Goodman ASZC180361A, DSZC180361A, ASZC180601A, ASZC180481A, ASZC180601B Technical Manual

...

TECHNICAL MANUTECHNICAL MANU

TECHNICAL MANU

TECHNICAL MANUTECHNICAL MANU

ALAL

AL

ALAL

*SZC 18 SEER

Split System Heat Pump s

• Refer to Service Manual RS6200007 for installation, operation, and troubleshooting information.

• All safety information must be followed as provided in the Service Manual.

• Refer to the appropriate Parts Catalog for part number information.

• See models on page 3.

This manual is to be used by qualified, professionally trained HVAC technicians only. Goodman does

not assume any responsibility for property damage or personal injury due to improper service

procedures or services performed by an unqualified person.

RT6214006 Rev. 1

October 2010

Copyright © 2009-2010 Goodman Manufacturing Company, L.P.

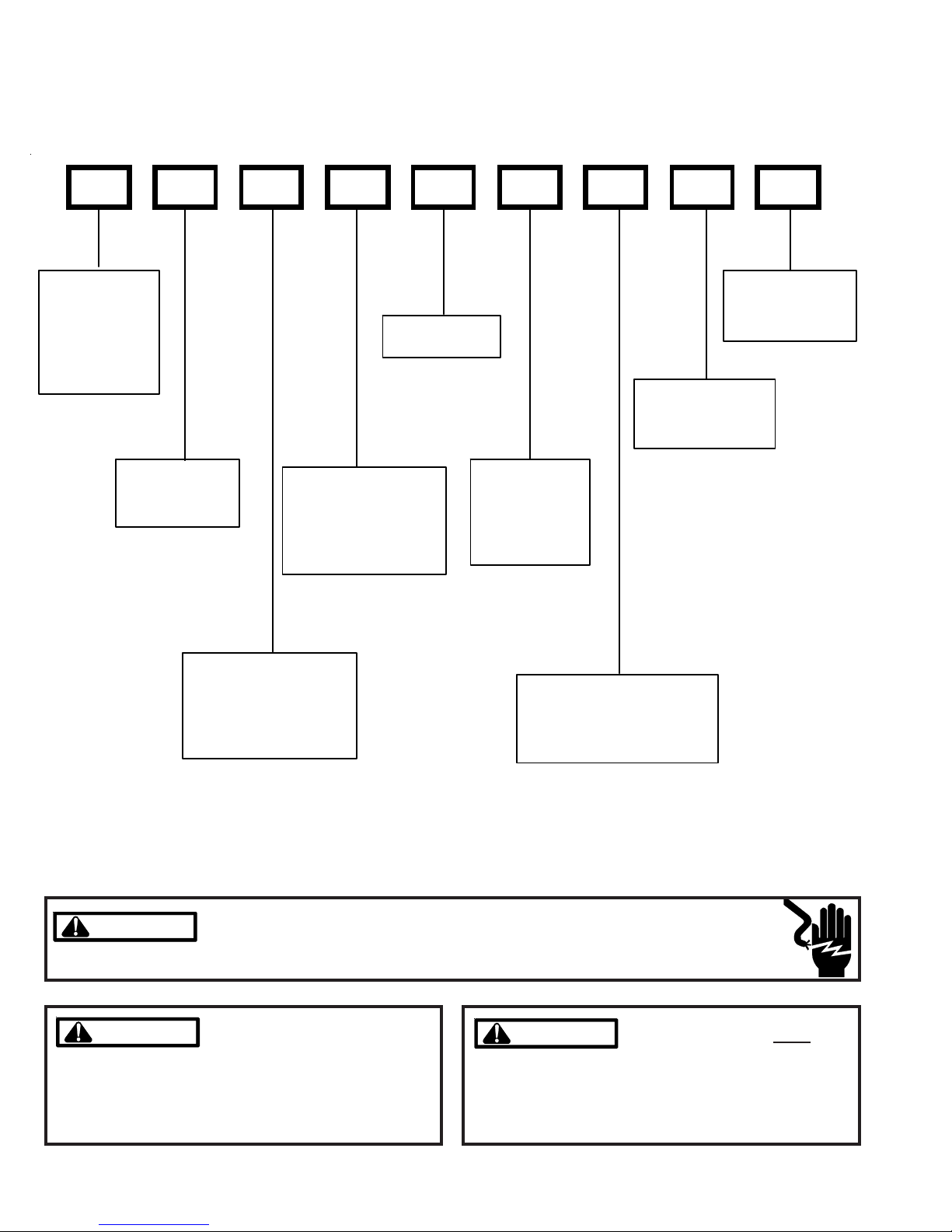

PRODUCT IDENTIFICATION

The model number is used for positive identification of component parts used in manufacturing. Please use this number

when requesting service or parts information.

D S Z C 18 036 1 A A

BRAND:

D: Deluxe

Goodman®

Brand

A: Aman a®

Brand

PRODUCT

FAMILY:

S: Split System

COMMUNICATION

FEATURE:

C: 4-wire

Communication

Ready

PRODUCT TYPE:

C: Condenser R-22

H: Heat Pum p R-22

X: Condenser R-410A

Z : Heat P ump R-410A

SEER:

SEER Rating

NOMINAL

CAPACITY:

0 3 6 : 3 T o ns

0 4 8 : 4 T o ns

0 6 0 : 5 T o ns

MINOR

REVISIO N:

A: I niti al Release

MAJOR

REVISION:

A: Init ial Release

ELEC TRICA L:

1: 208-230V/1ph/60Hz

3: 208-230v/3ph/60Hz

4: 460v/3ph/60Hz

WARNING

WARNING

WARNING

arising from improper service or service procedures. If

you install or perform service on this unit, you assume

responsibility for any personal injury or property damage

which may result. Many jurisdictions require a license to

install or service heating and air conditioning equipment.

2

Disconnect ALL power before servicing or installing this unit. Multiple power

sources may be present. Failure to do so may cause property damage, personal

injury or death.

Goodman will not be responsible

for any injury or property damage

WARNING

HIGH VOLTAGE!

WARNING

WARNING

ments of an "entry level technician", at a minimum, as

specified by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI). Attempting to install or repair this

unit without such background may result in product

damage, personal injury or death.

Installation and repair of this unit

should be performed

individuals meeting the require-

ONLY by

PRODUCT IDENTIFICATION

The model number is used for positive identification of component parts used in manufacturing. Please use this number

when requesting service or parts information.

ASZC180361A*

ASZC180481A*

ASZC180601A*

ASZC180601B*

* Indicates minor revision & is not used for order entry or inventory management

DSZC180361A*

DSZC180481A*

DSZC180601A*

DSZC180601B*

WARNING

WARNING

WARNING

WARNING

Serious property damage, personal injury, reduced unit

performance and/or hazardous conditions may result

from the use of such non-approved devices.

The United States Environmental Protection Agency (“EPA”) has issued various regulations regarding the introduction and disposal of refrigerants introduced into this unit. Failure to follow

these regulations may harm the environment and can lead to the imposition of substantial fines.

These regulations may vary by jurisdiction. Should questions arise, contact your local EPA office.

Do not connect or use any device

that is not design certified by

Goodman for use with this unit.

WARNING

WARNING

do not store combustible materials or use gasoline or

other flammable liquids or vapors in the vicinity of this

appliance.

To prevent the risk of property

damage, personal injury, or death,

3

PRODUCT DESIGN

Models covered by this manual come with a new 4-wire communicating PCB. When paired with a compatible communicating indoor unit and a communicating thermostat, these

models can support 4-wire communication protocol and provide more troubleshooting information. These models are

also backward compatible with the legacy thermostat wiring.

*SZC18 models are available in 3, 4 and 5 ton sizes and

use R-410A refrigerant. They are designed for 208/230 volt

single phase applications.

The condenser air is pulled through the condenser coil by a

direct drive propeller fan. This condenser air is then discharged out of the top of the cabinet.

These units are designed for free air discharge, so no additional resistance like duct work shall be attached.

The suction and liquid line connections on present models

are of the sweat type for field piping with refrigerant type copper. Front seating valves are factory installed to accept the

field run copper. The total refrigerant charge for a normal installation is factory installed in the condensing unit. *SZC

units are charged for the matching evaporator coil and a 15

foot refrigerant line set.

Systems should be properly sized by heat gain and loss

calculations made according to methods of the Air Conditioning Contractors Association (ACCA) or equivalent. It is

the contractors responsibility to ensure the system has adequate capacity to heat or cool the conditioned space.

*SZC models use high-efficiency Copeland® scroll "Ultratech"

compressors which are specifically desgined for R-410A refrigerant. There are a number of design characteristics which

are different from the scroll compared to the traditional reciprocating compressor.

"Ultratech" Series scroll compressors with Copeland

ComfortAlert diagnostics will not have a discharge thermostat. Some of the early model scroll compressors required

discharge thermostats.

Due to their design Scroll compressors are inherently more

tolerant of small quantities of liquid refrigerant.

NOTE: Even though the compressor section of a Scroll compressor is more tolerant of liquid refrigerant, continued

floodback or flooded start conditions may wash oil from the

bearing surfaces causing premature bearing failure.

"Ultratech" Series scroll compressors use "POE" or

polyolester oil which is NOT compatible with mineral oil based

lubricants like 3GS. "POE" oil must be used if additional oil

is required.

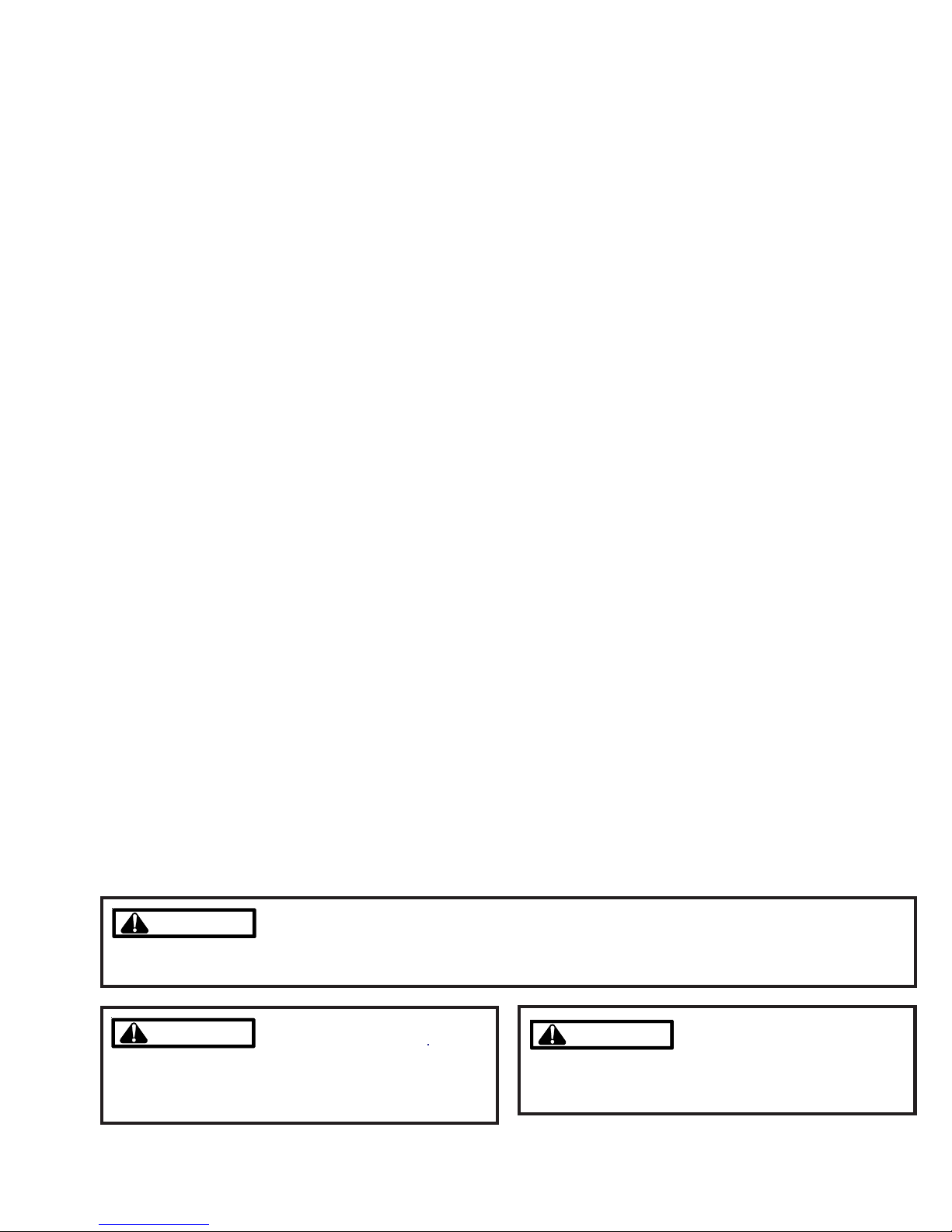

This unit is for outdoor installation only. Refer to figure for

minimum clearances from the sides of the unit to full walls

and other objects.

NOTE: This unit cannot be completely enclosed. At least

one side must be unrestricted.

These clearances will help avoid air recirculation. If installing

two or more units at the same location, allow at least 24

inches between units. If only one side is restricted (for example, against the outside wall of a house), the unit may be

placed as close as 8" to that one wall.

DO NOT locate the unit:

* Directly under a vent termination for a gas appliance.

* Within 3 feet of a clothes drier vent

* Where the refreezing of defrost water would create

a hazard

* Where water may rise into the unit.

NOT

RECOMMENDED

B B B

AA AAA

C

®

AA

A

AA

AA

C

AA

CC

B

AA

OK!

OK!

OK!

Minimum Airflow Clearance

Model Type A B C AA

Residential

Light Commercial

10" 10" 18" 20"

12" 12" 18" 24"

OK!

OK!

OK!

WARNING

To avoid possible injury, explosion or death, practice

safe handling of refrigerants.

Operating pressures and amp draws may differ from standard reciprocating and/or scroll compressors. This information may be found in the "Cooling Performance Data" section.

4

Model Dimensions - W x D x H

*SZC180361A* 35½ x 35½ x 38¼

*SZC180481A* 35½ x 35½ x 38¼

*SZC18060 1A*

*SZC18060 1B*

35½ x 35½ x 38¼

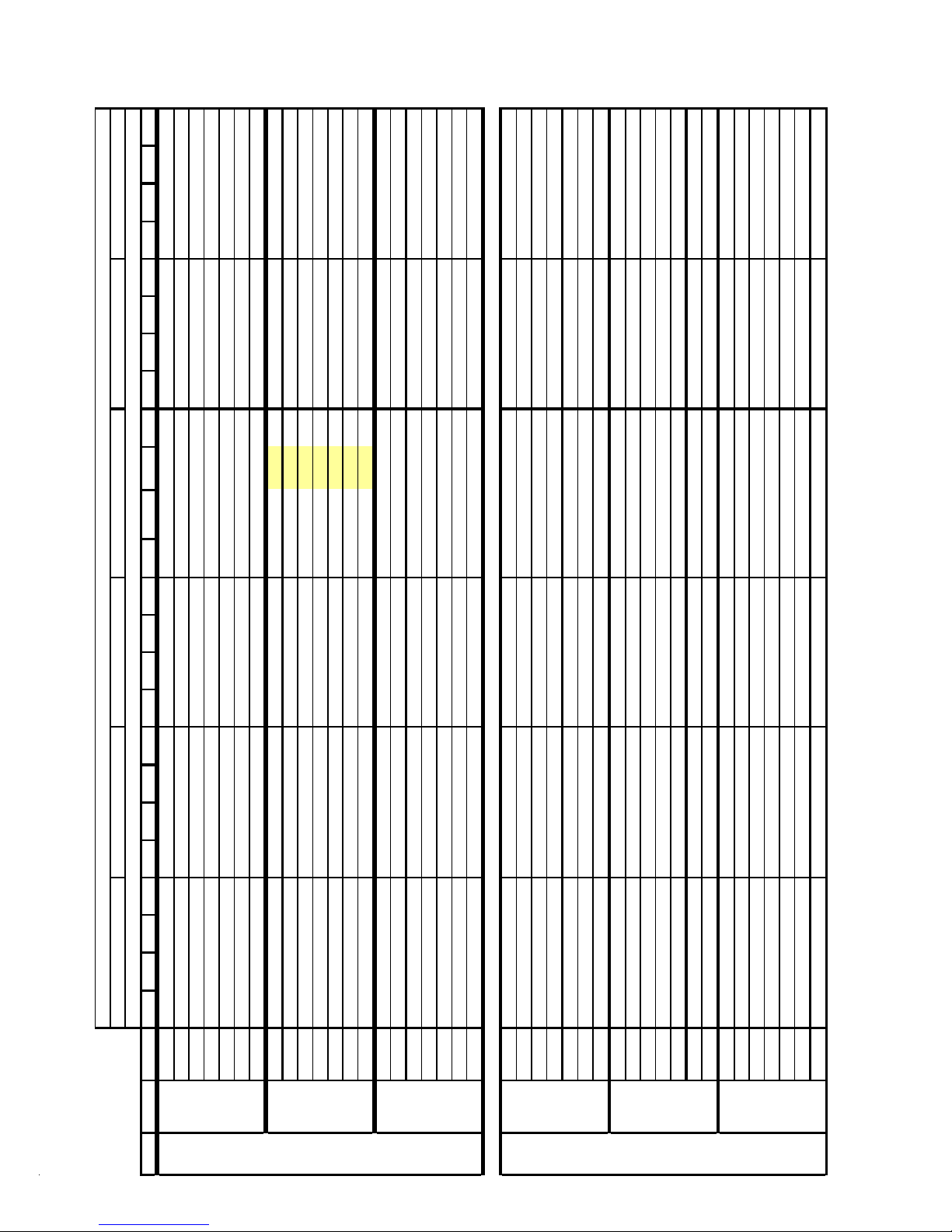

HEAT PUMP SPECIFICATIONS

*SZC180361A* - *SZC180601A*

*SZC180361A*

*SZC180481A*

*SZC180601A*

Cooling Capacity, BTUH 35,000 47,000 57,000

Compresso r

R.L. Amps

L.R. Amps

16.7 21.2 25.6

82.0 96.0 118.0

Low Pr es su re Swi tc h

Open 22 + / - 7 PSIG 22 + / - 7 PSIG 22 + / - 7 PSIG

Close 50 + / - 7 PSIG 50 + / - 7 PSIG 50 + / - 7 PSIG

High Pressure Switch

Open 610 PSIG 610 PSIG 610 PSIG

Close 420 PSIG 420 PSIG 420 PSIG

Co nde ns er Fan Motor

Horsepower 1/3 1/3 1/3

F.L. Amps 2.8 2.8 2.8

Liquid Line, Inches O.D.* 3/8" 3/8" 3/8"

Suction Line, Inches O.D.* 7/8" 1 1/8" 1 1/8

Refrigerant Charge 188.0 278.0 278.0

Power Supply 208/230-60-1 208/230-60-1 208/230-60-1

M inimum Circuit Ampa city

Ma xi mum Ov er c ur rent Devi c e

(1)

(2)

23.7 29.3 34.8

40 50 60

Electrical Conduit Size

Power Supply (Inches) 1/2 or 3/4 1/2 or 3/4 1/2 or 3/4

Approximate Shipping Weight

270 325 345

*

Up to 24' in equivalent line length

(1)

Wire size should be determined in accordance with National Electrical Codes; extensive wire runs will require larger wire sizes.

(2)

Maximum Overcurrent Protection Device: MUST use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

NOTES:

• Always check the serial plate for electrical data on the unit being installed.

• Installer will need to supply 7/8" to 1-1/8" adapters for suction line connections (4 & 5 ton units).

• Installer will need to supply 3/4" to 7/8" adapters for suction line connections (3 ton unit).

• Unit is charged with refrigerant for 15' of 3/8" liquid line. System charge must be adjusted per Installation Instructions Final Charge

Procedure.

• Installation of these units requires the specified TXV Kit to be installed on the indoor coil. THE SPECIFIED TXV IS DETERMINED BY THE

OUTDOOR UNIT, NOT THE INDOOR COIL.

NOTE: This data is provided as a guide, it is important to electrically connect the unit and properly size fuses/circuit breakers and

wires in accordance with all national and/or local electrical codes. Use copper wire only.

Unit specifications are subject to change without notice. ALWAYS refer to the unit's serial plate for the most up-to-date general

and electrical information.

5

HEAT PUMP SPECIFICATIONS

*SZC180601B*

Cooling Capacity, BTUH 57,000

Compressor

R.L. Amps

L.R. Amps

Low Pr es su re Swi tc h

Open 22 + / - 7 PSIG

Clos e 5 0 + / - 7 PSIG

High Pr essure Swi tch

Open 610 PSIG

Close 420 PSIG

Co nde ns er Fan Motor

Horsepower 1/3

F.L. Amps 2.8

Liquid Line, Inches O.D.* 3/8"

Suction Line, Inches O.D.* 1 1/8

Refrigerant Charge 278.0

Power Supply 208/230-60-1

Minimum Circuit Ampacity

Maximum Overcurrent Device

Electrical Conduit Size

Power Supply (Inches) 1/2 or 3/4

Approximate Shipping Weight

(1)

(2)

*SZC180601B*

23.0

118.0

31.6

50

345

*

Up to 24' in equivalent line length

(1)

Wire size should be determined in accordance with National Electrical Codes; extensive wire runs will require larger wire sizes.

(2)

Maximum Overcurrent Protection Device: MUST use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

NOTES:

• Always check the serial plate for electrical data on the unit being installed.

• Installer will need to supply 7/8" to 1-1/8" adapters for suction line connections (4 & 5 ton units).

• Installer will need to supply 3/4" to 7/8" adapters for suction line connections (3 ton unit).

• Unit is charged with refrigerant for 15' of 3/8" liquid line. System charge must be adjusted per Installation Instructions Final Charge

Procedure.

• Installation of these units requires the specified TXV Kit to be installed on the indoor coil. THE SPECIFIED TXV IS DETERMINED BY THE

OUTDOOR UNIT, NOT THE INDOOR COIL.

NOTE: This data is provided as a guide, it is important to electrically connect the unit and properly size fuses/circuit breakers and

wires in accordance with all national and/or local electrical codes. Use copper wire only.

Unit specifications are subject to change without notice. ALWAYS refer to the unit's serial plate for the most up-to-date general

and electrical information.

6

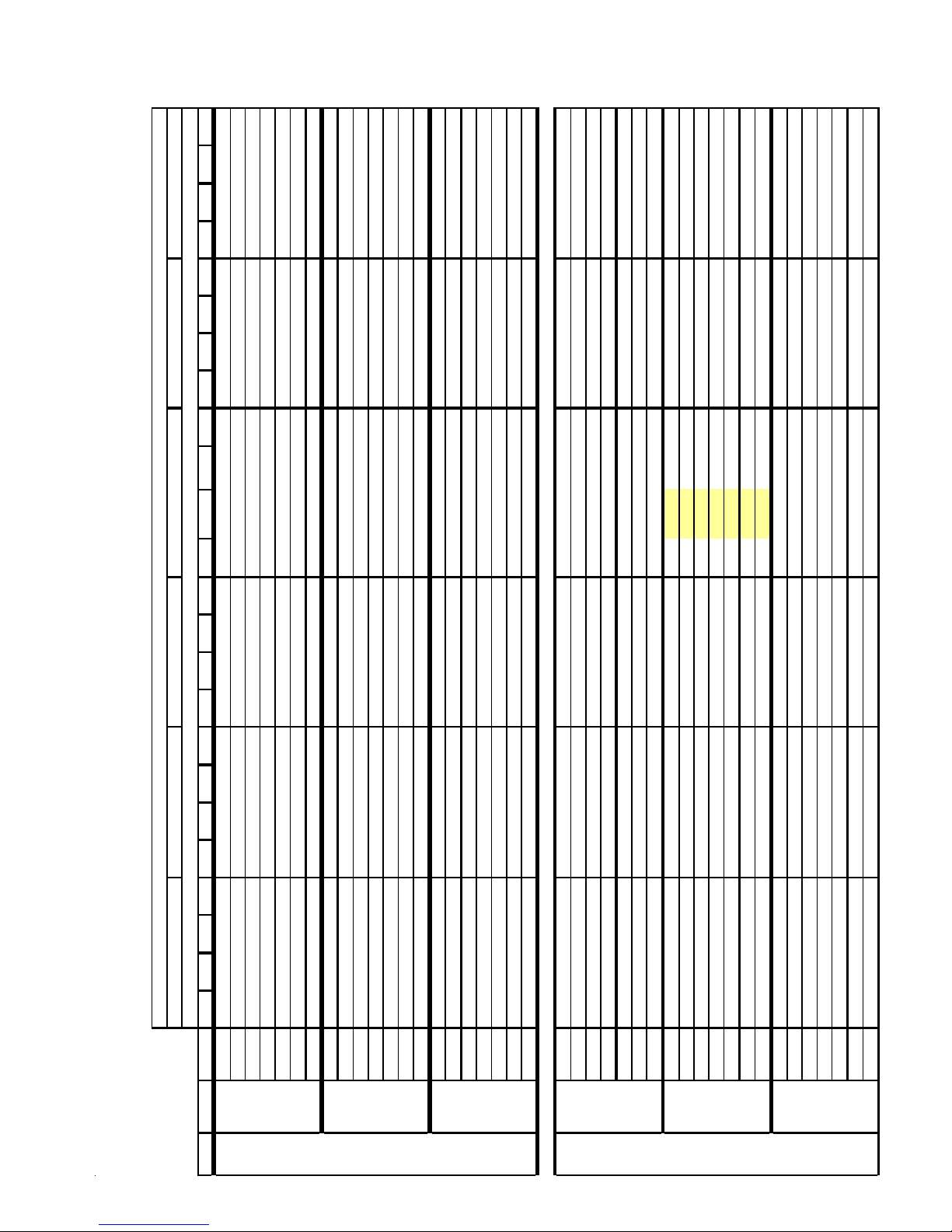

COOLING PERFORMANCE DA T A

g

p

q

COOL ING OPE RATION

*SZC180361A*-LOW ST AGE

EXPANDED PERFORMANCE DATA

16 11 21 20 16 11 20 18 15 10

7.1 7.4 7.2 7.3 7.6 7.9 7.6 7.8 8.0 8.4

349 364 345 371 392 409 381 410 433 452

150 159 135 144 157 167 140 149 162 173

1.75 1.81 1.72 1.76 1.83 1.89 1.79 1.83 1.89 1.96

26.1 28.0 22.3 22.9 24.8 26.6 20.6 21.2 23.0 24.7

0.65 0.42 0.99 0.89 0.67 0.43 1.00 0.89 0.68 0.44

20

6.9

330

137

1.69

24.1

0.85

Out door Amb ien t Temperatur e

Entering Indoor Wet Bulb Temperature

17 12 22 20 17 12 21 19 16 11

7.1 7.3 7.1 7.3 7.5 7.8 7.5 7.7 8.0 8.3

345 360 342 368 388 405 378 406 429 447

148 158 134 142 155 165 138 147 161 171

1.73 1.79 1.71 1.75 1.81 1.87 1.77 1.81 1.88 1.95

25.4 27.2 21.6 22.3 24.1 25.9 20.0 20.6 22.3 24.0

0.62 0.40 0.94 0.85 0.64 0.41 0.95 0.85 0.64 0.41

21

6.8

327

136

1.67

23.4

0.81

17 12 22 21 17 12 21 19 16 11

6.9 7.1 6.9 7.1 7.3 7.6 7.3 7.5 7.7 8.0

335 349 331 357 377 393 366 394 416 434

144 153 130 138 151 160 134 143 156 166

1.69 1.75 1.66 1.70 1.76 1.82 1.72 1.77 1.83 1.89

23.4 25.1 20.0 20.5 22.2 23.9 18.5 19.0 20.6 22.1

0.59 0.38 0.91 0.81 0.62 0.40 0.92 0.82 0.62 0.40

21

6.6

317

132

1.63

21.6

0.79

65 75 85 95 105 115

DT 181612 - 181612 - 181612 - 19 16 12 - 181612 - 171511 -

S/T 0.77 0.64 0.44 - 0.79 0.66 0.46 - 0.81 0.68 0.47 - 0.84 0.70 0.49 - 0.87 0.73 0.50 - 0.88 0.73 0.51 -

MBh 24.8 25.7 28.1 - 24.2 25.1 27.5 - 23.6 24.5 26.8 - 23.1 23.9 26.2 - 21.9 22.7 24.9 - 20.3 21.0 23.0 -

MOD E L: *SZC180 361A * / CA*F3743*6** + TXV / MBV C1600**-1** Des ig n Su bcooling 5 - 7 °F @ t he liquid service val ve, AH RI 95° F test cond itions

IDB*Airflow 59636771596367715963677159 63 67 715963677159636771

HI P R 2 09 225 237 - 234 2 5 2 2 66 - 267 287 3 03 - 304 327 345 - 342 368 388 - 377 4 06 429 -

AMPS 5.3 5.4 5.6 - 5.7 5.9 6.1 - 6.2 6.4 6.6 - 6.7 6.8 7.1 - 7.1 7.3 7.5 - 7.5 7.7 8.0 -

LO PR 111 118 128 - 117 124 1 36 - 121 12 9 1 41 - 128 136 148 - 134 142 155 - 138 147 161 -

956 KW 1.34 1.37 1.42 - 1.45 1.48 1.54 - 1.55 1.58 1.64 - 1.63 1.67 1.73 - 1.71 1.75 1.81 - 1.77 1.81 1.88 -

uid and suction service valves.

DT 191612 - 191713 - 191713 - 19 17 13 - 191713 - 181512 -

S/T 0.73 0.61 0.42 - 0.76 0.63 0.44 - 0.78 0.65 0.45 - 0.80 0.67 0.46 - 0.83 0.69 0.48 - 0.84 0.70 0.48 -

MBh 24.1 24.9 27.3 - 23.5 24.4 26.7 - 22.9 23.8 26.1 - 22.4 23.2 25.4 - 21.3 22.0 24.1 - 19.7 20.4 22.4 -

HI P R 2 07 223 235 - 232 2 5 0 2 64 - 264 284 3 00 - 301 324 342 - 338 364 38 4 - 374 4 02 425 -

AMPS 5.3 5.4 5.6 - 5.7 5.8 6.0 - 6.2 6.3 6.5 - 6.6 6.8 7.0 - 7.0 7.2 7.5 - 7.5 7.6 7.9 -

LO PR 110 117 127 - 116 123 1 34 - 120 12 8 1 40 - 126 134 147 - 132 141 15 4 - 137 146 159 -

70 850 KW 1.33 1.36 1.40 - 1.44 1.47 1.52 - 1.54 1.57 1.63 - 1.62 1.66 1.72 - 1.69 1.73 1.79 - 1.76 1.80 1.86 -

DT 191713 - 201713 - 201713 - 20 17 13 - 191713 - 181612 -

S/T 0.70 0.59 0.41 - 0.73 0.61 0.42 - 0.75 0.62 0.43 - 0.77 0.64 0.45 - 0.80 0.67 0.46 - 0.81 0.67 0.47 -

MBh 22.2 23.0 25.2 - 21.7 22.5 24.6 - 21.2 21.9 24.0 - 20.7 21.4 23.5 - 19.6 20.3 22.3 - 18.2 18.8 20.6 -

HI P R 2 01 216 228 - 225 2 4 2 2 56 - 256 276 2 91 - 292 314 331 - 328 353 37 3 - 363 3 90 412 -

AMPS 5.1 5.2 5.4 - 5.5 5.7 5.9 - 6.0 6.2 6.4 - 6.4 6.6 6.8 - 6.8 7.0 7.2 - 7.2 7.4 7.7 -

LO PR 106 113 123 - 112 119 1 30 - 117 12 4 1 35 - 123 130 142 - 128 137 14 9 - 133 141 154 -

744 KW 1.29 1.32 1.37 - 1.40 1.43 1.48 - 1.50 1.53 1.58 - 1.58 1.61 1.67 - 1.65 1.69 1.75 - 1.71 1.75 1.81 -

MBh 25.225.928.130.124.625.327.429.424.024.726.828.723.4

S/T 0.870.780.590.380.900.810.610.390.920.830.630.400.95

DT 21 19 16 11 21 20 16 11 21 20 16 11 22

HI P R 2 11 227 240 250 237 2 5 5 2 69 281 26 9 29 0 3 06 3 19 307

AMPS5.45.55.75.95.85.96.16.46.36.56.76.96.7

LO PR 112 119 130 13 8 11 8 1 26 1 37 146 12 3 13 1 1 43 1 5 2 1 29

956 KW 1.35 1.38 1.43 1.48 1.46 1.50 1.55 1.60 1.56 1.60 1.65 1.71 1.65

MBh 24.525.227.329.323.924.626.628.623.324.026.027.922.8

S/T 0.830.740.560.360.860.770.580.370.880.790.600.380.91

DT 22 20 17 11 22 20 17 12 22 20 17 12 22

HI P R 2 09 225 237 248 234 2 5 2 2 66 278 26 7 28 7 3 03 3 16 304

AMPS5.35.45.65.85.75.96.16.36.26.46.66.96.7

LO PR 111 118 128 13 7 11 7 1 24 1 36 145 12 1 12 9 1 41 1 5 0 1 28

75 850 KW 1.34 1.37 1.42 1.47 1.45 1.48 1.54 1.59 1.55 1.59 1.64 1.70 1.64

MBh 22.623.325.227.022.122.724.626.421.522.224.025.821.0

S/T 0.800.720.540.350.830.740.560.360.850.760.580.370.88

DT 22 21 17 12 23 21 17 12 23 21 17 12 23

HI P R 2 03 218 230 240 227 2 4 5 2 58 270 25 9 27 8 2 94 3 07 295

AMPS5.25.35.55.75.65.75.96.16.16.26.46.76.5

LO PR 107 114 125 13 3 11 3 1 21 1 32 140 11 8 12 5 1 37 1 4 6 1 24

res sures are m easured at the li

744 KW 1.31 1.34 1.38 1.43 1.41 1.45 1.50 1.55 1.51 1.54 1.60 1.65 1.59

h and low

Sha ded ar ea is AC C A ( T VA) conditi ons IDB: Entering I ndoor Dry Bulb Temper ature KW =To tal system pow er A M PS=outdoor unit a m ps (comp.+fan)

Hi

7

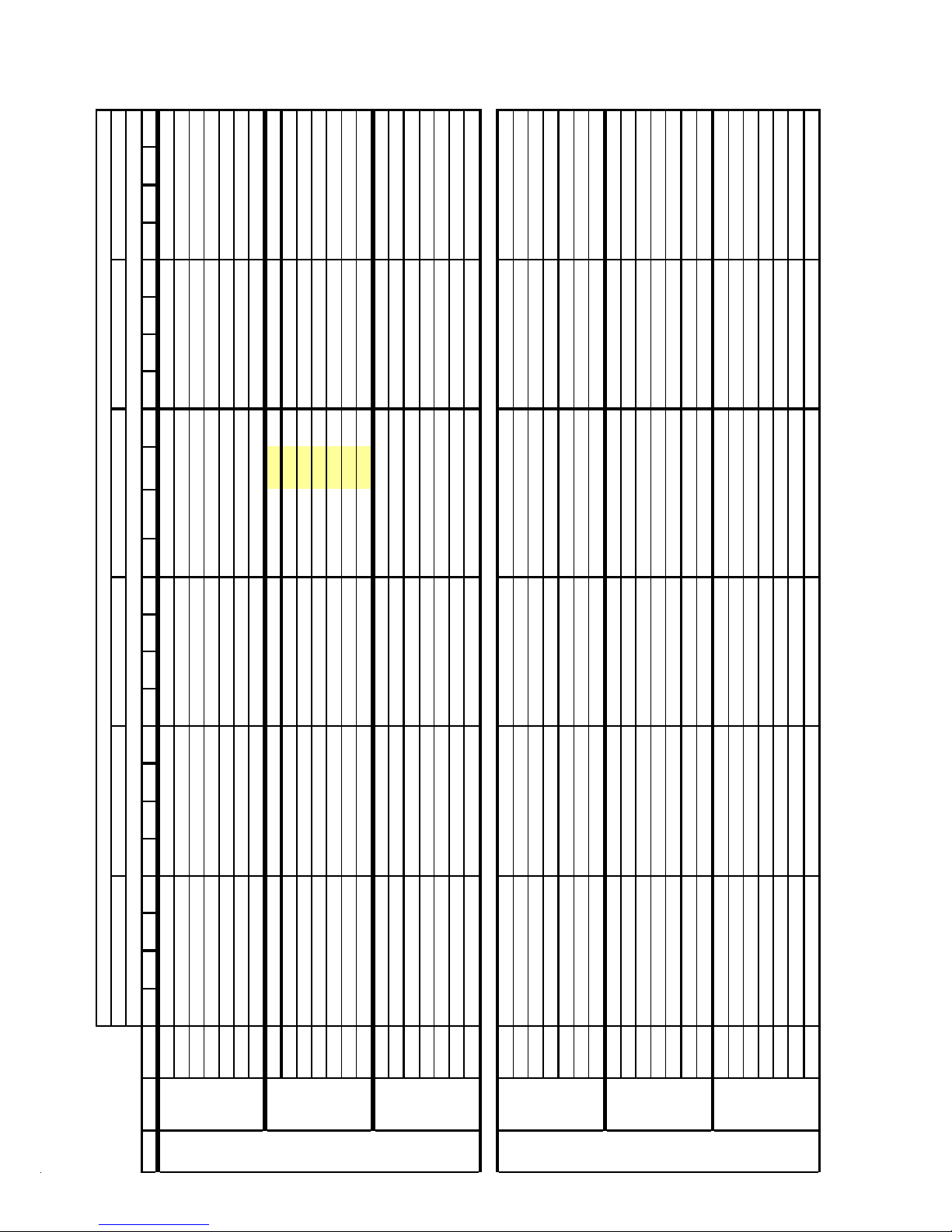

COOLING PERFORMANCE DA T A

CO OL ING OPE RATIO N

17 24 24 21 16 22 22 19 15

7.47.27.37.67.97.67.88.08.4

364 345 371 392 409 381 410 433 452

27.0 22.0 22.5 24.0 25.7 20.4 20.8 22.3 23.8

0.57 1.00 0.97 0.79 0.59 1.00 0.98 0.80 0.60

21

25.3

0.76

159 135 144 157 167 140 149 162 173

1.81 1.72 1.76 1.83 1.89 1.79 1.83 1.89 1.96

7.1

349

150

1.75

*SZC180361A*-LOW ST AGE

EXPA NDED PERFORMANCE DATA

O u t d o o r A m bient Tempe r at u re

Entering Indoor Wet Bul b Tempera ture

65 75 85 95 105 115

DT 24 23 20 16 24 23 20 16 24 23 20 16 23 23 20 16 22 22 20 16 20 21 18 15

S/T 0.95 0.90 0.73 0.54 1.00 0.93 0.75 0.56 1.00 0.95 0.77 0.58 1.00 1.00 0.80 0.60 1.00 1.00 0.83 0.62 1.00 1.00 0.84 0.63

MBh 25.7 26.2 28.0 29.9 25.1 25.6 27.4 29.2 24.5 25.0 26.7 28.5 23.9 24.4 26.0 27.8 22.7 23.2 24.7 26.5 21.0 21.5 22.9 24.5

HI P R 2 13 229 242 253 23 9 257 2 72 284 272 29 3 309 3 22 310 33 3 352 3 67 349 375 396 41 3 385 4 15 438 457

AMPS5.45.55.75.95.96.06.26.46.46.56.77.06.8 7.0 7.2 7.57.27.47.78.07.77.98.18.4

LO PR 113 120 131 140 119 1 27 138 147 124 13 2 144 1 53 130 13 8 151 1 61 136 145 158 16 9 141 1 50 164 175

DT 25 23 20 16 25 24 21 17 25 24 21 17 25 24

S/T 0.91 0.85 0.69 0.52 0.94 0.88 0.72 0.54 0.97 0.91 0.74 0.55 1.00 0.94

MBh 24.9 25.4 27.2 29.1 24.3 24.9 26.6 28.4 23.7 24.3 25.9 27.7 23.2 23.7

AMPS5.45.55.75.95.85.96.16.46.36.56.76.96.7 6.9

HI P R 2 11 227 240 250 23 7 255 2 69 281 269 29 0 306 3 19 307 33 0

LO PR 112 119 130 138 118 1 26 137 146 123 13 1 143 1 52 129 13 7

DT 25 24 21 17 25 24 21 17 25 24 21 17 25 24 21 17 25 24 21 17 23 22 20 16

S/T 0.88 0.82 0.67 0.50 0.91 0.85 0.69 0.52 0.93 0.87 0.71 0.53 0.96 0.90 0.73 0.55 1.00 0.94 0.76 0.57 1.01 0.94 0.77 0.57

MBh 23.0 23.5 25.1 26.8 22.5 22.9 24.5 26.2 21.9 22.4 23.9 25.6 21.4 21.8 23.3 25.0 20.3 20.8 22.2 23.7 18.8 19.2 20.5 22.0

HI P R 2 05 220 233 243 23 0 247 2 61 272 261 28 1 297 3 10 298 32 0 338 3 53 335 360 380 39 7 370 3 98 420 438

AMPS5.25.35.55.75.65.86.06.26.16.36.56.76.5 6.7 6.9 7.27.07.17.47.77.47.67.88.1

LO PR 108 115 126 134 115 1 22 133 142 119 12 7 138 1 47 125 13 3 145 1 55 131 139 152 16 2 136 1 44 157 168

DT 25 25 23 20 25 25 24 20 24 24 24 20 23 24 24 21 22 23 23 20 21 21 22 19

S/T 1.00 0.97 0.87 0.71 1.00 1.00 0.90 0.73 1.00 1.00 0.93 0.75 1.00 1.00 0.96 0.78 1.00 1.00 0.99 0.80 1.00 1.00 1.00 0.81

MBh 26.1 26.6 27.9 29.7 25.5 26.0 27.2 29.0 24.9 25.4 26.6 28.3 24.3 24.7 25.9 27.7 23.1 23.5 24.6 26.3 21.4 21.8 22.8 24.3

HI P R 2 15 232 245 255 24 2 260 2 75 286 275 29 6 312 3 26 313 33 7 356 3 71 352 379 400 41 7 389 4 19 442 461

AMPS5.55.65.86.05.96.06.26.56.46.66.87.06.9 7.0 7.3 7.57.37.57.78.07.77.98.28.5

LO PR 114 121 132 141 120 1 28 140 149 125 13 3 145 1 55 131 14 0 153 1 63 138 147 160 17 0 143 1 52 166 176

DT 26 26 24 21 26 26 25 21 26 26 25 21 25 26 25 21 24 25 24 21 22 23 23 20

S/T 0.95 0.92 0.83 0.67 0.99 0.95 0.86 0.70 1.00 0.98 0.88 0.72 1.00 1.00 0.91 0.74 1.00 1.00 0.95 0.77 1.00 1.00 0.95 0.77

MBh 25.3 25.8 27.1 28.9 24.7 25.2 26.4 28.2 24.2 24.6 25.8 27.5 23.6 24.0 25.2 26.8 22.4 22.8 23.9 25.5 20.7 21.1 22.1 23.6

HI P R 2 13 229 242 253 23 9 257 2 72 284 272 29 3 309 3 22 310 33 3 352 3 67 349 375 396 41 3 385 4 15 438 457

AMPS5.45.55.75.95.96.06.26.46.46.56.77.06.8 7.0 7.2 7.57.27.47.78.07.77.98.18.4

LO PR 113 120 131 140 119 1 27 138 147 124 13 2 144 1 53 130 13 8 151 1 61 136 145 158 16 9 141 1 50 164 175

DT 26.6 26 25 21 27 26 25 22 27 27 25 22 27 27 25 22 26 26 25 22 24 24 23 20

S/T 0.92 0.89 0.80 0.65 0.95 0.92 0.83 0.67 0.98 0.94 0.85 0.69 1.00 0.97 0.88 0.71 1.00 1.00 0.91 0.74 1.00 1.00 0.92 0.75

MBh 23.4 23.8 25.0 26.6 22.8 23.3 24.4 26.0 22.3 22.7 23.8 25.4 21.8 22.2 23.2 24.8 20.7 21.1 22.1 23.5 19.1 19.5 20.4 21.8

HI P R 2 07 223 235 245 23 2 250 2 64 275 264 28 4 300 3 13 301 32 3 342 3 56 338 364 384 40 1 374 4 02 425 443

AMPS5.35.45.65.85.75.86.06.26.26.36.56.86.6 6.8 7.0 7.37.07.27.47.77.57.67.98.2

LO PR 109 116 127 135 116 1 23 134 143 120 12 8 140 1 49 126 13 4 147 1 56 132 141 154 16 4 137 1 46 159 169

956 KW 1.36 1.39 1.44 1.49 1.48 1.51 1.56 1.62 1.58 1.61 1.67 1.73 1.66 1.70 1.76 1.83 1.74 1.78 1.84 1.91 1.80 1.85 1.91 1.98

MOD EL: * S ZC180 3 61A* / CA*F3743*6** + TXV / M BV C1600**-1* * Design Su bcooling 5 - 7 °F @ the li quid service val ve , AHRI 95° F test conditions

IDB*Airflow 59636771596367715963677159 63 67715963677159636771

8

744 KW 1.32 1.35 1.39 1.44 1.43 1.46 1.51 1.56 1.52 1.56 1.61 1.67 1.61 1.64 1.70 1.76 1.68 1.72 1.78 1.84 1.74 1.78 1.84 1.91

80 850 KW 1.35 1.38 1.43 1.48 1.46 1.50 1.55 1.60 1.56 1.60 1.65 1.71 1.65 1.69

956 KW 1.38 1.41 1.45 1.50 1.49 1.52 1.58 1.63 1.59 1.63 1.68 1.74 1.68 1.72 1.78 1.84 1.75 1.80 1.86 1.93 1.82 1.86 1.93 2.00

85 850 KW 1.36 1.39 1.44 1.49 1.48 1.51 1.56 1.62 1.58 1.61 1.67 1.73 1.66 1.70 1.76 1.83 1.74 1.78 1.84 1.91 1.80 1.85 1.91 1.98

744 KW 1.33 1.36 1.40 1.45 1.44 1.47 1.52 1.57 1.53 1.57 1.62 1.68 1.62 1.66 1.72 1.78 1.69 1.73 1.79 1.86 1.76 1.80 1.86 1.93

Sha ded ar ea i s AHR I Rating Conditio ns IDB : Entering Indoo r Dry Bulb Temper ature KW=To tal system power AM PS=outdoor uni t amps (comp.+fan)

High and l ow pr ess ur es are measured at the li quid and suc tion service val ves.

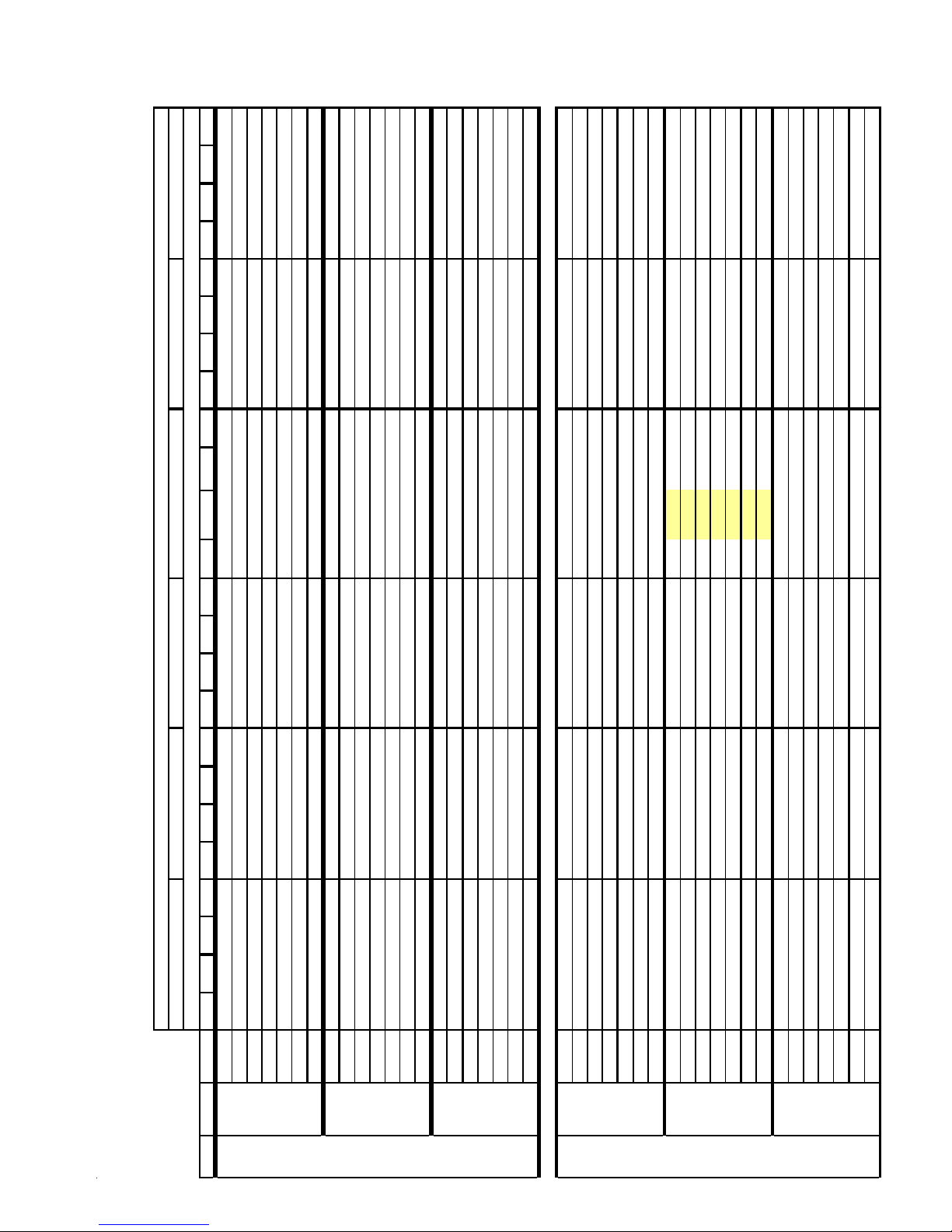

COOLING PERFORMANCE DA T A

g

p

q

COOL ING OPERATION

*SZC180481A*-LOW ST AGE

EXPANDED PERFOR MANCE DATA

16 11 21 19 16 11 20 18 15 10

0.1 0.1 0.1 0.1 0 .1 0.1 0.1 0.1 0.1 0.1

348 363 345 371 392 409 381 410 433 452

36.9 39.6 31.5 32.4 35.1 37.7 29.2 30.0 32.5 34.9

0.64 0.41 0.98 0.87 0.66 0.43 0.99 0.88 0.67 0.43

20

34.1

0.84

Out door Amb ien t Temperatur e

Entering Indoor Wet Bulb Tempe ratu re

149 158 134 143 156 166 139 148 161 172

2.42 2.51 2.39 2.45 2.53 2.63 2.48 2.54 2.63 2.73

0.1

330

136

2.34

17 12 22 20 16 11 20 19 15 11

0.1 0.1 0.1 0.1 0 .1 0.1 0.1 0.1 0.1 0.1

345 360 341 367 388 405 377 406 429 447

35.9 38.5 30.6 31.5 34.1 36.6 28.3 29.2 31.6 33.9

0.61 0.39 0.93 0.83 0.63 0.41 0.94 0.84 0.64 0.41

20

33.1

0.80

147 157 133 141 154 164 137 146 160 170

2.40 2.49 2.37 2.43 2.51 2.60 2.46 2.52 2.61 2.70

0.1

327

135

2.32

17 12 22 20 17 12 21 19 16 11

0.1 0.1 0.1 0.1 0 .1 0.1 0.1 0.1 0.1 0.1

334 349 331 356 376 392 366 394 416 434

33.1 35.5 28.2 29.0 31.4 33.7 26.1 26.9 29.1 31.3

0.59 0.38 0.90 0.80 0.61 0.39 0.91 0.81 0.61 0.40

21

30.6

0.78

143 152 129 137 150 159 133 142 155 165

2.34 2.42 2.31 2.36 2.44 2.53 2.39 2.45 2.54 2.63

0.1

317

131

2.26

65 75 85 95 105 115

DT 18 16 12 - 18 16 12 - 18 16 12 - 18 16 12 - 18 16 12 - 17 15 11 -

S/T 0.76 0.63 0.44 - 0.78 0.65 0.45 - 0.80 0.67 0.46 - 0.83 0.69 0.48 - 0.86 0.72 0.50 - 0.87 0.72 0.50 -

MBh 35.0 36.3 39.8 - 34.2 35.5 38.9 - 33.4 34.6 37.9 - 32.6 33.8 37.0 - 31.0 32.1 35.2 - 28.7 29.7 32.6 -

MODEL: *S ZC180481A* / CA *F49 61*6** + TXV / MBV C2000**-1** Des ign Sub cooling 5 - 7°F @ t he liq ui d servic e va lve, AHRI 95 test conditions

IDB*Airflow 59636771596367715963677159 63 67 715963677159636771

HI P R 209 225 237 - 234 2 52 266 - 266 287 3 0 3 - 303 326 345 - 341 367 3 88 - 377 4 06 429 -

AMPS0.10.10.1-0.10.10.1-0.10.10.1-0.10.1 0.1 -0.10.10.1-0.10.10.1-

1350 KW 1.85 1.89 1.96 - 2.01 2.05 2.13 - 2.14 2.20 2.27 - 2.27 2.32 2.40 - 2.37 2.43 2.51 - 2.46 2.52 2.61 -

LO PR 110 117 128 - 116 123 1 35 - 121 128 1 40 - 127 135 147 - 133 141 154 - 137 1 4 6 160 -

uid and suc tion ser vice v al ves.

DT 19 16 12 - 19 16 12 - 19 16 13 - 19 17 13 - 19 16 12 - 18 15 12 -

S/T 0.72 0.60 0.42 - 0.75 0.62 0.43 - 0.77 0.64 0.44 - 0.79 0.66 0.46 - 0.82 0.69 0.47 - 0.83 0.69 0.48 -

MBh 34.0 35.3 38.6 - 33.2 34.4 37.7 - 32.4 33.6 36.8 - 31.6 32.8 35.9 - 30.1 31.2 34.1 - 27.8 28.9 31.6 -

HI P R 207 222 235 - 232 2 50 264 - 264 284 3 0 0 - 300 323 341 - 338 364 3 84 - 373 4 02 424 -

AMPS0.10.10.1-0.10.10.1-0.10.10.1-0.10.1 0.1 -0.10.10.1-0.10.10.1-

70 1200 KW 1.84 1.88 1.94 - 1.99 2.04 2.11 - 2.13 2.18 2.25 - 2.25 2.30 2.38 - 2.35 2.40 2.49 - 2.44 2.49 2.58 -

DT 19 17 13 - 19 17 13 - 19 17 13 - 19 17 13 - 19 17 13 - 18 16 12 -

S/T 0.70 0.58 0.40 - 0.72 0.60 0.42 - 0.74 0.62 0.43 - 0.76 0.64 0.44 - 0.79 0.66 0.46 - 0.80 0.67 0.46 -

MBh 31.4 32.5 35.7 - 30.7 31.8 34.8 - 29.9 31.0 34.0 - 29.2 30.3 33.2 - 27.7 28.8 31.5 - 25.7 26.6 29.2 -

LO PR 109 116 126 - 115 122 1 33 - 119 127 1 39 - 125 133 146 - 131 140 153 - 136 1 4 5 158 -

HI P R 200 216 228 - 225 2 42 256 - 256 275 2 9 1 - 291 314 331 - 328 353 3 72 - 362 3 90 412 -

AMPS0.10.10.1-0.10.10.1-0.10.10.1-0.10.1 0.1 -0.10.10.1-0.10.10.1-

1050 KW 1.79 1.83 1.89 - 1.94 1.98 2.05 - 2.07 2.12 2.19 - 2.19 2.24 2.32 - 2.28 2.34 2.42 - 2.37 2.43 2.51 -

LO PR 106 112 123 - 111 119 1 29 - 116 123 1 35 - 122 129 141 - 128 136 148 - 132 1 4 0 153 -

MBh 35.636.739.742.634.835.838.841.634.035.037.940.633.1

DT 21 19 16 11 21 19 16 11 21 19 16 11 21

S/T 0.86 0.77 0.58 0.37 0.89 0.80 0.60 0.39 0.91 0.82 0.62 0.40 0.94

HI P R 211 227 240 250 237 2 55 269 280 269 29 0 3 0 6 3 19 306

AMPS 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1

LO PR 111 118 129 137 11 7 1 25 1 36 145 122 130 1 4 2 1 51 128

1350 KW 1.87 1.91 1.98 2.05 2.03 2.07 2.14 2.22 2.16 2.22 2.29 2.37 2.29

MBh 34.635.638.541.433.834.837.740.433.034.036.839.432.2

DT 22 20 16 11 22 20 17 11 22 20 17 11 22

S/T 0.82 0.73 0.55 0.36 0.85 0.76 0.57 0.37 0.87 0.78 0.59 0.38 0.90

HI P R 209 225 237 247 234 2 52 266 278 266 28 7 3 0 3 3 16 303

AMPS 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1

LO PR 110 117 128 136 11 6 1 24 1 35 144 121 128 1 4 0 1 49 127

75 1200 KW 1.85 1.89 1.96 2.03 2.01 2.05 2.13 2.20 2.15 2.20 2.27 2.35 2.27

MBh 31.932.935.638.231.232.134.837.330.431.333.936.429.7

DT 22 20 17 12 22 21 17 12 22 21 17 12 23

S/T 0.79 0.71 0.53 0.34 0.82 0.73 0.55 0.36 0.84 0.75 0.57 0.37 0.87

HI P R 203 218 230 240 227 2 45 258 269 258 27 8 2 9 4 3 06 294

AMPS 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1

LO PR 107 113 124 132 11 3 1 20 1 31 139 117 125 1 3 6 1 45 123

ressures are measured at the li

1050 KW 1.80 1.85 1.91 1.98 1.95 2.00 2.07 2.14 2.09 2.14 2.21 2.29 2.21

h an d low

Sha ded area is ACCA (T VA) condi ti ons IDB : Enteri ng I nd oor D r y Bulb T emperature KW = Tot al system pow er AMPS=outdoor unit a m ps (comp.+fan)

Hi

9

COOLING PERFORMANCE DA T A

COOL ING OPE RATION

16 24 23 20 16 22 22 19 15

0.10.10.10.10.10.10.10.10.1

363 345 371 392 409 381 410 433 452

158 134 143 156 166 139 148 161 172

38.2 31.1 31.8 34.0 36.3 28.8 29.4 31.5 33.6

2.51 2.39 2.45 2.54 2.63 2.48 2.54 2.63 2.73

0.56 1.00 0.96 0.78 0.58 1.00 0.97 0.79 0.59

21

0.1

348

149

2.42

35.8

0.75

*SZC180481A*-LOW ST AGE

EXPANDED PERFORMANCE DATA

Outdoor Ambient Temperature

Entering Indoor Wet Bulb Temperature

65 75 85 95 105 115

MBh 36.337.139.642.335.436.238.741.334.635.337.740.333.7 34.5 36.839.432.032.735.037.429.730.332.434.6

DT 23 22 19 15 24 23 20 16 24 23 20 16 23 23 20 16 22 22 20 16 20 21 18 15

S/T 0.94 0.88 0.72 0.54 1.00 0.92 0.75 0 .56 1.00 0.94 0.76 0.57 1.00 0.97 0.79 0.59 1.00 1.00 0.82 0.61 1.00 1.00 0 .83 0.62

HI P R 2 13 229 242 252 2 39 2 57 2 72 283 27 2 29 2 3 09 3 2 2 31 0 333 352 367 348 375 396 413 3 85 4 1 4 43 7 4 56

AMPS0.10.10.10.10.10.10.10.10.10.10.10.10.1 0.1 0.1 0.10.10.10.10.10.10.10.10.1

LO PR 112 119 130 13 9 11 8 1 26 1 3 8 14 7 1 23 13 1 1 43 1 52 129 138 150 160 136 144 157 168 1 40 1 4 9 16 3 1 73

MBh 35.236.038.441.134.435.137.540.133.634.336.639.232.7 33.5

DT 24 23 20 16 25 24 20 16 25 24 20 16 25 24

S/T 0.90 0.84 0.69 0.51 0.93 0.87 0.71 0 .53 0.96 0.90 0.73 0.54 0.99 0.92

HI P R 2 11 227 240 250 2 37 2 55 2 69 280 26 9 29 0 3 06 3 1 9 30 7 330

AMPS 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1

LO PR 111 118 129 13 7 11 7 1 25 1 3 6 14 5 1 22 13 0 1 42 1 51 128 136

MBh 32.533.235.537.931.732.434.637.031.031.733.836.230.2 30.9 33.035.328.729.331.333.526.627.229.031.0

DT 25 24 21 16 25 24 21 17 25 24 21 17 25 24 21 17 25 24 21 17 23 22 19 15

S/T 0.87 0.81 0.66 0.49 0.90 0.84 0.69 0 .51 0.92 0.86 0.70 0.53 0.95 0.89 0.73 0.54 0.99 0.93 0.75 0.56 0.99 0.93 0 .76 0.57

HI P R 2 05 220 232 242 2 30 2 47 2 61 272 26 1 28 1 2 97 3 0 9 29 7 320 338 352 334 360 380 396 3 70 3 9 8 42 0 4 38

AMPS0.10.10.10.10.10.10.10.10.10.10.10.10.1 0.1 0.1 0.10.10.10.10.10.10.10.10.1

LO PR 108 115 125 13 3 11 4 1 21 1 3 2 14 1 1 18 12 6 1 37 1 46 124 132 144 154 130 138 151 161 1 35 1 4 3 15 6 1 67

MBh 36.937.639.442.036.036.738.541.035.235.937.640.134.3 35.0 36.639.132.633.234.837.130.230.832.234.4

DT 25 24 23 20 25 25 23 20 24 24 23 20 23 24 24 20 22 23 23 20 21 21 22 19

S/T 0.99 0.95 0.86 0.70 1.00 0.99 0.89 0 .72 1.00 1.00 0.91 0.74 1.00 1.00 0.94 0.77 1.00 1.00 0.98 0.79 1.00 1.00 0 .99 0.80

HI P R 2 15 231 244 255 2 41 2 60 2 74 286 27 5 29 5 3 12 3 2 5 31 3 336 355 371 352 379 400 417 3 89 4 1 8 44 2 4 61

AMPS0.10.10.10.10.10.10.10.10.10.10.10.10.1 0.1 0.1 0.10.10.10.10.10.10.10.10.1

LO PR 113 120 132 14 0 12 0 1 27 1 3 9 14 8 1 24 13 2 1 44 1 54 131 139 152 162 137 146 159 169 1 42 1 5 1 16 4 1 75

MBh 35.836.538.240.835.035.737.439.834.234.836.538.933.3 34.0 35.638.031.732.333.836.129.329.931.333.4

DT 26 25 24 21 26 26 24 21 26 26 24 21 26 26 25 21 24 25 24 21 22 23 23 20

S/T 0.94 0.91 0.82 0.67 0.98 0.94 0.85 0 .69 1.00 0.97 0.87 0.71 1.00 1.00 0.90 0.73 1.00 1.00 0.93 0.76 1.00 1.00 0 .94 0.76

AMPS0.10.10.10.10.10.10.10.10.10.10.10.10.1 0.1 0.1 0.10.10.10.10.10.10.10.10.1

HI P R 2 13 229 242 252 2 39 2 57 2 72 283 27 2 29 2 3 09 3 2 2 31 0 333 352 367 348 375 396 413 3 85 4 1 4 43 7 4 56

LO PR 112 119 130 13 9 11 8 1 26 1 3 8 14 7 1 23 13 1 1 43 1 52 129 138 150 160 136 144 157 168 1 40 1 4 9 16 3 1 73

MBh 33.133.735.337.732.332.934.536.831.532.133.735.930.8 31.4 32.835.029.229.831.233.327.127.628.930.8

DT 26.3 26 24 21 27 26 25 21 27 26 25 21 27 26 25 22 26 26 25 21 24 24 23 20

S/T 0.91 0.88 0.79 0.64 0.94 0.91 0.82 0 .67 0.97 0.93 0.84 0.68 1.00 0.96 0.87 0.70 1.00 1.00 0.90 0.73 1.00 1.00 0 .91 0.74

HI P R 2 07 222 235 245 2 32 2 49 2 63 275 26 4 28 4 3 00 3 1 2 30 0 323 341 356 338 364 384 400 3 73 4 0 2 42 4 4 42

AMPS0.10.10.10.10.10.10.10.10.10.10.10.10.1 0.1 0.1 0.10.10.10.10.10.10.10.10.1

LO PR 109 116 126 13 5 11 5 1 22 1 3 3 14 2 1 19 12 7 1 39 1 48 125 133 146 155 131 140 153 163 1 36 1 4 5 15 8 1 68

135 0 KW 1.88 1.93 1.99 2.06 2.04 2.09 2.16 2.24 2.18 2.24 2.31 2.40 2.31 2.36 2 .45 2.53 2.41 2.47 2.56 2.65 2.50 2.56 2.65 2.75

MOD E L: *SZC180481A* / CA*F4961* 6** + TXV / MBVC2000**-1** Desig n Subcool ing 5 - 7°F @ t he liq uid service valve, AHRI 95 test conditions

IDB*Airflow 59636771596367715963677159 63 67 715963677159636771

10

105 0 KW 1.82 1.86 1.93 1.99 1.97 2.02 2.09 2.16 2.11 2.16 2.23 2.31 2.23 2.28 2 .36 2.44 2.33 2.38 2.47 2.56 2.41 2.47 2.56 2.65

80 1200 KW 1.87 1.91 1.98 2.05 2.03 2.07 2.15 2.22 2.16 2.22 2.29 2.38 2.29 2.34

135 0 KW 1.90 1.94 2.01 2.08 2.06 2.11 2.18 2.26 2.20 2.26 2.33 2.42 2.33 2.38 2 .47 2.56 2.43 2.49 2.58 2.67 2.53 2.59 2.68 2.78

85 1200 KW 1.88 1.93 1.99 2.06 2.04 2.09 2.16 2.24 2.18 2.24 2.31 2.40 2.31 2.36 2 .45 2.53 2.41 2.47 2.56 2.65 2.50 2.56 2.65 2.75

105 0 KW 1.84 1.88 1.94 2.01 1.99 2.04 2.11 2.18 2.13 2.18 2.25 2.33 2.25 2.30 2 .38 2.47 2.35 2.40 2.49 2.58 2.44 2.49 2.58 2.68

Shaded area i s AHRI Rating Conditions IDB: Enteri ng Indoor Dry Bulb Temperature KW=Total system power AMPS=outdoor unit amps (comp.+fan)

High and low pr ess ur es are me asured at the l i quid and su ction serv ice valves.

Loading...

Loading...