Page 1

GSH13

1½- To 5-Ton SpliT SySTem HeaT pumpS

13 SeeR / R-22

Contents

Nomenclature ....................................... 2

Product Specications .......................... 3

AHRI Ratings .......................................... 4

Dimensions ........................................... 5

Wiring Diagrams ................................... 6

Accessories ............................................ 7

Standard Features

• Energy-efcient compressor

• Quiet condenser fan system

• Copper tube/aluminum n coil

• For use with R-22 refrigerant and

charged with inert gas for shipping

• Factory-installed bi-ow liquid line lter drier

• Low-pressure switch

• Time-initiated, temperature-

terminated defrost control

• Service valves with sweat connections and easy-access gauge ports

• Contactor with lug connection

• Ground lug connection

• ETL Listed

Cabinet Features

• Louver design sound control top

• Steel louver coil guard

• Heavy-gauge, galvanized-steel

cabinet with rust-resistant screws

• Attractive Architectural Gray powder-paint

nish with 500-hour salt-spray approval

• Single-panel access to controls with space

provided for eld-installed accessories

• When properly anchored, meets the

2010 Florida Building Code unit integrity

requirements for hurricane-type winds

(Anchor bracket kits available.)

* Complete warranty details available

from your local dealer or at www.

goodmanmfg.com.

SS-GSH13 www.goodmanmfg.com 11/13

Supersedes 9/13

Page 2

P

Brand Engineering *

G

Goodman® (Standard

Minor Revision

Feature Set Models)

Engineering *

Product Category Major Revision

S Split System

Electrical

Unit Type 1 208/230 V, 1 Phase, 60 Hz

C Condenser R-22

H Heat Pump R-22 Nominal Capacity

018 1½ Tons 042 3½ Tons

Efficiency 024 2 Tons 048 4 Tons

13 13 SEER 030 2½ Tons 060 5 Tons

036 3 Tons

* Neither used for order entry

or inventory management.

11

A

S

2

1

G

H3036

6,7,8134,5

9110

A

roduct SPecificationS

nomenclaTuRe

2 www.goodmanmfg.com SS-GSH13

Page 3

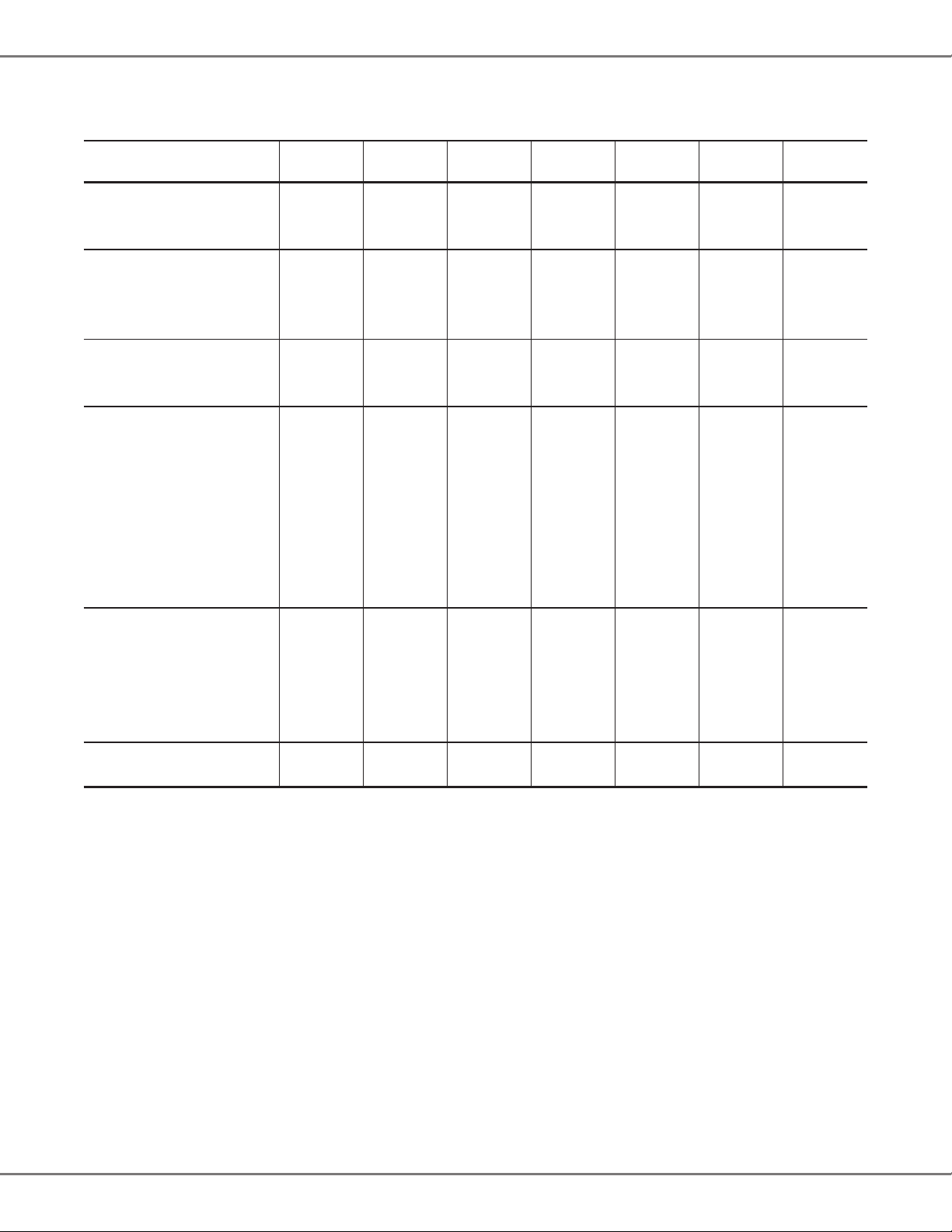

SpecificaTionS

P

roduct SPecificationS

GSH13

0181C*

Capacities and Ratings

Tonnage 1½ 2 2½ 3 3½ 4 5

Decibels 73 71 72 71 76 76 77

Compressor

RLA 8.3 10.8 13.5 14.1 19.2 19.9 25.0

LRA 40.3 56.0 68.0 75.0 112.0 104.0 148.0

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Condenser Fan Motor

Horsepower 1/8 1/8 1/8 ¼ ¼ ¼ 1/6

FLA 0.7 0.7 0.7 1.5 1.5 1.5 1.1

Refrigerant System

Refrigerant Line Size

Liquid Line Size (“O.D.) ⅜" ⅜" ⅜" ⅜" ⅜" ⅜" ⅜"

Sucon Line Size (“O.D.) ¾" ¾" ¾" ⅞" 1⅛" 1⅛" 1⅛"

Refrigerant Connecon Size

Liquid Valve Size (“O.D.) ⅜" ⅜" ⅜" ⅜" ⅜" ⅜" ⅜"

Sucon Valve Size (“O.D.) ¾" ¾" ¾" ⅞" ⅞" ⅞" ⅞"

Valve Type Sweat Sweat Sweat Sweat Sweat Sweat Sweat

Refrigerant Charge 127 122 130 188 246 208 233

Electrical Data

Voltage-Phase (60 Hz) 208/230-1 208/230-1 208/230-1 208/230-1 208/230-1 208/230-1 208/230-1

Minimum Circuit Ampacity ² 11.1 14.2 17.6 19.1 25.5 26.4 32.3

Max. Overcurrent Protecon ³ 15 25 30 30 40 45 50

Min / Max Volts 197/253 197/253 197/253 197/253 197/253 197/253 197/253

Electrical Conduit Size ½" or ¾" ½" or ¾" ½" or ¾" ½" or ¾" ½" or ¾" ½" or ¾" ½" or ¾"

Equipment Weight (lbs) 142 147 146 146 152 152 278

Ship Weight (lbs) 159 164 164 164 170 170 300

GSH13

0241C*

GSH13

0301C*

GSH13

0361C*

GSH13

0421B*

GSH13

0481B*

GSH13

0601A*

¹ Tested and rated in accordance with AHRI Standard 210/240

² Wire size should be determined in accordance with Naonal Electrical Codes; extensive wire runs will require larger wire sizes

³ Must use me-delay fuses or HACR-type circuit breakers of the same size as noted.

Notes

• Always check the S&R plate for electrical data on the unit being installed.

• Installer will need to supply ⅞” to 1⅛” adapters for sucon line connecons.

• Charge to be added for 15’ of ⅜” liquid line. System charge must be adjusted per Installaon Instrucons Final Charge Procedure.

• Installaon of these units requires the specied TXV Kit to be installed on the indoor coil. THE SPECIFIED TXV IS DETERMINED BY THE OUTDOOR UNIT NOT THE INDOOR COIL.

SS-GSH13 www.goodmanmfg.com 3

Page 4

P

roduct SPecificationS

aHRi RaTinGS

Outdoor

Unit

GSH130484A* AR*F486016B* 45,000 33,800 13.0 11.0 41,500 31,800 43,000 8.2 27,000 1,600 1492572

GSH130601A* AR*F486016B* 55,500 41,000 13.0 11.0 51,500 37,000 55,500 8.5 35,000 1,800 1492576

GSH130603A* AR*F486016B* 55,500 41,000 13.0 11.0 51,500 37,000 55,500 8.5 35,000 1,800 1492581

GSH130604A* AR*F486016B* 55,500 41,000 13.0 11.0 51,500 37,000 55,500 8.5 35,000 1,800 1492585

GSH130241(B,C)* AR*F182416B*+TXV 23,000 17,800 13.0 11.0 21,400 15,800 21,400 7.7 11,800 860 4675037

GSH130301(B,C)* AR*F363616B* 27,800 20,200 13.0 11.0 25,800 19,300 25,400 7.7 15,300 1,020 4692016

GSH130181(B,C)* AR*F182416B* 17,600 13,100 13.0 11.0 16,300 11,800 16,800 7.7 8,900 625 4675036

GSH130361(B,C)* AR*F374316B* 33,600 26,200 13.0 11.0 31,000 23,400 31,400 7.7 18,200 1,260 4692017

GSH130604AC AR*F486016B* 55,500 41,500 13.0 11.0 51,500 37,000 55,500 8.5 35,000 1,800 4982919

GSH130481B* AR*F486016B* 45,000 33,800 13.0 11.0 41,500 31,800 43,000 8.2 27,000 1,600 5528480

GSH130421B* AR*F364216B* 40,000 29,800 13.0 11.0 37,200 28,200 39,000 8.0 23,000 1,250 5528479

GSH130363A* AR*F374316B* 33,600 26,200 13.0 11.0 31,000 23,400 31,400 7.7 18,200 1,260 5528484

GSH130483B* AR*F486016B* 45,000 33,800 13.0 11.0 41,500 31,800 43,000 8.2 27,000 1,600 5528481

GSH130484AD AR*F486016B* 45,000 33,200 13.0 11.0 41,500 31,800 43,000 8.2 27,000 1,600 5528482

¹ BTU/h ² Seasonal Energy Eciency Rao; Cered per AHRI 210/240 @ 80°F/ 67°F/ 95°F

³ Energy Eciency Rao @ 80°F/ 67°F/ 95°F ⁴ TVA Rang: BTU/h @ 75°F/ 63°F - 95°F ⁵ HSPF = Heang Seasonal Performance Factor

Notes

• Always check the S&R plate for electrical data on the unit being installed.

• When matching outdoor unit to indoor unit, use the piston supplied with outdoor unit or that specied on the piston kit chart supplied with the indoor unit.

• EEP - Order from Service Dept. Part No. B13707-38 or new Solid State Board B13707-35S. Part No. B13707-38 is not interchangeable with B13707-35S. The Goodman Gas Furnace contains the EEP cooling me delay

Indoor

Unit

Cooling Capacity¹

SEER² EER³

Tota l Sens. Tota l Sens. High HSPF⁵ Low

TVA Ratings⁴ Heating Capacity¹

CFM AHRI #

4 www.goodmanmfg.com SS-GSH13

Page 5

DimenSionS

P

roduct SPecificationS

W

H

D

Dimensions

Model

W” D” H”

GSH130181C 26 26 32¼

GSH130241C 26 26 32¼

GSH130301C 29 29 34¾

GSH130361C 29 29 38¼

GSH130421B 29 29 32¼

GSH130481B 29 29 34¾

GSH130601A 35½ 35½ 34¾

SS-GSH13 www.goodmanmfg.com 5

Page 6

P

roduct SPecificationS

WiRinG DiaGRam

L2

C

T2

SC

1

2

SR

SEE RATING PLATE

OUTDOOR POWER SUPPLY

5

T1

C

L1

RCCF

HC

S

COMP

X

U

A

IO

C

C

SA

(IF USED)

F

R

N

I

A

M

POLE CONT ACTOR ONLY

ALTERNATE DOUBLE

N

I

X

A

U

A

M

CH

CM

IO

DF2

CHS

HVDR

DF1

NOTE 3

(IF USED)

C

Y

DC

DFT

DFT

R

C

RVC

LPS

Y

SUPPLY

W2

LVDR

W2

ORO

INDOOR POWER

O

R

USE N.E.C. CLASS 2 WIRE

NOTES:

1. TO INDOOR UNIT LOW VOLTAGE TERMINAL BLOCK & INDOOR

THERMOSTAT.

2. START ASSIST FACTORY EQUIPPED WHEN REQUIRED.

3. CRANKCASE HEATER & CRANKCASE HEATER SWITCH ARE

FACTORY INSTALLED OPTION.

4. USE COPPER CONDUCTOR ONLY.

0140R00019P-B

⚡

LVJB

CONTROL BOX

NOTE 1

W2

RCY

O

RD

WH

BLYLOR

COMPONENT CODE

C --------------- CONTACTOR

CH ------------- CRANKCASE HEATER

CHS ------------- CRANKCASE HEATER SWITCH

CM ------------ OUTDOOR FAN MOTOR

COMP -------- COMPRESSOR

DC ------------- DEFROST CONTROL

DFT ----------- DEFROST THERMOSTAT

HVDR -------- HIGH VOLTAGE DEFROST RELAY

IO -------------- INTERNAL OVERLOAD

LPS ------------ LOW PRESSURE SWITCH

LVDR --------- LOW VOLTAGE DEFROST RELAY

LVJB ---------- LOW VOLTAGE JUNCTION BOX

RCCF --------- RUN CAPACITOR FOR COMPRESSOR & FAN

RVC ----------- REVERSING VALVE COIL

SA ------------- START ASSIST

SC ------------- START CAPACITOR FOR COMPRESSOR (OPTIONAL)

SR ------------- START RELAY FOR COMPRESSOR (OPT IONAL)

OLOR CODE

BK --------------- BLACK

BL --------------- BLUE

BR --------------- BROWN

OR --------------- ORANGE

PU --------------- PURPLE

C

BK

BK

DF1

DF2

HVD

R

DFT

RR

DC

LVDR

W2

OO

YC

RD --------------- RED

RD

RD

RD

WH

BK

OR

YL

BL

WIRING CODE

WH -------------- WHITE

YL --------------- YELLOW

FACTORY WIRING

HIGH VOLTAGE

LOW VOLTAGE

OPTIONAL HIGH VOLTAGE

FIELD WIRING

HIGH VOLTAGE

BL

RD

SC

RD

C

RD

RD

L2

T2

BKBK

BK

T1

L1

BK

BL

BL

YL

SR

BK

5

RCCF

RD

PU

RD

BK

YL

YL

BL

1

YL

2

YL

FC

RD

SA

H

PU

NOTE 2

(IF USED)

RD

BR

YL

L2

T2

L1

T1

ALTERNATE

SEE NOTE 4

EQUIPMENT GROUND

BK

BK

RVC

BK

COMP

CONTACTOR

DOUBLE POLE

BK

RD

RD

BK

DFT

RD

RD

S

AUX

MAIN

C

BK

YL

RD

PU

AUX

MAIN

CONTROLS SHOWN WITH THERMOSTAT IN 'OFF' POSITION.

GR

High Voltage: Disconnect all power before servicing or installing this unit. Mulple power

sources may be present. Failure to do so may cause property damage, personal injury, or death.

CH

CHS

(IF USED)

SEE NOTE 3

YL

⚠ Warning

LPS

YL

R

Wiring is subject to change. Always

refer to the wiring diagram or the

BR

BK

CM

IO

unit for the most up-to-date wiring.

6 www.goodmanmfg.com SS-GSH13

Page 7

acceSSoRieS

P

roduct SPecificationS

Model Description

ABK-20 Anchor Bracket Kit

ASC01 An-Short Cycle Kit X X X X X X X

CSR-U-1 Hard-start Kit X X X X X X

CSR-U-2 Hard-start Kit

CSR-U-3 Hard-start Kit X

FSK01A¹ Freeze Protecon Kit X X X X X X X

OT/EHR18-60 Emergency Heat Relay kit X X X X X X X

OT18-60A² Outdoor Thermostat with Lockout Stat X X X X X X X

*

Contains 20 brackets; four brackets needed to anchor unit to pad

¹ Installed on indoor coil

² Required for heat pump applicaons where ambient temperatures fall below 0 °F with 50% or higher relave humidity.

³ Condensing units and heat pumps with reciprocang compressors require the use of start-assist components when used in conjuncon with an indoor

coil using a non-bleed thermal expansion valve refrigerant metering device. The TXV should always be sized based on the tonnage of the outdoor unit.

*

GSH13

018

GSH13

024

X X X X X X X

GSH13

030

GSH13

036

GSH13

042

GSH13

048

GSH13

060

SS-GSH13 www.goodmanmfg.com 7

Page 8

P

roduct SPecificationS

noTeS

Goodman Manufacturing Company, L.P., reserves the right to discontinue, or change at any time, specications or designs without

notice or without incurring obligations. © 2013 • Goodman Manufacturing Company, L.P. • Houston, Texas • Printed in the USA.

8 www.goodmanmfg.com SS-GSH13

Loading...

Loading...