Goodman ACV series, AMV series, AMH series, ADS series, AMS series Service Instructions Manual

...Page 1

Service

Instructions

80%, 90%, 95% Gas Furnaces

& Accessories

ACS, ACV, ADS, ADV, AMH, AMS, AMV, DCS, DDS,

DHS, DMS, GCH, GCS, GDH, GDS, GCV, GHS, GKS,

GME, GMH, GMS, GMV

This manual is to be used by qualified, professionally trained HVAC technicians only. Goodman does

not assume any responsibility for property damage or personal injury due to improper service

procedures or services performed by an unqualified person.

Copyright © 2006-2007 Goodman Manufacturing Company, L.P.

RS6610004 Rev. 2

November 2007

www.goodmanmfg.com www.amana-hac.com

Page 2

TABLE OF CONTENTS

IMPORTANT INFORMATION ........................... 2-3

PRODUCT IDENTIFICATION ........................ 4-14

OPERATING INSTRUCTIONS .................... 20-22

ACCESSORIES ........................................... 23-27

PRODUCT DESIGN .................................... 28-79

SYSTEM OPERATION ................................ 80-91

POLARIZATION & PHASING ............................. 92

MAINTENANCE ............................................ 93-95

SERVICING .................................................96-128

TROUBLESHOOTING .............................. 105-106

SERVICING TABLE OF CONTENTS ................ 98

ACCESSORIES WIRING DIAGRAMS ......129-131

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE

SERVICE MANUAL BEFORE BEGINNING REPAIRS.

IMPORTANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

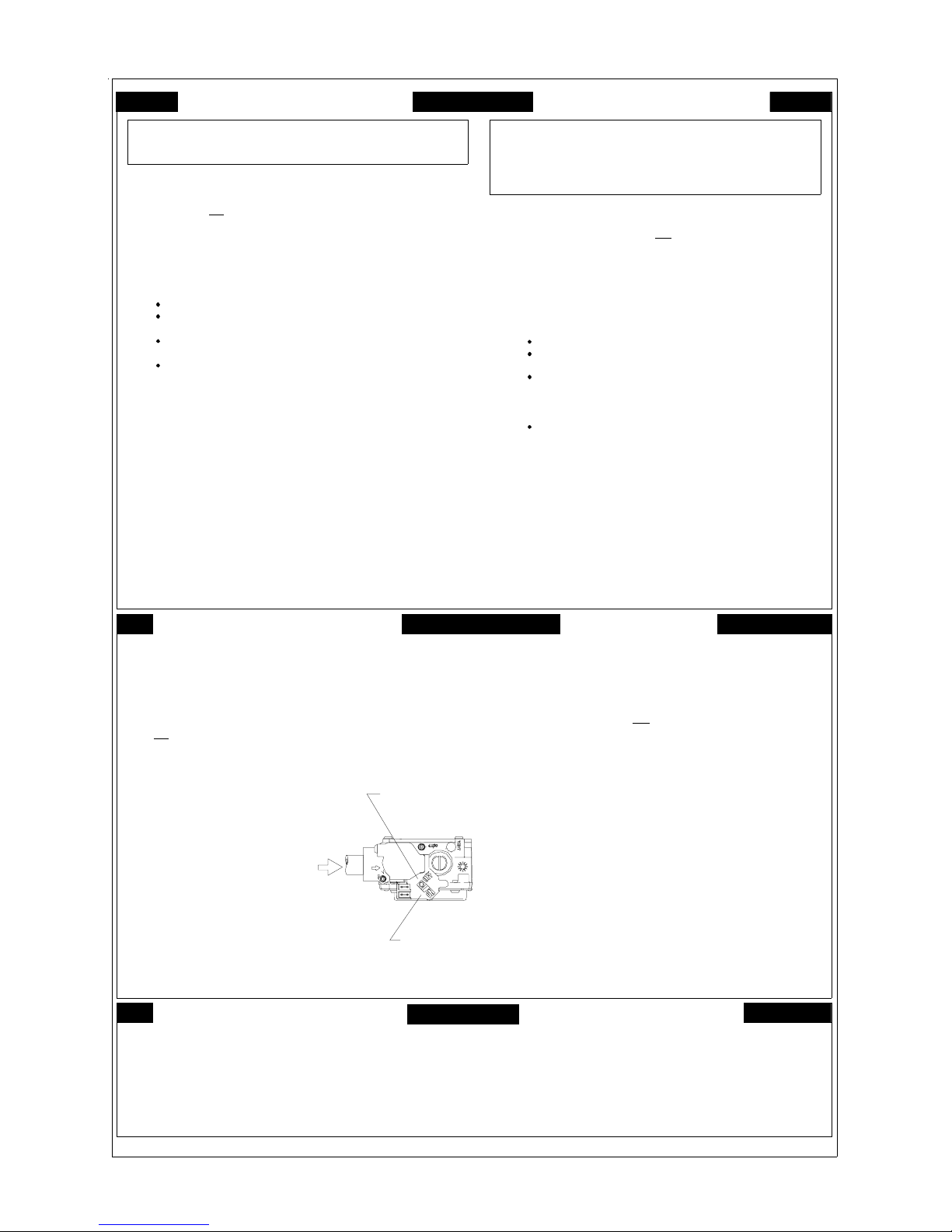

WARNING

T

O PREVENT THE RISK OF PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH,

DO NOT STORE COMBUSTIBLE MATER IALS OR USE GASOLINE OR OTHER

FLAMMABLE LIQUIDS OR VAPORS IN THE VICINITY OF THIS APPLIANCE.

WARNING

GOODMAN WILL NOT BE RESPONSIBLE FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM IMPROPER SERVICE OR SERVICE PROCEDURES.

IF YOU INSTALL OR PERFORM SERVICE ON THIS UNIT, YOU ASSUME RESPONSIBILITY FOR ANY PERSONAL INJURY OR PROPERTY DAMAGE WHICH

MAY RESULT.

MANY JURISDICTIONS REQUIRE A L ICENSE TO INSTALL O R SERVICE HEATING AND AIR CONDITIONING EQUIPMENT.

WARNING

HIGH VOLTAGE

ISCONNECT ALL POWER BEFORE SERVICING OR

D

INSTALLING THIS UNIT.

BE PRESENT.

DAMAGE, PERSONAL INJURY OR DEATH.

FAILURE TO DO SO MAY CAU SE PROPERTY

MULTIPLE POWER SOURCES MAY

2

Page 3

IMPORTANT INFORMATION

Special Warning for In stallation of Furna ce or Air Handling Units in

Enclosed Areas such as Garages, Utility Rooms or Parking Areas

Carbon monoxide producing devices (such as an automobile, space

heater, gas w ater heater, etc.) should not b e operated i n enclosed ar eas

such as unventilated garages, utility rooms or parking areas bec ause of

the danger of carbon monoxide (CO) poisoning resulting from the exhaust

emissions. If a furnace or air handler is installed in an enclosed area such

as a garage, utility ro om or parking area and a carbon monoxid e producing

device is operated therein, there must be adequate, direct outside

ventilation.

This vent ilation is necess ary to avoid the danger of C O poisoning wh ich

can occur if a carbon monoxide producing device continues to operate in

the enclo sed area. Carbon monoxide emis sions can be (re )circulated

througho ut the structure if the furnace or ai r handler is operating in any

mode.

CO can cause serious illness including permanent brain damage or death.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

CONSUMER INFORMATION LINE

GOODMAN® BRAND PRODUCTS

TOLL FREE

1-877-254-4729 (U.S. only)

email us at:

customerservice@goodmanmfg.com

fax us at: (731) 863-2382

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-713-861-2500.

(Not a technical assistance line for dealers.)

Your telephone company will bill you for the call.

Your telephone company will bill you for the call.

CONSUMER INFORMATION LINE

AMANA® BRAND PRODUCTS

TOLL FREE

1-877-254-4729 (U.S. only)

email us at:

hac.consumer.affairs@amanahvac.com

fax us at: (931) 438-4362

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-931-433-6101.

(Not a technical assistance line for dealers.)

3

Page 4

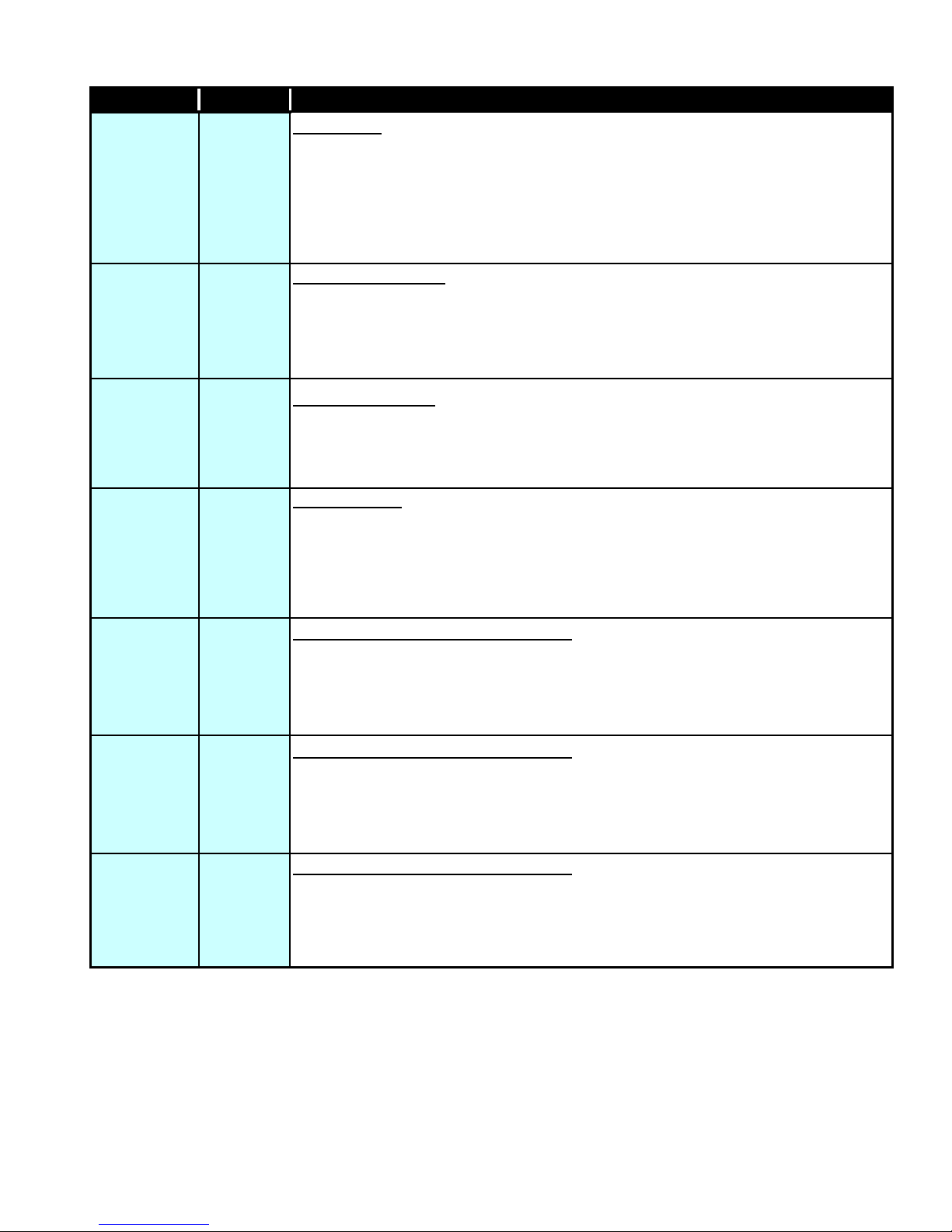

PRODUCT IDENTIFICATION

The model and manufacturing number are used for positive identification of component parts used in manufacturing.

Please use these numbers when requesting service or parts information.

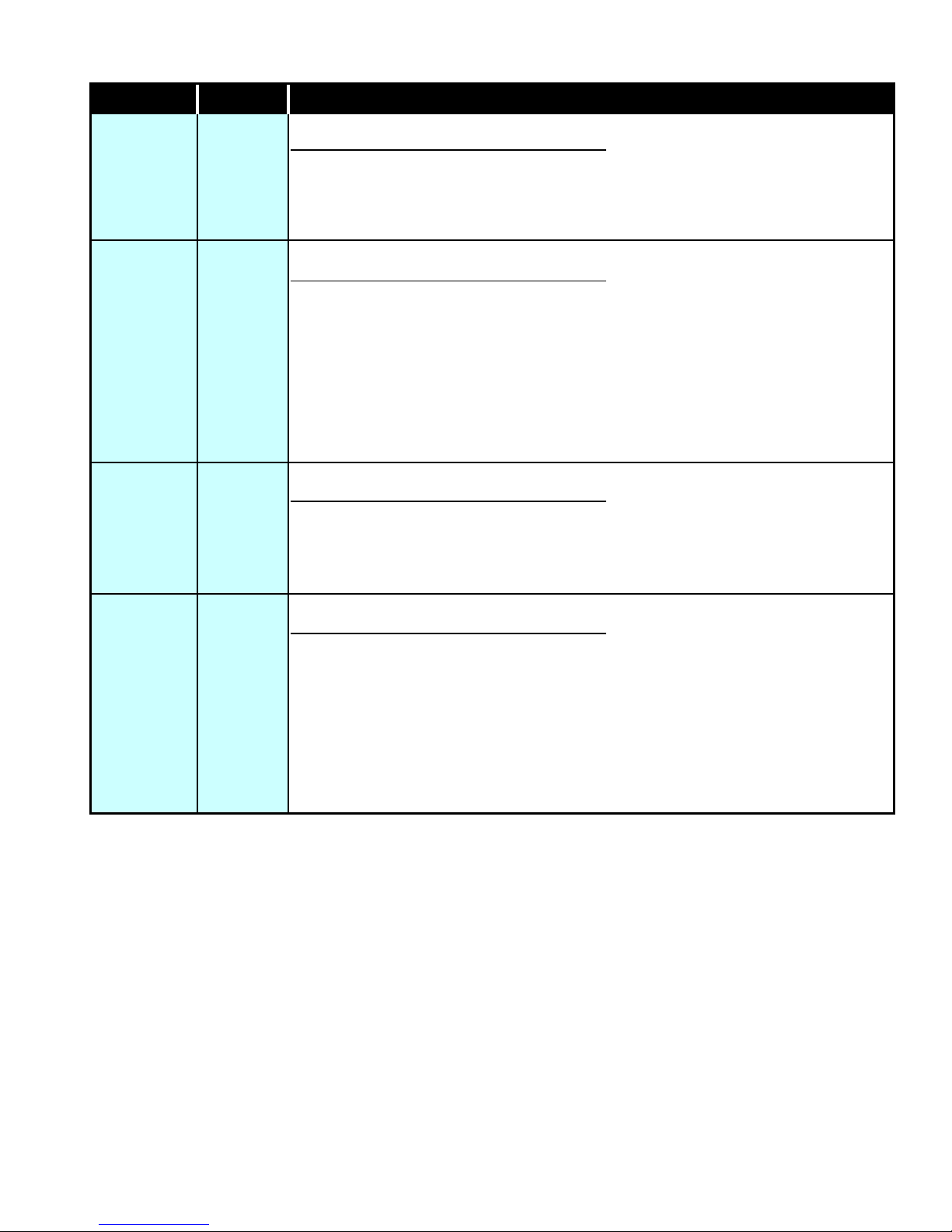

G M S 9 070 3 B X A A

Product Type

A: Amana® Brand

D: Amana

Distinctions

G: Goodman

®

TM

Supply Type

M: Upflow/Horizontal

D: Dedicated Downflow

C: Downflow/Horizontal

H: High Air Flow

Furnace Type

E: Two Stage/X-13 Motor

S: Single Stage/Multi-speed

V: Two Stage/Variable-speed

H: Two Stage/Multi-speed

Brand

AFUE

8: 80%

9: 90%

95: 95%

Nominal Input

Minor

Revision

A: Initial

Release

Major

Revision

A: Initial

Release

Additional Features

N: Natural Gas

X: Low NOx

Cabinet Width

A: 14"

B: 17 1/2"

C: 21"

D: 24 1/2"

Airflow Capability

@ 0.5" ESP

3: 1200 CFM

4: 1600 CFM

5: 2000 CFM

045: 45,000 Btuh

070: 70,000 Btuh

090: 90,000 Btuh

115: 115,000 Btuh

140: 140,000 Btuh

4

Page 5

PRODUCT IDENTIFICATION

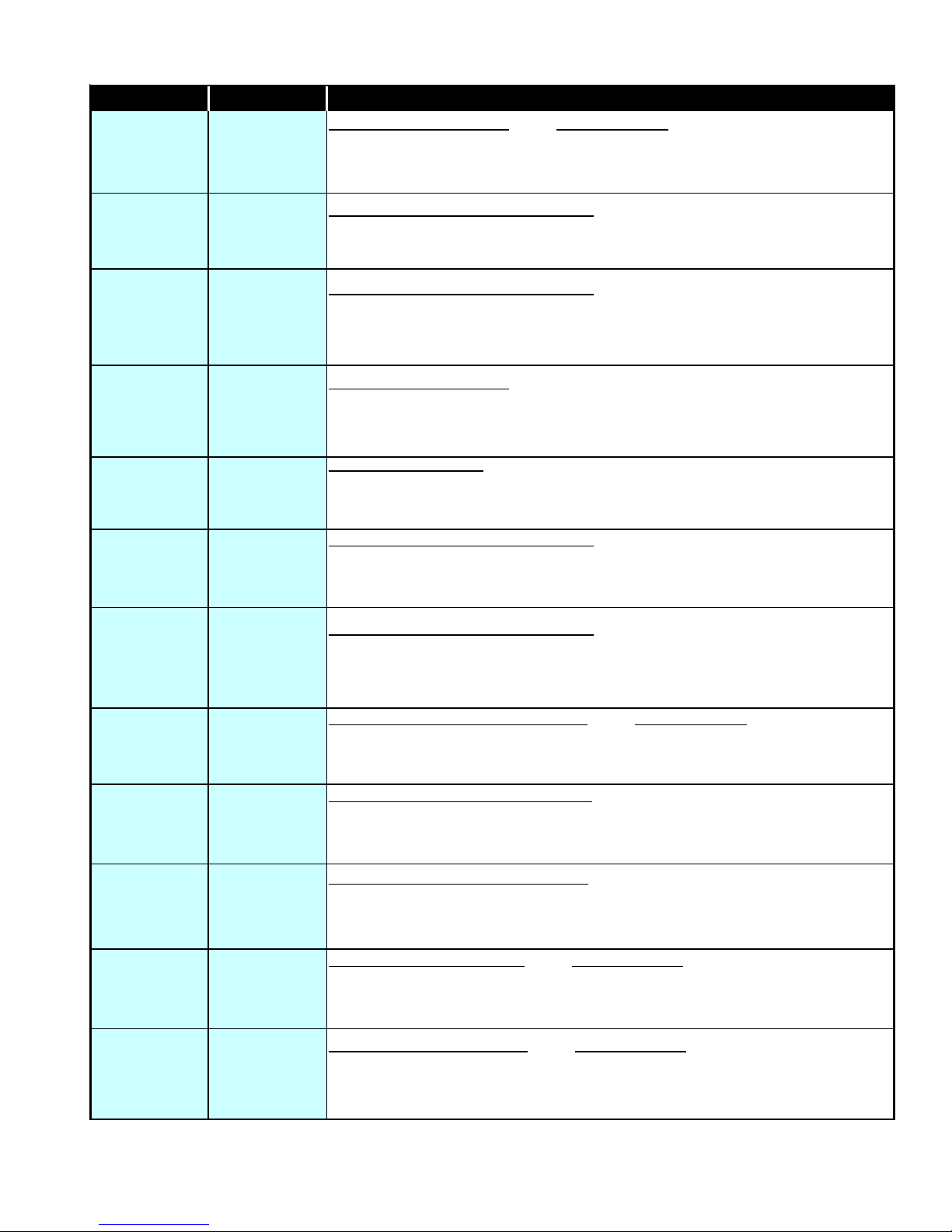

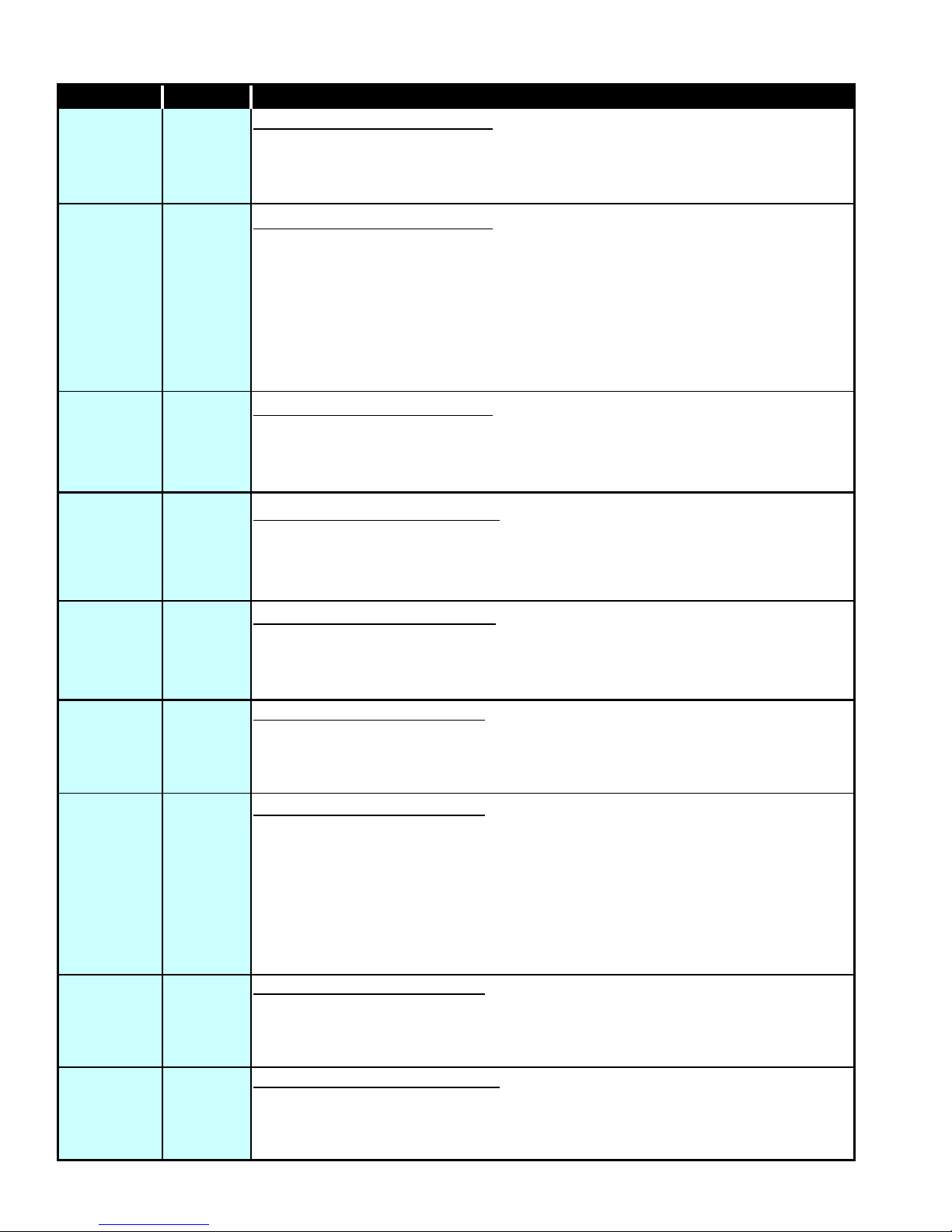

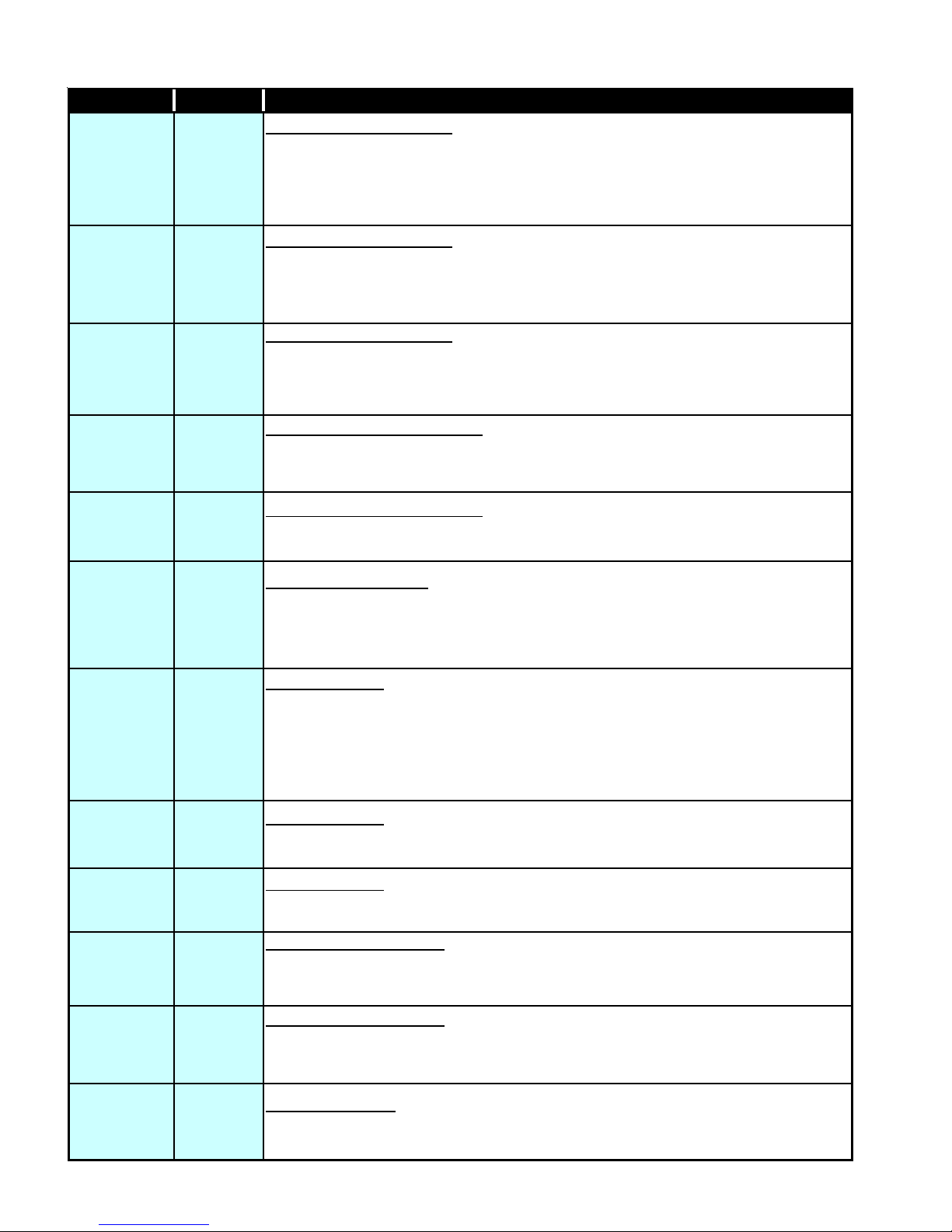

MODEL # MFG. # 80 % GAS FURNACES

ADS8* ADS8*****AA

Amana® Brand 80% Gas Furnace

changes that include new two tone grey painted cabinet and front panels, PSC motor, standardized blower

decks, and a Surestart Silicon Nitride Igniter. Left or right gas pipe entry.The furnaces also feature an integrated

electronic ignition control and a Million-Air stainless steel tubular heat exchanger. Chassis sizes are now 14",

17.5", 21" wide.

, 39" tall,

Dedicated Downflow

, Induced Draft, 39" 80% furnace redesign

ADV8* ADV8******AA

ADV8*****BA

ADV8*****BA

ADV8*****BB

AMH8*

AMS8* AMS8*****AA

AMV8* AMV8*****AA

AMH8*****AA

AMH8*****AB

AMH8*****AC

AMV8*****BA

AMV8*****BA

AMV8*****BB

Amana® Brand 80% Variable Speed Gas Furnace

2-Stage Induced Draft, new two tone grey painted cabinet and front panels, standardized blower decks and a

Surestart Silicon Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic

ignition control and Million-Air stainless steel tubular heat exchanger. Chassis sizes are now 17.5", 21" wide.

Amana® Brand 80% Variable Speed Gas Furnace

2-Stage Induced Draft, new two tone grey painted cabinet and front panels, standardized blower decks and a

Surestart Silicon Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic

ignition control,

sizes are now 17.5", 21" wide. BB models utilized the round nose inducer motor.

Amana® Brand 80% Gas Furnace

cabinet and front panels, PSC motor, standardized blower decks and a 120V silicon nitride igniter. Left or right

gas pipe entry. The furnaces also feature an integrated electronic ignition control and aluminized steel tubular

heat exchanger. Chassis sizes are now 14", 17.5" 21, and 24.5" wide. ***AB Models used a round nose

inducer motor. ***AC models revert back to Jakel square nose inducer.

Amana® Brand Gas Furnace

changes that include new two tone grey painted cabinet and front panels, PSC motor, standardized blower

decks and a Surestart Silicon Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an integrated

electronic ignition control and a Million-Air stainless steel tubular heat exchanger. Chassis sizes are now 14",

17.5", 21" and 24.5" wide.

Amana® Brand 80% Variable Speed Gas Furnace

or Right, 2-Stage Induced Draft, new two tone grey painted cabinet and front panels, standardized blower decks

and a Surestart Silicon Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an integrated

electronic ignition control and Million-Air stainless steel tubular heat exchanger. Chassis sizes are now 17.5",

21" wide.

Amana® Brand 80% Variable Speed Gas Furnace

2-Stage Induced Draft, new two tone grey painted cabinet and front panels, standardized blower decks and a

Surestart Silicon Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic

ignition control,120 volt silicon nitride igniter and Million-Air stainless steel tubular heat exchanger. Chassis

sizes are now 17.5", 21" wide. BB models used the round nose inducer motor.

120 volt silicon nitride igniter

, 39" tall, Upflow/Horizontal Left or Right, Induced Draft, new grey painted

, 39" tall, Upflow/Horizontal Right or Left, Induced Draft, furnace redesign

- 2 stage heat gas furnace, 39" tall, Dedicated Downflow,

- 2 stage heat gas furnace, 39" tall, Dedicated Downflow,

and Million-Air stainless steel tubular heat exchanger. Chassis

- 2 stage heat gas furnace, 39" tall, Upflow/Horizontal Left

- 2 stage heat gas furnace, 39" tall, Dedicated Downflow,

DDS8* DDS8******AA

DHS8* DHS8******AA

DMS8* DMS8******AA

GDH8*

GDS8*

GDH8*****AA

GDH8*****AB

GDH8*****AC

GDS8*****AA

GDS8*****BA

GDS8*****BB

GDS8*****BC

Amana®

redesign changes that include new two tone grey painted cabinet and front panels, PSC motor, standardized

blower decks and a Carbide Mini-Igniter. Left or right gas pipe entry. The furnaces also feature an integrated

electronic ignition control and aluminized steel tubular heat exchanger. Chassis sizes are now 14", 17.5" and

21" wide.

Amana® Distinctions™ Brand 80% Gas Furnace

design), Induced Draft, furnace design changes that include new two tone grey painted cabinet and front

panels, PSC motor, standardized blower decks and a Carbide Mini-Igniter. Left or right gas pipe entry. The

furnaces also feature an integrated electronic ignition control and aluminized steel tubular heat exchanger.

Chassis sizes are now 14", 17.5", 21" wide.

Amana® Distinctions™ Brand 80% Gas Furnace

furnace design changes that include new two tone grey painted cabinet and front panels, PSC motor,

standardized blower decks and a Carbide Mini-Igniter. Left or right gas pipe entry. The furnaces also feature an

integrated electronic ignition control and aluminized steel tubular heat exchanger. Chassis sizes are now 14",

17.5", 21" and 24.5" wide.

Goodman® Brand 80% Gas Furnace

and front panels, PSC motor, standardized blower decks and a 120V Silicon Nitride igniter. Left or right gas

pipe entry. The furnaces also feature an integrated electronic ignition control and aluminized steel tubular heat

exchanger. Chassis sizes are now 14", 17.5" and 21" wide. ***AB Models used a round nose inducer motor.

***AC models revert back to Jakel square nose inducer.

Goodman® Brand 80% Gas Furnace

new grey painted cabinet and front panels, PSC motor, standardized blower decks and a Carbide Mini-Igniter.

Left or right gas pipe entry. The furnaces also feature an integrated electronic ignition control and aluminized

steel tubular heat exchanger. Chassis sizes are now 14", 17.5", 21" wide. ***BB Models used a round nose

inducer motor. ***BC models revert back to Jakel square nose inducer.

Distinctions™ Brand 80% Gas Furnace

, 39" tall,

Dedicated Downflow

, 39" tall, Dedicated Downflow, 2-stage/multi-speed, Induced Draft,

, 39" tall,

, 39" tall, Upflow/Horizontal Left or Right, Induced Draft,

Dedicated Downflow

, 39" tall, Upflow/Horizontal Left or Right, (High Air Flow

, Induced Draft, new grey painted cabinet

, Induced Draft, furnace

5

Page 6

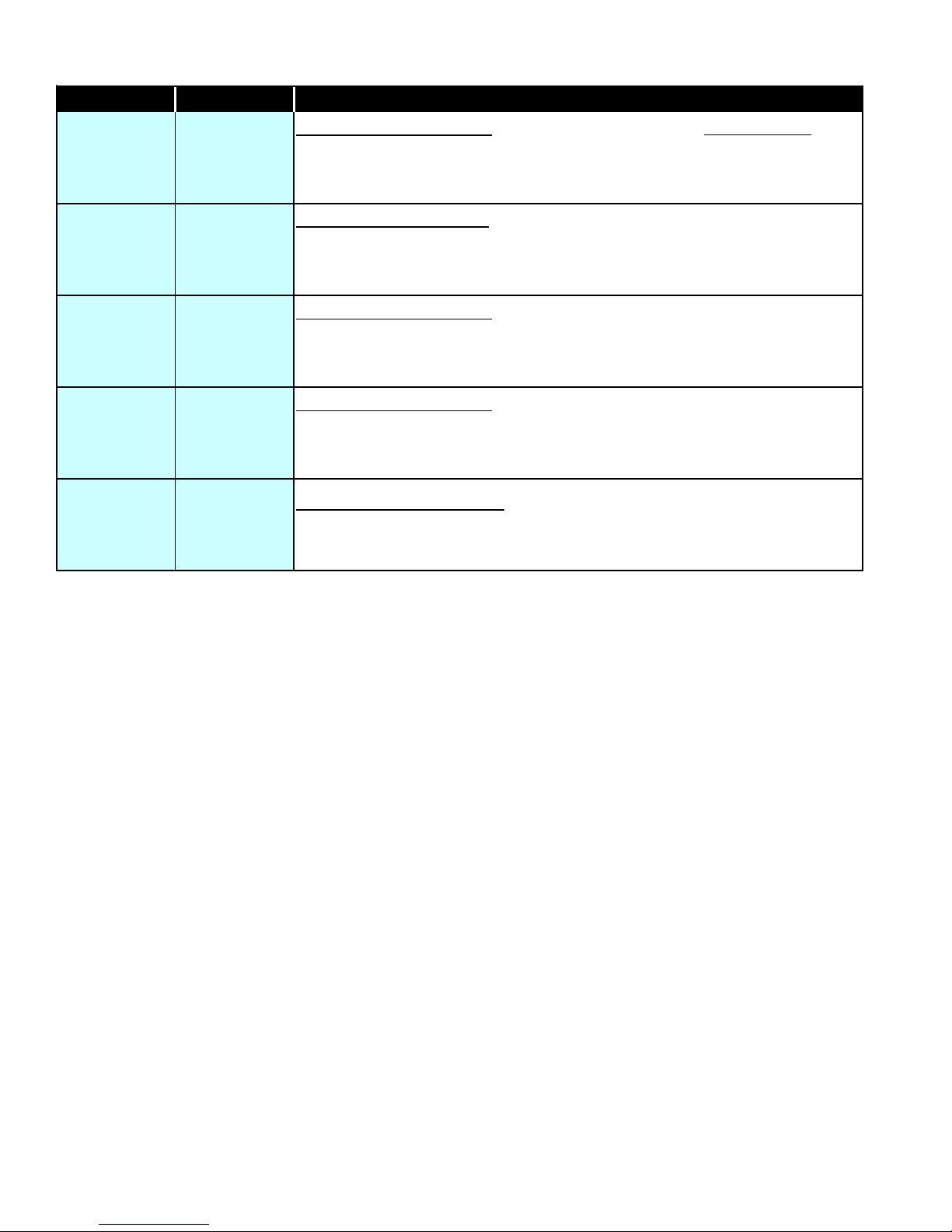

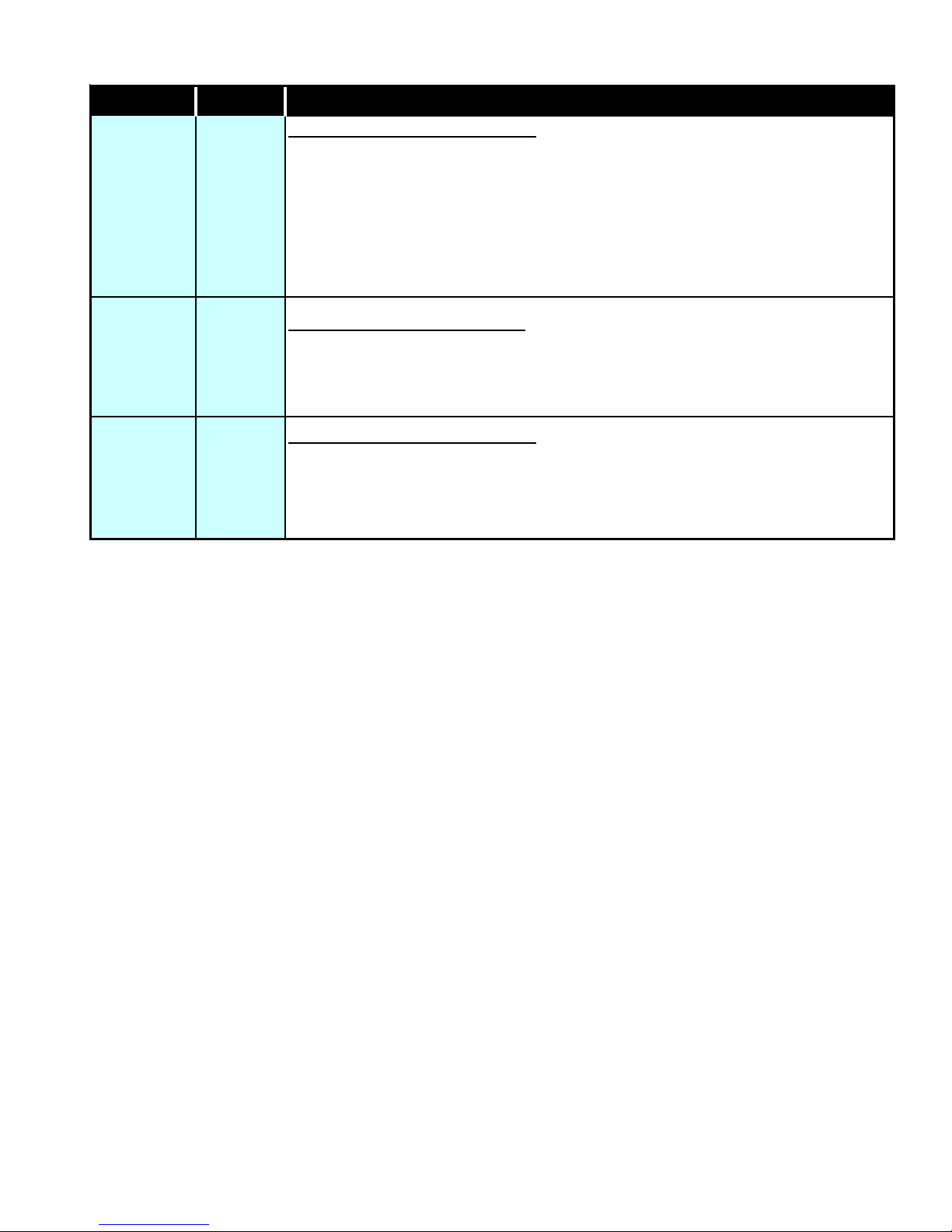

PRODUCT IDENTIFICATION

MODEL # MFG. # 80 % GAS FURNACES

GHS8*

GME8*

GMH8*

GMS8*

GMV8*

GHS8*****AA

GHS8*****BA

GHS8*****BB

GHS8*****BC

GHS8*****BD

GME8*****AA

GME8*****AB

GME8*****AC

GMH8*****AA

GMH8*****AB

GMH8*****AC

GMS8*****AA

GMS8*****BA

GMS8*****BB

GMS8*****BC

GMS8*****BD

GMV8*****AA

GMV8*****BA

Goodman® Brand 80% Gas Furnace

Induced Draft, new grey painted cabinet and front panels, PSC motor, standardized blower decks and a

Carbide Mini-Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic ignition

control and aluminized steel tubular heat exchanger. Chassis sizes are now 14", 17.5", 21" wide. ***BB Models

used a round nose inducer motor. ***BC models revert back to Jakel square nose inducer.

Goodman® Brand

cabinet and front panels, X-13 motor, standardized blower decks and a 120V silicon nitride igniter.. Left or right

gas pipe entry. The furnaces also feature an integrated electronic ignition control and aluminized steel tubular

heat exchanger. Chassis sizes are now 17.5" and 21" wide. ***AB Models used a round nose inducer motor.

***AC models revert back to Jakel square nose inducer.

Goodman® Brand 80% Gas Furnace

painted cabinet and front panels, PSC motor, standardized blower decks and a 120V silicon nitride igniter. Left

or right gas pipe entry. The furnaces also feature an integrated electronic ignition control and aluminized steel

tubular heat exchanger. Chassis sizes are now 14", 17.5" and 21" wide. ***AB Models used a round nose

inducer motor. ***AC models revert back to Jakel square nose inducer.

Goodman® Brand 80% Gas Furnace

painted cabinet and front panels, PSC motor, standardized blower decks and a Carbide Mini-Igniter. Left or

right gas pipe entry. The furnaces also feature an integrated electronic ignition control and aluminized steel

tubular heat exchanger. Chassis sizes are now 14", 17.5", 21" and 24.5" wide. ***BB Models used a round

nose inducer motor. ***BC models revert back to Jakel square nose inducer.

Goodman® Brand 80% Variable Speed

2-stage Induced Draft, new grey painted cabinet and front panels, standardized blower decks and a 120V

Silicon NitrideIgnitor. Left or right gas pipe entry. The furnaces also feature an integrated electronic ignition

control and aluminized steel tubular heat exchanger. Chassis sizes of 17.5", 21" wide.

80% Gas Furnace

, 39" tall, Upflow/Horizontal Left or Right, (High Air Flow Design),

, 39" tall, Upflow/Horizontal Left or Right, Induced Draft, new grey painted

, 39" tall, Upflow/Horizontal Left or Right, Induced Draft, new grey

, 39" tall, Upflow/Horizontal Left or Right, Induced Draft, new grey

- 2 stage heat Gas Furnace, 39" tall, Upflow/Horizontal Left or Right,

6

Page 7

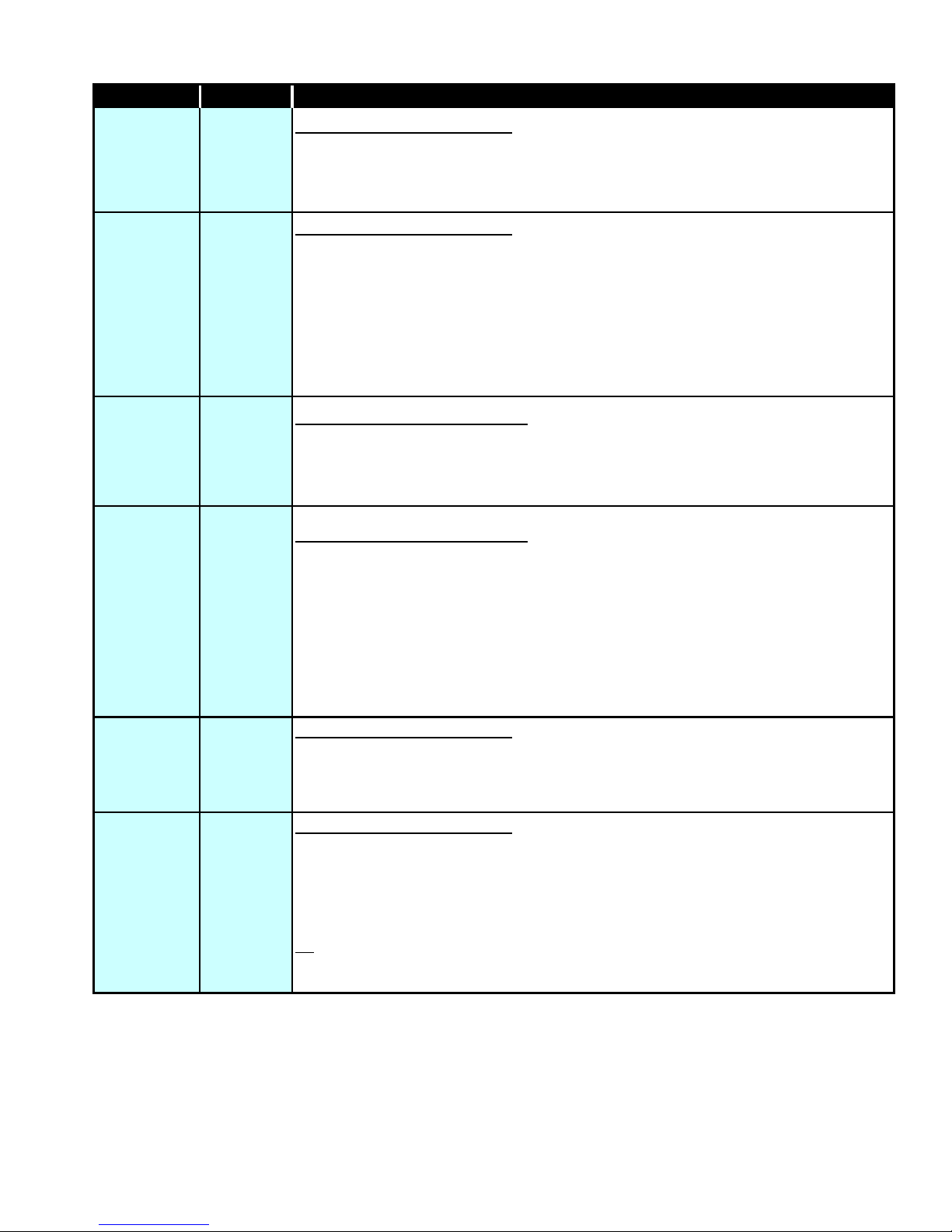

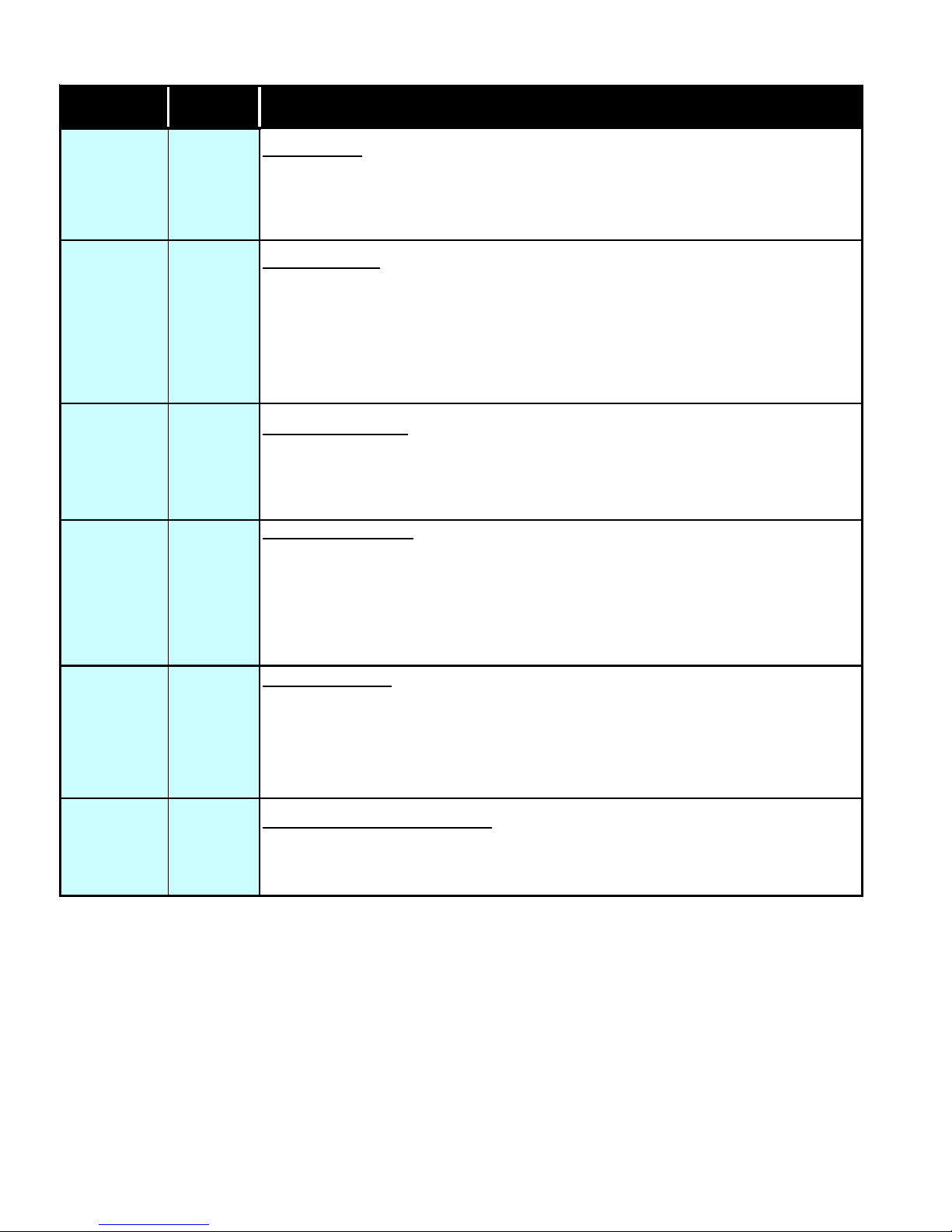

PRODUCT IDENTIFICATION

MODEL # MFG. # DESCRIPTION

ACS9*

ACS9*

ACV9*

ACV9*

P1257001F

through

P1257006F

P1257007F

through

P1257010F

P1257703F,

P1257705F

P1257707F

Amana® Brand 90% Gas Furnace

new two tone grey painted cabinet and front panels, PSC motor, standardized blower decks and a

Surestart Silicon Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an

integrated electronic ignition control and a Million-Air stainless steel tubular heat exchanger. NOx

Certified. Chassis sizes are now 17.5", 21" and 24.5" wide.

Amana® Brand 90% Gas Furnace

new two tone grey painted cabinet and front panels, PSC motor, standardized blower decks and a

Surestart Silicon Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an

integrated electronic ignition control and a Million-Air stainless steel tubular heat exchanger. NOx

Certified. Chassis sizes are now 17.5", 21" and 24.5" wide.

(Note: The "P" numbers to the left include the following design changes.)

new crimped designed blower housing and a new blower deck. The crimped blower housing will

not fit inside of the previous "P" numbers for this same model. Redesigned 90° drain elbow by

adding a side drain port hole. The side port drain tube is only used when placing the furnace in

the horizontal left application.

Amana® Brand 90% Variable Speed

Right, 40" tall, 2-stage Induced Draft, new two tone grey painted cabinet and front panels,

standardized blower decks and a Surestart Silicon Nitride Igniter. Left or right gas pipe entry. The

furnaces also feature an integrated electronic ignition control and a Million-Air stainless steel

tubular heat exchanger. NOx Certified. Chassis sizes are now 21" and 24.5" wide.

Amana® Brand 90% Variable Speed

Right, 40" tall, 2-stage Induced Draft, new two tone grey painted cabinet and front panels,

standardized blower decks and a Surestart Silicon Nitride Igniter. Left or right gas pipe entry. The

furnaces also feature an integrated electronic ignition control and a Million-Air stainless steel

tubular heat exchanger. NOx Certified. Chassis sizes are now 21" and 24.5" wide.

(Note: The "P" numbers to the left include the following design changes.)

new crimped designed blower housing and a new blower deck. The crimped blower housing will

not fit inside of the previous "P" numbers for this same model. We also have a new drain elbow

with a side drain port hole added. It is used when placing the furnace in the horizontal left

application.

, Downflow/Horizontal Left and Right, 40" tall, Induced Draft,

, Downflow/Horizontal Left and Right, 40" tall, Induced Draft,

Incorporates a

- 2 stage Gas Furnace, Downflow/Horizontal Left and

- 2 stage Gas Furnace, Downflow/Horizontal Left and

Incorporates a

AMS9*

AMS9*

P1256601F

P1256606F

P1256607F

through

P1256610F

Amana® Brand 90% Gas Furnace

two tone grey painted cabinet and front panels, standardized blower decks and a Surestart Silicon

Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic

ignition control and a Million-Air stainless steel tubular heat exchanger. NOx Certified. Chassis

sizes are now 17.5", 21" and 24.5" wide.

Amana® Brand 90% Gas Furnace

two tone grey painted cabinet and front panels, standardized blower decks and a Surestart Silicon

Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic

ignition control and a Million-Air stainless steel tubular heat exchanger. NOx Certified. Chassis

sizes are now 17.5", 21" and 24.5" wide.

(Note: The "P" numbers to the left include the following design changes.)

new crimped designed blower housing and a new blower deck. The crimped blower housing will

fit inside of the previous "P" numbers for this same model. Redesigned 90° drain elbow by

not

adding a side drain port hole. The side port drain tube is only used when placing the furnace in

the horizontal left application.

, Upflow/Horizontal Left and Right, 40" tall, Induced Draft, new

, Upflow/Horizontal Left and Right, 40" tall, Induced Draft, new

Incorporates a

7

Page 8

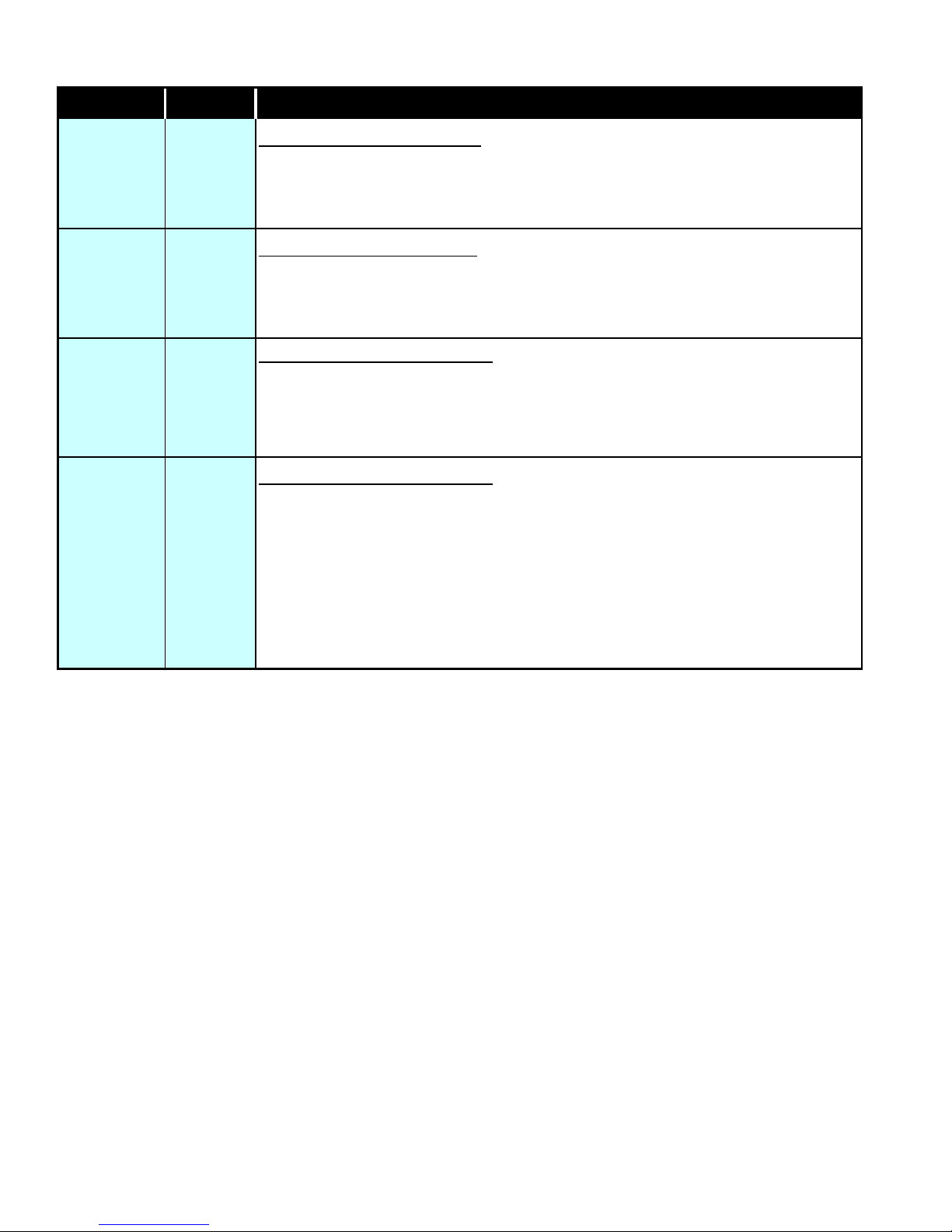

PRODUCT IDENTIFICATION

MODEL # MFG. # DESCRIPTION

Amana® Brand 95% Gas Furnace, Upflow/Horizontal Left or Right, 40" tall, Induced Draft, new

two tone grey painted cabinet and front panels, standardized blower decks and a 120V Silicon

Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic

ignition control and a Million-Air stainless steel tubular heat exchanger. NOx Certified. Chassis

sizes are now 17.5", 21" and 24.5" wide. Two stage heat, single stage cooling.

Amana® Brand 95% Gas Furnace, Upflow/Horizontal Left and Right, 40" tall, Induced Draft, new

two tone grey painted cabinet and front panels, standardized blower decks and a Surestart Silicon

Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic

ignition control and a Million-Air stainless steel tubular heat exchanger. NOx Certified. Chassis

sizes are now 17.5", 21" and 24.5" wide.

AMH95

AMS95

AMH95***AA

AMH95***AB

AMH95***AC

AMS95***AA

AMS95***AB

AMV9*

AMV9*

P1257401F,

P1257403F,

P1257405F

through

P1257406F

P1257407F,

P1257408F

Amana® Brand 90% Variable Speed - 2 stage Gas Furnace, Upflow/Horizontal Left and Right,

40" tall, 2-stage Induced Draft, furnace redesign changes that include new two tone grey painted

cabinet and front panels, standardized blower decks and a Surestart Silicon Nitride Igniter. Left or

right gas pipe entry. The furnaces also feature an integrated electronic ignition control and a

Million-Air stainless steel tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5", 21"

and 24.5" wide.

Amana® Brand 90% Variable Speed - 2 stage Gas Furnace, Upflow/Horizontal Left and Right,

40" tall, 2-stage Induced Draft, furnace redesign changes that include new two tone grey painted

cabinet and front panels, standardized blower decks and a Surestart Silicon Nitride Igniter. Left or

right gas pipe entry. The furnaces also feature an integrated electronic ignition control and a

Million-Air stainless steel tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5", 21"

and 24.5" wide.

(Note: The "P" numbers to the left include the following design changes.) Incorporates a

new crimped designed blower housing and a new blower deck. The crimped blower housing will

not fit inside of the previous "P" numbers for this same model. Redesigned 90° drain elbow by

adding a side drain port hole. The side port drain tube is only used when placing the furnace in

the horizontal left application.

8

Page 9

PRODUCT IDENTIFICATION

MODEL # MFG. # DESCRIPTION

Amana® Distinctions™ Brand 90% Gas Furnace, Downflow/Horizontal Left and Right, 40" tall,

Induced Draft, furnace design changes that include new two tone grey painted cabinet and front

panels, PSC motor, standardized blower decks and a Carbide Mini-Igniter. Left or right gas pipe

entry. The furnaces also feature an integrated electronic ignition control and aluminized steel

tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5", 21" and 24.5" wide.

Amana® Distinctions™ Brand 90% Gas Furnace, Downflow/Horizontal Left and Right, 40" tall,

Induced Draft, furnace design changes that include new two tone grey painted cabinet and front

panels, PSC motor, standardized blower decks and a Carbide Mini-Igniter. Left or right gas pipe

entry. The furnaces also feature an integrated electronic ignition control and aluminized steel

tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5", 21" and 24.5" wide.

(Note: The "P" numbers to the left include the following design changes.) Incorporates a

new crimped designed blower housing and a new blower deck. The crimped blower housing will

not fit inside of the previous "P" numbers for this same model. Redesigned 90° drain elbow by

adding a side drain port hole. The side port drain tube is only used when placing the furnace in

the horizontal left application.

Amana® Distinctions™ Brand 90% Gas Furnace, Upflow/Horizontal Left or Right, 40" tall,

Induced Draft, furnace design changes that include new two tone grey painted cabinet and front

panels, PSC motor, standardized blower decks and a Carbide Mini-Igniter. Left or right gas pipe

entry. The furnaces also feature an integrated electronic ignition control and aluminized steel

tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5", 21" and 24.5" wide.

DCS9*

DCS9*

DMS9*

P1257102F,

P1257104F,

P1257106F

P1257107F

P1257108F

P1256701F,

P1256706F

DMS9*

P1256707F

through

P1256710F

Amana® Distinctions™ Brand 90% Gas Furnace, Upflow/Horizontal Left or Right, 40" tall,

Induced Draft, furnace design changes that include new two tone grey painted cabinet and front

panels, PSC motor, standardized blower decks and a Carbide Mini-Igniter. Left or right gas pipe

entry. The furnaces also feature an integrated electronic ignition control and aluminized steel

tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5", 21" and 24.5" wide.

(Note: The "P" numbers to the left include the following design changes.) Incorporates a

new crimped designed blower housing and a new blower deck. The crimped blower housing will

not fit inside of the previous "P" numbers for this same model. Redesigned 90° drain elbow by

adding a side drain port hole. The side port drain tube is only used when placing the furnace in

the horizontal left application.

9

Page 10

PRODUCT IDENTIFICATION

MODEL # MFG. # DESCRIPTION

GCS9*

P1257201F,

P1257202F

P1257204F,

P1257206F

Goodman® Brand 90% Gas Furnace,

new grey painted cabinet and front panels, PSC motor, standardized blower decks and a Carbide

Mini-Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic ignition

control and aluminized steel tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5",

21" and 24.5" wide.

Downflow/Horizontal Left and Right, 40" tall, Induced Draft,

GCS9*

GCH9*

GCV9*

GKS9*

P1257207F

through

P1257209F

GCH9***AA

GCH9***AB

P1257803F,

P1257805F

GKS9****AA

GKS9****AB

GKS9****AC

Goodman® Brand 90% Gas Furnace,

Downflow/Horizontal Left and Right, 40" tall, Induced Draft,

new grey painted cabinet and front panels, PSC motor, standardized blower decks and a Carbide

Mini-Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic ignition

control and aluminized steel tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5",

21" and 24.5" wide.

(Note: The "P" numbers to the left include the following design changes.) Incorporates a new

crimped designed blower housing and a new blower deck. The crimped blower housing will not fit

inside of the previous "P" numbers for this same model. Redesigned 90° drain elbow by adding a

side drain port hole. The side port drain tube is only used when placing the furnace in the horizontal

left application.

Goodman® Brand 90% Gas Furnace,

Downflow/Horizontal Left and Right, 40" tall, Induced Draft,

new grey painted cabinet and front panels, PSC motor, standardized blower decks and a 120V

Silicon Nitride igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic

ignition control and aluminized steel tubular heat exchanger. NOx Certified. Chassis sie are now

17.5", 21" and 24.5" wide. Two stage heat, single stage cooling.

Goodman® Brand 90% Variable Speed

- 2 Stage Gas Furnace, 40" tall, Upflow/Horizontal Left or

Right, Induced Draft, new grey painted cabinet and front panels, standardized blower decks and a

Carbide Mini-Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic

ignition control and aluminized steel tubular heat exchanger. NOx Certified. Chassis sizes are now

21" and 24.5" wide. (BA models use Surestat Silicon Nitride igniters.)

Goodman® Brand 92.1% Gas Furnace

, Upflow/Horizontal Left or Right, 40" tall, Induced Draft,

new grey painted cabinet and front panels, PSC motor, standardized blower decks and a Carbide

Mini-Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic ignition

control and aluminized steel tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5",

21" and 24.5" wide.

GMS9*

GMS9*

GMS95*

GMV9*

P1256801F

through

P1256802F

P1256804F,

P1256806F

P1256807F

through

P1256809F

GMS9****AA

GMS9****AB

P1257603F -

P1257607F

Goodman® Brand 90% Gas Furnace, Upflow/Horizontal Left or Right, 40" tall, Induced Draft, new

grey painted cabinet and front panels, PSC motor, standardized blower decks and a Carbide MiniIgniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic ignition control

and aluminized steel tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5", 21" and

24.5" wide.

Goodman® Brand 90% Gas Furnace

, Upflow/Horizontal Left or Right, 40" tall, Induced Draft, new

grey painted cabinet and front panels, PSC motor, standardized blower decks and a Carbide MiniIgniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic ignition control

and aluminized steel tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5", 21" and

24.5" wide.

Note: The "P" numbers to the left include the following design changes.

(

) Incorporates a new

crimped designed blower housing and a new blower deck. The crimped blower housing will not fit

inside of the previous "P" numbers for this same model. Redesigned 90° drain elbow by adding a

side drain port hole. The side port drain tube is only used when placing the furnace in the horizontal

left application.

Goodman® Brand 95% Gas Furnace

, Upflow/Horizontal Left or Right, 40" tall, Induced Draft, new

grey painted cabinet and front panels, PSC motor, standardized blower decks and a Carbide MiniIgniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic ignition control

and aluminized steel tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5", 21" and

24.5" wide.

Goodman® Brand 90% Variable Speed

- 2 stage heat Gas Furnace, Upflow/Horizontal Left or

Right, 40" tall, 2-stage Induced Draft, new grey painted cabinet and front panels, standardized

blower decks and a Carbide Mini-Igniter. Left or right gas pipe entry. The furnaces also feature an

integrated electronic ignition control and aluminized steel tubular heat exchanger. NOx Certified.

Chassis sizes of 17.5", 21" and 24.5" wide.

10

Page 11

PRODUCT IDENTIFICATION

MODEL # MFG. # DESCRIPTION

GMV9*

GMH95*

GMV95*

P1257610F -

P1257611F

GMH95***AA

GMH95***AB

GMH95***AC

GMV95***AA

GMV95***AB

GMV95***BA

GMV95***BB

Goodman® Brand 90% Variable Speed

Right, 40" tall, 2-stage Induced Draft, new grey painted cabinet and front panels, standardized

blower decks and a Carbide Mini-Igniter. Left or right gas pipe entry. The furnaces also feature an

integrated electronic ignition control and aluminized steel tubular heat exchanger. NOx Certified.

Chassis sizes of 17.5", 21" and 24.5" wide.

(Note: The "P" numbers to the left include the following design changes.)

crimped designed blower housing and a new blower deck. The crimped blower housing will not fit

inside of the previous "P" numbers for this same model. Redesigned 90° drain elbow by adding a

side drain port hole. The side port drain tube is only used when placing the furnace in the horizontal

left application.

Goodman® Brand 95% Gas Furnace, Upflow/Horizontal Left or Right, 40" tall, Induced Draft, new

two tone grey painted cabinet and front panels, standardized blower decks and a 120V Silicon

Nitride Igniter. Left or right gas pipe entry. The furnaces also feature an integrated electronic ignition

control and a Million-Air stainless steel tubular heat exchanger. NOx Certified. Chassis sizes are

now 17.5", 21" and 24.5" wide. Two stage heat, single stage cooling.

Goodman® Brand 95% Variable Speed

40" tall, 2-stage Induced Draft, new grey painted cabinet and front panels, new standardized blower

decks, new blower housing and a Carbide Mini-Igniter.(BA model has 120V Silicon Nitride igniters.)

Left or right gas pipe entry. The furnaces also feature an integrated electronic ignition control and

aluminized steel tubular heat exchanger. NOx Certified. Chassis sizes are now 17.5", 21" and 24.5"

wide.

- 2 stage heat Gas Furnace, Upflow/Horizontal Left or

Incorporates a new

- 2 stage Gas Furnace, Upflow/Horizontal Left or Right,

11

Page 12

PRODUCT IDENTIFICATION

MODEL # MFG # DESCRIPTION

Fossil Fuel Kit. The AFE18-60A control is designed for use where the indoor coil is located

above/downstream of a gas or fossil fuel furnace when used with a heat pump. It will operate

AFE18-60A

N/A

with single and two stage heat pumps and single and two stage furnaces. The AFE18-60A

control will turn the heat pump unit off when the furnace is turned on. An anti-short cycle feature

initiates a 3 minute timed off delay when the compressor goes off.

AMU1620

AMU1625

AMU2020

AMU2025

GMU1620

GMU1625

GMU2020

GMU2025

ASAS-10

ASAS-11

ASAS-12

ASAS-18

CFB17

CFB21

CFB24

DCVK-20

DCVK-30

P1251305F

P1251306F

P1251307F

P1251308F

N/A

P1251301F

P1251302F

P1251303F

P1251304F

P1228004F

P1228005F

P1228003F

P1254001F

P1254002F

Media Air Cleaner. For use with current architectural grey Goodman® and Amana® Brand 80%

and 90% variable speed furnace models. The Amana (AMU*) and Goodman (GMU*) Media Air

Cleaner is a high efficiency air filtration device designed to remove dirt, dust, pollen and other

microscopic particles from the air passing through it. Flexible performance range up to 2,000

CFM capacity. The air cleaner should be installed in the system so that all the system air is

circulated through the air cleaner. The air cleaner will only remove the airborne contaminants

delivered to it. Maximum performance is obtained when the system blower is set for continuous

operation. Carbon filters (optional) are available.

Electronic Air Cleaner. For use with current architectural grey Goodman® and Amana® Brand

80% and 90% variable speed furnace models. The High-Efficiency Electronic Air Cleaner is

designed to remove air contaminants down to .01 microns. Carbon filters (optional) remove

odors. Dual indicator lights show unit operation at a glance. Electronic proving switch cycles the

air cleaner On/Off with the system fan. Durable powder-coat paint finish resists corrosion.

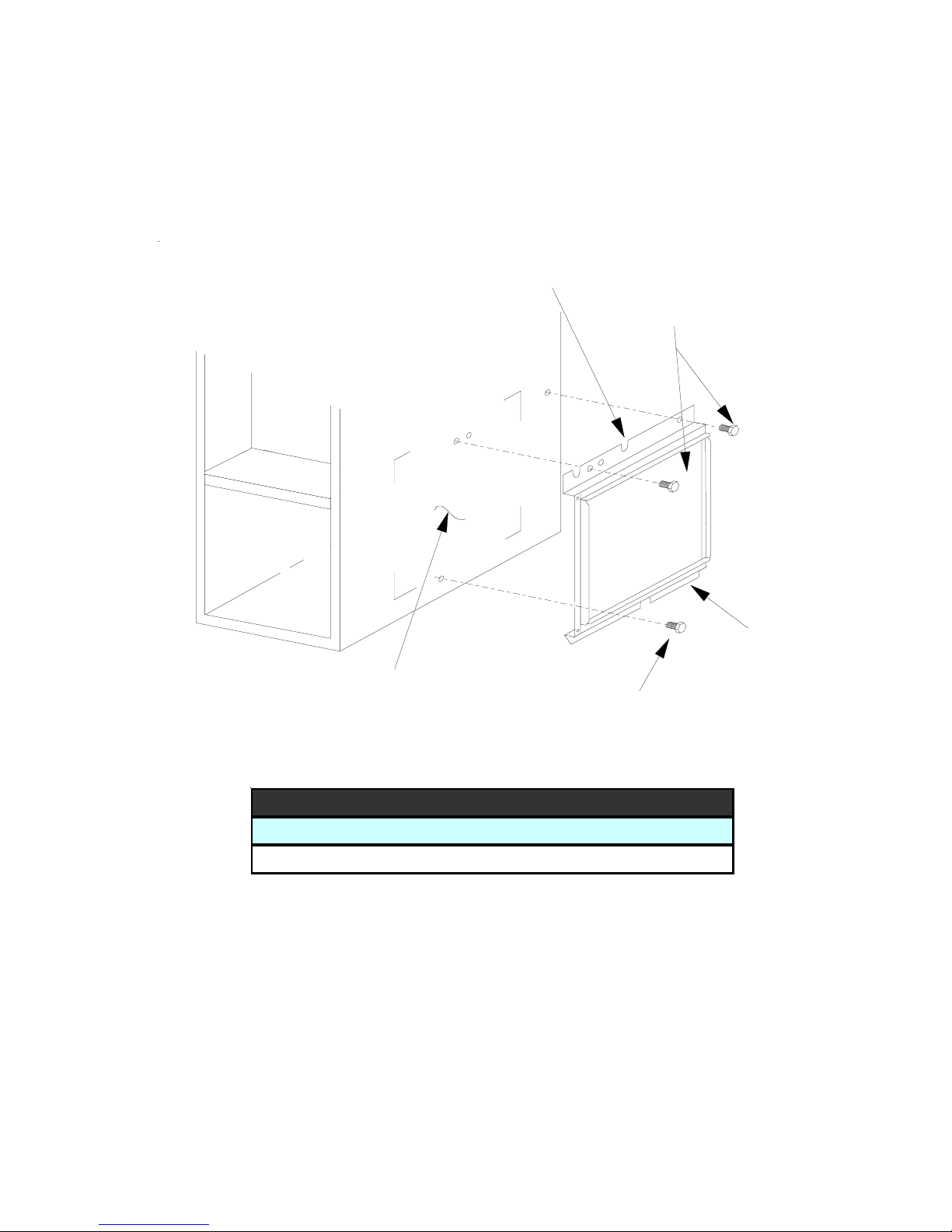

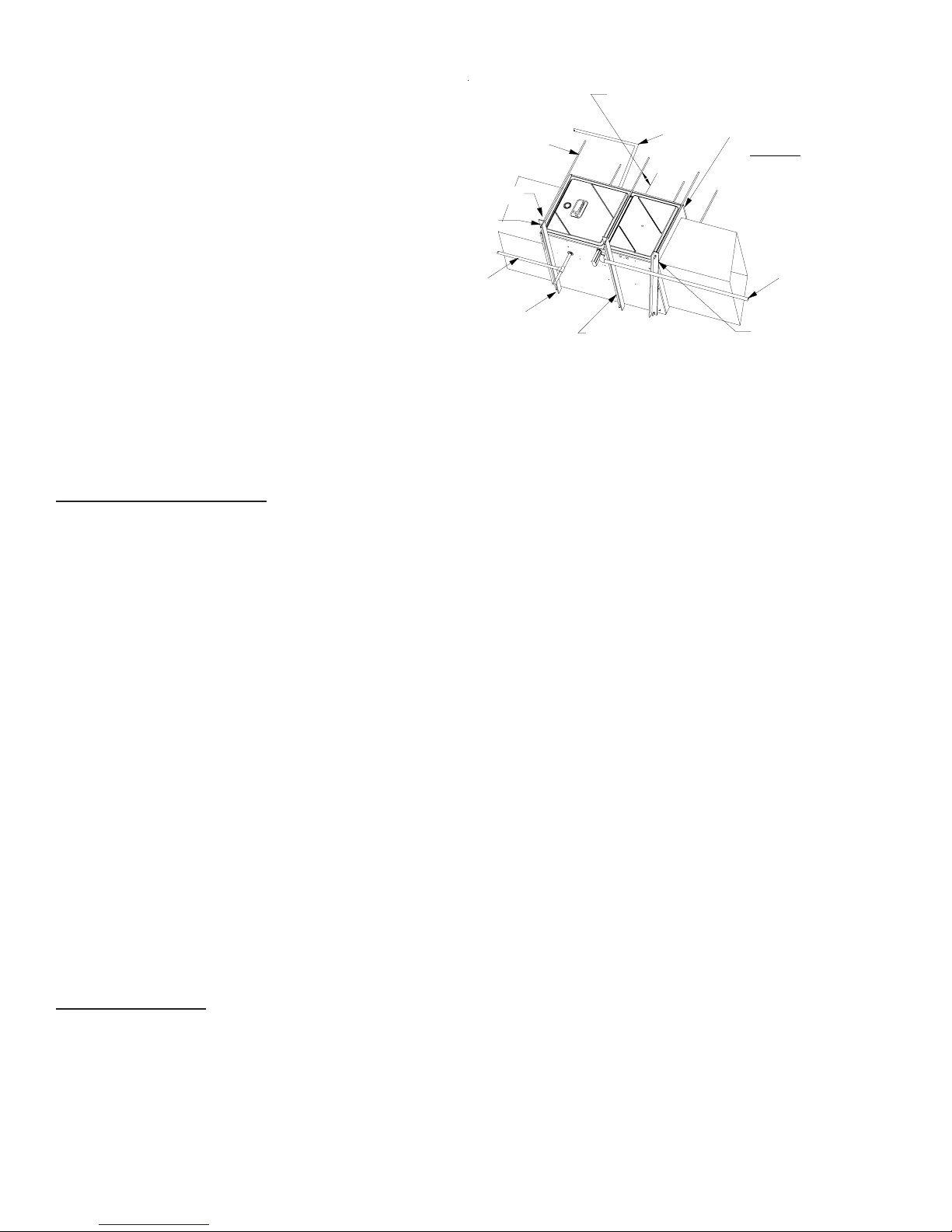

Downflow Subbase Kit. For use with select Goodman®, Amana® Brand & Amana®

Distinctions™ Brand furnace models ACS9, ACV9, DCS9, GCH9, GCS9, GCV9. These kits are

available for the following furnace widths: 17.5" wide (CFB17), 21" wide (CFB21) and 24" wide

(CFB24). The kits must be used to prevent excessive temperature from reaching combustible

materials, if the furnace is installed on a combustible floor. This subbase effectively separated

the furnace base and plenum from combustible materials. To ensure safe installation, do not

install the counterflow floor base directly on carpeting, tile, or other combustible material other

than wood flooring.

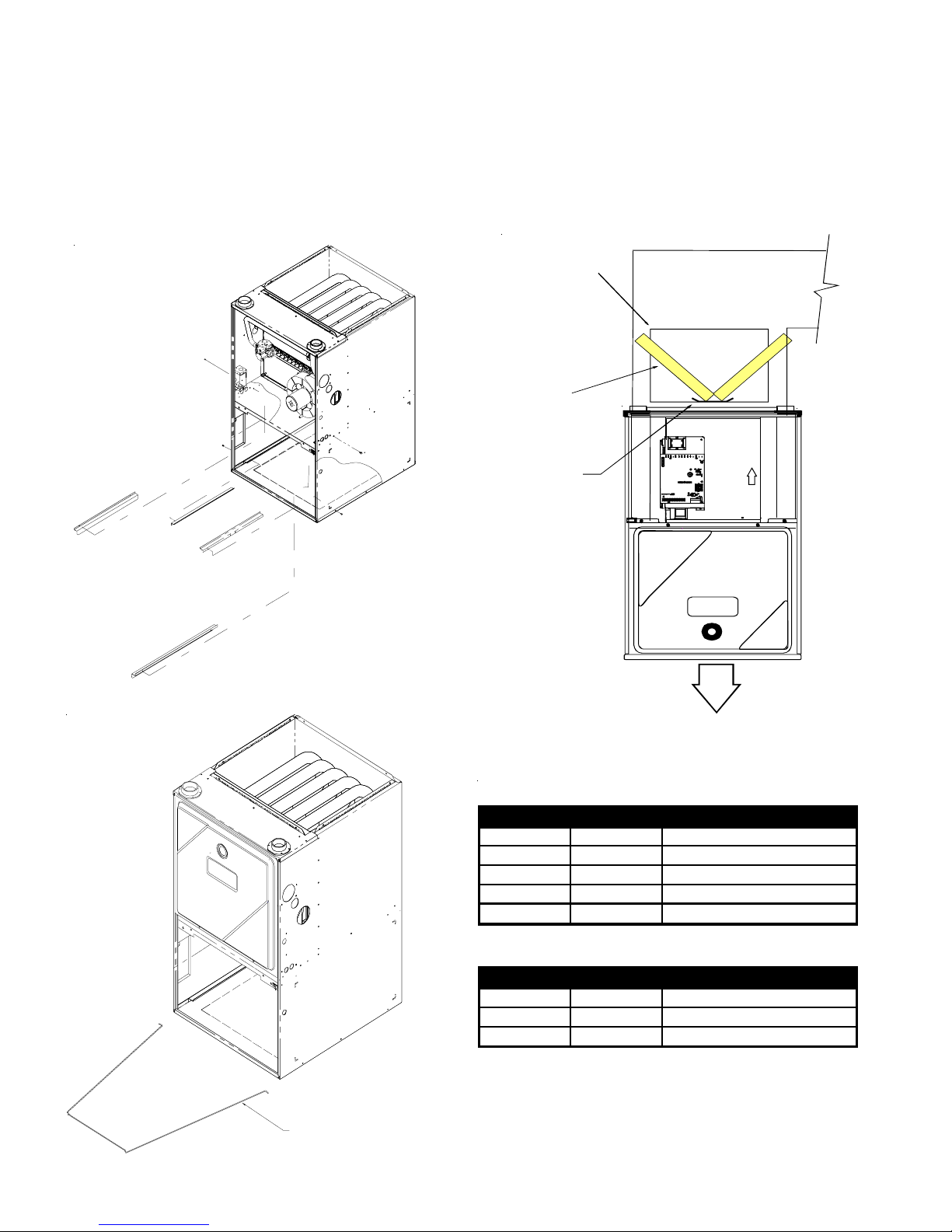

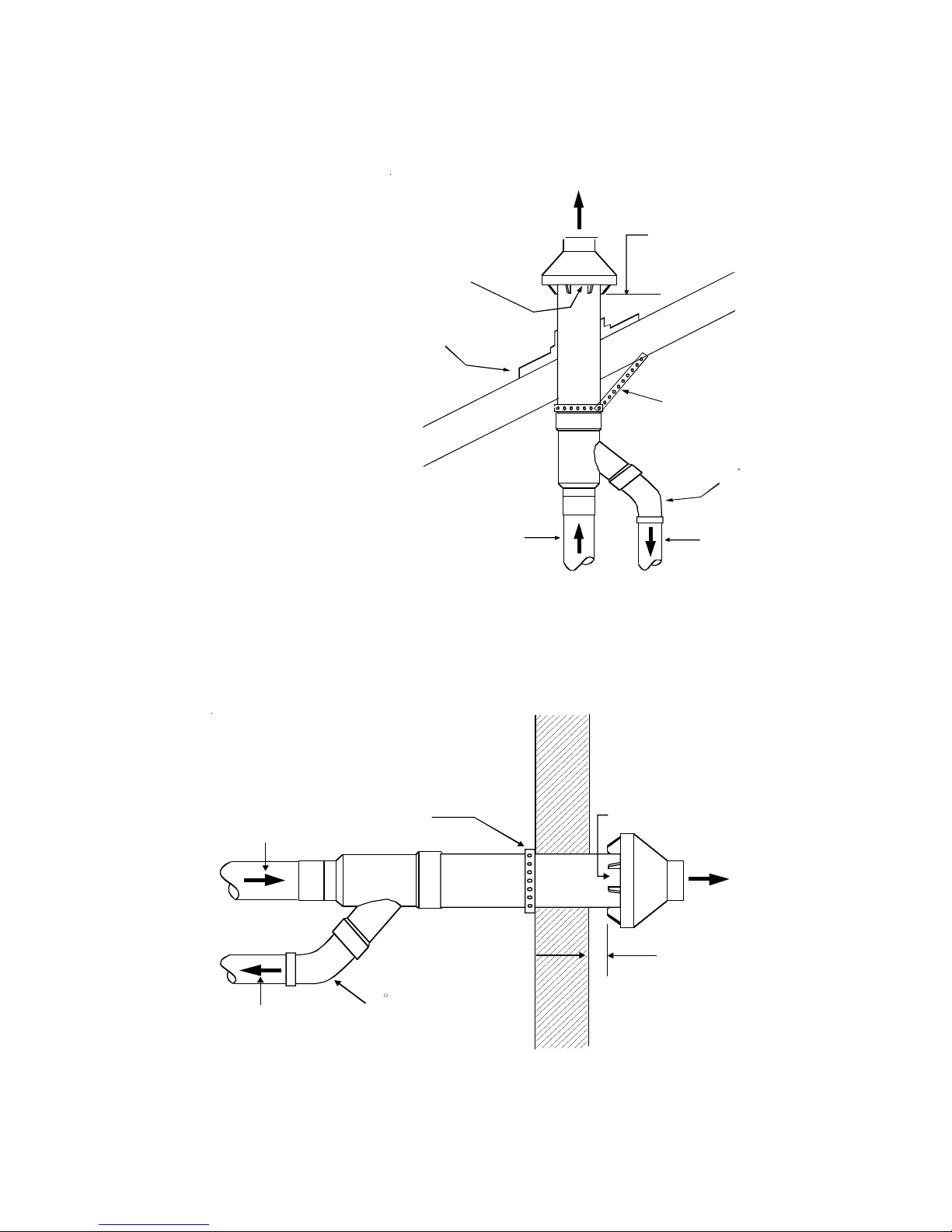

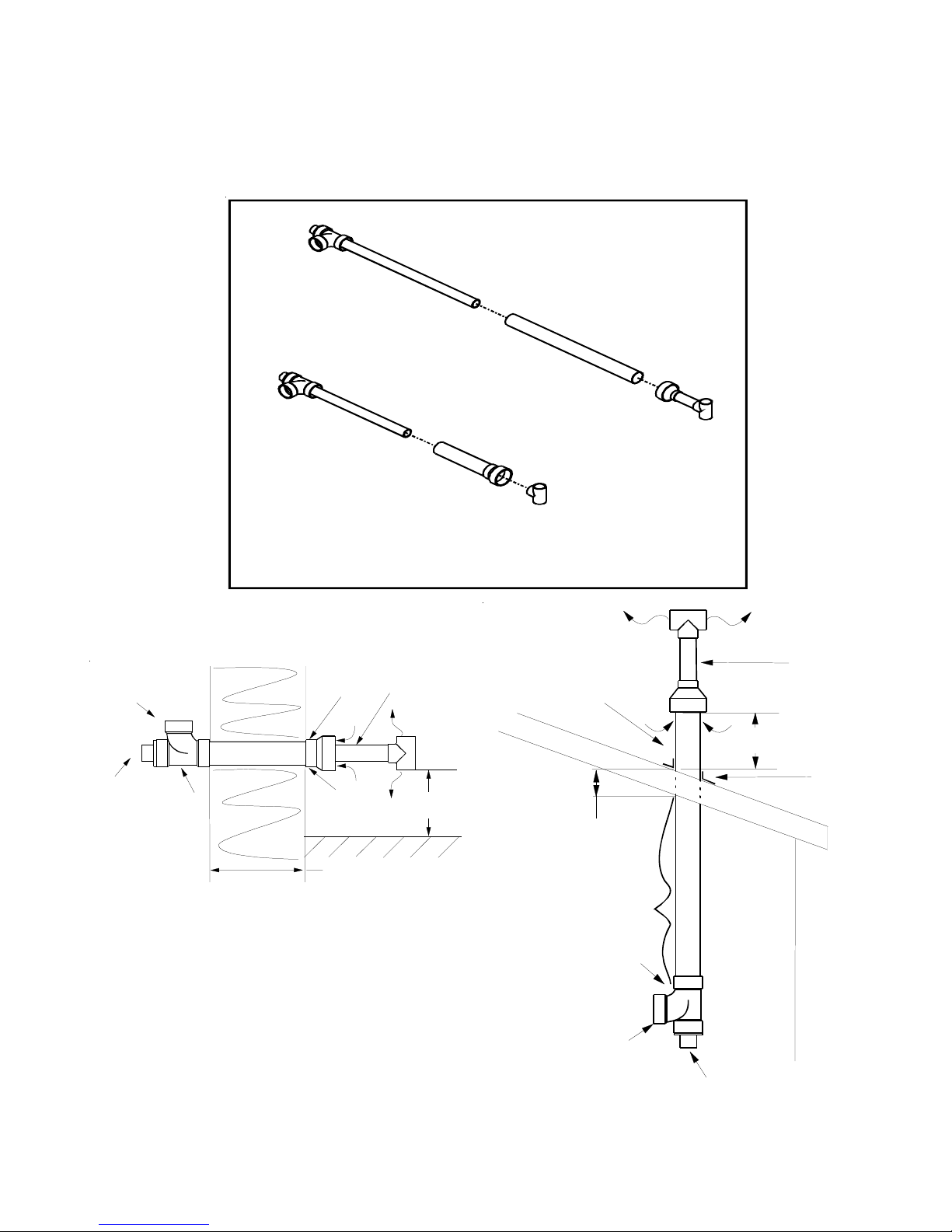

Concentric Vent Kit. For use with Amana® Brand furnace models ACS9, AMS9, AMS95,

ACV9, AMV9, AMH95, DCS9, DMS9, GCS9, GMS9, GMS95,GCH9, GKS9, GCV9,

GMV9,GMH95, GMV95. This kit is designed to allow terminations of a direct vent furnace to be

"concentrically" vented through a wall or roof. This kit allows a single penetration to support

terminations for both the vent/flue and the combustion air intake pipe. The DCVK-20 (2") and

DCVK-30 (3") kits are certified for models listed above. See specification sheets on future

models for use of the vent kit.

Side Wall Only Concentric Vent Kit. For use with 90% furnace models ACS9, AMS9, ACV9,

0170K00000S

N/A

AMV9, AMH95, DCS9, DMS9, GCH9, GCS9, GKS9, GMS9, GCV9, GMH95, GMV9, GMV95.

This kit is to be used with 2" or 3" vent systems. The vent kit must terminate outside the

structure. This kit is NOT intended for use with single pipe (indirect vent) installations.

12

Page 13

PRODUCT IDENTIFICATION

MODEL # MFG # DESCRIPTION

Dehumidistat. For use with Goodman® and Amana® Brand two-stage variable speed furnace

models ADV8, AMV8, ACV9, AMV9, GMV8, GCV9, GMV9, GMV95. Wall mounted, 24 volt

humidity control available as a Dehumidistat used to reduce the airflow in the air conditioning

DEHUM1

EFR01

FTK03A

HA02

P1227801F

P1221001

P1221002F

P1171304F

P1171305F

P1129112F

mode when necessary to lower the humidity in an occupied home to prevent dew build-up

associated with high humidity levels. This control features a moisture-sensitive nylon element

and also provides positive ON-OFF settings for manual operation. The control is a normally

closed switch that opens on humidity rise causing the blower to switch to a lower speed to

control the humidity within the structure.

External Filter Rack Kit. For use with Goodman® and Amana® Brand 90% upflow variable

speed gas furnace models AMH95, AMS9, AMS95, GMH95, GMS9, GMS95, DMS9, AMV9,

GMV9, GMV95. This kit is intended to provide a location, external to the furnace casing, for

installation of a permanent filter. The rack is mounted over the indoor air blower compartment

area of either side panel, and provide filter retention as well as a location for attaching return air

ductwork.

Furnace Twinning Kit. This kit allows Goodman® or Amana® Brand single stage 80% and

single stage 90% gas furnaces to operate at the same time from a single thermostat. The two

furnaces to be "twinned" must be the exact same model with their circulating air blowers set to

deliver the same air flow at the same time. The furnaces may deliver different CFM's in the

cooling mode, if applicable. This kit cannot be used to control more than two furnaces.

High Altitude Kit. The kit is designed to convert Goodman®, Amana® Brand & Amana®

Distinctions™ Brand 80% gas furnace models (AMH8*, AMS8*, ADS8*, DMS8*, DDS8*, DHS8*,

GDS8*, GMH8*, GMS8*, GDS8*, GHS8*) for higher altitudes. This kit is required when installing

these furnaces above their maximum rated altitude. This kit contains

# 43-49, 55-58 gas orifices. The orifices in the kit have been selected as a result of testing with

the American Gas Association. They will provide appropriate derating at the altitude listed in the

High Altitude Charts as shown in the installation instructions of the kit.

HALP10

HALP11

HALP13

P1129112F

P1129113F

P1129112F

High Altitude Propane Gas Conversion Kit. Used on Goodman® and Amana® Brand 90%

single stage (ACS9, AMS9, DCS9, DMS9, GCS9, GMS9) furnace models. This kit is required

when installing furnaces above their maximum rated altitude. This kit contains propane gas

orifices. The orifices in the kit have been selected as a result of testing with the American Gas

Association. They will provide appropriate derating at the altitude listed in the High Altitude

Charts as shown in the installation instructions of the kit.

High Altitude Propane Gas Conversion Kit. Used on Goodman® and Amana® Brand 90%

single stage (ACV9, AMV9, GCV9, GMV9, GMV95) furnace models. This kit is required when

installing furnaces above their maximum rated altitude. This kit contains propane gas orifices.

The orifices in the kit have been selected as a result of testing with the American Gas

Association. They will provide appropriate derating at the altitude listed in the High Altitude

Charts as shown in the installation instructions of the kit.

High Altitude Propane Gas Conversion Kit. Used on Goodman® and Amana® Brand 90% two

stage (ACV9, GCV9) furnace models. This kit is required when installing furnaces above their

maximum rated altitude. This kit contains propane gas orifices. The orifices in the kit have been

selected as a result of testing with the American Gas Association. They will provide appropriate

derating at the altitude listed in the High Altitude Charts as shown in the installation instructions

of the kit.

13

Page 14

PRODUCT IDENTIFICATION

MODEL # MFG # DESCRIPTION

HANG11-12

P1210305F

P1210306F

High Altitude Natural Gas Kit

models

ACS9, AMS9, DCS9, DMS9, GCS9

the furnaces above their maximum rated altitude. This kit contains natural gas orifices. The

orifices in the kit have been selected with the American Gas Association. They will provide

appropriate derating at the altitude listed in the High Altitude Charts as shown in the installations

of the kit.

. For use with Goodman® and Amana® Brand 90% furnace

and

GMS9.

These kits are required when installing

HANG13-14

HANG16

HAPS27-29

HAPS31

LPLP01

LPT-00A

P1210307F

P1210308F

P1210310F

P1210518F

through

P1210520F

P1210522F

P1237701F

N/A

High Altitude Natural Gas Kit

models

AMV9, GMV9, GMV95.

. For use with Goodman® and Amana® Brand 90% furnace

These kits are required when installing the furnaces above their

maximum rated altitude. The orifices in the kit have been selected as a result of testing with the

American Gas Association. They will provide appropriate derating at the altitude listed in the

High Altitude Charts as shown in the installations of the kit.

High Altitude Natural Gas Kit

models

ACV9, GCV9.

These kits are required when installing the furnaces above their

. For use with Goodman® and Amana® Brand 90% furnace

maximum rated altitude. The orifices in the kit have been selected as a result of testing with the

American Gas Association. They will provide appropriate derating at the altitude listed in the

High Altitude Charts as shown in the installations of the kit.

High Altitude Pressure Switch Kit

furnace models

AMS9, ACS9, DCS9, DMS9, GSC9, GMS9, AMV9, GMV9 and GMV95.

. For use with selected Goodman® and Amana® Brand 90%

This kit

contains a high altitude pressure switch that must be used at altitudes above the rated altitudes

because of reduced air density.

High Altitude Pressure Switch Kit

furnace models

ACV9, GCV9.

. For use with selected Goodman® and Amana® Brand 90%

This kit contains a high altitude pressure switch that must be

used at altitudes above the rated altitudes because of reduced air density.

LP Gas Low Pressure Kit. Designed for application on Goodman® and Amana® Brand's 90%

single-stage and two-stage gas fired furnace product installed on LP gas listed in this manual.

The kit monitors gas line pressure with a pressure switch and disables the unit's gas valve if the

line pressure drops below acceptable levels. Application of the LPLP kit is aimed at reducing the

occurrence of sooted heat exchangers in product installed on LP gas.

LP Conversion Kit

models

ADS8, AMS8, GDS8, GMS8, DMS8, DDS8, DHS8, GHS8, ACS9, AMS9, AMS95,

DCS9, DMS9, GCS9, GKS9, GMS9 and GMS95.

. For use with Goodman®, Amana® Brand & Amana® Distinctions™ Brand

This kit converts

only

single-stage gas fired

units from natural to propane gas. The conversion from natural gas (as shipped from the factory)

to propane gas requires: replacing the burner orifices, replacing gas valve regulator spring (all

single stage units) and applying identification labels.

NOx screens must be removed when

converting 80% furnaces to this LP kit.

LP Conversion Kit

LPM-03B

N/A

variable speed models. This kit includes the LP gas valve, (1.25mm, # 55 orifices), installation

instructions and a label to show that the furnace has been converted.

LP Conversion Kit

LPM-05

N/A

models using a White-Rodgers 36G54 2-stage gas valve kit. Includes regulator springs, #55

orifices, instructions and a label to show the furnace has been converted to L.P.

Internal Filter Retention Kit.

RF000180

N/A

Distinctions™ Brand 90%

bottom of the furnace and contains enough hardware for (10) furnaces. This kit is NOT to be

used on horizontal applications.

Internal Filter Retention Kit.

RF000181

N/A

Distinctions™ Brand 90%

bottom of the furnace and contains enough hardware for (10) furnaces. This kit is NOT to be

used on horizontal applications.

SBT14

SBT17

SBT21

SBT24

N/A

Downflow Subbase.

furnace models

furnace widths: 14" wide (SBT14) 17.5" wide (SBT17), 21" wide (SBT21) and 24" wide (SBT24).

14

. For use with Goodman® and Amana® Brand 80% and 90% 2-stage

. For use with Goodman® and Amana® Brand 2-stage variable speed

For use with Goodman®, Amana® Brand & Amana®

upflow only

furnaces. This kit allows a filter to be installed in the

For use with Goodman®, Amana® Brand and Amana®

counterflow only

furnaces. This kit allows a filter to be installed in the

For use with Goodman® and Amana® Brand 80% dedicated downflow

ADV8, ADS8, GDS8 and GDH8

. These kits are available for the following

Page 15

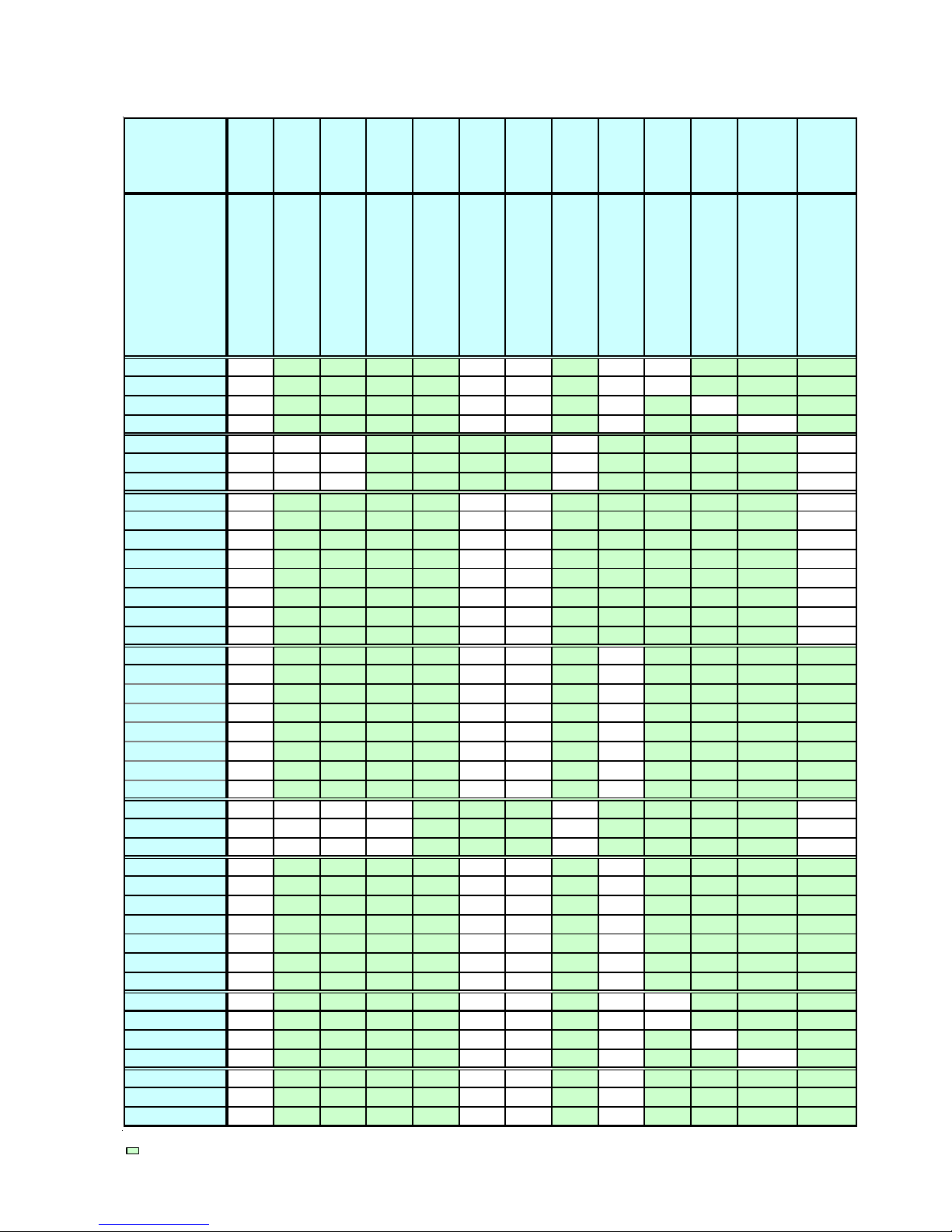

ACCESSORIES

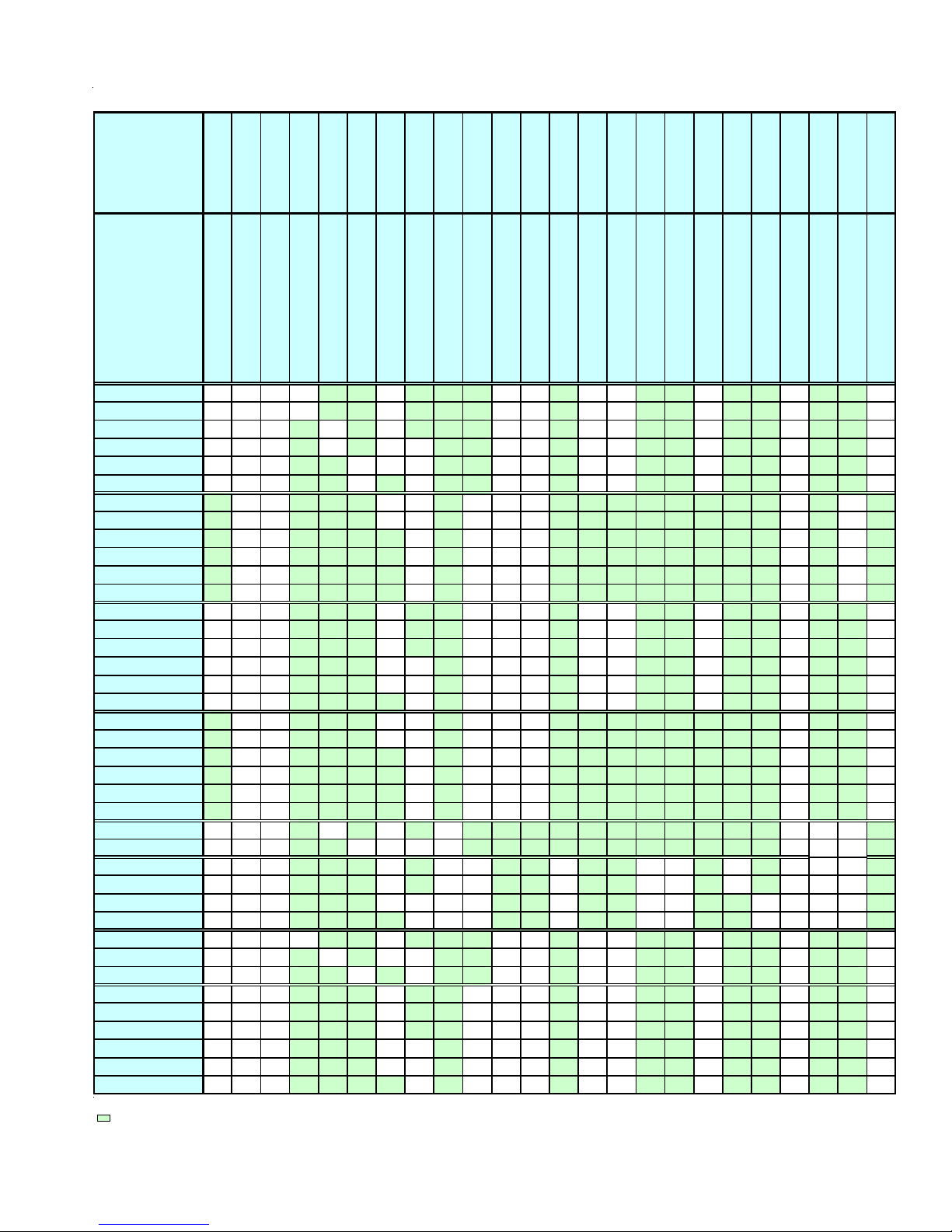

AMANA® BRAND & AMANA® DISTINCTIONS™ BRAND 80% FURNACE ACCESSORIES

Model Number

Description

ADS80453ANA X X X X X

ADS80703ANA X X X X X

ADS80904BNA X X X X X

ADS81155CNA X X X X X

ADV80703BX X X X X X

ADV80905CX X X X X X

ADV81155CX X X X X X

AMH80453ANA X

AMH80703ANA X

AMH80704BNA X

AMH80903BNA X

AMH80904BNA X

AMH80905CNA X

AMH81155CNA X

AMH81405DNA X

AMS80453ANA X X X X

AMS80703ANA X X X X

AMS80704BNA X X X X

AMS80903BNA X X X X

AMS80904BNA X X X X

AMS80905CNA X X X X

AMS81155CNA X X X X

AMS81405DNA X X X X

AMV80704BXA X X X X X X

AMV80905CXA X X X X X X

AMV81155CXA X X X X X X

DMS80453ANA X X X X

DMS80703ANA X X X X

DMS80704BNA X X X X

DMS80904BNA X X X X

DMS80905CNA X X X X

DMS81155CNA X X X X

DMS81405DNA X X X X

DDS80453AXA X X X X X

DDS80703AXA X X X X X

DDS80904BXA X X X X X

DDS81155CXA X X X X X

DHS80453AXA X X X X

DHS80704BXA X X X X

DHS80905CXA X X X X

X - Available for this model (1) Up to 7,000 ft. (2) 7,001 to 11,000 ft. (3) 7,001 to 9,000 ft.

Not used in this application. (4) 9,001 to 11,000 ft. (5) MUST use single stage thermostat with FTK03A

Note: All installations above 7,000 ft. require a pressure switch change.

AFE180-60A

Fossil Fuel Kit

AMU

ASAS

Media Air Cleaners

Electronic Air Cleaner

EFR01

DEHUM1

Dehumidistat

FTK03A

External Filter Rack

Furnace Twinning Kit

(5)

(5)

HA02

LPM-03B

Propane Gas Conversion Kit

High Altitude Natural Gas Kit

XX

XX

SBT14

LPT-00A

Propane Gas Conversion Kit

SBT17

Downflow Subbase 14"

Downflow Subbase 17.5"

SBT21

Downflow Subbase 21"

(5) XX

(5) XX

(5)

(5)

(5)

(5)

XX

XX

XX

XX

LPM-05

Propane Gas Conversion Kit

15

Page 16

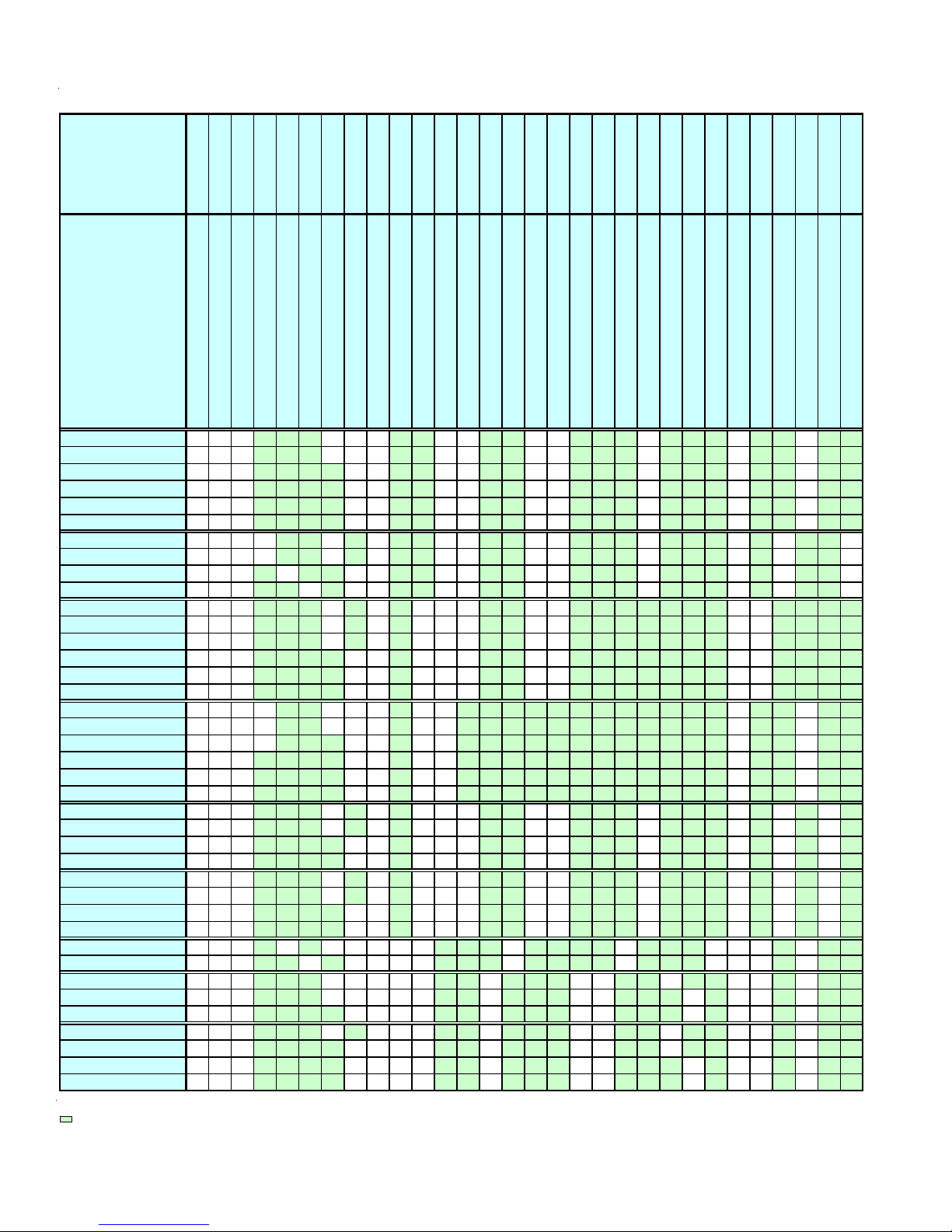

ACCESSORIES

GOODMAN® BRAND 80% FURNACE ACCESSORIES

16

Model Number

Description

GDS80453ANA X X X X X

GDS80703ANA X X X X X

GDS80904BNA X X X X X

GDS81155CNA X X X X X

GDH80453AXA

GDH80703AXA

GDH80904BXA

GDH81155CXA

GHS80453A*A X X X X

GHS80704C*A X X X X

GHS80703B*A X X X X

GME80704BX* X X X X X

GME80905CX* X X X X X

GME81155CX* X X X X X

GMH80453ANA X (5) X X

GMH80453AXA X (5) X X

GMH80703ANA X (5) X X

GMH80703AXA X (5) X X

GMH80704BNA X (5) X X

GMH80704BXA X (5) X X

GMH80903BNA X (5) X X

GMH80904BNA X (5) X X

GMH80904BXA X (5) X X

GMH80905CNA X (5) X X

GMH80905CXA X (5) X X

GMH81155CNA X (5) X X

GMH81155CXA X (5) X X

GMH81405DNA X (5) X X

GMH81405DXA X (5) X X

GMS80453ANA X X X X

GMS80703ANA X X X X

GMS80704BNA X X X X

GMS80903BNA X X X X

GMS80904BNA X X X X

GMS80905CNA X X X

GMS81155CNA X X X

GMS81405DNA X X X

GMV80704BXA X X X X X X

GMV80905CXA X X X X X X

GMV81155CXA X X X X X X

X - Available for this model (1) Up to 7,000 ft. (2) 7,001 to 11,000 ft. (3) 7,001 to 9,000 ft.

Not used in this application. (4) 9,001 to 11,000 ft. (5) MUST use single stage thermostat with FTK03A

Note: All installations above 7,000 ft. require a pressure switch change.

X(5)XXXX

X(5)XXXX

X (5)XXXX

X(5)XXXX

GMU

GSAS

AFE180-60A

Media

Electronic

Air Cleaner

Fossil Fuel Kit

Air Cleaners

EFR01

DEHUM1

Furnace

External

Dehumidistat

Filter Rack

HA02

FTK03A

High Altitud

Twinning Kit

LPM-03B

Propane Gas

Propane Gas

Conversion Kit

Natural Gas Kit

SBT14

SBT17

17.5"

SBT21

21"

Downflow Subbase

LPT-00A

14"

Conversion Kit

Downflow Subbase

Downflow Subbase

LPM-05

Propane Gas

Conversion Kit

Page 17

ACCESSORIES

AMANA® BRAND & AMANA® DISTINCTIONS™ BRAND 90% & 95% Furnace Accessories

Model Number

Description

ACS90453BXA X X X X X X

ACS90703BXA X X X X X X

ACS90704CXA X X X X X X

ACS90904CXA X X X X X X X

ACS90905DXA X X X X X X X

ACS91155DXA X X X X X X

AMH950453BXA X X X X X

AMH950703BXA X X X X X

AMH950704CXA X X X X

AMH950904CXA X X X X

AMH950905DXA X X X X

AMH951155DXA X X X X

AMS90453BXA X X X X X X

AMS90703BXA X X X X X X

AMS90704CXA X X X X X X

AMS90904CXA X X X X X X X

AMS90905DXA X X X X X X X

AMS91155DXA X X X X X X

AMS950453BXA X X X X X X

AMS950703BXA X X X X X X

AMS950704CXA X X X X X

AMS950905CXA X X X X X

AMS950905DXA X X X X X

AMS951155DXA X X X X X

ACV90704CXA X X X X X X X X X

ACV90905DXA XXX XXXX XXX

AMV90453BXA X X X X X X

AMV90704CXA X X X X X X

AMV90905DXA XXX XXXX

AMV91155DXA X X X X X X

DCS90703BXA X X X X X X

DCS90904CXA X X X X X X X

DCS91155DXA X X X X X X

DMS90453BXA X X X X X X

DMS90703BXA X X X X X X

DMS90704CXA X X X X X X

DMS90904CXA X X X X X X X

DMS90905DXA X X X X X X X

DMS91155DXA X X X X X X

AMU

ASAS

CFB17

CFB21

CFB24

DCVK-20

AFE180-60A

Fossil Fuel Kit

Media Air Cleaners

Electronic Air Cleaner

Downflow Subbase 21"

Downflow Subbase 17.5"

Downflow Subbase 24"

DCVK-30

Concentric Vent Kit (2")

Concentric Vent Kit (3")

EFR01

FTK03A

HALP10

HALP11

HANG11

HANG12

DEHUM1

Dehumidistat

External Filter Rack

Furnace Twinning Kit

High Altitude Propane Gas Kit

High Altitude Natural Gas Kit

High Altitude Propane Gas Kit

HANG13

High Altitude Natural Gas Kit

High Altitude Natural Gas Kit

HAPS27

HANG14

High Altitude Natural Gas Kit

HAPS28

High Altitude Pressure Switch

High Altitude Pressure Switch

(4) (1) (2) (4)

(4) (1) (2) (4)

(4) (1) (2) (4)

(4) (1) (2) (4)

(4) (1) (2) (4)

(4) (1) (2) (4)

(5) (2)

(5) (2)

(5) (2)

(5) (2)

(5) (2)

(5) (2)

(4) (1) (2) (4)

(4) (1) (2) (4)

(4) (1) (2) (4)

(4) (1) (2) (4)

(4) (1) (2) (4)

(4) (1) (2) (4)

(2)

(2)

(2)

(2)

(2)

(2)

(2) (3) (4)

(2) (3) (4)

(2) X X X

(2) X X X

(2) (3) (4)

(2) (3) (4)

(4) (1) (2)

(4) (1) (2)

(4) (1) (2)

(4) (1) (2)

(4) (1) (2)

(4) (1) (2)

(4) (1) (2)

(4) (1) (2)

(4) (1) (2)

(4) X X

(4) X X

(4) X X

(4) X X

(4) X X

(4) X X

(4) X X

(4) X X

(4) X X

LPLP01

HAPS29

High Altitude Pressure Switch

Propane Low Pressure Switch

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

(2) X X X

(2) X X X

LPM-03B

Propane Gas Conversion Kit

LPM-05

Propane Gas Conversion Kit

X - Available for this model (1) Up to 7,000 ft. (2) 7,001 to 11,000 ft. (3) 7,001 to 9,000 ft.

Not used in this application. (4) 9,001 to 11,000 ft. (5) MUST use single stage thermostat with FTK03A

Note: All installations above 7,000 ft. require a pressure switch change.

Note: For installations in Canada the Goodman 90% furnace is certified only to 4,500 ft.

LPT-00A

Propane Gas Conversion Kit

17

Page 18

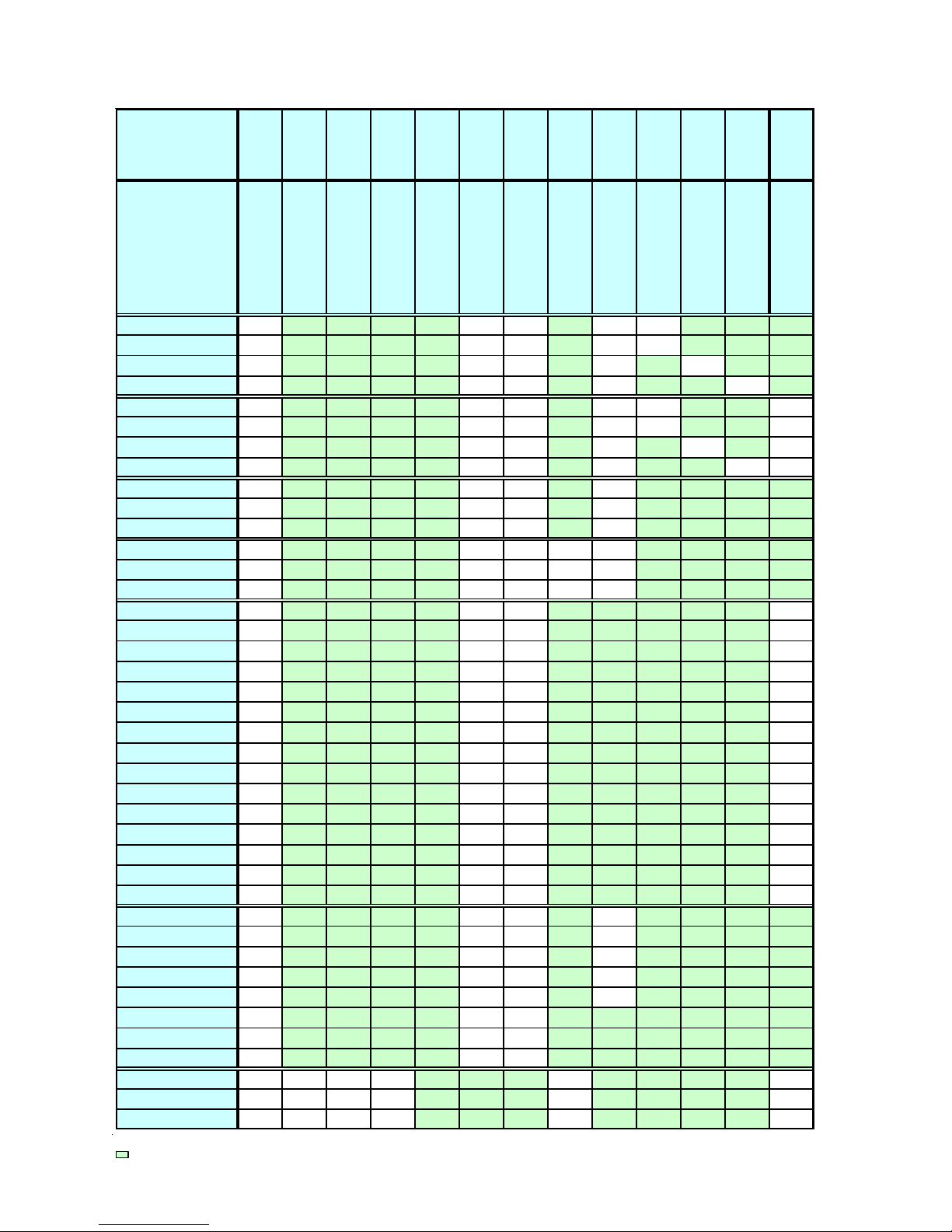

ACCESSORIES

GOODMAN® BRAND 90% & 95% Furnace Accessories

Model Number

Description

GCH90453BXA X X X X X X

GCH90703BXA X X X X X X

GCH90704CXA X X X X X

GCH90904CXA X X X X X

GCH90905CXA X X X X X

GCH91155DXA X X X X X

GCS90453BXA XXXX X X X

GCS90703BXA XXXX X X X

GCS90904CXA X X X X X X X

GCS91155DXA X X X X X X X

GKS90453BXA* X X X X X X X

GKS90703BXA* X X X X X X X

GKS90704CXA* X X X X X X X

GKS90904CXA* X X X X X X X

GKS90905DXA* X X X X X X X

GKS91155DXA* X X X X X X X

GMH950453BXA XXXX XXX X

GMH950703BXA XXXX XXX X

GMH950704CXA XXXX XX X

GMH950904CXA X X X X X X

GMH950905DXA X X X X X X

GMH951155DXA X X X X X X

GMS90453BXA X X X X X X X

GMS90703BXA X X X X X X X

GMS90904CXA X X X X X X X

GMS91155DXA X X X X X X X

GMS950453BXA X X X X X X X

GMS950703BXA X X X X X X X

GMS950904CXA X X X X X X X

GMS951155DXA X X X X X X X

GCV90704CXA X X X X XXXXX

GCV90905DXA X X X X XXXX (2) (2) (2) X (1) (1)

GMV90703BXA X X X XXXXX

GMV90905CXA X X X XXXXX

GMV91155DXA X X X XXXX

GMV950453BXA X X X X X X X

GMV950704CXA X X X XXXX

GMV950905DXA X X X XXXX (2)(3)(4)(2)X (1) (1)

GMV951155DXA X X X XXXX (2)(3)(4)(2)X (1) (1)

X - Available for this model (1) Up to 7,000 ft. (2) 7,001 to 11,000 ft. (3) 7,001 to 9,000 ft.

Not used in this application. (4) 9,001 to 11,000 ft. (5) MUST use single stage thermostat with FTK03A

Note: All installations above 7,000 ft. require a pressure switch change.

Note: For installations in Canada the Goodman 90% furnace is certified only to 4,500 ft.

AFE180-60A

Fossil Fuel Kit

GMU

Media Air Cleaners

GSAS

CFB17

CFB21

CFB24

DCVK-20

DCVK-30

Electronic Air C leaner

Downflow Subbase 21"

Downflow Subbase 24"

Concentric Vent Kit (2")

Downflow Subbase 17.5"

Concentric Vent Kit (3")

0170K00000S

Concentric Side Wall Vent Kit (3")

EFR01

FTK03A

HALP10

HALP11

HALP13

HANG11

DEHUM1

Dehumidistat

External Filter Rack

Furnace Twinn ing Kit

High Altitude Propane Gas Kit

High Altitude Propane Gas Kit

HANG12

High Altitude Natural Gas Kit

High Altitude Natural Gas Kit

High Altitude Propane Gas Kit

(5) (2) (3) (4) (2)

HAPS27

HANG13

HANG14

High Altitude Natural Gas Kit

High Altitude Natural Gas Kit

HAPS28

HANG16

High Altitude Natural Gas Kit

High Altitude Pressure Switch

High Altitude Pressure Switch

LPLP01

HAPS29

HAPS31

LPM-03B

High Altitude Pressure Switch

Propane Gas Conversion Kit

High Altitude Pressure Switch

Propane Low Pressure Switch

XX

LPT-00A

Propane Gas Conversion Kit

(5) (2) (3) (4) (2) XX

(5) (2) (3) (4) (2) XX

(5) (2) (3) (4) (2) XX

(5) (2) (3) (4) (2) XX

(5) (2) (3) (4) (2)

(2) (1) (4) (2)

(2) (3) (4) (2)

(2) (3) (4) (2)

(2) (3) (4) (2)

XX

XX X

XX X

XX X

XX X

(3) (1) (2) XX

(3) (1) (2) XX

(3) (1) (2) XX

(3) (1) (2) XX

(3) (1) (2)

(3) (1) (2)

(5)

(5)

(5)

XX

XX

XX

XX

XX

(5) XX

(5) XX

(5) XX

(2) (3) (4) (2) XXX

(2) (3) (4) (2)

(2) (3) (4) (2)

(2) (3) (4) (2)

(2) (3) (4) (2)

(2) (3) (4) (2)

XXX

XXX

XXX

XXX

XXX

(2) (3) (4) (2) XXX

(2) (3) (4) (2) XXX

(2) (2) (2) X (1) (1)

(2) (3) (4)

(2) (3) (4)

(2) (3) (4)

(2) (3) (4) (2)

(2) (3) (4) (2)

(2) X

(2) X

(2) X

(1) (1)

(1) (1)

(1) (1)

X

(1) (1)

X

(1) (1)

LPM-05

RF000180

RF000181

Propane Gas Conversion Kit

Internal Filter Retention Kit (Downflow)

Internal Filter Retention Kit (Upflow/Horiz)

18

Page 19

OPERATING INSTRUCTIONS

F

O

Y

O

R

R

E

A

D

B

E

o

n

d

u

o

y

W

A

R

N

p

lo

x

e

s

n

o

s

r

e

p

a

s

i

T

h

A

.

w

a

h

it

th

b

e

u

B

.

B

E

O

F

a

fo

e

a

r

a

e

c

b

u

s

ttle

e

H

A

W

D

D

d

I

p

I

c

C

. U

o

e

s

N

r

e

v

e

d

a

,

n

h

te

h

n

c

p

x

e

r

o

o

n

D

o

D

.

Im

m

e

th

a

e

p

m

e

t

s

y

s

f

I

IN

G

:

io

m

n

y

a

lt c

u

s

e

r

u

l in

a

ju

r

p

li

p

e

c

a

n

ig

n

itio

n

n

r

D

o

.

r

e

O

R

E

P

g

. B

r

s

a

o

m

s

e

s

o

th

e

f

n

T

D

T

O

o

n

o

tr

t

o

t

t

o

n

o

o

n

t u

o

s

a

m

i

e

d

m

h

.

n

F

e

o

a

c

o

u

f

y

ll th

a

fir

e

h

r

o

u

y

ly

n

o

t

o

e

s

u

y

r

t

't

n

d

o

ic

ia

.

F

n

o

l

io

s

o

n

.

t

h

is

t

e

u

s

ia

d

te

ly

c

p

lia

a

e

c

n

a

d

a

n

n

a

o

y

d

d

n

n

E

e

g

e

lo

o

O

to

y

u

c

e

e

t

llo

o

n

n

e

a

ls

.

o

t

c

r

a

ll

a

n

y

f

o

lo

s

s

r

a

h

t

o

n

e

s

o

w

ic

v

e

e

h

g

li

o

t

y

r

t

o

t

R

A

T

IN

G

e

to

s

m

r

u

s

e

a

h

s

i

a

s

.

r

Y

O

F

U

I

lig

a

n

t

y

h

e

y

a

n

h

e

l

e

n

h

o

p

a

n

y

a

ll

c

ly

r

o

u

y

th

w

e

g

a

a

e

r

o

t

y

h

c

d

e

tm

r

p

a

e

to

n

d

p

u

s

If t

le

e

h

e

v

it

ir

p

a

e

r

,

a

r

o

t

e

te

m

e

n

c

a

li

p

p

u

q

a

ie

f

a

li

d

to

p

r

la

e

r

t

n

o

c

s

g

a

S

U

R

A

F

E

T

Y

F

O

R

E

O

P

E

R

A

T

IN

G

llo

o

f

t

o

w

e

s

e

h

t

in

s

lif

v

ic

h

s

ie

v

S

a

t

c

in

g

s

o

n

h

in

r

a

c

p

if

d

e

c

l

o

e

p

g

p

o

r

ty

r

.

e

e

p

a

a

h

u

e

h

t

t

e

m

ll n

e

h

t

r

E

M

p

lia

p

s

ic

r

y

o

s

s

a

u

s

p

a

g

u

r

t.

o

w

ill n

ll

a

te

d

r

n

a

y

v

r

e

s

n

a

w

ic

h

e

s

i

t

I

.

t

o

il

tic

a

m

o

a

t

lly

b

y

e

r

n

r

b

u

l

l

a

ll

e

a

L

w

p

r

e

p

y

d

u

n

o

a

r

t to

x

th

flo

e

d

a

n

a

ir

n

G

A

S

L

.

e

c

n

;

h

c

it

b

r

u

u

ild

in

g

li

p

p

u

o

r

f

r

e

lie

's

in

r

tr

s

i

l

p

p

u

s

s

e

r

tu

n

th

r

g

e

o

t p

in

h

s

u

ifi

l

a

q

u

s

d

e

r

y

ir

p

a

m

a

b

s

a

h

t

r

a

n

ic

h

c

e

t

ic

e

p

f

t

th

o

r

a

a

h

h

e

b

e

s

io

s

n

t

u

c

r

in

t

s

m

a

d

e

,

a

g

u

ip

q

e

d

p

ig

h

l

s

t

.

n

h

d

a

ia

e

c

n

l

p

p

a

e

h

t

o

r

w

l

il

.

m

a

tio

c

u

,

c

s

a

o

r

c

i

v

e

r

s

e

u

n

e

e

i

n

a

e

c

o

u

n

n

tu

u

t

n

n

o

e

lt in

n

o

n

d

's

e

ig

o

h

r

b

.

s

l

o

r

.

t

le

n

e

r

v

b

n

r

y

fir

a

e

e

r

d

.

e

r

w

t

a

in

t

c

p

e

s

tr

o

l

.

r

e

w

t

a

r

e

A

R

V

E

A

I

L

A

V

S

S

E

la

le

is

q

u

r

tra

n

e

p

r

o

c

C

e

A

.

m

u

a

u

d

'a

A

B

.

V

e

n

r

u

n

c

e

p

e

Q

U

N

e

C

.

q

u

S

i la

é

p

r

te

n

d

é

D

N

e

.

d

a

te

c

e

m

r

to

u

E

R

ttr

e

în

o

r

a

t

n

i d

o

m

t

llu

A

le

f

i

e

o

ta

r

u

v

E

o

p

'à

m

a

r

e

t

l

c

e

p

n

s

h

n

p

e

t

e

d

a

l'e

M

T

I

le

e

a

lle

e

p

p

'u

a

m

N

r

d

in

s

e

n

N

N

n

A

e

R

f

S

in

u

la

a

e

r

d

e

n

c

s

ic

la

c

c

o

E

in

s

t

s

c

u

r

le

c

é

d

h

c

e

t d

n

d

s

e

m

a

o

s

la

u

p

o

c

e

n

il

e

a

r

is

d

itif

s

p

o

n

iq

e

m

u

t

t

e

n

le

r

e

b

le

û

u

r

T

D

E

L

E

r

o

u

t

a

u

u

t

o

t

r

u

e

d

e

g

.

a

z

s

z

a

g

n

t

o

p

u

'a

u

s

m

c

c

t

S

R

E

F

A

I

t

e

n

t

s

a

p

e

h

u

c

o

t

e

r

e

a

u

is

il

r

e

'u

t

le

e

p

p

im

r

m

e

m

p

n

lo

a

y

p

s

e

à

r

e

t

e

c

n

is

r

e

u

s

r

o

u

p

i

e

n

o

n

s

e

r

d

e

ie

n

c

.

s

o

u

t

u

o

e

r

s

s

m

n

a

in

e

;

ja

e

tte

n

te

s

r

e

u

r

e

l

p

a

e

p

;

fo

la

e

r

c

m

r

e

x

e

n

u

r

h

e

d

ir

s

v

e

s

r

e

u

, c

a

lè

p

m

o

u

q

ie

n

lifié

a

r

p

a

u

t

o

t

e

r

m

m

q

d

a

e

n

N

T

M

D

E

E

E

N

A

M

R

C

Q

ic

u

q

o

N

T

tio

n

u

r

m

t

r

e

p

m

d

'a

b

le

m

r

F

d

e

R

e

lu

s

le

r

'IL

d

r

e

c

a

u

n

u

c

é

d

l

n

t

la

d

e

n

e

n

e

r

m

a

c

o

e

t

n

a

n

p

lo

e

c

e

te

m

p

o

u

e

i

t

d

i o

u

n

:

d

s

le

s

n

a

p

ie

d

n

e

c

in

n

m

s

g

e

a

té

a

h

ie

v

s

d

e

e

o

e

d

s

p

a

e

t

r

llu

m

e

a

q

g

u

p

N

e

.

u

r

e

l

û

r

a

n

lle

u

e

n

e

m

A

IR

E

F

O

p

ie

'a

l

r

a

p

p

l

ifle

n

d

p

s

è

r

r

e

u

q

lo

d

s

r

u

n

u

a

e

le

g

r

is

s

d

iv

u

e

a

A

Y

U

N

E

r

e

'a

m

u

ll

'a

p

l

t

u

p

r

r

e

in

t

n

u

o

p

h

é

l

é

t

ia

r

in

c

e

io

t

e

r

u

n

d

e

n

n

t le

e

te

m

fo

é

lé

p

t

e

n

h

o

ttr

e

le

in

s

s

.

z

a

p

a

,

d

o

é

n

p

l

e

l

'a

d

ie

v

e

r

lo

p

e

m

d

e

r

, n

é

e

c

a

p

e

e

i

c

i

n

h

u

q

n

tte

o

d

u

la

e

n

o

in

u

n

u

s

l

i

e

r

p

a

a

p

o

u

t

e

n

n

p

l'a

in

r

e

t

e

c

p

s

e

è

m

t

s

y

s

t é

té

p

lo

g

n

o

l'a

u

T

T

R

E

H

E

IR

L

E

e

e

r

s

n

e

u

é

r

o

u

rie

m

u

i

e

v

i a

a

s

t.

N

C

r

u

u

p

ir

s

O

a

p

r

e

u

a

n

u

ú

d

t

u

r

e

le

p

d

m

'o

u

te

s

ié

f

li

a

r

e

e

c

a

'il

tie

a

r

p

d

e

é

s

lle

llu

o

r

n

c

s

ls

a

e

t

d

la

e

.

D

i

é

s

n

r

r

i

til à

p

n

é

p

c

d

e

p

t m

e

n

n

a

n

u

p

x

e

e

, d

lé

e

s

in

.

e

s

Il

.

e

s

u

e

s

e

m

e

r

t

n

T

IO

N

N

e

c

é

r

e

l

h

e

n

c

c

,

r

t

l

E

U

R

D

l

e

iq

u

e

r

le

t

c

e

im

â

t

b

le

d

is

r

e

u

s

v

.

n

o

is

i

tio

d

s

n

u

s

le

c

i

v

e

r

d

u

io

s

s

n

f

e

f

c

e

t

te

n

d

r

e

la

q

o

n

c

Q

i

u

.

r

e

a

r

u

p

e

.

e

i

d

é

t

g

n

o

l

p

. A

e

p

p

le

r

e

il

t

e

r

a

ô

r

n

t

o

e

e

l

l'e

u

a

s

a

n

á

a

s

p

te

c

e

l

u

lo

io

s

n

io

s

s

n

t

E

R

,

r

a

E

G

A

Z

;

.

n

t

z

a

g

e

e

s

d

e

a

g

z

e

t

.

e

u

t

é

n

u

t

.

E

S

E

I

r

p

m

e

s

o

i

d

R

h

'y

s

o

i

e

e

p

le

p

s

itio

p

M

L

is

e

E

Ê

T

R

!

le

c

,

r

r

e

r

if

p

E

tio

p

e

p

e

n

u

le

l'a

c

.

f

r

z

e

ie

s

r

é

u

u

r

p

à

a

t

t

s

o

m

r

h

e

t

lim

ta

e

n

tio

n

r

g

n

e

a

é