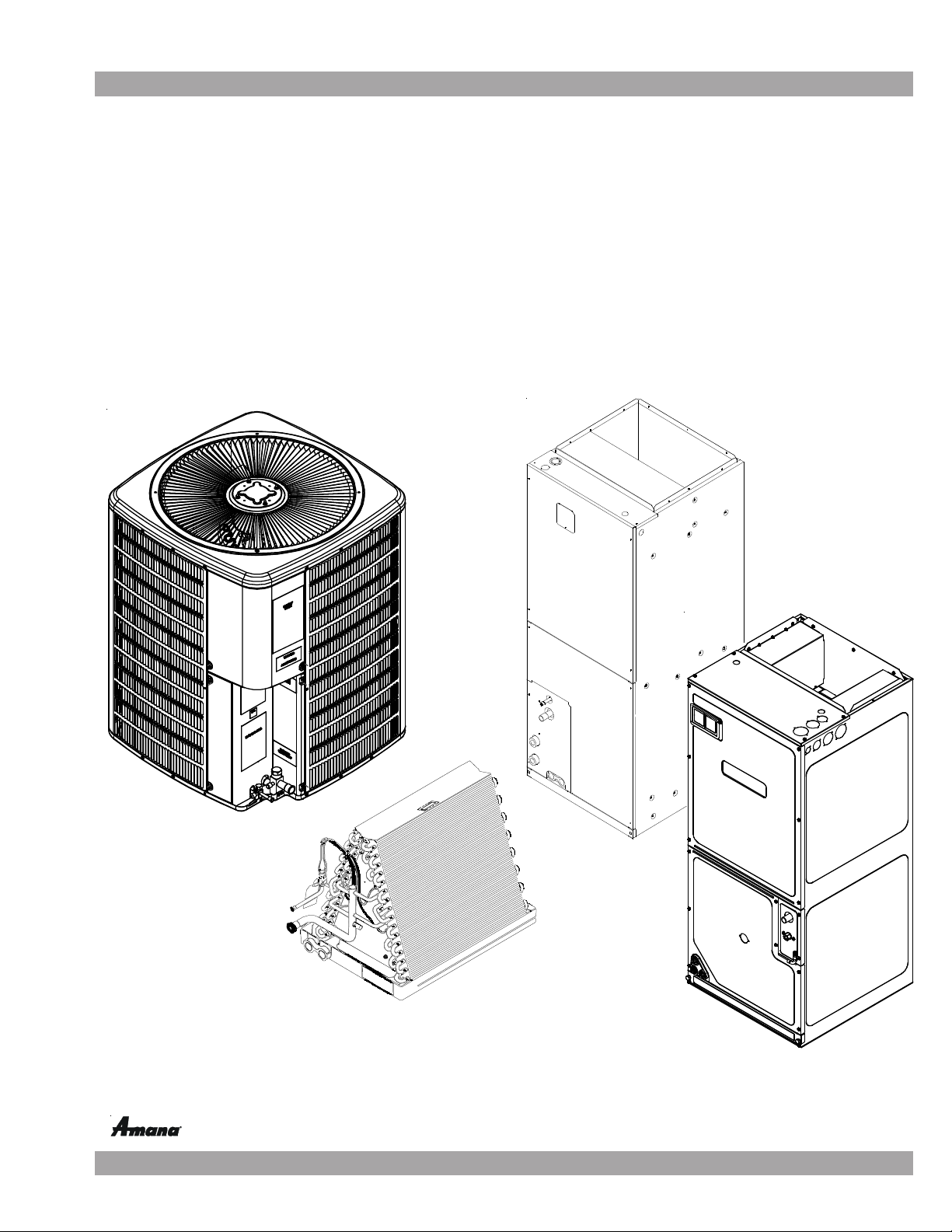

Goodman ComfortNet Service manual

Service Instructions

ComfortNet™

ASXC, DSXC, and GSXC Condensing Units,

ASZC & DSZC Split System Heat Pumps

with R-410A Refrigerant

Blowers, Coils, & Accessories

This manual is to be used by qualified, professionally trained HVAC technicians only. Goodman

does not assume any responsibility for property damage or personal injury due to improper

service procedures or services performed by an unqualified person.

Copyright © 2015-2017 Goodman Manufacturing Company, L.P.

is a registered trademark of Maytag Corporation or its related companies and is used under license to Goodman Company, L.P., Houston, TX. All rights reserved.

RS6200007r12

September 2017

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however, that

during its lifetime a product may require service. Products should be serviced only by a qualified service technician who is

familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing instruments

and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE SERVICE MANUAL BEFORE

BEGINNING REPAIRS.

IMPORTANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

WARNING

O

NLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL, ADJUST, SERVICE OR

REPAIR (HEREINAFTER

MANUAL SHOULD SERVICE THE EQUIPMENT

BE RESPONSIBLE FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM

IMPROPER SERVICE OR SERVICE PROCEDURES

ASSUME RESPONSIBILITY FOR ANY INJURY OR PROPERTY DAMAGE WHICH MAY

RESULT

. IN

LICENSES TO SERVICE THE EQUIPMENT SPECIFIED IN THIS MANUAL, ONLY

LICENSED PERSONNEL SHOULD SERVICE THE EQUIPMENT

INSTALLATION, ADJUSTMENT, SERVICING OR REPAIR OF THE EQUIPMENT

SPECIFIED IN THIS MANUAL, OR ATTEMPTING TO INSTALL, ADJUST, SERVICE OR

REPAIR THE EQUIPMENT SPECIFIED IN THIS MANUAL WITHOUT PROPER

TRAINING MAY RESULT IN PRODUCT DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH

, “

SERVICE

”)

THE EQUIPMENT SPECIFIED IN THIS

. THE

MANUFACTURER WILL NOT

. IF

YOU SERVICE THIS UNIT, YOU

ADDITION, IN JURISDICTIONS THAT REQUIRE ONE OR MORE

. I

MPROPER

.

T

O PREVENT THE RISK OF PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH,

DO NOT STORE COMBUSTIBLE MATER IALS OR USE GASO LINE OR OTHER

FLAMMABLE LIQUIDS OR VAPORS IN THE VI CINITY OF T HIS APPLIANCE.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this product.

For further assistance, please contact:

CONSUMER INFORMATION LINE

GOODMAN® BRAND PRODUCTS

TOLL FREE

1-877-254-4729 (U.S. only)

email us at: customerservice@goodmanmfg.com

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-713-861-2500.

(Not a technical assistance line for dealers.) Your telephone company will bill you for the call.

is a registered trademark of Maytag Corporation or its related companies and is used under license to Goodman Company, L.P., Houston, TX. All rights reserved.

email us at: customerservice@goodmanmfg.com

AMANA® BRAND PRODUCTS

TOLL FREE

1-877-254-4729 (U.S. only)

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

2

IMPORTANT INFORMATION

SAFE REFRIGERANT HANDLING

While these items will not cover every conceivable situation, they should serve as a useful guide.

WARNING

REFRIGERANTS ARE H EAVIER THAN AIR. THEY CAN "PUSH OUT" THE

OXYGEN IN YOUR LUNGS OR IN ANY ENCLOSED SPACE.

POSSIBLE DIFFICULTY IN BREATHIN G OR D EATH:

EVER PURGE REFRIGERANT INTO AN ENCLOSED ROOM OR SPACE. BY

•

N

LAW, ALL REFRIGERANTS MUST BE RECLAIMED.

IF AN INDOOR LEAK IS SUSPECTED, THOROUGHLY VENTIL ATE THE AREA

•

BEFORE BEGINNING WORK.

IQUID REFRIGERANT CAN BE VERY COLD. TO AVOID POSSIBLE FROST-

•

L

BITE OR BL INDNESS, AVOID CONTACT WITH REFRIGERANT AND WEAR

I

GLOVES AND GOGGLES.

SKIN OR EYES, SEEK MEDICAL HELP IMMEDIATELY.

A

LWAYS FOLLOW

•

AS POIS ONOUS GAS WI LL BE PRODUCED .

F LIQUID REFRIGERANT DOES CONTACT YOUR

EPA

REGULATIONS. NEVER BURN REFRIGERANT,

O AVO ID

T

WARNING

HE UNITED STATES ENVIRONMENTAL PROTECTION AGENCY ( "

T

HAS ISSUED VARIOUS REGULATIONS REGARDING THE INTRODUCTION AND

DISPOSA L OF REFRIGERANTS INTRODUCED INTO THIS UNIT.

FOLLOW THESE REGULATIONS MAY HARM THE ENVI RONMENT AND CAN

LEAD TO THE H IMPOSITION OF SUBSTANTIAL FINES.

MAY VARY BY JURISDICTION.

EPA OFFICE.

LOCAL

SHOULD QUEST IONS ARISE, CO NTACT YOUR

THESE REGULATIONS

EPA

AILURE TO

F

WARNING

TO AVOID POSSIBLE EXPLOSION:

EVER APPL Y FLAME OR STEA M TO A REFRIGERAN T CYLINDER. IF YOU

•

N

MUST HEA T A CYLINDER FOR FASTER CHARGING, PARTIALLY IMMERSE

IT IN WARM WATER.

NEVER FILL A CYLIN DER MORE THAN 80% FU LL OF LIQUID REFRIGER ANT.

•

NEVER ADD ANYTHING OTHER THAN R-22 TO AN R-22 CYLINDER OR

•

R-410 A TO AN R-410A CYLINDER. THE SERVICE EQUIPMENT USED MUST

BE LISTED OR CERTIFIED FOR THE TYPE OF REFRIGERANT USED.

TORE CYLINDERS IN A COOL, DRY PLACE. NEVER US E A CYLINDER

•

S

AS A PLATFORM OR A ROLLER.

WARNING

TO AVOID POSSIBLE EXPLOSION, USE ONLY RETURNABLE (NOT DISPOSABLE)

SERVICE CYLINDERS WHEN REMOVING REFRIGERANT FROM A SYSTEM.

•

ENSURE THE CYLINDER IS FREE OF DAMAGE WHICH COULD LEAD TO A

LEAK OR EXPLOS ION.

•

")

ENSURE THE HYDROSTATIC T EST DATE DOES NOT EXCEED 5 YEARS.

•

ENSURE THE PRESSURE RATING MEETS OR EXCEEDS 400 LBS.

WHEN IN DOUBT, DO NOT USE CYLINDER.

WARNING

WARNING

SYSTEM CONTAMINANTS, IMPROPER SERVICE PROCEDURE AND/OR PHYSICAL

ABUSE AFFECTING HERMETIC COMPRESSOR ELECTRI CAL TERMINALS MAY

CAUSE DANGEROUS SYSTEM VENTING.

The successful development of hermetically sealed refrigeration compressors has completely sealed the compressor's

moving parts and electric motor inside a common housing,

minimizing refrigerant leaks and the hazards sometimes

associated with moving belts, pulleys or couplings.

Fundamental to the design of hermetic compressors is a

method whereby electrical current is transmitted to the

compressor motor through terminal conductors which pass

through the compressor housing wall. These terminals are

sealed in a dielectric material which insulates them from the

housing and maintains the pressure tight integrity of the

hermetic compressor. The terminals and their dielectric

embedment are strongly constructed, but are vulnerable to

careless compressor installation or maintenance procedures and equally vulnerable to internal electrical short

circuits caused by excessive system contaminants.

T

O AVOID POSSIBLE INJURY, EX PLOSI ON OR DEATH, PRACTICE SAFE

HANDLING OF RE FRIGERA NTS.

In either of these instances, an electrical short between the

terminal and the compressor housing may result in the loss

of integrity between the terminal and its dielectric embedment. This loss may cause the terminals to be expelled,

thereby venting the vaporous and liquid contents of the

compressor housing and system.

A venting compressor terminal normally presents no danger

to anyone, providing the terminal protective cover is properly

in place.

If, however, the terminal protective cover is not properly in

place, a venting terminal may discharge a combination of

(a) hot lubricating oil and refrigerant

(b) flammable mixture (if system is contaminated

with air)

in a stream of spray which may be dangerous to anyone in the

vicinity. Death or serious bodily injury could occur.

Under no circumstances is a hermetic compressor to be

electrically energized and/or operated without having the

terminal protective cover properly in place.

See Service Section S-17 for proper servicing.

3

PRODUCT IDENTIFICATION

s

AS X C 16 024 1 AA

1 2 3 4,5 6 6 7 8,9

ComfortNet™

Brand

A - Amana ® bran d Maj or/Mi nor Revi si on

D - Deluxe Goodman® brand

G - Goodman® brand

Type 1 - 208/230V Single-Phase 60 Hz

S 3 - 208/230V Three-Phase 60 Hz

Split Sys tem

4 - 460V Three-Phase 60 Hz

Type

C: Condenser R-22

H: Heat Pump R-22 024 - 2 Tons

X: Condenser R-410A 036 - 3 Tons

Z: Heat Pump R-410A 048 - 4 Tons

060 - 5 Tons

Communication Feature

C: 4-Wi re Communicati on Ready

SEER

16 - 16 SEER

18 - 18 SEER

Engineering

Voltage

Nominal Capacity

4

PRODUCT IDENTIFICATION

A

=

ComfortNet™

CAP F 1824 A 6 A

1 2 3 4 5,6,7,8 9 10 11,12

Brand Engineering*

C Indoor Coi l

Unit Application 2 = R-22

A Upflow/Downflow Coi l

H Horizontal A-Coil

Horizontal Slab Coil

S

Coated Coils

T

Nominal Width for Gas Furnace

A = Fits 14" Furna ce Cabinet

B = Fits 17-1/2" Furnace Cabi net

C =

Fits 21" Furnace Cabinet

D = Fits 24-1/2" Furnace Cabinet

N

Does Not Apply (Horizontal Slab Coils

Major/Minor Revisions

Refrigerant Charge

4 = R-410A

6 = R-410A or R-22

Cabinet Finish

U Unpainted

PPainted

N Unpai nted Case

Expansion Device

FFlowrator

T 4 - 5 Tons

Expansi on Valve 4 - 5 Tons

1824 =

3030 =

3131 =

3636 =

3642 =

3743 =

4860 = Factory-Installed Non-Adjustable

4961 =

Nominal Capacity @ 13 SEER

1-1/2 - 2 Tons

2-1/2 Tons

2-1/2 Tons

3 Tons

3 - 3-1/2 Tons

3 - 3-1/2 Tons

5

PRODUCT IDENTIFICATION

H

MB V C 12 00 A A 1

1,2 3 4 4 5,6 7 8 9

ComfortNet™

Brand

MB - Modular Blower 1: 208-230V/60Hz/1 P

Type A: First Seri es

Speed

V:

Communication Feature A: No Circui t Br eaker

C: 4-Wire Communication Ready

Airflow

12:

1200 CFM

16:

1600 CFM

20:

2000 CFM

B: Ci rcuit Breaker

Elect rical

Design Se ries

Circuit Breaker

Factory Heat

00 No Heat

6

PRODUCT IDENTIFICATION

A V P T C 1830 1 6 AA

1 2 3 4 5 6,7,8,9 11 12 13,14

ComfortNet™

Brand

A Airhandler

Unit Application

Vari a bl e Sp eed Motor

V

Cabinet Finish

U: Unpa inted

P: Painted 1 208/240V, 1 Phase, 60 Hz

N: Uncas ed

Expansion Device

F: Flowrator

T: Expans ion Valve

Communications

C: 4-Wire Communi cati on Ready

Multi-Position & Downflow Applications

Ceiling Mount & Wall Mount Applications

Maj or/Mi nor Revi si ons

1830 = 1-1/2 to 2-1/2 Tons

3137 = 3 Tons

4260 = 3-1/2 to 5 Tons

Engineering*

Refrigerant Charge

No Di git = R-22 Onl y

6 = R-410A or R-22

Electrical

Nominal Capacity

7

PRODUCT IDENTIFICATION

A

V

PTC 18 B 1 4 AA

1 2 3 4 5 6,7 8 9 10 11,12

ComfortNet™

Brand

A Si ngl e Piec e

Ai rhandl er

Unit Application

C Ceiling Mount PSC Motor 4 = R-410a

R Multi Position PSC Motor

S Multi Posi tion EEM Motor

W Wall Mount PSC/EEM Motor 1 208/240V, 1 Phase, 60 Hz

VMulti Position

Variable Speed Motor -

Communi cating

Cabinet Finish

U Unpainted

PPainted

NUncased

Expansion Device

FFlowrator 31 = 2 Tons

TExpansion Valve 33 = 1 1/2 - 2 Tons

Communications

ComfortNet

C

TM

Compatible

*Not used for inventory management

Nominal Capacity

Major/Minor Revisions

18 = 1-1/2 Tons

24 = 2 Tons

25 = 2 Tons

29 = 2 Tons

30 = 2-1/2 Tons

36 = 3 Tons

37 = 2 1/2 - 3 1/2 Tons

39 = 2 1/2 - 3 Tons

42 = 3-1/2 Tons

48 = 4 Tons

49 = 3 - 3 1/2 Tons

59 = 4 - 5 Tons

60 = 5 Tons

61 = 4 - 5 Tons

Engineering*

Refrige rant Charge

Electrical

Cabinet Width

B = 17-1/2"

C = 21"

D = 24-1/2"

All Airhandlers use DIRECT DRIVE MOTORS. Power supply is AC 208-230v, 60 hz, 1 phase.

8

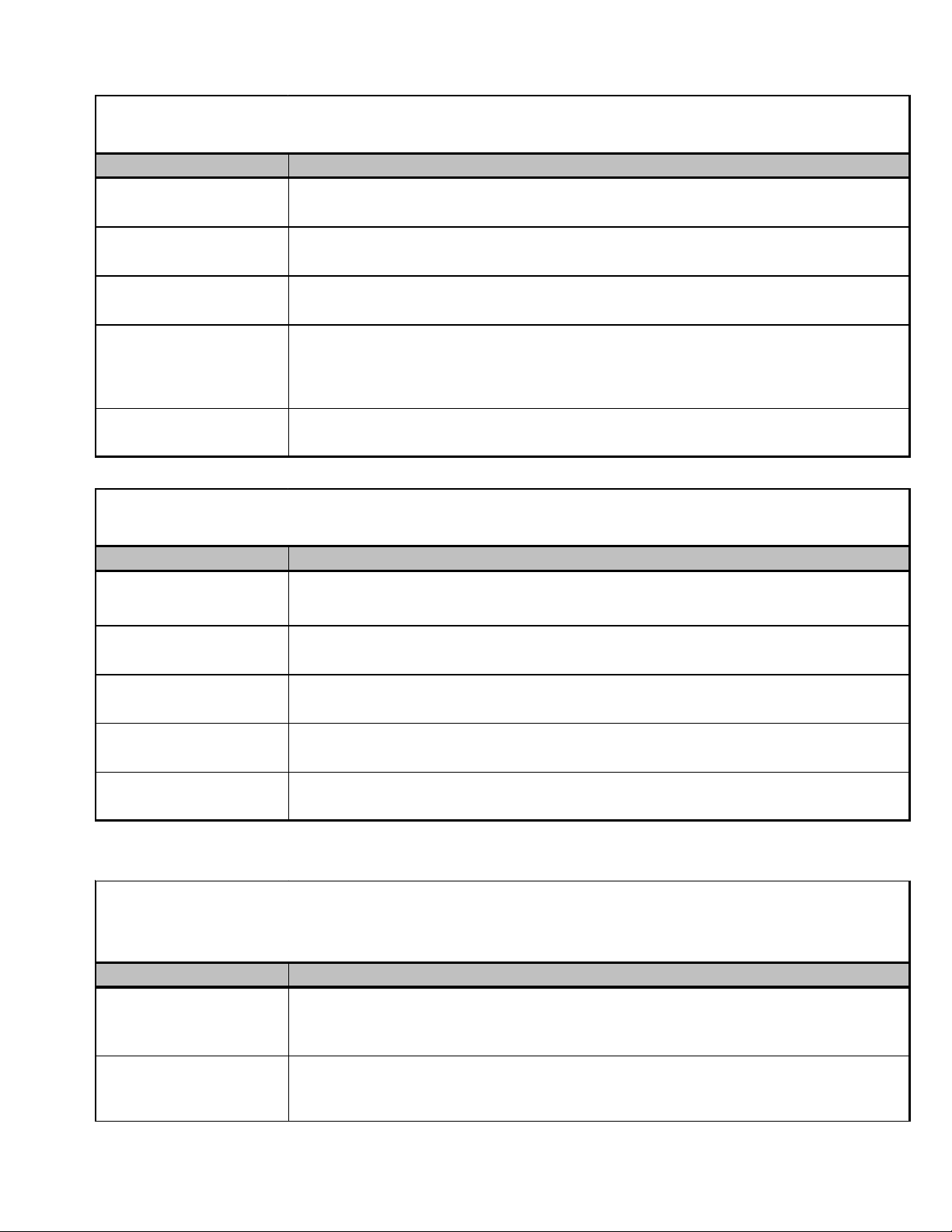

PRODUCT IDENTIFICATION

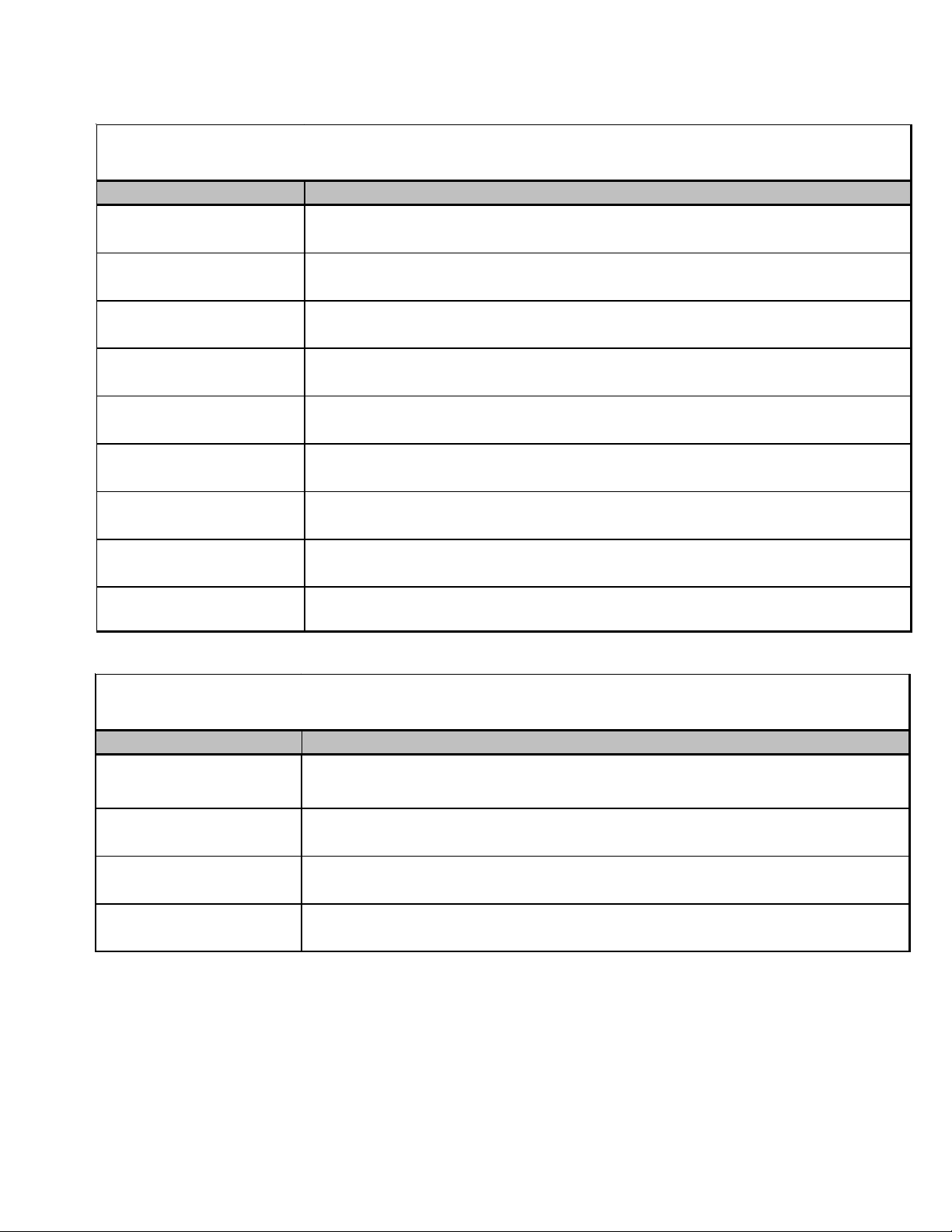

ASXC1 6

MANA® BRAND SPLIT

A

Model/Rev Description

ASXC160**1AA

ASXC160601BA Use ZPS49 compressor.

ASXC160481BA SmartCoil® coils

ASXC160(24/36)1BB Wiring diagram updated with notes.

ASXC160(48-60)1BB Motor changed to Nidec.

Introduces Amana® brand 2-stage 16 SEER condensing units with R-410A,

communic ating models.

OMMUNICATING CONDENSERS R-410A 16 SEER

X-C

ASXC160(24/36)1BC

ASXC160(48-60)1BC

ASXC160(24/36)1BD

ASXC160(48-60)1BD

ASXC160(241, 481)BE Refrigerant charge reduction

ASXC160(24,36,48,60)1CA 16 SEER 2-Stage AC Development with improved performance.

Ultratech® 2.0 compressor change.

Replaced PCBHR103 Communicating Heat Pump Control Board with PCBHR104

Communicating Heat Pump Control Board.

ASXC18

MANA® BRAND SPLIT

A

Model/Rev Description

ASXC18**1AA

ASXC180(36/48/60)1AB Wiring diagram updated with notes.

ASXC180(36/48-60)1AC Replaced compressors ZPS20K4EPFV230 with ZPS20K5EPFV130 and compressor

Initial release of Amana® brand 2-stage 16 SEER condensing units with R-410A,

communicating models.

ZPS30K4EPFV230 with ZPS30K5EPFV130.

OMMUNICATING CONDENSERS R-410A 18 SEER

X-C

ASXC180(24/36/48/60)1BA 18 SEER 2-Stage AC Development with improved performance.

9

PRODUCT IDENTIFICATION

GSXC1 6

OODMAN® BRAND SPLIT

G

Model/Rev Description

GSXC160( 24/36/48/60)1CA

OODMAN® BRAND SPLIT

G

Model/Rev Description

GSXC180( 24/36/48/60)1BA

OMMUNICATING CONDENSERS R-410A 16 SEER

X-C

16 SEER 2-Stage AC Development with improved performance.

GSXC1 8

OMMUNICATING CONDENSERS R-410A 18 SEER

X-C

18 SEER 2-Stage AC Development with improved performance.

10

PRODUCT IDENTIFICATION

DSXC1 6

ELUXE SPLIT

D

Model/Rev Description

DSXC160**1AA

DSXC160(24/36)1AB Wiring diagram updated with notes.

DSXC160(24/36)1AC

DSXC160(48-60)1BC

DSXC160481BA SmartCoil® coils.

DSXC160601BA ZPS49K compressor.

DSXC160(48-60)1BB Motor changed to Nidec.

DSXC160241AF

DSXC160481BE

Initial releas e of Goodman® Deluxe brand 2-stage 16 SEER condensing units with R410A, communicating models.

Ultratech® 2.0 compressor.

Refrigerant charge reduction

OMMUNICATING CONDENSERS R-410A 16 SEER

X-C

DSXC1 8

DELUXE SPLIT X-C

Model/Rev Description

DSXC18**1AA

DSXC180(36/48/60]1AB W iring diagram updated with notes.

DSXC18036AC

DSXC180(48-60)1AC Ultratech® 2.0 compressor change.

Initial releas e of Goodman® Deluxe brand 2-stage 18 SEER condensing units with R410A, c ommunicating models.

Replaced compressors ZPS20K4EPFV230 with ZPS20K5EPFV130 and compressor

ZPS30K4EPFV230 with ZPS30K5EPFV130.

OMMUNICATING CONDENSERS R-410A 18 SEER

11

PRODUCT IDENTIFICATION

ASZC16

MANA® BRAND SPLIT

A

Model/Rev Description

ASZC160**1AA

ASZC160(24/36)1AB

ASZC160(48/60)1AB

ASZC160(24-48)1AC

ASZC160601BA

ASZC160(24-36])1AD

ASZC160601BB

ASZC160(24-36)1AE

ASZC160481AE Ultratech® 2.0 compressor change.

Introduces Amana® brand 2-stage 16 SEER heat pump units with R-410A,

communicating models.

Sanhua (RANCO) revers ing valves

Release of models with accumulators and crankcase heaters.

Motor changed to Nidec.

Replaced compressors ZPS20K4EPFV230 with ZPS20K5EPFV130 and compressor

ZPS30K4EPFV230 with ZPS30K5EPFV130.

OMMUNICATING HEAT PUMP R-410A 16 SEER

Z-C

ASZC18

MANA® BRAND SPLIT

A

Model/Rev Description

OMMUNICATING HEAT PUMPS R-410A 18 SEER

Z-C

ASZC180**1AA

ASZC180601BC

ASZC180601BB

ASZC180(36/48/60)1AB Release of models with accumulators and crankcase heaters.

ASZC180(36-4)]1AC

ASZC180601BA

ASZC180361AD

Introduces Amana® brand 2-stage 18 SEER heat pump units with R-410A,

communicating models.

Ultratech® 2.0 c ompressor change.

Sanhua (RANCO) revers ing valves

12

PRODUCT IDENTIFICATION

DSZC16

ELUXE SPLIT

D

Model/Rev Description

DSZC16**1AA

DSZC160(24/36)1AB

DSZC160(48/60)1AB

DSZC160(24-48)1AC

DSZC160601BA

DSZC160(24-48)]1AD

DSZC160601BB

DSZC160481AE

DSZC160601BC

DSZC160(24-36)1AE

Initial releas e of Goodman® brand Deluxe 2-stage 16 SEER heat pump units with R410A, communicating models.

Sanhua (RANCO) revers ing valves.

Release of models with accumulators and crankcase heaters.

Ultratech® 2.0 c ompressor change.

Replaced compressors ZPS20K4EPFV230 with ZPS20K5EPFV130 and compressor

ZPS30K4EPFV230 with ZPS30K5EPFV130.

OMMUNICATING HEAT PUMP R-410A 16 SEER

Z-C

DSZC18

DELUXE SPLIT Z-C

Model/Rev Description

DSZC18**1AA

Initial releas e of Goodman® brand Deluxe 2-stage 18 SEER heat pump units with R410A, c ommunicating models.

OMMUNICATING HEAT PUMP R-410A 18 SEER

DSZC180(36/48/60)1AB Sanhua (RANCO) reversing valves.

DSZC180361AD

DSZC180(36-48)1AC

DSZC180601BA

DSZC160(24-48)1AD

DSZC160601BB

Replaced compressors ZPS20K4EPFV230 with ZPS20K5EPFV130 and compressor

ZPS30K4EPFV230 with ZPS30K5EPFV130.

Release of models with accumulators and crankcase heaters.

Ultratech® 2.0 c ompressor change.

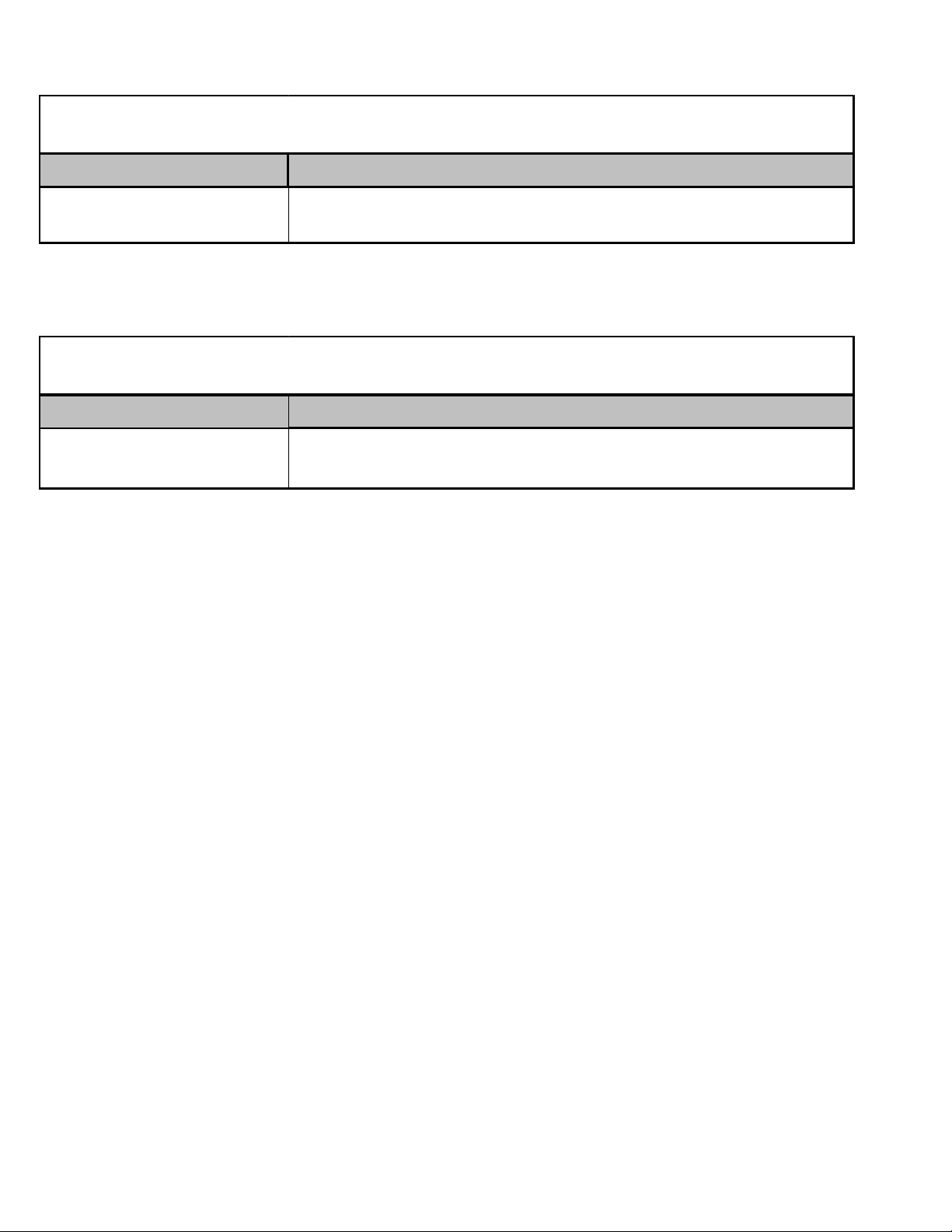

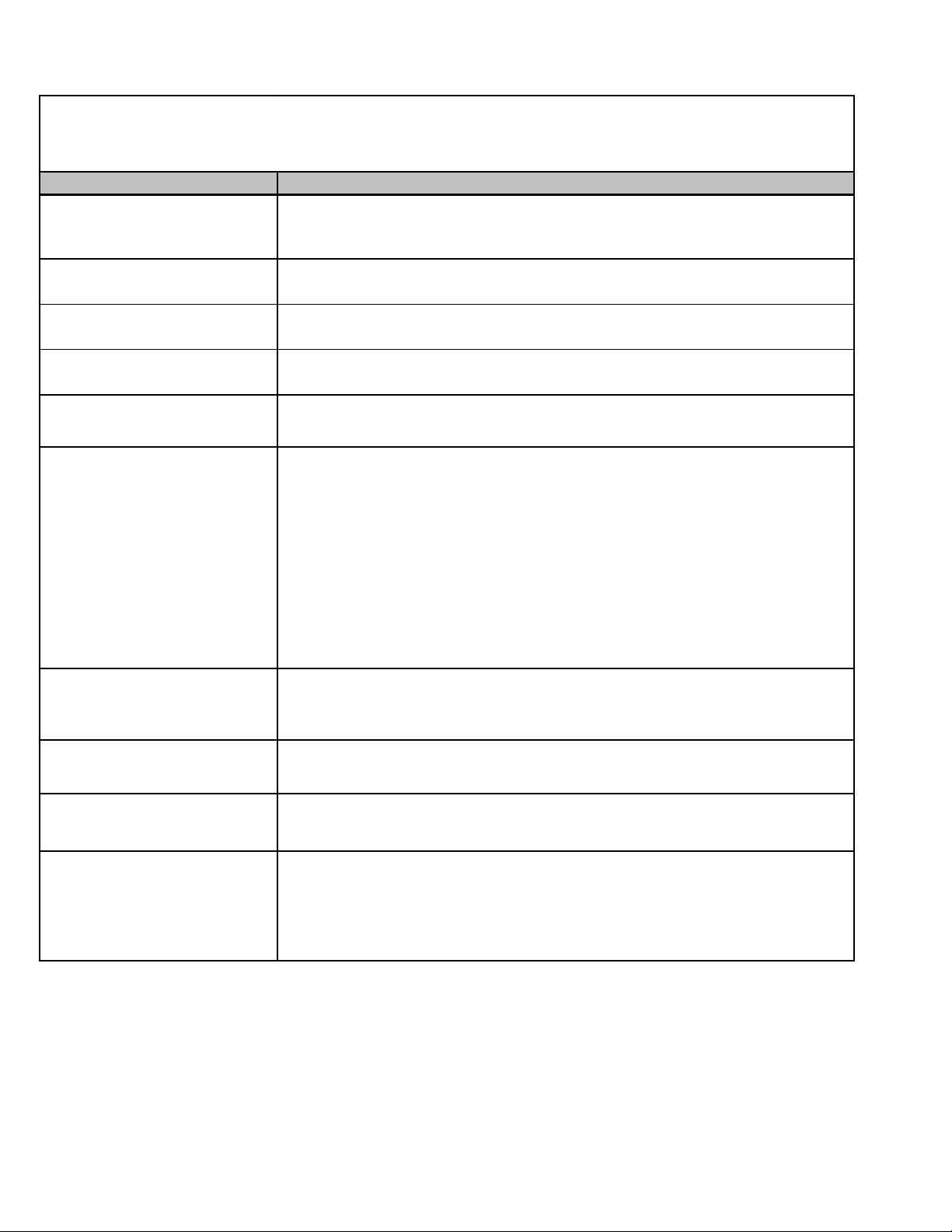

AVPTC****14

SINGLE PIECE AIR HANDLER MULTIPLE-POSITION VARIABLE SPEED

AINTE D TXV WITH 4-WIRE COMMUNICATING CONTROL

P

Model/Rev Description

AVPTC183014AA

AVPTC313714AA

AVPTC426014AA

AVPTC183014AB

AVPTC313714AB

AVPTC426014AB

Initial release of 13 SEER air handler with communicating control and serial

communicating indoor blower motor.

Replaced PCBJA10 communic ating air handler control board with PCBJA103.

13

PRODUCT IDENTIFICATION

AVPTC**14

SINGLE PIECE AIR HANDLER MULTIPLE-POSITION VARIABLE SPEED

AINTED TXV W ITH 4-W IR E COMMUNICATING CONTROL

P

Model/Rev Description

AVPTC24B14AA

AVPTC(30/36)C14AA

AVPTC(42/48/60)D14AA

AVPTC48C14AA Updated S&R and travel labels.

Initial release of 13 SEER air handler with communicating control and serial

communicating indoor blower motor. Redesign of AVPTC models to new air handler

cabinetry. Incorporated 4-way, mult-position body utilized on ARTP/ASPt mdoels.

AVPTC(42/48/60)14AB

AVPTC60D14AC Serial plate update

AVPTC24B14AC

AVPTC30C14AB

AVPTC25B14AA

AVPTC29B14AA

AVPTC31C14AA

AVPTC37B14AA

AVPTC37C14AA

AVPTC37D14AA

AVPTC49D14AA

AVPTC59C14AA

AVPTC59D14AA

AVPTC61D14AA

AVPTC33C14AA

AVPTC39C14AA

AVPTC49C14AA

AVPTC35B14AA Introducing 2.5 and 3 Ton Air Handler product lines.

Redesign of AVPTC models to new air handler cabinetry. Incorporated 4-way, multposition body utilized on ARTP/ASPt mdoels.

Heater Kit airflow update.

AVPTC Efficiency Upgrades

The new AVPTC redesign will incorporate the upgrade blower, coil pan and coil design

intended to increase efficienc y and standardize production.

Upgrade the current AVPTC C-49 cabinets to include 1. quality improvements captured in

Ready15 design. 2.include redesigned drain pan, Morris on blower housing and Emerson

NXT Booster Charge Adjustable TXV.

AVPTC[31,37,39,49,59]C14AB

AVPTC[37,59,61]D14AB

AVPTC[25,29, 37]B14AB

AVPTC33C14AB

AVPTC[31, 37,39,49,59]C14AC

AVPTC49D14AB

AVPTC[37,59,61]D14AB

14

Revisions because of New Heater kits released

Air handler revisions due to using an upgraded (thicker with higher R value)

Quietflex wrapper insulation.

PRODUCT IDENTIFICATION

MBVC

ODULAR BLOWER AIR HANDLER V-MULTI-POSITION VARIABLE-SPEED

M

OMMUNICATING READY W/4-WIRES

C

Model/Rev Description

MBVC1200AA1-AA

MBVC1600AA1-AA

MBVC2000AA1-AA

MBVC1200AA1-AB

MBVC1600AA1-AB

MBVC2000AA1-AB

MBVC1200AA1-AC

MBVC1600AA1-AC

MBVC2000AA1-AC

MBVC1200AA1-AD

MBVC1600AA1-AD

MBVC2000AA1-AD

MBVC[1200,1600,2000]AA1-AE Release of MBR/MBVC Models(Minor Revisions) for 11th St Plant. - Dayton to Houston

Introduction of module blower with variable speed blower motor with the new

communicating control & serial communicating indoor blower motor.

Introduction of a module blower with variable speed blower motor with communicating

control & serial communicating indoor blower motor. Replaces exis ting Emerson motors

(013M00111 & 013M00112).

Introduction of a module blower with variable speed blower motor with communicating

control & serial communicating indoor blower motor. Quality improvement to use 0.75"

Quiet Flex Insulation.

Introduction of a module blower with variable speed blower motor with communicating

control & serial communicating indoor blower motor. Introduces a new Communicating Air

Handler Control Board (PC).

MBVC[1200,1600,2000]AA1-AF

Add permanent sealing/condensation-control upgrades to all MB units and remove highvoltage knockouts

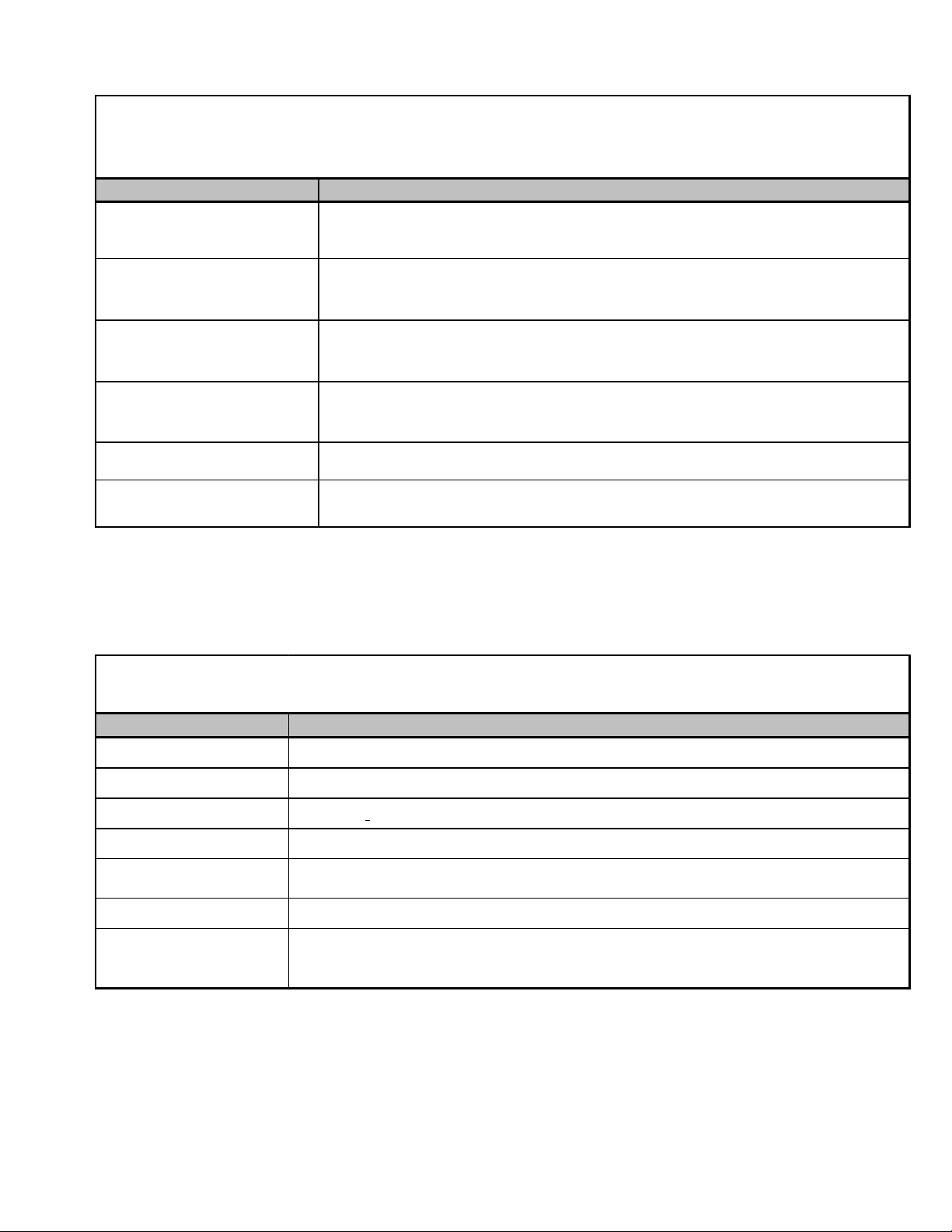

CAUF

INDOOR COIL A-UPFLOW/DOWNFLOW UNCASED FLOW RATOR

C-

Model/Rev Description

CAUF*****6AA Initial release of CAUF Dayton Upflow/Downflow coils.

CAUF*****6BA Burr Oak Louvered Fin released in place of the Wavy Fin.

CAUF****6*DA Replaced

CAUF*****6DB Drain pan material changed.

CAUF1824A6RDB

CAUF1824B6RDB

CAUF36***CA Redesign from 2 row to 3 row for performance improvement .

CAUF3030(A/B)6RDB

CAUF3030(C/D)6RDB

CAUF3131(B/C)6RDB

Manufacturing Location Change from Dayton to Houston. Designated by "R".

Manufacturing Location Change from Dayton to Houston. Designated by "R".

existing copper coils and other associated parts with aluminum components.

15

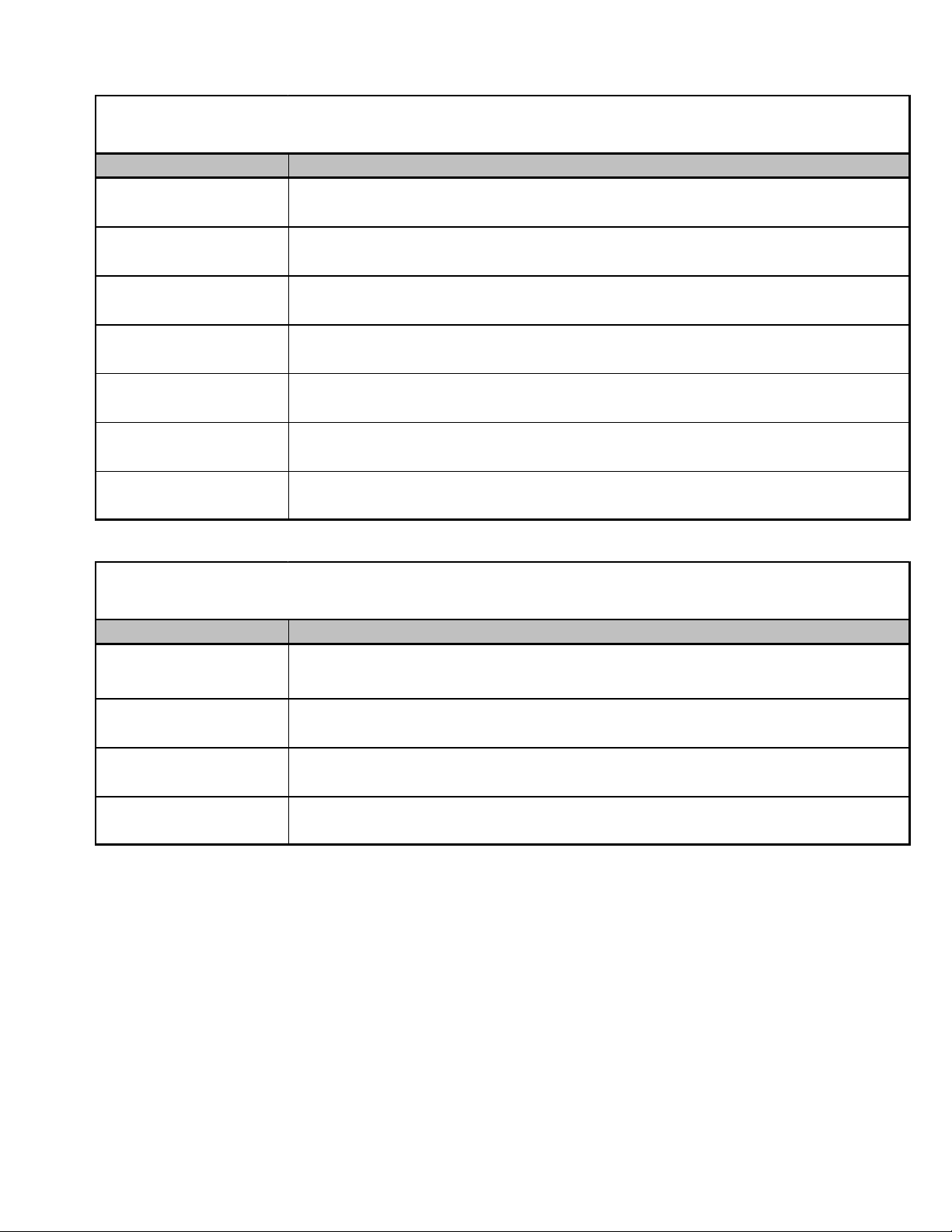

PRODUCT IDENTIFICATION

CHPF

-INDOOR COIL HORIZONT AL A-COIL PAINTED FLOWRATOR

C

Model/Rev Description

CHPF*****6AA Intial release of 13 SEER CHPF horizontal A coil.

CHPF*****6BA

CHPF1824A6CA

CHPF2430B6CA

CHPF3636B6CA

CHPF3642C6CA

CHPF3642D6CA

CHPF3743C6BA

CHPF3743D6BA

CHPF4860D6DA

CHPF1824A6CB

CHPF2430B6CB

CHPF3636B6CB

CHPF3642C6CB

CHPF3642D6CB

CHPF3743C6BB

CHPF3743D6BB

CHPF4860D6DB

CHPF1824A6CC

CHPF2430B6CC

CHPF3636B6CC

CHPF3642C6CC

CHPF3642D6CC

CHPF3743C6BC

CHPF3743D6BC

CHPF4860D6DC

Released Burr Oak Louvered Fin in place of the Wavy Fin. The rows changed by one, (i.e.

4 row to 3 row; 3 row to 2 row) where applicable.

Louvered fins. Replac ed copper tube hairpins with aluminum hairpins.

Drain pan material c hange to a Decabromodiphenyl Ether free resin.

Change to prepainted wrappers

16

PRODUCT IDENTIFICATION

CAPF

INDOOR C OIL A-UPFLOW/DOWNFLOW PAINTE D FLOW RATOR

C-

Model/Rev Description

CAPF*****6AA Initial release of CAPF Dayton Upflow/Downflow coils.

CAPF*****6BA Burr Oak Louvered Fin released in place of the Wavy Fin.

CAPF36***CA Redesigned for performance improvement from 2 row to 3 row.

CAPF*****6DA Replaced existing copper coils and other associated parts with aluminum components.

CAPF*****6DB Drain pan material changed.

CAPF1824A6DC

CAPF1824B6DC

CAPF1824C6DC

CAPF3030A6DC

CAPF3030B6DC

CAPF3030C6DC

CAPF3030D6DC

CAPF3131B6DC

CAPF3131C6DC

CAPF3137B6AB

CAPF3636A6DC

CAPF3636B6DC

CAPF3636C6DC

CAPF3636D6DC

CAPF3642C6DC

CAPF3642D6DC

CAPF3743C6DC

CAPF3743D6DC

CAPF4860C6DC

CAPF4860D6DC

CAPF4961C6DC

CAPF4961D6DC

Redesign the wrapper for the CAPF to provide increased ease of installation.

CAPT

INDOOR

C-

Model/Rev Description

CAPT3131B4BA

CAPT3131C4BA

CAPT3743C4AA

CAPT3743D4AA

CAPT4961C4AA

CAPT4961D4AA

CAPT3131B4AB

CAPT3131C4AB

CAPT3743C4AB

CAPT3743D4AB

CAPT4961C4AB

CAPT4961D4AB

COIL

UPFLOW/DOWNFLOW PAINTED CAS ED FLOWRATOR W/TXV

A-

Initial releas e of coils with factory-installed, non-adjus table TXV. Single stage AHRI ratings

for CAPT3131 NTC combinations.

Initial releas e of single stage AHRI ratings for CAPT3743 NTC combinations.

Initial releas e of single stage AHRI ratings for CAPT4961C4 NTC combinations.

Redesign the wrapper for the CAPT to provide increased ease of installation.

17

PRODUCT IDENTIFICATION

CSCF

INDOOR C OIL S-HORIZONTAL SLAB COIL C-UNPAINTED FLOW RATOR

C-

Model/Rev Description

CSCF*****6AA Initial release of 13 SEER CSCF horizontal slab coils.

CSCF*****6BA

CSCF1824N6BB

CSCF3036N6BB

CSCF3642N6CB

CSCF4860N6CB

CSCF1824N6CA

CSCF3036N6CA

CSCF3642N6CA

CSCF4860N6CA

Burr Oak Louvered Fin released in place of the W avy Fin. Rows reduced by one where

applicable.

Drain pan material changed.

Replaced copper coils and other associated parts with aluminum components.

18

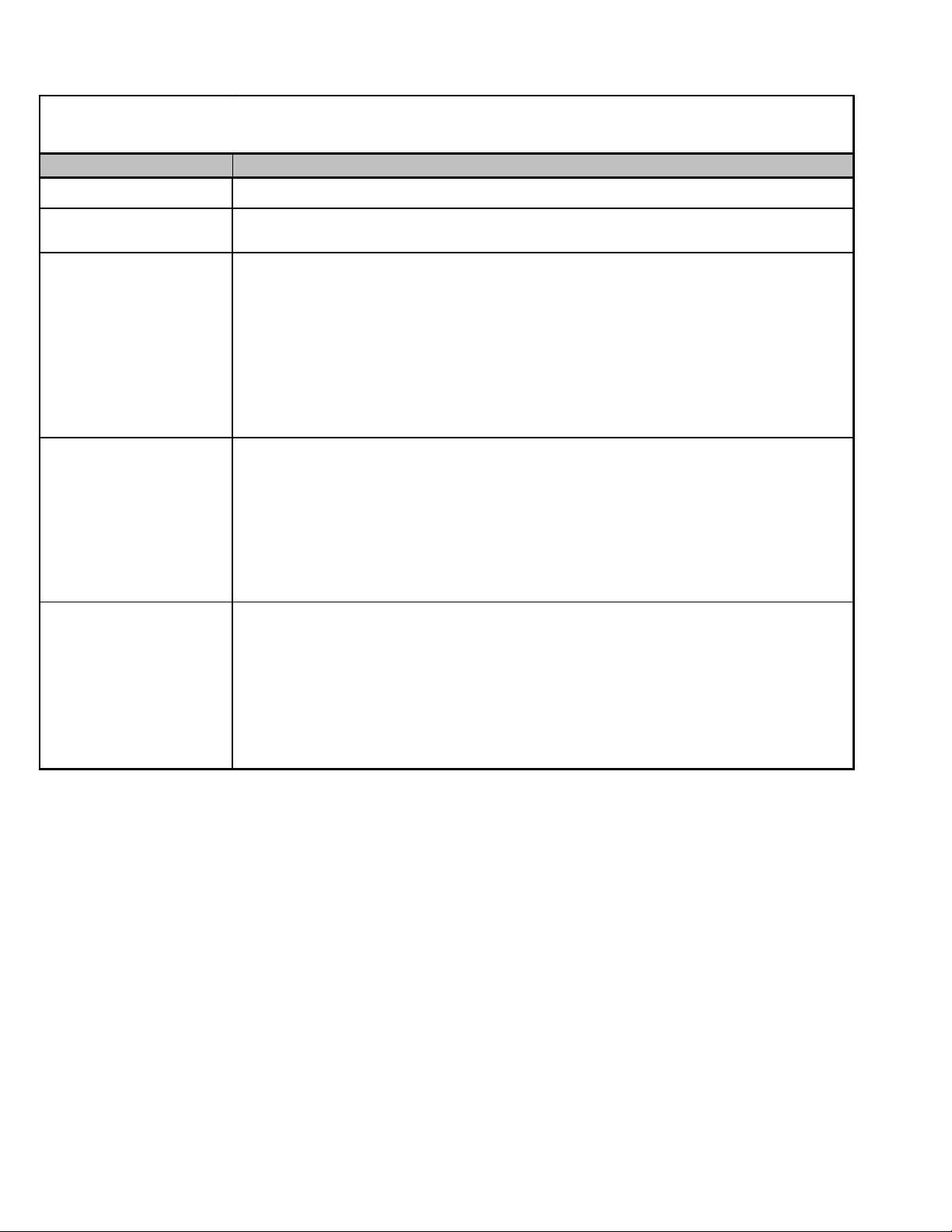

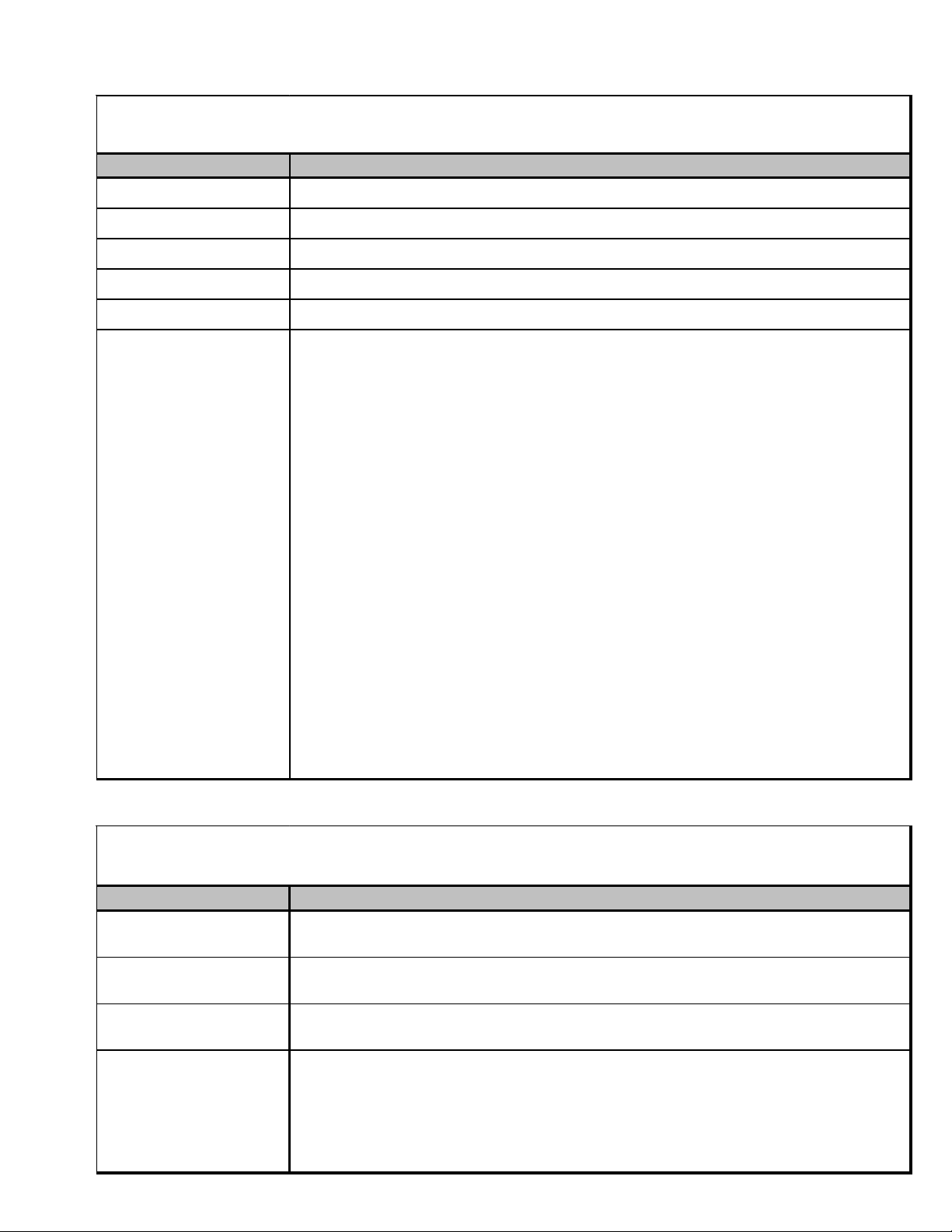

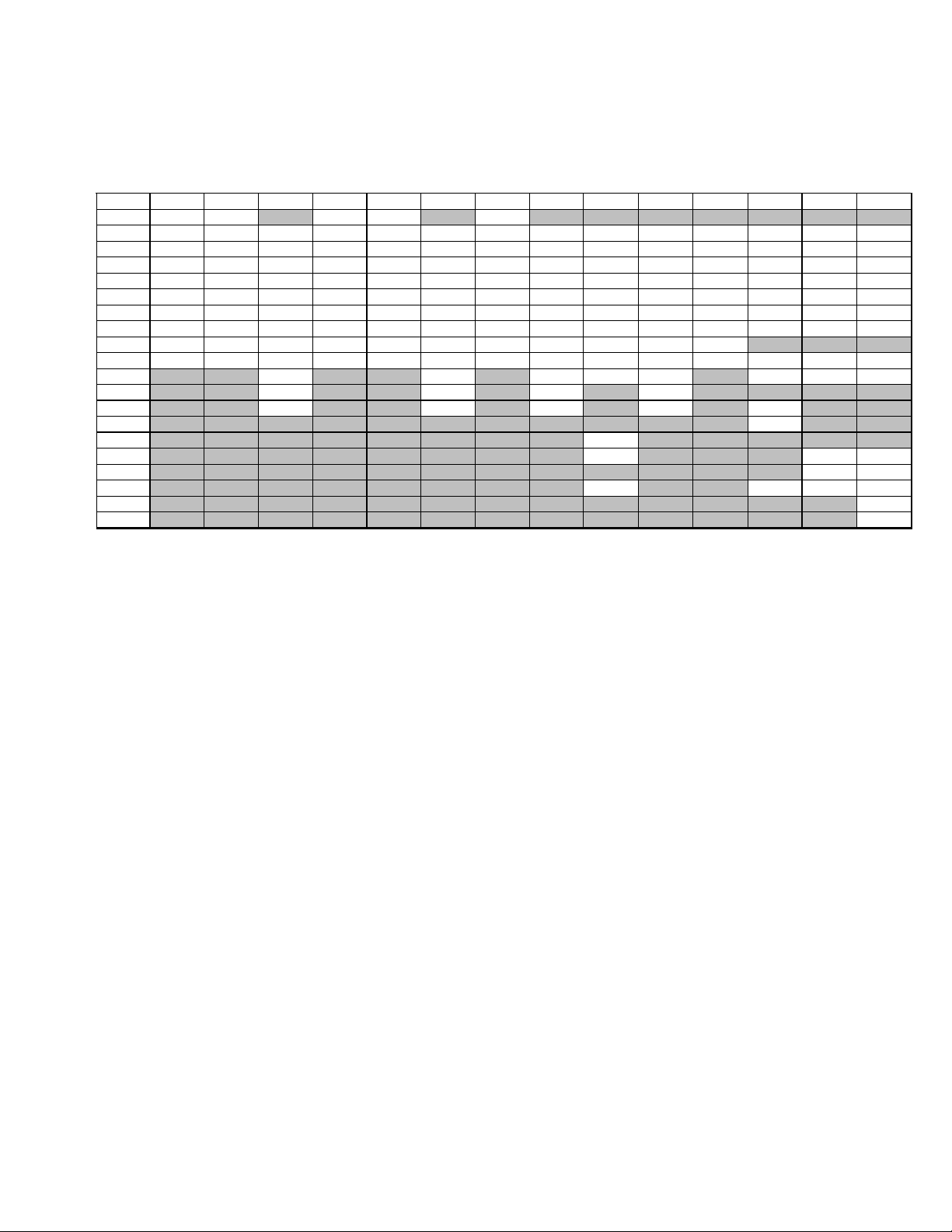

ACCESSORIES

ComfortNet™

ASXC/DSXC 16

ASXC/DSXC/GSXC 18

Model Description

ABK-20 Anc hor Bracket Kit X X X X X X X X

ASXC16024

DSXC16024

ASXC16036

DSXC16036

ASXC16048

DSXC16048

ASXC16060

DSXC16060

ASXC18024

DSXC18024

GSXC18024

ASXC18036

DSXC18036

GSXC18036

ASXC18048

DSXC18048

GSXC18048

ASXC18060

DSXC18060

GSXC18060

TX2N4A TXV Kit

TX3N4 TXV Kit

TX5N4 TXV Kit

CSR-U-1 Hard-start Kit

CSR-U-2 Hard-start Kit

CSR-U-3 Hard-start Kit

1

FSK01A

LSK02*

B1141643

* Contains 20 brackets; four brackets needed to anchor unit to pad.

Installed on the indoor coil.

Available in 24V legacy mode only. This feature is integrated in the communicating mode.

This component is included in the CTK0*** communicating thermostat kit.

Freeze Protecti on Kit

Liqui d Line S olenoid

Valv e

3

24V Transformer

XX

XX

XX X X

XX

XX

XX X X

XXXXX X X X

XXXXX X X X

XXXXX X X X

ASZC/DSZC 16

ASZC/DSZC 18

Model Description

ASZC16024

DSZC16024

ABK-20Anchor Bracket KitXXXXXXX

1

TX2N4

TX3N4

TX5N4

TXV Kit X

1

TXV Kit X X

1

TXV Kit X X X X

CSR-U-1 Hard-start Kit X X X

CSR-U-2 Hard-start Kit X X X X X X

CSR-U-3 Hard-start Kit X X X X

2

FSK01A

LSK02*

OT18-60A

B1141643

Freeze Protection KitXXXXXXX

Liquid Line Solenoid

Valv e

Outdoor Thermos tat/

3

Lock out Thermostat

4

24V TransformerXXXXXXX

XXXXXXX

XXXXXXX

ASZC16036

DSZC16036

ASZC16048

DSZC16048

ASZC1 606 0

DSZC1 606 0

ASZC18036

DSZC18036

ASZC18048

DSZC18048

ASZC18060

DSZC18060

* Contains 20 brackets; four brackets needed to anchor unit to pad

1

Field-installed, non-bleed, ex pansion valve kit - Condensing units and heap pumps with reciprocating compressors require the

use of start-ass ist components when used in c onjunction with an indoor coil using a non-bleed thermal ex pansion valve

refrigerant

2

Installed on the indoor coil

3

Available in 24V legacy mode only. This feature is integrated in the communicating mode. Required for heat pump applications

where ambient temperature fall below 0 °F with 50% or higher relative humidity.

4

This component is included in the CTK0*** communicating thermostat kit.

19

ACCESSORIES

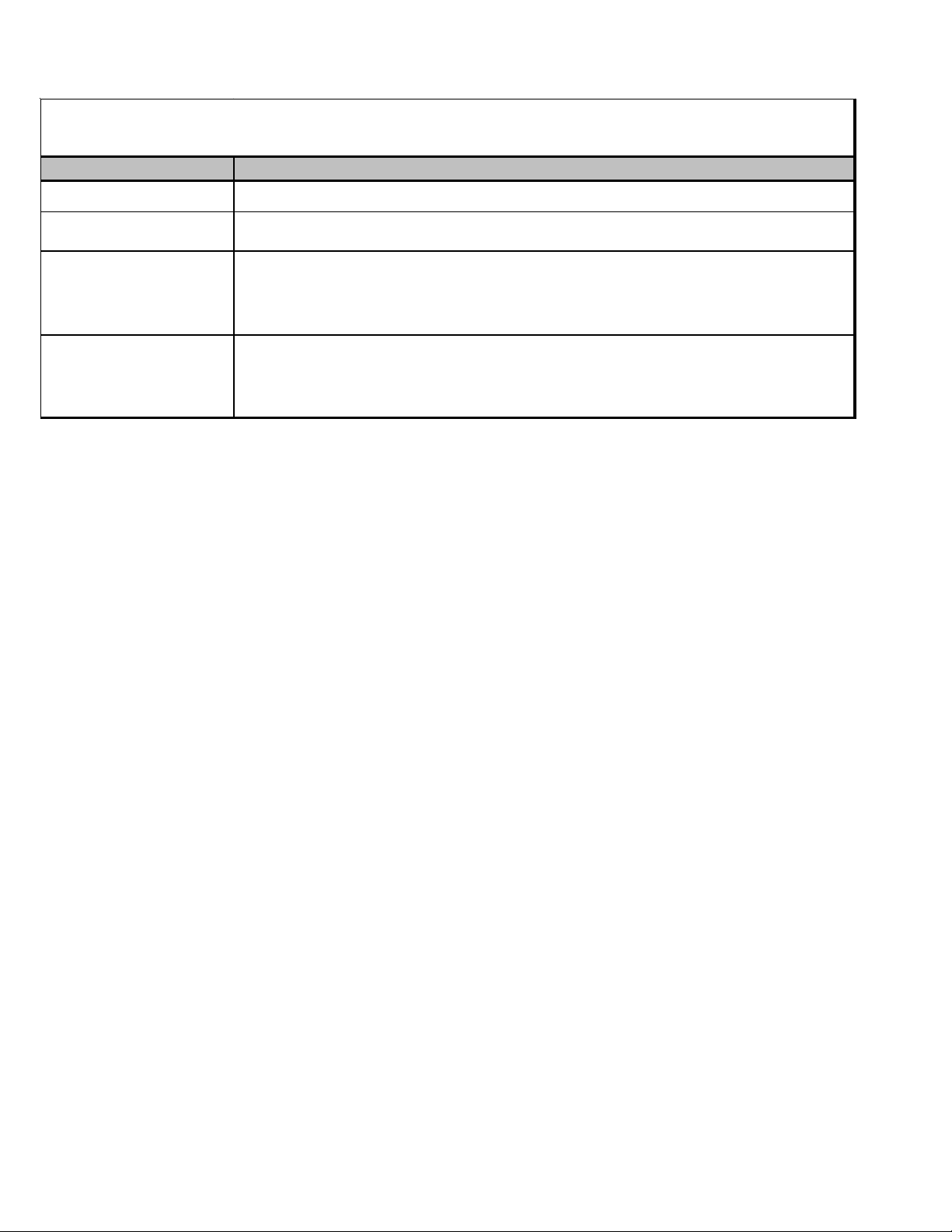

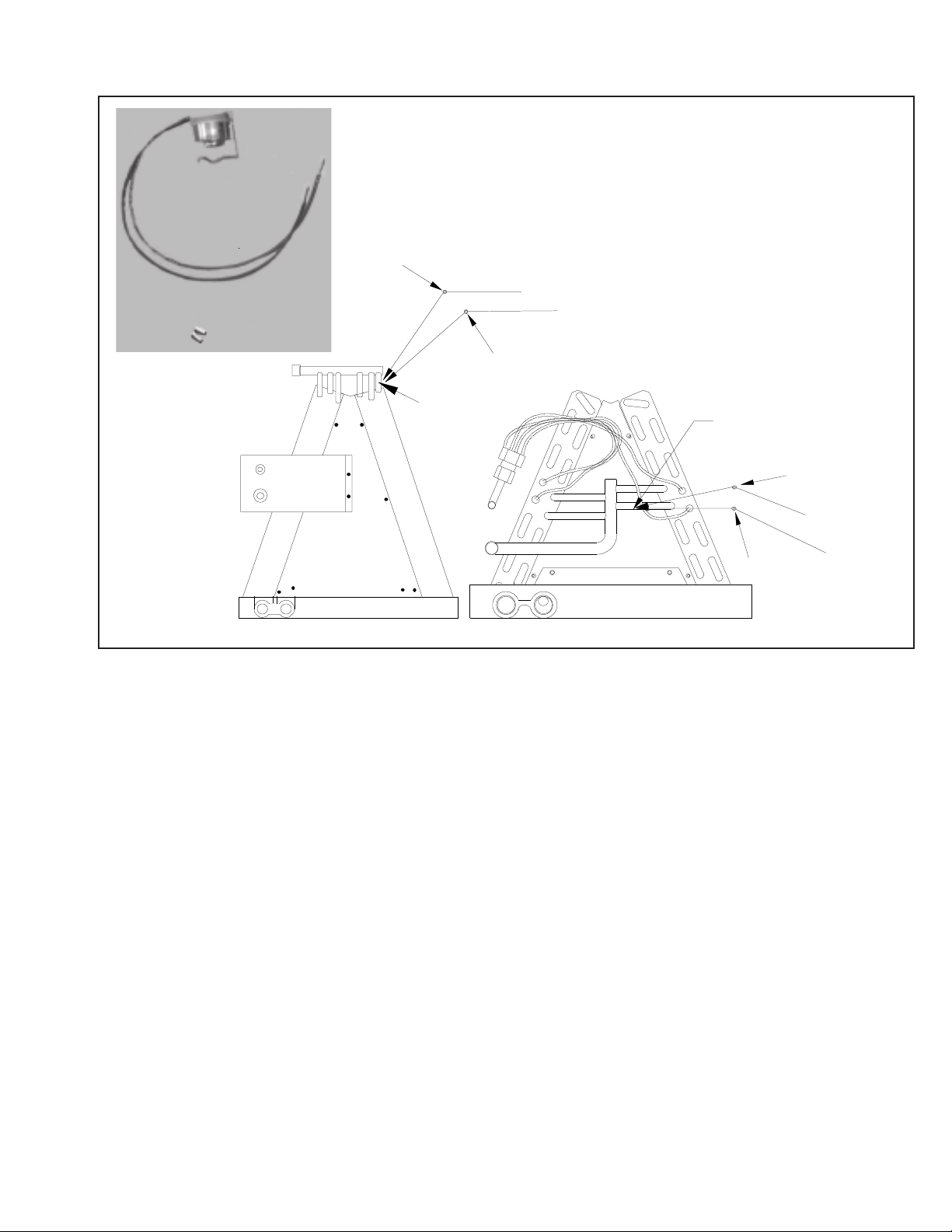

EXPANSION VALVE KITS

1/4 FLARE CONNECTION

BULB TO BE LOCATED

AT 10 OR 2 O'CLOCK

For Applications requiring

a field installed access fitting

EVAPORATOR COIL

EVAPORATOR COIL

1/4' FLARE

CONNECTION

SEAL SUPPLIED W/ KIT

REMOVE BEFORE INSTALLING EXPANSION VALVE

SUCTION LINE

BULB

EXPANSION VALVE

SUCTION LI NE

EXPAN SION VALV E

BULB

SEAL SUPPLIED W/ KIT

BULB TO BE LOCATED

AT 10 OR 2 O'CLOCK

DISTRIBUTOR

BODY

For Applications not requiring

a field installed access fitting

DISTRIBUTOR

BODY

7/8" NUT

PISTON

SEAL

PISTON

SEAL

TAILPIECE

3/8"SWEAT

TAILPIECE

3/8"SWEAT

SEAL SUPPLIED W/ KIT

20

REMOVE BEFORE

INSTALLING

EXPANSION VALVE

SEAL SUPPLIED W/ KIT

7/8" NUT

ACCESSORIES

Wire Nut

FSK01A

FREEZE THERMOSTAT

KIT

Y

k

c

a

l

B

k

c

a

l

B

Wire Nut

Y

Install Line

Thermostat

Here

Install Line

Thermostat

Here

B

l

a

c

B

l

Wire Nut

Wire Nut

Y

k

a

c

k

Y

21

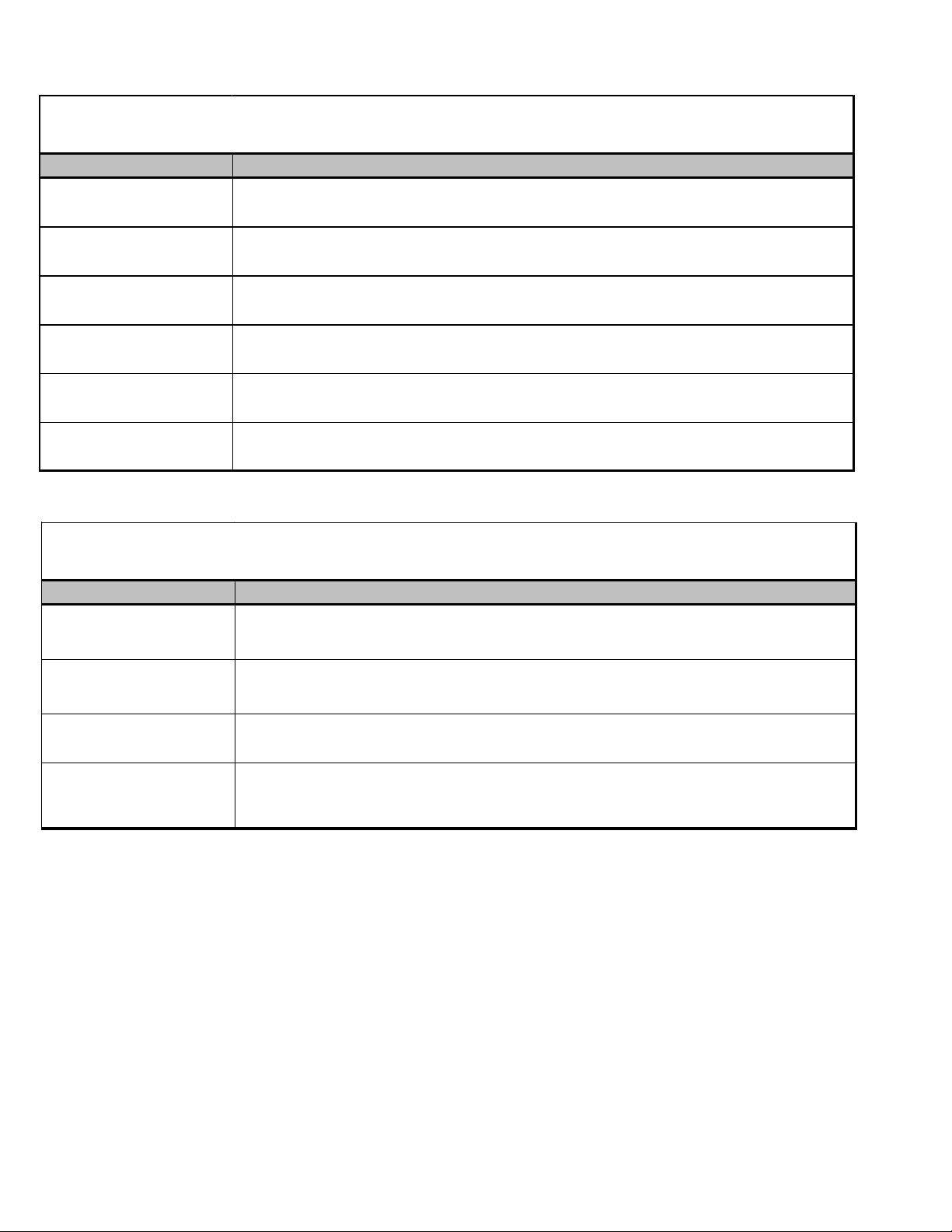

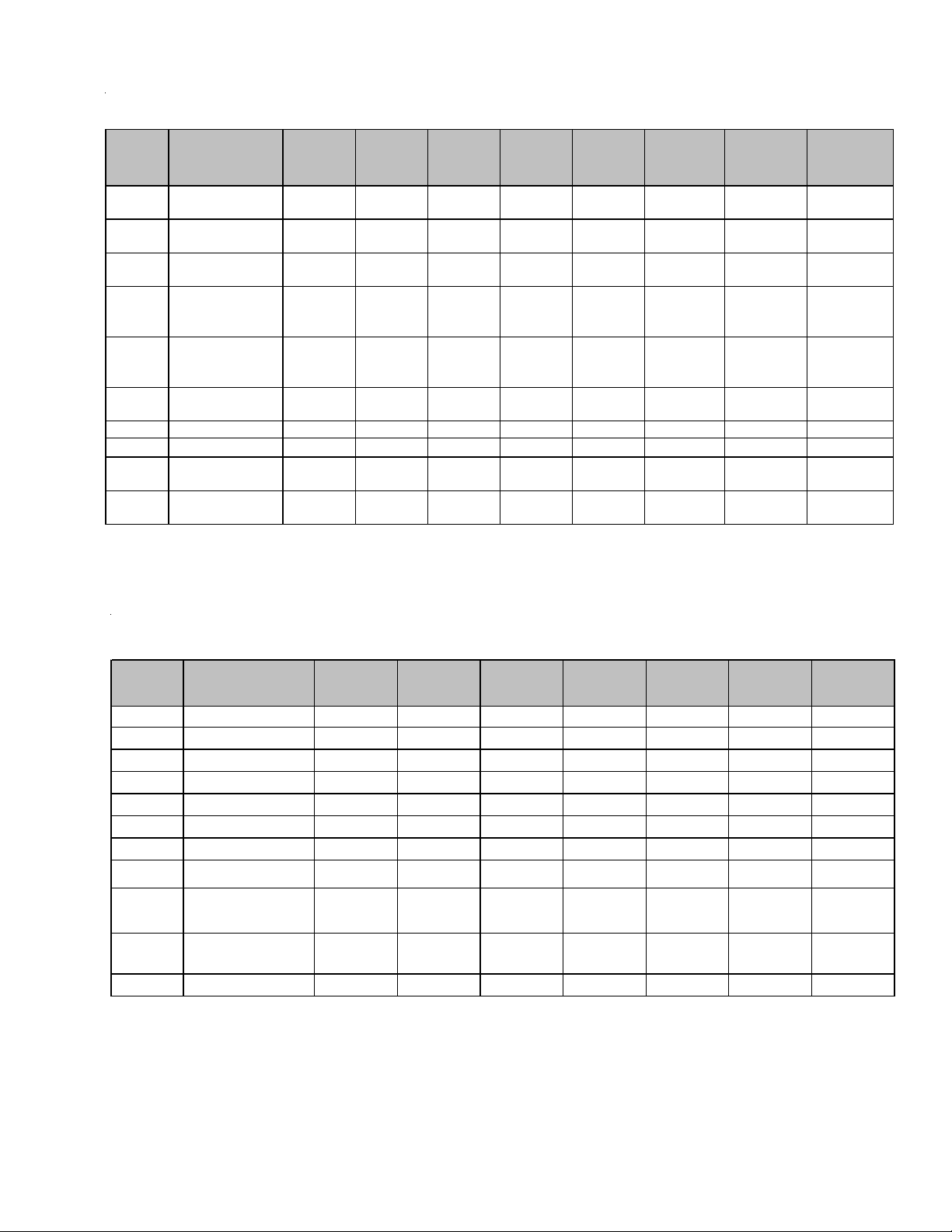

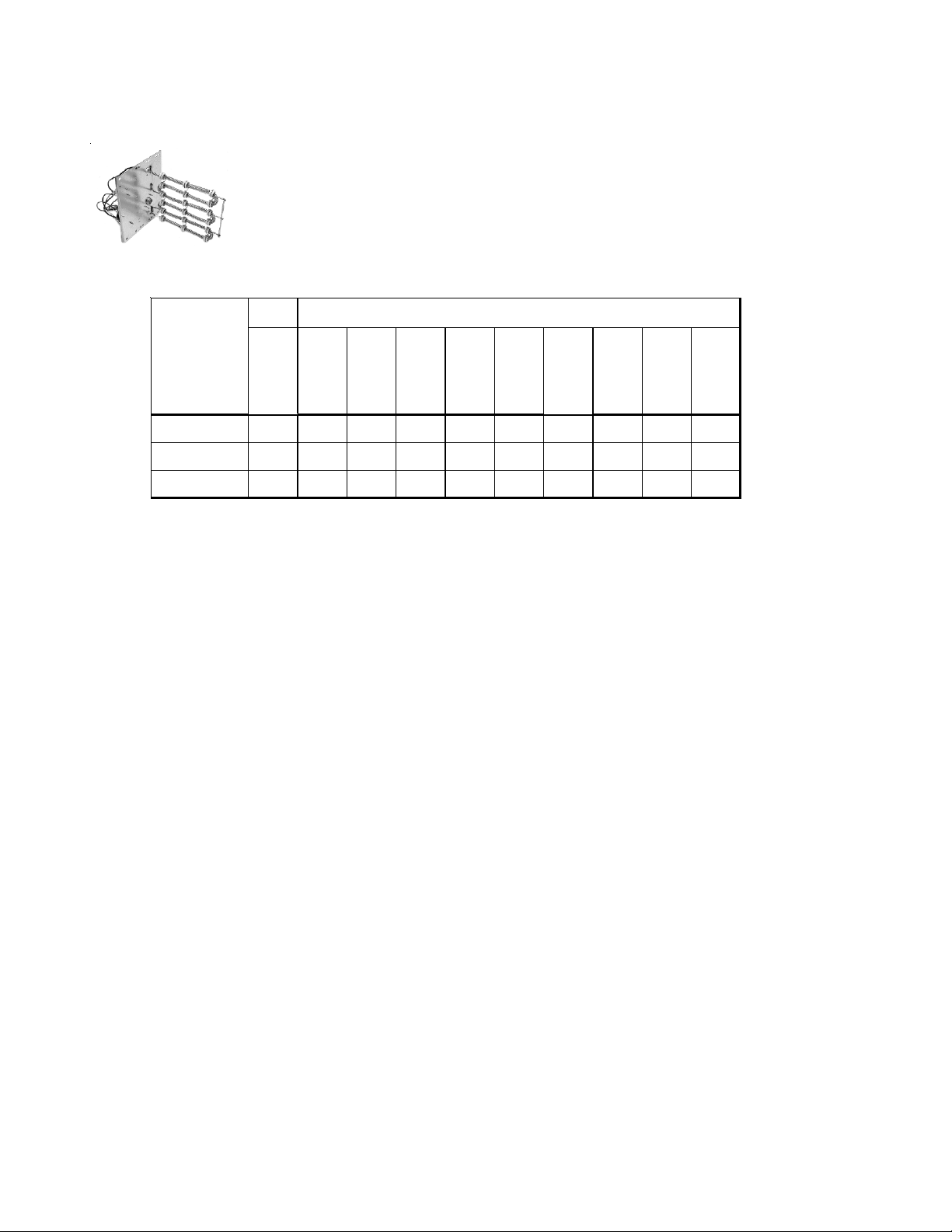

ACCESSORIES

BLOW ER

ELECTRI C HEAT KIT

NO HEAT

MBVC1200AA-1**

MBVC1600AA-1**

MBVC2000AA-1**

X = Allowable combinations

- = Restricted combinations

- XXXXXX - - -

- XXXXXX - - -

- XXXXX - X - -

ELECTRIC HEAT KIT APPLICATIONS - MBVC

HKR-03*

^ = Circuit 1: Single Phase for Air Handler Motor

Circuit 2: 3-Phase for HKR3 Heater Kits

HKR05-(C)'

HKR-06*

HKR-08(C)*

HKR-10(C)*

HKA-15C*

HK* SERIES ELETRIC HEAT KITS -

HKA-20C*

^HKR3-15*

^HKR3-20A

22

ACCESSORIES

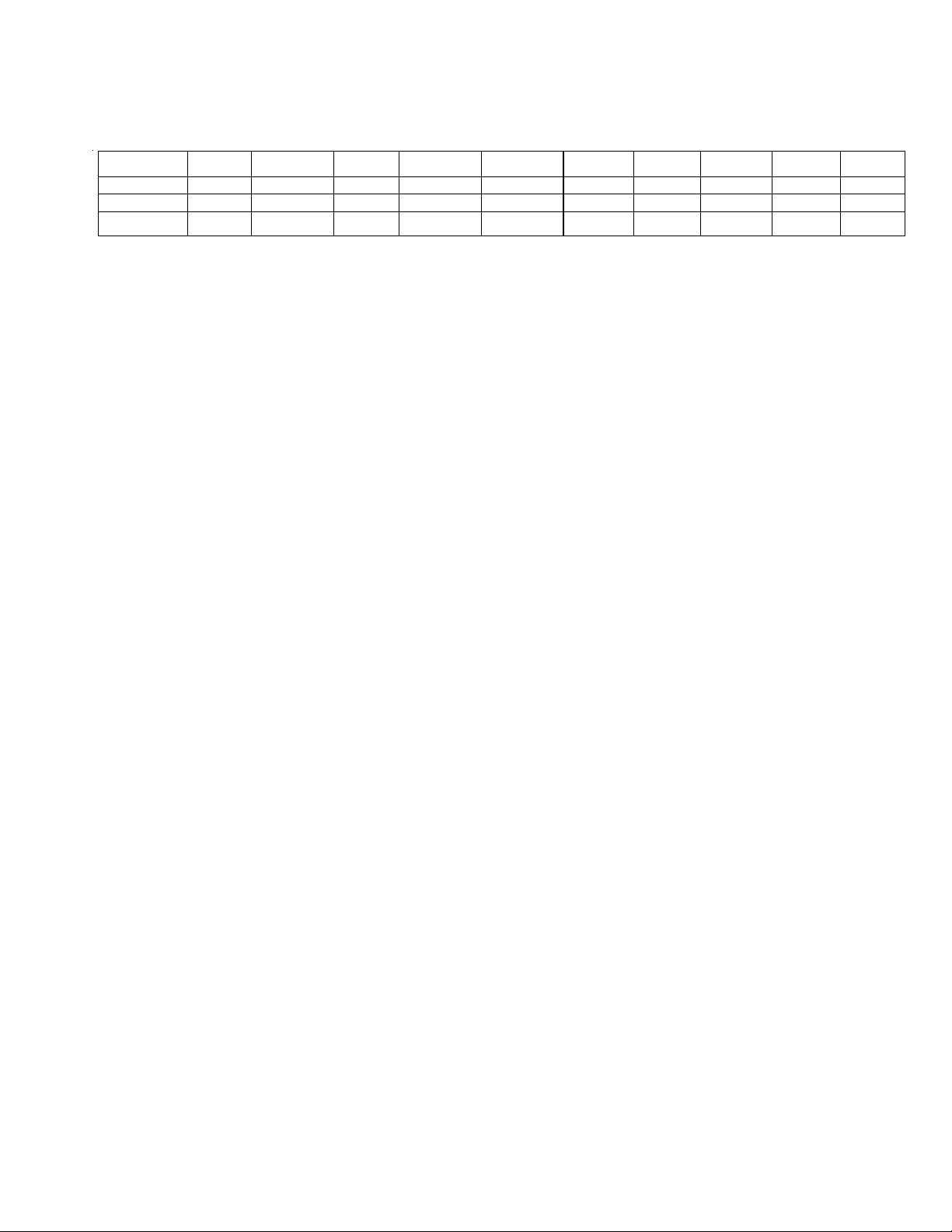

ELECTRIC HEAT KIT APPLICATIONS - AVPTC

MODE LS HKR-03* H KR-05*/ -05C* HKR-06 * HKR-08*/-08C* HKR-10*/ -10C* H KR-15C* HKR-20C* HKR-21 C* HK A-15C* HKA-20C*

AVPTC183014A* X X X

AVPTC313714A* X X X

AVPTC426014A* X X X X X X X3 X3 X

* Revision level that may or may not be designated.

C Circuit breaker option.

NOTE:

When 8kW and 10kW heat kits are used with an AVPTC1830 and AVPTC3137, matched with 2- ton outdoor unit, see Note 1 below.

1

Set Heater Kit dip switches 9, 10 and 11 to 6kW setting (9-ON, 10-OFF,11-ON) to obtain 840 CFM.

2

This heater kit can only be used for ‘1000 CFM or higher’ applications.

3

This heater kit can only be used for ‘1200 CFM or higher’ applications.

1

X

1

X

1

X

1

X

--- --- --- --- ---

X2 --- ---

2

X

X

3

X

23

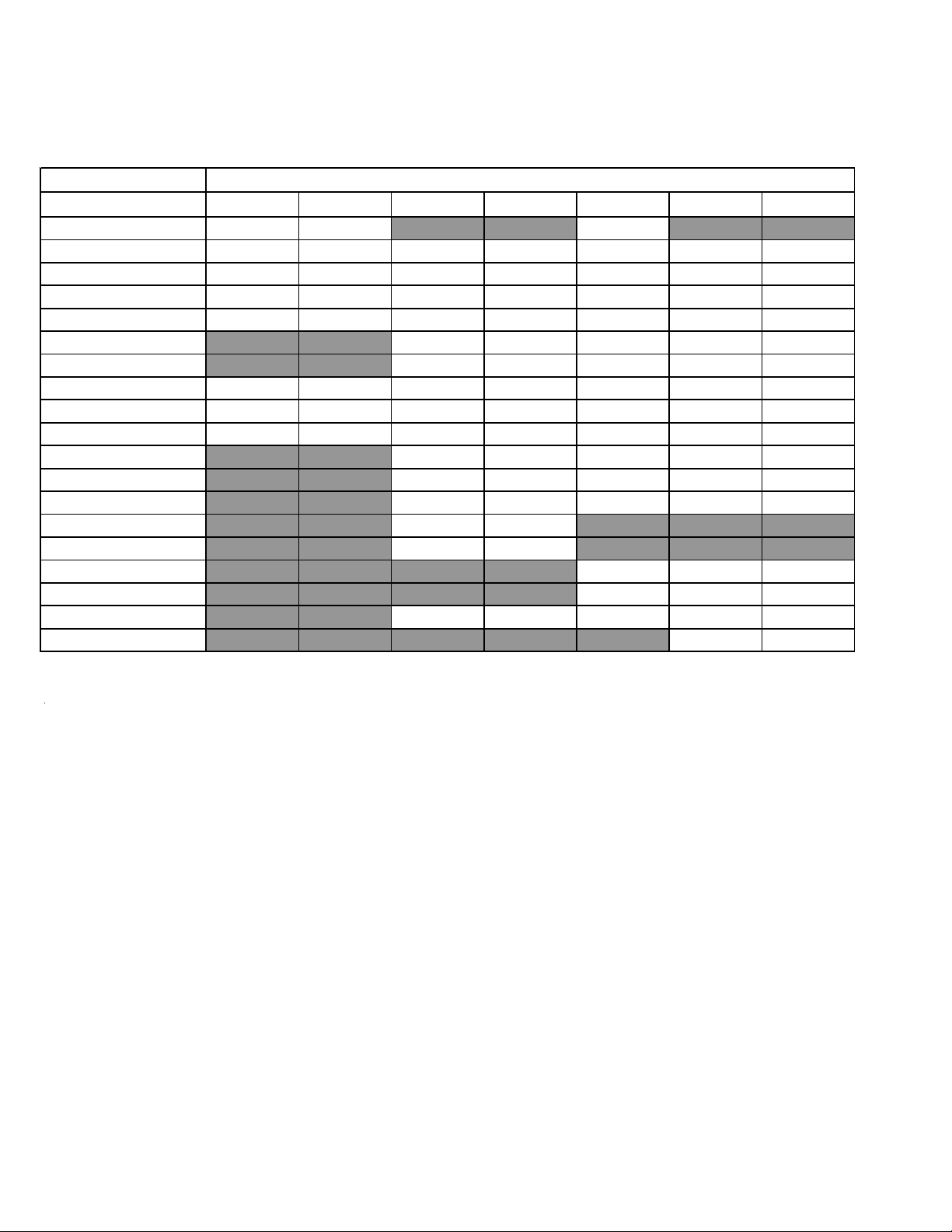

ACCESSORIES

p

p

p

p

p

AVPTC**14**

Heat Kit A pplications

Type / M odel 24B14-A* 30C14-A* 36C14-A* 48C14-A* 42D14-A*

HKSX03XC X X X

HKSX05XC XXXXXXX

HKSX06XC XXXXXXX

HKSX08XC XXXXXXX

HKSX10XC XXXXXXX

HKSX15XF* XXXXX

HKSX20XF* XXXXX

HKSC05XC XXXXXXX

HKSC08XC XXXXXXX

HKSC10XC XXXXXXX

HKSC15XA XXXXX

HKSC15XB XXXXX

HKSC15XF* XXXXX

HKSC19CA* X X

HKSC19CB* X X

HKSC20DA XXX

HKSC20DB XXX

HKSCX20XF* XXXXX

HKSC25DC* XX

* Revis io n level that may or m ay no t be designat ed.

Refer to t he minimum airflow requireme nts fo r each o f the heat k its.

AVPTC

†

48D14-A*

††

60D14-A*

†††

†For match u p wi th a 2 ton outdoo r uni t: Hea ter ki t ap plica Ɵon shall not exceed 10 kW.

Ai rflow fo r 5 kW u

††For ma tch u

Airflo w for 5 kW u

†††For ma tch u

Airflow for 5 kW u

** 3 kW heater kit is not applicable for this indoor application.

to 10 kW hea ter kits s hall be s et to 850 cfm speed tap of ON-ON-ON.

wi th a 3 to n ou tdoor uni t: Hea ter ki t applicaƟon shall not exceed 15 kW.

to 15 kW hea ter ki ts s hal l b e s et to 1400 cfm speed tap of ON-ON-OF F.

wi th a 3.5 ton ou tdoo r uni t: Hea ter ki t applicaƟon shall not exceed 20 kW.

to 20 kW hea ter ki ts s hal l be se t to 1620 cfm speed tap of ON-ON-OFF

24

ACCESSORIES

READY 15 AVPTC

Model AVPTC25B14 AVPTC29B14 AVPTC31C14 AVPTC33C14 AVPTC35B14 AVPTC39C14 AVPTC37B14 AVPTC37C14 AVPTC37D14 AVPTC49C14 AVPTC49D14 AVPTC59C14 AVPTC59D14 AVPTC61D14

HKSX03XC XX XX X

HKSX05XC XXXXXXXXXXXXXX

HKSX06XC XXXXXXXXXXXXXX

HKSX08XC XXXXXXXXXXXXXX

HKSX10XC XXXXXXXXXXXXXX

HKSC05XC XXXXXXXXXXXXXX

HKSC08XC XXXXXXXXXXXXXX

HKSC10XC XXXXXXXXXXXXXX

HKSC15XA XXXXXXXXXXX

HKSC15XB XXXXXXXXX XXXXX

HKSC15XF XXXXXXXX

HKSC19CA XXXX

HKSC19CB XXXXX

HKSC19CH X

HKSC20DA X

HKSC20DB XXX

HKSC20DH XX

HKSC20XF XXXX

HKSC25DA X

HKSC25DB X

25

PRODUCT DESIGN

This section gives a basic description of cooling unit operation, its various components and their basic operation.

Ensure your system is properly sized for heat gain and loss

according to methods of the Air Conditioning Contractors

Association (ACCA) or equivalent.

CONDENSING UNIT

The condenser air is pulled through the condenser coil by a

direct drive propeller fan. This condenser air is then discharged out of the top of the cabinet. These units are

designed for free air discharge, so no additional resistance,

like duct work, shall be attached.

The suction and liquid line connections on present models

are of the sweat type for field piping with refrigerant type

copper. Front seating valves are factory installed to accept

the field run copper. The total refrigerant charge for a normal

installation is factory installed in the condensing unit.

ASXC, ASZC, DSXC, DSZC models are available in 2

through 5 ton sizes and use R-410A refrigerant. They are

designed for 208/230 volt single phase applications.

ASXC, ASZC, DSXC, DSZC R-410A model units use the

Copeland Scroll "Ultratech" Series compressors which are

specifically designed for R-410A refrigerant. These units also

have Copeland® ComfortAlert diagnostics. The Copeland

ComfortAlert diagnostics are integrated into the unitary (UC)

control. These models are ComfortNetTM ready.

There are a number of design characteristics which are

different from the traditional reciprocating and/or scroll compressors.

"Ultractech" Series scroll compressors will not have a discharge thermostat. Some of the early model scroll compressors required discharge thermostat.

"Ultratech" Series scroll compressors use "POE" or

polyolester oil which is NOT compatible with mineral oil

based lubricants like 3GS. "POE" oil must be used if

additional oil is required.

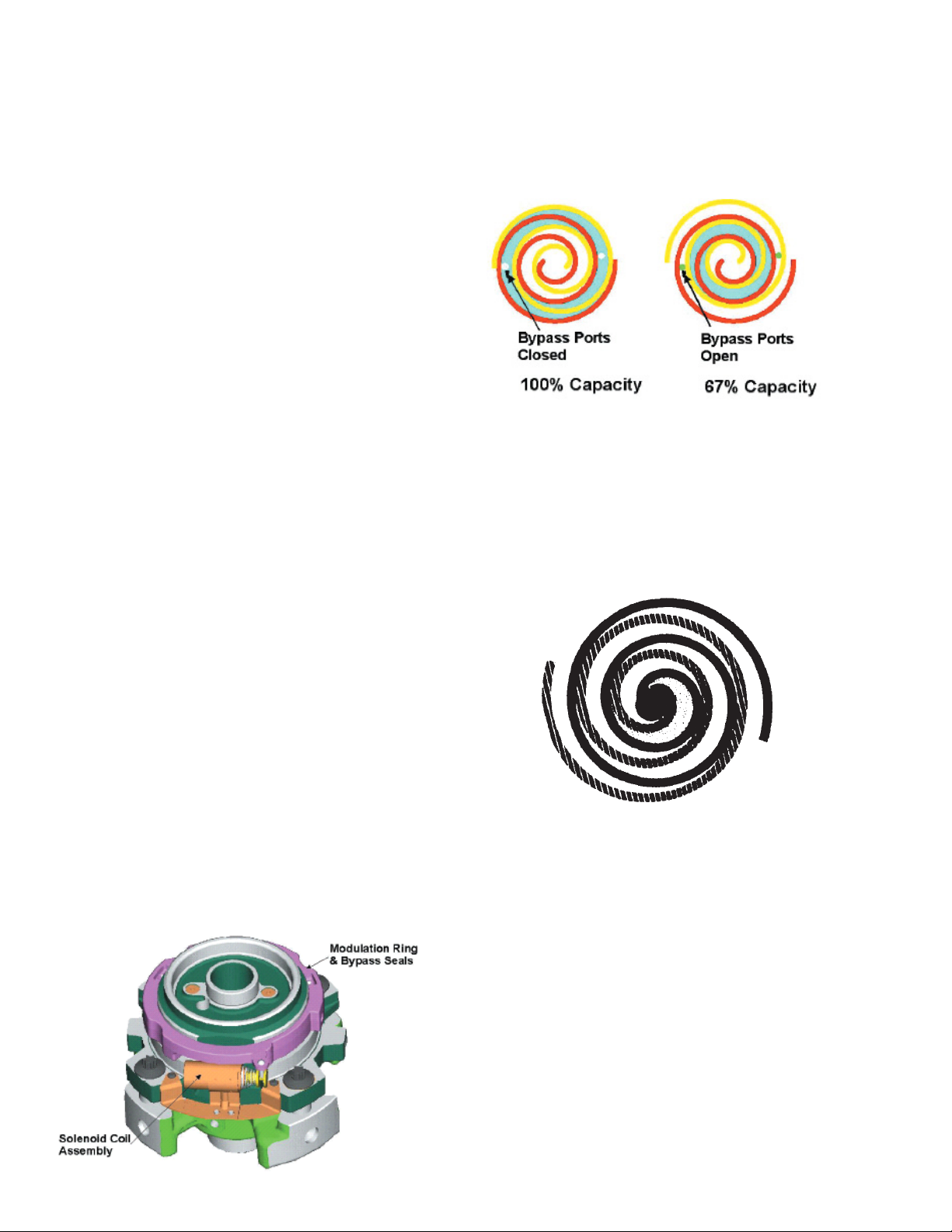

The ASXC [16 & 18], ASZC [16 & 18], DSXC [16 & 18] and

DSZC [16 & 18] series split system units use a two-stage

scroll compressor. The two-step modulator has an internal

unloading mechanism that opens a bypass port in the first

compression pocket, effectively reducing the displacement

of the scroll. The opening and closing of the bypass port is

controlled by an internal electrically operated solenoid.

The ZPS two-step modulated scroll uses a single step of

unloading to go from full capacity to approximately 67%

capacity. A single speed, high efficiency motor continues to

run while the scroll modulates between the two capacity

steps.

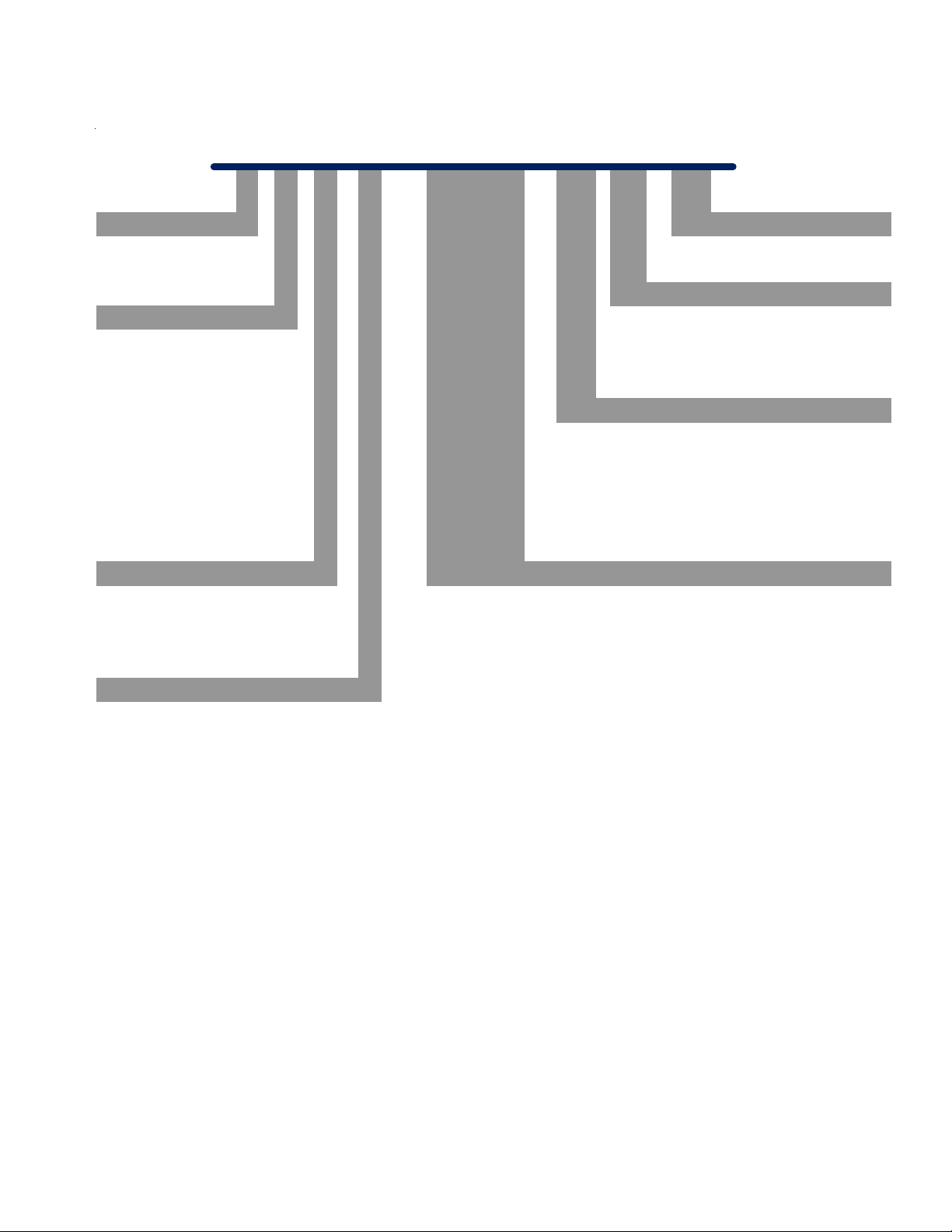

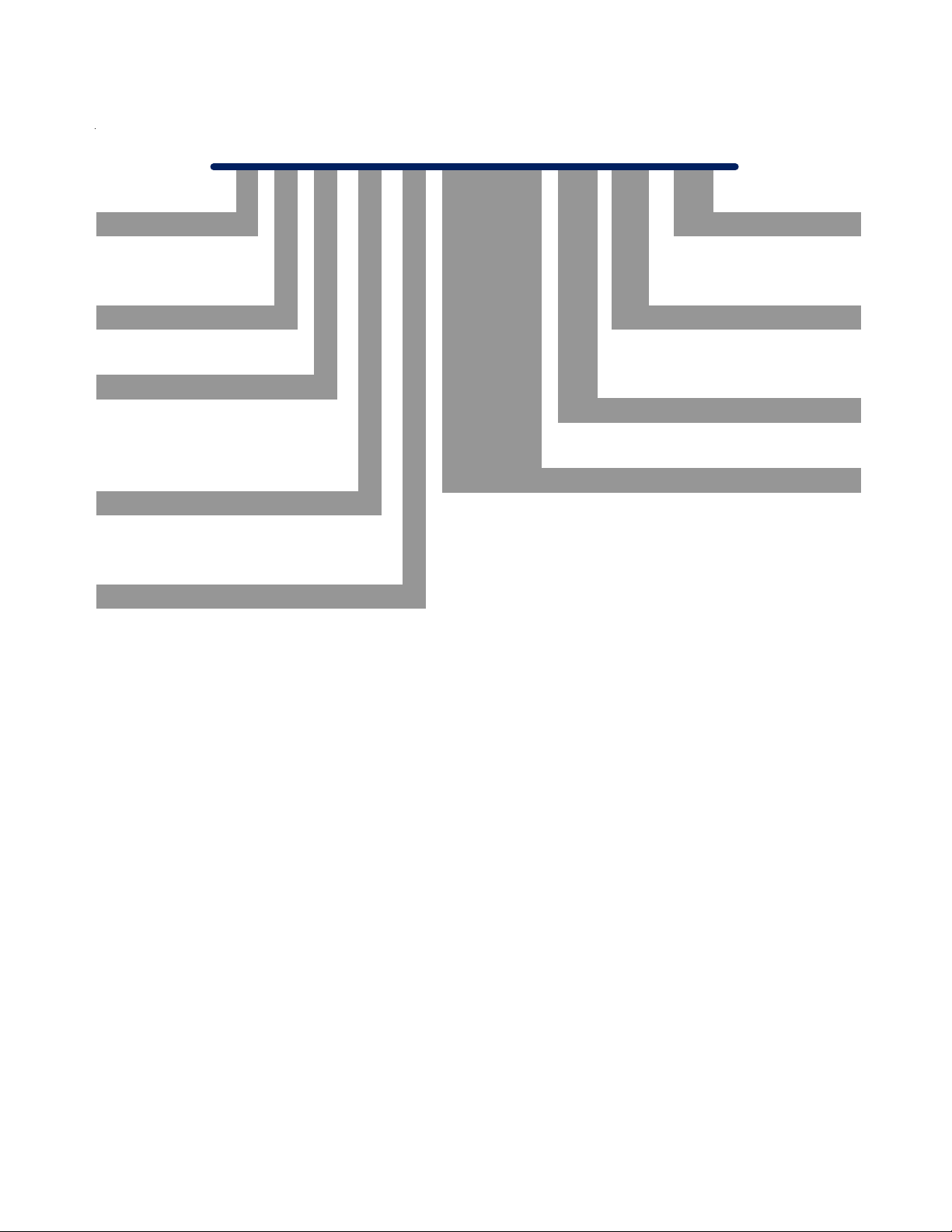

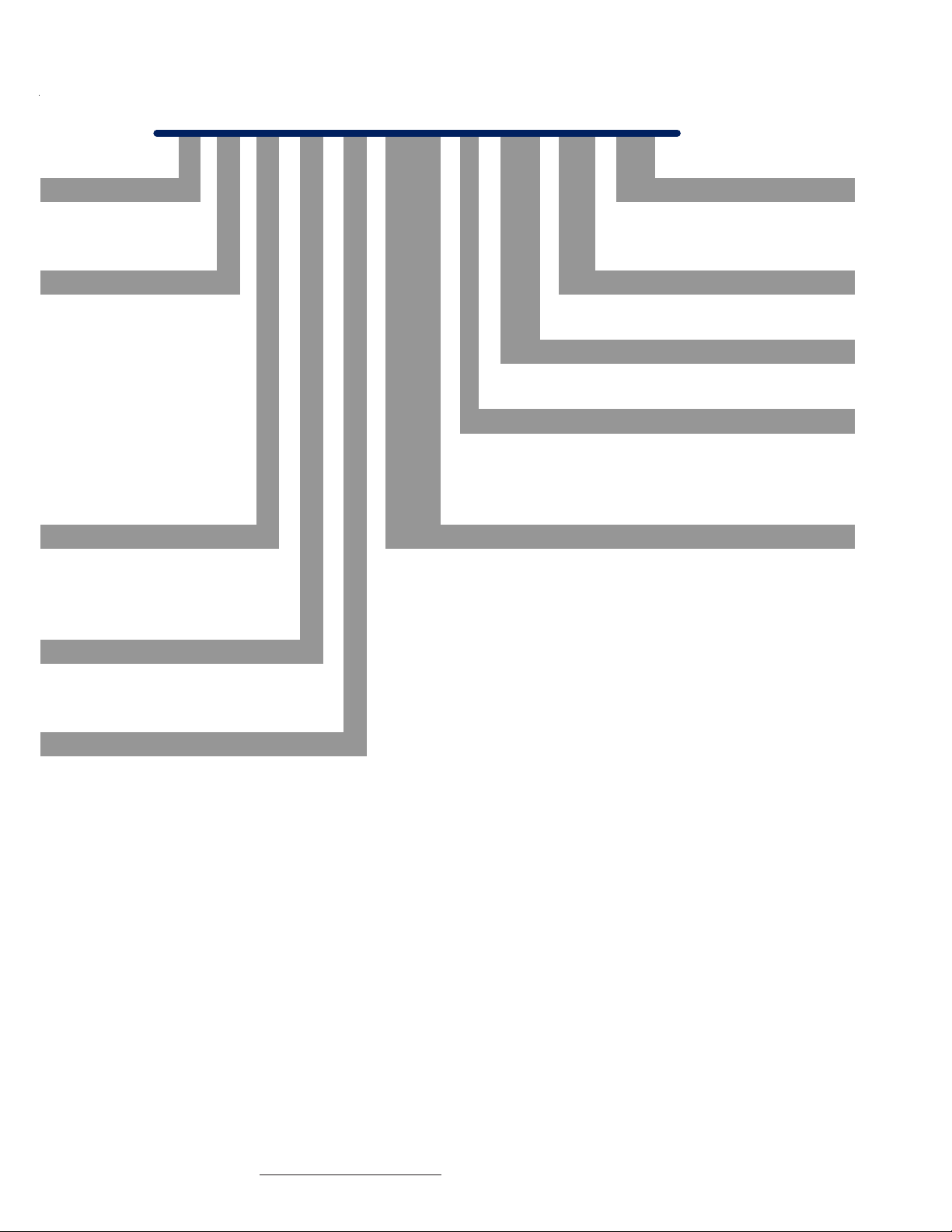

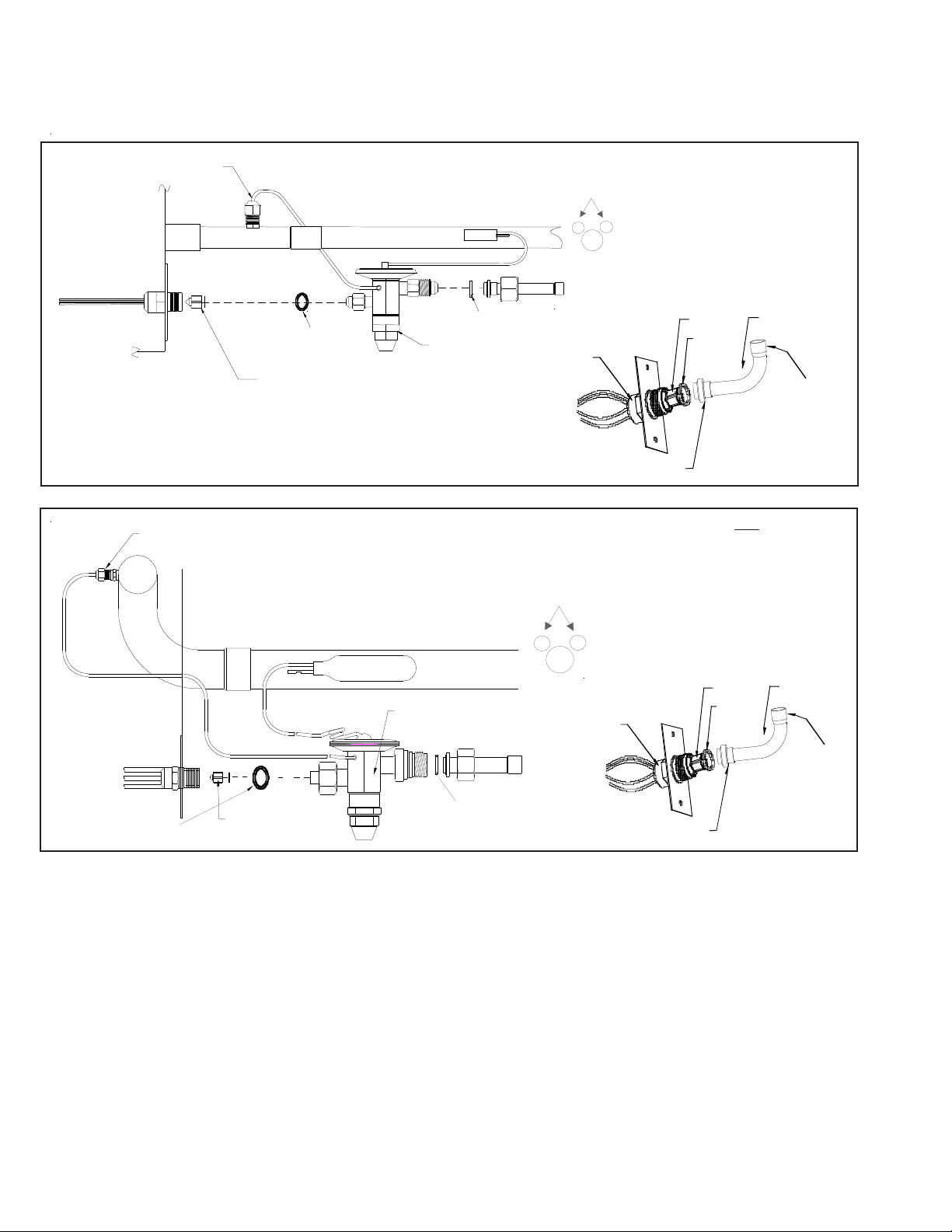

FIGURE A

A scroll is an involute spiral which, when matched with a

mating scroll form as shown, generates a series of crescent

shaped gas pockets between the two members.

During compression, one scroll remains stationary (fixed

scroll) while the other form (orbiting scroll) is allowed to orbit

®

(but not rotate) around the first form.

As this motion occurs, the pockets between the two forms

are slowly pushed to the center of the two scrolls while

simultaneously being reduced in volume. When the pocket

reaches the center of the scroll form, the gas, which is now

at a high pressure, is discharged out of a port located at the

center.

During compression, several pockets are being compressed

simultaneously, resulting in a very smooth process. Both the

suction process (outer portion of the scroll members) and the

discharge process (inner portion) are continuous.

Some design characteristics of the Compliant Scroll compressor are:

• Compliant Scroll compressors are more tolerant of liquid

refrigerant.

NOTE: Even though the compressor section of a Scroll

compressor is more tolerant of liquid refrigerant, continued floodback or flooded start conditions may wash oil

from the bearing surfaces causing premature bearing

failure.

26

PRODUCT DESIGN

• Compliant scroll compressors perform "quiet" shutdowns

that allow the compressor to restart immediately without

the need for a time delay. This compressor will restart

even if the system has not equalized.

NOTE: Operating pressures and amp draws may differ

from standard reciprocating compressors. This information can be found in the unit's Technical Information

Manual.

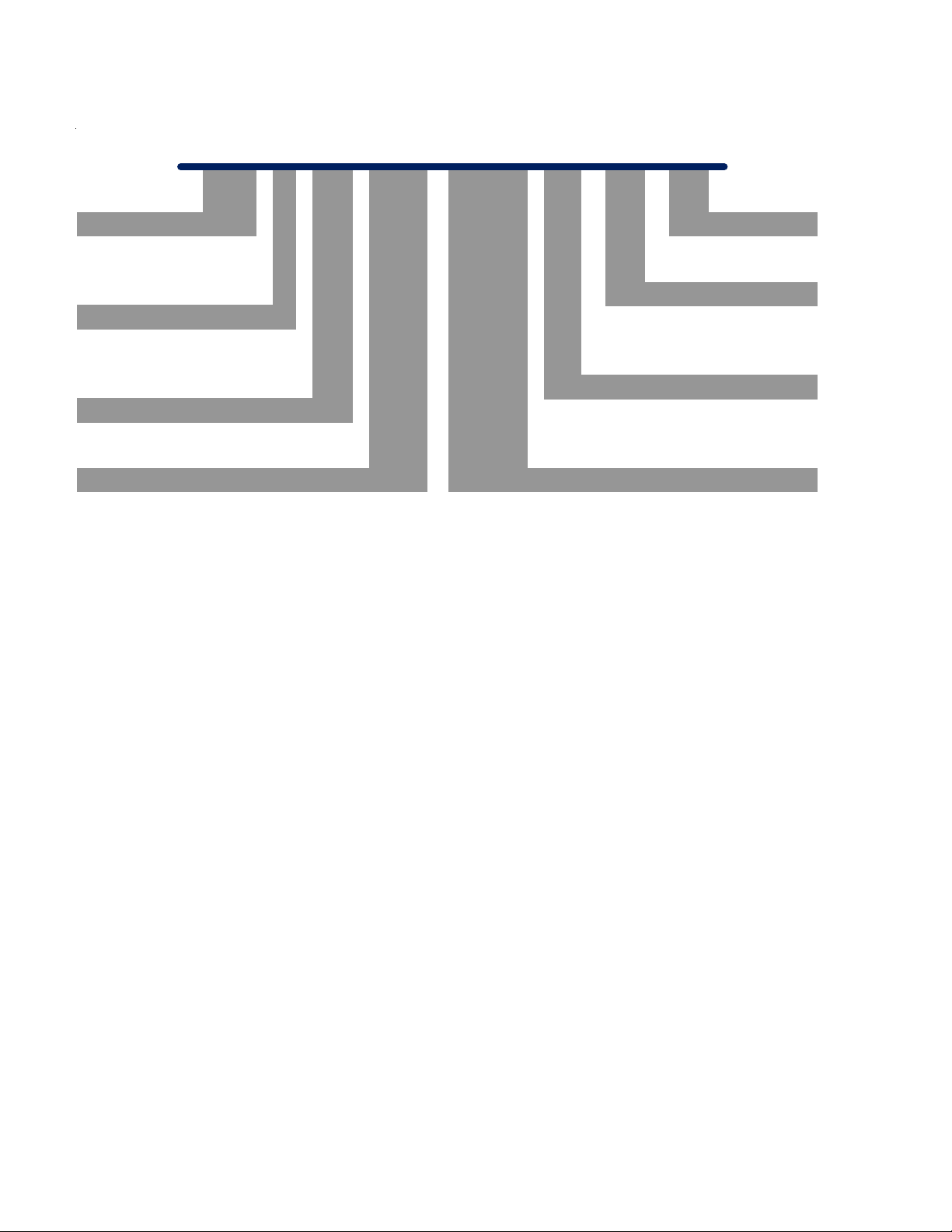

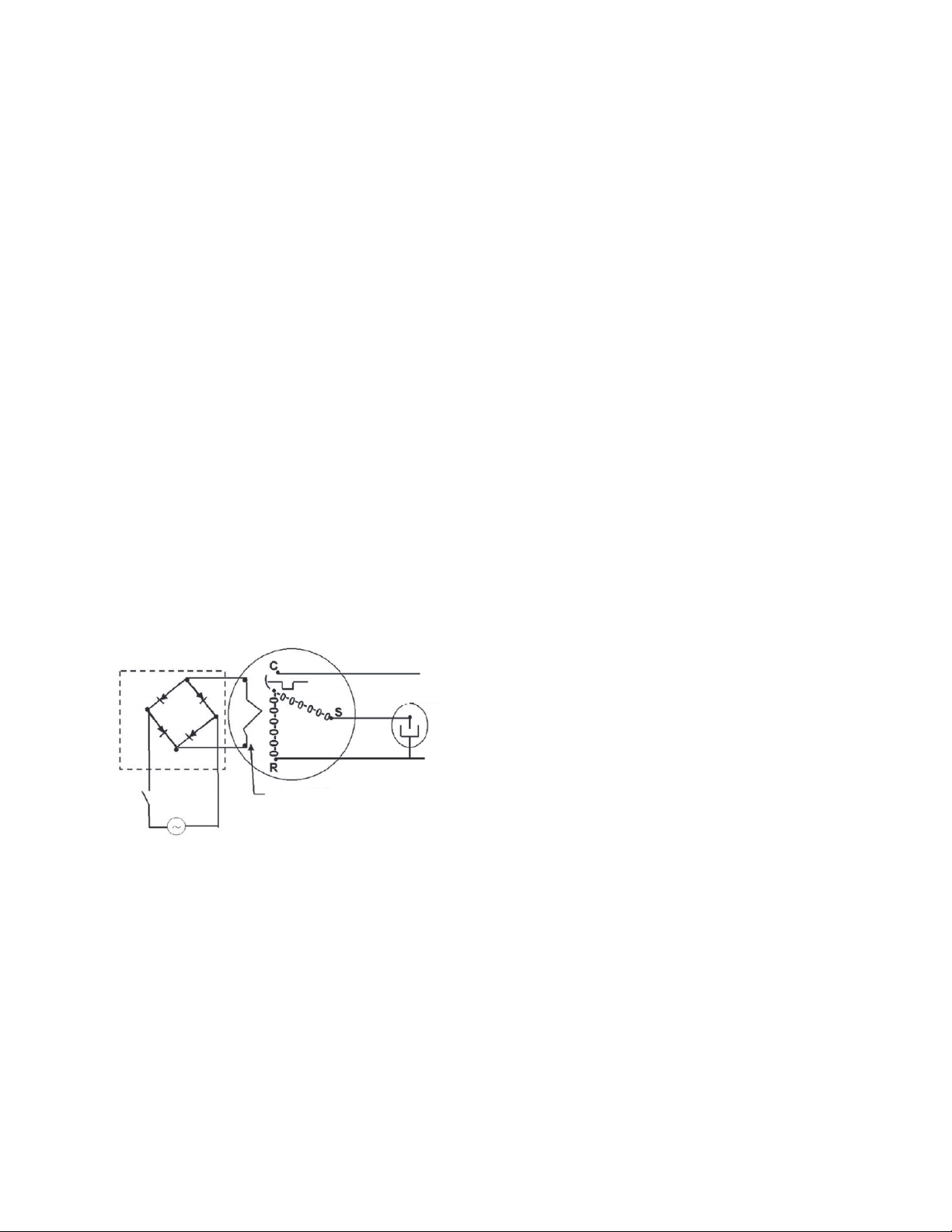

CAPACITY CONTROL - COMFORTNET

TM

MODELS

During the compression process, there are several pockets

within the scroll that are compressing gas. Modulation is

achieved by venting a portion of the gas in the first suction

pocket back to the low side of the compressor thereby

reducing the effective displacement of the compressor. See

Figure A. Full capacity is achieved by blocking these vents,

increasing the displacement to 100%. A solenoid in the

compressor, controlled by an external 24-volt ac signal,

moves the slider ring that covers and uncovers these vents.

The vent covers are arranged in such a manner that the

compressor operates somewhere around 67% capacity

when the solenoid is not energized and 100% capacity when

the solenoid is energized. The loading and unloading of the

two step scroll is done “on the fly” without shutting off the

motor between steps. See Figure C below. The unloaded

mode default was chosen for two reasons:

Molded Plug*

Line

Run Capacitor

Line

Internal Unloader

Coil

24 vdc

*Rectifier is integrated on the UC PCB

FIGURE C

1. It is expected that the majority of run hours will be in the

low capacity, unloaded mode.

2. It allows a simple two-stage thermostat to control capacity through the second stage in both cooling and possibly

heating if desired.

18 to 28 volt ac. The coil power requirement is 20 VA. The

external electrical connection is made with a molded plug

assembly. This plug is connected to the Communicating

Unitary Control PCB (UC PCB) which contains a full wave

rectifier to supply direct current to the unloader coil.

COILS AND BLOWER COILS

MBVC blower cabinets are designed to be used as a twopiece blower and coil combination and can be utilized with the

CAUF, CAPF and CAPT coils for upflow and downflow

applications. The CACF and CHPF coils are designed for

horizontal applications. This two-piece arrangement allows

for a variety of mix-matching possibilities providing greater

flexibility.

The MBVC blower cabinets use a variable speed motor that

maintains a constant airflow with a higher duct static. MBVC

blower cabinets are approved for applications with cooling

coils of up to 0.8 inches W.C. external static pressure. The

MBVC models allow airflow trimming of +/-10%.

All units are constructed with R-4.2 insulation. In areas of

extreme humidity (greater than 80% consistently), insulate

the exterior of the blower with insulation having a vapor barrier

equivalent to ductwork insulation, providing local codes

permit.

AVPTC Multi-Position Air Handler

AVPTC is a multi-position, variable-speed air handler used

with R-410A and are available in 2 to 5 ton sizes with optional

3 kW to 25kW electric heat kits available for field installation.

The AVPTC unit’s blower design includes a variable-speed

ECM motor and is compatible with heat pumps and variablecapacity cooling applications.

This appliance can be installed in the vertical or left horizontal

position without modification. The horizontal right and downflow

positions require product modification. This product is designed for zero inches (0 inches) clearance; however, adequate access for service or replacement must be considered without removing permanent structure. This unit can be

installed on a platform when deemed necessary.

In an attic installation a secondary drain pan must be provided

by the installer and placed under the entire unit with a

separate drain line properly sloped and terminated in an area

visible to the owner. This secondary drain pan is required in

the event that there is a leak or main drain blockage. Closed

cell insulation should be applied to the drain lines in unconditioned spaces where sweating may occur.

UNLOADER SOLENOID

A nominal 24-volt direct current coil activates the internal

unloader solenoid. The input control circuit voltage must be

27

PRODUCT DESIGN

NOTE: AVPTC air handlers are factory-sealed to achieve a

2% or less leakage rate at 1.0" water gauge external duct

static pressure.

Communicating Unitary Control (UC) PCB

The Communicating System Unitary Control PCB is a microprocessor-based control for heat pump and air conditioning

condensing units with single-phase compressors up to 5 ton

capacity operating on standard residential or Delta and Wye

commercial power. The control incorporates the basic functionality of existing defrost controls, outdoor thermostats,

contactors, compressor staging controls, short cycle controls, line voltage monitors, Comfort Alert™ or CoreSense

Module (dependent upon which module you are using), two

speed condenser fan relays and the Active Protection component of enabled thermostats. The control is designed to

work as part of a fully communicating HVAC system with 4

wires. The control also supports legacy 24VAC thermostat

inputs for Y1, Y2, O and 24VAC outputs for RVS, W1, and L

for non-communicating systems. Outputs include compressor power, compressor stage select, and outdoor fan high

and outdoor fan low speed. System inputs include high/low

pressure switches, as well as thermistor inputs for outdoor

coil temperature and outdoor air temperature.

28

SYSTEM OPERATION

COOLING

The refrigerant used in the system is R-410A. It is a clear,

colorless, non-toxic and non-irritating liquid. R-410A is a

50:50 blend of R-32 and R-125. The boiling point at atmospheric pressure is -62.9°F.

A few of the important principles that make the refrigeration

cycle possible are: heat always flows from a warmer to a

cooler body. Under lower pressure, a refrigerant will absorb

heat and vaporize at a low temperature. The vapors may be

drawn off and condensed at a higher pressure and temperature to be used again.

The indoor evaporator coil functions to cool and dehumidify

the air conditioned spaces through the evaporative process

taking place within the coil tubes.

NOTE: The pressures and temperatures shown in the

refrigerant cycle illustrations on the following pages are for

demonstration purposes only. Actual temperatures and pressures are to be obtained from the "Expanded Performance

Chart".

Liquid refrigerant at condensing pressure and temperatures,

(270 psig and 122°F), leaves the outdoor condensing coil

through the drier and is metered into the indoor coil through

the metering device. As the cool, low pressure, saturated

refrigerant enters the tubes of the indoor coil, a portion of the

liquid immediately vaporizes. It continues to soak up heat and

vaporizes as it proceeds through the coil, cooling the indoor

coil down to about 48°F.

Heat is continually being transferred to the cool fins and tubes

of the indoor evaporator coil by the warm system air. This

warming process causes the refrigerant to boil. The heat

removed from the air is carried off by the vapor.

As the vapor passes through the last tubes of the coil, it

becomes superheated. That is, it absorbs more heat than is

necessary to vaporize it. This is assurance that only dry gas

will reach the compressor. Liquid reaching the compressor

can weaken or break compressor valves.

The compressor increases the pressure of the gas, thus

adding more heat, and discharges hot, high pressure superheated gas into the outdoor condenser coil.

In the condenser coil, the hot refrigerant gas, being warmer

than the outdoor air, first loses its superheat by heat transferred from the gas through the tubes and fins of the coil. The

refrigerant now becomes saturated, part liquid, part vapor and

then continues to give up heat until it condenses to a liquid

alone. Once the vapor is fully liquefied, it continues to give up

heat which subcools the liquid, and it is ready to repeat the

cycle.

HEATING

The heating portion of the refrigeration cycle is similar to the

cooling cycle. By energizing the reversing valve solenoid coil,

the flow of the refrigerant is reversed. The indoor coil now

becomes the condenser coil, and the outdoor coil becomes

the evaporator coil.

The check valve at the indoor coil will open by the flow of

refrigerant letting the now condensed liquid refrigerant bypass the indoor expansion device. The check valve at the

outdoor coil will be forced closed by the refrigerant flow,

thereby utilizing the outdoor expansion device.

COOLING CYCLE

For communicating room thermostat: When the room thermostat calls for either low stage cool or high stage cool,

appropriate commands are sent via the data 1 and data 2 lines

to the outdoor unit's UC control. The UC control energizes the

on-board compressor relay and the on-board outdoor fan

relay. The compressor high stage solenoid is energized if it

is a high stage call.

The UC control sends a fan command to the indoor unit (air

handler or furnace). The indoor unit operates the indoor

blower at the appropriate airflow level. The system operates

at the cooling level demanded by the thermostat.

When the thermostat is satisfied, appropriate commands are

sent to the UC control. The compressor relay and outdoor

fan relay is de-energized. The compressor high stage

solenoid is de-energized if it was energized. The UC control

sends an appropriate command to the indoor unit to deenergize the indoor blower motor.

If room thermostat fan status is set to be “on”, then indoor

blower would run continuously rather than cycling with the

compressor.

For heat pumps, the reversing valve is energized during the

cooling cycle. The call for cooling from the communicating

thermostat indicates to the control that the reversing valve is

to be energized during cooling operation.

HEATING CYCLE

For communicating room thermostat: When the room thermostat calls for either low stage heat or high stage heat,

appropriate commands are sent via the data 1 and data 2 lines

to the outdoor unit's UC control. The UC control energizes the

on-board compressor relay and the on-board outdoor fan

relay. The compressor high stage solenoid is energized if it

is a high stage call. The UC control sends a fan command

to the indoor unit (air handler or furnace). The indoor unit

operates the indoor blower at the appropriate airflow level.

The system operates at the cooling level demanded by the

thermostat.

When the thermostat is satisfied, appropriate commands are

sent to the UC control. The compressor relay and outdoor

fan relay is de-energized. The compressor high stage

solenoid is de-energized if it was energized. The UC control

sends an appropriate command to the indoor unit to deenergize the indoor blower motor.

29

SYSTEM OPERATION

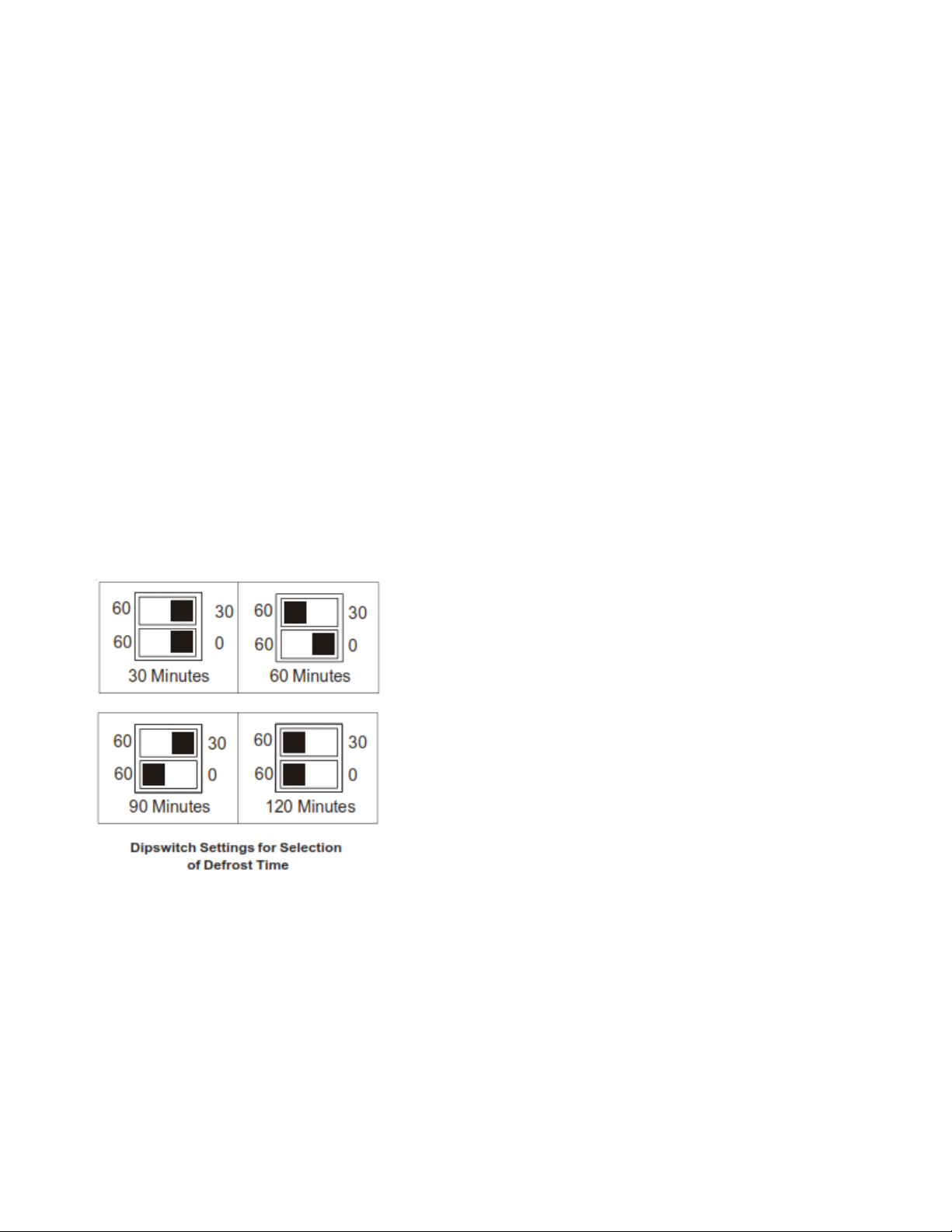

DEFROST CYCLE - COMFORTNETTM MODELS

The defrosting of the outdoor coil is jointly controlled by the

UC PCB and the outdoor coil temperature (OCT) sensor.

The OCT sensor is clamped to a feeder tube entering the

outdoor coil. Defrost timing periods of 30, 60, 90 or 120

minutes may be selected via the dipswitch settings on the UC

PCB. In a communicating system, the defrost timing periods

can also be selected in the communicating thermostat user

menu. During operation, if the coil temperature is low enough

(approximately 31° F), the microprocessor will accumulate

the compressor run time. When the total compressor run

time reaches 30, 60, 90 or 120 minutes, and there is a call for

heat, the PCB will initiate a defrost cycle. When the

microprocessor detects the coil temperature to be high

enough (approximately 75 0F), or 10 minutes of maximum

defrost cycle time has elapsed, whichever occurs first, the

defrost cycle is terminated and the timing period is reset. The

field service personnel can also advance a heat pump to the

defrost cycle by simultaneously pressing the “TEST” button

and the “RECALL” button on the UC board.

Use the dipswitches to select defrost time interval (30, 60, 90

or 120 minutes) See chart below

30

Loading...

Loading...