Goodman EXPANSION VALVE KITS Installation Manual

EXPANSION VALVE KITS

INSTALLATION INSTRUCTIONS

A

TTENTION INSTALLING PERSONNEL

S

HIPPING INSPECTION

As a professional installer you have an obligation to know the

product better than the customer. This includes all safety

precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with

this Instruction Manual. Pay special attention to all safety

warnings. Often during installation or repair it is possible to

place yourself in a position which is more hazardous than

when the unit is in operation.

Remember, it is your responsibility to install the product safely

and to know it well enough to be able to instruct a customer

in its safe use.

Safety is a matter of common sense...a matter of thinking

before acting. Most dealers have a list of specific good safety

practices...follow them.

The precautions listed in this Installation Manual are intended

as supplemental to existing practices. However , if there is a

direct conflict between existing practices and the content of

this manual, the precautions listed here take precedence.

WARNING

HIGH VOLTAGE !

D

ISCONNECT

ULTIPLE POWER SOURCES MAY BE PRESENT

M

TO DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH

ALL

POWER BEFORE SERVICING

.

.

. F

AILURE

Upon receiving the product, inspect it for damage from shipment. Shipping damage, and subsequent investigation is the

responsibility of the carrier . V erify the model number, specifications, electrical characteristics, and accessories are correct prior to installation. The distributor or manufacturer will

not accept claims from dealers for transportation damage or

installation of incorrectly shipped units.

C

ODES

& R

EGULATIONS

This product is designed and manufactured to comply with

national codes. Installation in accordance with such codes

and/or prevailing local codes/regulations is the responsibility of the installer. The manufacturer assumes no responsibility for equipment installed in violation of any codes or regulations.

PRE-I

NSTALLATION INSTRUCTIONS

IMPORTANT: Piston must be removed from the Flowrator

Distributor Assembly for proper Expansion V alve operation.

Piston Removal:

1. Loosen the 13/16 nut 1 TURN ONLY to allow high

pressure tracer gas to escape. No gas indicates a

possible leak.

2. After the gas has escaped, remove the nut and discard

the cap, which may be black, clear or a brass cap.

3. Remove the check piston and seal and discard.

NOTE: SPECIFICATIONS AND PERFORMANCE DATA LISTED HEREIN ARE SUBJECT TO CHANGE WITHOUT NOTICE

Quality Makes the Difference!

All of our systems are designed and manufactured with the same high quality standards regardless of size or

efficiency . W e have designed these units to significantly reduce the most frequent causes of product failure.

They are simple to service and forgiving to operate. We use quality materials and components. Finally, every

unit is run tested before it leaves the factory. That’ s why we know. . .There’s No Better Quality.

Visit our website at www.daikincomfort.com, www.goodmanmfg.com or www.amana-hac.com for information on:

IO-630G

12/2013

• Products

• Warranties

• Customer Services

© 2004, 2006, 2009-2010, 2012-2013 Goodman Manufacturing Company, L.P.

is a registered trademark of Maytag Corporation or its related companies

and is used under license. All rights reserved.

• Parts

• Contractor Programs and Training

• Financing Options

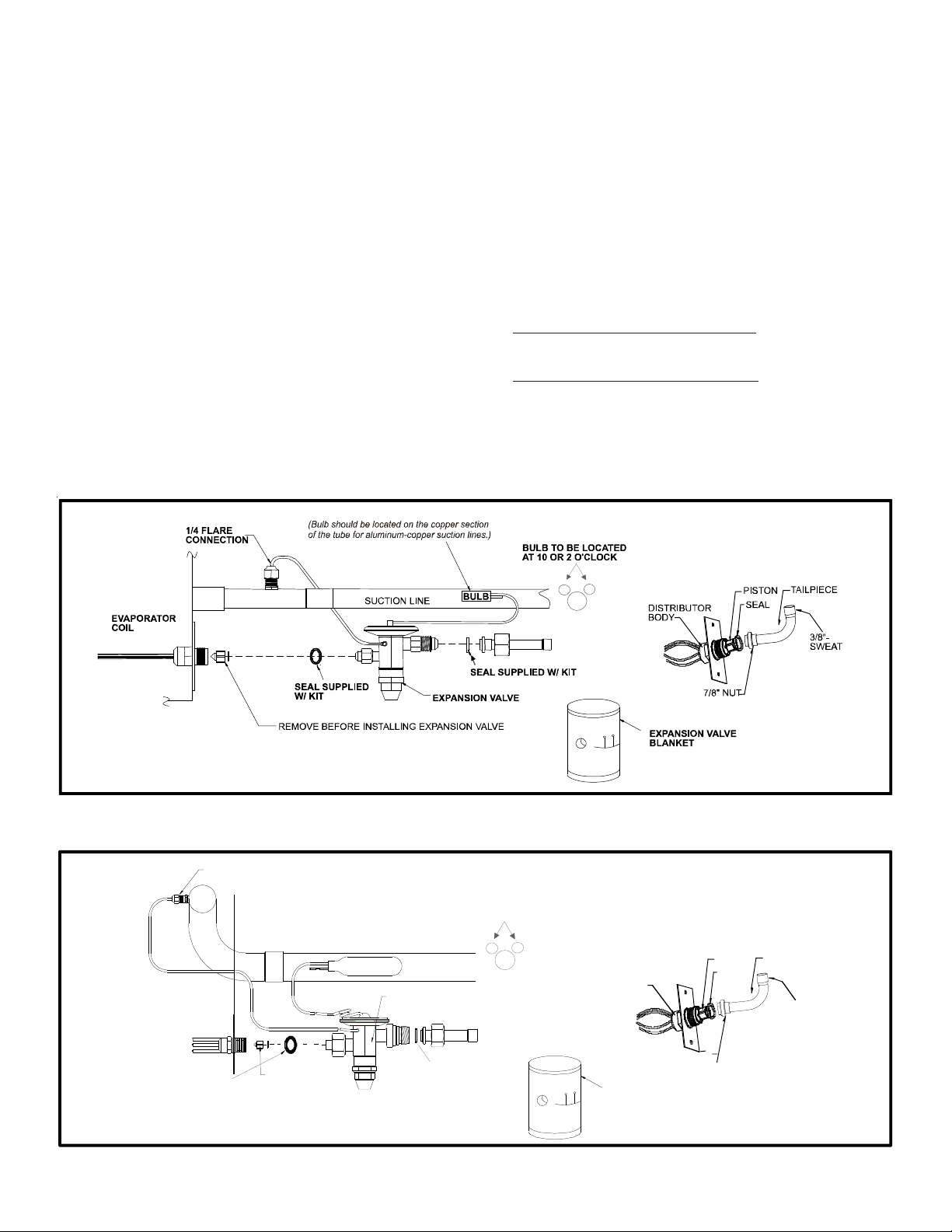

4. Use a tube cutter to remove the spin closure on the

suction line.

5. Slide the 13/16 nut into place on the tailpiece supplied

with the unit.

6. For Applications requiring a Field-Installed Access

Fitting (see Figure 1 on following page).

a. Braze the appropriate equalizer stub to suction line

field connection on coil. Slide grommet and insulation back before brazing. Plan fitting position for

convenient connection to 1/4" flare nut on equal-

izer tube.

b. Braze suction line tubing (line set) to the stub.

c. Reinstall the suction line grommet and insulation.

For Applications NOT Requiring a Field-Installed Access

Fitting (see Figure 2).

FIGURE 1: Applications Requiring A Field Installed Access Fitting

a. Braze the suction line field connection on coil. Slide

grommet and insulation back before brazing and

feed the valve equalizer line through the grommet.

b. Reinstall the suction line grommet and feed the

equalizer line through the opening.

I

NSTALLA TION INSTRUCTIONS

1. Connect expansion valve outlet with new seal supplied

with kit to flowrator body. Make sure the seal is in

place.

NOTE DIRECTION OF FLOW (Fluid is flowing towards

the evaporator coil).

2. Slide the 13/16 nut into position. Braze tailpiece to

the liquid tube (line set).

AFTER THE TAILPIECE HAS COOLED, position the seal

3.

and hand tighten the nut.

1/4' FLARE

CONNECTION

EVAPORATOR COIL

SEAL SUPPLIED W/ KIT

FIGURE 2: Applications NOT Requiring A Field Installed Access Fitting

BULB TO BE LOCATED

AT 10 OR 2 O'CLOCK

REMOVE BEFORE

INSTALLING

EXPANSION VALVE

BULB

SUCTION LINE

EXPANSION VALVE

SEAL SUPPLIED W/ KIT

DISTRIBUTOR

BODY

7/8" NUT

EXPANSION VALVE

BLANKET

2

PISTON

SEAL

TAILPIECE

3/8"SWEAT

Loading...

Loading...