Page 1

TECHNICAL MANUTECHNICAL MANU

TECHNICAL MANU

TECHNICAL MANUTECHNICAL MANU

ALAL

AL

ALAL

GCH9

40" 95% Gas Furnace

• Refer to Service Manual RS6610004 for installation, operation, and troubleshooting information.

• All safety information must be followed as provided in the Service Manual.

• Refer to the appropriate Parts Catalog for part number information.

• Model numbers listed on page 3.

This manual is to be used by qualified, professionally trained HVAC technicians only.

Goodman does not assume any responsibility for property damage or personal

injury due to improper service procedures or services performed by an unqualified

person.

Copyright © 2007, 2009-2010 Goodman Manufacturing Company, L.P.

®

C

RT6612019 Rev. 2

US

April 2010

Page 2

PRODUCT IDENTIFICATION

The model and manufacturing number are used for positive identification of component parts used in manufacturing.

Please use these numbers when requesting service or parts information.

G

Brand:

G: Goodman

Air Flow Direction

M:Upflow/Horizontal

D: Dedicated Downflow

C: Downflow/Horizontal

H: Hi Air Flow

Description

H: Dual $aver/Multi-speed

V: Two-Stage/Variable-speed

C

H

AFUE

9: 90%

045: 45,000

070: 70,000

090: 90,000

115: 115,000

KBTUH

9

045

3

Maximum CFM @ 0.5" ESP

3: 1200

4: 1600

5: 2000

B

XA

NOx

N: Natural Gas

X: Low NOx

Cabinet Width

B: 17 1/2"

C: 21"

D: 24 1/2"

A

Minior

Revision

A: Revision

Major Revision

A: Initial Release

WARNING

WARNING

WARNING

WARNING

arising from improper service or service procedures. If

you install or perform service on this unit, you assume

responsibility for any personal injury or property damage

which may result. Many jurisdictions require a license to

install or service heating and air conditioning equipment.

2

HIGH VOLTAGE!

Disconnect ALL power before servicing or installing this unit. Multiple power

sources may be present. Failure to do so may cause property damage, personal

injury or death.

Goodman will not be responsible

for any injury or property damage

Installation and repair of this unit

WARNING

WARNING

of an "entry level technician", at a minimum, as specified

by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI). Attempting to install or repair this unit

without such background may result in product damage,

personal injury or death.

should be performed

viduals meeting the requirements

ONLY by indi-

Page 3

PRODUCT IDENTIFICATION

The model and manufacturing number are used for positive identification of component parts used in manufacturing.

Please use these numbers when requesting service or parts information.

GCH90453BXA*

GCH90703BXA*

GCH90704CXA*

GCH90904CXA*

GCH90905DXA*

GCH91155DXA*

These models are Low NOx.

WARNING

WARNING

WARNING

WARNING

Serious property damage, personal injury, reduced unit

performance and/or hazardous conditions may result

from the use of such non-approved devices.

The United States Environmental Protection Agency (“EPA”) has issued various regulations regarding the introduction and disposal of refrigerants introduced into this unit. Failure to follow

these regulations may harm the environment and can lead to the imposition of substantial fines.

These regulations may vary by jurisdiction. Should questions arise, contact your local EPA office.

Do not connect or use any device

that is not design certified by

Goodman for use with this unit.

WARNING

WARNING

do not store combustible materials or use gasoline or

other flammable liquids or vapors in the vicinity of this

appliance.

To prevent the risk of property

damage, personal injury, or death,

3

Page 4

PRODUCT DESIGN

General Operation

The GCH9 furnaces are equipped with an electronic ignition

device used to light the burners and an induced draft blower

to exhaust combustion products.

An interlock switch prevents furnace operation if the blower

door is not in place. Keep the blower access door in place

except for inspection and maintenance.

This furnace is also equipped with a self-diagnosing electronic control module. In the event a furnace component is

not operating properly, the control module LED will flash on

and off in a factory-programmed sequence, depending on

the problem encountered. This light can be viewed through

the observation window in the blower access door. Refer to

the Troubleshooting Chart for further explanation of the LED

codes and Abnormal Operation - Integrated Ignition Control

section in the Service Instructions for an explanation of the

possible problem.

The rated heating capacity of the furnace should be greater

than or equal to the total heat loss of the area to be heated.

The total heat loss should be calculated by an approved

method or in accordance with “ASHRAE Guide” or “Manual

J-Load Calculations” published by the Air Conditioning Contractors of America.

*Obtain from: American National Standards Institute 1430

Broadway New York, NY 10018

Location Considerations

• The furnace should be as centralized as is practical

with respect to the air distribution system.

• Do not install the furnace directly on carpeting, tile, or

combustible material other than wood flooring.

• When suspending the furnace from rafters or joists,

use 3/8" threaded rod and 2” x 2” x 3/8” angle as

shown in the Installation and Service Instructions. The

length of the rod will depend on the application and

clearance necessary.

• When installed in a residential garage, the furnace

must be positioned so the burners and ignition source

are located not less than 18 inches (457 mm) above

the floor and protected from physical damage by vehicles.

Notes:

1. Installer must supply one or two PVC pipes: one for combustion air (optional) and one for the flue outlet (required).

Vent pipe must be either 2” or 3” in diameter, depending

upon furnace input, number of elbows, length of run and

installation (1 or 2 pipes). The optional Combustion Air

Pipe is dependent on installation/code requirements and

must be 2” or 3” diameter PVC.

2. Line voltage wiring can enter through the right or left side

of the furnace. Low voltage wiring can enter through the

right or left side of furnace.

3. Conversion kits for high altitude natural or propane gas

operation are available. See High Altitude Derate chart

for details.

4. Installer must supply the following gas line fittings, depending on which entrance is used:

Left -- Two 90º Elbows, one close nipple, straight pipe.

Right -- Straight pipe to reach gas valve.

Accessibility Clearances (Minimum)

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

(INCHES)

POSITION* FRONT SIDES REAR TOP FLUE FLOOR

Upflow30010C

Horizontal 3 6 0 6 0 C

*= All positioning is determined as installed unit is viewed from the front.

C= If placed on combustible floor, floor MUST be wood only.

NC= For instalaltion on non-combustible floors only. A non-combustible

subbase must be used for installations on combustible flooring.

24" at front is required for servicing or cleaning.

Note: In all cases accessibility clearance shall take prece-

dence over clearances from the enclosure where accessibility clearances are greater. All dimensions are given in inches.

High Altitude Derate

When this furnace is installed at high altitude, the appropriate High Altitude orifice kit must be installed. This is required due to the natural reduction in the density of both the

gas fuel and combustion air as altitude increases. The kit

will provide the proper design certified input rate within the

specified altitude range.

MODEL

NUMBER

GCH9*****XA*

1

LPM -03 / LPM-05 supports W hite-Rodgers 2-s tage valves only

2

LPM -06 s uppor ts Honeyw ell and W hite-Rodgers 2 s tage valves

PROPANE AND HIGH ALTITUDE KITS

0 to

7,000 ft.

LPM -03

LPM -05

LPM -06

Propane

Conversion Kit

(#55 Orifices)

1

1

2

High Altitude

Natural Gas Kit

(#44 Orifices)

7,001 to

9,000 ft.

HANG11

9,001 to

11,000 ft.

HANG12

High A ltitud e

Natural Gas Kit

(#45 Orifices)

7,001 to

11,000 ft.

HALP 10

High Altitude

LP Gas Kit

(#56 Orifices)

7,001 to

11,000 ft.

TBD

High altitude kits are purchased according to the installation altitude and usage of either natural or propane gas. Refer

to the chart above for a tabular listing of appropriate altitude

ranges and corresponding manufacturer’s high altitude Natural Gas and Propane Gas kits. For a tabular listing of appropriate altitude ranges and corresponding manufacturer's High

Altitude Pressure Switch kits, refer to either the Pressure

Switch Trip Points & Usage Chart in this manual or the Accessory Charts in Service Instructions.

4

Page 5

COMPONENT IDENTIFICATION

25

20

13

31

18

23

31

24

19

5

26

27

10

11

28

3

15

3

14

29

30

16

17

18

20

19

12

9

7

Downflow /Horizontal

1 Two-Stage Gas Valve

2 Gas Line Entrance (Alternate)

3 Pressure Switch(es)

4 Gas Manifold

5 Combustion Air Intake Connection

6 Hot Surface Igniter

7 Rollout Limit

8 Burners

9 Flame Sensor

10 Flue Pipe Connection

11 Flue Pipe

1 2 Primary Limit

13 Gas Line Entrance

14 Flue Pipe Connection (Alternate)

15 Rubber Elbow

16 Induced Draft Blower

17 Electrical Connection Inlets (Alternate)

18 Coil Front Cover Pressure Tap

2

21

6

8

7

4

19 Coil Front Cover Drain Port

20 Drain Line Penetrations

21 Drain Trap

22 Blower Door Interlock Switch

23 Capicitor

24 Integrated Control Module

25 24 Volt Thermostat Connections

26 Transformer (40 VA)

27 Circulator Blower

28 Auxiliary Limits

29 Junction Box

30 Electrical Connection Inlet

31 Coil Front Cover

1

(with fuse and diagnostic LED)

5

Page 6

COMPONENT IDENTIFICATION

GCH9*****XA*

3/4

LEFT SIDE

VIEW

20 1/4

LOW VOLTAGE

ELECTRICAL HOLE

HIGH VOLTAGE

ELECTRICAL HOLE

LEFT SIDE

DRAIN LINE

HOLES

STANDARD GAS

SUPPLY HOLE

18 5/8

UNFOLDED FLANGES

20 5/32

FOLDED FLANGES

AIR

DISCHARGE

28 3/4

DRAIN

TRAP

C

FRONTVIEW

2 1/2

AIR INTAKE PIPE

2" PVC

1 3/4

2 5/8

L

4 1/8

9 13/16

15 1/2

11 1/2

3/4

40

28 5/16

A

B

(RETURN)

D

UNFOLDED FLANGES

E

FOLDED FLANGES

DISCHARGE

3/4

2 1/16

CONDENSATE

DRAIN TRAP

w/ 3/4" PVC

DISCHARGE

(RIGHT O R

LEFT SIDE)

2

8 1/4

28 5/16

19 7/8

VENT/FLUE PIPE

2" PVC

1 3/4

2 11/16

18 13/16

14

11 5/8

6 1/8

9 3/4

7 3/8

RIGHT SIDE

VIEW

LOW VOLTAGE

ELECTRICAL HOLE

HIGH VOLTAGE

ELECTRICAL HOLE

ALTERNATE

VENT/FLUE

LOCATION

ALTERNATE

AIR INTAKE LOCATION

DRAIN

2 5/8

TRAP

C

L

RIGHT SIDE

DRAIN LINE

HOLES

ALTERNATE GAS

SUPPLY HOLE

AIR

DISCHARGE

Cabinet Size A B C D E

GCH90453BX**

GCH90703BX**

GCH90704CXA*

GCH90904CXA*

GCH90905DXA*

GCH91155DXA*

17-1/2

21

24-1/2

16

19-1/2

23

12-15/16

15-15/16

20-7/16

12-1/8

16

19-3/8

All dimensions are in inches.

13-5/8

17-1/2

20-7/8

6

Page 7

PRODUCT DESIGN

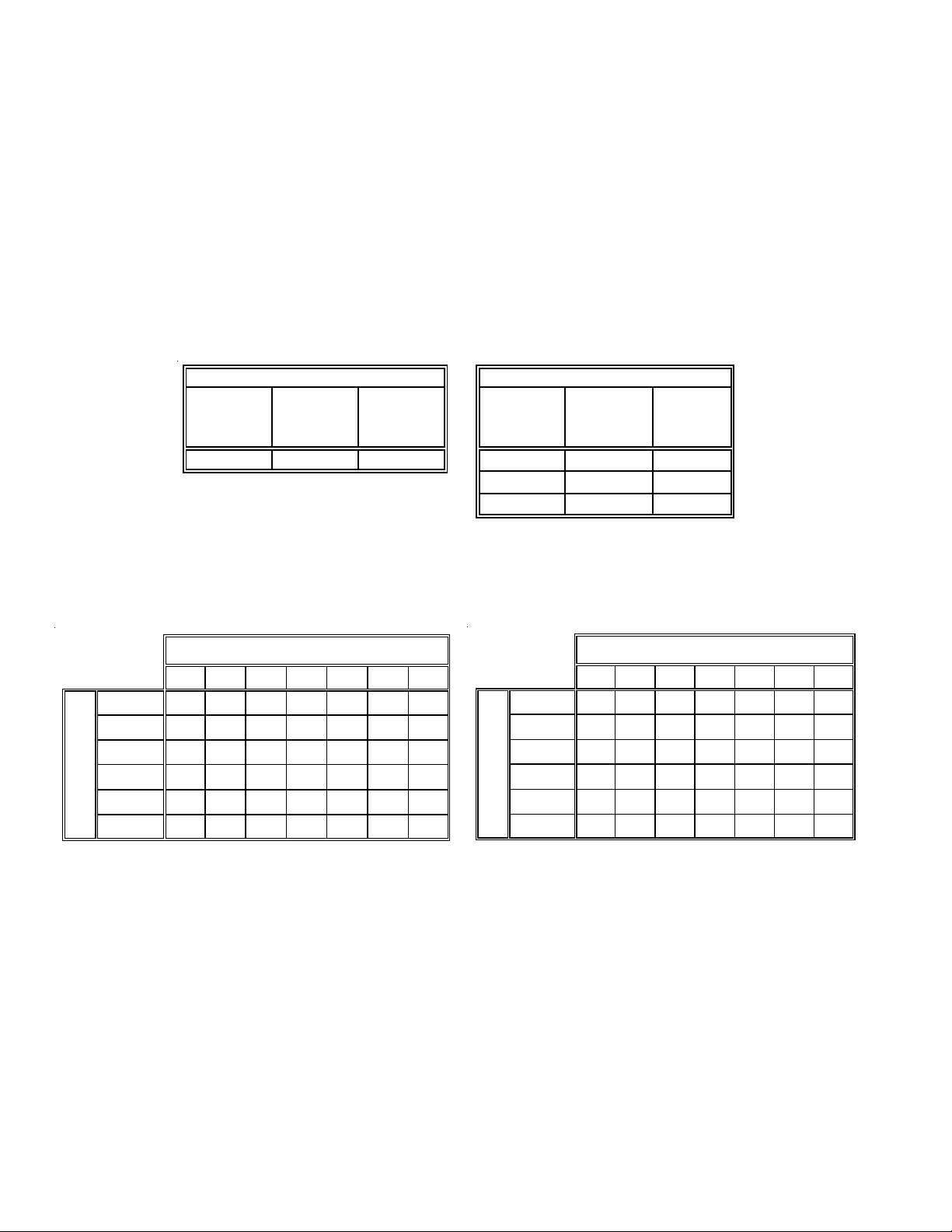

PRESSURE SWITCH TRIP POINTS AND USAGE CHART

0 to 7,000 ft.

MODEL

GCH90453BX

GCH90703BX

GCH90704CX

GCH90904CX

GCH90905CX

GCH91155DX

Note: Replacement pressure switch number is listed below hig h al titude kit number.

Note: All negative pressure readings are in inches of water column (" w.c.).

TRIP POINT

COIL COVER

PRESSURE SWITCH

-.60 20197311 -.60 20197311

-.60 20197311 -.60 20197311

-.37 20197313 -.37 20197313

-.60 20197311 -.60 20197311

-.37 20197313 -.37 20197313

-.60 20197311 -.60 20197311

PRESSURE

SWITCH

PART #

TRIP POINT

ID BLOWER

PRESSURE SWITCH

ID BLOWER

PRESSURE

SWITCH

PART #

T.O.D. PRIMARY LIMIT

Part Number 20162906 20162904 20162907

Open Setting (°F)

GCH90453BX

GCH90703BX

GCH90704CX

GCH90904CX

GCH90905DX

GCH91155DX

170 150 155

1

1

1

1

1

1

7

Page 8

PRODUCT DESIGN

ROLLOUT LIMIT SWITCHES

Part Number 10123517 10123534

Open Setting (°F)

GCH90453BX

GCH90703BX

GCH90704CX

GCH90904CX

GCH90905DX

GCH91155DX

AUXILIARY LIMIT SWITCHES

Part Number 10123518 10123519

Open Setting (°F)

210 220

1

2

2

2

2

170 160

2

GCH90453BX

GCH90703BX

GCH90704CX

GCH90904CX

GCH90905DX

GCH91155DX

2

2

2

2

2

2

8

Page 9

PRODUCT DESIGN

Coil Matches:

A large array of Amana® brand coils are available for use with the GCH9 furnaces, in either counterflow or horizontal

applications. These coils are available in both cased and uncased models (with the option of a field installed TXV expansion

device). These 90%+ furnaces match up with the existing Amana® brand coils as shown in the chart below.

Coil Matches (Goodman® units using R22 and R-410A):

CAPF1824A6A

PRODUCT

TYPE:

C: Indoor Coil

APPLICATION

A: U pflow/Downflow C oil

H: Horizontal A Coil

S: Hor iz ontal Slab Coil

EXPANSION

DEVICE:

F: Flowrater

CAB I NET FINI S H:

U: Unpainted

P: Painted

N: Unp ainted Case

NOMINAL CA P ACIT Y RA NGE

@ 13 SEER

1824: 1 1/2 to 2 Tons

3030: 2 1/2 Tons

3636: 3 Tons

3642: 3 to 3 1/2 Tons

3743: 3 to 3 1/2 Tons

4860: 4 & 5 Tons

4961: 4 & 5 Tons

REV ISI ON

A: Revision

REFRIGERANT

CHARGE:

6: R- 4 10A or R- 22

2: R- 22

4: R- 410a

NOM INAL WIDTH FOR GAS FURNACE

A: Fits 14" Furnace Cabinet

B: Fits 17 1/2" Furnace Cabinet

C: Fits 21" Fu rnace Cabinet

D: Fits 24 1/2" Furnace Cabi net

N : Does Not A pp ly (Horiz onta l S l ab Coils)

• All CAPF coils in B, C, & D widths have insulated blank off plates for use with one size smaller furnaces.

• All CAPF coils have a CAUF equivalent.

• All CHPF coils in B, C & D heights have an insulated Z bracket for use with one size smaller furnace.

• All proper coil combinations are subject to being ARI rated with a matched outdoor unit.

9

Page 10

PRODUCT DESIGN

Thermostats:

NOTE: Complete lineup of thermostats can be found in the Thermostat Specification Sheets.

Filters:

Filters are required with this furnace and must be provided by the installer. The filters used must comply with UL900 or

CAN/ULCS111 standards. Installing this furnace without filters will void the unit warranty.

Upflow Filters

This furnace has provisions for the installation of return air filters at the side and/or bottom return. The furnace will

accommodate the following filter sizes depending on cabinet size:

Side Return(s) Bottom Return

Cabinet

Width

(in.)

Nominal

Filter Size

(in.)

Approx.

Flow Area

2

)

(in

Cabinet

Width

(in.)

Nominal

Filter Size

(in.)

All 16 x 25 x 1 400 17-1/2 14 x 25 x 1 350

21 16 x 25 x 1 400

24-1/2 20 x 25 x 1 500

Approx.

Flow Area

2

)

(in

Refer to Minimum Filter Area tables to determine filter area requirement. NOTE: Filters can also be installed elsewhere in

the duct system such as a central return.

COOLING AIRFLOW REQUIREMENT (CFM)

600 800 1000 1200 1400 1 600 2000

0453BXA* 388* 388* 480 576 --- --- --0703BXA* --- 647* 647* 647* 672 --- --0704CXA* --- --- 583 * 583* 672 768 --0904CXA* --- --- 863 * 863* 863* 863* -- -

Input__Airflow

0905DXA* --- --- --- 777* 777* 777* 960

1155DXA* --- --- --- 971* 971* 971* 971*

*Minimum filter area dictated by heating airflow requirement.

Disposable Minimum Filter Area (in2)

[Based on a 300 ft/min filter face velocity]

0453BXA* 194* 194* 240 288 --- --- --0703BXA* --- 324* 324* 324* 336 --- --0704CXA* --- --- 291* 291* 336 384 --0904CXA* --- --- 432* 432* 432* 432* ---

Input__Airflow

0905DXA* --- --- --- 388* 388* 388* 480

1155DXA* --- --- --- 486* 486* 486* 486*

*Minimum filter area dictated by heating airflow requirement.

Permanent Minimum Filter Area (in2)

[Based on 600 ft/min filter face velocity]

COOLING AIRF L OW REQU I R EMEN T (CFM)

600 800 1000 1200 1400 1600 2000

10

Page 11

PRODUCT DESIGN

Dual $aver Configuration & Operation

Dual $aver

This furnace is capable fo the following heating modes:

• Single Stage (Factory Setting)

• Modified Two-Stage

> Fixed 5-Min. Low Stage

> Auto Time (1-12 Min.) Low Stage

To change from the factory single-stage operation,

adjust the dipswitches on the ignition control as follows:

OFF ON

Mode

5 Min. Fixed

Auto

Note: This furnace is designed to be used

with a single-stage room thermosat.

Start Start

Call for Heat Call for Heat

Safety Circuit Check Safety Circuit Check

Start Furnace

in Low Stage

Low-Heat Blower Low-Heat Blower

Mode Dipswitch

2nd Stage Delay

Dipswitch

Start Furnace

in Low Stage

Delay Time (5 Min) Delay Time (1-12 Min)

Gas Valve Swi t ch

to 2nd Stage

Blower Switch to

Hi Heat Operation

T-Stat Satisfied T-Stat Satisfied

Gas Valve Switch

to 2nd Stage

Blower Switch to

Hi Heat Operation

11

Page 12

FURNACE SPECIFICATIONS

MODEL GCH90453BX GCH90703BX GCH90704BX GCH90904CX GCH90905CX GCH91155DX

Btuh Input (US) 46,000 69,000 69,000 92,000 92,000 115,000

Output (US) 42,800 64,400 64,400 86,000 86,000 106,500

BTUH Output (US) LP 38,502 57,753 57,753 77,004 77,004 96,255

A.F.U.E. 93 93 93 93 93 93

Rated External Static (" w.c.) .20" - .50" .20" - .50" .20" - .50" .20" - .50" .20" - .50" .20" - .50"

Temperatur e Rise (°F) 35-65 35-65 35-65 35-65 35-65 35-65

Pressure Switch Trip Point (" w. c .) -0.60 -0.60 -0.37 -0.60 -0.37 -0.60

Front Cover Pressure Switch Trip Point (" w.c) -0.60 -0.60 -0.37 -0.60 -0.37 -0.60

Blower Wheel (D" x W") 10 X 8 10 X 8 10 X 10 10 X 10 11 X 10 11 x 10

Blower Horsepower 1/3 1/3 1/2 1/2 3/4 3/4

Blower Speeds 4 4 4 4 4 4

Max CFM @ 0.5 E.S.P. 1,200 1,200 1,600 1600 2000 2000

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Minimum Circuit Ampacity (MCA)

Maximum Overcurrent Device

Transfor mer (VA) 40 40 40 40 40 40

Primary Limit Setting (°F) 170 170 170 150 170 155

Auxiliary Limit Setting ( ° F) 160 160 170 160 170 160

Rollout Limit Setting (°F) 210 210 210 220 220 210

Fan Delay On Heating 30 30 30 30 30 30

Off Heating

Fan Delay On Cooling 5 5 5 5 5 5

Off Cooling 45 45 45 45 45 45

Fan Delay On - Fan Only 0 0 0 0 0 0

Gas Supply Pressure (Natural/Propane) (" w.c.) 7/11 7/11 7/11 7/11 7/11 7/11

Manifold Pressure (Natural/ P ropane) 3.5/10 3.5/10 3.5/10 3.5/10 3.5/10 3.5/10

Orifice Size (Natural/Propane) 43/55 43/55 43/55 43/55 43/55 43/5 5

Number of Burners 2 3 3 4 4 5

Vent Connector Diameter (inches)

Shipping Weight (lbs.) 132 135 136 158 172 178

(3)

(1)

(2)

(4)

9.40 9.40 13.80 13.80 13.20 13.20

15 15 15 15 15 15

150 150 150 150 150 150

222222

GCH9

(1)

Wire size should be determined in accordance with National Electrical Codes. Extensive wire runs will require larger wire sizes.

(2)

Maximum Overcurrent Protection Device: May use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

(3)

Off Heating - this fan delay timing is adjustable (100 or 150 seconds), 150 seconds as shipped.

(4)

See Installation Instructions for appropriate vent diameter, length and number of elbows.

NOTE: This data is provided as a guide, it is important to electrically connect the unit and properly size fuses/circuit breakers and wires in

accordance with all national and/or local electrical codes. Use copper wire only.

1. These furnaces are manufactured for natural gas operation. Optional kits are available for conversion to propane operation.

2. For elevations above 2000 feet the rating should be reduced by 4% for each 1000 feet above sea level. The furnace must not be derated, orifice changes should only

be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufacturers method or in accordance with the "A.S.H.R.A.E.

GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal

to or less than the heating capacity. Output based on D.O.E. test procedures.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

Unit specifications are subject to change without notice.

ALWAYS refer to the units serial plate for the most up-to-date general and electrical information.

12

Page 13

BLOWER PERFORMANCE SPECIFICATIONS

BLOWER PERFORMANCE

(CFM & Temperature Rise vs. External Static Pressure)

Model

Motor

Heating Speed

()

As Shipped

Speed

Tons AC

at 0.5" 0.6 0.7 0. 8

0.1 0.2 0.3 0.4 0.5

ESP CFM RISE CFM RISE CFM RISE CFM RISE CFM RISE CFM CFM CFM

EXTERNAL STATIC PRESSURE (Inches Water Column)

HIGH 3.0

GCH90453BXA* MED 2.5

(MED-HI) MED-LO 2.0

LOW 1.5

HIGH 3.0

GCH90703BXA* MED 2.5

(MED-HI) MED-LO 2.0

LOW 1.5

HIGH 4.0

GCH90704CXA* MED 3.5

(MED-HI) MED-LO 3.0

LOW 2.5

HIGH 4.0

GCH90904CXA* MED 3.5

(MED-HI) MED-LO 3.0

LOW 2.5

1352 29 1318 30 1260 31 1202 33 1128 35 1044 955 853

1214 32 1172 34 1123 35 1064 37 1012 39 938 859 741

997 40 994 40 960 41 923 43 884 45 817 741 611

757 52 753 52 734 54 704 56 674 59 620 524 438

1449 41 1409 42 1326 45 1273 47 1201 49 1194 1136 1018

1192 50 1172 51 1141 52 1094 54 1046 57 973 904 793

981 61 962 62 943 63 917 65 888 67 830 764 665

750 79 730 81 714 83 692 86 657 90 620 570 502

2069 29 1965 30 1871 32 1756 34 1661 36 1549 1415 1275

1752 34 1724 34 1667 36 1603 37 1488 40 1402 1290 1082

1437 41 1437 41 1417 42 1369 43 1320 45 1256 1140 984

1184 50 1177 50 1161 51 1132 52 1095 54 1047 928 837

1970 40 1874 42 1757 45 1667 48 1566 51 1431 1334 1182

1713 46 1650 48 1572 50 1510 52 1418 56 1313 1211 1079

1439 55 1412 56 1370 58 1327 60 1260 63 1166 1078 956

1183 67 1155 69 1122 71 1108 72 1062 75 1011 931 816

HIGH 5.0

GCH90905DXA* MED 4.0

(MED-HI) MED-LO 3.5

LOW 3.0

HIGH 5.0

GCH91155DXA* MED 4.0

(MED-HI) MED-LO 3.5

LOW 3.0

1. CFM in chart is without filters(s). Filters do not ship with this furnace, but must be provided by the installer.

2. All furnaces ship as high speed cooling. Installer must adjust blower cooling speed as needed.

3. For most jobs, about 400 CFM per ton when cooling is desirable.

4. INSTALLATION IS TO BE ADJUSTED TO OBTAIN TEMPERATURE RISE WITHIN THE RANGE SPECIFIED ON THE RATING PLATE.

5. The chart is for information only. For satisfactory operation, external static pressure must not exceed value shown on rating plate. The shaded

area indicates ranges in excess of maximum external static pressure allowed when heating. The data for 0.6" w.c. to 0.8" w.c. is shown for

air conditioning purposes only.

6 The dashed (---) areas indicate a temperature rise not recommended for this model.

7. The above chart is for U.S. furnaces installed at 0-4000 feet. At higher altitudes, a properly derated unit will have approximately the same

temperature rise at a particular CFM, while the ESP at that CFM will be lower.

2147 37 2114 37 2057 39 2030 39 1978 40 1889 1784 1713

1675 47 1686 47 1640 48 1623 49 1557 51 1501 1455 1360

1489 53 1470 54 1436 55 1409 56 1361 58 1318 1243 1130

1307 61 1265 63 1234 64 1203 66 1168 68 1096 1053 991

2134 46 2103 47 2029 48 1941 51 1906 51 1818 1733 1625

1678 58 1643 60 1643 60 1577 62 1527 64 1489 1423 1339

1453 68 1440 68 1426 69 1363 72 1349 73 1314 1253 1205

1259 78 1239 79 1220 80 1181 83 1159 85 1118 1082 1015

13

Page 14

BLOWER PERFORMANCE SPECIFICATIONS

÷ CFM

130 140 150

FORMULAS

BTU OUTPUT = CFM x 1.08 x RISE

1.08

BTU OUTPUT

RISE =

100

2400 CFM

2200

2000

1800

1600

1400

1200

1100

1000

900

800

OUTPUT BTU/HR x 10 0 0

14

BTU OUTPUT vs TEMPERATURE RISE CHART

600 CFM

700

30 40 50 60 70 80 90 110 120

100

90

80

70

60

50

40

30

20

10

TEMPERATURE RISE

Page 15

WIRING DIAGRAMS

2

A

4

V

C

H

I

U

F

I

E

M

I

D

R

2

4

C

V

A

C

A

V

1

1

S

N

E

1

A

OMP

OMP

B

E

R

I

S

S

S

S

S

S

S

S

I

O

O

N

E

K

F

5

T

A

T

S

G

R

C

W

Y

K

B

F

S

U

E

A

R

D

T

E

G

E

T

I

N

L

O

R

T

N

C

O

L

E

U

O

D

M

ON

OFF

2ND

STAGE

DELAY

*

MODE

*

HEAT

OFF

DELAY

F

C

A

T

S

H

W

O

G

S

A

N

I

O

D

5

1

V

H

C

A

C

H

-

O

L

O

H

W

*

S

O

E

G

T

R

S

N

T

Y

I

N

C

I

T

*

T

A

O

N

D

K

B

L

B

O

R

D

R

H

S

N

SEE

NOTE 6

A

P

A

E

E

O

H

(

(

M

M

(

L

(

XFMR-H

E

S

T

R

A

I

N

M

R

L

K

-

H

T

N

L

E

I

E

E

T

4

I

)

)

D

E

)

D

W

L

E

O

)

W

O

R

T

I

C

O

P

A

T

T

E

N

M

R

A

M

T

T

E

N

R

A

D

N

G

B

K

H

W

U

D

E

D

I

N

C

D

F

A

R

E

R

W

B

L

O

Y

N

O

R

E

W

L

O

S

S

E

R

U

T

I

C

H

U

C

I

T

R

O

N

T

E

C

E

A

C

F

E

R

T

O

N

N

Y

= C

H

=

H

E

= P

S

R

H

E

P

S

R

H

E

P

= O

S

L

F

H

E

S

H

E

=

S

H

E

O

= L

S

H

E

= C

S

H

O

U

U

N

S

R

/

S

E

:

D

W

G

E

E

L

N

9

2

5

0

0

L

C

V

C

2

A

4

H

M

D

I

R

U

F

I

E

I

1

M

P

G

2

C

=

O

R

N

O

=

E

E

=

E

M

A

W

E

A

P

P

B

W

B

G

R

R

B

3

I

H

A

S

G

L

A

R

M

A

E

O

P

L

U

I

F

A

T

R

L

O

E

U

S

R

S

S

W

I

T

T

S

W

I

S

U

S

R

E

N

I

M

I

H

L

T

I

G

H

S

W

N

E

S

E

E

I

F

S

L

G

A

E

M

K

I

C

G

N

R

I

E

T

L

F

A

H

E

S

D

I

S

K

I

P

N

K

R

W

O

B

N

R

H

T

W

I

H

E

U

L

L

E

B

G

Y

R

Y

A

D

E

R

D

.

V

E

A

4

2

O

H

R

V

T

E

M

N

O

C

N

E

C

T

O

I

D

L

D

G

N

B

R

R

B

C

R

E

W

L

O

B

C

R

B

U

E

R

N

C

D

R

R

O

H

W

I

D

P

R

S

W

I

2 C

N

C

O

H

T

O

R

U

S

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT . FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

N

I

G

0

E

D

T

A

S

F

O

F

1

A

L

1 F

A

L

2 F

2

3 F

A

L

3

4

A

4 F

L

5

L

5 F

A

A

6 F

L

6

A

7 F

L

7

8

A

8 F

L

C

C

T

O

N

C

O

L

R

O

C

L

L

E

L

Y

Y

O

R

O

R

A

U

P

P

P

U

R

G

N

G

R

E

K

B

B

L

C

A

4

0

0

1

GCH9*****X[AA,AB]

B

O

R

L

W

O

R

Y

G

H

W

O

R

1

3

2

K

P

4

5

6

9

2

1

Y

G

O

R

FS

2

1

H

-

R

D

K

B

M

A

(

(

T

C

Y

R

L

A

V

V

E

O

N

I

T

R

E

T

U

S

C

H

T

C

U

S

H

H

T

O

U

I

T

L

N

A

=

O

I

R

R

P

M

E

R

V

R

E

T

N

O

E

1

.

S

T

E

2

.

N

M

A

3

.

F

I

A

H

V

A

F

4

I

H

.

B

O

L

5

U

I

N

.

6. TO RECALL THE LAST 5 FAULTS, MOST RECEN T TO LEAST RECENT, DEPRESS SWITCH FOR MORE THAN 2 SECONDS WHILE IN

STANDBY

R

O

8

7

B

1

1

Y

L

0

1

R

O

B

D

R

Y

G

TERMINALS

115 VAC NE UTR AL

H

W

K

B

K

P

Y

L

S

E

R

T

E

N

A

A

U

L

U

L

I

I

I

X

T

M

L

I

R

A

Y

)

1

W

O

I

U

F

N

P

L

E

B

D

W

E

L

O

R

)

2

I

C

'

F

N

L

O

W

O

R

B

H

W

E

L

O

H

W

H

W

U

P

L

B

O

R

P

K

F

N

R

O

P

R

E

S

N

O

G

D

N

R

O

D

E

S

L

C

O

C

K

K

C

E

N

O

P

E

V

L

A

G

V

A

S

G

R

U

O

O

P

R

E

1

1

V

C

5

A

E

S

D

:

S

E

H

A

T

A

C

N

I

T

P

I

A

S

U

S

'

F

A

T

R

R

C

U

E

A

O

T

O

I

Y

E

F

R

N

H

G

G

N

I

T

E

M

A

P

E

R

T

O

N

N

A

C

A

D

I

G

E

T

E

D

E

L

A

R

W

S

U

S

M

E

T

S

M

B

P

R

U

T

E

M

(NO THERMOST AT INPUTS)

L

O

R

W

P

S

K

C

S

U

T

S

N

D

T

O

P

E

N

I

A

U

O

L

T

A

N

G

G

R

R

PK

H

WH

BL

WH

OR

U

I

G

N

D

R

V

C

E

O

R

I

W

T

S

E

R

U

H

C

Y

G

R

G

N

I

G

R

O

I

A

L

P

T

Y

O

R

T

E

M

N

O

H

R

O

C

F

I

E

I

R

P

D

A

E

L

C

E

S

U

W

A

S

P

R

I

P

E

L

F

R

O

A

N

A

T

I

R

G

T

E

L

P

W

N

E

B

S

I

B

E

E

O

G

R

L

P

O

"

A

N

E

C

D

E

G

U

D

R

N

L

N

O

T

Y

E

C

P

R

O

M

M

A

T

E

T

N

D

W

R

O

I

S

O

C

T

H

(

P

N

E

W

O

E

H

N

R

O

O

E

)

O

D

P

N

C

BK

24V THERMOSTAT CONNECTIONS

BK

G

T

O

Y

M

C

I

Y

GR

RD

YL

OR

GY

OR

R

W

R

3

T

(

H

X

M

F

R

INTEGRATED CONTRO L MODULE

BR

L

N

I

E

O

O

D

W

I

S

O

T

O

J

U

O

N

N

T

C

L

B

L

F

A

E

N

S

L

O

L

O

W

H

H

I

G

N

E

T

P

M

O

R

S

N

M

E

T

D

L

E

I

L

A

E

S

E

S

D

A

P

R

K

"

A

D

N

E

M

P

A

0

A

7

T

T

.

T

A

U

T

A

T

S

P

M

B

R

S

H

W

T

F

E

R

T

I

U

N

H

C

°

U

C

E

.

S

1

5

T

0

H

T

A

N

T

S

E

E

O

R

E

M

N

T

O

I

R

F

L

A

S

O

N

C

T

D

F

O

R

M

O

I

X

O

B

H

W

B

K

M

E

O

S

W

V

V

I

I

V

R

A

L

U

G

S

.

U

E

C

A

P

O

P

A

M

E

N

I

T

N

.

R

V

(

2

O

L

T

A

G

E

E

G

A

O

T

L

F

E

I

1

O

1

T

L

A

5

(

G

E

E

G

A

O

T

L

I

E

F

I

T

U

C

N

J

R

I

M

E

T

N

E

I

T

R

N

N

L

A

O

C

N

D

E

T

T

R

C

N

O

N

I

T

C

E

E

E

W

S

H

N

S

D

E

R

U

T

S

M

B

R

P

E

E

E

E

L

D

O

N

U

T

C

E

C

R

O

S

A

I

C

R

D

J

,

M

D

U

E

R

T

C

D

A

G

T

O

E

N

N

.

A

L

D

.

A

O

C

C

L

H

M

I

D

I

R

U

F

I

E

R

6

(

T

)

D

G

8

(

N

)

V

)

C

M

9

(

H

M

1

(

)

V

2

M

L

)

2

V

(

N

R

F

T

O

R

S

P

E

S

S

P

1

(

)

0

4

P

(

O

)

S

O

(

H

)

I

7

L

L

H

1

O

(

)

1

(

)

O

1

2

R

O

5

1

R

(

)

)

H

-

S

F

N

G

I

I

D

N

H

E

A

COOL-H

I

H

A

E

H

E

H

A

-

C

-

H

R

T

H

C

Ø

/

C

A

1

1

1

V

5

V

R

E

C

U

E

R

R

N

D

G

C

O

N

O

C

V

R

E

S

W

T

H

I

C

R

U

E

2

4

V

C

A

A

1

V

C

1

5

F

E

A

L

M

S

N

O

E

S

S

R

T

A

H

E

U

F

O

C

I

N

T

R

I

G

E

D

I

R

L

B

W

L

O

T

-

H

C

R

U

A

I

O

C

L

T

R

R

L

B

W

H

-

T

E

E

L

C

N

R

C

T

I

O

A

R

I

A

C

E

N

R

L

E

O

B

J

N

O

U

C

I

N

T

D

N

G

L

O

W

/

H

P

Z

6

0

C

R

E

O

P

T

T

N

4

V

)

L

D

)

V

L

D

O

N

A

L

O

T

O

L

O

N

V

G

C

I

.

N

I

T

I

M

A

U

C

D

E

,

N

Y

L

O

R

.

S

E

B

F

R

P

E

O

R

E

A

O

T

P

R

O

L

R

C

O

E

.

D

S

E

Q

U

F

W

S

W

I

S

T

O

V

E

P

R

E

S

B

R

W

P

A

E

T

E

L

C

D

C

B

O

N

O

C

L

I

G

N

E

T

N

E

D

.

T

N

E

R

T

I

D

A

G

E

T

O

N

C

L

R

L

D

M

O

U

O

E

C

A

G

S

H

I

V

A

V

L

E

M

P

D

I

B

O

R

L

W

E

P

E

S

R

S

U

E

R

S

C

W

T

H

I

N

O

C

0

4

A

V

R

N

F

R

T

A

S

M

R

O

E

R

INTEGRATED CONT ROL MODULE

LINE NEUTRALS

X

C

D

S

N

O

C

I

N

E

T

N

R

P

E

P

U

S

N

O

I

T

V

E

D

H

Y

T

I

L

W

I

C

E

N

D

G

N

L

T

N

E

M

G

N

P

I

I

T

C

R

O

W

D

D

F

G

I

N

D

L

E

P

S

L

I

L

D

E

C

H

T

(

E

M

I

G

N

I

E

T

S

E

R

P

(

H

C

U

R

R

N

E

D

V

C

E

I

.

T

I

H

G

W

R

T

I

N

I

E

L

A

S

R

D

.

E

E

I

C

.

P

)

R

.

S

)

T

E

T

M

R

A

A

E

I

L

U

U

E

N

S

D

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

15

Page 16

WIRING DIAGRAMS

A

A

(

)

)

)

A

GCH9*****XAC

OR

GY

40 VA

TRANSFORMER

WH

BK

OR

1

3

2

PU

4

65

98

121110

*

*

*

GY

OR

FS

XFMR-H

LINE-H

RD

OR

7

BL

GR

YL

OR

OR

BR

RD

GY

TERMINALS

115 VAC NEUTRAL

WH

2

1

WH

BK

GY

PK

WH

BK

YL

WH

24V THERMOSTAT

CONNECTIONS

DIAGNOSTIC

LED

GND

BR

BR

24 VAC

HUMIDIFIER

24 VAC

115 VAC

R

CG W

*

115 VAC HOT AN D PARK TERMINALS

COOL-H

Y

FUSE

INTEGRATED

CONTROL

MODULE

ON

OFF

2ND

STAGE

DELAY

MODE

HEAT

OFF

DELAY

FACTORY SETTINGS

SHOWN

SEE

NOTE 6

HEAT-H

SEE

NOTE 4

WH

BK (HI)

BL (MED)

OR (MED LOW)

RD (LOW)

CIRCULATOR

BLOWER

CAPACITOR

GY

BLOWER COMPARTMENT

PU

BURNER COMPARTMENT

GND

BK

OR

PK

C

WH

WH

PU

BL

FRONT COVER

PRESSURE SWITCH

N

O

GND

BR

RD

(HONEYWELL)

WH

INDUCED DRAFT

BLOWER

AUTO RESET

PRIMARY LIMIT

CONTROL

RD

OR

N

O

WH

ID BLOWER

PRESSURE

SWITCH

2 CIRCUIT

CONNECTOR

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT . FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

HOT

SURFACE

IGNITER

0

STEADY ON = NORMAL OPERATION

YL

C

MANUAL RESET ROLLOUT LIMIT CONTROL(S)

( SINGLE CONTROL ON 45K BTU )

24 VAC

HUMIDIFIER

1

PM

GY

2

C

OR

3

HI

GAS VALVE

OFF = CONTROL FAILURE

1

1 FLASH =

2 FLASHES = PRESSURE SWITCH STUCK CLOSED

2

3

3 FLASHES = PRESSURE SWITCH STUCK OPEN

4

4 FLASHES = OPEN HIGH LIMIT

5

5 FLASHES = FLAME SENSE WITHOUT GAS VALVE

6

6 FLASHES =

7 FLASHES = LOW FLAME SIGNAL

7

8

8 FLASHES = CHECK IGNITER OR IMPROPER GROUNDING

C

CONTINUOUS/RAPID FLASHES = REVERSED 115 VAC POLARITY

COLOR CODES:

YL YELLOW

OR ORANGE

PU PURPLE

GN GREEN

BK BLACK

0140F00647 REV. B

SYSTEM LOCKOUT (RETRIES EXCEEDED)

OPEN ROLLOUT OR OPEN FUSE

PK PINK

BR BROWN

WH WHITE

BL BLUE

GY GRAY

RD RED

NOTES:

1. SET HEAT ANTICIPATOR ON ROOM THERMOSTAT AT 0.7 AMPS.

2. MANUFACTURER'S SPECIFIED REPLACEMENT P ARTS MUST BE USED WHEN SERVICING.

3. IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE FURNACE MUST BE REPLACED, IT MUST BE REPLACED WITH WIRING MA TERIAL

HAVING A TEMPERATURE RA TING OF AT LEAST 105

4. IF HEATING AND COOLING BLOWER SPEEDS ARE NOT THE SAME, DISCARD JUMPER BEFORE CONNECTING BLOWER LEADS. UNUSED

BLOWER LEADS MUST BE PLACED ON "PARK" TERMINALS OF INTEGRATED CONTROL OR T APED.

5. UNIT MUST BE PERMANENTLY GROUNDED AND CONFORM TO N.E.C. AND LOCAL CODES.

6. TO RECALL THE LAST 5 FAULTS, MOST RECENT TO LEAST RECENT, DEPRESS SWITCH FO R MORE THAN 2 SECONDS WHILE IN

STANDBY (NO THERMOSTAT INPUTS)

BLOWER

COMPARTMENT

DOOR SWITCH

(OPEN WHEN

DOOR OPEN)

C

BK

24V THERMOSTAT CONNECTIONS

BK

G

TO

Y

GY

PU

GY

MICRO

W

R

TH (3)

XFMR-H

INTEGRATED CONTROL MODULE

GR

YL

RD

OR

BL

OR

BR

OR

LINE-H

DOOR

SWITCH

WARNING:

DISCONNECT POWER

BEFORE SERVICING.

WIRING TO UNIT

MUST BE

PROPERLY

POLARIZED

AND GROUNDED.

TO 115VAC/ 1

OVERCURRENT PROTECTION DEVICE

JUNCTION

BL

BOX

GY

WH

GR

FLAME

SENSOR

BK

LOW VOLTAGE (24V)

LOW VOLTAGE FIELD

HI VOLTAGE (115V)

HI VOLTAGE FIELD

JUNCTION

TERMINAL

INTERNAL TO

INTEGRATED CONTROL

PLUG CONNECTION

°C. USE COPPER CONDUCTORS ONLY .

HUMIDIFIER

TR (6)

GND (8)

MVC (9)

MVH (12)

UXILIARY LIMIT CONTROLS

MVL(2)

PS (10

PSO (4

HLI (7)

HLO (1)

UTO RESET PRIMARY

LIMIT CONTROL

RO2 (11)

RO1 (5)

MANUAL RESET ROLLOUT

LIMIT CONTROL(S)

SINGLE CONTROL ON 45K BTU

24 VAC

115 VAC

FLAME SENSOR

FS

HOT SURFACE

IGN

IND

EAC-H

IGNITER

ID

BLWR

L

O

H

E

A

T

-

H

COOL-H

CIRCULATOR

BLWR

I

H

H

-

T

A

E

H

ELECTRONIC

IR CLEANER

JUNCTION BOX

GND

LN

Ø /60 HZ POWER SUPPLY WITH

WARNING:DISCONNECT POWER BEFORE

SERVICING.WIRING TO UNIT MUST BE

PROPERLY POLARIZED AND GROUNDED.

DISCONNECT

INTEGRATED

CONTROL MODULE

GND

NO

FRONT COVER

PRESSURE SWITCH

C

40 VA

TRANSFORMER

DISCONNECT

N

GND

L

EQUIPMENT GND

FIELD GND

FIELD SPLICE

SWITCH (TEMP.)

IGNITER

SWITCH (PRESS.)

OVERCURRENT

PROT. DEVICE

C

HI

VALVE

PM

ID BLOWER

PRESSURE

SWITCH

GAS

C

NO

INTEGRATED CONTROL MODULE

LINE NEUTRALS

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

16

Loading...

Loading...