Page 1

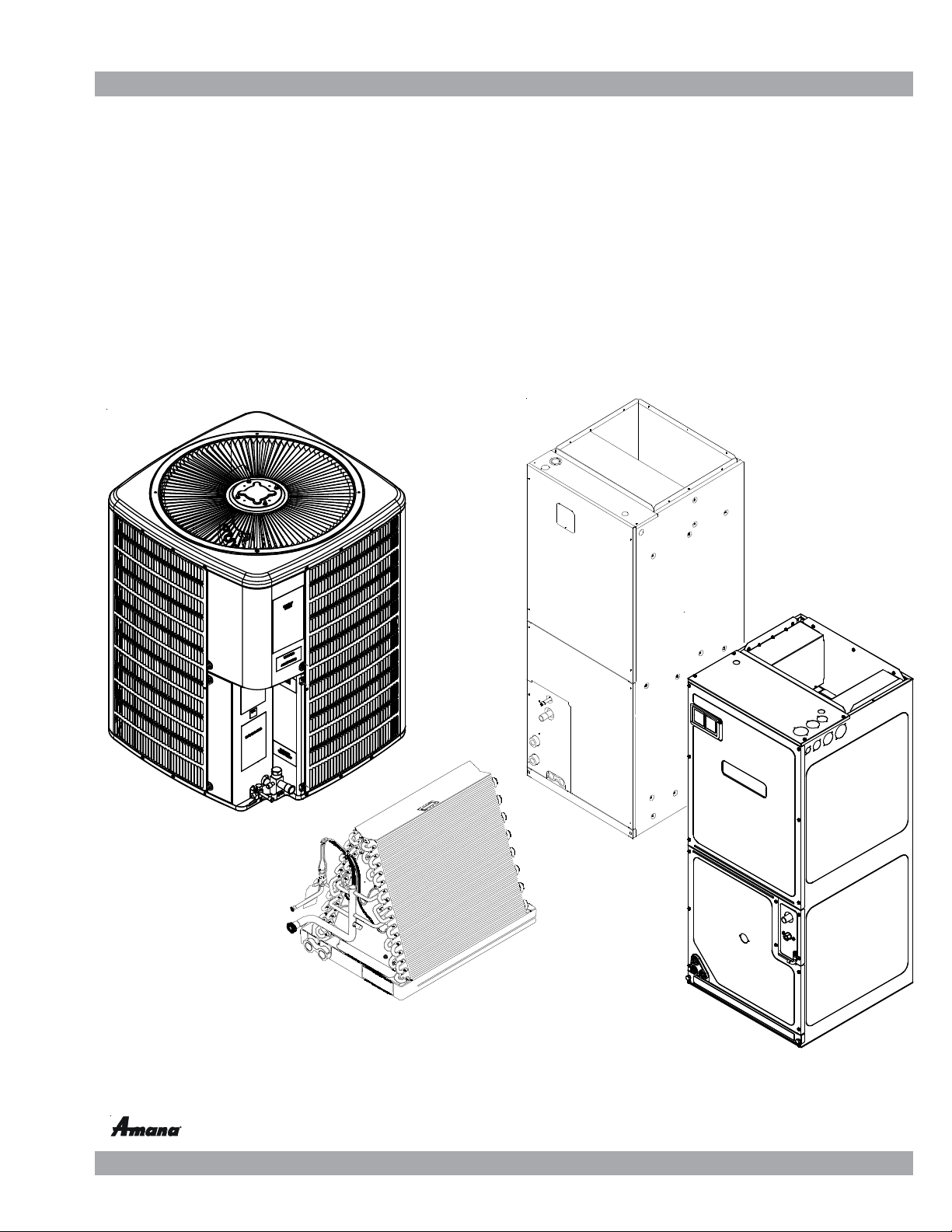

Service Instructions

ComfortNet™

ASXC, DSXC, and GSXC Condensing Units,

ASZC, DSZC and GSZC

with R-410A Refrigerant

Blowers, Coils, & Accessories

Split System Heat Pumps

This manual is to be used by qualified, professionally trained HVAC technicians only. Goodman

does not assume any responsibility for property damage or personal injury due to improper

service procedures or services performed by an unqualified person.

Copyright © 2015-2017 Goodman Manufacturing Company, L.P.

is a registered trademark of Maytag Corporation or its related companies and is used under license to Goodman Company, L.P., Houston, TX. All rights reserved.

RS6200007r14

December 2017

Page 2

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however, that

during its lifetime a product may require service. Products should be serviced only by a qualified service technician who is

familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing instruments

and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE SERVICE MANUAL BEFORE

BEGINNING REPAIRS.

IMPORTANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

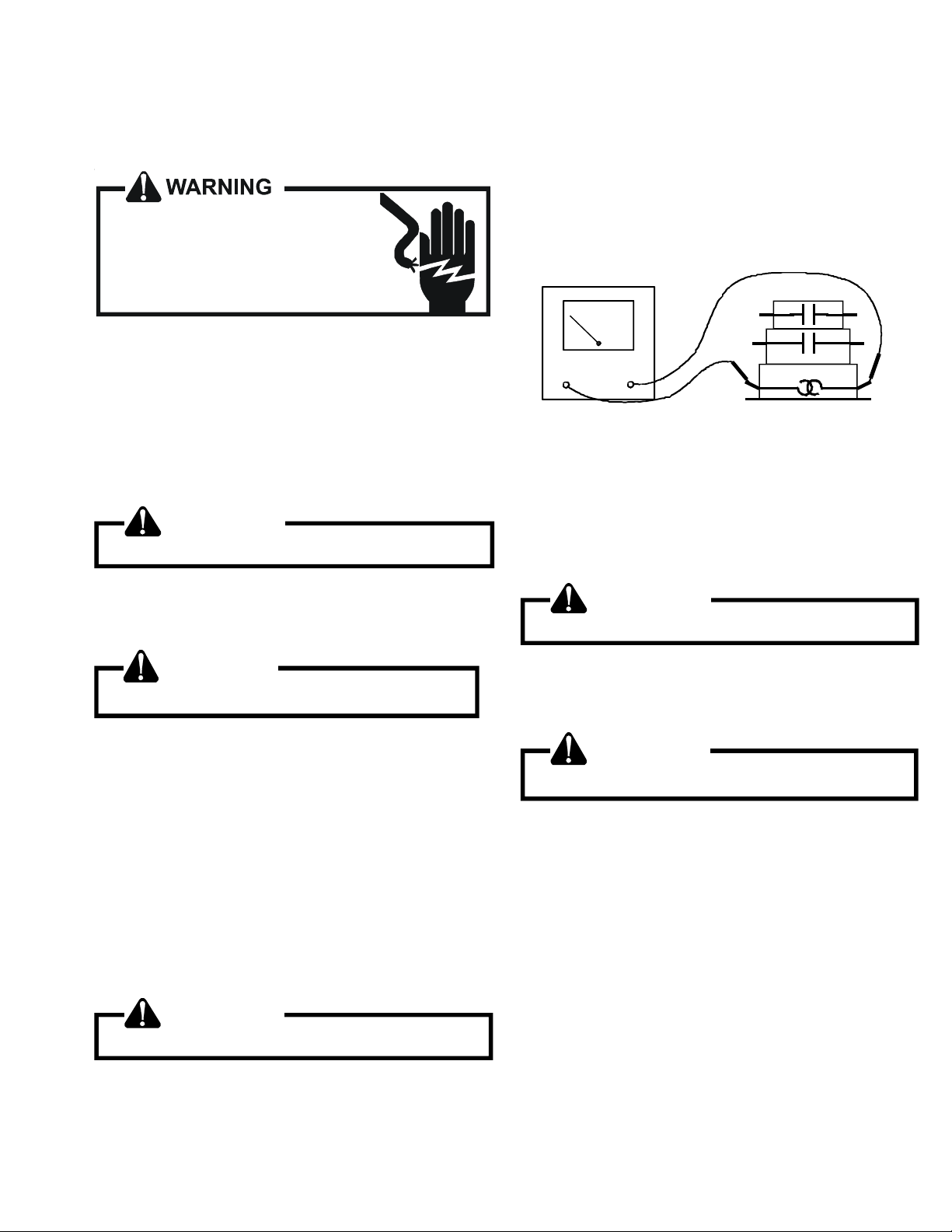

WARNING

O

NLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL, ADJUST, SERVICE OR

REPAIR (HEREINAFTER

MANUAL SHOULD SERVICE THE EQUIPMENT

BE RESPONSIBLE FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM

IMPROPER SERVICE OR SERVICE PROCEDURES

ASSUME RESPONSIBILITY FOR ANY INJURY OR PROPERTY DAMAGE WHICH MAY

RESULT

. IN

LICENSES TO SERVICE THE EQUIPMENT SPECIFIED IN THIS MANUAL, ONLY

LICENSED PERSONNEL SHOULD SERVICE THE EQUIPMENT

INSTALLATION, ADJUSTMENT, SERVICING OR REPAIR OF THE EQUIPMENT

SPECIFIED IN THIS MANUAL, OR ATTEMPTING TO INSTALL, ADJUST, SERVICE OR

REPAIR THE EQUIPMENT SPECIFIED IN THIS MANUAL WITHOUT PROPER

TRAINING MAY RESULT IN PRODUCT DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH

, “

SERVICE

”)

THE EQUIPMENT SPECIFIED IN THIS

. THE

MANUFACTURER WILL NOT

. IF

YOU SERVICE THIS UNIT, YOU

ADDITION, IN JURISDICTIONS THAT REQUIRE ONE OR MORE

. I

MPROPER

.

T

O PREVENT THE RISK OF PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH,

DO NOT STORE COMBUSTIBLE MATER IALS OR USE GASOLINE OR OTHER

FLAMMABLE LIQUIDS OR VAPORS IN THE VICINITY OF THIS APPLIANC E.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this product.

For further assistance, please contact:

CONSUMER INFORMA TION LINE

GOODMAN® BRAND PRODUCTS

TOLL FREE

1-877-254-4729 (U.S. only)

email us at: customerservice@goodmanmfg.com

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-713-861-2500.

(Not a technical assistance line for dealers.) Your telephone company will bill you for the call.

is a registered trademark of Maytag Corporation or its related companies and is used under license to Goodman Company, L.P., Houston, TX. All rights reserved.

email us at: customerservice@goodmanmfg.com

AMANA® BRAND PRODUCTS

TOLL FREE

1-877-254-4729 (U.S. only)

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

2

Page 3

IMPORTANT INFORMATION

SAFE REFRIGERANT HANDLING

While these items will not cover every conceivable situation, they should serve as a useful guide.

WARNING

REFRIGERANTS ARE H EAVIER T HAN AIR. THEY CAN "PUS H OUT" THE

OXYGEN IN YOUR LUNGS OR IN ANY ENCLOSED SPACE.

POSSI BLE DIFFI CULTY IN BRE ATHIN G OR DEATH:

EVER PURGE REFRIGERANT INTO AN ENCLOSED ROOM OR SPACE. BY

•

N

LAW, ALL REFRIGERANTS MUST BE RECLAIMED.

IF AN INDOOR LEAK IS SUSPECTED, THOROUGHLY VENTIL ATE THE AREA

•

BEFORE BEGINNING WORK.

IQUID REFRIGERANT CAN BE VERY COLD. TO AVOID POSSIBLE FROST-

•

L

BITE OR BL INDNESS, AVOID CONTACT W ITH REFR IGERANT AND WEAR

I

GLOVES AND GOGGLES.

SKIN OR EYES, SEEK MEDICAL HELP IMMEDIATELY.

A

LWAYS FOLLOW

•

AS POIS ONOUS GA S WILL BE PRODUC ED.

F LIQUID REFRIGERANT DOES CONTACT YOUR

EPA

REGULATIONS. NEVER BURN REFRIGERANT,

O AVO ID

T

WARNING

HE UNITED STATES ENVIRONME NTAL PROTECTION AGENCY ( "

T

HAS ISSUED VARIOUS REGULATIONS REGARDING THE INTRODUCTION AN D

DISPOSA L OF REFRI GERANTS INTRODUC ED INTO T HIS UNIT .

FOLLOW T HESE REGU LATIONS MAY HARM TH E ENVIRON MENT AND CAN

LEAD TO THE H IMPOSI TION O F SUBSTAN TIAL FIN ES.

MAY VARY BY JURISDICTION.

EPA OFFICE.

LOCAL

SHOULD QUEST IONS ARI SE, CO NTACT YOUR

THESE REGULATIONS

EPA

AILURE TO

F

WARNING

TO AVOID POSSIBLE EXPLOSION:

EVER APPL Y FLAME O R STEA M TO A REFR IGERAN T CYLINDE R. IF YOU

•

N

MUST HEA T A CYLIND ER FOR FAS TER CHARG ING, PARTI ALLY IMME RSE

IT IN WARM WATER.

NEVER FILL A CYLINDER MORE THAN 80% FULL OF LIQUID REFRIG ERANT.

•

NEVER ADD ANYTHING OTHER T HAN R-22 TO AN R-22 CYLINDER OR

•

R-410A TO AN R-410A CYLINDER. THE SERVICE EQUIPMENT USED MUST

BE LISTED OR CERTIFIED FOR THE TYPE OF REFRIGERANT USED.

TORE CYLIN DERS IN A COOL, DRY PL ACE. NEVER US E A CYLIND ER

•

S

AS A PLATFORM OR A ROLLER.

WARNING

TO AVOID POSSIBLE EXPLOSION, USE ONLY RETURNABLE (NOT DISPOSABLE)

SERVICE CYLINDERS WHEN REMOVING REFRIGERANT FROM A SYSTEM.

•

ENSURE THE CYLINDER IS FREE OF DAMA GE WHICH COULD LEAD TO A

LEAK OR EX PLOS ION.

•

")

ENSURE THE HYDROST ATIC TEST DATE DOES NO T EXCEED 5 YEARS.

•

ENSURE THE PRESSURE RATING MEETS OR EXCEEDS 400 LBS.

WHEN IN DOUBT, DO NOT USE CYLINDER.

WARNING

WARNING

SYSTEM CONTAMINANTS, IMPROPER SERVICE PROCEDURE AND/OR PHYSICAL

ABUSE AFFECTING HERMETIC COMPRESSOR ELE CTRICAL TERMINALS MAY

CAUSE DANGEROUS SYSTEM VENTING.

The successful development of hermetically sealed refrigeration compressors has completely sealed the compressor's

moving parts and electric motor inside a common housing,

minimizing refrigerant leaks and the hazards sometimes

associated with moving belts, pulleys or couplings.

Fundamental to the design of hermetic compressors is a

method whereby electrical current is transmitted to the

compressor motor through terminal conductors which pass

through the compressor housing wall. These terminals are

sealed in a dielectric material which insulates them from the

housing and maintains the pressure tight integrity of the

hermetic compressor. The terminals and their dielectric

embedment are strongly constructed, but are vulnerable to

careless compressor installation or maintenance procedures and equally vulnerable to internal electrical short

circuits caused by excessive system contaminants.

T

O AVOID POSSIBLE INJURY, EX PLOSION OR DEATH, PRACTICE SAFE

HANDLING OF RE FRIGERANTS.

In either of these instances, an electrical short between the

terminal and the compressor housing may result in the loss

of integrity between the terminal and its dielectric embedment. This loss may cause the terminals to be expelled,

thereby venting the vaporous and liquid contents of the

compressor housing and system.

A venting compressor terminal normally presents no danger

to anyone, providing the terminal protective cover is properly

in place.

If, however, the terminal protective cover is not properly in

place, a venting terminal may discharge a combination of

(a ) hot lubricating oil and refrigerant

(b ) flammable mixture (if system is contaminated

with air)

in a stream of spray which may be dangerous to anyone in the

vicinity. Death or serious bodily injury could occur.

Under no circumstances is a hermetic compressor to be

electrically energized and/or operated without having the

terminal protective cover properly in place.

See Service Section S-17 for proper servicing.

3

Page 4

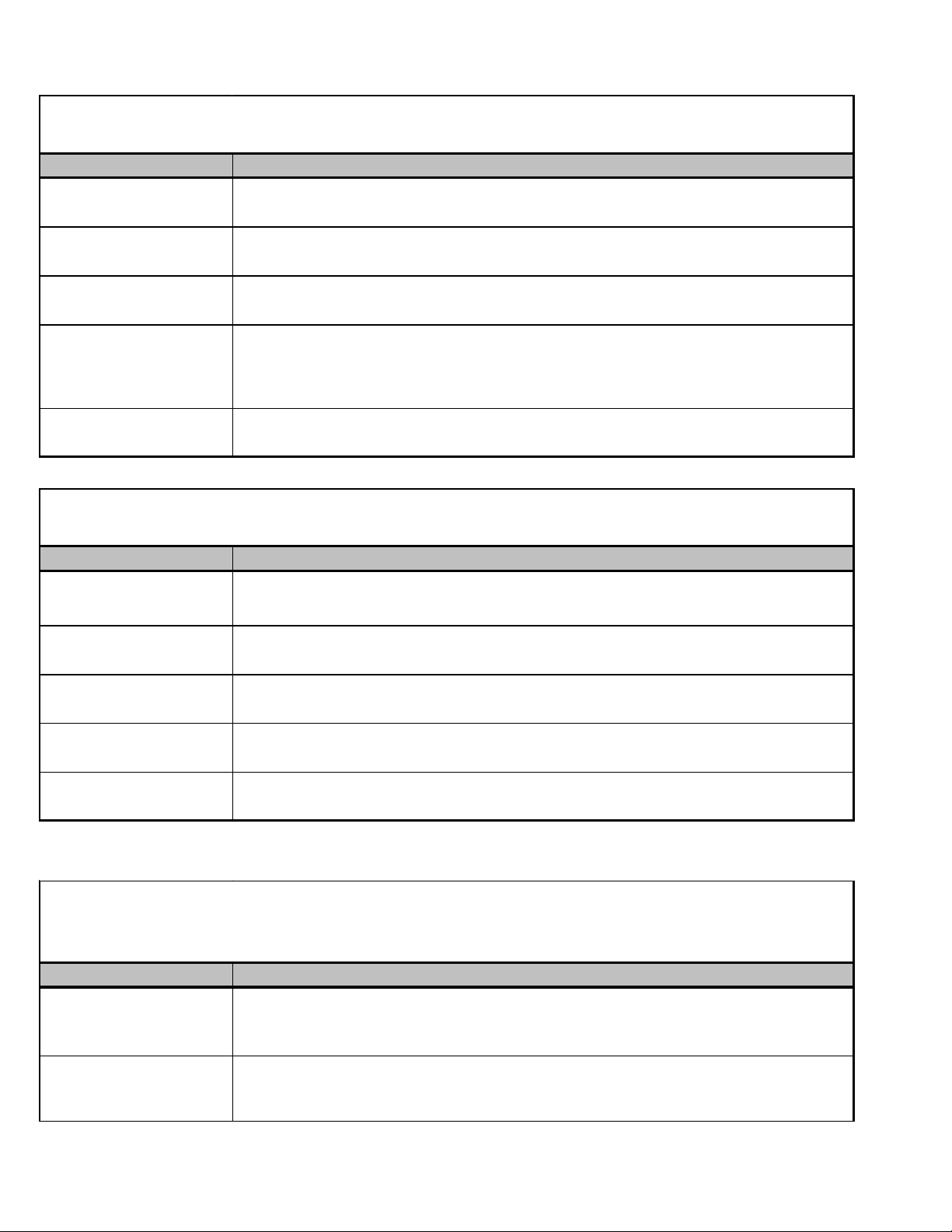

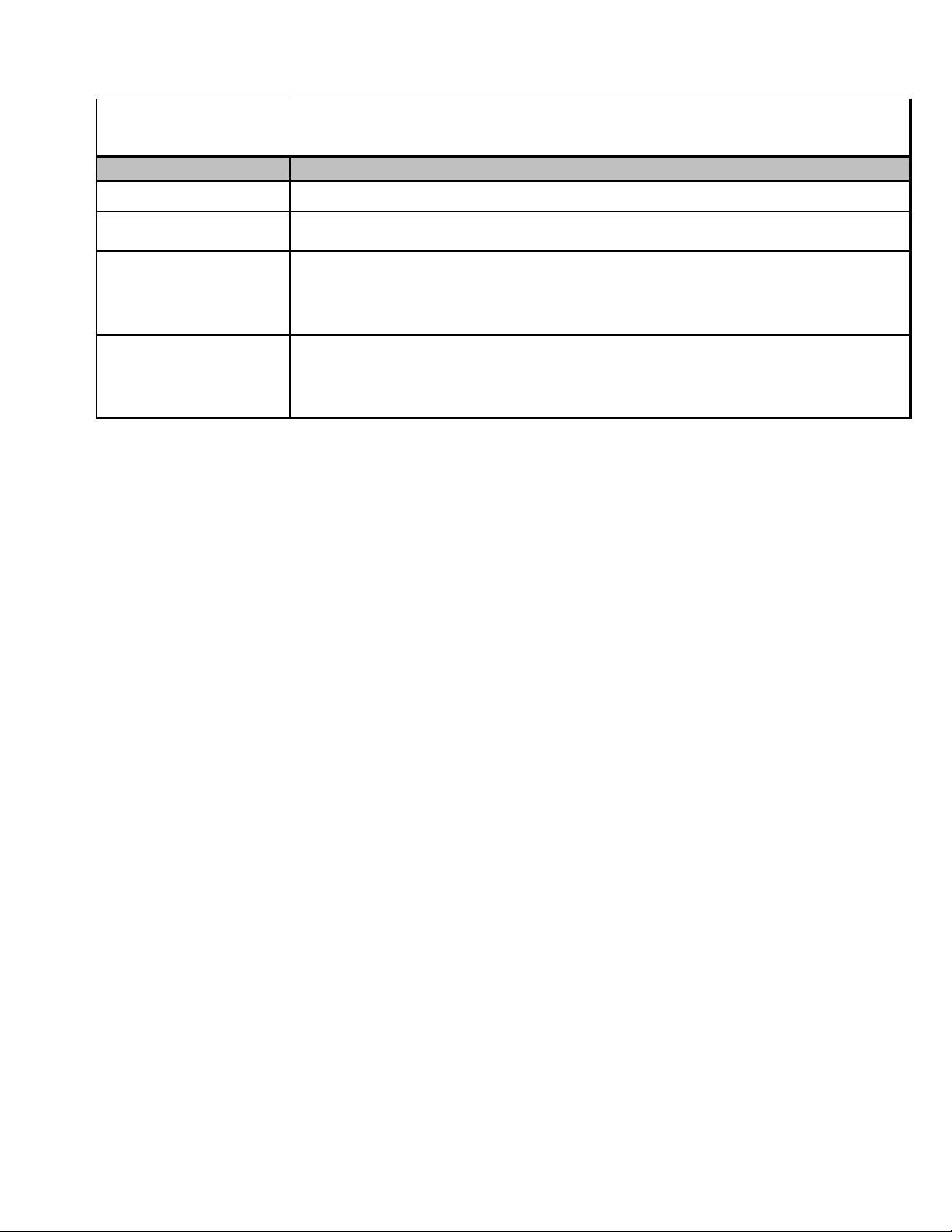

PRODUCT IDENTIFICATION

s

ASXC 160241 AA

1 2 3 4,5 6 6 7 8,9

ComfortNet™

Brand

A - Ama na® bra nd Maj or/Mi nor Revi si on

D - Deluxe Goodman® brand

G - Goodman® brand

Type 1 - 208/230V Single-Phase 60 Hz

S 3 - 208/230V Three-Phase 60 Hz

Split Sys tem

4 - 460V Three-Phase 60 Hz

Type

C: Condenser R-22

H: Heat Pump R-22 024 - 2 Tons

X: Condenser R-410A 036 - 3 Tons

Z: Heat Pump R-410A 048 - 4 Tons

060 - 5 Tons

Communication Feature

C: 4-Wi re Communicati on Ready

SEER

16 - 16 SEER

18 - 18 SEER

Engineering

Voltage

Nominal Capacity

4

Page 5

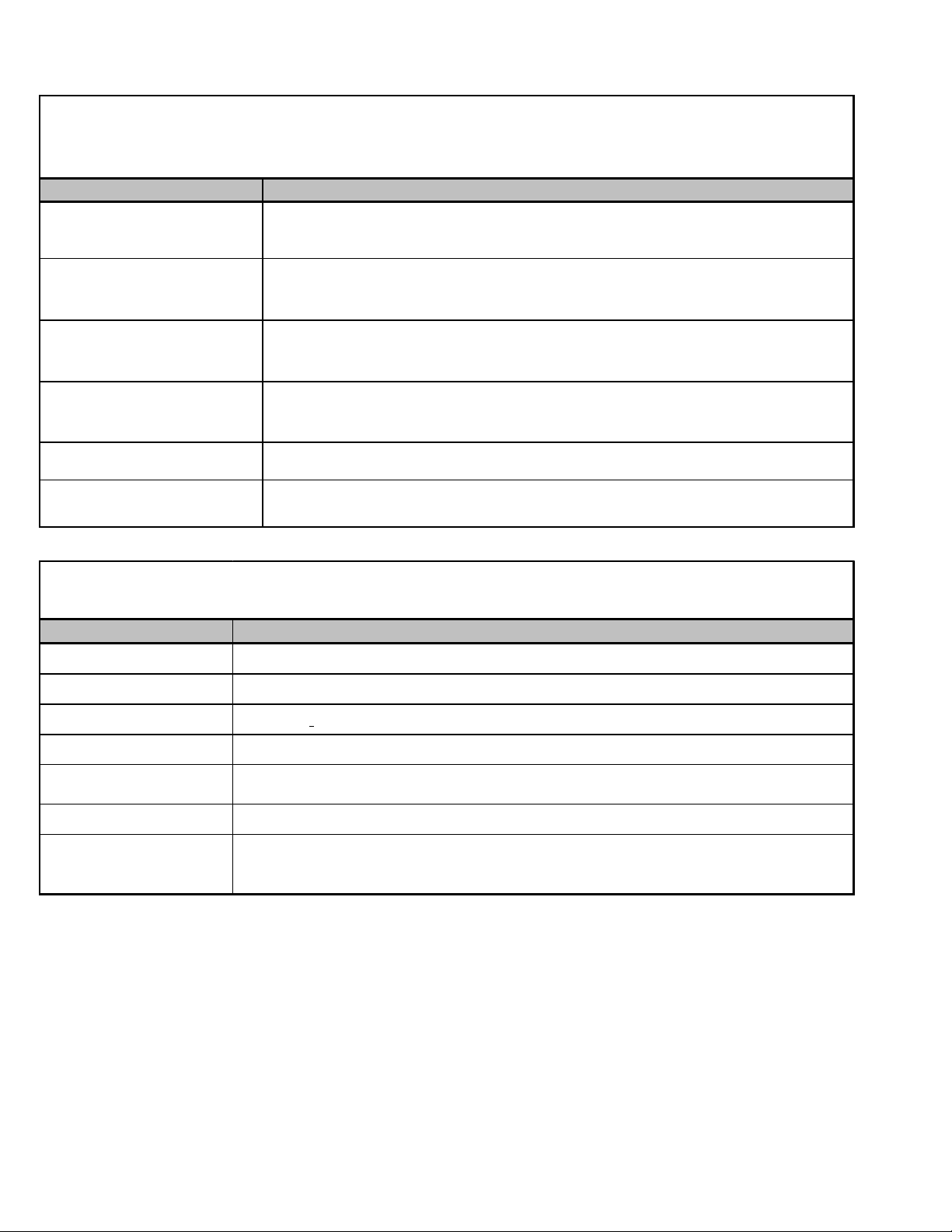

PRODUCT IDENTIFICATION

A

=

ComfortNet™

CAP F 1824 A 6 A

1 2 3 4 5,6,7,8 9 10 11,12

Brand Engineering*

C Indoor Coi l

Unit Application 2 = R-22

A Upflow/Downflow Coi l

H Horizontal A-Coil

Horizontal Slab Coil

S

Coated Coils

T

Nominal Width for Gas Furnace

A = Fits 14" Furna ce Cabinet

B = Fits 17-1/2" Furnace Cabi net

C =

Fits 21" Furnace Cabinet

D = Fits 24-1/2" Furnace Cabinet

N

Does Not Apply (Horizontal Slab Coils

Major/Minor Revisions

Refrigerant Charge

4 = R-410A

6 = R-410A or R-22

Cabinet Finish

U Unpainted

PPainted

N Unpai nted Ca se

Expansion Device

FFlowrator

T 4 - 5 Tons

Expansi on Valve 4 - 5 Tons

1824 =

3030 =

3131 =

3636 =

3642 =

3743 =

4860 = Factory-Installed Non-Adjustable

4961 =

Nominal Capacity @ 13 SEER

1-1/2 - 2 Tons

2-1/2 Tons

2-1/2 Tons

3 Tons

3 - 3-1/2 Tons

3 - 3-1/2 Tons

5

Page 6

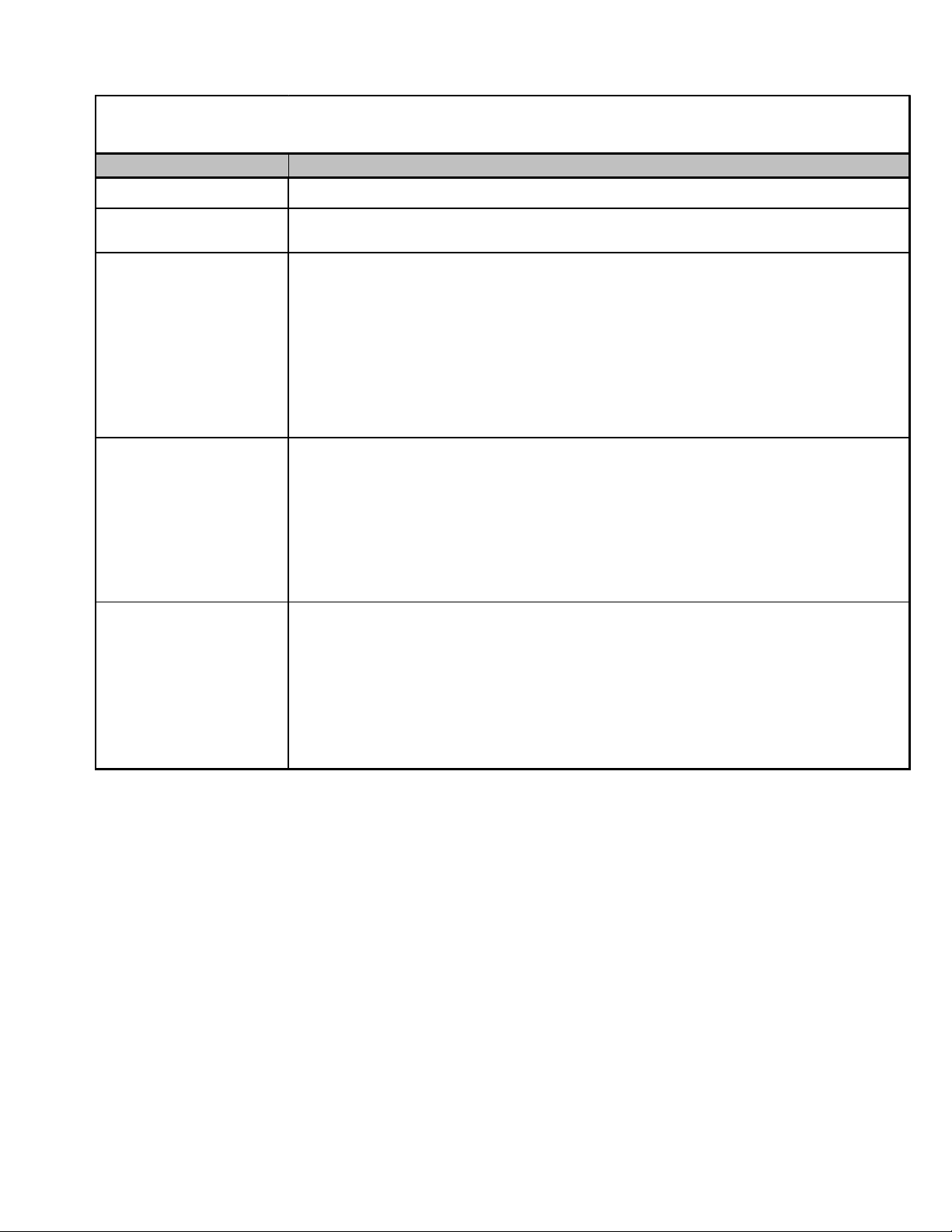

PRODUCT IDENTIFICATION

H

MB V C 12 00 A A 1

1,2 3 4 4 5,6 7 8 9

ComfortNet™

Brand

MB - Modular Blower 1: 208-230V/60Hz/1 P

Type A: First Seri es

Speed

V:

Communication Feature A: No Circui t Br eaker

C: 4-Wire Communication Ready

Airflow

12:

1200 CFM

16:

1600 CFM

20:

2000 CFM

B: Ci rcuit Breaker

Elect rical

Design Se ries

Circuit Breaker

Factory Heat

00 No Heat

6

Page 7

PRODUCT IDENTIFICATION

A V P T C 1830 1 6 AA

1 2 3 4 5 6,7,8,9 11 12 13,14

ComfortNet™

Brand

A Airhandler

Unit Application

Vari a bl e Sp eed Motor

V

Cabinet Finish

U: Unpa inted

P: Painted 1 208/240V, 1 Phase, 60 Hz

N: Uncas ed

Expansion Device

F: Fl owrator

T: Expansion Valve

Communications

C: 4-Wire Communi cati on Ready

Multi-Position & Downflow Applications

Ceiling Mount & Wall Mount Applications

Maj or/Mi nor Revi si ons

1830 = 1-1/2 to 2-1/2 Tons

3137 = 3 Tons

4260 = 3-1/2 to 5 Tons

Engineering*

Refrigerant Charge

No Di git = R-22 Onl y

6 = R-410A or R-22

Electrical

Nominal Capacity

7

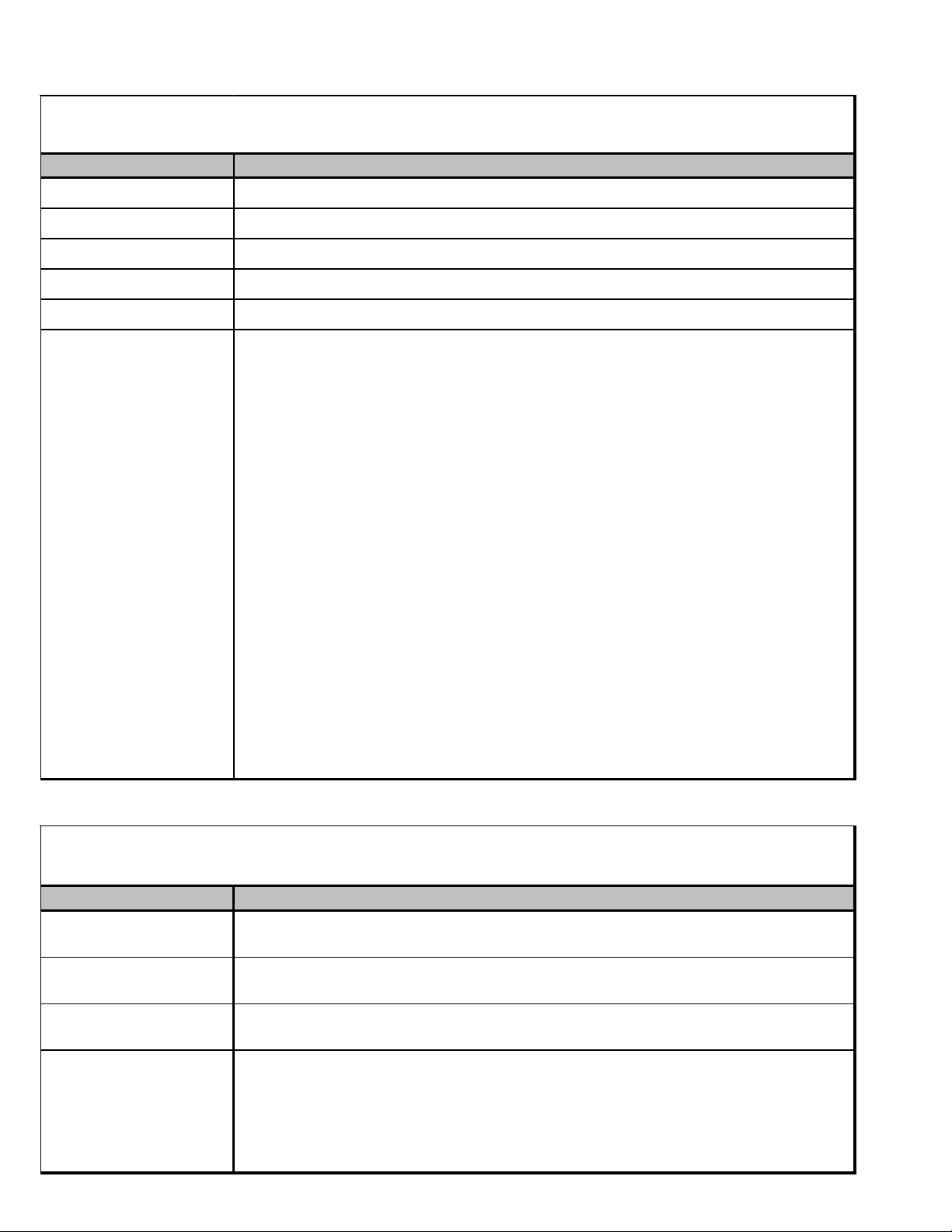

Page 8

PRODUCT IDENTIFICATION

A

V

PTC18B1 4AA

1 2 3 4 5 6,7 8 9 10 11,12

ComfortNet™

Brand

A Si ngl e Piec e

Ai rhandl er

Unit Application

C Ceiling Mount PSC Motor 4 = R-410a

R Multi Position PSC Motor

S Multi Posi tion EEM Motor

W Wall Mount PSC/EEM Motor 1 208/240V, 1 Phase, 60 Hz

VMulti Position

Variable Speed Motor -

Communi cating

Cabinet Finish

U Unpainted

PPainted

NUncased

Expansion Device

FFlowrator 31 = 2 Tons

TExpansion Valve 33 = 1 1/2 - 2 Tons

Communications

ComfortNet

C

TM

Compatible

*Not used for inventory management

Nominal Capacity

Major/Minor Revisions

18 = 1-1/2 Tons

24 = 2 Tons

25 = 2 Tons

29 = 2 Tons

30 = 2-1/2 Tons

36 = 3 Tons

37 = 2 1/2 - 3 1/2 Tons

39 = 2 1/2 - 3 Tons

42 = 3-1/2 Tons

48 = 4 Tons

49 = 3 - 3 1/2 Tons

59 = 4 - 5 Tons

60 = 5 Tons

61 = 4 - 5 Tons

Engineering*

Refrige rant Charge

Electrical

Cabinet Width

B = 17-1/2"

C = 21"

D = 24-1/2"

All Airhandlers use DIRECT DRIVE MOTORS. Power supply is AC 208-230v, 60 hz, 1 phase.

8

Page 9

PRODUCT IDENTIFICATION

ASXC16

MANA® BRAND SPLIT

A

Model/Rev Description

ASXC160 **1AA

AS XC160601BA Use ZPS49 compress or.

AS XC160481BA Smart Coi l® coil s

AS XC160(24/36)1BB Wi ring diagram updat ed wit h notes .

AS XC160(48-60)1BB Motor changed t o Nidec.

Introduces Amana® brand 2-stage 16 SEER condensing units with R-410A,

communicati ng m o dels.

OMMUNICATING CONDENSERS R-410A 16 SEER

X-C

ASXC160 (2 4/36)1BC

ASXC160 (4 8- 60) 1BC

ASXC160 (2 4/36)1BD

ASXC160 (4 8- 60) 1BD

AS XC160(241, 481)B E Refrigerant charge reduction

AS XC160(24,36,48,60)1CA 16 SE ER 2-Stage AC Developm ent with improved performance.

Ultrat ec h® 2.0 c ompressor change.

Replaced P CB HR103 Communicating Heat P um p Control B oard wit h PCBHR104

Communicating Heat P um p Control Board.

ASXC18

MANA® BRAND SPLIT

A

Model/Rev Description

ASXC18**1AA

AS XC180(36/48/ 60)1AB Wi ring di agram updated wit h not es .

ASXC180 (3 6/48-60)1AC

Initial release of Amana® brand 2-st age 18 SEER condensing units with R-410A ,

communicati ng m o dels.

Replaced compressors ZP S 20K4EPFV230 with ZPS20K5E P F V130 and compressor

ZPS30K4EPFV230 with ZPS30K5EPFV130.

OMMUNICATING CONDENSERS R-410A 18 SEER

X-C

ASXC180 (3 6/48/60)1AD

ASXC180 48 1BB

Replaced P CB HR103 Communicating Heat P um p Control B oard wit h PCBHR104

Communicating Heat P um p Control Board.

[Design Improvement]: Updating shared data for 18 SEER, 2-stage, 4 ton AC in

com m unicating installat i ons. Releasi ng m inor revision for affec ted models

9

Page 10

PRODUCT IDENTIFICATION

GSXC16

OODMAN® BRAND SPLIT

G

Model / Re v Description

GSXC160( 24/36/48/60)1CA

OODMAN® BRAND SPLIT

G

Model / Rev Description

GSXC180( 24/36/48/60)1BA

GSXC180481BB

OMM UNICA T IN G CONDENSERS R-410A 16 SEER

X-C

16 SEER 2-Stage AC Development wi t h i m proved performan c e.

GSXC18

OMM UNICA T ING CONDEN SERS R-410A 18 SEER

X-C

18 SEER 2-Stage AC Development with improved performance.

[Design Improvement]: Updating shared data for 18 SEER, 2-stage, 4 ton AC in

communic a t i ng i nstall ations . Releasi n g m i no r revision for affect ed m odel s

10

Page 11

PRODUCT IDENTIFICATION

DSXC16

ELUXE SPLIT

D

Model/Rev Description

DSXC160**1AA

DSXC160(24/36)1AB Wiring diagram updat ed with notes.

DSXC160(24/36)1AC

DSXC160(48-60)1BC

DSXC160481BA Sm artCoil ® coils.

DSXC160601BA ZPS49K compress or.

DSXC160(48-60)1BB Motor c hanged t o Nidec.

DSXC160241AF

DSXC160481BE

Initial release of Goodman® Deluxe brand 2-st age 16 S E ER condensing units with R410A, communicating models.

Ult ratech® 2.0 compressor.

Refri gerant charge reduction

OMMUNICATING CONDENSERS R-410A 16 SEER

X-C

DSXC18

DELUXE SPLIT X-C

Model/Rev Description

DSXC18**1AA

DSXC180(36/48/60] 1AB W i ring di agram updat ed wit h not es.

DSXC18036AC

DSXC180(48-60)1AC Ult ratech® 2.0 compress or c hange.

Initial release of Goodm an® Deluxe brand 2-s tage 18 SEE R c ondens ing uni t s with R410A, communic ating models .

Replaced c om pres sors ZPS20K4E P F V230 with ZPS20K5E P F V 130 and c om pres s or

ZPS30K4EPFV230 with ZPS30K5EPFV130.

OMMUN ICATING CONDENSERS R-410A 18 SEER

11

Page 12

PRODUCT IDENTIFICATION

Model/Rev Description

ASZC160**1AA

MANA® BRAND SPLIT

A

Introduces A m ana ® brand 2-stage 16 SE ER heat pum p u ni ts with R-410A,

com municating m odel s.

OMMUNICATING HEAT PUMP R-410A 16 SEER

Z-C

ASZC16

ASZC160(24/36)1AB

ASZC160(48/60)1AB

ASZC160(24-48)1AC

ASZC160601BA

ASZC160(24-36])1AD

ASZC160601BB

ASZC160(24-36)1AE

AS ZC160481A E Ult rat e ch® 2. 0 compres sor change.

ASZC160[24/36/48/60]1C A

Sanhua ( RA NCO) reversing valves

Releas e of mod el s with accum ul ators and crankcase heaters.

Mot or changed t o Ni dec.

Replaced compres sors ZPS20K4EP F V 230 wit h ZPS20K 5E P F V 130 and com pres s or

ZPS30K4EPFV230 with ZPS30K5EPFV130.

Replac ed compres sors with Copeland's UltraTech™ 3 l i neup . Trans i tioned coils to 7mm.

Offers improved performance.

ASZC18

Model/Rev Description

ASZC180**1AA

MANA® BRAND SPLIT

A

Introduces A m ana ® brand 2-stage 18 SE ER heat pum p u ni ts with R-410A,

com municating m odel s.

OMMUNI CATING HEAT PUMPS R-410 A 18 SEER

Z-C

ASZC180601BC

ASZC180601BB

ASZC180(36/48/60)1A B Relea se of models with accum ul ators and crankcase heaters.

ASZC180(36-4)]1AC

ASZC180601BA

ASZC180361AD

ASZC180[24/36/48/60]1C A

Ult rat e ch® 2. 0 compres sor change.

Sanhua ( RA NCO) reversing valves

Replac ed compres sors with Copeland's UltraTech™ 3 l i neup . Trans i tioned c oils to 7mm.

Offers improved performance.

12

Page 13

PRODUCT IDENTIFICATION

GSZC16

OODMAN® BRAND SPLIT

G

Model/Re v Description

GSZC160[24/36/48/60]

OODMAN® BRAND SPLIT

G

Model/Rev Descripti on

GSZC180[24/36/48/60]

OMMUN ICATING HEAT PUMP R-410A 16 SEER

Z-C

Replaced c om pres s ors with Copeland's UltraTech™ 3 l ineup. Transit i oned c oi ls

to 7mm . O ffers improved performance.

GSZC18

OMMUNICATING HEAT PUMP R-410A 16 SEER

Z-C

Replac ed c om pressors wi t h Copel and's Ul t raTech™ 3 li neup. Transiti oned coils

to 7m m. Offers i m proved performance.

13

Page 14

PRODUCT IDENTIFICATION

DSZC16

ELUXE SPLIT

D

Model/Rev Description

DSZC16**1AA

DSZC160( 24 /36)1AB

DSZC160( 48 /60)1AB

DSZC160( 24 - 48) 1 AC

DSZC160601 BA

DSZC160( 24 - 48) ]1AD

DSZC160601 BB

DSZC160481 AE

DSZC160601 BC

DSZC160( 24 - 36) 1 AE

Initial release of Goodman® brand Deluxe 2-st age 16 S E ER heat pump units with R410A, communicating models.

Sanh ua (RANCO) revers i ng valves .

Release of models wi t h ac cumulators and crankcase heaters.

Ultrat ec h® 2.0 com pres sor change.

Replaced c om pres sors ZPS20K4E P F V230 with ZPS20K5E P F V 130 and c om pres s or

ZPS30K4EPFV230 with ZPS30K5EPFV130.

OMMUN ICATING HEA T PUMP R-410A 16 SEER

Z-C

DSZC18

DELUXE SPLIT Z-C

Model/Rev Description

DSZC18**1AA

Initial release of Goodm an® brand Delux e 2-s t age 18 S E E R heat pum p unit s with R410A, communic ating models .

OMMUN ICATING HEAT PUMP R-410A 18 SEER

DSZC180(36/ 48/ 60)1A B Sanhua (RANCO) reversing valves.

DSZC180361 AD

DSZC180( 36 - 48) 1 AC

DSZC180601 BA

DSZC160( 24 - 48) 1 AD

DSZC160601 BB

Replaced c om pres sors ZPS20K4E P F V230 with ZPS20K5E P F V 130 and c om pres s or

ZPS30K4EPFV230 with ZPS30K5EPFV130.

Release of models wi t h ac cumulators and crankcase heaters.

Ultrat ec h® 2.0 com pres sor change.

AVPTC****14

SINGLE PIECE AIR HANDLER MULTIPLE-POSITION VA RIA BLE SPEED

AINTED TXV WITH 4 -WIRE COMMUNICATING CON TROL

P

Model/Rev Description

AVPTC183014AA

AVPTC313714AA

AVPTC426014AA

AVPTC183014AB

AVPTC313714AB

AVPTC426014AB

Initial release of 13 SEER air handler with communicating control and serial

com m unicating indoor blower mot or.

Replaced P CBJA 10 c om m unicating air handler c ont rol board wit h P CB JA103.

14

Page 15

PRODUCT IDENTIFICATION

AVPTC**14

SINGLE PIECE AIR HANDLER MULTIPLE-POSITION VARIABLE SPEED

AINTED TXV WITH 4-WIRE COMMUNICATING CONTROL

P

Model/Re v Description

AVPTC24B14AA

AVPTC(30/36)C14AA

AVPTC(42/48/60)D14AA

AVPTC48C14AA Updated S&R and travel labels.

Initial release of 13 SEER air handler with communicating control and serial

comm uni cating indoor blower motor. Redes ign of AV PTC models to new ai r handler

cabinetry. Incorporated 4-way, mult-position body utilized on ARTP/ASPt mdoels.

AVPTC(42/48/60)14AB

AVPTC60D14AC Serial plate update

AVPTC24B14AC

AVPTC30C14AB

AVPTC25B14AA

AVPTC29B14AA

AVPTC31C14AA

AVPTC37B14AA

AVPTC37C14AA

AVPTC37D14AA

AVPTC49D14AA

AVPTC59C14AA

AVPTC59D14AA

AVPTC61D14AA

AVPTC33C14AA

AVPTC39C14AA

AVPTC49C14AA

AVPTC35B14AA Introducing 2.5 and 3 Ton Air Handler product lines.

Redesign of AVPTC models to new air handler cabinetry. Incorporated 4-way, mul t position body utilized on ARTP/ASPt mdoels.

Heater Kit ai rflow update.

AV PTC Effi cienc y Upgrades

The new A V P TC redesign will i ncorporat e t he upgrade blower, c oil pan and coi l design

int e nded to inc rease effici en cy and standard i ze production.

Upgrade the current AVPTC C-49 cabinets to include 1. quality improvements captured in

Ready15 design. 2.include redesi gned drain pan, Morrison blower hous i ng and Em ers on

NXT Booster Charge Adjustable TXV.

AVPTC[31,37,39,49,59]C14AB

AVPTC[37,59,61]D14AB

AVPTC[25,29, 37]B14AB

AVPTC33C14AB

AVPTC[31, 37,39,49,59]C14AC

AVPTC49D14AB

AVPTC[37,59,61]D14AB

AVPTC35B14AA

Revis ions because of New Heater kit s released

Air handler revisions due to us i ng an upgraded (thic ker with higher R value)

Quietflex wrapper insulation.

The SR plate format i s chang i ng from SR075 to SR099 and in ord er to track t hi s chan ge

a minor revision is nec essary.

15

Page 16

PRODUCT IDENTIFICATION

MBVC

ODULAR BLOWER AIR HAN DLER V-MULT I-POSITION VARIABL E-SPEED

M

OMMUNICAT ING REA D Y W/4-WIRES

C

Model/Rev Description

MBVC1200AA1-AA

MBVC1600AA1-AA

MBVC2000AA1-AA

MBVC1200AA1-AB

MBVC1600AA1-AB

MBVC2000AA1-AB

MBVC1200AA1-AC

MBVC1600AA1-AC

MBVC2000AA1-AC

MBVC1200AA1-AD

MBVC1600AA1-AD

MBVC2000AA1-AD

MBVC[1200,1600,2000]A A 1-A E Release of MBR/MBVC Models (M inor Revisions) for 11th St Plant. - Dayton to Houston

Introducti on of module blower with variabl e s peed blower motor wit h t he new

comm uni c at i ng c ont rol & s erial c om m unicating indoor blower motor.

Introducti on of a module blower with variable speed blower mot or wit h communic at ing

cont rol & s eri al c om m unicating indoor blower motor. Replac es exist ing E m ers on motors

(013M00111 & 013M00112).

Introducti on of a module blower with variable speed blower mot or wit h communic at ing

cont rol & s eri al c om m unicating indoor blower motor. Quali t y improvement t o us e 0.75"

Quiet Flex Insulation.

Introducti on of a module blower with variable speed blower mot or wit h communic at ing

cont rol & s eri al c om m unicating indoor blower motor. Introduc es a new Communic ating Air

Handler Control Board (PC).

MBVC[1200,1600,2000]AA1-AF

Add permanent s eali ng/ condensation-c ont rol upgrades t o all MB units and remove highvolt age knockout s

CAUF

INDOOR COIL A-UPFLOW/DOWNFLOW UNCASED FLOWRATOR

C-

Model/Rev Description

CAUF*****6AA Initial release of CAUF Dayton Upflow/ Downfl ow coil s .

CAUF*****6BA Burr Oak Louvered Fin released in place of the Wavy Fin.

CAUF****6*DA Replace d

CAUF*****6DB Drain pan material c hanged.

CAUF1824A6RDB

CAUF1824B6RDB

CAUF36***CA Redesign from 2 row to 3 row for performanc e im provement .

CAUF3030(A/B)6RDB

CAUF3030(C/D)6RDB

CAUF3131(B/C)6RDB

Manufact uring Loc at i on Change from Dayton t o Hous t on. Designated by "R".

Manufact uring Loc at i on Change from Dayton t o Hous t on. Designated by "R".

exi s ting copper coi ls and other ass ociated parts with aluminum components .

16

Page 17

PRODUCT IDENTIFICATION

CHPF

-INDOOR COIL HORIZONTAL A-COIL PAINTED FLOWRATOR

C

Model/Rev Description

CHPF*****6AA Intial release of 13 S E E R CHPF horizont al A c oi l.

CHPF*****6BA

CHPF1824A6CA

CHPF2430B6CA

CHPF3636B6CA

CHPF3642C6CA

CHPF3642D6CA

CHPF3743C6BA

CHPF3743D6BA

CHPF4860D6DA

CHPF1824A6CB

CHPF2430B6CB

CHPF3636B6CB

CHPF3642C6CB

CHPF3642D6CB

CHPF3743C6BB

CHPF3743D6BB

CHPF4860D6DB

CHPF1824A6CC

CHPF2430B6CC

CHPF3636B6CC

CHPF3642C6CC

CHPF3642D6CC

CHPF3743C6BC

CHPF3743D6BC

CHPF4860D6DC

Released B urr Oak Louvered Fin in place of the Wavy F i n. The rows changed by one, (i. e.

4 row to 3 row; 3 row to 2 row) where appli cable.

Louvered fins. Replaced copper tube hairpins wi t h al umi num hairpins.

Drain pan material change to a Decabromodipheny l E t her free resin.

Change to prepainted wrappers

17

Page 18

PRODUCT IDENTIFICATION

CAPF

INDOOR COIL A-UPFLOW/DOWNFLOW PAINTED FLOWRATOR

C-

Model/Rev Description

CAPF*****6A A Initial release of CAPF Dayt on Upflow/Downflow coils .

CAPF*****6B A Burr Oak Louvered Fin released in place of the Wavy F in.

CAPF36***CA Redesigned for performance improvement from 2 row t o 3 row.

CAPF* ****6DA Replaced exi sting c opper c oil s and other ass ociated parts with aluminum components .

CAPF*****6DB Drain pan mat erial c hanged.

CAPF182 4A6DC

CAPF182 4B6DC

CAPF182 4C 6D C

CAPF303 0A6DC

CAPF303 0B6DC

CAPF303 0C 6D C

CAPF303 0D 6D C

CAPF313 1B6DC

CAPF313 1C 6D C

CAPF313 7B6AB

CAPF363 6A6DC

CAPF363 6B6DC

CAPF363 6C 6D C

CAPF363 6D 6D C

CAPF364 2C 6D C

CAPF364 2D 6D C

CAPF374 3C 6D C

CAPF374 3D 6D C

CAPF486 0C 6D C

CAPF486 0D 6D C

CAPF496 1C 6D C

CAPF496 1D 6D C

Redesign t he wrapper for the CAPF t o provide increased eas e of ins tallati on.

C-

Model/Rev Description

CAPT3131B4BA

CAPT3131C4BA

CAPT3743C4AA

CAPT3743D4AA

CAPT4961C4AA

CAPT4961D4AA

CAPT3131B4AB

CAPT3131C4AB

CAPT3743C4AB

CAPT3743D4AB

CAPT4961C4AB

CAPT4961D4AB

18

INDOOR

CAPT

COIL

UPFLOW /DOWNFLOW PAINTED CASED FLOWRATOR W/TXV

A-

Initial release of coils with factory-installed, non-adjus table TXV . Single s t age A HRI ratings

for CAPT3131 NTC combinat i ons .

Initial release of single s t age A HRI ratings for CAPT3743 NTC c ombi nat i ons .

Initial release of single s t age A HRI ratings for CAPT4961C4 NTC com binations.

Redesign t he wrapper for the CAPT to provide inc reased ease of inst all at i on.

Page 19

PRODUCT IDENTIFICATION

CSCF

INDOOR COIL S-HORIZONTAL SLAB COIL C-UNPAINTED FLOWRATOR

C-

Model/Rev Description

CSCF*****6AA Initial release of 13 SEER CSCF horizontal slab coils.

CSCF*****6BA

CSCF1824N6BB

CSCF3036N6BB

CSCF3642N6CB

CSCF4860N6CB

CSCF1824N6CA

CSCF3036N6CA

CSCF3642N6CA

CSCF4860N6CA

Burr Oak Louvered F in releas ed i n place of the Wavy Fin. Rows reduc ed by one where

applicable.

Drain pan material changed.

Replaced c opper c oil s and other ass oc i at ed part s with alumi num components .

19

Page 20

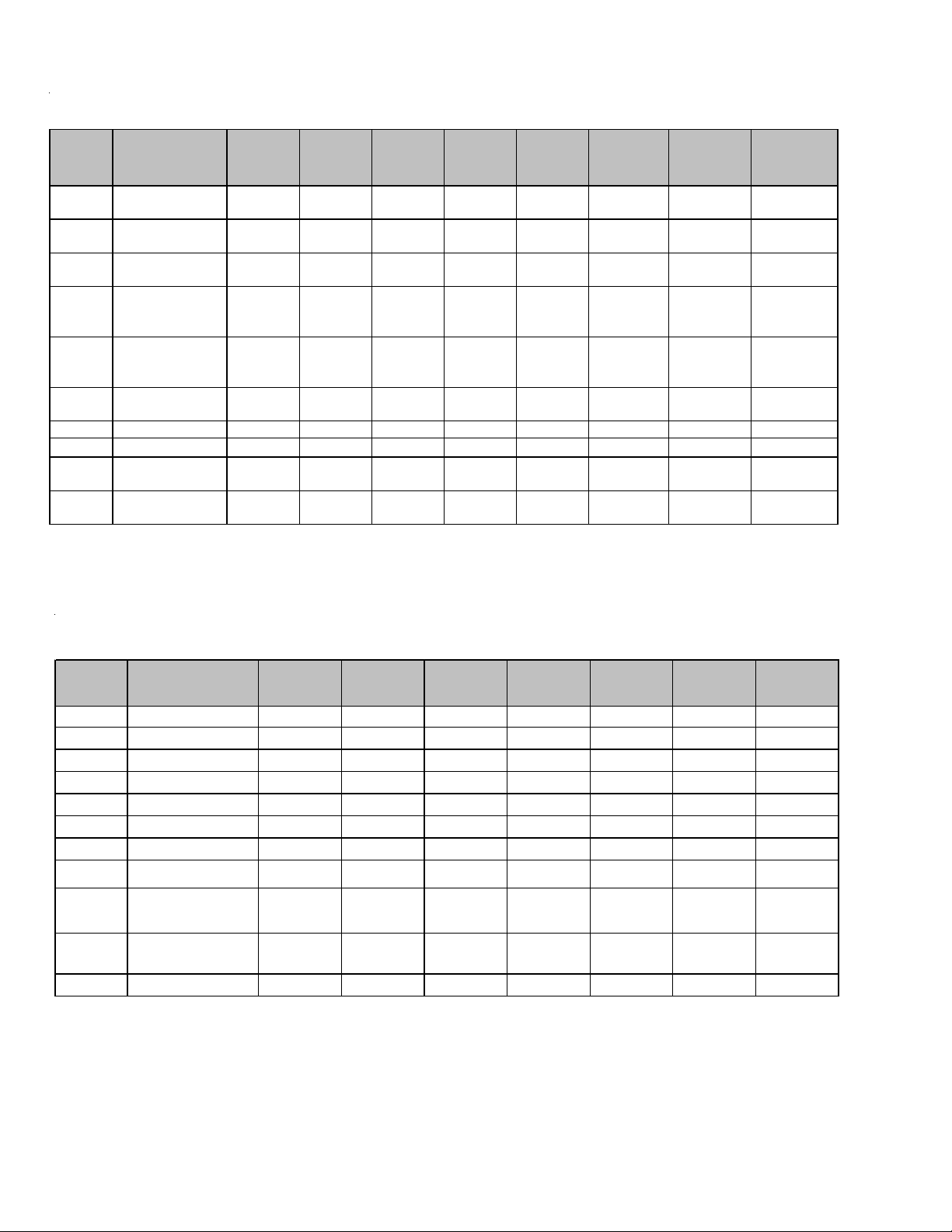

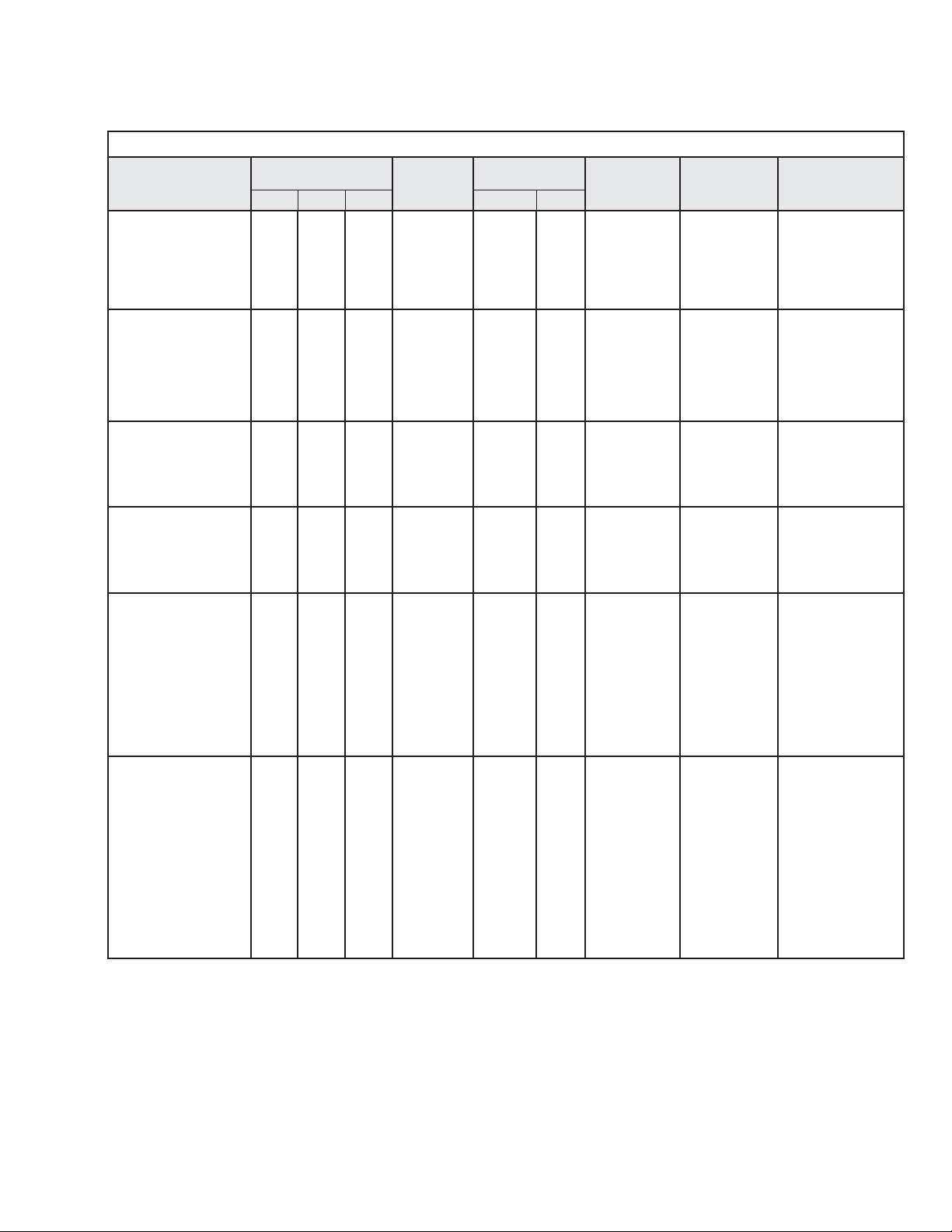

ACCESSORIES

ComfortNet™

ASXC/DSXC 16

ASXC/DSXC/GSXC 18

Model Description

ABK-20 Anchor B racket Kit X X X X X X X X

ASXC16024

DSXC16024

ASXC16036

DSXC16036

ASXC16048

DSXC16048

ASXC16060

DSXC16060

ASXC18024

DSXC18024

GSXC18024

ASXC18036

DSXC18036

GSXC18036

ASXC18048

DSXC18048

GSXC18048

ASXC18060

DSXC18060

GSXC18060

TX2N4A TXV Kit

TX3N4 TXV Kit

TX5N4 TXV Kit

CSR-U-1 Hard-start Kit

CSR-U-2 Hard-start Kit

CSR-U-3 Hard-start Kit

1

FSK01A

LSK02*

B1141643

* Contains 20 brackets; four brackets needed to anchor unit to pad.

Installed on the indoor coil.

Available in 24V legacy mode only. This feature is integrated in the communicating mode.

This component is included in the CTK0*** communicating thermostat kit.

Freeze Prot ection Kit

Liquid Line Solenoid

Valve

3

24V Transformer

XX

XX

XX X X

XX

XX

XX X X

XXXXX X X X

XXXXX X X X

XXXXX X X X

ASZC/DSZ C 16

ASZC/DSZ C 18

Model Description

ASZC16024

DSZC16024

ABK-20Anchor Bracket KitXXXXXXX

1

TX2N4

TX3N4

TX5N4

TXV Kit X

1

TXV Kit X X

1

TXV Kit X X X X

CSR- U-1 Hard -star t Kit X X X

CSR- U-2 Hard -star t Kit X X X X X X

CSR- U-3 Hard -star t Kit X X X X

2

FSK01A

LSK02*

OT18-60A

B1141643

Freeze Protection KitXXXXXXX

Liquid Line Solenoid

Valve

Outdoor Thermostat/

3

Lockout Thermostat

4

24V TransformerXXXXXXX

XXXXXXX

XXXXXXX

ASZC16036

DSZC16036

ASZC16048

DSZC16048

ASZC16060

DSZC16060

ASZC18036

DSZC18036

ASZC18048

DSZC18048

ASZC18060

DSZC18060

20

* Conta ins 20 bracke t s; four brack et s needed to ancho r unit to pad

1

Field -installed, non-bleed, ex p ans i on valve k i t - Condensing unit s and heap pumps wi t h reciprocat i ng c o mp res sors require t he

use of s t art -assist com ponent s when used in conjunct i on with an indoor coil using a non-bleed the rmal expansion valve

refrigerant

2

Insta ll ed on t he i ndoor c oi l

3

Available in 24V l egacy mode onl y. This feature is integrat ed i n t he c om m uni c ating mode. Requi red for heat pum p appl ications

where ambient t em pe rat ure fall bel ow 0 °F with 50% or higher relat i ve humidit y.

4

This c om ponent i s incl uded in the CTK 0*** c omm unic at ing t hermost at kit.

Page 21

ACCESSORIES

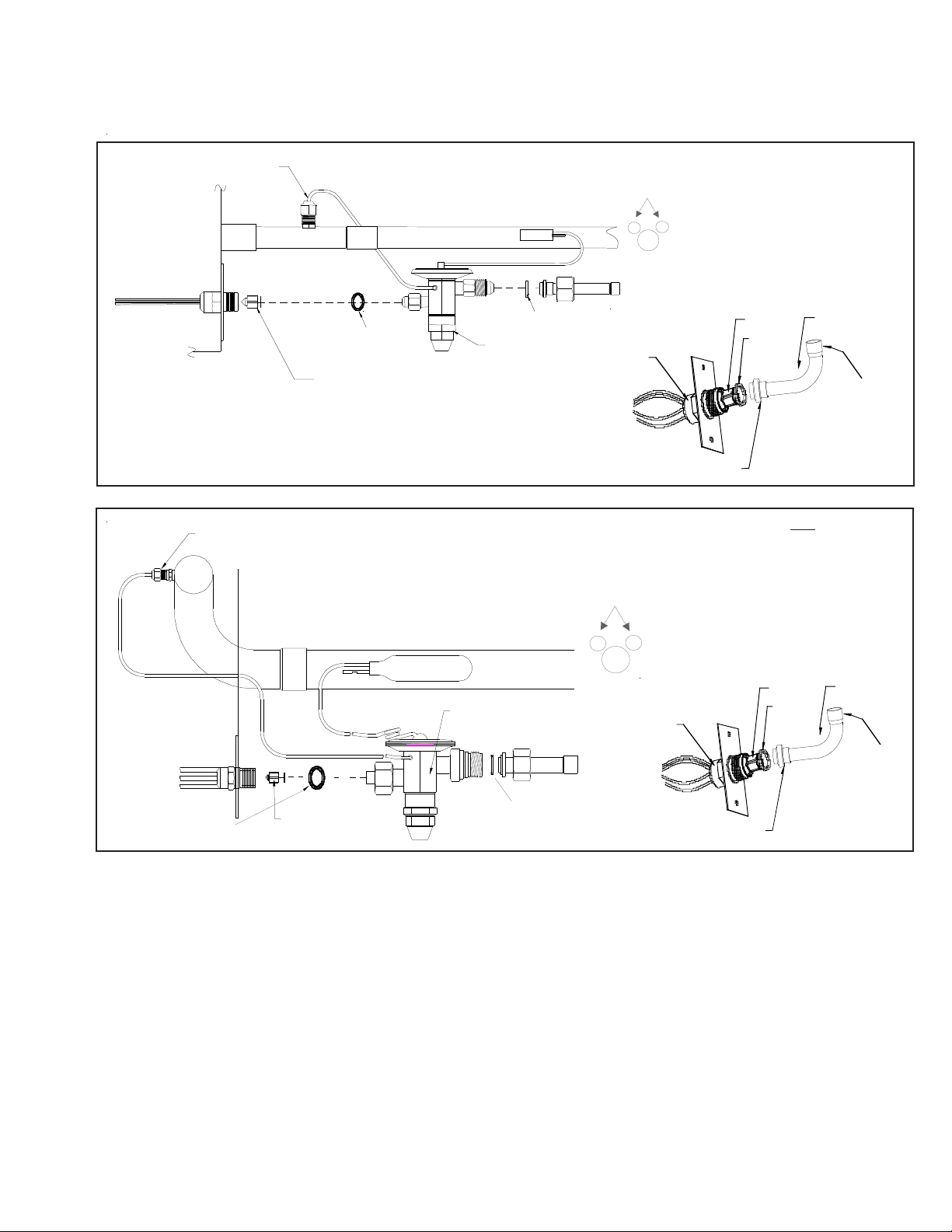

EXP ANSION VALVE KITS

1/4 FLARE CONNECTION

BULB TO BE LOCATED

AT 10 OR 2 O'CLOCK

For Applications requiring

a field installed access fitting

EVAPORATOR COIL

EVAPORATOR COIL

1/4' F L A RE

CONNECTION

SEAL SUPP L IE D W/ KIT

REMOVE BEFORE INSTALLI NG EXP ANS IO N VALVE

SUCTION LINE

BULB

EXPANSION VALVE

SUCTION LINE

EXPANSION VALVE

BULB

SEAL SUPPLIED W/ KIT

BULB TO BE LOCATED

AT 10 OR 2 O'CLOCK

DISTRIBUTOR

BODY

For Applications not requiring

a field installed access fitting

DISTRIBUTOR

BODY

7/8" NUT

PISTON

SEAL

PISTON

SEAL

TAILPIECE

3/8"SWEAT

TAILPIECE

3/8"SWEAT

SEAL SUPPLIED W/ KIT

REMO VE BEFORE

INSTALLING

EXPANSION VALVE

SEAL SUPPLIED W/ KIT

7/8" NUT

21

Page 22

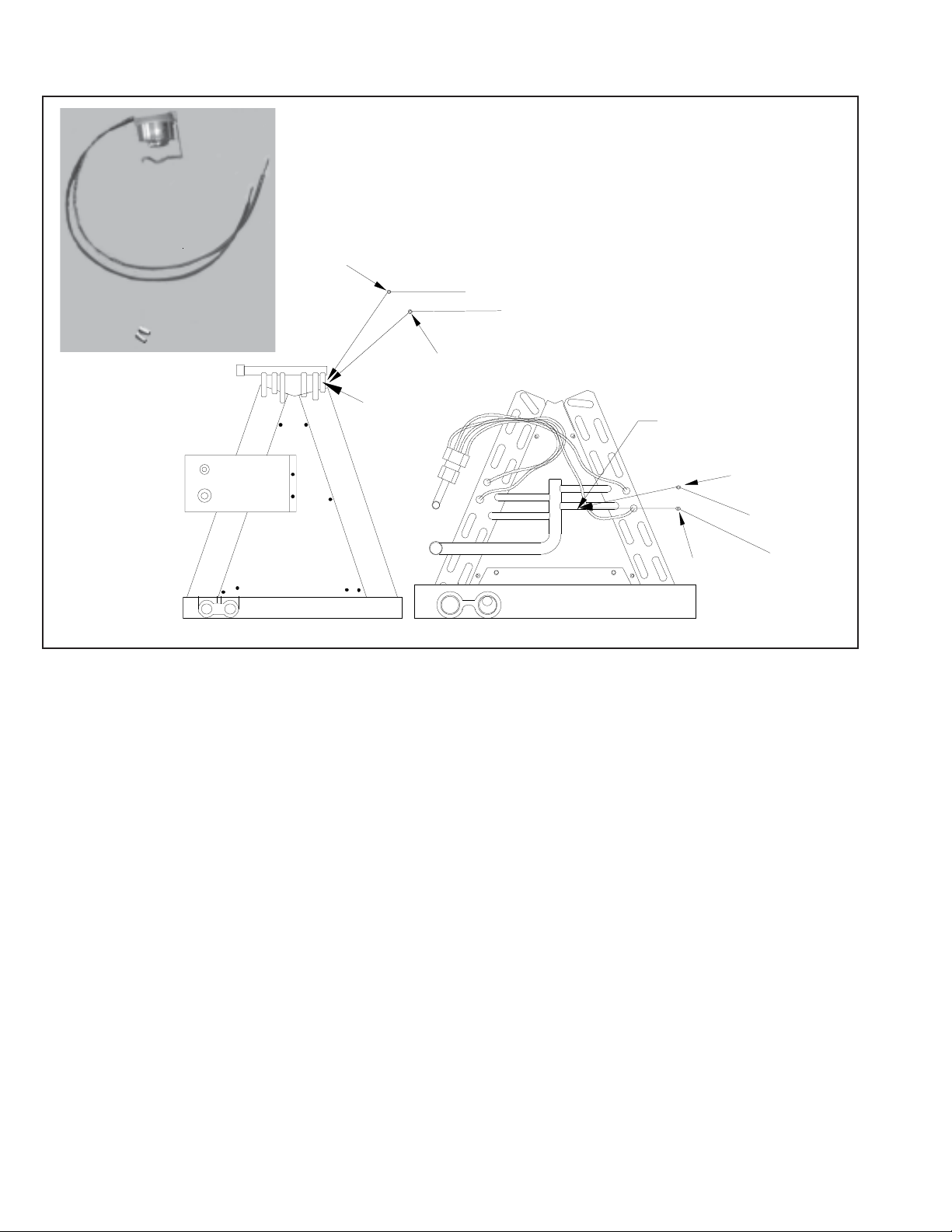

ACCESSORIES

Wire Nut

FSK01A

FREEZE THERMOSTAT

KIT

Y

k

c

a

l

B

k

c

a

l

B

Wire Nut

Y

Install Line

Thermostat

Here

Install Line

Thermostat

Here

B

l

a

c

B

l

Wire Nut

Wire Nut

Y

k

a

c

k

Y

22

Page 23

ACCESSORIES

BLOWER

ELECTRIC HEAT KIT

NO HEAT

MBVC1200 AA-1* *

MBVC1600 AA-1* *

MBVC2000 AA-1* *

X = A llowable combinations

- = Restricted combinations

-XXXXXX- - -

-XXXXXX- - -

-XXXXX- X- -

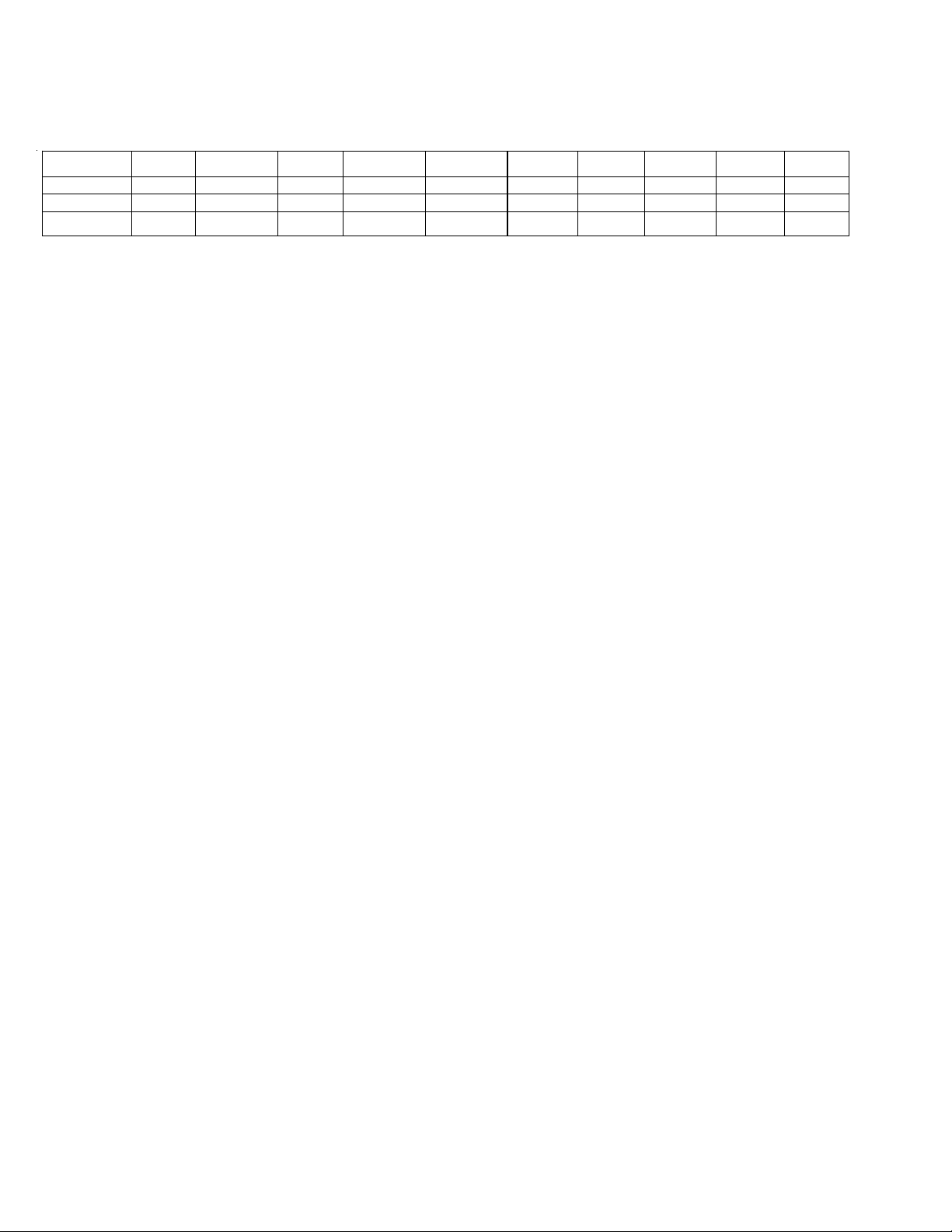

ELECTRIC HEAT KIT APPLICATIONS - MBVC

HKR-03*

^ = Circuit 1: Single P hase for A ir Handler Motor

Circuit 2: 3-Phase for HKR3 Heater Kits

HKR05-(C)'

HKR-06*

HKR-08(C)*

HKR-10(C)*

HKA-15C*

HK* SERIES ELETRIC HEA T KITS -

HKA-20C*

^HKR3-15*

^HKR3-20A

23

Page 24

ACCESSORIES

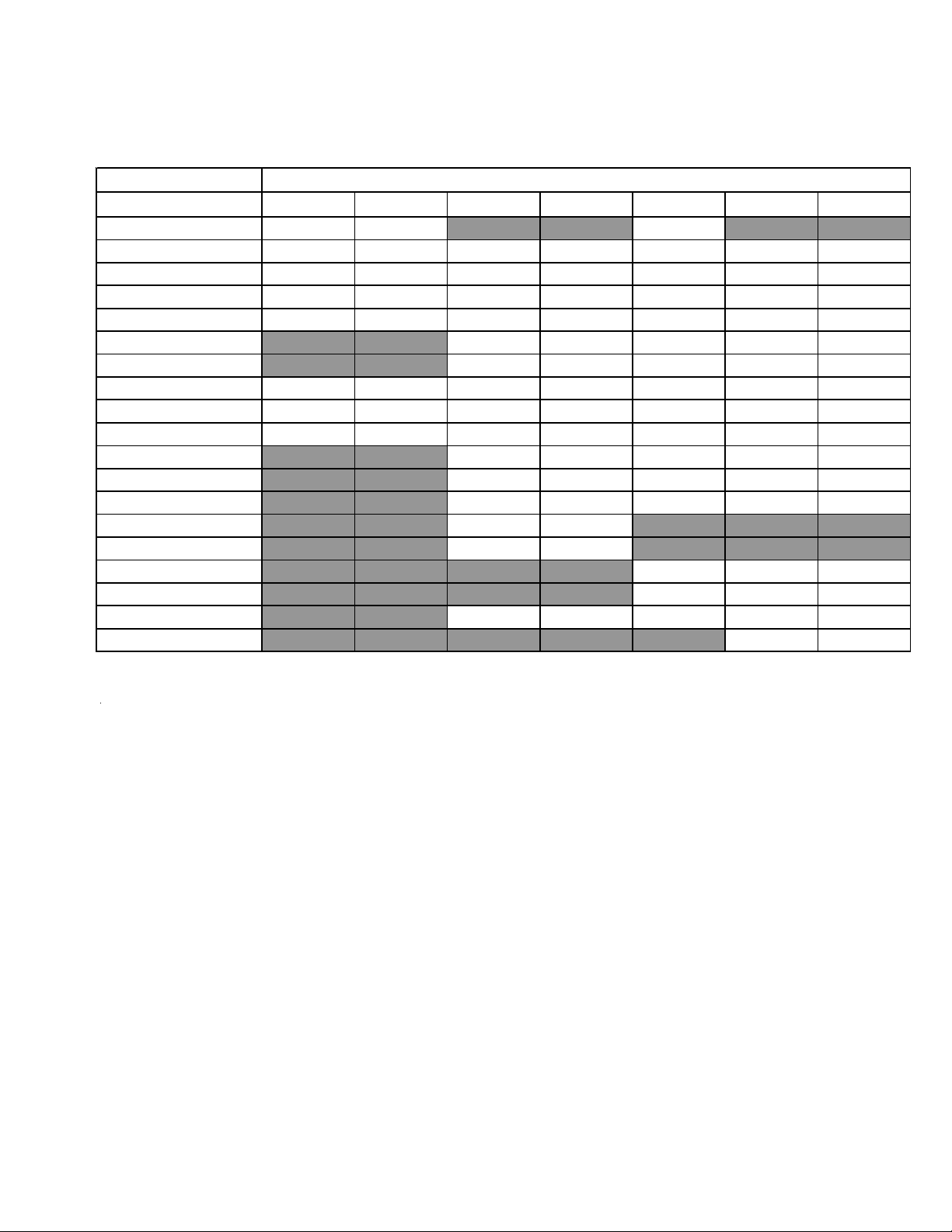

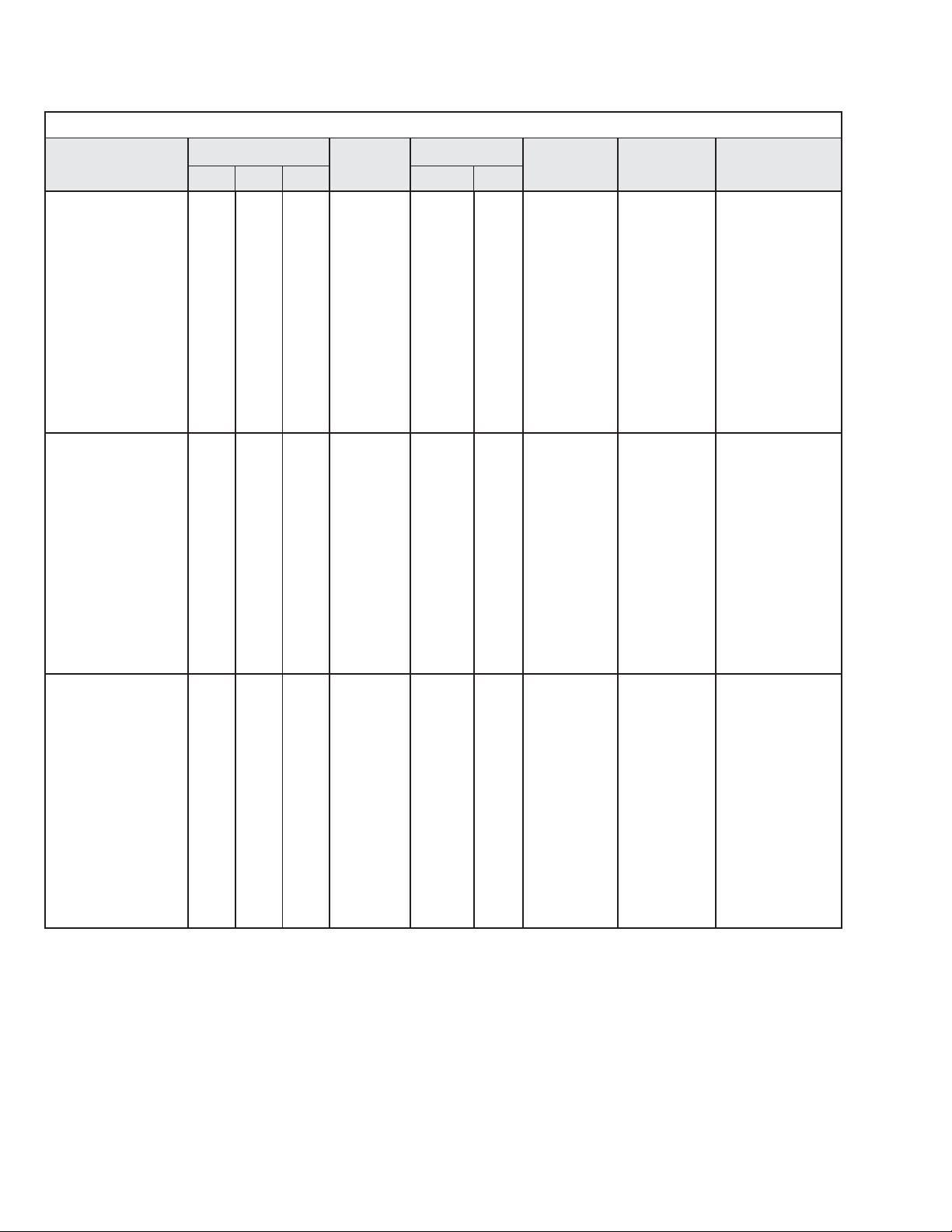

ELECTRIC HEAT KIT APPLICATIONS - A VPTC

MODELS HKR-03* HKR-05*/-05C* HKR-06* HKR-08*/-08C* HKR-10*/-10C* HKR-15C* HKR-20C* HKR-21C* HKA-15C* HKA-20C*

AVPTC183014A* X X X

AVPTC313714A* X X X

AVPTC426014A* X X X X X X X3 X3 X

* Revision level that may or may not be designated.

C Circuit breaker option.

NOTE:

When 8kW and 10kW heat kits are used with an AVPTC1830 and AVPTC3137, matched with 2- ton outdoor unit, see Note 1 below.

1

Set Heater Kit dip switches 9, 10 and 11 to 6kW setting (9-ON, 10-OFF,11-ON) to obtain 840 CFM.

2

This heater kit can only be used for ‘1000 CFM or higher’ applications.

3

This heater kit can only be used for ‘1200 CFM or higher’ applications.

1

X

1

X

1

X

1

X

--- --- --- --- ---

X 2 --- ---

2

X

X

3

X

24

Page 25

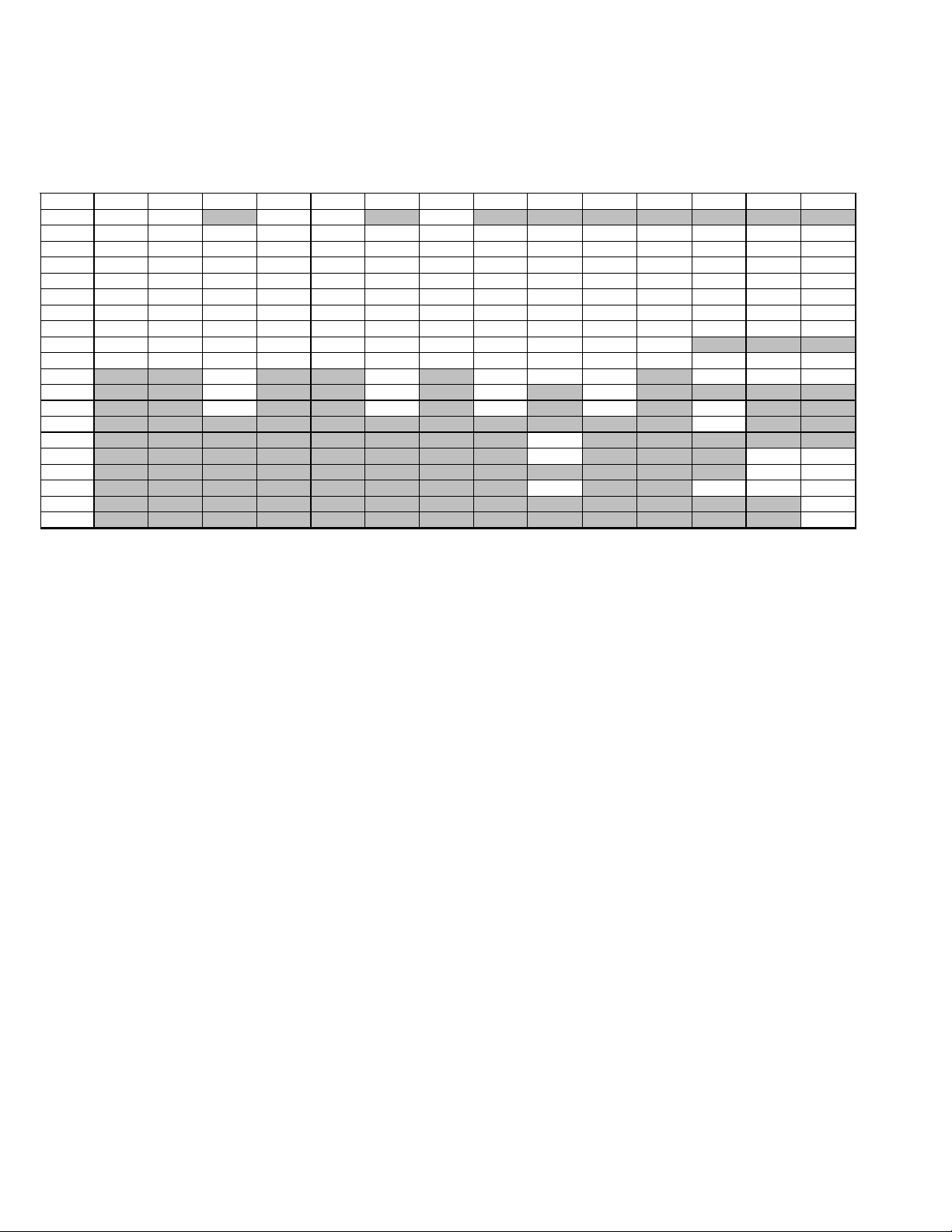

ACCESSORIES

p

p

p

p

p

AVPTC**14**

Heat Kit Applications

Type / Model 24B14-A* 30C14-A* 36C14-A* 48C14-A* 42D14-A*

HKSX03XC X X X

HKSX05XC XXXXXXX

HKSX06XC XXXXXXX

HKSX08XC XXXXXXX

HKSX10XC XXXXXXX

HKSX15XF* XXXXX

HKSX20XF* XXXXX

HKSC05XC XXXXXXX

HKSC08XC XXXXXXX

HKSC10XC XXXXXXX

HKSC15XA XXXXX

HKSC15XB XXXXX

HKSC15XF* XXXXX

HKSC19CA* X X

HKSC19CB* X X

HKSC20DA XXX

HKSC20DB XXX

HKSCX20XF* XXXXX

HKSC25DC* XX

* Revision level that may or may not be designated.

Refer to the minimum airflow requirements for each of the heat kits.

AVPTC

†

48D14-A*

††

60D14-A*

†††

†For m atch u p wi th a 2 ton outdoo r uni t: Hea ter ki t ap pli caƟon shall not exceed 10 kW.

Airflow for 5 kW u

††For ma tch u

Airflo w for 5 kW u

†††For ma tch u

Airflo w for 5 kW u

** 3 kW heater kit is not applicable for this indoor application.

to 10 kW hea ter ki ts s hall be s et to 850 cfm speed tap of ON-ON-ON.

wi th a 3 ton ou tdoo r uni t: Hea ter ki t applicaƟon shall not exceed 15 kW.

to 15 kW hea ter ki ts s hall be s et to 1400 cfm speed tap of ON-ON-OFF.

wi th a 3.5 ton ou tdoo r uni t: Hea ter ki t applicaƟon shall not exceed 20 kW.

to 20 kW hea ter ki ts s hall be s et to 1620 cfm speed tap of ON-ON-OFF

25

Page 26

ACCESSORIES

READY 15 AVPTC

Model AVPTC25B14 AVPTC29B14 AVPTC31C14 AVPTC33C14 AVPTC35B14 AVPTC39C14 AVPTC37B14 AVPTC37C14 AVPTC37D14 AVPTC49C14 AVPTC49D14 AVPTC59C14 AVPTC59D14 AVPTC61D14

HKSX03XC XX XX X

HKSX05XC XXXXXXXXXXXXXX

HKSX06XC XXXXXXXXXXXXXX

HKSX08XC XXXXXXXXXXXXXX

HKSX10XC XXXXXXXXXXXXXX

HKSC05XC XXXXXXXXXXXXXX

HKSC08XC XXXXXXXXXXXXXX

HKSC10XC XXXXXXXXXXXXXX

HKSC15XA XXXXXXXXXXX

HKSC15XB XXXXXXXXX XXXXX

HKSC15XF XXXXXXXX

HKSC19CA XXXX

HKSC19CB XXXXX

HKSC19CH X

HKSC20DA X

HKSC20DB XXX

HKSC20DH XX

HKSC20XF XXXX

HKSC25DA X

HKSC25DB X

26

Page 27

PRODUCT DESIGN

This section gives a basic description of cooling unit operation, its various components and their basic operation.

Ensure your system is properly sized for heat gain and loss

according to methods of the Air Conditioning Contractors

Association (ACCA) or equivalent.

CONDENSING UNIT

The condenser air is pulled through the condenser coil by a

direct drive propeller fan. This condenser air is then discharged out of the top of the cabinet. These units are

designed for free air discharge, so no additional resistance,

like duct work, shall be attached.

The suction and liquid line connections on present models

are of the sweat type for field piping with refrigerant type

copper. Front seating valves are factory installed to accept

the field run copper. The total refrigerant charge for a normal

installation is factory installed in the condensing unit.

ASXC, ASZC, DSXC, DSZC models are available in 2

through 5 ton sizes and use R-410A refrigerant. They are

designed for 208/230 volt single phase applications.

ASXC, ASZC, DSXC, DSZC R-410A model units use the

Copeland Scroll "Ultratech" Series compressors which are

specifically designed for R-410A refrigerant. These units also

have Copeland

ComfortAlert diagnostics are integrated into the unitary (UC)

control. These models are ComfortNetTM ready.

There are a number of design characteristics which are

different from the traditional reciprocating and/or scroll compressors.

"Ultractech" Series scroll compressors will not have a discharge thermostat. Some of the early model scroll compressors required discharge thermostat.

"Ultratech" Series scroll compressors use "POE" or

polyolester oil which is NOT compatible with mineral oil

based lubricants like 3GS. "POE" oil must be used if

additional oil is required.

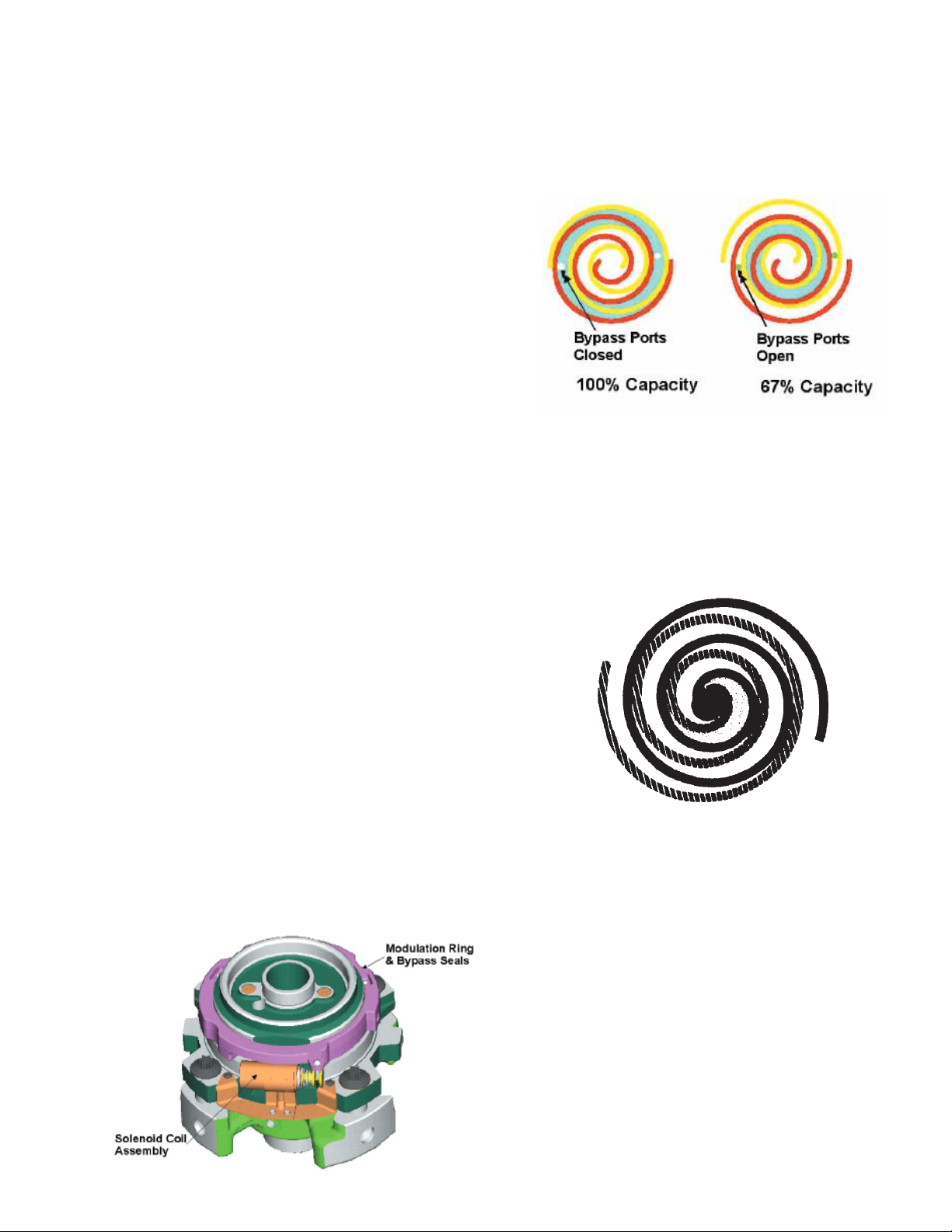

The ASXC [16 & 18], ASZC [16 & 18], DSXC [16 & 18] and

DSZC [16 & 18] series split system units use a two-stage

scroll compressor. The two-step modulator has an internal

unloading mechanism that opens a bypass port in the first

compression pocket, effectively reducing the displacement

of the scroll. The opening and closing of the bypass port is

controlled by an internal electrically operated solenoid.

®

ComfortAlert diagnostics. The Copeland

The ZPS two-step modulated scroll uses a single step of

unloading to go from full capacity to approximately 67%

capacity. A single speed, high efficiency motor continues to

run while the scroll modulates between the two capacity

steps.

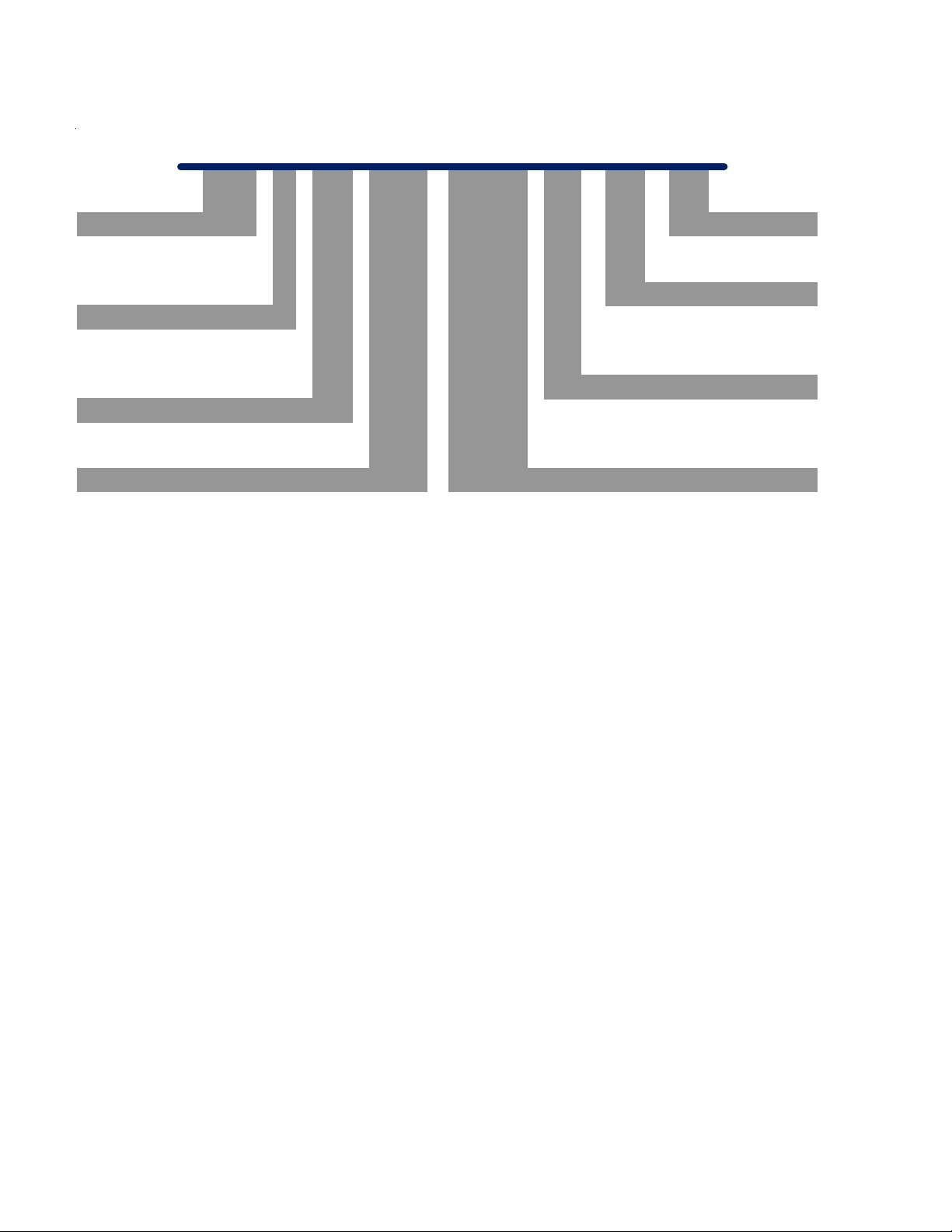

FIGURE A

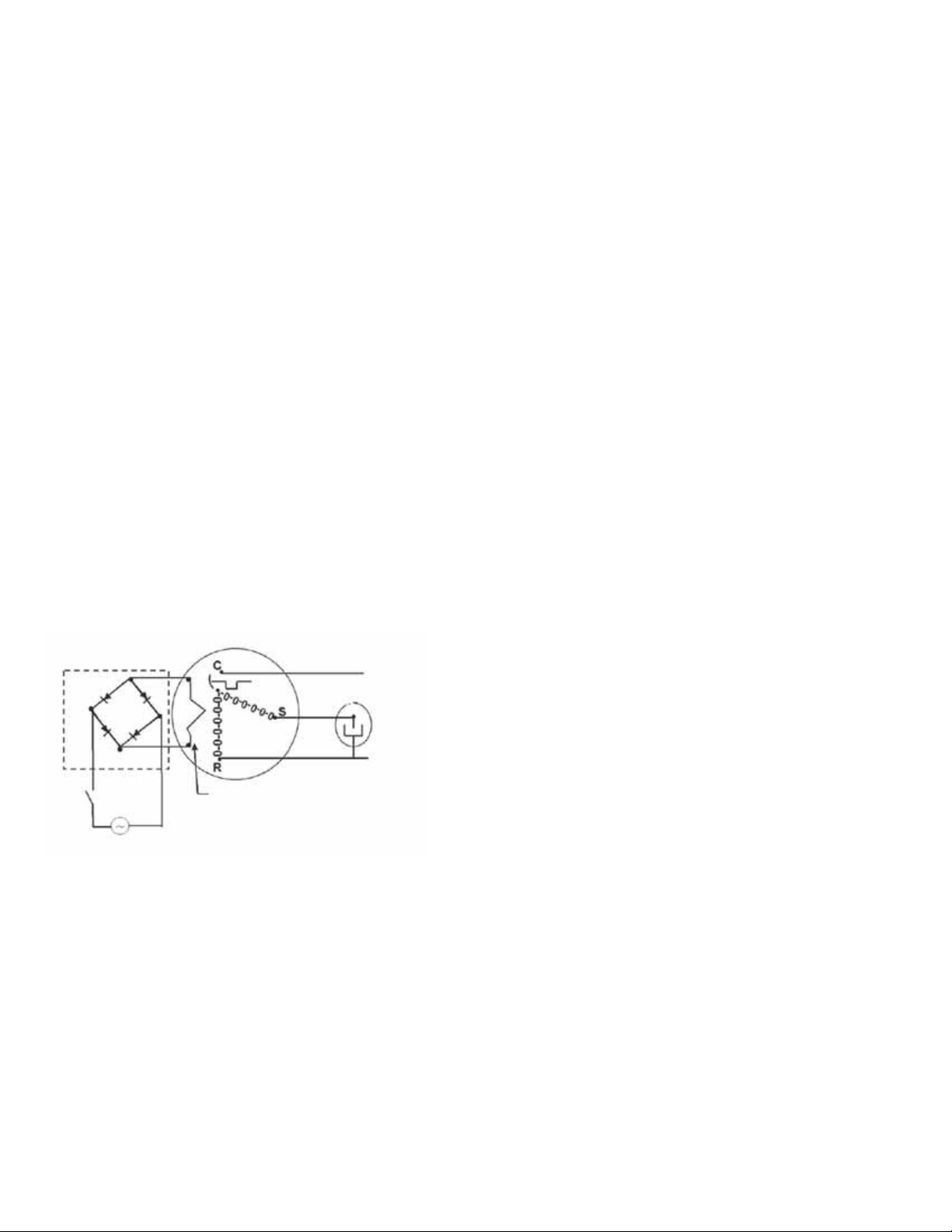

A scroll is an involute spiral which, when matched with a

mating scroll form as shown, generates a series of crescent

shaped gas pockets between the two members.

During compression, one scroll remains stationary (fixed

scroll) while the other form (orbiting scroll) is allowed to orbit

®

(but not rotate) around the first form.

As this motion occurs, the pockets between the two forms

are slowly pushed to the center of the two scrolls while

simultaneously being reduced in volume. When the pocket

reaches the center of the scroll form, the gas, which is now

at a high pressure, is discharged out of a port located at the

center.

During compression, several pockets are being compressed

simultaneously, resulting in a very smooth process. Both the

suction process (outer portion of the scroll members) and the

discharge process (inner portion) are continuous.

Some design characteristics of the Compliant Scroll compressor are:

• Compliant Scroll compressors are more tolerant of liquid

refrigerant.

NOTE: Even though the compressor section of a Scroll

compressor is more tolerant of liquid refrigerant, continued floodback or flooded start conditions may wash oil

from the bearing surfaces causing premature bearing

failure.

27

Page 28

PRODUCT DESIGN

• Compliant scroll compressors perform "quiet" shutdowns

that allow the compressor to restart immediately without

the need for a time delay. This compressor will restart

even if the system has not equalized.

NOTE: Operating pressures and amp draws may differ

from standard reciprocating compressors. This information can be found in the unit's Technical Information

Manual.

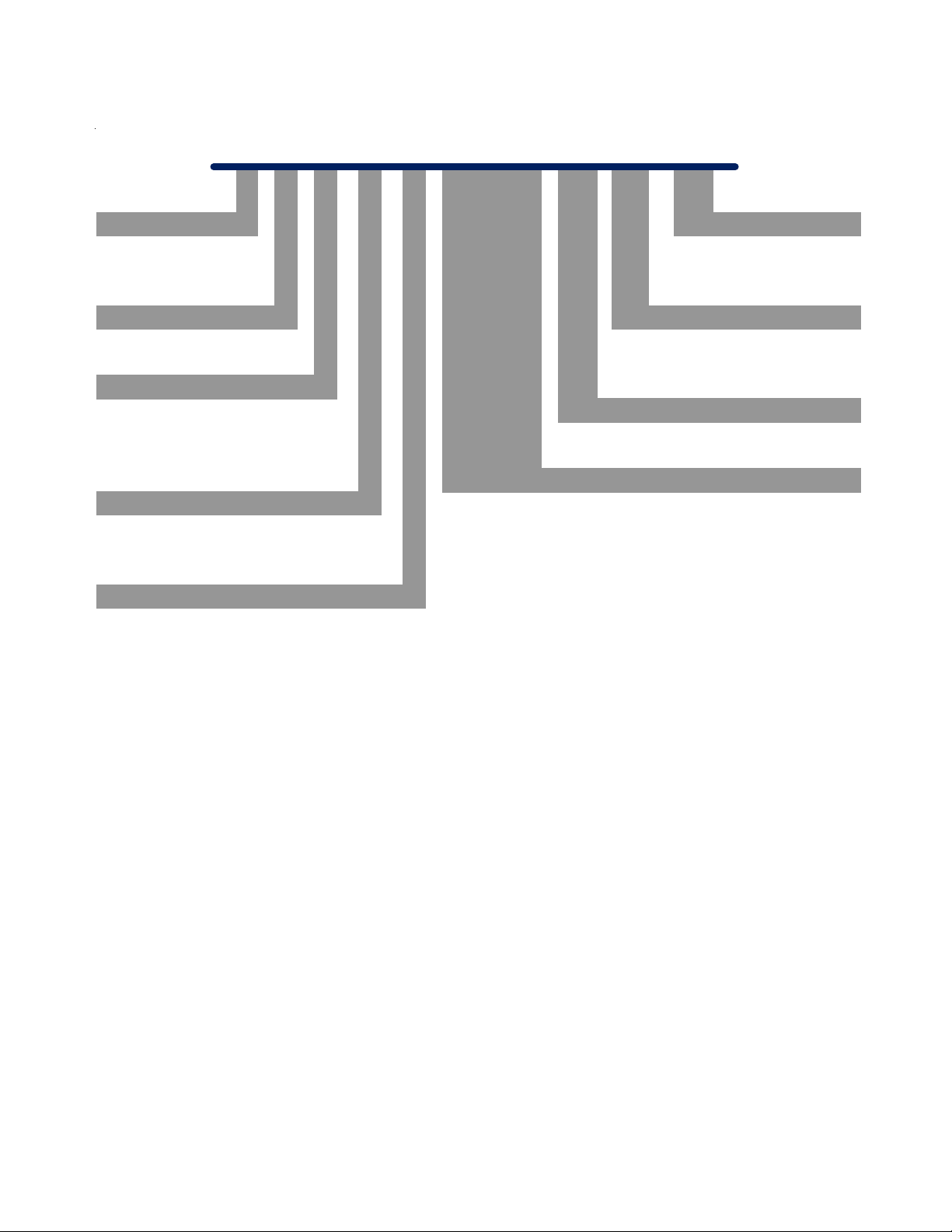

CAPACITY CONTROL - COMFORTNET

TM

MODELS

During the compression process, there are several pockets

within the scroll that are compressing gas. Modulation is

achieved by venting a portion of the gas in the first suction

pocket back to the low side of the compressor thereby

reducing the effective displacement of the compressor. See

Figure A. Full capacity is achieved by blocking these vents,

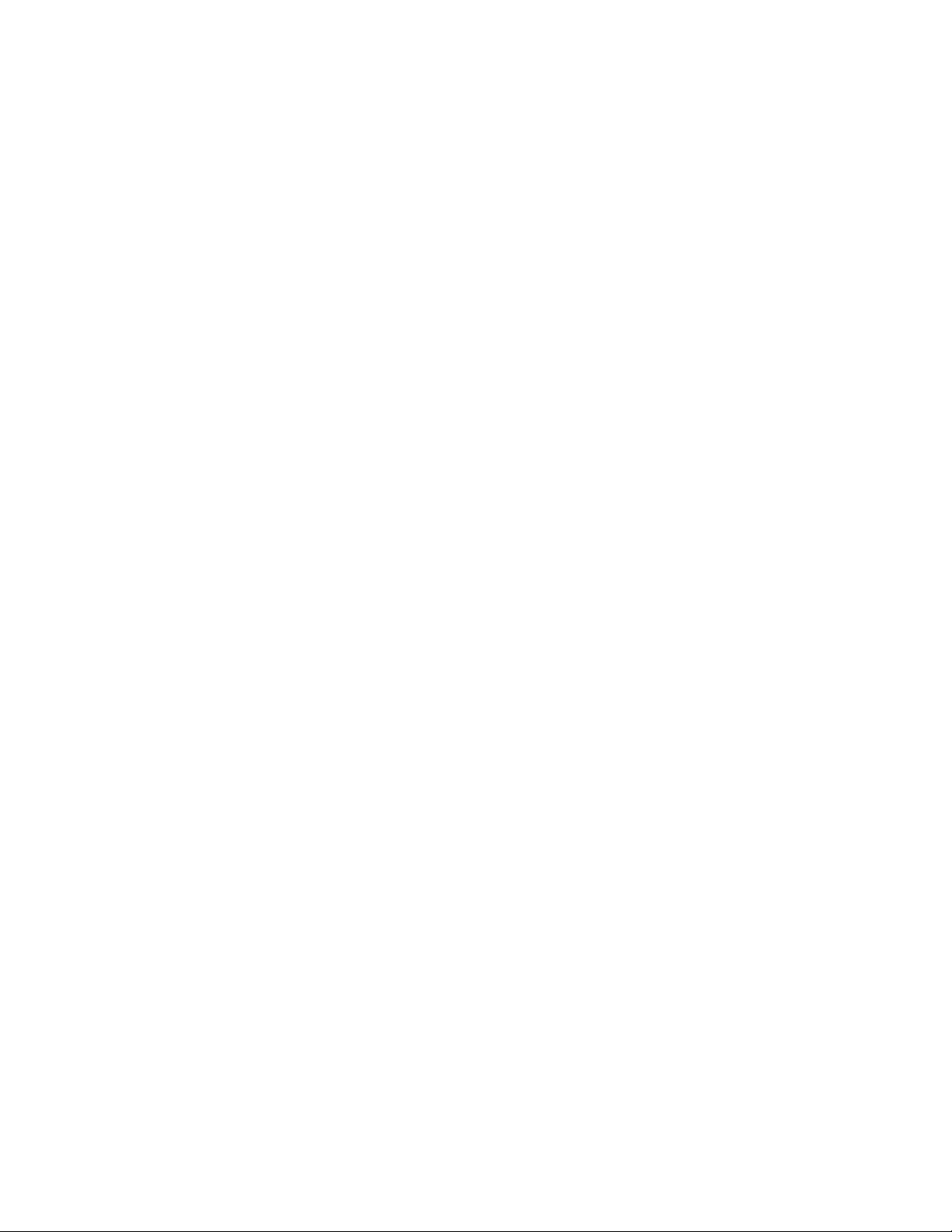

increasing the displacement to 100%. A solenoid in the

compressor, controlled by an external 24-volt ac signal,

moves the slider ring that covers and uncovers these vents.

The vent covers are arranged in such a manner that the

compressor operates somewhere around 67% capacity

when the solenoid is not energized and 100% capacity when

the solenoid is energized. The loading and unloading of the

two step scroll is done “on the fly” without shutting off the

motor between steps. See Figure C below. The unloaded

mode default was chosen for two reasons:

Molded Plug*

Line

Run Capacitor

Line

Internal Unloader

Coil

24 vdc

*Rectifier is integrated on the UC PC B

FIGURE C

1. It is expected that the majority of run hours will be in the

low capacity, unloaded mode.

2. It allows a simple two-stage thermostat to control capacity through the second stage in both cooling and possibly

heating if desired.

18 to 28 volt ac. The coil power requirement is 20 VA. The

external electrical connection is made with a molded plug

assembly. This plug is connected to the Communicating

Unitary Control PCB (UC PCB) which contains a full wave

rectifier to supply direct current to the unloader coil.

COILS AND BLOWER COILS

MBVC blower cabinets are designed to be used as a twopiece blower and coil combination and can be utilized with the

CAUF, CAPF and CAPT coils for upflow and downflow

applications. The CACF and CHPF coils are designed for

horizontal applications. This two-piece arrangement allows

for a variety of mix-matching possibilities providing greater

flexibility.

The MBVC blower cabinets use a variable speed motor that

maintains a constant airflow with a higher duct static. MBVC

blower cabinets are approved for applications with cooling

coils of up to 0.8 inches W.C. external static pressure. The

MBVC models allow airflow trimming of +/-10%.

All units are constructed with R-4.2 insulation. In areas of

extreme humidity (greater than 80% consistently), insulate

the exterior of the blower with insulation having a vapor barrier

equivalent to ductwork insulation, providing local codes

permit.

AVPTC Multi-Position Air Handler

AVPTC is a multi-position, variable-speed air handler used

with R-410A and are available in 2 to 5 ton sizes with optional

3 kW to 25kW electric heat kits available for field installation.

The AVPTC unit’s blower design includes a variable-speed

ECM motor and is compatible with heat pumps and variablecapacity cooling applications.

This appliance can be installed in the vertical or left horizontal

position without modification. The horizontal right and downflow

positions require product modification. This product is designed for zero inches (0 inches) clearance; however, adequate access for service or replacement must be considered without removing permanent structure. This unit can be

installed on a platform when deemed necessary.

In an attic installation a secondary drain pan must be provided

by the installer and placed under the entire unit with a

separate drain line properly sloped and terminated in an area

visible to the owner. This secondary drain pan is required in

the event that there is a leak or main drain blockage. Closed

cell insulation should be applied to the drain lines in unconditioned spaces where sweating may occur.

UNLOADER SOLENOID

A nominal 24-volt direct current coil activates the internal

unloader solenoid. The input control circuit voltage must be

28

Page 29

PRODUCT DESIGN

NOTE: AVPTC air handlers are factory-sealed to achieve a

2% or less leakage rate at 1.0" water gauge external duct

static pressure.

Communicating Unitary Control (UC) PCB

The Communicating System Unitary Control PCB is a microprocessor-based control for heat pump and air conditioning

condensing units with single-phase compressors up to 5 ton

capacity operating on standard residential or Delta and Wye

commercial power. The control incorporates the basic functionality of existing defrost controls, outdoor thermostats,

contactors, compressor staging controls, short cycle controls, line voltage monitors, Comfort Alert™ or CoreSense

Module (dependent upon which module you are using), two

speed condenser fan relays and the Active Protection component of enabled thermostats. The control is designed to

work as part of a fully communicating HVAC system with 4

wires. The control also supports legacy 24VAC thermostat

inputs for Y1, Y2, O and 24VAC outputs for RVS, W1, and L

for non-communicating systems. Outputs include compressor power, compressor stage select, and outdoor fan high

and outdoor fan low speed. System inputs include high/low

pressure switches, as well as thermistor inputs for outdoor

coil temperature and outdoor air temperature.

29

Page 30

SYSTEM OPERA TION

COOLING

The refrigerant used in the system is R-410A. It is a clear,

colorless, non-toxic and non-irritating liquid. R-410A is a

50:50 blend of R-32 and R-125. The boiling point at atmospheric pressure is -62.9°F.

A few of the important principles that make the refrigeration

cycle possible are: heat always flows from a warmer to a

cooler body. Under lower pressure, a refrigerant will absorb

heat and vaporize at a low temperature. The vapors may be

drawn off and condensed at a higher pressure and temperature to be used again.

The indoor evaporator coil functions to cool and dehumidify

the air conditioned spaces through the evaporative process

taking place within the coil tubes.

NOTE: The pressures and temperatures shown in the

refrigerant cycle illustrations on the following pages are for

demonstration purposes only. Actual temperatures and pressures are to be obtained from the "Expanded Performance

Chart".

Liquid refrigerant at condensing pressure and temperatures,

(270 psig and 122°F), leaves the outdoor condensing coil

through the drier and is metered into the indoor coil through

the metering device. As the cool, low pressure, saturated

refrigerant enters the tubes of the indoor coil, a portion of the

liquid immediately vaporizes. It continues to soak up heat and

vaporizes as it proceeds through the coil, cooling the indoor

coil down to about 48°F.

Heat is continually being transferred to the cool fins and tubes

of the indoor evaporator coil by the warm system air. This

warming process causes the refrigerant to boil. The heat

removed from the air is carried off by the vapor.

As the vapor passes through the last tubes of the coil, it

becomes superheated. That is, it absorbs more heat than is

necessary to vaporize it. This is assurance that only dry gas

will reach the compressor. Liquid reaching the compressor

can weaken or break compressor valves.

The compressor increases the pressure of the gas, thus

adding more heat, and discharges hot, high pressure superheated gas into the outdoor condenser coil.

In the condenser coil, the hot refrigerant gas, being warmer

than the outdoor air, first loses its superheat by heat transferred from the gas through the tubes and fins of the coil. The

refrigerant now becomes saturated, part liquid, part vapor and

then continues to give up heat until it condenses to a liquid

alone. Once the vapor is fully liquefied, it continues to give up

heat which subcools the liquid, and it is ready to repeat the

cycle.

HEATING

The heating portion of the refrigeration cycle is similar to the

cooling cycle. By energizing the reversing valve solenoid coil,

the flow of the refrigerant is reversed. The indoor coil now

becomes the condenser coil, and the outdoor coil becomes

the evaporator coil.

The check valve at the indoor coil will open by the flow of

refrigerant letting the now condensed liquid refrigerant bypass the indoor expansion device. The check valve at the

outdoor coil will be forced closed by the refrigerant flow,

thereby utilizing the outdoor expansion device.

COOLING CYCLE

For communicating room thermostat: When the room thermostat calls for either low stage cool or high stage cool,

appropriate commands are sent via the data 1 and data 2 lines

to the outdoor unit's UC control. The UC control energizes the

on-board compressor relay and the on-board outdoor fan

relay. The compressor high stage solenoid is energized if it

is a high stage call.

The UC control sends a fan command to the indoor unit (air

handler or furnace). The indoor unit operates the indoor

blower at the appropriate airflow level. The system operates

at the cooling level demanded by the thermostat.

When the thermostat is satisfied, appropriate commands are

sent to the UC control. The compressor relay and outdoor

fan relay is de-energized. The compressor high stage

solenoid is de-energized if it was energized. The UC control

sends an appropriate command to the indoor unit to deenergize the indoor blower motor.

If room thermostat fan status is set to be “on”, then indoor

blower would run continuously rather than cycling with the

compressor.

For heat pumps, the reversing valve is energized during the

cooling cycle. The call for cooling from the communicating

thermostat indicates to the control that the reversing valve is

to be energized during cooling operation.

HEATING CYCLE

For communicating room thermostat: When the room thermostat calls for either low stage heat or high stage heat,

appropriate commands are sent via the data 1 and data 2 lines

to the outdoor unit's UC control. The UC control energizes the

on-board compressor relay and the on-board outdoor fan

relay. The compressor high stage solenoid is energized if it

is a high stage call. The UC control sends a fan command

to the indoor unit (air handler or furnace). The indoor unit

operates the indoor blower at the appropriate airflow level.

The system operates at the cooling level demanded by the

thermostat.

When the thermostat is satisfied, appropriate commands are

sent to the UC control. The compressor relay and outdoor

fan relay is de-energized. The compressor high stage

solenoid is de-energized if it was energized. The UC control

sends an appropriate command to the indoor unit to deenergize the indoor blower motor.

30

Page 31

SYSTEM OPERA TION

DEFROST CYCLE - COMFORTNETTM MODELS

The defrosting of the outdoor coil is jointly controlled by the

UC PCB and the outdoor coil temperature (OCT) sensor.

The OCT sensor is clamped to a feeder tube entering the

outdoor coil. Defrost timing periods of 30, 60, 90 or 120

minutes may be selected via the dipswitch settings on the UC

PCB. In a communicating system, the defrost timing periods

can also be selected in the communicating thermostat user

menu. During operation, if the coil temperature is low enough

(approximately 31° F), the microprocessor will accumulate

the compressor run time. When the total compressor run

time reaches 30, 60, 90 or 120 minutes, and there is a call for

heat, the PCB will initiate a defrost cycle. When the

microprocessor detects the coil temperature to be high

enough (approximately 75 0F), or 10 minutes of maximum

defrost cycle time has elapsed, whichever occurs first, the

defrost cycle is terminated and the timing period is reset. The

field service personnel can also advance a heat pump to the

defrost cycle by simultaneously pressing the “TEST” button

and the “RECALL” button on the UC board.

Use the dipswitches to select defrost time interval (30, 60, 90

or 120 minutes) See chart below

31

Page 32

SYSTEM OPERA TION

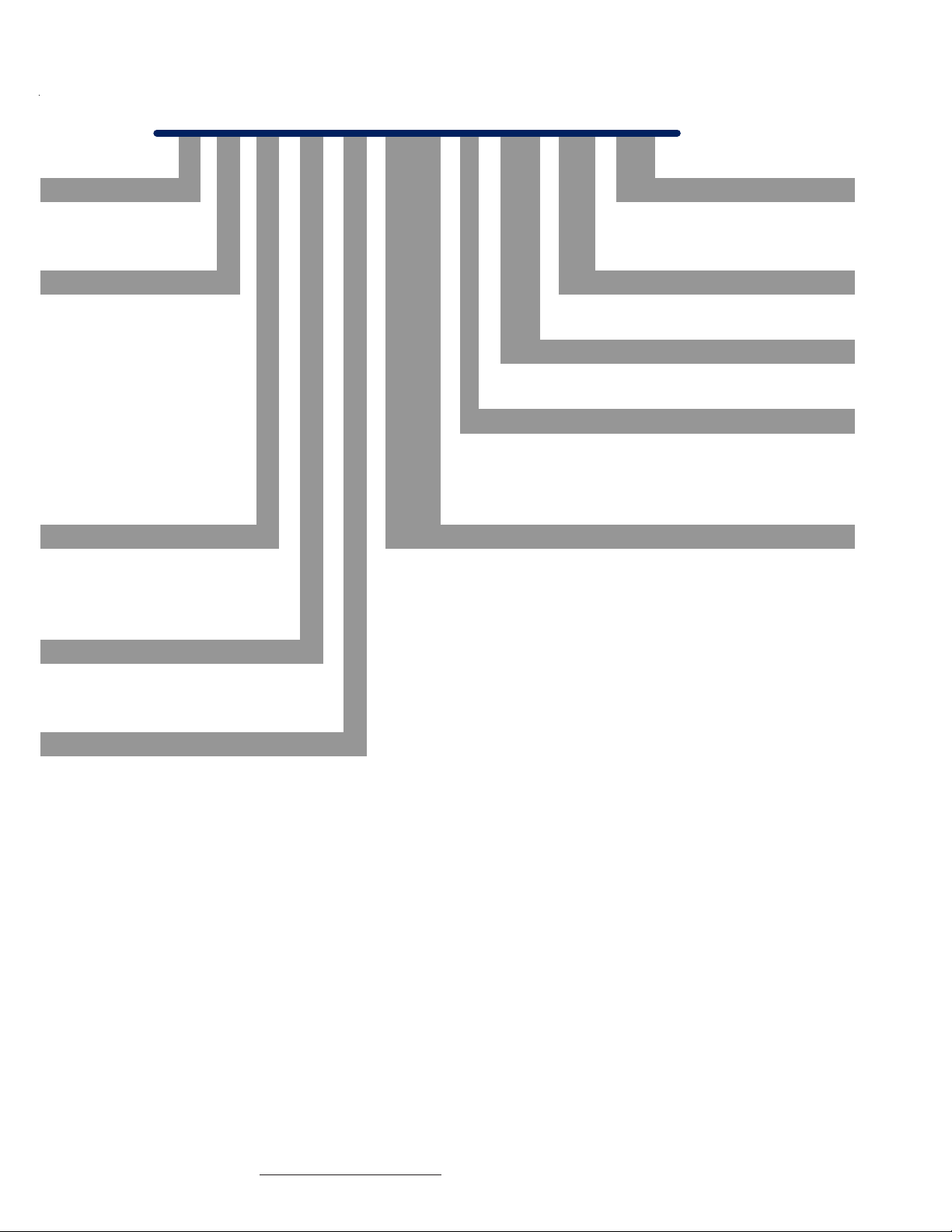

COOLING CYCLE

Reversing Va lve

(Energized)

Indoor

Coil

HEATING CYCLE

Outdoor

Coil

Accumulator

Thermostatic

Expansion

Valve

Bi-Flow

Filter Dryer

Check Valve

32

Indoor

Coil

Reversing Va lve

(De-Energized)

Outdoor

Coil

Accumulator

Thermostatic

Expansion

Valve

Bi-Flow

Filter Dryer

Check Valve

Page 33

SYSTEM OPERA TION

EXPANSION VALVE/CHECK VALVE ASSEMBLY

IN COOLING OPERATION

Most expansion valves used in current Goodman/Amana

use an internally checked expansion valve.

This type of expansion valve does not require an external check valve as shown above.

However, the principle of operation is the same.

EXPANSION VALVE/CHECK VALVE ASSEMBLY

IN HEATING OPERATION

®

Brand Heat Pump products

33

Page 34

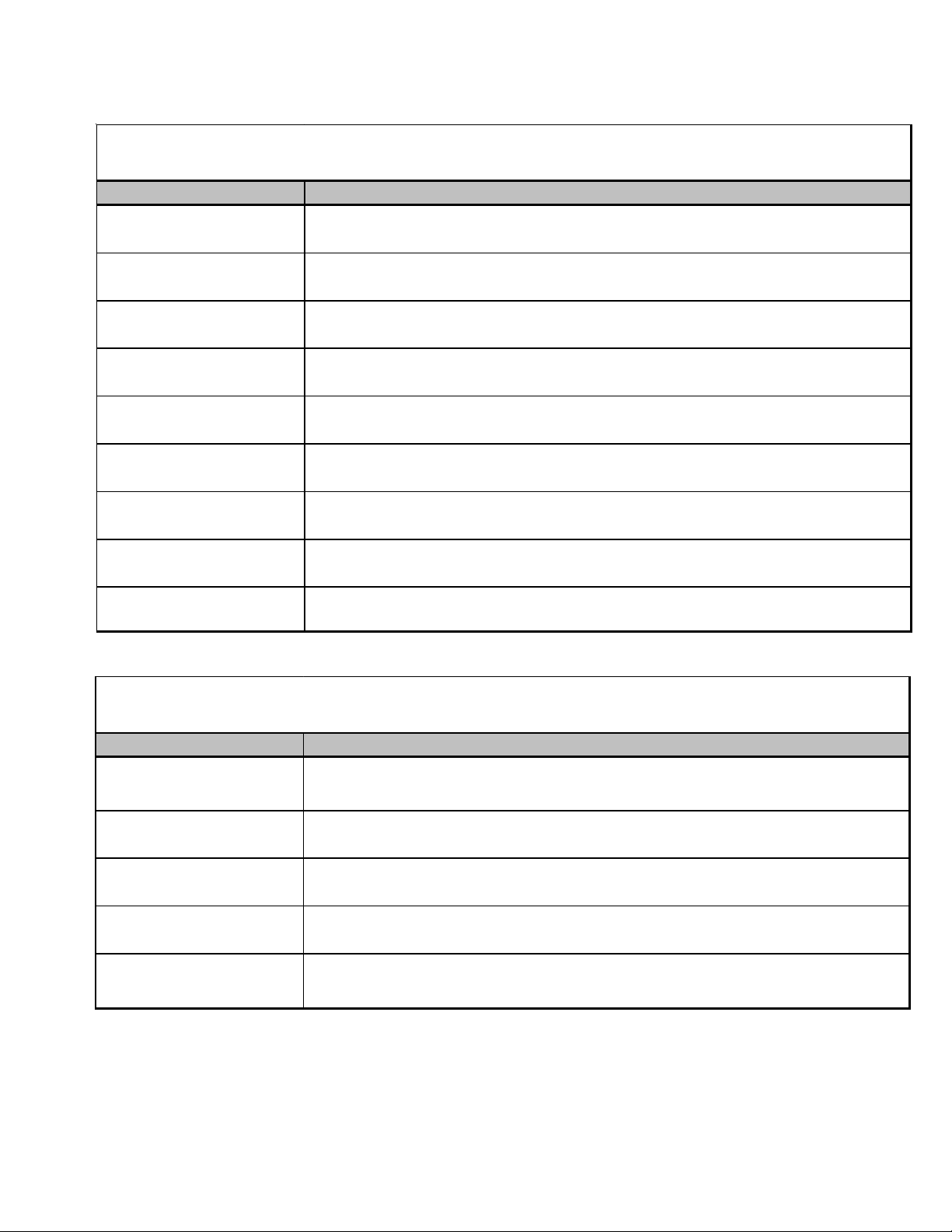

TROUBLESHOOTING CHART

COOLING/HP ANALYSIS CHART

Com plaint

PO SSIBLE CAUS E

DOTS IN ANALYSIS

GUIDE INDICATE

"POS S I BLE CAUS E"

Pow er Failure

Blow n Fuse

Loose Connection

Shorted or Broken Wires

Open Fan Overload

Faulty Thermostat

Faulty Transf ormer

Shorted or Open Capacitor

Internal Compressor Overload Open

Shorted or Grounded Compressor

Compressor Stuck

Faulty Compressor Contactor

Faulty Fan Relay

Open Control Circuit

Low Voltage

Faulty Evap. Fan Motor

Shorted or Grounded Fan Motor

Improper Cooling Anticipator

Shortage of Refrigerant

Restric ted Liquid Line

Open Element or Limit on Elec. Heater

Dirt y Air Filter

Dirty Indoor Coil

Not enough air across Indoor Coil

Too much air across Indoor Coil

Overcharge of Refr igerant

Dirty Outdoor Coil

Noncondensibles

Recirculation of Condens ing Air

Infiltration of Outdoor Air

Improperly Located Thermostat

Air Flow Unbalanced

System Undersized

Broken Internal Parts

Broken Valves

Inefficient Compressor

Wrong Type Expans ion Valve

Expansion Device Restricted

Oversized Expansion Valve

Undersized Expansion Valve

Expansion Valve Bulb Loose

Inoperative Expansion Valve

Loose Hold-dow n Bolts

Faulty Reversing Valve

Faulty Defros t Control

Faulty Defros t Thermostat

Flow rator Not Seating Properly

No Coolin g

SYMPTOM

System will not start

Compressor will not start - fan runs

Comp. and Cond. Fan will not start

Eva porator fan will not start

Condenser fan will not start

Compressor runs - goes off on overload

Compressor cycles o n overload

Unsatisfactory

Cooling/Heating

System runs continuously - little cooling/htg

Too cool and then too warm

•

•••

•••

••••••

••

••• •

••

• ••••

•

••

•••

•••

•

•

•••

••

••

••

••

•• •• •

♦♦

••• •

••• •

••• •

•• •

•• •

••

•• •

•••

••

••

••

•• ••

•

••• • ••

••• • •• •

••

••• • •

•• •

•

•

• Cooling or Heat ing Cycle (Heat Pump)

•••

System

Ope rating

Pressures

Not cool enough on warm days

Certain areas too cool, others too warm

Compressor is no isy

System runs - blows cold air in heating

Unit will not terminate de frost

Unit will not defrost

Low suction pr essure

Low head pressure

High suction pressure

High head pressure

♦

♦

♦

♦

♦

♦

♦

•

♦

••

♦

♦

••

♦

♦

♦

•

••

•

•

♦

••

•

♦♦♦ ♦♦♦

♦♦♦♦♦ ♦

♦♦♦♦♦♦♦

Heating Cycle Only (He a t Pum p)

♦

Test Method

Rem edy

See Service Procedure Ref.

Test Voltage S-1

Inspect Fuse Size & Type S-1

Inspect Connection - Tighten S-2, S-3

Test Circuits W ith Ohmmeter S-2, S-3

Test Continuity of Overload S-17A

Test Continuity of Thermos tat & Wiring S-3

Check Control Cir cuit with Voltmeter S-4

Test Capacitor S-15

Test Continuity of Overload S-17A

Test Motor Windings S-17B

Use Tes t Co rd S-1 7D

Tes t Continuity of Coi l & Contacts S-7, S - 8

Test Continuity of Coil And Contacts S-7

Test Control Circuit w ith Voltmeter S-4

Test Voltage S-1

Repair or Replac e S-16

Test Motor Windings S-16

Check Resistance of Anticipator S-3B

Test For Leaks, A dd Refrigerant S-101,103

Remove Restriction, Replace Restricted Part S-112

Test Heater Element and Controls S-26,S-27

Inspect Filter-Clean or Replace

Inspect Coil - Clean

Check Blow er Speed, Duct Static Press, Filter S-200

Reduce Blow er Speed S-200

Recover Part of Charge S-113

Inspect Coil - Clean

Recover Charge, Evacuate, Recharge S-114

Remove Obstruction to Air Flow

Check Window s, Doors, Vent Fans, Etc.

Relo c ate Thermostat

Readjust A ir V olume Dampers

Refigure Cooling Load

Replace Compressor S-115

Test Compressor Eff iciency S-104

Test Compressor Eff iciency S-104

Replace Valve S-110

Remove Restriction or Replace Expansion Device S-110

Replace Valve

Replace Valve

Tighten Bulb Bracket S-105

Check V alv e Ope ration S-110

Tighten Bolts

Replace Valve or Solenoid S-21, 122

Test Contr ol S-24

Test Defrost Thermostat S-25

Check Flowrator & Seat or Replace Flow rator S-111

34

Page 35

SERVICING TABLE OF CONTENTS

S-1 CHECKING VOLT AGE ................................................ 35

S-2 CHECKING WIRING ................................................... 35

S-3E CTK0*** COMFORTNETTM THERMOST A T..............35

S-4 CHECKING TRANSFORMER

AND CONTROL CIRCUIT ......................................48

S-6 CHECKING TIME DELAY RELA Y ...............................48

S-8A CHECKING UNITARY (UC) CONTROL

COMPRESSOR CONT ACTOR/RELA Y

CONTACTS .............................................................48

S-9 CHECKING HIGH AND LOW VOLT AGE

TO ECM MOTOR..........................................................49

S-10A COPELAND COMFORT ALER T™..............................49

S-12 CHECKING HIGH PRESSURE CONTROL...............63

S-13 CHECKING LOW PRESSURE CONTROL................63

S-14 CHECKING HIGH AND LOW PRESSURE SWITCH

VOLTAGE .................................................................63

S-15 CHECKING CAP ACITOR ...........................................63

S-15A RESISTANCE CHECK USING A DIGIT AL

MULTI-METER.........................................................63

S-15B CAPACITANCE CHECK USING A DIGIT AL

MUL TI-METER (IN CAP ACIT ANCE MODE).............64

S-16G CHECKING EMERSON ULTRATECH™

ECM MOTORS ........................................................64

S-16H ECM CFM ADJUSTMENTS A VPTC/MBVC .................67

S-17 CHECKING COMPRESSOR ..................................... 75

S-17A RESIST ANCE TEST...................................................75

S-17B GROUND TEST .........................................................75

S-17C UNLOADER TEST PROCEDURE ............................ 76

S-17D OPERA TION TEST.................................................... 77

S-18 TESTING CRANKCASE HEATER

(OPTIONAL ITEM) ...................................................77

S-21 CHECKING REVERSING V AL VE

AND SOLENOID .....................................................77

S-24 TESTING DEFROST CONTROL................................77

S-26 TESTING TEMPERA TURE SENSORS

(COMFORTNET READY MODELS ONL Y) .............78

S-40A AVPTC/MBVC ELECTRONIC

BLOWER/HEA TER CONTROL...............................78

S-60 ELECTRIC HEA TER (OPTIONAL ITEM) .................... 83

S-61A CHECKING HEATER LIMIT CONTROL(S) ................84

S-61BCHECKING HEATER FUSE LINK..............................84

(OPTIONAL ELECTRIC HEA TERS) ....................... 84

S-62 CHECKING HEA TER ELEMENTS ............................. 84

S-100 REFRIGERATION REP AIR PRACTICE..................... 84

S-101 LEAK TESTING

(NITROGEN OR NITROGEN-TRACED) ................ 85

S-102 EV

S-103 CHARGING.................................................................86

S-104 CHECKING COMPRESSOR EFFICIENCY................87

S-106 OVERFEEDING ..........................................................87

S-107 UNDERFEEDING ....................................................... 87

S-108 SUPERHEAT .............................................................. 87

S-109 CHECKING SUBCOOLING........................................87

S-1 10 CHECKING EXP ANSION V AL VE OPERA TION..........88

S-112 CHECKING RESTRICTED LIQUID LINE .................. 88

S-113 OVERCHARGE OF REFRIGERANT ..........................88

S-114 NON-CONDENSABLES ............................................. 88

S-115 COMPRESSOR BURNOUT .......................................91

S-120 REFRIGERANT PIPING .............................................91

S-203 SINGLE PIECE AIR HANDLER EXTERNAL

S-203A TWO PIECE AIR HANDLER EXTERNAL

ACUA TION .............................................................85

STATIC PRESSURE............................................92

STATIC PRESSURE............................................92

35

Page 36

SERVICING

S-1 CHECKING VOLTAGE

1. Remove outer case, control panel cover, etc., from unit

being tested.

With power ON:

WARNING

Line Voltage now present.

2. Using a voltmeter, measure the voltage across terminals

L1 and L2 of the contactor for the condensing unit or at the

field connections for the air handler or heaters.

ComfortNetTM Ready Condensing Units: Measure the

voltage across the L1 and L2 lugs on the unitary (UC)

control.

3. No reading - indicates open wiring, open fuse(s) no power

or etc., from unit to fused disconnect service. Repair as

needed.

4. With ample voltage at line voltage connectors, energize

the unit.

5. Measure the voltage with the unit starting and operating,

and determine the unit Locked Rotor Voltage. NOTE: If

checking heaters, be sure all heating elements are

energized.

Locked Rotor Voltage is the actual voltage available at

the compressor during starting, locked rotor, or a stalled

condition. Measured voltage should be above minimum

listed in chart below.

To measure Locked Rotor Voltage attach a voltmeter to

the run "R" and common "C" terminals of the compressor,

or to the T1 and T2 terminals of the contactor. Start the unit

and allow the compressor to run for several seconds, then

shut down the unit. Immediately attempt to restart the

unit while measuring the Locked Rotor Voltage.

ComfortNet Ready Condensing Units: To measure the

Locked Rotor Voltage, attach a voltmeter to the run "R"

and common "C" terminals of the compressor or across

the "R" and "C" lugs on the unitary (UC) control. Start the

unit and allow the compressor to run for several seconds,

then shut down the unit. Immediately attempt to restart

the unit while measuring the Locked Rotor Voltage.

6. Locked rotor voltage should read within the voltage tabulation as shown. If the voltage falls below the minimum

voltage, check the line wire size. Long runs of undersized

wire can cause low voltage. If wire size is adequate, notify

the local power company in regard to either low or high

voltage.

Unit Supply Voltage

Voltage Min. Max

208/230 197 253

460 414 506

NOTE: When operating electric heaters on voltages other

than 240 volts, refer to the System Operation section on

electric heaters to calculate temperature rise and air flow.

Low voltage may cause insufficient heating.

S-2 CHECKING WIRING

HIGH VOLTAGE!

Disconnect ALL power before servicing

or installing. Multiple power sources

may be pr es ent. Fa ilur e to do s o ma y

cause pro pe rty dam age , pe rs onal in jury

or death.

1. Check wiring visually for signs of overheating, damaged

insulation and loose connections.

2. Use an ohmmeter to check continuity of any suspected

open wires.

3. If any wires must be replaced, replace with comparable

gauge and insulation thickness.

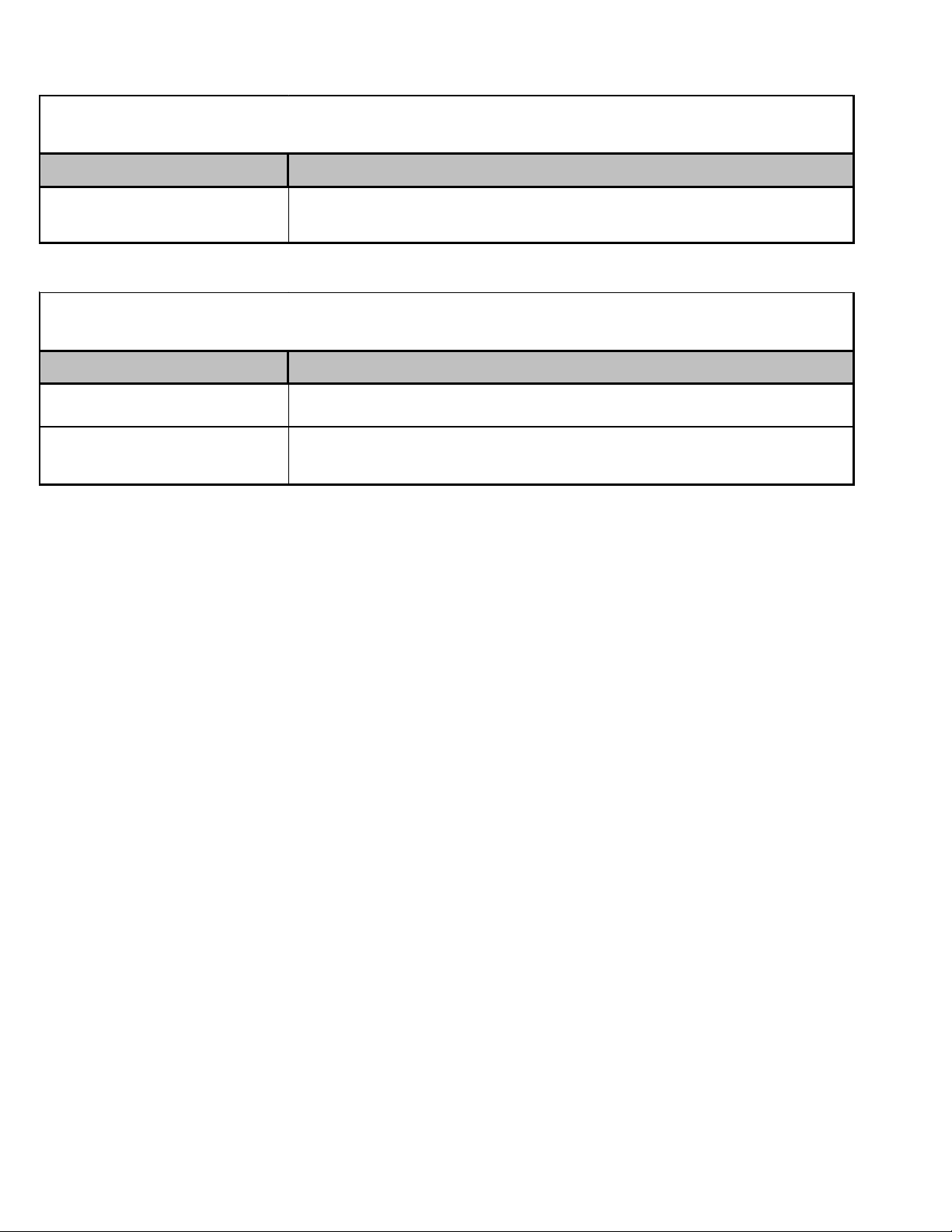

S-3E CTK0*** COMFORTNETTM THERMOSTAT

COMFORTNET™ SYSTEM

The ComfortNet system (or CT system) is a system that

includes a ComfortNet compatible air handler/furnace/modular blower and air conditioner or heat pump with a CTK0*

thermostat. Any other system configurations are considered

invalid ComfortNet systems and must be connected as a

tradition (or legacy) system. The table below compares the

valid CT systems.

CT compatible Air Handler or

Modular Blo w er

CT compatible Air Handler or

Modular Blo w er

A ComfortNet heating/air conditioning system differs from a

legacy/traditional system in the manner in which the indoor

unit, outdoor unit and thermostat interact with one another. In

a traditional system, the thermostat sends commands to the

indoor and outdoor units via analog 24 VAC signals. It is a

one-way communication path in that the indoor and outdoor

units typically do not return information to the thermostat.

On the other hand, the indoor unit, outdoor unit, and thermostat comprising a ComfortNet system “communicate” digitally with one another. It is now a two-way communications

path. The thermostat still sends commands to the indoor and

outdoor units. However, the thermostat may also request and

receive information from both the indoor and outdoor units.

This information may be displayed on the CT thermostat. The

indoor and outdoor units also interact with one another. The

outdoor unit may send commands to or request information

from the indoor unit. This two-way digital communications

CT compatible

Air Conditioner

CT compatible

Heat Pump

Full CT system

benefits & features

Full CT system

benefits & features

36

Page 37

SERVICING

between the thermostat and subsystems (indoor/outdoor

unit) and between subsystems is the key to unlocking the

benefits and features of the ComfortNet system.

Two-way digital communications is accomplished using

only two wires. The thermostat and subsystem controls are

powered with 24 VAC Thus, a maximum of 4 wires between

the equipment and thermostat is all that is required to operate

the system.

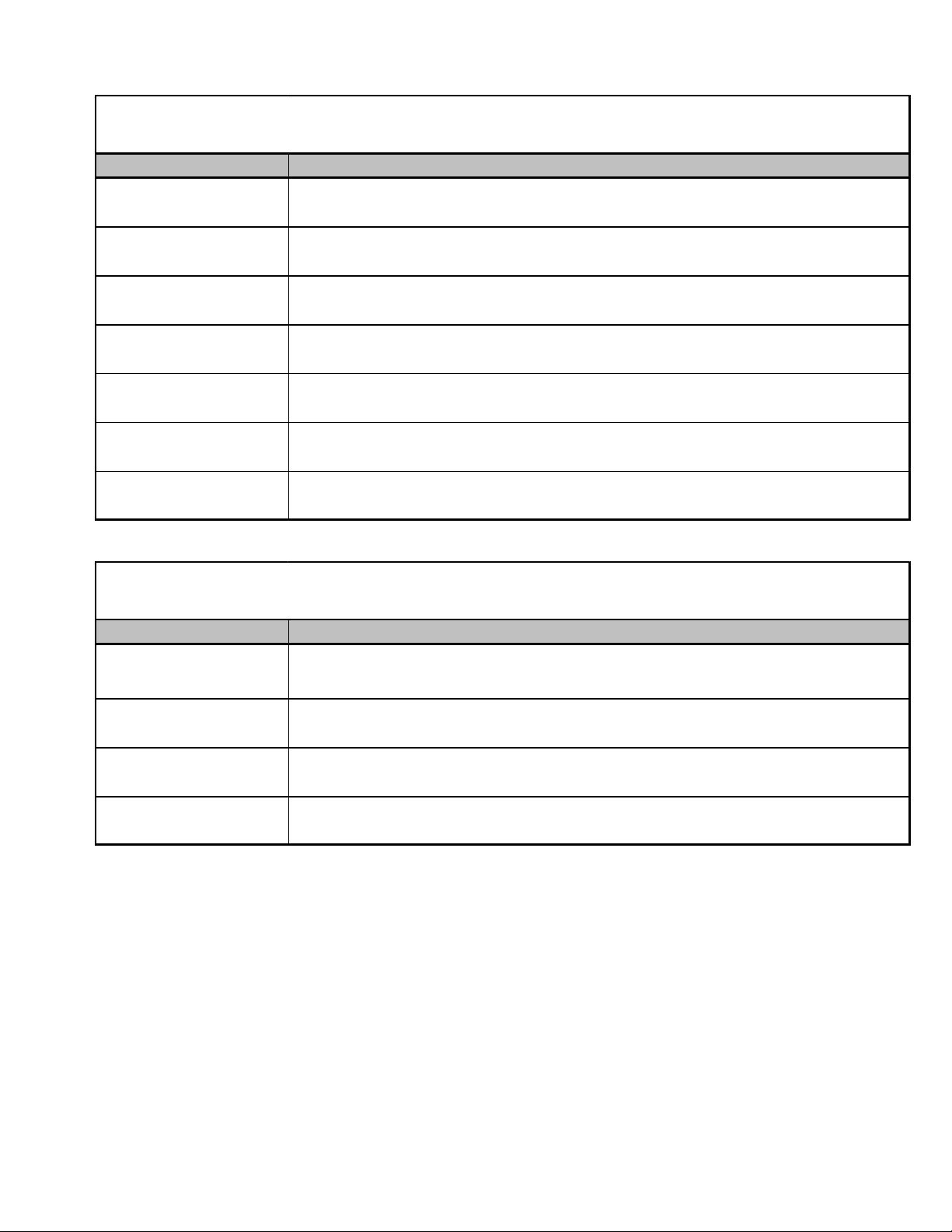

AIRFLOW CONSIDERATIONS

Airflow demands are managed differently in a fully communicating system than they are in a legacy wired system. The

system operating mode (as determined by the thermostat)

determines which unit calculates the system airflow demand.

If the indoor unit is responsible for determining the airflow

demand, it calculates the demand and sends it to the ECM

motor. If the outdoor unit or thermostat is responsible for

determining the demand, it calculates the demand and

transmits the demand along with a fan request to the indoor

unit. The indoor unit then sends the demand to the ECM

motor. The following table lists the various ComfortNet™

systems, the operating mode, and airflow demand source.

For example, assume the system is an air conditioner

matched with an air handler. With a call for low stage cooling,

the air conditioner will calculate the system’s low stage

cooling airflow demand. The air conditioner will then send a

fan request along with the low stage cooling airflow demand

to the air handler. Once received, the air handler will send the

low stage cooling airflow demand to the ECM motor. The

ECM motor then delivers the low stage cooling airflow. The

table below lists the nominal high and low stage airflow for the

ComfortNet air conditioners and heat pumps.

CONTROL WIRING

NOTE: Refer to section Electrical Connections - High

Voltage Connections for 208/230 volt line connections to

the air conditioner or heat pump.

NOTE: A removable plug connector is provided with the

control to make thermostat wire connections. This plug

may be removed, wire connections made to the plug, and

replaced. It is

strongly recommended that you do not

connect multiple wires into a single terminal. Wire nuts

are recommended to ensure one wire is used for each

terminal. Failure to do so may result in intermittent

operation.

Typical 18 AWG thermostat wire may be used to wire the

system components. 150 feet is the maximum length of wire

recommended between indoor unit and outdoor unit, or

between indoor unit and thermostat.

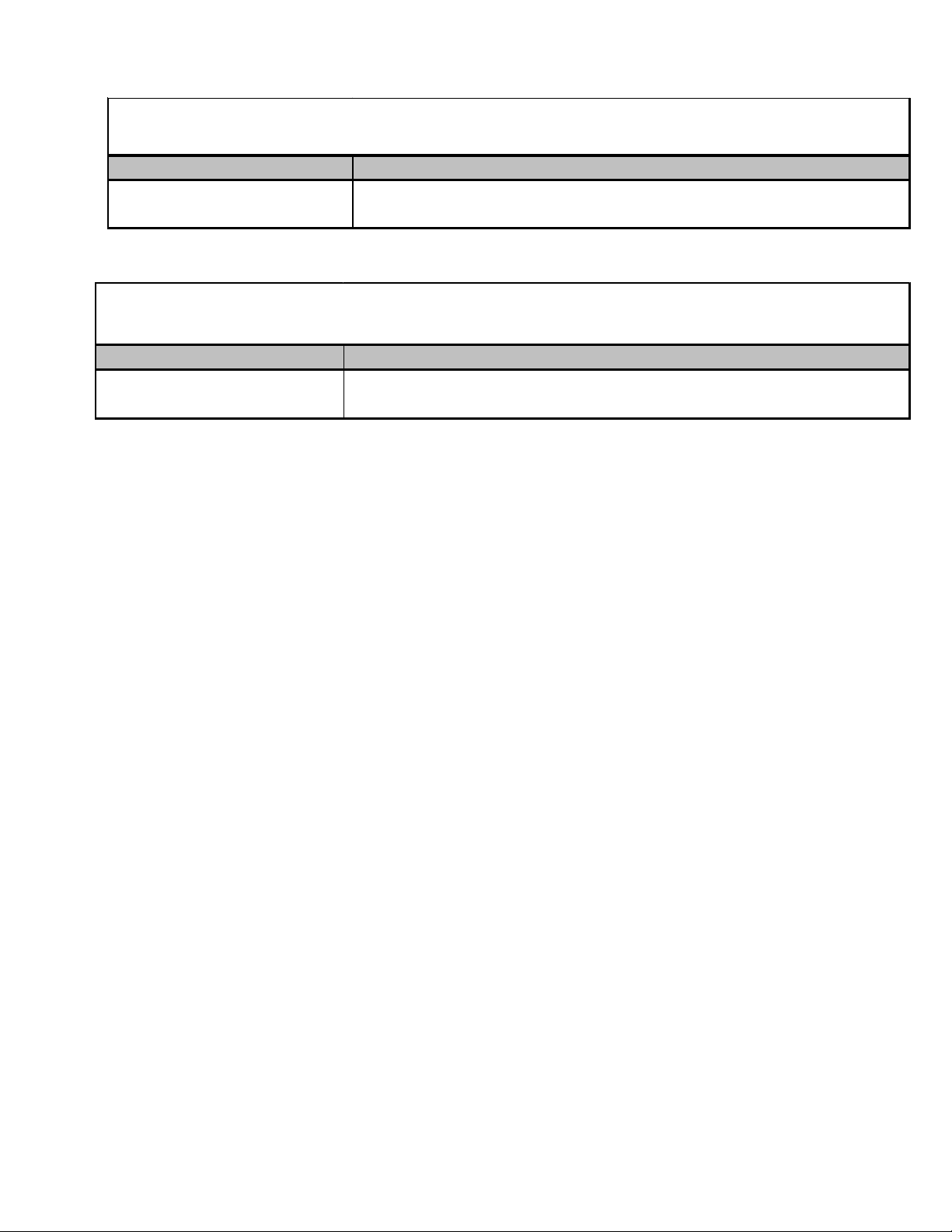

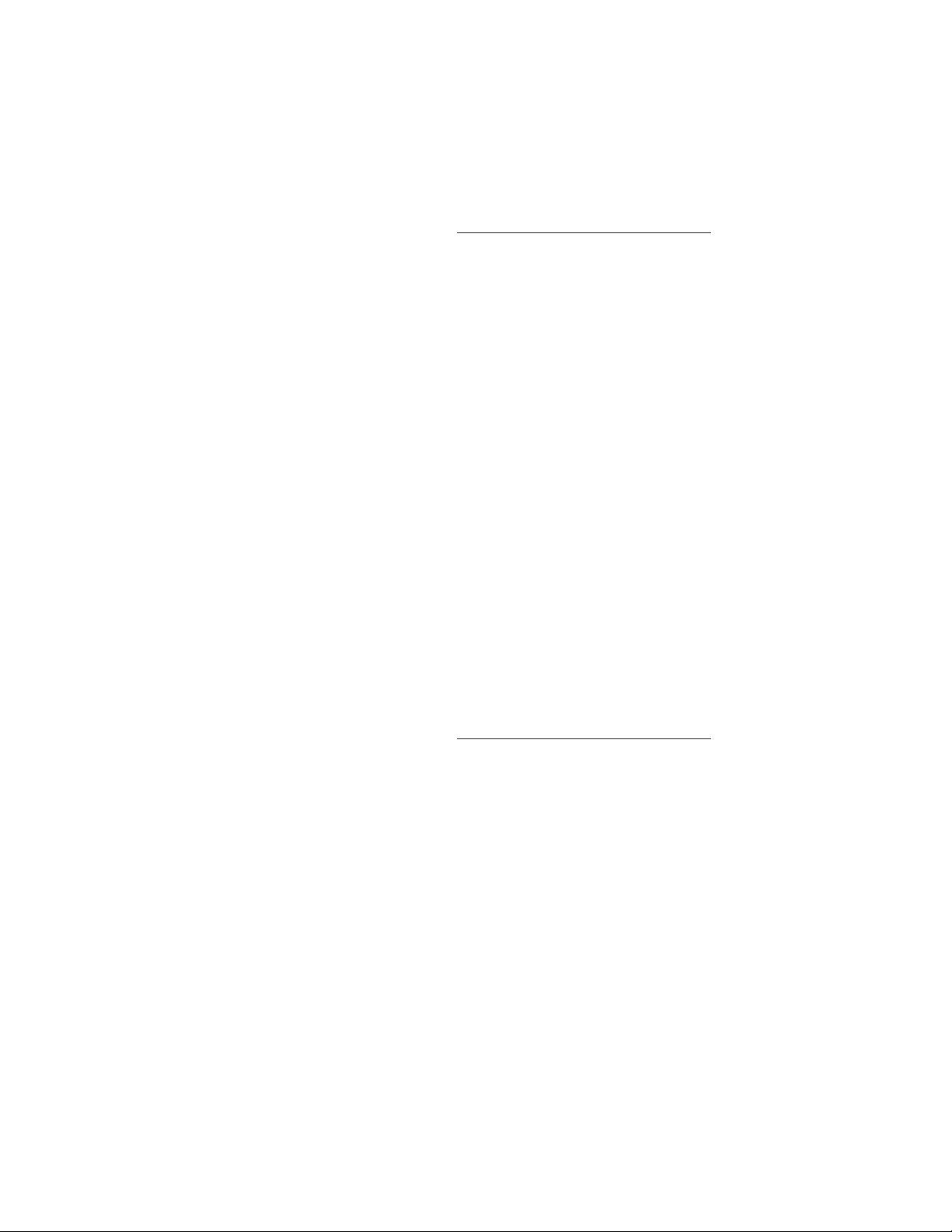

CTK04 STANDARD WIRING SCHEME:

Two wires may be utilized between the indoor and outdoor

units. For this wiring scheme, only the data lines, 1 and 2,

are required between the indoor and outdoor units. A 40VA,

208/230 VAC to 24 VAC transformer must be installed in the

outdoor unit to provide 24 VAC power to the outdoor unit’s

electronic control. The “C” 24v common of the outdoor

transformer should be grounded to the equipment (earth)

ground. The transformer is included with the CTK0* kit. See

kit instructions for mounting and wiring instructions. Four

wires are required between the indoor unit and thermostat.

12RC

Thermostat

Models

*SZC160241 800 600 800 600

*SZC160361 1200 800 1200 800

*SZC160481 1550 1100 1550 1100

*SZC160601 1800 1210 1800 1210

*SZC180241 850 550 850 550

*SZC180361 1250 850 1250 850

*SZC180481 1750 1210 1750 1210

*SZC180601 1750 1210 1750 1210

Cooling Heating

High Low High Low

40VA Transformer (included in

CTK04 kit)

208/230 VAC

24 VAC

12RC

12RC

Note

: Recommended (Field Provided)

System Wiring

Air Handler/Furnace/PCB

AC/HP/ PCB

(Ground Indicator)

37

Page 38

SERVICING

g

(

1

2R

12RC

40VA Transformer

CTK0*** kit)

208/230 VAC

and Four Wires between Air Handler and Thermostat

included in

12

24 VAC

CTK04 System Wiring Using Three-Wires

between Air Handler and AC / HP

CTK 04 ALTERNATE WIRING SCHEME:

Three wires should be utilized between the indoor and outdoor

units. For this wiring scheme, two wires for the data lines, 1

and 2 are required and a wire connecting the common “C”

terminals between the indoor and outdoor units. This connects both commons to the same ground potential allowing

for better communication. A 40VA, 208/230 VAC to 24 VAC

transformer must be installed in the outdoor unit to provide

24 VAC power to the outdoor unit’s electronic control. The

transformer is included with the CTK0* kit. See kit instructions for mounting and wiring instructions. Four wires are

required between the indoor unit and thermostat.

C

RC

Thermostat

Modular Blower

Inte

rated Control Module

AC/H P Integrate d

Control Module

COMFORTNET™ SYSTEM ADVANCED FEATURES

The ComfortNet™ system permits access to additional

system information, advanced setup features, and advanced

diagnostic/troubleshooting features. These advanced features are organized into a menu structure. Refer to the

Installation and Start-Up instructions shipped with your

particular CTKO*** thermostat.

Diagnostics

Accessing the air handler’s diagnostics menu provides ready

access to the last six faults detected by the air handler.

Faults are stored most recent to least recent. Any consecutively repeated fault is stored a maximum of three times.

Example: A clogged return air filter causes the air handler’s

motor to repeatedly enter a limiting condition. The control will

only store this fault the first three consecutive times the fault

occurs.

NOTE: It is highly recommended that the fault history be

cleared after performing maintenance or servicing the air

handler.

38

Page 39

SERVICING

Network Troubleshooting

The ComfortNet™ system is a fully communicating system,

and thus, constitutes a network. Occasionally the need to

troubleshoot the network may arise. The integrated air

handler control has some on-board tools that may be used

to troubleshoot the network. These tools are: red communications LED, green receive (Rx) LED, and learn button.

Refer to the Communications Troubleshooting Chart and Air

Handler Diagnostic Codes below for error codes, possible

causes and corrective actionS.

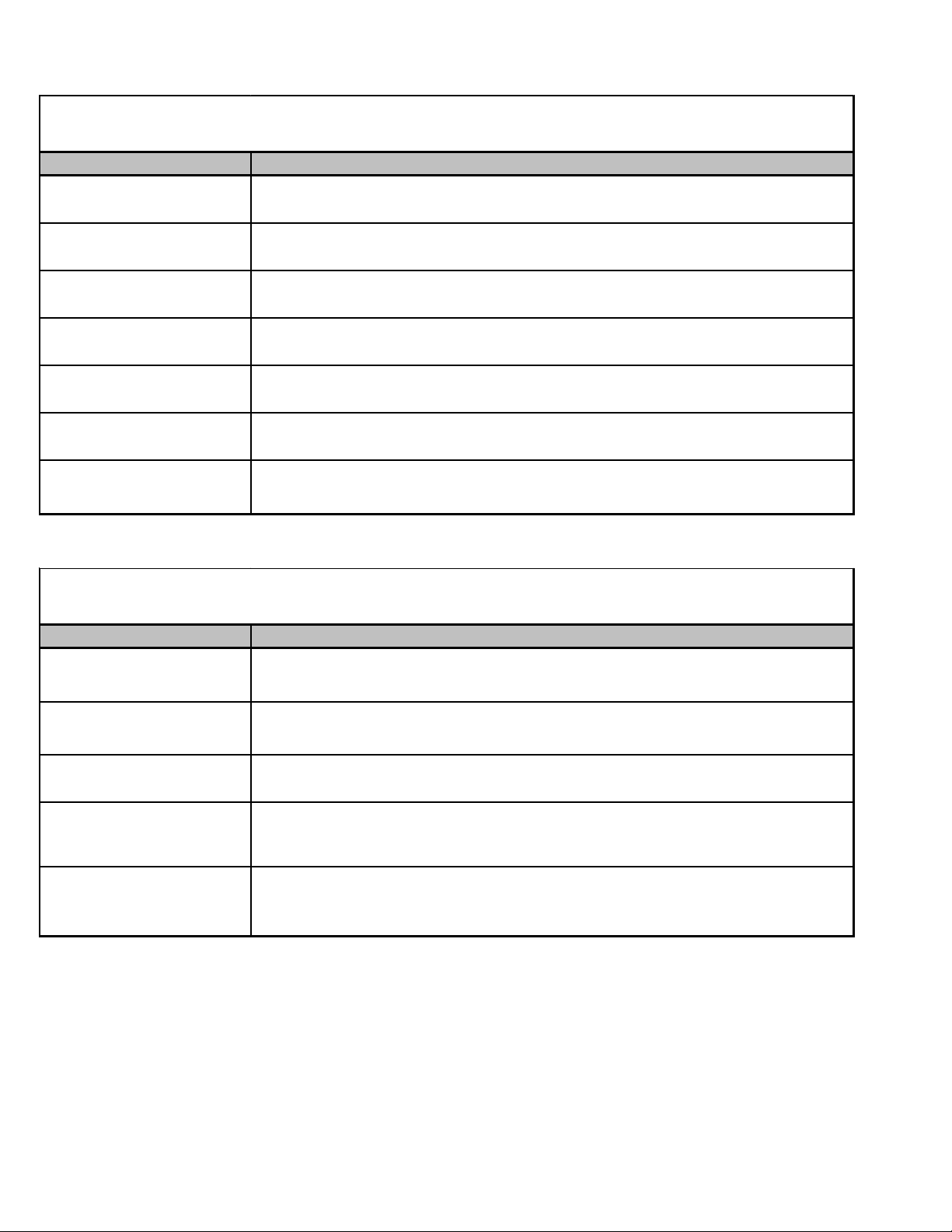

COMMUNICATIONS TROUBLESHOOTING CHART

LED LED

Status

Off

1 Flash

Red

Communications

LED

2 Flashes

Off

1 Steady

Flash

Green Receive

LED

Rapid

Flashing

On Solid

Indication Possible Causes Corrective Action(s) Notes & Cautions

x Normal condition x None x None x None

x Communications

Failure

x Out-of-box reset x Control power up

x No power

x Communications

error

x No network found x Broken/ disconnected

x Normal network

traffic

x Data 1/ Data 2

miss-wire

x Communications

Failure

x Learn button

depressed

x No power to air

handler

x Open fuse

x Communications error

data wire(s)

x Air handler is installed

as a noncommunicating/

traditional system

x Control is “talking” on

network as expected

x Data 1 and data 2

wires reversed at air

handler, thermostat,

or ComfortNet™

compatible outdoor

AC/HP

x Short between data 1

and data 2 wires

x Short between data 1

or data 2 wires and R

(24VAC) or C (24VAC

common)

• Red communications LED – Indicates the status of the

network. The table below indicates the LED status and the

corresponding potential problem.

• Green receive communication LED – Indicates network

traffic. The table below indicates the LED status and the

corresponding potential problem.

• Learn button – Used to reset the network. Depress the

button for approximately 2 seconds to reset the network.

x Depress Learn Button

x Verify that bus BIAS

and TERM

dipswitches are in the

ON position.

x None x None

x Check fuses and

circuit breakers;

replace/reset

x Replace blown fuse

x Check for shorts in

low voltage wiring in

air handler/system

x Reset network by

depressing learn

button

x Check data 1/ data 2

voltages

x Check

communications

wiring (data 1/ data 2

wires)

x Check wire

connections at

terminal block

x Verify air handler