e measured at the liq ui d and suct i on s ervice valves .

9

Page 10

COOLING PERFORMANCE DAT A

COOLING OPERATION

GSH130363AF

EXPANDED PERFORMANCE DATA

15 21 21 18 15 19 20 17 14

33.627.327.929.831.925.325.927.629.5

0.59 1.00 1.00 0.82 0.61 1.00 1.00 0.83 0.62

19

31.4

0.79

Outdoor Ambient Temperature

En t er ing Ind oor We t Bu lb Temp e ra t ure

3.00 2.86 2.93 3.03 3.14 2.97 3.04 3.15 3.26

2.90

7.57.27.47.67.97.67.88.18.4

253 241 259 273 285 266 286 302 315

7.2

243

95 80 86 93 99 83 88 97 103

89

10

65 75 85 95 105 115

DT 21 20 18 14 21 20 18 14 20 20 18 14 20 20 18 14 19 19 18 14 17 18 16 13

S/T 1.000.920.750.561.000.960.780.581.000.980.800.601.001.000.830.621.001.000.860.641.001.000.860.65

MBh 31.432.134.336.630.731.333.535.829.930.632.734.929.229.831.934.127.728.330.332.425.726.328.030.0

MODE L: GSH130363A* / ARUF49-00*-1* / ARUF36421A*

IDB*Airflow 596367715963677159636771596367715963677159636771

HI PR148159168176166179189197189203215224215232245 255242261275287268288304317

AMPS 5.6 5.7 5.9 6.1 6.0 6.1 6.3 6.5 6.5 6.6 6.8 7.0 6.9 7.0 7.2 7.5 7.3 7.4 7.7 8 .0 7.7 7.9 8.1 8.4

L O PR 67 71 78 83 71 75 82 8 8 74 78 85 91 7 7 82 90 96 81 86 94 10 0 84 89 9 7 104

1350 KW 2.25 2.30 2.38 2.46 2.44 2.50 2.58 2.67 2.61 2.67 2.76 2.86 2.75 2.82 2.92 3.02 2.88 2.95 3.05 3.16 2.99 3.06 3.17 3.28

MBh 30.931.633.836.130.230.933.035.229.530.132.234.428.829.4

S/T 0.940.880.720.540.980.920.750.561.000.940.770.571.000.97

DT 22 21 18 15 22 21 19 15 22 21 19 15 22 22

HI PR147158167174165178188196188202213223214230

AMPS5.55.75.86.05.96.16.36.56.46.66.87.06.87.0

LO PR 67 71 77 82 70 75 82 87 73 78 85 90 77 82

80 1217 KW 2.24 2.29 2.37 2.45 2. 42 2.48 2.57 2.66 2.59 2.65 2.74 2.84 2.74 2.80

MBh 28.529.231.233.327.928.530.432.527.227.829.731.826.527.129.031.025.225.827.529.423.423.925.527.3

S/T 0.910.850.690.520.940.880.720.540.970.910.740.551.000.940.760.571.040.970.790.591.040.980.800.60

DT 23 22 19 15 23 22 19 15 23 22 19 15 23 22 19 15 23 22 19 15 21 20 18 14

HI PR143154162169160172182190182196207216207223236 246233251265277258277293306

AMPS 5.4 5.5 5.7 5.9 5.8 5.9 6.1 6.3 6.3 6.4 6.6 6.8 6.7 6.8 7.0 7.3 7.0 7.2 7.4 7 .7 7.4 7.6 7.8 8.1

L O PR 65 69 75 80 68 73 79 8 4 71 75 82 88 7 4 79 86 92 78 83 91 96 81 86 9 4 100

1050 KW 2.18 2.23 2.30 2.39 2.36 2.42 2.50 2.59 2.52 2.58 2.67 2.77 2.66 2.73 2.82 2.92 2.78 2.85 2.95 3.06 2.89 2.96 3.06 3.17

MBh 31.932.534.136.431.231.833.335.530.431.032.534.729.730.331.733.828.228.830.132.126.126.627.929.8

S/T 1.001.000.900.731.001.000.930.761.001.000.960.781.001.000.990.801.001.001.000.831.001.001.000.84

DT 22 22 21 18 21 22 21 18 21 21 21 18 20 21 21 18 19 20 21 18 18 18 19 17

HI PR150161170177168181191199191205217226217234247 258245263278290270291307320

AMPS 5.6 5.7 5.9 6.1 6.0 6.2 6.4 6.6 6.5 6.7 6.9 7.1 6.9 7.1 7.3 7.6 7.3 7.5 7.7 8 .0 7.8 7.9 8.2 8.5

L O PR 68 72 79 84 71 76 83 8 8 74 79 86 92 7 8 83 91 97 82 87 95 10 1 85 90 9 8 105

1350 KW 2.27 2.32 2.40 2.49 2.46 2.52 2.61 2.70 2.63 2.69 2.79 2.89 2.78 2.84 2.94 3.05 2.90 2.97 3.08 3.19 3.01 3.09 3.20 3.31

MBh 31.532.133.635.830.731.332.835.030.030.632.034.229.329.831.233.327.828.329.731.725.826.327.529.3

S/T 0.990.950.860.701.000.990.890.721.001.000.920.741.001.000.940.771.001.000.980.801.001.000.990.80

DT 24 23 22 19 23 23 22 19 23 23 22 19 22 23 22 19 21 21 22 19 19 20 21 18

HI PR149160169176167179189198190204215225216232245 256243261276288268289305318

AMPS 5.6 5.7 5.9 6.1 6.0 6.1 6.3 6.5 6.5 6.6 6.8 7.1 6.9 7.0 7.3 7.5 7.3 7.5 7.7 8 .0 7.7 7.9 8.1 8.4

L O PR 67 71 78 83 71 76 82 8 8 74 78 86 91 7 7 82 90 96 81 86 94 10 0 84 89 9 8 104

85 1217 KW 2.26 2.31 2.39 2.47 2. 45 2.50 2.59 2.68 2.61 2.67 2.77 2.87 2.76 2.83 2.93 3.03 2.89 2.96 3.06 3.17 2.99 3.07 3.18 3.29

MBh 29.029.631.033.128.428.930.332.327.728.229.631.527.027.528.830.825.726.227.429.223.824.225.427.1

S/T 0.950.920.830.670.990.950.860.701.000.980.880.721.001.000.910.741.001.000.950.771.001.000.950.77

DT 24 24 23 20 25 24 23 20 24 24 23 20 24 24 23 20 22 23 23 20 21 21 21 18

HI PR144155164171162174184192184198209218209225238 248236254268279260280296309

AMPS 5.4 5.6 5.7 5.9 5.8 6.0 6.2 6.4 6.3 6.5 6.6 6.9 6.7 6.9 7.1 7.3 7.1 7.3 7.5 7 .8 7.5 7.7 7.9 8.2

L O PR 65 69 76 81 69 73 80 8 5 72 76 83 89 7 5 80 87 93 79 84 91 97 81 87 9 5 101

1050 KW 2.20 2.25 2.33 2.41 2.38 2.44 2.52 2.61 2.54 2.60 2.69 2.79 2.69 2.75 2.85 2.95 2.81 2.88 2.98 3.08 2.91 2.98 3.09 3.20

Sha ded area is AHRI Rating Conditions IDB: Entering Indoor Dry Bulb Te mperature KW=Total system power AMPS=outdoor unit amps (comp.+fan)

High and low pre ssures are measured a t the liqui d and suction service valves.

Page 11

COOLING PERFORMANCE DAT A

CO OLING OPERATION

GSH130483AE

EXPANDED PERFORMANCE DATA

15 11 20 18 15 10 19 17 14 10

46.5 49.9 39.6 40.8 44.2 4 7.4 36.7 37.8 40.9 43.9

0.64 0.41 0.98 0.88 0.66 0.43 0.99 0.89 0.67 0.43

19

42.9

0.85

Outdoor Ambient Temperature

En t er in g Ind oor Wet Bulb Temp e ra t u re

3.97 4.10 3.92 4.00 4.14 4.27 4.05 4.14 4.28 4.43

3.84

84 89 76 81 88 94 78 83 91 97

242 253 240 258 273 284 265 285 301 314

13.3 13.8 13.3 13.7 14.1 1 4.6 14.1 14.5 14.9 15.5

77

229

12.9

16 11 21 19 16 11 19 18 15 10

45.1 48.4 38.5 39.6 42.9 4 6.0 35.6 36.7 39.7 42.6

0.61 0.39 0.94 0.84 0.63 0.41 0.94 0.84 0.64 0.41

19

41.7

0.81

3.94 4.07 3.89 3.97 4.10 4.24 4.02 4.11 4.25 4.39

3.81

83 88 75 80 87 93 77 82 90 96

240 250 238 256 270 282 262 282 298 311

13.2 13.6 13.2 13.5 14.0 1 4.5 14.0 14.3 14.8 15.4

76

227

12.7

16 11 21 19 16 11 20 18 15 10

41.7 44.7 35.5 36.6 39.6 4 2.5 32.9 33.9 36.7 39.3

0.59 0.38 0.90 0.81 0.61 0.39 0.91 0.81 0.62 0.40

20

38.5

0.78

3.84 3.96 3.79 3.87 4.00 4.13 3.92 4.01 4.14 4.28

3.72

81 86 73 77 84 90 75 80 87 93

233 243 230 248 262 273 255 274 289 302

12.8 13.3 12.9 13.2 13.6 1 4.1 13.6 13.9 14.4 14.9

74

220

12.4

65 75 85 95 105 115

S/T 0.76 0.63 0.44 - 0.79 0.66 0.46 - 0.81 0.67 0.47 - 0.83 0.70 0.48 - 0.86 0.72 0.50 - 0.87 0.73 0.50 -

MBh 44.1 45.7 50.1 - 43.1 44.6 48.9 - 42.0 43.6 47.7 - 41.0 42.5 46.6 - 39.0 40.4 44.3 - 36.1 37.4 41.0 -

MODE L: GSH1304 83A* / ARUF61-00*-1* / ARUF 48601A*

IDB*Airflow 59636771596367715963677159 63 67715963677159636771

HI PR 145 156 165 - 163 175 185 - 185 199 211 - 211 227 240 - 237 256 270 - 262 282 298 -

AMPS 10.0 10.2 10.5 - 10.8 11.0 11.4 - 11.7 11.9 12.3 - 12.4 12.7 13.2 - 13.2 13.5 14.0 - 14.0 14.3 14.8 -

Del ta T 17 15 11 - 17 15 11 - 17 15 1 1 - 17 15 11 - 17 15 11 - 16 14 11 -

1800 KW 3.10 3.17 3.27 - 3.34 3.41 3.52 - 3.55 3.62 3.74 - 3.73 3.81 3.93 - 3.88 3.97 4.10 - 4.02 4.11 4.24 -

S/T 0.72 0.60 0.42 - 0.75 0.63 0.43 - 0.77 0.64 0.45 - 0.79 0.66 0.46 - 0.82 0.69 0.48 - 0.83 0.69 0.48 -

MBh 42.8 44.4 48.6 - 41.8 43.3 47.5 - 40.8 42.3 46.4 - 39.8 41.3 45.2 - 37.8 39.2 43.0 - 35.0 36.3 39.8 -

L O PR 62 66 72 - 65 70 76 - 68 7 2 79 - 7 1 7 6 8 3 - 7 5 80 87 - 77 82 90 -

HI PR 144 155 163 - 161 174 183 - 184 197 209 - 209 225 238 - 235 253 267 - 260 280 295 -

AMPS 9.9 10.1 10.5 - 10.7 10.9 11.3 - 11.6 11.8 12.2 - 12.3 12.6 13.0 - 13.1 13.4 13.9 - 13.9 14.2 14. 7 -

Del ta T 18 15 12 - 18 16 12 - 18 16 1 2 - 18 16 12 - 18 16 12 - 17 14 11 -

70 1600 KW 3.08 3.14 3.24 - 3.31 3.38 3.49 - 3.52 3.59 3.71 - 3. 70 3.78 3.90 - 3.85 3.94 4.07 - 3.99 4.07 4.21 -

S/T 0.70 0.58 0.40 - 0.72 0.60 0.42 - 0.74 0.62 0.43 - 0.77 0.64 0.44 - 0.79 0.66 0.46 - 0.80 0.67 0.46 -

MBh 39.5 41.0 44.9 - 38.6 40.0 43.8 - 37.7 39.1 42.8 - 36.8 38.1 41.7 - 34.9 36.2 39.7 - 32.3 33.5 36.7 -

L O PR 61 65 71 - 65 69 75 - 67 7 2 78 - 7 1 7 5 8 2 - 7 4 79 86 - 77 82 89 -

HI PR 139 150 159 - 157 168 178 - 178 192 202 - 203 218 230 - 228 245 259 - 252 271 286 -

AMPS 9.6 9.9 10.2 - 10.4 10.6 11.0 - 11.3 11.5 11.9 - 12.0 12.3 12.7 - 12.8 13.1 13.5 - 13.5 13.8 14.3 -

Del ta T 18 16 12 - 18 16 12 - 18 16 1 2 - 18 16 12 - 18 16 12 - 17 15 11 -

L O PR 60 63 69 - 63 67 73 - 65 7 0 76 - 6 9 7 3 8 0 - 7 2 77 84 - 74 79 86 -

1400 KW 3.01 3.07 3.16 - 3.23 3.30 3.40 - 3.43 3.51 3.62 - 3.61 3.69 3.81 - 3.76 3.84 3.97 - 3.89 3.97 4.10 -

MBh 44.846.250.053.643.845.148.852.442.844.047.751.141.7

S/T 0.860.770.580.380.890.800.610.390.920.820.620.400.95

Delta T20181510201815102018151020

1800 KW 3.13 3.19 3.29 3.40 3.37 3.44 3.55 3.66 3.58 3.65 3.77 3.89 3.76

HI PR 14 7 158 167 174 1 65 177 187 1 9 5 187 2 01 213 222 213

AMPS 10.1 10.3 1 0.6 11.0 10.9 11.1 11.5 11.9 11.8 12.1 12.4 12.9 1 2.6

L O PR 63 67 73 77 6 6 70 77 82 69 73 80 85 72

Delta T21191611211916112119161121

75 1600 KW 3.10 3.17 3.27 3.37 3.34 3.41 3.52 3.63 3.55 3.62 3 .74 3.86 3.73

HI PR 14 5 156 165 172 1 63 175 185 1 9 3 185 1 99 211 220 211

AMPS 10.0 10.2 1 0.5 10.9 10.8 11.0 11.4 11.8 11.7 11.9 12.3 12.8 1 2.5

S/T 0.820.740.560.360.850.760.580.370.870.780.590.380.90

MBh 43.544.848.552.142.543.847.450.941.542.746.349.740.5

S/T 0.790.710.540.350.820.740.560.360.840.750.570.370.87

MBh 40.241.444.848.139.340.443.746.938.339.542.745.837.4

L O PR 62 66 72 77 6 5 70 76 81 68 72 79 84 71

Delta T21191611212016112120161121

1400 KW 3.03 3.09 3.19 3.29 3.26 3.33 3.43 3.54 3.46 3.53 3.65 3.77 3.64

AMPS9.7 10.010.310.610.510.711.111.511.411.612.012.412.1

HI PR 14 1 152 160 167 1 58 170 180 1 8 7 180 1 94 204 213 205

L O PR 60 64 70 74 6 4 68 74 79 66 70 77 82 69

Shaded area is ACCA (TVA) conditi ons IDB: Ente ri ng I ndoor Dry Bulb Temperature KW=T otal system power AMPS =o u tdoor unit amps (comp.+fan)

High and low pre ss ures are measur e d at the l iqui d and suction service va l ves.

11

Page 12

COOLING PERFORMANCE DAT A

CO OLING OPERATION

GSH130483AE

EXPANDED PERFORMANCE DATA

16 23 22 19 15 21 21 18 14

48.1 39.2 40.0 42.8 45.7 36.3 37.1 39.6 42.3

0.56 1.00 0.96 0.78 0.59 1.00 0.97 0.79 0.59

20

45.0

3.97

0.76

Outdoor Ambient Temperature

En t er in g Ind oor Wet Bulb Te mpe ra t u re

89 76 81 88 94 78 83 91 97

253 240 258 273 284 265 285 301 314

4.10 3.92 4.00 4.14 4.27 4.05 4.14 4.28 4.43

13.8 13.4 13.7 14.1 14.6 14.1 14.5 14.9 15.5

84

242

13.3

12

65 75 85 95 105 115

S/T 0.950.890.720.541.000.920.750.561.000.940.770.571.00 1.00 0.790.591.001.000.820.611.001.000.830.62

MBh 45.646.649.853.344.645.648.752.043.544.547.550.842.5 43.4 46.449.540.341.244.047.137.438.240.843.6

MODE L: GSH1304 83A* / ARUF61-00* - 1* / ARUF48601A*

IDB*Airflow 59636771596367715963677159 63 67715963677159636771

Delta T22211815232119152221191522 22 19152121181519191714

1800 KW 3.15 3.22 3.32 3.42 3.39 3.46 3.58 3.69 3.60 3.68 3.80 3.93 3.79 3.87 4.00 4.13 3.95 4.04 4.17 4.31 4.09 4.18 4.32 4.46

HI PR 148 159 168 176 166 179 189 197 189 204 215 224 215 232 245 255 242 261 275 287 268 288 304 317

AMPS 10.2 10.4 1 0.7 11.1 11.0 11.2 11.6 1 2.0 11.9 12.2 12.6 13.0 1 2.7 13.0 13.4 13.9 1 3.5 13.8 14.2 1 4.8 14.3 14.6 15.1 15.6

S/T 0.900.850.690.510.940.880.710.530.960.900.730.550.99 0.93

MBh 44.345.348.451.743.344.247.350.542.343.246.149.341.2 42.1

L O PR 63 67 73 78 6 7 71 78 83 69 74 81 86 73 78 85 90 76 81 89 9 5 79 84 92 98

Delta T23221915232219152322191623 22

80 1600 KW 3.13 3.19 3.29 3.40 3.37 3.44 3.55 3.66 3.58 3.65 3.77 3.89 3.76 3.84

HI PR 14 7 158 167 174 1 6 5 17 7 187 1 9 5 18 7 202 213 222 213 23 0

AMPS 10.1 10.3 1 0.6 11.0 10.9 11.1 11.5 1 1.9 11.8 12.1 12.4 12.9 1 2.6 12.9

S/T 0.870.820.660.500.900.850.690.510.920.870.710.530.95 0.90 0.730.540.990.930.760.571.000.940.760.57

MBh 40.941.844.747.739.940.843.646.639.039.842.645.538.0 38.9 41.544.436.136.939.542.233.534.236.639.1

L O PR 63 67 73 77 6 6 70 77 82 69 73 80 85 72 77

Delta T23221916242320162423201624 23 20162423201622211815

1400 KW 3.05 3.12 3.21 3.32 3.28 3.35 3.46 3.57 3.49 3.56 3.68 3.80 3.67 3.75 3.87 4.00 3.82 3.90 4.03 4.17 3.95 4.04 4.17 4.31

AMPS9.8 10.010.410.710.610.811.211.611.511.712.112.612.2 12.5 12.913.413.013.313.714.213.714.114.515.1

HI PR 142 153 162 169 160 172 181 189 182 195 206 215 207 223 235 245 233 250 264 276 257 277 292 305

L O PR 61 65 71 75 6 4 68 75 79 67 71 77 82 70 75 81 87 73 78 85 9 1 76 81 88 94

MBh 46.447.349.652.945.446.248.451.744.345.147.350.443.2 44.0 46.149.241.041.843.846.738.038.840.643.3

S/T 0.990.960.860.701.000.990.900.731.001.000.920.741.00 1.00 0.950.771.001.000.980.801.001.000.990.80

Delta T24232219232322192323221922 22 22192121221919202118

1800 KW 3.18 3.24 3.35 3.45 3.42 3.49 3.60 3.72 3.63 3.71 3.83 3.96 3.82 3.91 4.03 4.17 3.98 4.07 4.21 4.35 4.12 4.21 4.35 4.50

HI PR 150 161 170 177 168 181 191 199 191 206 217 226 218 234 247 258 245 263 278 290 270 291 307 321

AMPS 10.3 10.5 1 0.8 11.2 11.1 11.3 11.7 1 2.1 12.0 12.3 12.7 13.1 1 2.8 13.1 13.5 14.0 1 3.6 13.9 14.4 1 4.9 14.4 14.7 15.2 15.8

S/T 0.950.910.820.670.980.950.850.691.000.970.880.711.00 1.00 0.900.731.001.000.940.761.001.000.950.77

MBh 45.146.048.151.444.044.947.050.243.043.845.949.041.9 42.8 44.847.839.840.642.545.436.937.639.442.0

L O PR 64 68 74 79 6 7 72 78 83 70 75 81 87 74 78 86 91 77 82 90 9 5 80 85 93 99

Delta T25242320252423202524232024 25 23202323232021222119

85 1600 KW 3.15 3.22 3.32 3.42 3.39 3.46 3.58 3.69 3.60 3.68 3.80 3.93 3.79 3.87 4.00 4.13 3.95 4.04 4.17 4.31 4.09 4.18 4.32 4.46

HI PR 148 159 168 176 166 179 189 197 189 204 215 224 215 232 245 255 242 261 275 287 268 288 304 317

AMPS 10.2 10.4 1 0.7 11.1 11.0 11.2 11.6 1 2.0 11.9 12.2 12.6 13.0 1 2.7 13.0 13.4 13.9 1 3.5 13.8 14.2 1 4.8 14.3 14.6 15.1 15.6

S/T 0.910.880.790.640.950.910.820.670.970.940.840.681.00 0.97 0.870.711.001.000.900.731.001.000.910.74

MBh 41.642.444.447.440.641.443.446.339.740.442.445.238.7 39.5 41.344.136.837.539.341.934.134.736.438.8

L O PR 63 67 73 78 6 7 71 78 83 69 74 81 86 73 78 85 90 76 81 89 9 5 79 84 92 98

Delta T25252320252523202525232025 25 24202425232022232219

1400 KW 3.08 3.14 3.24 3.34 3.31 3.38 3.49 3.60 3.52 3.59 3.71 3.83 3.70 3.78 3.90 4.03 3.85 3.94 4.07 4.20 3.99 4.07 4.21 4.35

AMPS9.9 10.110.410.810.710.911.311.711.611.812.212.712.3 12.6 13.013.513.113.413.914.413.914.214.715.2

d i tions IDB: Entering I ndoor Dry Bulb Temperature KW=Total syst em power AMPS=outdoor unit amps (comp.+ fan)

HI PR 144 155 163 170 161 174 183 191 183 197 208 217 209 225 237 248 235 253 267 279 260 279 295 308

L O PR 61 65 71 76 6 5 69 75 80 67 72 78 83 71 75 82 88 74 79 86 9 2 77 82 89 95

Sh ad ed area is A H RI Rating Co ndi tions

High and low pre ss ures are measur e d at the l i quid and s ucti o n ser vice valv es.

Page 13

COOLING PERFORMANCE DAT A

COOLING OPERATION

GSH130603AC

EXPANDED PERF ORMANCE DATA

17 11 22 20 16 11 20 19 15 11

55.7 59.7 47.5 48.9 52.9 56.8 44.0 45.3 49.0 52.6

0.58 0.37 0.89 0.80 0.60 0.39 0.90 0.81 0.61 0.39

20

51.4

0.77

Outdoor Ambi ent Temper ature

Entering Indoo r Wet Bulb Temperature

76 81 69 73 80 85 71 76 83 88

241 251 238 257 271 283 263 284 299 312

5.17 5.35 5.10 5.22 5.39 5.58 5.28 5.40 5.59 5.78

17.3 17.9 17.4 17.8 18.4 19.1 18.4 18.9 19.5 20.2

70

228

5.00

16.7

65 75 85 95 105 115

S/T 0.72 0.60 0.42 - 0.75 0.63 0.43 - 0.77 0.64 0.45 - 0.79 0.66 0.46 - 0.82 0.69 0.48 - 0.83 0.69 0.48 -

MBh 54.4 56.4 61.8 - 53.1 55.1 60.3 - 51.9 53.7 58.9 - 50.6 52.4 57.5 - 48.1 49.8 54.6 - 44.5 46.1 50.6 -

MOD E L: GSH130603A* / ARUF6 1- 00*-1* / ARUF48601A*

IDB Airflow 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71

HI PR 146 157 166 - 164 176 186 - 186 200 211 - 212 228 241 - 238 257 271 - 263 283 299 -

AMPS 13.0 13.3 13.8 - 14.1 14.4 14.9 - 15.3 15.7 16.2 - 16.3 16.7 17.3 - 17.4 17.8 18.4 - 18.4 18.9 19.5 -

Delta T 18 15 12 - 18 16 12 - 18 16 12 - 18 16 12 - 18 16 12 - 17 15 11 -

2025 KW 4.03 4.12 4.25 - 4.35 4.45 4.60 - 4.64 4.74 4.90 - 4.89 5.00 5.17 - 5.10 5.22 5.39 - 5.28 5.40 5.59 -

S/T 0.69 0.58 0.40 - 0.72 0.60 0.41 - 0.73 0.61 0.42 - 0.76 0.63 0.44 - 0.79 0.66 0.45 - 0.79 0.66 0.46 -

MBh 52.8 54.7 60.0 - 51.6 53.5 58.6 - 50.3 52.2 57.2 - 49.1 50.9 55.8 - 46.7 48.4 53.0 - 43.2 44.8 49.1 -

L O PR 57 61 66 - 60 64 70 - 63 67 73 - 66 70 76 - 69 73 80 - 71 76 83 -

HI PR 144 155 164 - 162 174 184 - 184 198 209 - 210 226 238 - 236 254 268 - 261 281 296 -

AMPS 12.9 13.2 13.7 - 14.0 14.3 14.8 - 15.1 15.5 16.0 - 16.2 16.6 17.1 - 17.2 17.6 18.2 - 18.2 18.7 19.3 -

Delta T 19 16 12 - 19 16 12 - 19 16 12 - 19 16 12 - 19 16 12 - 17 15 11 -

70 1800 KW 4.00 4.09 4.22 - 4.32 4.41 4.56 - 4.60 4.70 4.86 - 4.84 4.96 5.12 - 5.06 5.17 5.35 - 5.24 5.36 5.54 -

S/T 0.67 0.56 0.39 - 0.69 0.58 0.40 - 0.71 0.59 0.41 - 0.73 0.61 0.42 - 0.76 0.63 0.44 - 0.76 0.64 0.44 -

MBh 48.7 50.5 55.3 - 47.6 49.3 54.1 - 46.5 48.2 52.8 - 45.3 47.0 51.5 - 43.1 44.6 48.9 - 39.9 41.4 45.3 -

L O PR 57 60 66 - 60 64 69 - 62 66 72 - 65 69 76 - 68 73 79 - 71 75 82 -

HI PR 140 151 159 - 157 169 179 - 179 192 203 - 204 219 231 - 229 246 260 - 253 272 287 -

AMPS 12.6 12.9 13.3 - 13.6 13.9 14.4 - 14.7 15.1 15.6 - 15.7 16.1 16.7 - 16.7 17.1 17.7 - 17.7 18.2 18.8 -

Delta T 19 16 12 - 19 17 13 - 19 17 13 - 19 17 13 - 19 16 13 - 18 15 12 -

1575 KW 3.90 3.99 4.12 - 4.21 4.30 4.44 - 4.48 4.58 4.73 - 4.72 4.83 4.99 - 4.93 5.04 5.21 - 5.10 5.22 5.40 -

L O PR 55 58 64 - 58 62 67 - 60 64 70 - 63 67 73 - 66 70 77 - 69 73 80 -

S/T 0.820.740.560.360.850.760.580.370.870.780.590.380.90 0.81 0.61 0.390.940.840.630.410.940.840.640.41

MBh 55.31 56.94 61.64 66.15 54.02 55.62 60.20 64.61 52.73 54.30 58.77 63.08 51.45 52.97 57.34 61.54 48.88 50.32 54.47 58.46 45.27 46. 61 50.46 54.15

Delta T21191611211916112119161121 19 16 112119161119181510

2025 KW 4.07 4.16 4.29 4.43 4.39 4.49 4.64 4.79 4.68 4.78 4.94 5.11 4.93 5.04 5.21 5.39 5.14 5.26 5.44 5.63 5.33 5.45 5.64 5.83

HI P R 147 1 59 16 7 17 5 16 5 17 8 188 1 9 6 188 2 02 214 223 2 1 4 2 30 243 254 241 2 5 9 274 2 85 26 6 2 86 302 31 5

AMPS 13.2 13.5 13.9 14.4 14.2 14.5 15.0 15.6 15.4 15.8 16.3 16.9 16.5 16.9 17.4 18.1 17.5 18.0 18.6 19.3 18.6 19.0 19.7 20.4

S/T 0.780.700.530.340.810.730.550.350.830.750.560.360.86

MBh 53.7 55.3 59.8 64.2 52.4 54.0 58.4 62.7 51.2 52.7 57.1 61.2 50.0

L O PR 58 61 67 71 61 65 71 75 63 67 74 78 67 71 77 82 70 7 4 81 86 72 77 84 89

Delta T22201611222016112220161122

75 1800 KW 4.03 4.12 4.26 4.40 4.35 4.45 4.60 4.75 4.64 4.74 4.90 5.07 4.89

HI P R 146 1 57 16 6 17 3 16 4 17 6 186 1 9 4 186 2 00 211 221 2 1 2

AMPS 13.0 13.3 13.8 14.3 14.1 14.4 14.9 15.4 15.3 15.7 16.2 16.8 16.3

S/T 0.760.680.510.330.780.700.530.340.800.720.540.350.83 0.74 0.56 0.360.860.770.580.380.870.780.590.38

MBh 49.6 51.0 55.2 59.3 48.4 49.8 53.9 57.9 47.3 48.7 52.7 56.5 46.1 47.47 51.4 55.1 43.8 45.1 48.8 52.4 40.6 41.8 45.2 48.5

L O PR 57 61 66 71 60 64 70 75 63 67 73 78 66

Delta T22201711222017122220171222 21 17 122220171121191611

1575 KW 3.93 4.02 4.15 4.29 4.24 4.34 4.48 4.63 4.52 4.62 4.78 4.94 4.76 4.87 5.03 5.21 4.97 5.08 5.25 5.44 5.15 5.26 5.44 5.63

HI P R 141 1 52 16 1 16 8 15 9 17 1 180 1 8 8 181 1 94 205 214 2 0 6 2 21 234 244 231 2 4 9 263 2 74 25 6 2 75 290 30 3

AMPS 12.7 13.0 13.4 13.9 13.7 14.0 14.5 15.0 14.9 15.2 15.7 16.3 15.9 16.3 16.8 17.4 16.9 17.3 17.9 18.6 17.9 18.3 18.9 19.7

L O PR 55 59 64 68 59 62 68 72 61 65 71 75 64 68 74 79 67 7 1 78 83 69 74 80 86

Shaded area is ACCA (TVA) conditi ons IDB: Entering Indoor Dry Bulb Tem perat ur e KW=Tot al system power AMPS =outdoor unit amps (comp.+fan)

High and low pressures are measur ed at the li quid and suction servi ce valv es.

13

Page 14

COOLING PERFORMANCE DAT A

COOLING O PERATION

GSH130603AC

EXPANDED PERF ORM ANCE DA TA

16 24 23 20 16 23 22 19 15

5.39 5.14 5.26 5.44 5.63 5.33 5.45 5.64 5.84

0.54 0.98 0.92 0.75 0.56 0.99 0.93 0.75 0.56

59.3 48.3 49.4 52.7 56.4 44.7 45.7 48.8 52.2

20

0.72

55.5

Outdoor Ambi ent Temper ature

Entering Indoor Wet Bulb Temperature

82 70 74 81 86 72 77 84 89

254 241 259 274 285 266 286 302 315

18.1 17.5 18.0 18.6 19.3 18.6 19.0 19.7 20.4

77

243

17.4

5.21

14

65 75 85 95 105 115

S/T 0.900.850.690.510.940.880.710.530.960.900.730.551.00 0.93 0.76 0.561.000.960.780.591.001.000.790.59

MBh 56.29 57.52 61.45 65.69 54.98 56.18 60.02 64.16 53.67 54.84 58.59 62.64 52.36 53.51 57.17 61.11 49.74 50.83 54.31 58.05 46.08 47.09 50.31 53.78

MOD E L: GSH130603A* / ARUF6 1- 00*-1* / ARUF48601A*

IDB*Airflow 59636771596367715963677159 63 67 715963677159636771

Delta T23221915232219162322191624 23 20 162322191521211814

2025 KW 4.10 4.19 4.33 4.47 4.43 4.53 4.68 4.83 4.72 4.82 4.98 5.16 4.97 5.08 5.26 5.44 5.19 5.31 5.49 5.68 5.38 5.50 5.69 5.89

HI P R 149 1 60 16 9 17 6 16 7 18 0 190 1 9 8 190 2 04 21 6 2 25 21 6 233 246 256 2 43 26 2 27 6 288 269 289 3 0 5 319

AMPS 13.3 13.6 14.0 14.5 14.3 14.7 15.2 15.7 15.6 15.9 16.5 17.1 16.6 17.0 17.6 18.3 17.7 18.1 18.7 19.4 18.8 19.2 19.9 20.6

S/T 0.860.810.660.490.890.840.680.510.910.860.700.520.94 0.89

MBh 54.7 55.8 59.7 63.8 53.4 54.5 58.3 62.3 52.1 53.2 56.9 60.8 50.8 51.9

L O PR 58 62 68 72 62 65 71 76 64 68 74 79 67 71 78 83 70 7 5 82 87 73 77 85 90

Delta T24232016242320162423201625 23

80 1800 KW 4.07 4.16 4.29 4.43 4.39 4.49 4.64 4.79 4.68 4.78 4.94 5.11 4.93 5.04

HI P R 147 1 59 16 7 17 5 16 5 17 8 188 1 9 6 188 2 02 21 4 2 23 21 4 230

AMPS 13.2 13.5 13.9 14.4 14.2 14.5 15.0 15.6 15.4 15.8 16.3 16.9 16.5 16.9

S/T 0.830.780.630.470.860.810.660.490.880.830.670.500.91 0.85 0.69 0.520.940.890.720.540.950.890.730.54

MBh 50.4 51.5 55.1 58.9 49.3 50.3 53.8 57.5 48.1 49.1 52.5 56.1 46.9 47.9 51.2 54.8 44.6 45.6 48.7 52.0 41.3 42.2 45.1 48.2

L O PR 58 61 67 71 61 65 71 75 63 67 74 78 67 71

Delta T24232016252421162524211625 24 21 172524201623221915

1575 KW 3.97 4.05 4.18 4.32 4.28 4.38 4.52 4.67 4.56 4.66 4.82 4.98 4.80 4.91 5.08 5.25 5.01 5.13 5.30 5.48 5.19 5.31 5.49 5.68

HI P R 143 1 54 16 2 16 9 16 0 17 3 182 1 9 0 182 1 96 20 7 2 16 20 8 223 236 246 2 34 25 1 26 6 277 258 278 2 9 3 306

AMPS 12.8 13.1 13.5 14.0 13.8 14.2 14.6 15.2 15.0 15.4 15.9 16.5 16.0 16.4 17.0 17.6 17.1 17.5 18.1 18.7 18.1 18.5 19.1 19.9

L O PR 56 60 65 69 59 63 69 73 61 65 71 76 65 69 75 80 68 7 2 79 84 70 74 81 87

S/T 0.950.910.820.670.980.950.850.691.000.970.880.711.00 1.00 0.90 0.731.001.000.940.761.001.000.950.77

MBh 57.27 58.38 61.15 65.23 55.94 57.02 59.72 63.72 54.61 55.67 58.30 62.20 53.28 54.31 56.88 60.68 50.61 51.59 54.04 57.65 46.88 47.79 50.05 53.40

Delta T25242320252423202525232024 25 23 202323232021222119

2025 KW 4.13 4.22 4.36 4.51 4.46 4.56 4.72 4.88 4.76 4.86 5.03 5.20 5.01 5.13 5.30 5.49 5.23 5.35 5.54 5.73 5.42 5.55 5.74 5.94

HI P R 150 1 62 17 1 17 8 16 9 18 1 192 2 0 0 192 2 06 21 8 2 27 21 8 235 248 259 2 46 26 4 27 9 291 271 292 3 0 9 322

AMPS 13.4 13.7 14.2 14.7 14.5 14.8 15.3 15.9 15.7 16.1 16.6 17.2 16.8 17.2 17.8 18.4 17.9 18.3 18.9 19.6 18.9 19.4 20.0 20.8

S/T 0.900.870.790.640.940.900.810.660.960.930.840.680.99 0.96 0.86 0.701.000.990.890.731.001.000.900.73

MBh 55.6 56.7 59.4 63.3 54.3 55.4 58.0 61.9 53.0 54.0 56.6 60.4 51.7 52.7 55.2 58.9 49.1 50.1 52.5 56.0 45.5 46.4 48.6 51.8

L O PR 59 63 68 73 62 66 72 77 65 69 75 80 68 72 79 84 71 7 6 83 88 74 78 85 91

Delta T26252421262624212626242126 26 24 212525242123242219

85 1800 KW 4.10 4.19 4.33 4.47 4.43 4.53 4.68 4.83 4.72 4.82 4.98 5.16 4.97 5.08 5.26 5.44 5.19 5.31 5.49 5.68 5.38 5.50 5.69 5.89

HI P R 149 1 60 16 9 17 6 16 7 18 0 190 1 9 8 190 2 04 21 6 2 25 21 6 233 246 256 2 43 26 2 27 6 288 269 289 3 0 5 319

AMPS 13.3 13.6 14.0 14.5 14.3 14.7 15.2 15.7 15.6 15.9 16.5 17.1 16.6 17.0 17.6 18.3 17.7 18.1 18.7 19.4 18.8 19.2 19.9 20.6

S/T 0.870.840.760.610.900.870.790.640.920.890.810.650.95 0.92 0.83 0.670.990.960.860.701.000.960.870.71

MBh 51.3 52.3 54.8 58.5 50.1 51.1 53.5 57.1 48.9 49.9 52.2 55.7 47.7 48.7 51.0 54.4 45.4 46.2 48.4 51.7 42.0 42.8 44.9 47.9

L O PR 58 62 68 72 62 65 71 76 64 68 74 79 67 71 78 83 70 7 5 82 87 73 77 85 90

Delta T26262421262625212626252127 26 25 212626242124242320

1575 KW 4.00 4.09 4.22 4.36 4.32 4.41 4.56 4.71 4.60 4.70 4.86 5.02 4.84 4.95 5.12 5.30 5.05 5.17 5.35 5.53 5.24 5.36 5.54 5.73

HI P R 144 1 55 16 4 17 1 16 2 17 4 184 1 9 2 184 1 98 20 9 2 18 21 0 226 238 249 2 36 25 4 26 8 280 261 281 2 9 6 309

AMPS 12.9 13.2 13.6 14.1 13.9 14.3 14.7 15.3 15.1 15.5 16.0 16.6 16.2 16.6 17.1 17.8 17.2 17.6 18.2 18.9 18.2 18.7 19.3 20.0

L O PR 56 60 66 70 60 64 69 74 62 66 72 77 65 69 76 81 68 7 3 79 84 71 75 82 87

Shaded area is AHRI Ra ting Condit i ons ID B: Entering Indoor D ry Bul b Te m perature KW=Total s ystem power AMP S=outdoor un it amps ( comp.+fan)

High and low pressures are measur ed at the li quid and suction service va l ves.

Page 15

COOLING PERFORMANCE DAT A

COOLING OPERATION

GSH130484AC

EXPANDED PERF ORMANCE DATA

17 11 22 20 16 11 20 19 15 11

55.7 59.7 47.5 48.9 52.9 56.8 44.0 45.3 49.0 52.6

0.58 0.37 0.89 0.80 0.60 0.39 0.90 0.81 0.61 0.39

20

51.4

0.77

Outdoor Ambi ent Temper ature

Entering Indoo r Wet Bulb Temperature

76 81 69 73 80 85 71 76 83 88

241 251 238 257 271 283 263 284 299 312

5.17 5.35 5.10 5.22 5.39 5.58 5.28 5.40 5.59 5.78

17.3 17.9 17.4 17.8 18.4 19.1 18.4 18.9 19.5 20.2

70

228

5.00

16.7

MOD E L: GSH130484A* / AR*f486016B

65 75 85 95 105 115

S/T 0.72 0.60 0.42 - 0.75 0.63 0.43 - 0.77 0.64 0.45 - 0.79 0.66 0.46 - 0.82 0.69 0.48 - 0.83 0.69 0.48 -

MBh 54.4 56.4 61.8 - 53.1 55.1 60.3 - 51.9 53.7 58.9 - 50.6 52.4 57.5 - 48.1 49.8 54.6 - 44.5 46.1 50.6 -

IDB Airflow 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71

HI PR 146 157 166 - 164 176 186 - 186 200 211 - 212 228 241 - 238 257 271 - 263 283 299 -

AMPS 13.0 13.3 13.8 - 14.1 14.4 14.9 - 15.3 15.7 16.2 - 16.3 16.7 17.3 - 17.4 17.8 18.4 - 18.4 18.9 19.5 -

Delta T 18 15 12 - 18 16 12 - 18 16 12 - 18 16 12 - 18 16 12 - 17 15 11 -

2025 KW 4.03 4.12 4.25 - 4.35 4.45 4.60 - 4.64 4.74 4.90 - 4.89 5.00 5.17 - 5.10 5.22 5.39 - 5.28 5.40 5.59 -

S/T 0.69 0.58 0.40 - 0.72 0.60 0.41 - 0.73 0.61 0.42 - 0.76 0.63 0.44 - 0.79 0.66 0.45 - 0.79 0.66 0.46 -

MBh 52.8 54.7 60.0 - 51.6 53.5 58.6 - 50.3 52.2 57.2 - 49.1 50.9 55.8 - 46.7 48.4 53.0 - 43.2 44.8 49.1 -

L O PR 57 61 66 - 60 64 70 - 63 67 73 - 66 70 76 - 69 73 80 - 71 76 83 -

HI PR 144 155 164 - 162 174 184 - 184 198 209 - 210 226 238 - 236 254 268 - 261 281 296 -

AMPS 12.9 13.2 13.7 - 14.0 14.3 14.8 - 15.1 15.5 16.0 - 16.2 16.6 17.1 - 17.2 17.6 18.2 - 18.2 18.7 19.3 -

Delta T 19 16 12 - 19 16 12 - 19 16 12 - 19 16 12 - 19 16 12 - 17 15 11 -

70 1800 KW 4.00 4.09 4.22 - 4.32 4.41 4.56 - 4.60 4.70 4.86 - 4.84 4.96 5.12 - 5.06 5.17 5.35 - 5.24 5.36 5.54 -

S/T 0.67 0.56 0.39 - 0.69 0.58 0.40 - 0.71 0.59 0.41 - 0.73 0.61 0.42 - 0.76 0.63 0.44 - 0.76 0.64 0.44 -

MBh 48.7 50.5 55.3 - 47.6 49.3 54.1 - 46.5 48.2 52.8 - 45.3 47.0 51.5 - 43.1 44.6 48.9 - 39.9 41.4 45.3 -

L O PR 57 60 66 - 60 64 69 - 62 66 72 - 65 69 76 - 68 73 79 - 71 75 82 -

HI PR 140 151 159 - 157 169 179 - 179 192 203 - 204 219 231 - 229 246 260 - 253 272 287 -

AMPS 12.6 12.9 13.3 - 13.6 13.9 14.4 - 14.7 15.1 15.6 - 15.7 16.1 16.7 - 16.7 17.1 17.7 - 17.7 18.2 18.8 -

Delta T 19 16 12 - 19 17 13 - 19 17 13 - 19 17 13 - 19 16 13 - 18 15 12 -

1575 KW 3.90 3.99 4.12 - 4.21 4.30 4.44 - 4.48 4.58 4.73 - 4.72 4.83 4.99 - 4.93 5.04 5.21 - 5.10 5.22 5.40 -

L O PR 55 58 64 - 58 62 67 - 60 64 70 - 63 67 73 - 66 70 77 - 69 73 80 -

S/T 0.820.740.560.360.850.760.580.370.870.780.590.380.90 0.81 0.61 0.390.940.840.630.410.940.840.640.41

MBh 55.31 56.94 61.64 66.15 54.02 55.62 60.20 64.61 52.73 54.30 58.77 63.08 51.45 52.97 57.34 61.54 48.88 50.32 54.47 58.46 45.27 46. 61 50.46 54.15

Delta T21191611211916112119161121 19 16 112119161119181510

2025 KW 4.07 4.16 4.29 4.43 4.39 4.49 4.64 4.79 4.68 4.78 4.94 5.11 4.93 5.04 5.21 5.39 5.14 5.26 5.44 5.63 5.33 5.45 5.64 5.83

HI P R 147 1 59 16 7 17 5 16 5 17 8 188 1 9 6 188 2 02 214 223 2 1 4 2 30 243 254 241 2 5 9 274 2 85 26 6 2 86 302 31 5

AMPS 13.2 13.5 13.9 14.4 14.2 14.5 15.0 15.6 15.4 15.8 16.3 16.9 16.5 16.9 17.4 18.1 17.5 18.0 18.6 19.3 18.6 19.0 19.7 20.4

S/T 0.780.700.530.340.810.730.550.350.830.750.560.360.86

MBh 53.7 55.3 59.8 64.2 52.4 54.0 58.4 62.7 51.2 52.7 57.1 61.2 50.0

L O PR 58 61 67 71 61 65 71 75 63 67 74 78 67 71 77 82 70 7 4 81 86 72 77 84 89

Delta T22201611222016112220161122

75 1800 KW 4.03 4.12 4.26 4.40 4.35 4.45 4.60 4.75 4.64 4.74 4.90 5.07 4.89

HI P R 146 1 57 16 6 17 3 16 4 17 6 186 1 9 4 186 2 00 211 221 2 1 2

AMPS 13.0 13.3 13.8 14.3 14.1 14.4 14.9 15.4 15.3 15.7 16.2 16.8 16.3

S/T 0.760.680.510.330.780.700.530.340.800.720.540.350.83 0.74 0.56 0.360.860.770.580.380.870.780.590.38

MBh 49.6 51.0 55.2 59.3 48.4 49.8 53.9 57.9 47.3 48.7 52.7 56.5 46.1 47.47 51.4 55.1 43.8 45.1 48.8 52.4 40.6 41.8 45.2 48.5

L O PR 57 61 66 71 60 64 70 75 63 67 73 78 66

Delta T22201711222017122220171222 21 17 122220171121191611

1575 KW 3.93 4.02 4.15 4.29 4.24 4.34 4.48 4.63 4.52 4.62 4.78 4.94 4.76 4.87 5.03 5.21 4.97 5.08 5.25 5.44 5.15 5.26 5.44 5.63

HI P R 141 1 52 16 1 16 8 15 9 17 1 180 1 8 8 181 1 94 205 214 2 0 6 2 21 234 244 231 2 4 9 263 2 74 25 6 2 75 290 30 3

AMPS 12.7 13.0 13.4 13.9 13.7 14.0 14.5 15.0 14.9 15.2 15.7 16.3 15.9 16.3 16.8 17.4 16.9 17.3 17.9 18.6 17.9 18.3 18.9 19.7

L O PR 55 59 64 68 59 62 68 72 61 65 71 75 64 68 74 79 67 7 1 78 83 69 74 80 86

Shaded area is ACCA (TVA) conditi ons IDB: Entering Indoor Dry Bulb Tem perat ur e KW=Tot al system power AMPS =outdoor unit amps (comp.+fan)

High and low pressures are measur ed at the li quid and suction servi ce valv es.

15

Page 16

COOLING PERFORMANCE DAT A

C OOLING OPERATION

GSH130484AC

EXP ANDED PERFORMANCE DATA

16 24 23 20 16 23 22 19 15

59.3 48.3 49.4 52.7 56.4 44.7 45.7 48.8 52.2

0.54 0.98 0.92 0.75 0.56 0.99 0.93 0.75 0.56

5.39 5.14 5.26 5.44 5.63 5.33 5.45 5.64 5.84

20

55.5

0.72

Outdoor Ambient Temperature

Entering Indoor Wet Bulb Temperature

82 70 74 81 86 72 77 84 89

254 241 259 274 285 266 286 302 315

18.1 17.5 18.0 18.6 19.3 18.6 19.0 19.7 20.4

77

243

5.21

17.4

16

MODEL: GSH1 30484A* / AR* f486016B

65 75 85 95 105 115

MBh 56.29 57.52 61.45 65.69 54.98 56.18 60.02 64.16 53.67 54.84 58.59 62.64 52.36 53.51 57.17 61.11 49.74 50.83 54.31 58.05 46.08 47.09 50.31 53.78

IDB*Airflow 59636771596367715963677159 63 67 715963677159636771

S/T 0.900.850.690.510.940.880.710.530.960.900.730.551.00 0.93 0.76 0.561.000.960.780.591.001.000.790.59

Delta T23221915232219162322191624 23 20 162322191521211814

2025 KW 4.10 4.19 4.33 4 .47 4.43 4.53 4.68 4.83 4.72 4.82 4.98 5.16 4.97 5.08 5.26 5.44 5.19 5.31 5.49 5.68 5.38 5.50 5.69 5.89

HI PR 149 160 169 176 167 180 190 198 190 204 216 225 216 233 246 256 243 262 276 288 269 289 305 319

AMPS 13. 3 13.6 14.0 14.5 14.3 14.7 15.2 15.7 15.6 15.9 16.5 17.1 16.6 17.0 17.6 18.3 17.7 18.1 18.7 19.4 18.8 19.2 19.9 20.6

L O PR 58 62 68 72 62 65 71 76 64 68 74 79 67 71 78 83 70 75 82 87 73 77 85 90

Delta T24232016242320162423201625 23

80 1800 KW 4.07 4.16 4.29 4.43 4.39 4.49 4.64 4.79 4.68 4.78 4.94 5.11 4.93 5.04

HI PR 147 159 167 175 165 178 188 196 188 202 214 223 214 230

AMPS 13. 2 13.5 13.9 14.4 14.2 14.5 15.0 15.6 15.4 15.8 16.3 16.9 16.5 16.9

S/T 0.860.810.660.490.890.840.680.510.910.860.700.520.94 0.89

MBh54.755.859.763.853.454.558.362.352.153.256.960.850.8 51.9

S/T 0.830.780.630.470.860.810.660.490.880.830.670.500.91 0.85 0.69 0.520.940.890.720.540.950.890.730.54

MBh 50.4 51.5 55.1 5 8.9 49.3 50.3 53.8 57.5 48.1 49.1 52.5 56.1 46.9 47.9 51.2 54.8 44.6 45.6 4 8.7 52.0 41.3 42.2 45.1 48.2

L O PR 58 61 67 71 61 65 71 75 63 67 74 78 67 71

Delta T24232016252421162524211625 24 21 172524201623221915

1575 KW 3.97 4.05 4.18 4 .32 4.28 4.38 4.52 4.67 4.56 4.66 4.82 4.98 4.80 4.91 5.08 5.25 5.01 5.13 5.30 5.48 5.19 5.31 5.49 5.68

HI PR 143 154 162 169 160 173 182 190 182 196 207 216 208 223 236 246 234 251 266 277 258 278 293 306

AMPS 12. 8 13.1 13.5 14.0 13.8 14.2 14.6 15.2 15.0 15.4 15.9 16.5 16.0 16.4 17.0 17.6 17.1 17.5 18.1 18.7 18.1 18.5 19.1 19.9

L O PR 56 60 65 69 59 63 69 73 61 65 71 76 65 69 75 80 68 72 79 84 70 74 81 87

S/T 0.950.910.820.670.980.950.850.691.000.970.880.711.00 1.00 0.90 0.731.001.000.940.761.001.000.950.77

MBh 57.27 58.38 61.15 65.23 55.94 57.02 59.72 63.72 54.61 55.67 58.30 62.20 53.28 54.31 56.88 60.68 50.61 51.59 54.04 57.65 46.88 47.79 50.05 53.40

Delta T25242320252423202525232024 25 23 202323232021222119

2025 KW 4.13 4.22 4.36 4 .51 4.46 4.56 4.72 4.88 4.76 4.86 5.03 5.20 5.01 5.13 5.30 5.49 5.23 5.35 5.54 5.73 5.42 5.55 5.74 5.94

HI PR 150 162 171 178 169 181 192 200 192 206 218 227 218 235 248 259 246 264 279 291 271 292 309 322

AMPS 13. 4 13.7 14.2 14.7 14.5 14.8 15.3 15.9 15.7 16.1 16.6 17.2 16.8 17.2 17.8 18.4 17.9 18.3 18.9 19.6 18.9 19.4 20.0 20.8

S/T 0.900.870.790.640.940.900.810.660.960.930.840.680.99 0.96 0.86 0.701.000.990.890.731.001.000.900.73

MBh 55.6 56.7 59.4 6 3.3 54.3 55.4 58.0 61.9 53.0 54.0 56.6 60.4 51.7 52.7 55.2 58.9 49.1 50.1 5 2.5 56.0 45.5 46.4 48.6 51.8

L O PR 59 63 68 73 62 66 72 77 65 69 75 80 68 72 79 84 71 76 83 88 74 78 85 91

Delta T26252421262624212626242126 26 24 212525242123242219

85 1800 KW 4.10 4.19 4.33 4.47 4.43 4.53 4.68 4.83 4.72 4.82 4.98 5.16 4.97 5.08 5.26 5.44 5.19 5.31 5.49 5.68 5.38 5.50 5.69 5.89

HI PR 149 160 169 176 167 180 190 198 190 204 216 225 216 233 246 256 243 262 276 288 269 289 305 319

AMPS 13. 3 13.6 14.0 14.5 14.3 14.7 15.2 15.7 15.6 15.9 16.5 17.1 16.6 17.0 17.6 18.3 17.7 18.1 18.7 19.4 18.8 19.2 19.9 20.6

S/T 0.870.840.760.610.900.870.790.640.920.890.810.650.95 0.92 0.83 0.670.990.960.860.701.000.960.870.71

MBh 51.3 52.3 54.8 5 8.5 50.1 51.1 53.5 57.1 48.9 49.9 52.2 55.7 47.7 48.7 51.0 54.4 45.4 46.2 4 8.4 51.7 42.0 42.8 44.9 47.9

L O PR 58 62 68 72 62 65 71 76 64 68 74 79 67 71 78 83 70 75 82 87 73 77 85 90

Delta T26262421262625212626252127 26 25 212626242124242320

1575 KW 4.00 4.09 4.22 4 .36 4.32 4.41 4.56 4.71 4.60 4.70 4.86 5.02 4.84 4.95 5.12 5.30 5.05 5.17 5.35 5.53 5.24 5.36 5.54 5.73

HI PR 144 155 164 171 162 174 184 192 184 198 209 218 210 226 238 249 236 254 268 280 261 281 296 309

AMPS 12. 9 13.2 13.6 14.1 13.9 14.3 14.7 15.3 15.1 15.5 16.0 16.6 16.2 16.6 17.1 17.8 17.2 17.6 18.2 18.9 18.2 18.7 19.3 20.0

L O PR 56 60 66 70 60 64 69 74 62 66 72 77 65 69 76 81 68 73 79 84 71 75 82 87

Shaded area is AHRI Ra ting Condition s IDB: Entering Indoor Dry Bulb Temperature KW=Total system power AMPS=outdoor unit amps (comp.+fan)

High and low pressures are measured at t he liquid and suction service valves.

Page 17

COOLING PERFORMANCE DAT A

GSH130484AD

17 12 22 21 17 12 21 19 16 11

49.7 53.4 42.4 43.6 47.2 50.7 39.3 40.4 43.7 47.0

0.60 0.39 0.92 0.83 0.63 0.40 0.93 0.83 0.63 0.41

21

45.9

0.80

Outdoor Am bient Temperature

Entering Indo or W et Bulb Tem per atur e

3.62 3.76 3.57 3.66 3.80 3.95 3.71 3.81 3.95 4.11

3.49

82 87 74 79 86 91 77 81 89 95

9.7 10.1 9.8 10.0 10.3 10.6 10.3 10.5 10.9 11.2

199 208 197 212 224 234 218 235 248 258

75

9.4

189

EXPANDED PERFORMA NCE DA TA COOLING OPERATION

65 75 85 95 105 115

S/T 0.69 0.57 0.40 - 0.71 0.60 0.41 - 0.73 0.61 0.42 - 0.75 0.63 0.44 - 0.78 0.65 0.45 - 0.79 0.66 0.46 -

MBh 43.5 45.1 49.4 - 42.5 44.1 48.3 - 41.5 43.0 47.1 - 40.5 42.0 46.0 - 38.5 39.9 43.7 - 35.6 36.9 40.5 -

MODEL: GSH130484A* / AR*F486016B*

IDB Airflow 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71

AMPS 7.3 7.4 7.7 - 7.8 8.0 8.2 - 8.4 8.6 8.8 - 8.9 9.1 9.4 - 9.4 9.6 9.9 - 9.9 10.2 10.5 -

Delta T 20 17 13 - 20 17 13 - 20 17 13 - 20 17 13 - 20 17 13 - 18 16 12 -

1400 KW 2.63 2.70 2.80 - 2.87 2.95 3.06 - 3.09 3.16 3.28 - 3.27 3.36 3.48 - 3.43 3.52 3.65 - 3.57 3.66 3.80 -

S/T 0.71 0.60 0.41 - 0.74 0.62 0.43 - 0.76 0.63 0.44 - 0.78 0.65 0.45 - 0.81 0.68 0.47 - 0.82 0.68 0.47 -

MBh 47.2 48.9 53.5 - 46.1 47.7 52.3 - 45.0 46.6 51.1 - 43.9 45.5 49.8 - 41.7 43.2 47.3 - 38.6 40.0 43.8 -

HI PR 116 125 132 - 130 140 148 - 148 159 168 - 168 181 191 - 190 204 215 - 209 225 238 -

LO PR 59 63 68 - 62 66 72 - 65 69 75 - 68 72 79 - 71 76 82 - 73 78 85 -

AMPS 7.5 7.6 7.8 - 8.0 8.2 8.4 - 8.6 8.8 9.1 - 9.1 9.4 9.6 - 9.7 9.9 10.2 - 10.2 10.4 10.8 -

Delta T 19 17 13 - 20 17 13 - 20 17 13 - 20 17 13 - 19 17 13 - 18 16 12 -

70 1600 KW 2.71 2.78 2.88 - 2.96 3.03 3.15 - 3.18 3.26 3.38 - 3.37 3.46 3.59 - 3.54 3.63 3.76 - 3.68 3.77 3.92 -

S/T 0.75 0.62 0.43 - 0.78 0.65 0.45 - 0.80 0.66 0.46 - 0.82 0.69 0.47 - 0.85 0.71 0.49 - 0.86 0.72 0.50 -

MBh 48.6 50.3 55.2 - 47.4 49.2 53.9 - 46.3 48.0 52.6 - 45.2 46.8 51.3 - 42.9 44.5 48.7 - 39.8 41.2 45.1 -

HI PR 119 129 136 - 134 144 152 - 152 164 173 - 174 187 197 - 195 210 222 - 216 232 245 -

LO PR 61 64 70 - 64 68 74 - 67 71 77 - 70 74 81 - 73 78 85 - 76 81 88 -

HI PR 121 130 137 - 135 146 154 - 154 166 175 - 175 189 199 - 197 212 224 - 218 235 248 -

AMPS 7.5 7.7 7.9 - 8.1 8.2 8.5 - 8.7 8.9 9.1 - 9.2 9.4 9.7 - 9.8 10.0 10.3 - 10.3 10.5 10.9 -

Delta T 19 16 12 - 19 16 12 - 19 16 12 - 19 16 12 - 19 16 12 - 17 15 11 -

LO PR 61 65 71 - 65 69 75 - 67 71 78 - 71 75 82 - 74 79 86 - 76 81 89 -

1800 KW 2.73 2.80 2.91 - 2.99 3.06 3.18 - 3.21 3.29 3.41 - 3.40 3.49 3.62 - 3.57 3.66 3.80 - 3.71 3.81 3.95 -

S/T 0.78 0.70 0.53 0.34 0.81 0.73 0.55 0.35 0.83 0.74 0.56 0.36 0.86 0.77 0.58 0.37 0.89 0.80 0.60 0.39 0.90 0.80 0.61 0.39

MBh 44.3 45.6 49.3 52.9 43.2 44.5 48.2 51.7 42.2 43.4 47.0 50.5 41.2 42.4 45.9 49.2 39.1 40.3 43.6 46.8 36.2 37.3 40.4 43.3

Delta T23211712232117122321171223 21 18 122321171221201611

1400 KW 2.66 2.72 2.83 2.93 2.90 2.97 3.09 3.20 3.12 3.19 3.32 3.44 3.31 3.39 3.52 3.65 3.47 3.56 3.69 3.83 3.61 3.70 3.84 3.99

AMPS 7.4 7.5 7.7 8.0 7.9 8.0 8.3 8.6 8.5 8.7 8.9 9.2 9.0 9.2 9.5 9.8 9.5 9.7 10.0 10.4 10.0 10.3 10.6 10.9

HI PR 117 126 133 139 131 141 149 156 149 161 170 177 170 183 193 202 191 206 218 227 212 228 240 251

LO PR 59 63 69 73 63 67 73 78 65 69 76 81 68 73 80 85 72 76 83 89 74 79 86 92

S/T 0.81 0.73 0.55 0.35 0.84 0.75 0.57 0.37 0.86 0.77 0.58 0.38 0.89

MBh 48.0 49.4 53.4 57.4 46.8 48.2 52.2 56.0 45.7 47.1 51.0 54.7 44.6

Delta T22211712232117122321171223

75 1600 KW 2.73 2.80 2.91 3.02 2.99 3.06 3.18 3.30 3.21 3.29 3.41 3.54 3.40

HI PR 121 130 137 143 135 146 154 161 154 166 175 183 175

AMPS 7.5 7.7 7.9 8.2 8.1 8.2 8.5 8.8 8.7 8.9 9.1 9.5 9.2

LO PR 61 65 71 76 65 69 75 80 67 71 78 83 71

S/T 0.85 0.76 0.58 0.37 0.88 0.79 0.60 0.38 0.90 0.81 0.61 0.39 0.93 0.83 0.63 0.41 0.97 0.87 0.66 0.42 0.98 0.87 0.66 0.43

MBh 49.4 50.9 55.0 59.1 48.2 49.7 53.8 57.7 47.1 48.5 52.5 56.3 45.9 47.30 51.2 55.0 43.6 44.9 48.6 52.2 40.4 41.6 45.1 48.4

Delta T21201611222016112220161122 20 17 112220161120191511

1800 KW 2.76 2.83 2.94 3.05 3.01 3.09 3.21 3.33 3.24 3.32 3.45 3.58 3.44 3.52 3.66 3.80 3.60 3.70 3.84 3.98 3.75 3.85 3.99 4.15

HI PR 122 131 139 145 137 147 155 162 156 167 177 184 177 191 201 210 199 215 227 236 220 237 250 261

AMPS 7.6 7.8 8.0 8.2 8.1 8.3 8.6 8.8 8.8 9.0 9.2 9.5 9.3 9.5 9.8 10.1 9.8 10.1 10.4 10.7 10.4 10.6 10.9 11.3

LO PR 62 66 72 76 65 69 76 81 68 72 79 84 71 76 83 88 75 79 87 92 77 82 90 96

Shaded area is ACCA (TVA) con ditions IDB: En t ering Indoor Dry Bulb T em perat u re KW=Tot al sy s tem power AMPS=outdoor u n it amps ( com p.+fan)

High an d low pressures ar e m easu red at t h e liquid an d su ct ion serv ice v alv es.

17

Page 18

COOLING PERFORMANCE DAT A

COOLING OPERATION

GSH130484AD

EXPANDED PERFORMANCE DATA

17 25 24 21 17 23 22 20 16

0.56 1.00 0.95 0.77 0.58 1.00 0.96 0.78 0.58

0.75

21

3.80 3.60 3.70 3.84 3.99 3.75 3.85 3.99 4.15

3.66

53.0 43.1 44.1 47.1 50.3 40.0 40.8 43.6 46.6

49.6

Outdoor Ambient Tem perature

Entering Indo or W et Bul b Tem perat ure

88 75 79 87 92 77 82 90 96

210 199 215 227 236 220 237 250 261

10.1 9.8 10.1 10.4 10.7 10.4 10.6 10.9 11.3

83

9.8

201

18

65 75 85 95 105 115

S/T 0.86 0.80 0.65 0.49 0.89 0.83 0.68 0.51 0.91 0.86 0.70 0.52 0.94 0.88 0.72 0.54 0.98 0.92 0.75 0.56 0.98 0.92 0.75 0.56

MBh 45.0 46.0 49.2 52.6 44.0 45.0 48.0 51.3 43.0 43.9 46.9 50.1 41.9 42.8 45.7 48.9 39.8 40.7 43.5 46.5 36.9 37.7 40.3 43.0

MODEL: GSH130484A* / AR*F486016B*

IDB*Airflow 59636771596367715963677159 63 67 715963677159636771

Delta T25242117262521172625211726 25 22 172624211724232016

1400 KW 2.68 2.75 2.85 2.96 2.93 3.00 3.12 3.23 3.15 3.23 3.35 3.48 3.34 3.42 3.55 3.69 3.50 3.59 3.73 3.87 3.64 3.73 3.88 4.03

AMPS 7.4 7.6 7.8 8.0 7.9 8.1 8.3 8.6 8.5 8.7 9.0 9.3 9.1 9.3 9.6 9.9 9.6 9.8 10.1 10.5 10.1 10.3 10.7 11.0

HI PR 118 127 134 140 133 143 151 157 151 162 172 179 172 185 195 204 193 208 220 229 214 230 243 253

LO PR 60 64 70 74 63 67 74 78 66 70 76 81 69 74 80 86 72 77 84 90 75 80 87 93

S/T 0.89 0.83 0.68 0.51 0.92 0.86 0.70 0.53 0.95 0.89 0.72 0.54 0.98 0.92

MBh 48.8 49.9 53.3 57.0 47.7 48.7 52.0 55.6 46.5 47.5 50.8 54.3 45.4 46.4

Delta T25242117252421172524211725 24

80 1600 KW 2.76 2.83 2.94 3.05 3.01 3.09 3.21 3.33 3.24 3.32 3.45 3.58 3.44 3.52

HI PR 122 131 139 145 137 147 155 162 156 167 177 184 177 191

AMPS 7.6 7.8 8.0 8.2 8.1 8.3 8.6 8.8 8.8 9.0 9.2 9.5 9.3 9.5

LO PR 62 66 72 76 65 69 76 81 68 72 79 84 71 76

S/T 0.93 0.87 0.71 0.53 0.97 0.91 0.74 0.55 1.00 0.93 0.76 0.57 1.00 0.96 0.78 0.58 1.00 1.00 0.81 0.61 1.00 1.00 0.82 0.61

MBh 50.3 51.4 54.9 58.7 49.1 50.2 53.6 57.3 47.9 49.0 52.3 55.9 46.8 47.8 51.0 54.6 44.4 45.4 48.5 51.8 41.1 42.0 44.9 48.0

Delta T24232016242320162423201624 23 20 162323201621211915

1800 KW 2.79 2.86 2.96 3.08 3.04 3.12 3.24 3.36 3.27 3.35 3.48 3.61 3.47 3.56 3.69 3.84 3.64 3.73 3.87 4.02 3.79 3.88 4.03 4.19

HI PR 123 133 140 146 138 149 157 164 157 169 179 186 179 193 203 212 201 217 229 239 223 239 253 264

AMPS 7.7 7.8 8.0 8.3 8.2 8.4 8.6 8.9 8.8 9.0 9.3 9.6 9.4 9.6 9.9 10.2 9.9 10.2 10.5 10.8 10.5 10.7 11.0 11.4

LO PR 62 66 73 77 66 70 77 82 69 73 80 85 72 77 84 89 75 80 88 93 78 83 91 97

DT 27 27 25 22 27 27 25 22 27 27 26 22 28 27 26 22 27 27 25 22 25 25 24 20

S/T 0.90 0.87 0.78 0.64 0.93 0.90 0.81 0.66 0.96 0.92 0.83 0.68 0.99 0.95 0.86 0.70 1.00 0.99 0.89 0.72 1.00 1.00 0.90 0.73

MBh 45.8 46.7 48.9 52.2 44.8 45.6 47.8 51.0 43.7 44.5 46.7 49.8 42.6 43.5 45.5 48.6 40.5 41.3 43.2 46.1 37.5 38.2 40.1 42.7

1400 KW 2.71 2.78 2.88 2.99 2.96 3.03 3.15 3.27 3.18 3.26 3.38 3.51 3.37 3.46 3.59 3.72 3.53 3.62 3.76 3.91 3.68 3.77 3.91 4.06

HI PR 119 129 136 142 134 144 152 159 152 164 173 181 174 187 197 206 195 210 222 232 216 232 245 256

AMPS 7.5 7.6 7.8 8.1 8.0 8.2 8.4 8.7 8.6 8.8 9.1 9.4 9.1 9.3 9.6 10.0 9.7 9.9 10.2 10.6 10.2 10.4 10.8 11.1

LO PR 61 64 70 75 64 68 74 79 66 71 77 82 70 74 81 86 73 78 85 91 76 81 88 94

DT 27 26 25 21 27 26 25 22 27 27 25 22 27 27 25 22 25 26 25 22 23 24 23 20

S/T 0.93 0.90 0.81 0.66 0.97 0.93 0.84 0.68 0.99 0.96 0.86 0.70 1.00 0.99 0.89 0.72 1.00 1.00 0.92 0.75 1.00 1.00 0.93 0.76

MBh 49.7 50.6 53.0 56.6 48.5 49.4 51.8 55.2 47.3 48.3 50.5 53.9 46.2 47.1 49.3 52.6 43.9 44.7 46.8 50.0 40.6 41.4 43.4 46.3

85 1600 KW 2.79 2.86 2.96 3.08 3.04 3.12 3.24 3.36 3.27 3.35 3.48 3.61 3.47 3.56 3.69 3.84 3.64 3.73 3.87 4.02 3.79 3.88 4.03 4.19

HI PR 123 133 140 146 138 149 157 164 157 169 179 186 179 193 203 212 201 217 229 239 223 239 253 264

AMPS 7.7 7.8 8.0 8.3 8.2 8.4 8.6 8.9 8.8 9.0 9.3 9.6 9.4 9.6 9.9 10.2 9.9 10.2 10.5 10.8 10.5 10.7 11.0 11.4

LO PR 62 66 73 77 66 70 77 82 69 73 80 85 72 77 84 89 75 80 88 93 78 83 91 97

DT 26 25 24 21 26 25 24 21 25 25 24 21 24 25 24 21 23 24 24 21 21 22 22 19

S/T 0.98 0.94 0.85 0.69 1.00 0.98 0.88 0.72 1.00 1.00 0.91 0.73 1.00 1.00 0.93 0.76 1.00 1.00 0.97 0.79 1.00 1.00 0.98 0.79

MBh 51.1 52.1 54.6 58.3 50.0 50.9 53.3 56.9 48.8 49.7 52.1 55.5 47.6 48.5 50.8 54.2 45.2 46.1 48.3 51.5 41.9 42.7 44.7 47.7

1800 KW 2.81 2.88 2.99 3.11 3.07 3.15 3.27 3.39 3.30 3.39 3.51 3.65 3.50 3.59 3.73 3.87 3.67 3.77 3.91 4.06 3.82 3.92 4.07 4.23

HI PR 124 134 141 147 140 150 159 165 159 171 180 188 181 195 205 214 203 219 231 241 225 242 255 266

AMPS 7.7 7.9 8.1 8.4 8.3 8.4 8.7 9.0 8.9 9.1 9.4 9.7 9.5 9.7 10.0 10.3 10.0 10.2 10.6 10.9 10.6 10.8 11.1 11.5

LO PR 63 67 73 78 67 71 77 82 69 74 80 86 73 77 84 90 76 81 89 94 79 84 92 98

Shaded area is AHR I Rating Con ditions I DB: En terin g I n door Dry Bu lb T em per atu re KW=Tot al sy s tem power AMPS=outdoor unit amps (comp.+fan )

High an d low pressures are m easu r ed at th e liqu id and su ct ion serv ice v alv es.

Page 19

COOLING PERFORMANCE DAT A

*

COOLING OPERATION

GSH130604AC

EXPANDED PERF ORMANCE DATA

16 11 21 19 16 11 20 18 15 10

55.7 59.7 47.5 48.9 52.9 56.8 44.0 45.3 49.0 52.6

0.60 0.38 0.91 0.82 0.62 0.40 0.92 0.82 0.62 0.40

20

51.4

0.79

Outdoor Ambi ent Temper ature

Entering Indoo r Wet Bulb Temperature

81 86 73 77 85 90 75 80 87 93

247 257 244 263 277 289 270 290 306 320

4.90 5.06 4.84 4.94 5.10 5.26 5.00 5.11 5.27 5.44

10.4 10.8 10.5 10.7 11.0 11.3 11.0 11.2 11.6 11.9

74

233

4.75

10.1

65 75 85 95 105 115

S/T 0.70 0.58 0.40 - 0.72 0.60 0.42 - 0.74 0.62 0.43 - 0.77 0.64 0.44 - 0.79 0.66 0.46 - 0.80 0.67 0.46 -

MBh 52.3 54.2 59.4 - 51.1 52.9 58.0 - 49.8 51.7 56.6 - 48.6 50.4 55.2 - 46.2 47.9 52.5 - 42.8 44.4 48.6 -

MOD E L: GSH130604A* / AR*F4 86016B

IDB Airflow 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71 59 63 67 71

HI PR 146 157 166 - 164 176 186 - 186 200 211 - 212 228 241 - 238 257 271 - 263 284 299 -

AMPS 8.1 8.2 8.5 - 8.6 8.8 9.0 - 9.2 9.4 9.7 - 9.8 10.0 10.2 - 10.3 10.5 10.8 - 10. 8 11.0 11.3 -

Delta T 19 16 12 - 19 16 12 - 19 16 12 - 19 16 12 - 19 16 12 - 18 15 12 -

1800 KW 3.84 3.92 4.03 - 4.12 4.20 4.33 - 4.36 4.45 4.58 - 4.57 4.67 4.81 - 4.75 4.85 5.01 - 4.91 5.01 5.17 -

S/T 0.71 0.59 0.41 - 0.73 0.61 0.42 - 0.75 0.63 0.43 - 0.77 0.65 0.45 - 0.80 0.67 0.46 - 0.81 0.68 0.47 -

MBh 52.8 54.7 60.0 - 51.6 53.5 58.6 - 50.3 52.2 57.2 - 49.1 50.9 55.8 - 46.7 48.4 53.0 - 43.2 44.8 49.1 -

L O PR 59 63 68 - 62 66 72 - 65 69 75 - 68 72 79 - 71 76 83 - 74 78 85 -

HI PR 148 159 168 - 166 178 188 - 189 203 214 - 215 231 244 - 242 260 275 - 267 287 303 -

AMPS 8.2 8.3 8.5 - 8.7 8.9 9.1 - 9.3 9.5 9.8 - 9.8 10.1 10.3 - 10.4 10.6 10.9 - 10. 9 11.1 11.5 -

Delta T 18 16 12 - 18 16 12 - 18 16 12 - 19 16 12 - 18 16 12 - 17 15 11 -

70 1883 KW 3.88 3.96 4.07 - 4.16 4.24 4.37 - 4.40 4.49 4.63 - 4.62 4.72 4.86 - 4.80 4.90 5.06 - 4.96 5.07 5.23 -

S/T 0.71 0.59 0.41 - 0.73 0.61 0.42 - 0.75 0.63 0.43 - 0.77 0.65 0.45 - 0.80 0.67 0.46 - 0.81 0.68 0.47 -

MBh 52.8 54.7 60.0 - 51.6 53.5 58.6 - 50.3 52.2 57.2 - 49.1 50.9 55.8 - 46.7 48.4 53.0 - 43.2 44.8 49.1 -

L O PR 60 63 69 - 63 67 73 - 65 70 76 - 69 73 80 - 72 77 84 - 75 79 87 -

HI PR 148 159 168 - 166 178 188 - 189 203 214 - 215 231 244 - 242 260 275 - 267 287 303 -

AMPS 8.2 8.3 8.5 - 8.7 8.9 9.1 - 9.3 9.5 9.8 - 9.8 10.1 10.3 - 10.4 10.6 10.9 - 10. 9 11.1 11.5 -

Delta T 18 16 12 - 18 16 12 - 18 16 12 - 18 16 12 - 18 16 12 - 17 15 11 -

1900 KW 3.88 3.96 4.07 - 4.16 4.24 4.37 - 4.40 4.49 4.63 - 4.62 4.72 4.86 - 4.80 4.90 5.06 - 4.96 5.07 5.23 -

L O PR 60 63 69 - 63 67 73 - 65 70 76 - 69 73 80 - 72 77 84 - 75 79 87 -

S/T 0.790.710.540.350.820.740.560.360.840.750.570.370.87 0.78 0.59 0.380.900.810.610.390.910.810.620.40

MBh 53.16 54.73 59.24 63.58 51.92 53.46 57.87 62.10 50.69 52.19 56.49 60.63 49.45 50.91 55.11 59.15 46.98 48.37 52.35 56.19 43.52 44. 80 48.50 52.05

Delta T22201611222016112220161122 20 17 112220161120191511

1800 KW 3.87 3.95 4.06 4.19 4.15 4.23 4.36 4.49 4.39 4.48 4.62 4.76 4.61 4.70 4.85 5.00 4.79 4.89 5.05 5.21 4.95 5.06 5.21 5.38

HI P R 147 1 59 16 7 17 5 16 5 17 8 188 1 9 6 188 2 02 214 223 2 1 4 2 30 243 254 241 2 5 9 274 2 85 26 6 2 86 302 31 5

AMPS 8.2 8.3 8.5 8.8 8.7 8.9 9.1 9.4 9.3 9.5 9.7 10.1 9.8 10.0 10.3 10.6 10.4 10.6 10.9 11.2 10.9 11.1 11.4 11.8

S/T 0.800.720.540.350.830.740.560.360.850.760.580.370.88

MBh 53.7 55.3 59.8 64.2 52.4 54.0 58.4 62.7 51.2 52.7 57.1 61.2 50.0

L O PR 59 63 69 74 63 67 73 78 65 69 76 81 69 73 80 85 72 7 6 83 89 74 79 86 92

Delta T21191611212016112120161121

75 1883 KW 3.91 3.99 4.10 4.23 4.19 4.27 4.40 4.54 4.44 4.53 4.67 4.81 4.66

HI P R 149 1 61 17 0 17 7 16 7 18 0 190 1 9 8 190 2 05 216 226 2 1 7

AMPS 8.2 8.4 8.6 8.9 8.8 8.9 9.2 9.5 9.4 9.6 9.8 10.2 9.9

S/T 0.800.720.540.350.830.740.560.360.850.760.580.370.88 0.79 0.60 0.380.910.820.620.400.920.820.620.40

MBh 53.7 55.3 59.8 64.2 52.4 54.0 58.4 62.7 51.2 52.7 57.1 61.2 50.0 51.43 55.7 59.7 47.5 48.9 52.9 56.8 44.0 45.3 49.0 52.6

L O PR 60 64 70 75 64 68 74 79 66 70 77 82 69

Delta T21191611211916112119161121 20 16 112119161120181510

1900 KW 3.91 3.99 4.10 4.23 4.19 4.27 4.40 4.54 4.44 4.53 4.67 4.81 4.66 4.75 4.90 5.06 4.84 4.94 5.10 5.26 5.00 5.11 5.27 5.44

HI P R 149 1 61 17 0 17 7 16 7 18 0 190 1 9 8 190 2 05 216 226 2 1 7 2 33 247 257 244 2 6 3 277 2 89 27 0 2 90 306 32 0

AMPS 8.2 8.4 8.6 8.9 8.8 8.9 9.2 9.5 9.4 9.6 9.8 10.2 9.9 10.1 10.4 10.8 10.5 10.7 11.0 11.3 11.0 11.2 11.6 11.9

L O PR 60 64 70 75 64 68 74 79 66 70 77 82 69 74 81 86 73 7 7 85 90 75 80 87 93

Shaded area is ACCA (TVA) conditi ons IDB: Entering Indoor Dry Bulb Tem perat ur e KW=Tot al system power AMPS =outdoor unit amps (comp.+fan)

High and low pressures are measur ed at the li quid and suction servi ce valv es.

19

Page 20

COOLING PERFORMANCE DAT A

C OOLING OPERATION

GSH130604AC

EXP ANDED PERFORMANCE DATA

16 24 23 20 16 22 21 18 15

59.3 48.3 49.4 52.7 56.4 44.7 45.7 48.8 52.2

0.55 1.00 0.94 0.76 0.57 1.00 0.95 0.77 0.58

5.10 4.88 4.98 5.14 5.31 5.04 5.15 5.31 5.49

20

55.5

0.74

Outdoor Ambient Temperature

Entering Indoor Wet Bulb Temperature

87 74 78 85 91 76 81 88 94

260 247 265 280 292 272 293 310 323

10.8 10.5 10.8 11.1 11.4 11.1 11.3 11.6 12.0

82

249

4.94

10.5

20

65 75 85 95 105 115

S/T 0.870.820.660.500.900.850.690.510.920.870.710.530.95 0.90 0.73 0.540.990.930.760.571.000.940.760.57

MBh 54.10 55.29 59.07 63.14 52.85 54.00 57.69 61.67 51.59 52.71 56.32 60.20 50.33 51.43 54.95 58.74 47.81 48.86 52.20 55.80 44.29 45.26 48.35 51.69

MODEL: GSH1 30604A* / AR* F4 86016B*

IDB*Airflow 59636771596367715963677159 63 67 715963677159636771

Delta T24232016242320162423201625 24 20 162423201623221915

1800 KW 3.90 3.98 4.09 4 .22 4.18 4.26 4.39 4.53 4.43 4.52 4.66 4.80 4.64 4.74 4.89 5.04 4.83 4.93 5.09 5.25 4.99 5.10 5.26 5.43

HI PR 149 160 169 176 167 180 190 198 190 204 216 225 216 233 246 256 243 262 276 288 269 289 305 319

AMPS 8.2 8.4 8.6 8.9 8.7 8.9 9.2 9.4 9.4 9.6 9.8 10.1 9.9 10.1 10.4 10.7 10.4 10.7 11.0 11.3 11.0 11.2 11.5 11.9

S/T 0.880.820.670.500.910.850.700.520.930.880.710.530.96 0.90

MBh54.755.859.763.853.454.558.362.352.153.256.960.850.8 51.9

L O PR 60 64 70 74 63 67 74 78 66 70 77 82 69 74 80 86 73 77 84 90 75 80 87 93

Delta T23222016242320162423201624 23

80 1883 KW 3.94 4.02 4.13 4.26 4.22 4.31 4.44 4.57 4.47 4.56 4.70 4.85 4.69 4.79

HI PR 151 162 171 179 169 182 192 200 192 207 219 228 219 236

AMPS 8.3 8.5 8.7 8.9 8.8 9.0 9.3 9.5 9.5 9.7 9.9 10.2 10.0 10.2

S/T 0.880.820.670.500.910.850.700.520.930.880.710.530.96 0.90 0.74 0.551.000.940.760.571.000.950.770.58

MBh 54.7 55.8 59.7 6 3.8 53.4 54.5 58.3 62.3 52.1 53.2 56.9 60.8 50.8 51.9 55.5 59.3 48.3 49.4 5 2.7 56.4 44.7 45.7 48.8 52.2

L O PR 61 65 71 75 64 68 75 80 67 71 78 83 70 75