Goodman GPH1424H41C, GPH1424H41D, GPH1430H41C, GPH1430H41D, GPH1436H41C User Manual

...

Service Instructions

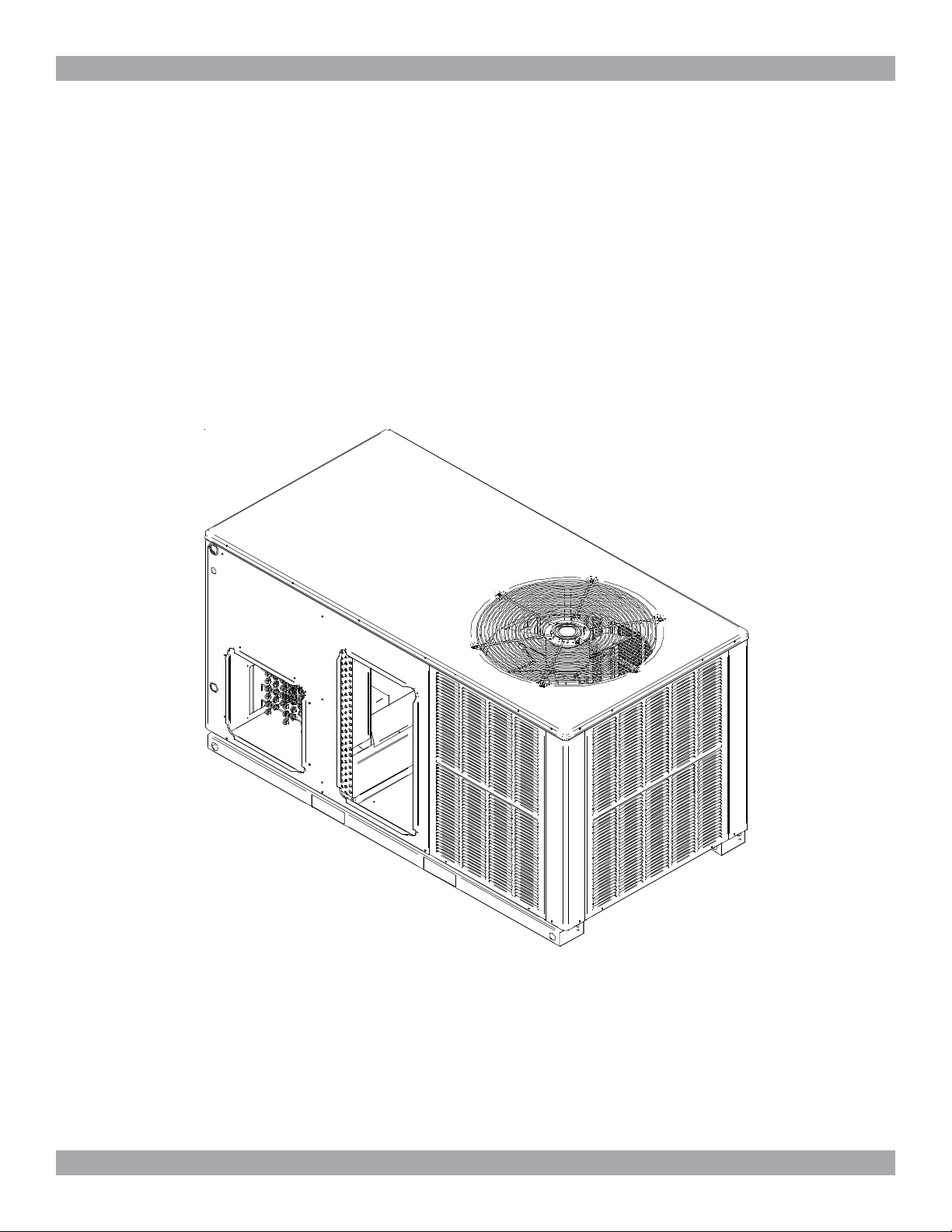

*PH 14 PACKAGE HEAT PUMPS

*PC 14 PACKAGE COOLING

HORIZONTAL MODELS

WITH R-410A

This manual is to be used by qualified, professionally trained HVAC technicians only.

Goodman does not assume any responsibility for property damage or personal injury

due to improper service procedures or services performed by an unqualified person.

©2008 - 2014 Goodman Manufacturing Company, L.P.

RS6300014

September 2014

1

INDEX

IMPORTANT INFORMATION ......................................................................................................... 4 - 5

PRODUCT IDENTIFICATION - *PC/*PH14**H41** ...................................................................... 6 - 8

ACCESSORIES ................................................................................................................................... 9

PCCP101-103 ROOF CURB ........................................................................................................................................ 10

PCP101-103 DOWNFLOW PLENUM .......................................................................................................................... 10

PCEF101-103 ELBOW AND FLASHING KIT ................................................................................................................11

PCE101-103 ECONOMIZER .......................................................................................................................................... 11

PCMD101-103 DOWNFLOW MANUAL DAMPER ....................................................................................................... 12

GPHMD101-103 HORIZONTAL MOTORIZED DAMPER WITH DUCT FLANGE ........................................................... 12

SQRPC SQUARE TO ROUND CONVERTER ............................................................................................................... 13

SQRPCH SQUARE TO ROUND CONVERTER ............................................................................................................ 13

PCFR101-103 EXTERNAL FILTER KIT ....................................................................................................................... 14

PRODUCT DESIGN .......................................................................................................................... 15

ELECTRICAL WIRING ................................................................................................................................................. 16

LINE VOLTAGE WIRING .............................................................................................................................................. 17

SYSTEM OPERATION ...................................................................................................................... 18

*PC/*PH14**H41**

COOLING .................................................................................................................................................................... 18

COOLING CYCLE ........................................................................................................................................................ 18

HEATING CYCLE ......................................................................................................................................................... 18

DEFROST CYCLE ....................................................................................................................................................... 19

FAN OPERATION ........................................................................................................................................................ 19

SCHEDULED MAINTENANCE......................................................................................................... 22

ONCE A MONTH ......................................................................................................................................................... 22

ONCE A YEAR ............................................................................................................................................................. 22

TEST EQUIPMENT ...................................................................................................................................................... 22

SERVICING ....................................................................................................................................... 23

COOLING/HEAT PUMP- SERVICE ANALYSIS GUIDE ................................................................................................ 23

S-1 CHECKING VOLTAGE ........................................................................................................................................... 24

S-2 CHECKING WIRING .............................................................................................................................................. 24

S-3 CHECKING THERMOSTAT, WIRING, AND ANTICIPATOR .................................................................................... 24

S-3A Thermostat and Wiring ..................................................................................................................................... 24

S-3B Cooling Anticipator ........................................................................................................................................... 25

S-3C Heating Anticipator ........................................................................................................................................... 25

S-4 CHECKING TRANSFORMER AND CONTROL CIRCUIT ....................................................................................... 25

S-7 CHECKING CONTACTOR AND/OR RELAYS ........................................................................................................ 25

S-8 CHECKING CONTACTOR CONTACTS .................................................................................................................. 26

S-11 CHECKING LOSS OF CHARGE PROTECTOR ................................................................................................... 27

S-15 CHECKING CAPACITOR ..................................................................................................................................... 27

S-15A RESISTANCE CHECK ....................................................................................................................................... 28

S-15B CAPACITANCE CHECK ..................................................................................................................................... 28

S-16 CHECKING MOTORS .......................................................................................................................................... 29

S-16A CHECKING FAN AND BLOWER MOTOR WINDINGS (PSC MOTORS) ............................................................ 29

S-16D CHECKING EEM MOTORS ............................................................................................................................... 29

S-17 CHECKING COMPRESSOR WINDINGS ............................................................................................................. 30

S-17A RESISTANCE TEST .......................................................................................................................................... 30

S-17B GROUND TEST ................................................................................................................................................. 30

S-17D Operation Test ................................................................................................................................................. 31

2

INDEX

S-18 TESTING CRANKCASE HEATER ........................................................................................................................ 31

S-18A CHECKING CRANKCASE HEATER THERMOSTAT ........................................................................................... 31

S-21 CHECKING REVERSING VALVE AND SOLENOID .............................................................................................. 31

S-24 TESTING DEFROST CONTROL .......................................................................................................................... 32

S-25 TESTING DEFROST THERMOSTAT .................................................................................................................... 32

S-50 CHECKING HEATER LIMIT CONTROL(S) ........................................................................................................... 32

S-52 CHECKING HEATER ELEMENTS ........................................................................................................................ 32

S-100 REFRIGERATION REPAIR PRACTICE ............................................................................................................... 33

S-101 LEAK TESTING ................................................................................................................................................. 33

S-102 EVACUATION ..................................................................................................................................................... 33

S-103 CHARGING ........................................................................................................................................................ 34

S-104 CHECKING COMPRESSOR EFFICIENCY ......................................................................................................... 35

S-108 SUPERHEAT ...................................................................................................................................................... 35

S-109 CHECKING SUBCOOLING ................................................................................................................................36

S-111 FIXED ORIFICE RESTRICTION DEVICES ......................................................................................................... 36

S-112 CHECKING RESTRICTED LIQUID LINE ............................................................................................................ 37

S-113 REFRIGERANT OVERCHARGE ......................................................................................................................... 37

S-114 NON-CONDENSABLES ...................................................................................................................................... 37

S-115 COMPRESSOR BURNOUT ................................................................................................................................40

S-122 REVERSING VALVE REPLACEMENT ................................................................................................................ 40

S-200 CHECKING EXTERNAL STATIC PRESSURE .................................................................................................... 41

S-201 CHECKING TEMPERATURE RISE ..................................................................................................................... 41

WIRING DIAGRAMS .......................................................................................................................... 42

OT18-60A OUTDOOR THERMOSTAT ......................................................................................................................... 42

OT18-60A OUTDOOR THERMOSTAT ......................................................................................................................... 43

SINGLE PHASE HKR/P** HEAT KITS......................................................................................................................... 44

PCE* ECONOMIZER .................................................................................................................................................... 45

SPK* - SINGLE POINT WIRING KIT ......................................................................................................................... 46

3

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE

SERVICE MANUAL BEFORE BEGINNING REPAIRS.

IMPORTANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

WARNING

THI S UNIT SHOULD NOT BE CONNECTED TO. OR USED IN CONJUNCTION WITH, ANY DEVICES THAT ARE NOT DESIGN CERTIFI ED FOR USE WITH THIS UNIT OR HAVE NOT BEEN

TESTED AND APPROVED BY

FROM THE USE OF DEVICES THAT HAVE NOT BEEN APPROVED OR CERTIF ED BY

OODMAN. SERIOUS PROPERTY DAMAGE OR PERSONAL INJURY, REDUCED UNIT PERFORMANCE AND/OR HAZARDOUS CONDITIONS MAY RESULT

G

OODMAN.

G

WARNING

O PREVENT THE RISK OF PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH,

T

DO NOT STORE COMBUSTIBLE MATERIALS OR USE GASOLINE OR OTHER

FLAMMABLE LIQUIDS OR VAPORS IN THE VICINITY OF THIS APPLIANCE.

WARNING

OODMA N WILL NO T BE R ESPONSIBLE FOR AN Y INJURY O R PROPERTY DAM AGE ARI SING FROM IMPROPER SERVICE OR SERVIC E PROCED URES.

G

IF YOU INSTALL OR PERFORM SERVICE ON THIS UNIT, YOU ASSUME RE SPONSIBILITY FOR A NY PERSONA L INJURY OR P ROPERTY DAM AGE WHICH

MAY RESULT.

ANY JURISDICTIONS REQUIRE A LICENSE TO INSTALL OR SERVICE HEATING AND AIR CONDITIONING EQUIPMENT.

M

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

CONSUMER INFORMATION LINE

GOODMAN® BRAND PRODUCTS

TOLL FREE 1-877-254-4729 (U.S. only)

email us at: customerservice@goodmanmfg.com

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-713-861-2500

(Not a technical assistance line for dealers.)

Your telephone company will bill you for the call.

4

IMPORTANT INFORMATION

SAFE REFRIGERANT HANDLING

While these items will not cover every conceivable situation, they should serve as a useful guide.

WARNING

EFRIGERANTS ARE HEAVIER THAN AIR. THEY CAN "PUSH OUT" THE

R

OXYGEN IN YOUR LUNGS OR IN ANY ENCLOSED SPACE.

POSSIBL E DIFF ICULTY IN BREAT HING O R DEATH:

EVER PURGE REFR IGERANT INTO AN ENCLOSED ROO M OR SPACE . BY

•

N

LAW, ALL REF RIGERANTS MUST BE RECLAIMED.

F AN INDOOR LEAK IS SUSPECTED, THOROUGHLY VENTILATE THE AREA

•

I

BEFORE BEGINNING WORK.

•

IQUID REFRIGERANT CAN BE VE RY COLD. TO AVOID POSSIBLE FROST-

L

BITE OR BLINDNESS, AVOID CONTACT WITH REFRIGERANT AND WEAR

GLOVES AND GOGGLES.

SKIN OR E YES, SEEK M EDICAL HELP IMMEDI ATELY.

•

ALWAYS FOLLOW EPA REG ULATIO NS. NEVER BURN REFRIGE RANT,

AS POISON OUS GAS WI LL BE PRODUC ED.

F LIQUID REFRIGERANT DOES CONTACT YOUR

I

O AVO ID

T

WARNING

TO AVOID POSSIBLE EXPLOSION:

• NEVER APPLY FLAME OR STEAM TO A REFRIGERANT CYLINDER. IF YOU

MUST HEAT A CYLINDE R FOR FASTER CHARGING, PARTI ALLY IMMERSE

IT IN WARM WATER.

• NEVER FILL A CYLINDER MORE THAN 80% FULL OF LIQUID REFRIGERANT.

• NEVER ADD ANYTHING OTHER T HAN R-22 TO AN R-22 CYLINDER OR

R-410A TO AN R-410A CYLINDER. THE SERVICE EQUIPMENT USED MUST

BE LISTED OR CERTIF IED FOR THE TYPE OF REFRIGERANT US ED.

• STORE CYLINDERS IN A CO OL, DRY PLACE. NEVER USE A CYLIND ER

AS A PLATFORM OR A ROLLER.

WARNING

O AVOI D POSSI BLE EX PLOSION, USE ONLY RETURNABLE (NOT DISPOSABL E)

T

SERVICE CYLINDERS WHEN REMOVING REFRIGERANT FROM A SYSTEM.

•

NSURE THE CYLIND ER IS FREE O F DAMAGE WHICH COULD LEAD TO A

E

LEAK OR EXPLOSION.

•

NSURE THE HYDROSTA TIC TEST DATE DOES NOT EXCEE D 5 YEARS .

E

•

NSURE THE PRESSURE RATING MEETS OR EXCEEDS 400 LBS.

E

HEN IN DOUBT, DO NOT USE CYLIND ER.

W

WARNING

WARNING

YSTEM CONTAMINANTS, IMPROPER SERVICE PROCEDURE AND/OR PHYSICAL

S

ABUSE AFFECTING HE RMETIC COMPRESSOR ELECTRICAL TERMI NALS MAY

CAUSE DANGEROUS SYSTEM VENTING.

The successful development of hermetically sealed refrigeration compressors has completely sealed the compressor's

moving parts and electric motor inside a common housing,

minimizing refrigerant leaks and the hazards sometimes associated with moving belts, pulleys or couplings.

Fundamental to the design of hermetic compressors is a

method whereby electrical current is transmitted to the compressor motor through terminal conductors which pass

through the compressor housing wall. These terminals are

sealed in a dielectric material which insulates them from the

housing and maintains the pressure tight integrity of the hermetic compressor. The terminals and their dielectric embedment are strongly constructed, but are vulnerable to careless compressor installation or maintenance procedures and

equally vulnerable to internal electrical short circuits caused

by excessive system contaminants.

T

O AVOID POSSIBLE INJURY, EXPLOSION OR DEATH, PRACTICE SAFE

HANDLING OF REFRIGERANTS.

In either of these instances, an electrical short between the

terminal and the compressor housing may result in the loss

of integrity between the terminal and its dielectric embedment. This loss may cause the terminals to be expelled,

thereby venting the vaporous and liquid contents of the compressor housing and system.

A venting compressor terminal normally presents no danger

to anyone, providing the terminal protective cover is properly

in place.

If, however, the terminal protective cover is not properly in

place, a venting terminal may discharge a combination of

(a) hot lubricating oil and refrigerant

(b) flammable mixture (if system is contaminated

with air)

in a stream of spray which may be dangerous to anyone in

the vicinity. Death or serious bodily injury could occur.

Under no circumstances is a hermetic compressor to be electrically energized and/or operated without having the terminal

protective cover properly in place.

See Service Section S-17 for proper servicing.

5

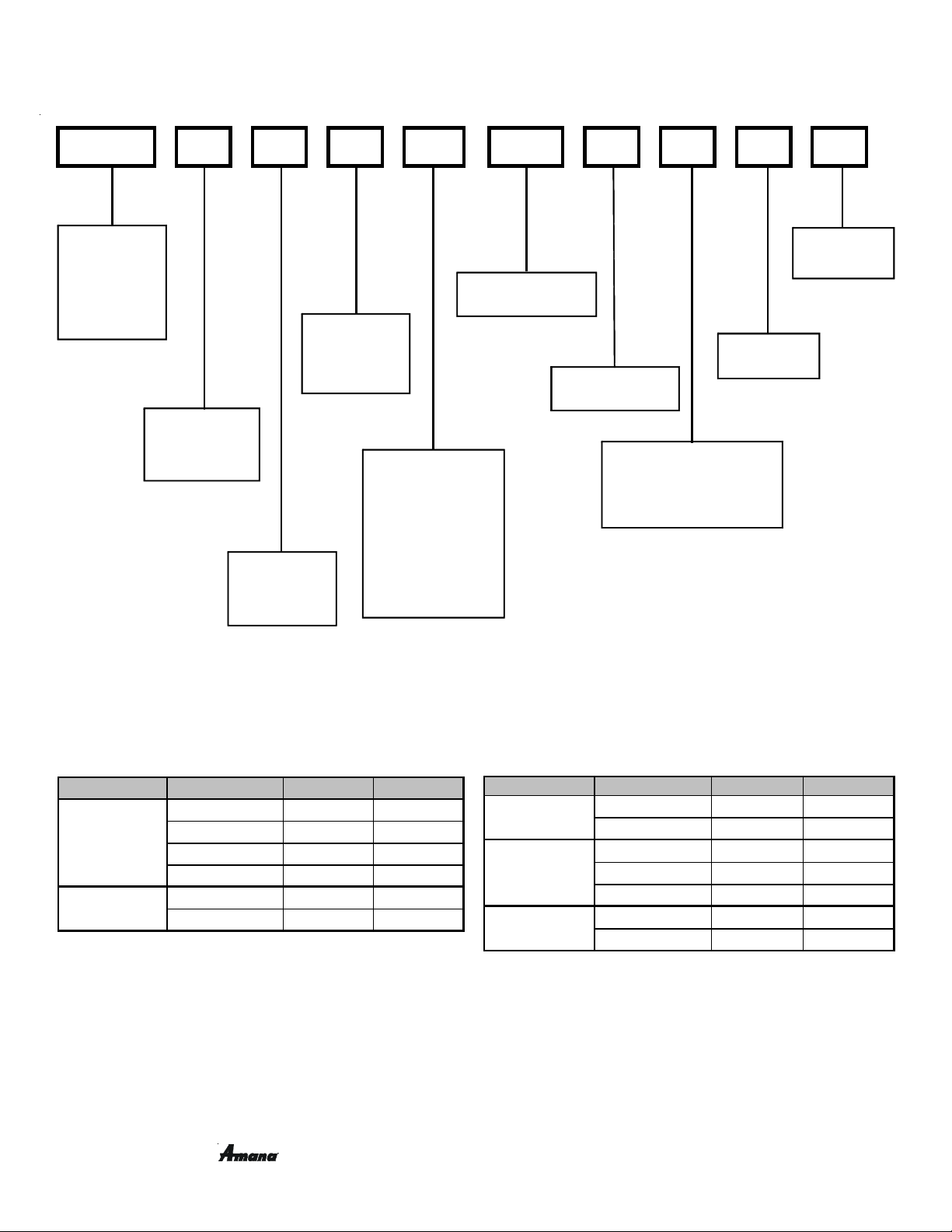

PRODUCT IDENTIFICATION

The model number is used for positive identification of component parts used in manufacturing. Please use this number when

requesting service or parts information.

PC1424 H 4 1 * *G / A

BRAND:

G: Goodman

Brand or

Distinctions

A: Amana

®

Brand

®

PRODUCT

TYPE:

Package

Cooling/Heating

PRODUCT

14: 14 SEER

PRODUCT

FAMILY:

C: Cooling

H: Heat Pump

SERIES:

Rating

CONFIGURATION:

H: Horizontal

NOMINAL

CAPACITY:

24: 24,000 BTUH

30: 30,000 BTUH

36: 36,000 BTUH

42: 42,000 BTUH

48: 48,000 BTUH

49: 48,000 BTUH

60: 60,000 BTUH

MINOR

REVISION:

MAJOR

REVIS ION:

REFRIGERANT:

4: R-410A

VOLTAGE:

1: 208-230V/1ph/60Hz

3: 208-230v/3ph/ 60Hz

4: 460v/3ph/60Hz

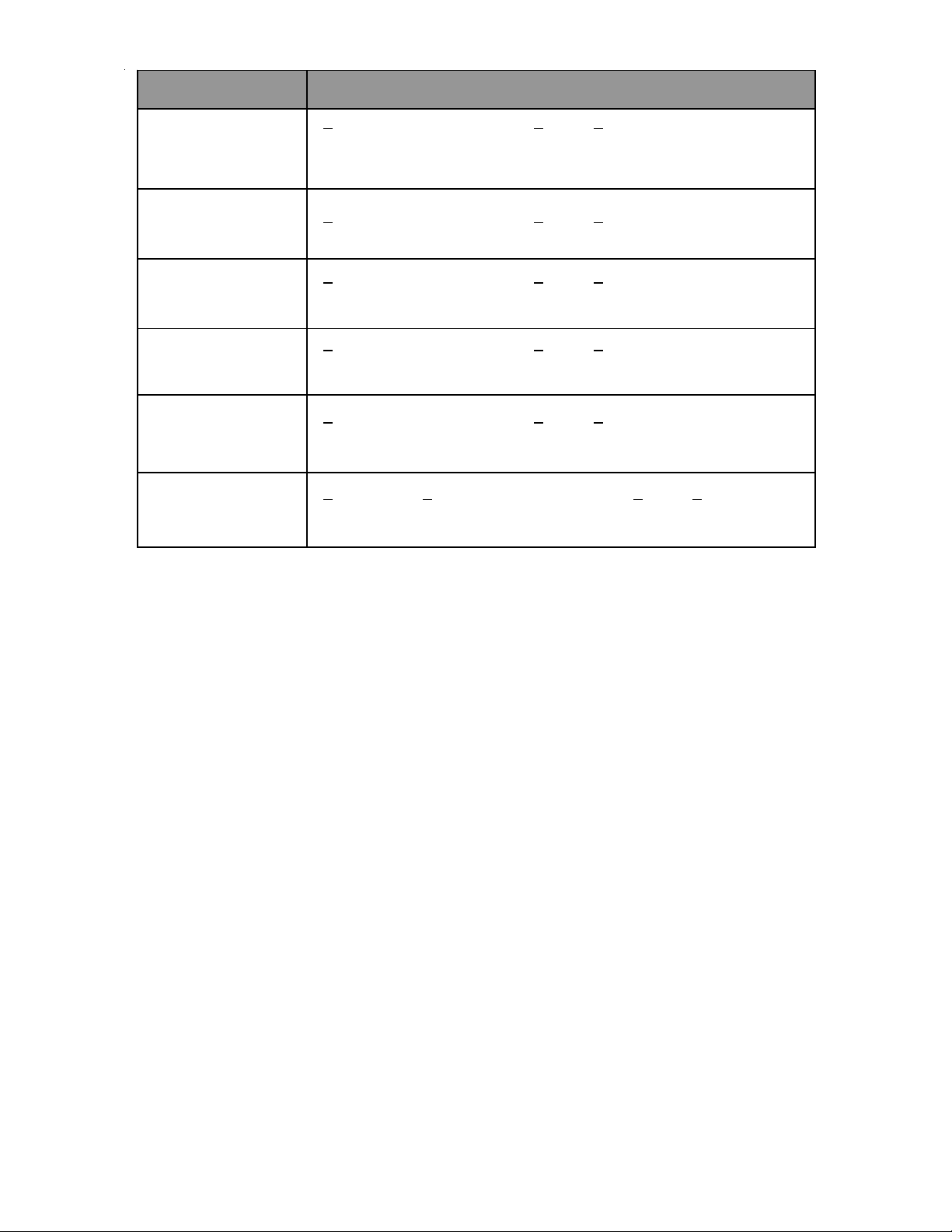

Chassis Model A B

*PC1424 22 30

Small

Medium

Dimensions in inches

*PC1430 22 30

*PC1436 22 30

*PC1442 22 30

*PC1448 24 35

*PC1460 24 35

is a registered trademark of Maytag Corporation or its related entities and is used under license. All rights reserved.

6

Chassis Model A B

Small

Medium

Large

Dimensions in inches

*PH142441** 22.000 29.932

*PH143041** 22.000 29.932

*PH143641** 24.000 34.932

*PH144241** 24.000 34.932

*PH144841B* 24.000 34.932

*PH144841A* 24.000 38.682

*PH146041** 24.000 38.682

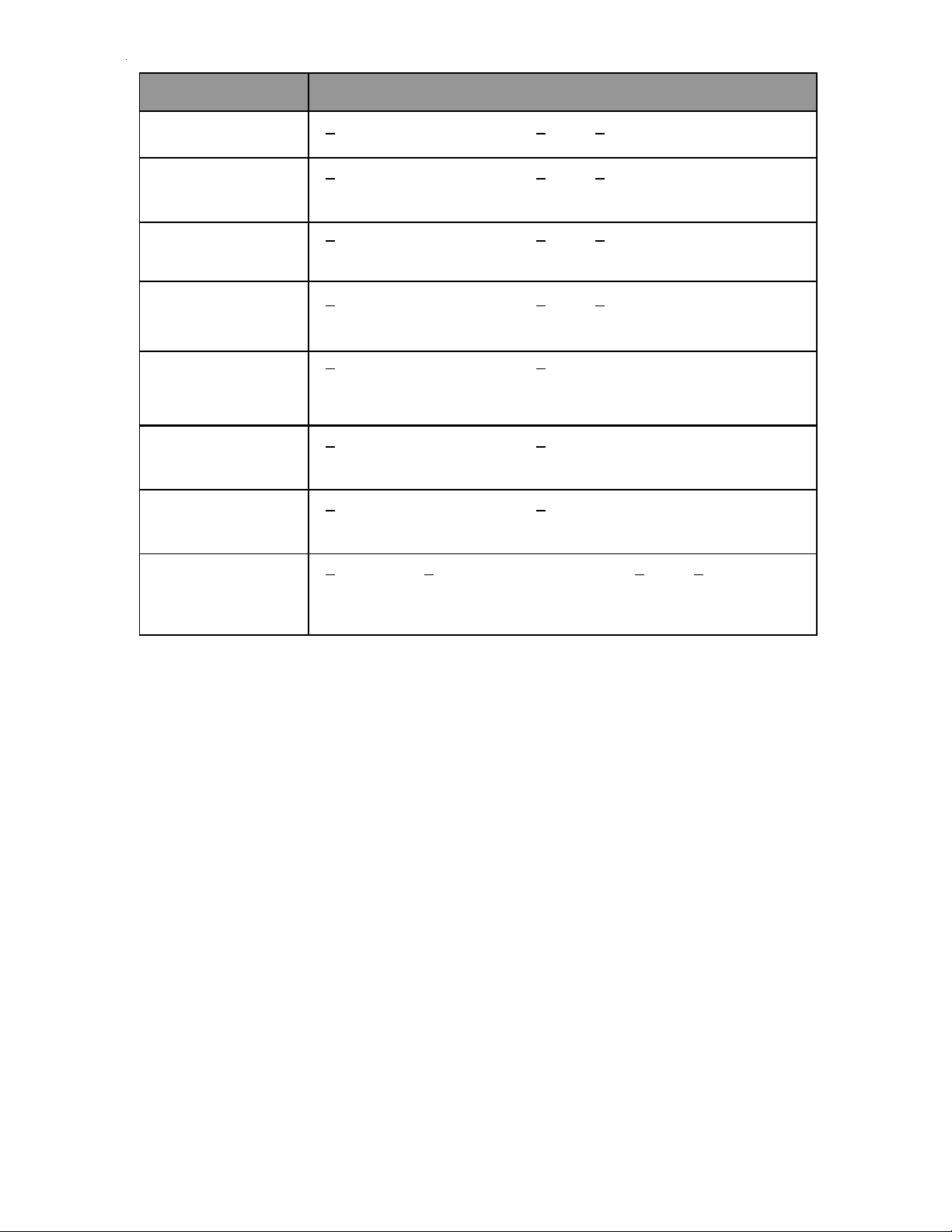

PRODUCT IDENTIFICATION

®

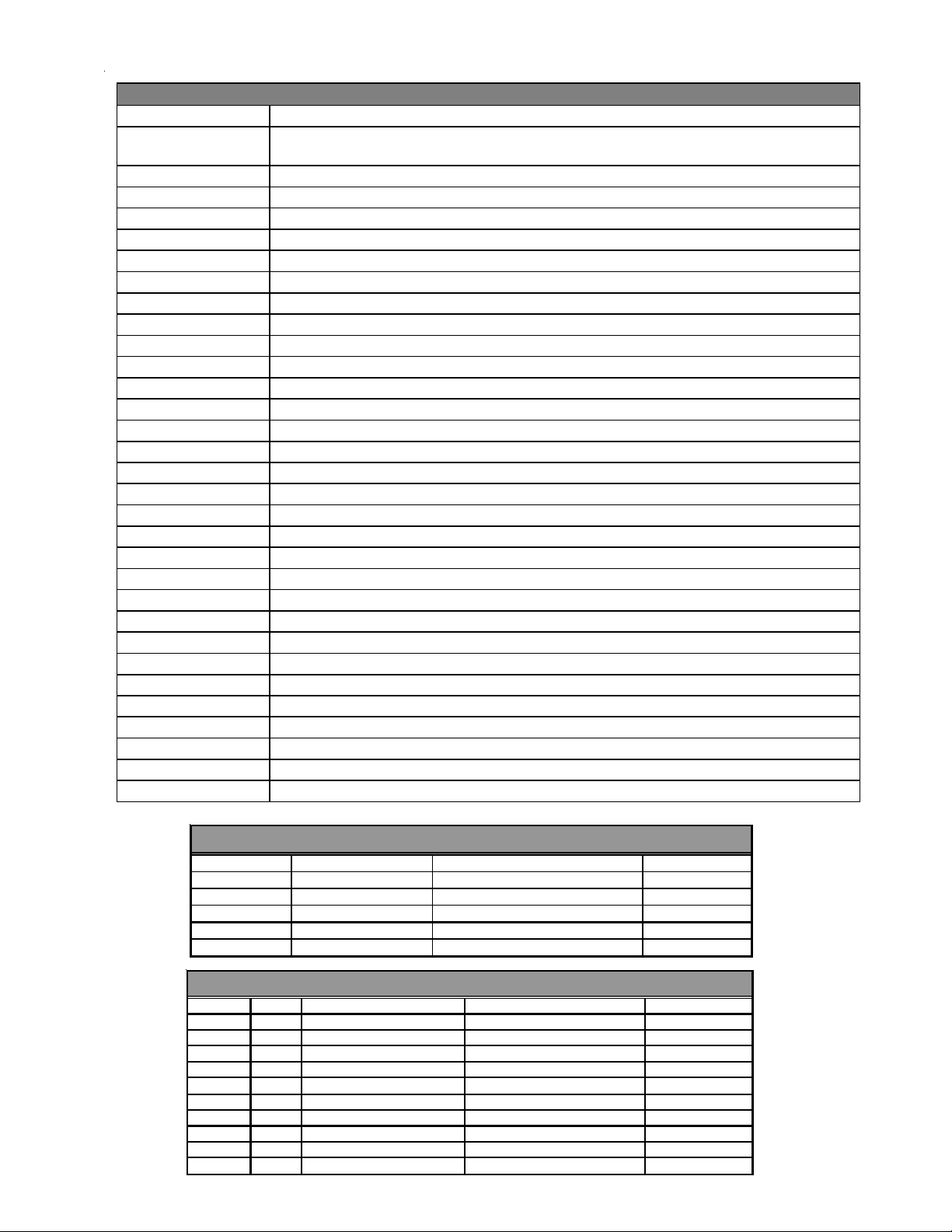

MODEL # PACKAGE COOLING DESCRIPTION

oodman® Brand or Distinctions Package Cooling -

GPC1424-48H41AA

GPC1424-48H41AB

GPC1424-48H41BA

GPC1460H41BA

GPC1424-48H41AC

GPC1460H41AB

GPC1424H41CA

GPC1430-60H41CA

A/GPC1424-60H41DA

G

14 Seer 208-230/1/60 Single-Phase Electric Cooling Unit with R-410A.

oodman® Brand or Distinctions Package Cooling -

G

14 Seer 208-230/1/60 Single-Phase Electric Cooling Unit with R-410A.

Models with 5 mm condenser coils.

oodman® Brand or Distinctions Package Cooling -

G

14 Seer 208-230/1/60 Single-Phase Electric Cooling Unit with R-410A.

Models with aluminum evaporator coils.

oodman® Brand or Distinctions Package Cooling -

G

14 Seer 208-230/1/60 Single-Phase Electric Cooling Unit with R-410A.

Models with 5 mm condenser coils and aluminum evaporator coils.

oodman

G

14 Seer 208-230/1/60 Single-Phase Electric Cooling Unit with R-410A.

Adds "T" to liquid line and re-locates the pressure switch on "H" series

cooling models.

oodman

G

14 Seer 208-230/1/60 Single-Phase Electric Cooling Unit with R-410A. Two

ton models with a Rechi compressor.

oodman

G

14 Seer 208-230/1/60 Single-Phase Electric Cooling Unit with R-410A.

Models with Broad Ocean Digi motor.

mana® Brand/Goodman

A

14 Seer 208-230/1/60 Single-Phase Electric Cooling Unit with R-410A.

Models that change static ratings to be max 0.88 on all E-Heat kits besides

20 kW.

Brand or Distinctions

®

Brand or Distinctions

®

Brand or Distinctions

ackage Cooling -

P

ackage Cooling -

P

ackage Cooling -

P

®

Brand or Distinctions

ackage Cooling -

P

7

PRODUCT IDENTIFICATION

-

MODEL # PACKAGE HEAT PUMP DESCRIPTION

®

Brand or Distinctions

GPH1424-60H41AB

GPH1424-60H41AA

GPH1424-60H41AC

GPH1424-60H41BA

GPH1424-60H41CA

oodman

G

14 Seer 208-230/1/60 Single-Phase Heat Pump with R-410A. Models are

changing to the PCBDM133 defrost control and with the addition of the

crankcase heaters where necessary.

oodman® Brand or Distinctions Package Heat Pum p -

G

14 Seer 208-230/1/60 Single-Phase Heat Pump with R-410A.

oodman® Brand or Distinctions Package Heat Pum p - 14 Seer 208-

G

230/1/60 Single-Phase Heat Pump with R-410A. Adds "T" to liquid line and re

locates the pressure switch on "H" series heat pumps.

oodman® Brand or Distinctions Package Heat Pum p - 14 Seer 208-

G

230/1/60 Single-Phase Heat Pump with R-410A. Models with Aluminum

Evaporator Coils.

oodman® Brand or Distinctions Package Heat Pum p - 14 Seer 208-

G

230/1/60 Single-Phase Heat Pump with R-410A. Models with Broad Ocean

Digi m otor.

ackage Heat Pum p -

P

A/GPH1424-42H41DA

A/GPH1448H41DA

GPH1460H41DA

mana® Brand/Goodman

A

14 Seer 208-230/1/60 Single-Phase Heat Pump with R-410A. Models that

change static ratings to be max 0.88 on all E-Heat kits besides 20 kW.

®

Brand or Distinctions

ackage Heat Pum p -

P

8

ACCESSORIES

Part Number Description

OT18-60A

OT/HER-60A Outdoor Thermostat with Emergency Heat Relay

HKR05A, 08, 10, CA Heater Kit for all *PC/*PH (H) Series

HKP05C, 10C Heater Kit for all *PC/*PH (H) Series

HKP15* Heater kit for *PC/*PH13/14 (30-60) (H) Series

HKP20* Heater Kit for *PC/*PH13/14 (42-60) (H) Series

PCCP101-103 Roof Curb

PCP101-103 Downflow Plenum Kit

PCP101-103R8 Downflow Plenum Kit w/ R-8 Insulation

GPCED101-103 Downflow Economizer for H Series Package Units (A/C) - To Be Used With PCP101-103

GPHED101-103 Downflow Economizer for H Series Package Units (Heat Pump) - To Be Used With PCP101-103

GPCEH101-103 Horizontal Economizer for H Series Package Units (A/C)

GPHEH101-103 Horizontal Economizer for H Series Package Units (Heat Pump)

PCMD101-103 Manual Damper - To Be Used With PCP101-103

PCMDM101-103 Motorized Damper - To Be Used With PCP101-103

GPHMD101-103 Manual Damper for Horizontal Applications

SPK* Single Point Wiring Kit

SQRPCH101 Square to Round Adapters 16"&14"

SQRPCH102-103 Square to Round Adapters 18"&14"

SQRPC101 Square to Round Adapter - For Use With PCCP101-103 Curb 16" Rounds

SQRPC102-103 Square to Round Adapter For Use With PCCP101-103 Curb 18" Rounds

PCFR101-103 External Horizontal Filter Rack

PCEF101-103 Elbow & Flashing w/ R-8 Liner

CDK36 Flush Mount Concentric Duct Kit

CDK36515 Flush Mount Concentric Duct Kit w/ Filter

CDK36530 Step Down Concentric Duct Kit

CDK36535 Step Down Concentric Duct Kit w/ Filter

CDK4872 Flush Mount Concentric Duct Kit

CDK4872515 Flush Mount Concentric Duct Kit w/ Filter

CDK4872530 Step Down Concentric Duct Kit

CDK4872535 Step Down Concentric Duct Kit w/ Filter

*PC/*PH14**H41*

ACCESSORIES *PC/*PH H SERIES

Outdoor Thermostat (Required for heat pumps with 0° outdoor

ambient and 50% or higher relative humidity.

GOODMAN® BRAND THERMOSTATS

CH70TG Manual Changeover

CHSATG Manual Changeover

CHT18-60 Manual Changeover

CHT90-120 Manual Changeover Mechanical, Nonprogrammable 2 Heat - 2 Cool

CHTP18-60HD Manual Changeover Digital, Nonprogrammable 2 Heat - 1 Cool

CT18-60 Manual Changeover

Digital, Nonprogrammable 1 Heat - 1 Cool

Mechanical, Nonprogrammable 1 Heat - 1 Cool

Mechanical, Nonprogrammable 1 Heat - 1 Cool

Mechanical, Nonprogrammable Cool Only

AMANA® BRAND THERMOSTATS

1213401 White Manual Changeover

1213402 White Manual Changeover

1213403 White Manual Changeover 7 Day Programming Digital 2 Heat - 1 Cool

1213404 White Manual Changeover

1213406

1213407

1213408

1213410

1213411

1213412

1213431

Beige

White

White

White

White

White

White

Manual/Auto Ch angeover 5 + 2 Programming Digital 3 Heat - 2 Cool

Manual Changeover

Manual/Auto Changeover

Manual Changeover 5 + 2 Programming Digital 2 Heat - 1 Cool

Manual Changeover

Manual/Auto Changeover 7 Day Programming Digital 3 Heat - 2 Cool

Manual/Auto Changeover

5 + 2 Programming Digital 1 Heat - 1 Cool

Nonprogrammable Digital 1 Heat - 1 Cool

Nonprogrammable Digital 2 Heat - 1 Cool

5 + 2 Programming Digital 2 Heat - 2 Cool

7 Day Programming Digital 1 Heat - 1 Cool

Nonprogrammable Digital 2 Heat - 2 Cool

7 Day Programming Digital 3 Heat - 2 Cool

9

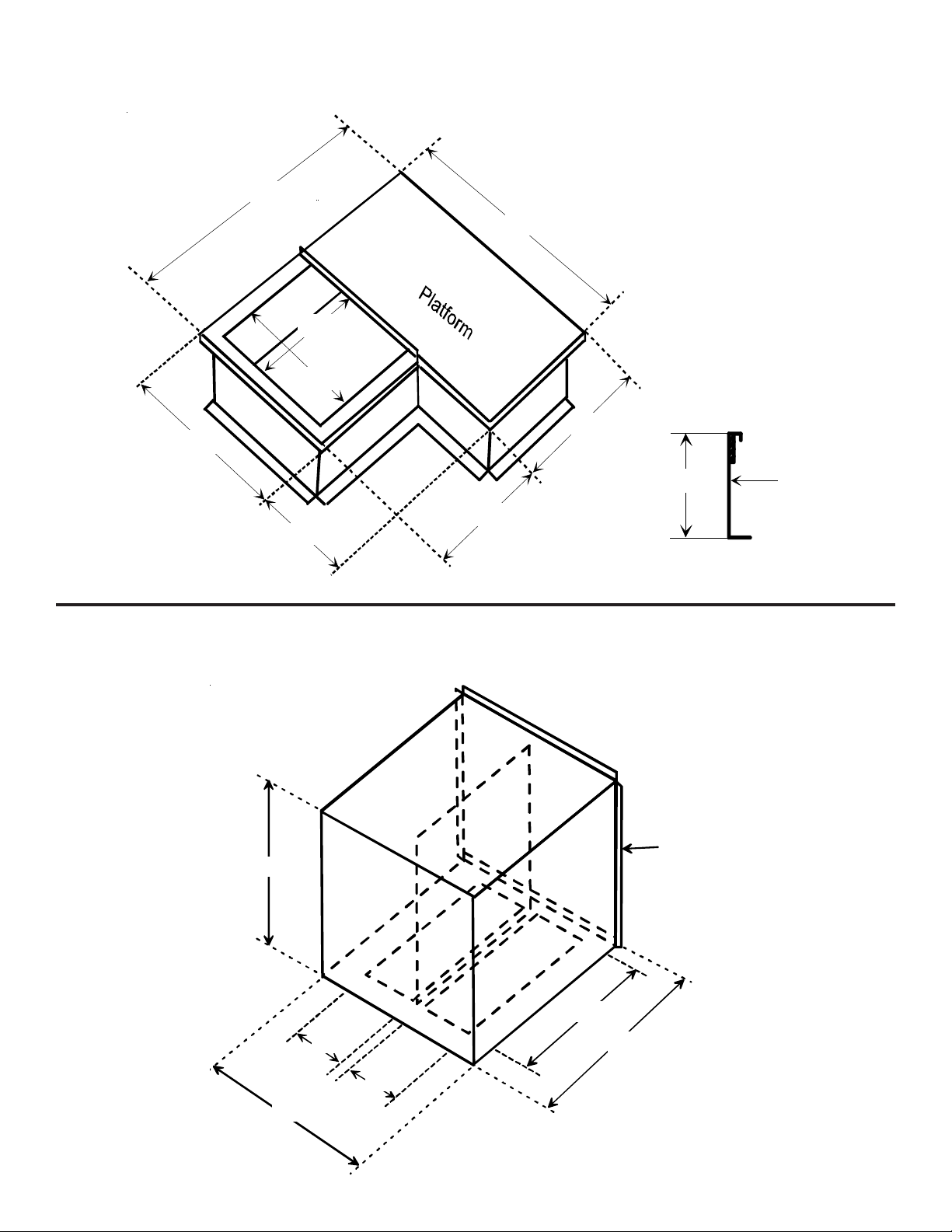

ACCESSORIES

33"

*PC/*PH14H41*

PCCP101-103 ROOF CURB

64"

59"

29 3/8"

29 3/4"

33"

26"

28 3/4"

31"

PCP101-103 DOWNFLOW PLENUM

(Use with PCCP Roof Curb)

14"

1" Flange

Roof

Curb

10

37"

13"

25 1/2"

33"

13"

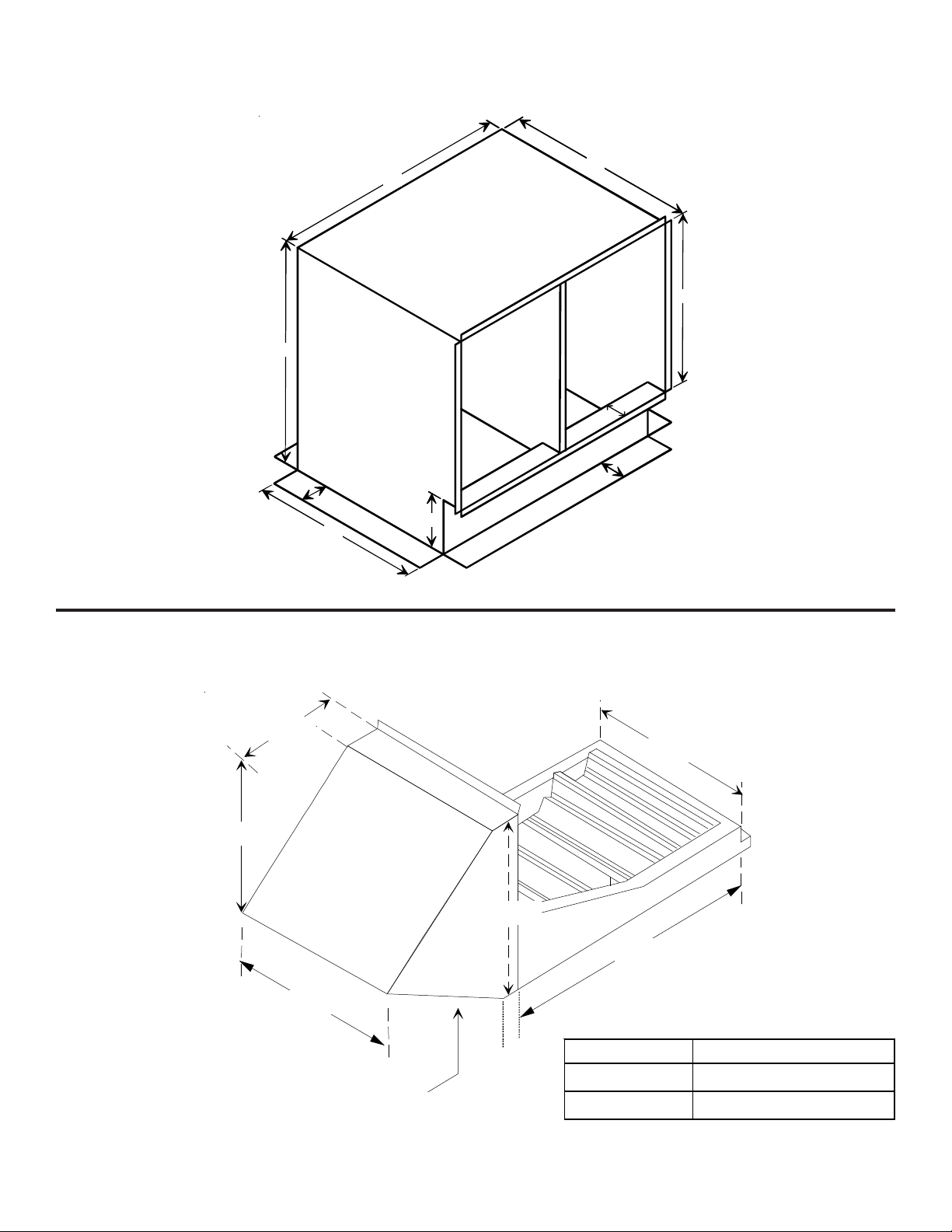

ACCESSORIES

*PC/*PH14H41*

PCEF101-103 ELBOW AND FLASHING KIT

28"

35"

25"

33"

3"

4"

20 3/8"

17 3/4"

4"

25"

8"

PCE*101-103 ECONOMIZER*

(DOWNFLOW APPLICATIONS)

5"

27 3/4"

16 1/2"

17 3/4"

20" x 17 1/2"

Filter

3"

31 1/4"

Model Used With

PCEC101-103* *PC HORIZONTAL A/C

PCEH101-103* *PH HORIZONTAL HP

*Must be used with PCP101-103

11

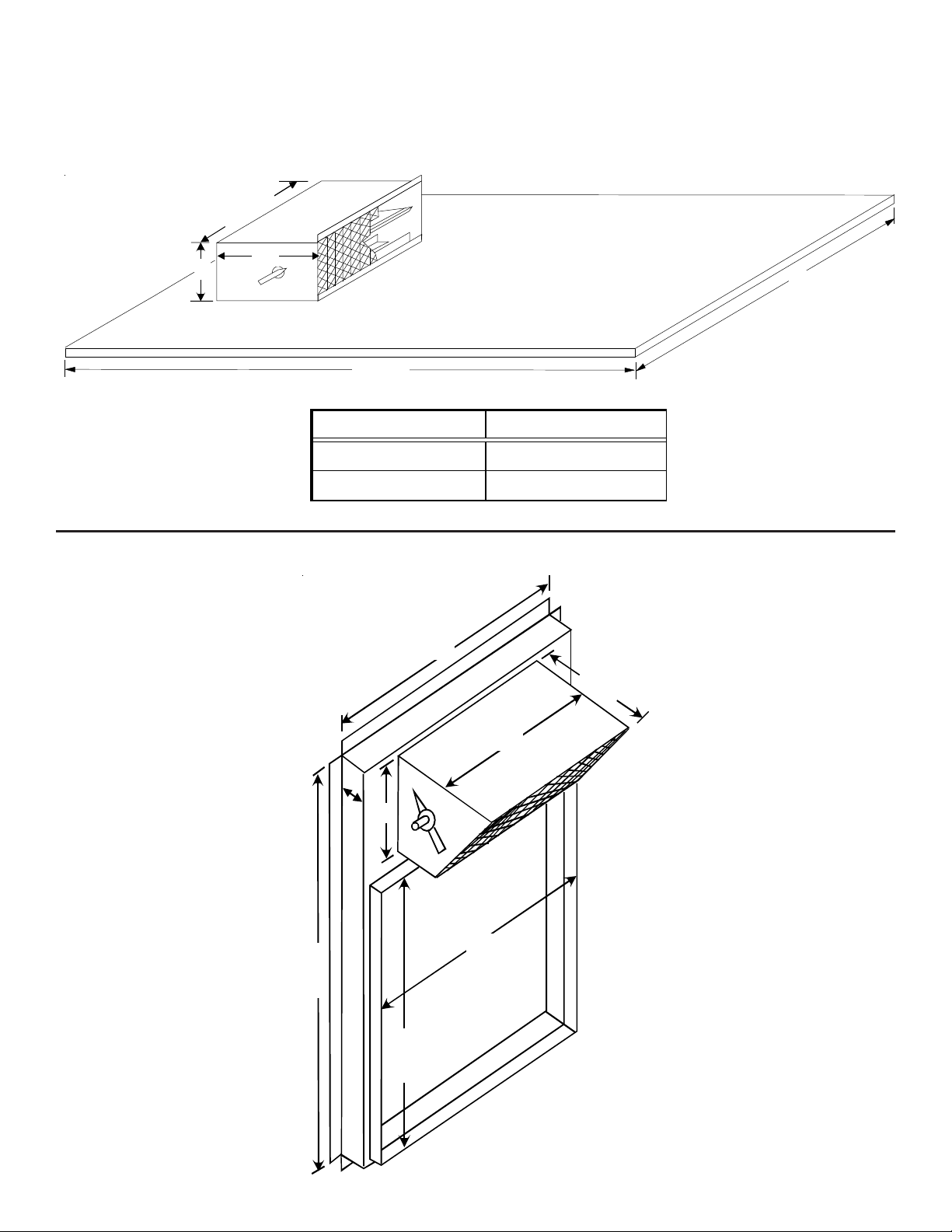

ACCESSORIES

PCMDM101-103 DOWNFLOW MOTORIZED DAMPER*

2

1

PCMD101-103 DOWNFLOW MANUAL DAMPER*

*USED WITH PCP101-103 DOWNFLOW PLENUM

"

8

/

1

*PC/*PH14H41*

6"

10"

29 3/4"

MODEL DESCRIPTION

PCMDH101-103 Manual Damper

PCMDM101-103 Motorzied Damper

GPHMD101-103 HORIZONTAL MANUAL DAMPER WITH DUCT FLANGE

18"

8

1

/

4

"

18"

12

12"

6"

2"

17"

25 1/4"

17 1/4"

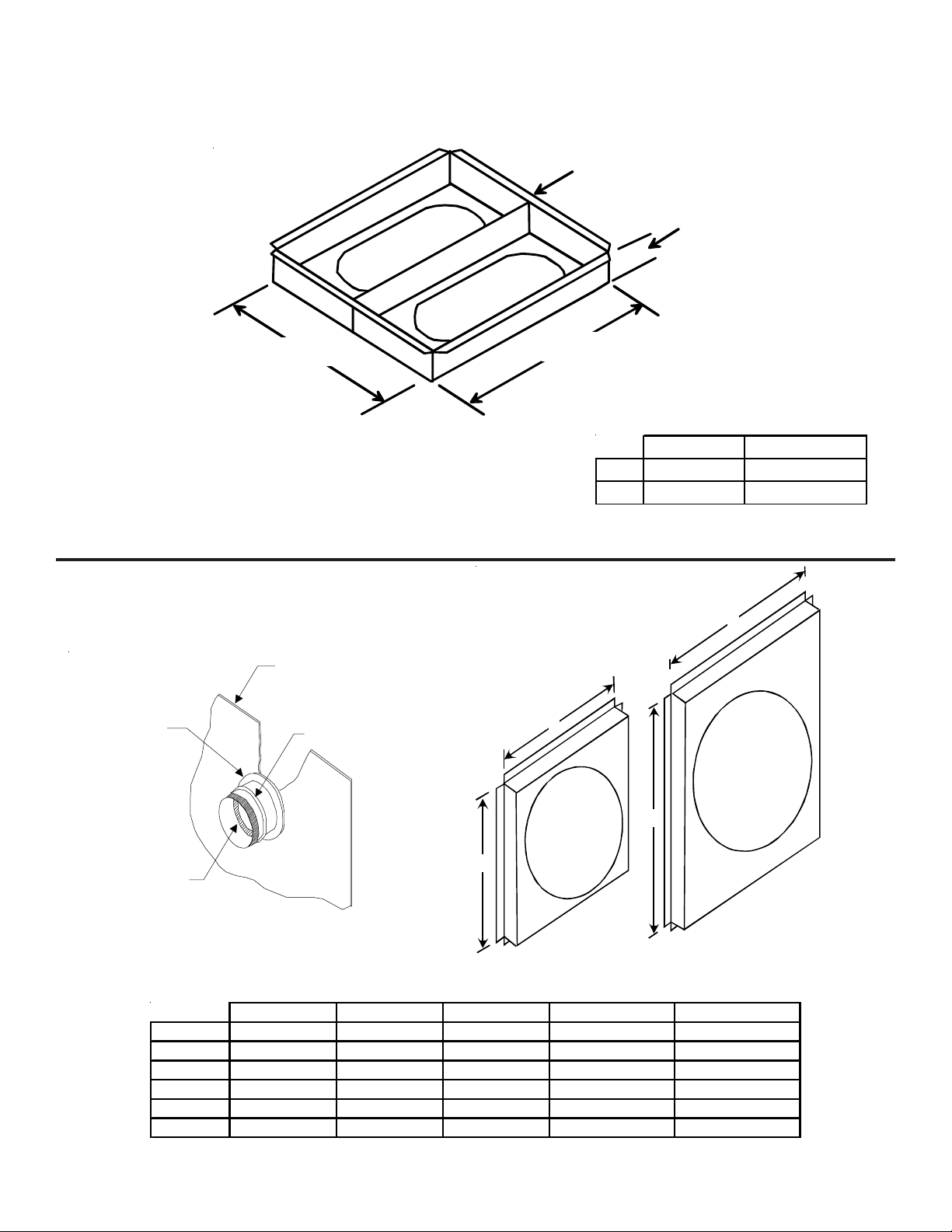

ACCESSORIES

"

A

*PC/*PH14H41*

SQRPC SQUARE TO ROUND CONVERTER

(DOWNFLOW APPLICATIONS)

1" FLANGES

1 1/2

SA

RA

OUTER FLANGE

29 1/2"

29 1/4"

SA 16" 18"

RA 16" 18"

SQRPCH SQUARE TO ROUND CONVERTER

(HORIZONTAL APPLICATIONS)

SQUARE TO ROUND

DUCT CONVERTER PANEL

BEAD

A

SQRPC101 SQRP102-103

C

2"

RETURN

2"

SUPPLY

B

STARTER FLANGE

SQRPCH-101 SQRPCH-102 SQRPCH-103 SQRPCH102-14 SQRPCH103-14

15" 17" 17" 15" 15"

B

C 17" 17" 19" 15" 15"

D

SUPPLY 14" 16" 16" 14" 14"

RETURN

15" 17" 17" 15" 15"

22 1/2" 24 1/2" 24 1/2" 24 1/2" 24 1/2"

16" 16" 18" 14" 14"

D

13

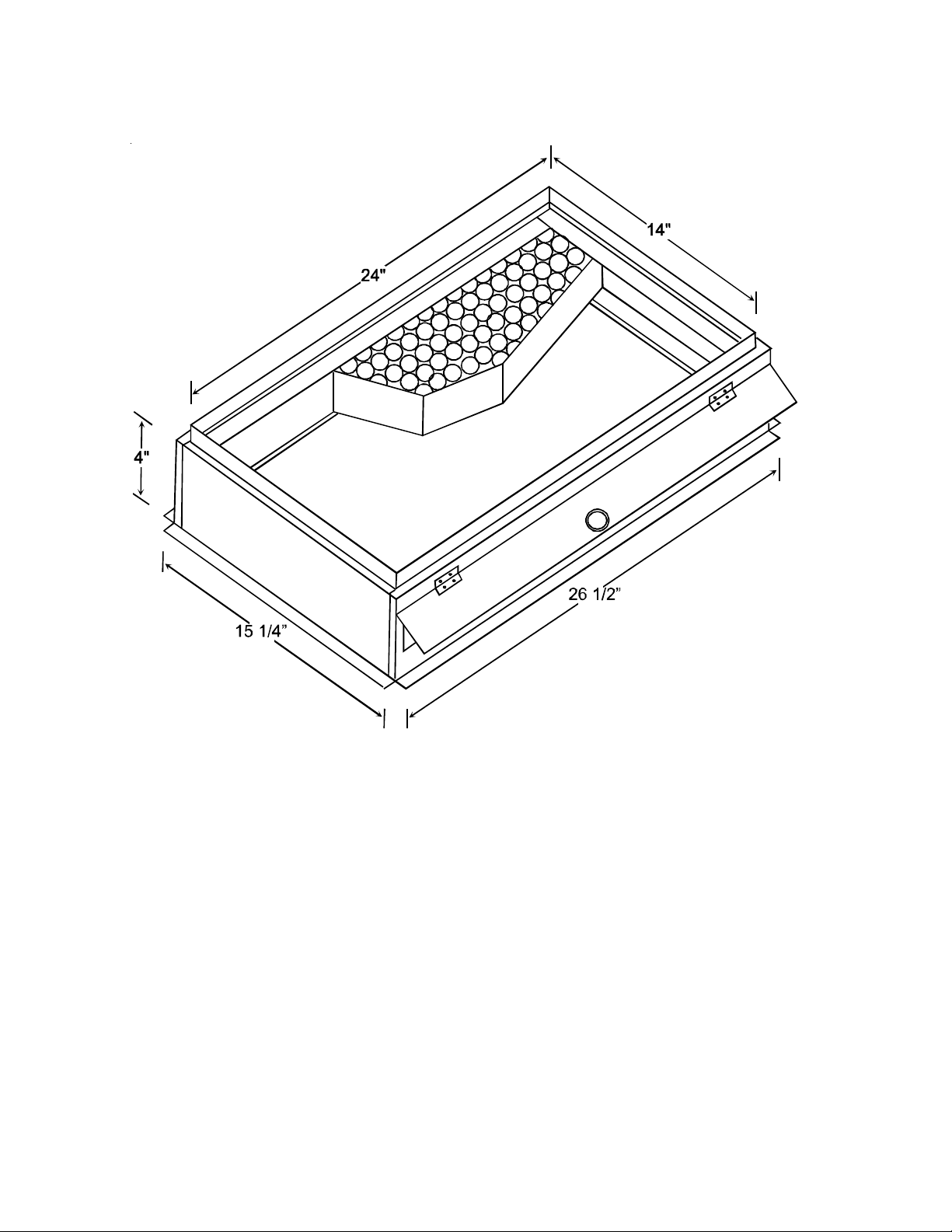

ACCESSORIES

*PC/*PH14H41*

PCFR101-103 EXTERNAL FILTER KIT

(HORIZONTAL APPLICATIONS)

14" x 25" x 2" FILTER

14

Loading...

Loading...