Goodman ARUF31B14, ARUF37C14, ARUF47D14, ARUF61D14, ASPT33C14 Installation Manual

...

ARUF**14** / ASPT**14**

AIR HANDLERS INSTALLATION & OPERATING INSTRUCTIONS

Contents

1 Important Safety Instructions................................... 1

2 Shipping Inspection ............................................... 3

2.1 Parts.............................................................3

2.2 Handling ........................................................3

3 Codes & Regulations .............................................. 3

4 Replacement Parts ................................................ 3

5 Pre-Installation Considerations ................................ 3

5.1 Preparation.....................................................3

5.2 System Matches................................................3

5.3 Interconnecting Tubing .......................................3

5.4 Clearances......................................................3

5.5 Horizontal Applications ......................................3

6 Installation Location ............................................. 4

6.1 Upflow Installation ...........................................4

6.2 Horizontal Left Installation .................................4

6.3 Horizontal Right Installation / Downflow Installation ..4

7 Refrigerant Lines .................................................. 6

7.1 Tubing Size .....................................................6

7.2 Tubing Preparation ............................................6

7.3 Special Instructions ...........................................6

7.4 Tubing Connections for Flowrator Model ..................8

7.5 Tubing Connections for TXV Models ........................8

7.6 ASPT**14** Models with Non-Adjustable TXV .............8

7.7 Thermal Expansion Valve System Adjustment ............9

8 Condensate Drain Lines ......................................... 10

9 Ductwork........................................................... 11

9.1 Return Ductwork ............................................ 11

10 Return Air Filters ............................................... 11

11 Electric Heat..................................................... 11

12 Electrical and Control Wiring ................................ 12

12.1 Building Electrical Service Inspection .................. 12

12.2 Wire Sizing .................................................. 12

12.3 Maximum Overcurrent Protection (MOP) .............. 12

12.4 Electrical Connections – Supply Voltage................ 12

12.4.1 Air Handler Only (Non-Heat Kit Models) ...... 14

12.4.2 Air Handler - Non-Circuit Breaker Heat Kits . 14

12.4.3 Air Handler With Circuit Breaker Heat Kit ... 14

12.5 Low Voltage Connections ................................. 14

12.5.1 Thermostats ....................................... 14

12.6 Speed Tap Adjustment .................................... 14

13 Achieving 1.4% Low Leakage Rate .........................14

14 Start-Up Procedure............................................. 15

15 Regular Maintenance........................................... 15

16 Airflow Data ..................................................... 16

17 Air Handler Low Voltage Connections ...................... 18

18 Wiring Diagrams................................................. 19

Only personnel that have been trained to install,

adjust, service or repair (hereinafter, “service”) the

equipment specified in this manual shou ld service

the equipment. The man u fa cturer will not be

responsible for any injury or property damage aris ing

from improper service or service procedures. If you

service this un it, you assume responsibility for any

injury or property damage which may result. In

addition, in jurisdictions that require one or more

licenses to service the equipment specified in this

manual, only licensed personnel should service the

equipment. Improper installation, adjustment,

servicing or repair of the equipment specified in this

manual, or attempting t o install, adjust, service or

repair the equipment specified in this manual without

proper t raining may result in product damage,

propert y damage, personal injury or death.

IO-901G

12/2017

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION.

Keep this literature in a safe place for future reference.

ATTENTION INSTALLING PERSONNEL

Prior to installation, thoroughly familiarize yourself with this Installation Manual.

Observe all safety warnings. During installation or repair, caution is to be observed.

It is your responsibility to install the product safely and to educate the customer on its safe use.

HIGH VOLTAGE!

Disconnect ALL power before ser vicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injur y or death.

To prevent the risk of property damage, personal

injury , or dea th, do not store comb ustible m aterials or

use gasoline or other flammable liquids or vapors in

the vicin ity of this unit.

This product is factory-shipped for use with

208/240/1/60 electrical power supply.

DO NOT

reconfigure this air handler to operate with any other

power supply.

When installing or servicing this equipment, safety

clothing, including hand and eye protection, is

strongly recommended. If installing in an area that has

special safety requirements (hard hats, etc.), bserve

o

these requirements.

To avoid property damage, personal injury or death

due to electrical shock, this unit MUST have an

uninterrupted, unbroken

electrical ground. The

electrical ground circuit may consist of an

appropriately sized electrical wire connecting the

ground lug in the unit control box to the building

electrical service panel.

Other meth ods of gro unding ar e p ermit te d i f pe rfo rmed

in accordance with the National Electric Code

(NEC) /Amer ican National Stan dards I nsti tute

(ANSI)/ Nati onal Fire P rotec tion A ssocia tion (NFP A) 70

and local /s ta te c ode s. I n Canada, e le ctr ica l gro undi ng

is to be in accordance with t he Cana di an El ec tri c C ode

(CSA) C22.1.

1 Important Safety Instructions

The following symbols and labels are used throughout this

manual to indicate immediate or potential safety hazards.

It is the owner’s and installer’s responsibility to read and

comply with all safety information and instructions accompanying these symbols. Failure to heed safety information

increases the risk of personal injury, property damage, and/

or product damage.

CO can cause serious illness including perm anent bra in

damag e or death.

B10259-216

Advertenci a e spe cia l p ara la instalación de calentadores ó ma nejadoras

de aire en áreas cerradas como estacionamientos ó cuartos de servic io.

Las emis ion es de monóxido de carbono puede n c irc ula r a través

del aparat o c uando se opera en cualquier modo.

El monóx i do de carbono pued e causar enfermedades severas

como daño cerebral permanente ó muerte.

B10259-216

2

RISQUE D'E MPO ISO N NEM EN T AU

Cett e v entilation est nécessaire pour év iter le danger d'intoxication

au CO pouvant survenir si un appareil produisant du monoxyde

de carbon e continue de fonctionner au sei n de l a zone confin é e .

Le monoxyde de

des

dommages permanents au cerveau et meme la mort.

carbone peut causer des maladies graves telles que

MONOXYDE DE CARBONE

B10259-216

2 Shipping Inspection

Always transport the unit upright; laying the unit on its side

or top during transit may cause equipment damage. The

installer should inspect the product upon receipt for shipping damage and subsequent investigation is the responsibility of the carrier. The installer must verify the model

number, specifications, electrical characteristics, and accessories are correct prior to installation. The distributor

or manufacturer will not accept claims from dealers for

transportation damage or installation of incorrectly shipped

units.

2.1 Parts

Also inspect the unit to verify all required components

are present and intact. Report any missing components

immediately to the manufacturer or to the distributor.

Use only factory authorized replacement parts (see Section 5). Make sure to include the full product model

number and serial number when reporting and/or obtaining service parts.

2.2 Handling

Use caution when transporting/carrying the unit. Do not

move unit using shipping straps. Do not carry unit with

hooks or sharp objects. The preferred method of carrying the unit after arrival at the job site is to carry via

a two-wheel hand truck from the back or sides or via

hand by carrying at the cabinet corners.

3 Codes & Regulations

This product is designed and manufactured to comply with

applicable national codes. Installation in accordance with

such codes and/or prevailing local codes/regulations is the

responsibility of the installer. The manufacturer assumes

no responsibility for equipment installed in violation of any

codes or regulations.

The United States Environmental Protection Agency (EPA)

has issued various regulations regarding the introduction

and disposal of refrigerants. Failure to follow these regulations may harm the environment and can lead to the

imposition of substantial fines. Should you have any ques-

tions please contact the local office of the EPA and/or refer to EPA’s website www.epa.gov.

4 Replacement Parts

When reporting shortages or damages, or ordering repair

parts, give the complete product model and serial numbers

as stamped on the product. Replacement parts for this

product are available through your contractor or local distributor. For the location of your nearest distributor consult the white business pages, the yellow page section of

the local telephone book or contact:

5 Pre-Installation Considerations

5.1 Preparation

Keep this document with the unit. Carefully read all

instructions for the installation prior to installing product. Make sure each step or procedure is understood

and any special considerations are taken into account

before starting installation. Assemble all tools, hardware and supplies needed to complete the installation.

Some items may need to be purchased locally. Make

sure everything needed to install the product is on hand

before starting.

5.2 System Matches

The entire system (combination of indoor and outdoor

sections) must be manufacturer approved and Air-Conditioning, Heating, and Refrigeration Institute (AHRI)

listed. NOTE: Installation of unmatched systems is not

permitted.

5.3 Interconnecting Tubing

Give special consideration to minimize the length of

refrigerant tubing when installing air handlers. Refer

to Remote Cooling/Heat Pump Service Manual

RS6200006, and TP-107 Long Line Set Application R410A for tubing guidelines. If possible, allow adequate

length of tubing such that the coil may be removed (for

inspection or cleaning services) from the cabinet without disconnecting the tubing.

5.4 Clearances

The unit clearance from a combustible surface may be

0". However, service clearance must take precedence.

A minimum of 24" in front of the unit for service clearance is required. Additional clearance on one side or

top will be required for electrical wiring connections.

Consult all appropriate regulatory codes prior to determining final clearances. When installing this unit in

an area that may become wet (such as crawl spaces),

elevate the unit with a sturdy, non-porous material. In

installations that may lead to physical damage (i.e. a

garage) it is advised to install a protective barrier to

prevent such damage. Always install units such that a

positive slope in condensate line (1/4" per foot) is allowed.

5.5 Horizontal Applications

If installed above a finished living space, a secondary

drain pan (as required by many building codes), must

be installed under the entire unit and its condensate

drain line must be routed to a location such that the

user will see the condensate discharge.

HOMEOWNER SUPPORT

GOODMAN MANUFACTURING COMPANY, L.P.

19001 KERMIER ROAD

WALLER, TEXAS 77484

(877) 254-4729

3

6 Installation Location

D

E

NOTE: These air handlers are designed for indoor installa-

tion only.

The ARUF**14** and ASPT**14** product lines may be installed

in one of the upflow, downflow, horizontal left or horizontal right orientations as shown in Figures 2, 3, 4 and 5. The

unit may be installed in upflow or horizontal left orientation as shipped (refer to specific sections for more information).

No field modifications are mandatory. However, to obtain

maximum efficiency, the horizontal drip shield, side drain

pan and drain pan extension can be removed.

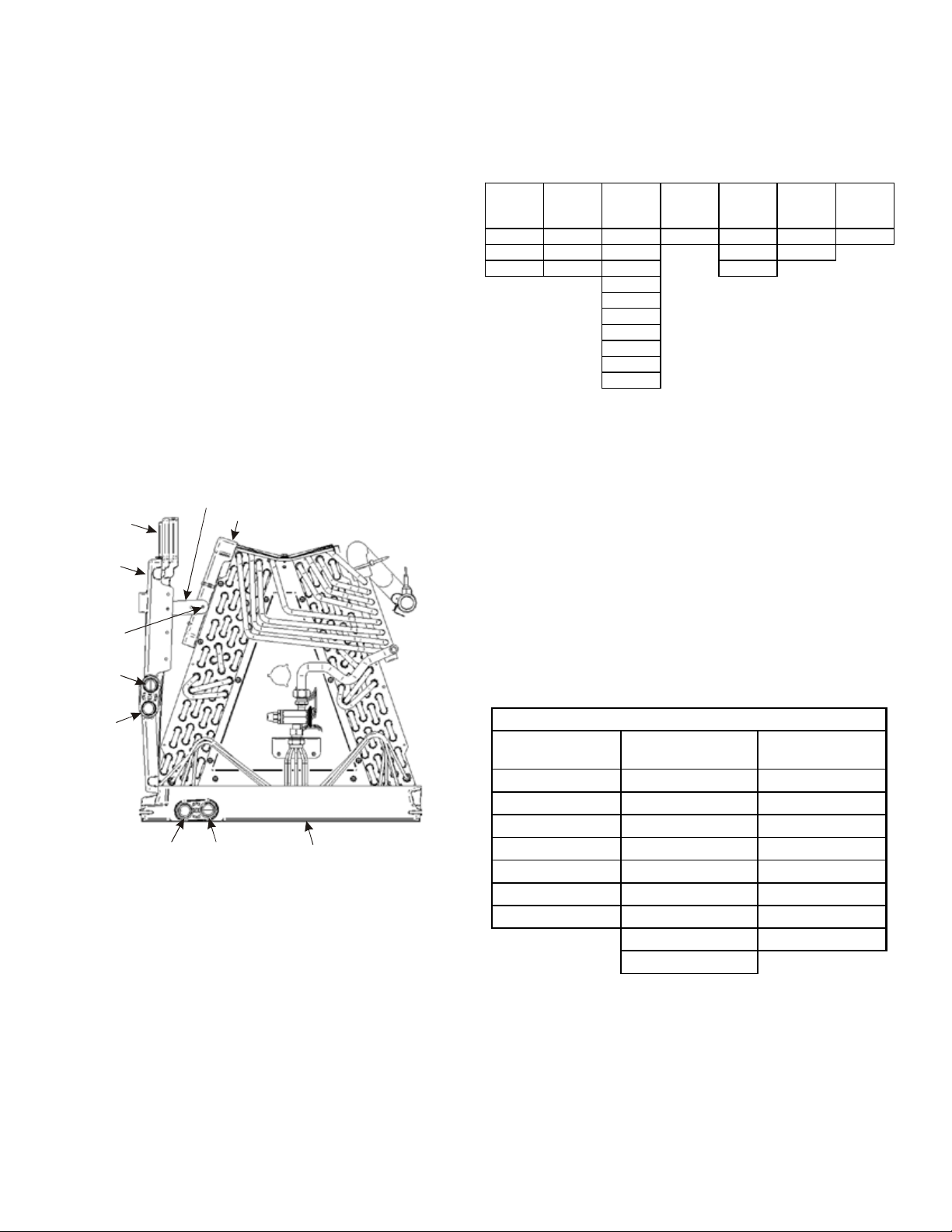

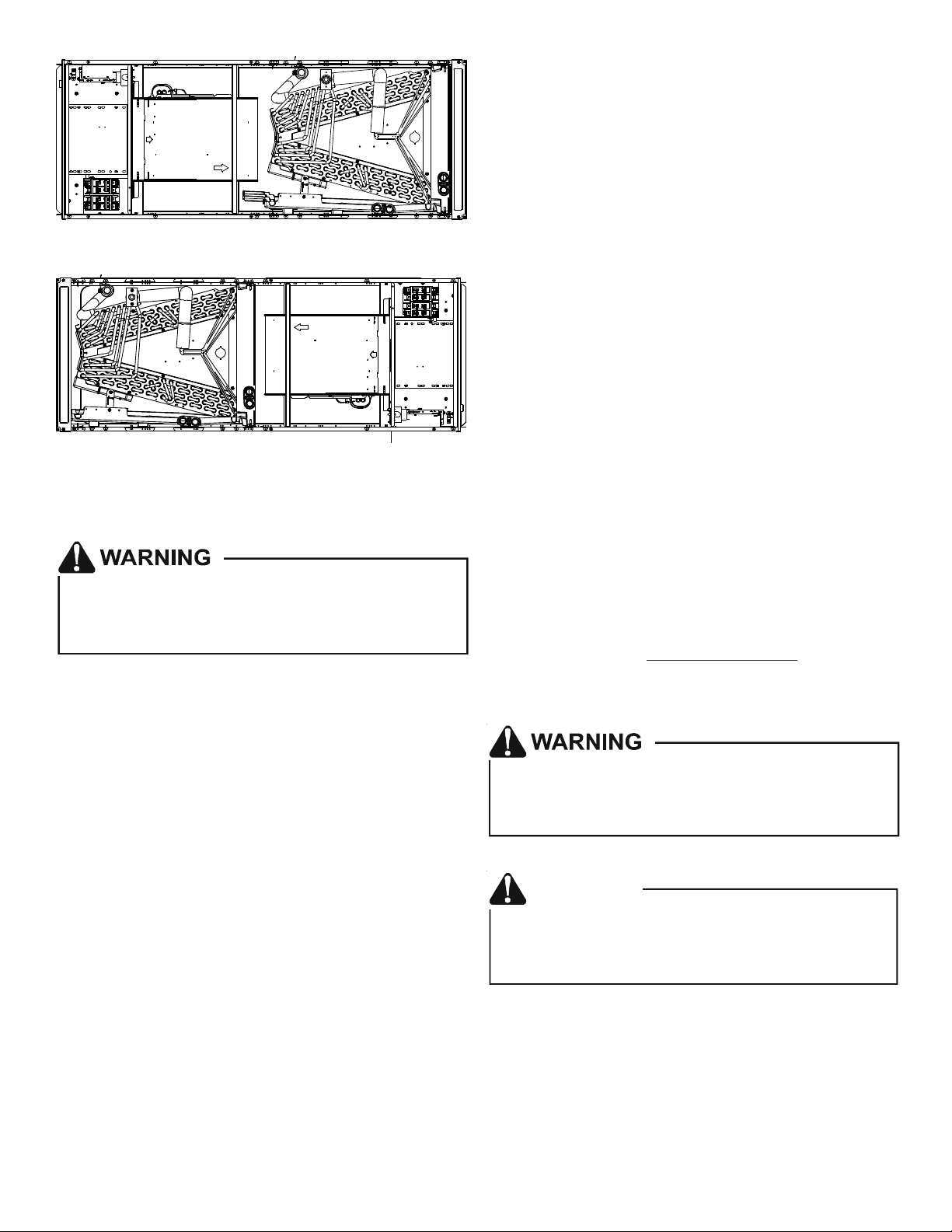

Side Drain Pan and Extension Removal: Refer to Figure 1,

remove the two (2) screws that secure the drip shield support brackets to the condensate collectors (front and back).

Unsnap the side drain pan from the bottom drain pan using

a screw driver or any small lever. The side drain pan, drip

shield brackets and the drain pan extension may now be

removed. From Figure 1, drain port labeled (A) is the primary drain for this application and condensate drain line

must be attached to this drain port. Drain port (a) is for the

secondary drain line (if used).

rip Pan

xtension

Side

Drain

Pan

Screw

Drip Shield Bracket

Drip Shield

In applications where the air handler is installed in the horizontal left position, and the return air environment see

humidity levels above 65% relative humidity coupled with

total external static levels above 0.5” e.s.p., a condensate

kit is available for field application. Kit nomenclature can

be found in Table 1.

Kit

CMK0014

Condensate

Kit

CMK0008

Condensate

ARUF25B14 ARUF31B14 ARUF37C14 ARUF47D14 ARUF61D14 ASPT33C14 ASPT49C14

ARUF29B14 ASPT29B14 ARUF37D14 ASPT49D14 ASPT39C14

ASPT25B14 ASPT37B14 ARUF43C14 ASPT61D14

CMK0009

Condensate

Kit

CMK0010

Condensate

Kit

ARUF43D14

ARUF49C14

ARUF49D14

ASPT37C14

ASPT47C14

ASPT47D14

ASPT59C14

CMK0011

Condensate

Kit

CMK0012

Condensate

Kit

CMK0013

Condensate

Kit

CONDENSATE KIT

Table 1

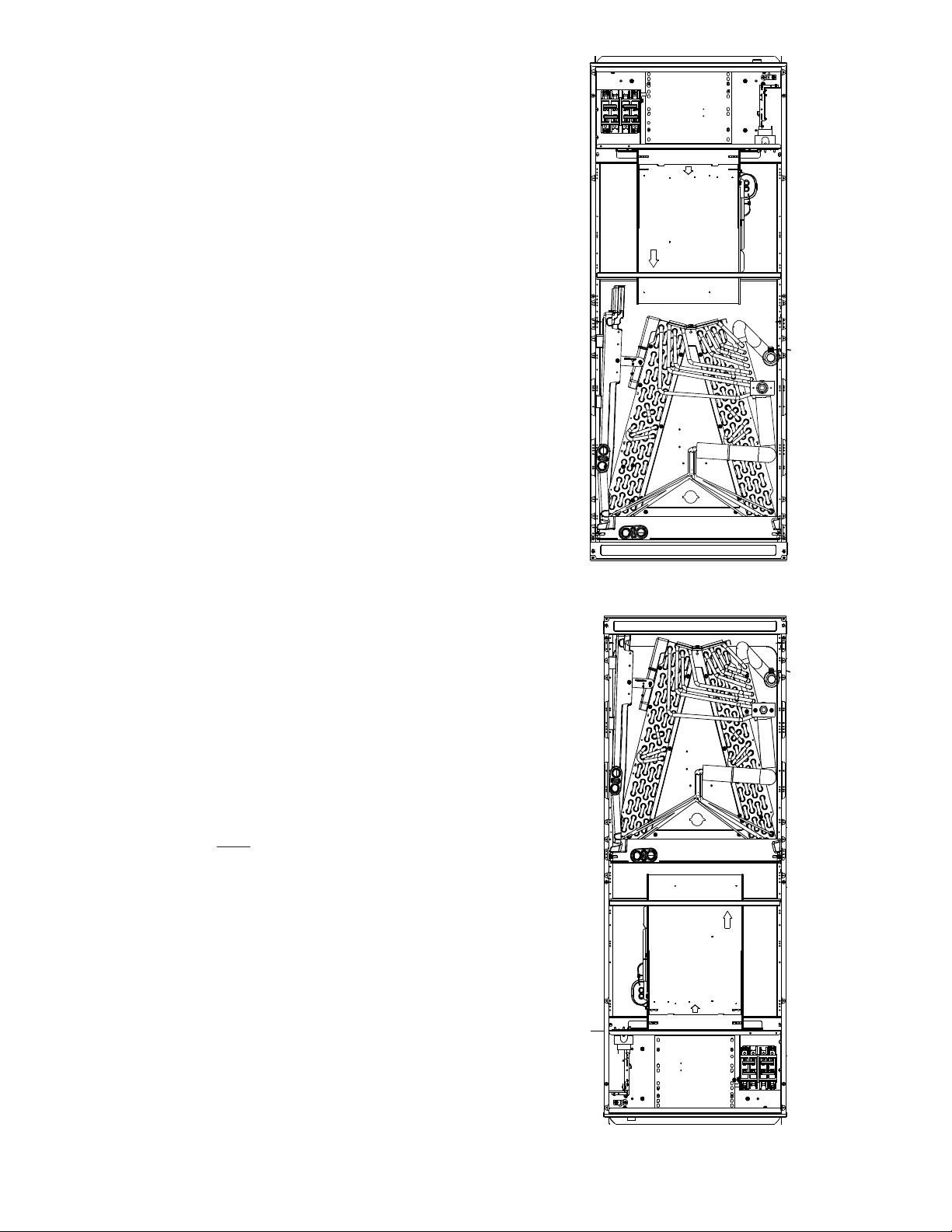

6.3 Horizontal Right Installation / Downflow

Installation

When installing unit in the downflow position the appropriate (DFK) downflow kit is required to prevent “coil pan

sweating”. The DFK kit is not supplied with the air handler

and is available through your local distributor. See Table 2

for the correct DFK and follow the instructions provided for

installation.

Side drain pan extension must be removed in the downflow

and horizontal right applications for all models except:

ARUF47D14**, ARUF61D14**, ASPT61D14**, ASPT49D14**.

b

B

A

Pna

Main Drain Pan

SIDE DRAIN PAN REMOVAL

Figure 1

6.1 Upflow Installation

No field modifications are mandatory.

6.2 Horizontal Left Installation

No field modifications are permissible for this application.

Install unit as shown in Figure 4.

Remove red plugs from side drain pan before connecting

condensate drain pipes. Use removed plug to close drain

ports on vertical drain pan. The bottom right drain connection in side drain pan is the primary drain for this application and condensate drain line must be attached to this

drain connection. The bottom left drain connection in side

drain pan is for the secondary drain line (if used).

Refer to Figure 6 and 7 for the location of the components referenced in the following steps.

MODEL LIST FOR DOWNFLOW KIT

DFK-B

DOWNFLOW KIT

ARUF25B14** ARUF37C14** ARUF37D14**

ARUF29B14** ARUF43C14** ARUF43D14**

ARUF31B14** ARUF49C14** ARUF47D14**

ASPT25B14** ASPT33C14** ARUF49D14**

ASPT29B14** ASPT37C14** ARUF61D14**

ASPT35B14** ASPT39C14** ASPT61D14**

ASPT37B14** ASPT47C14** ASPT47D14**

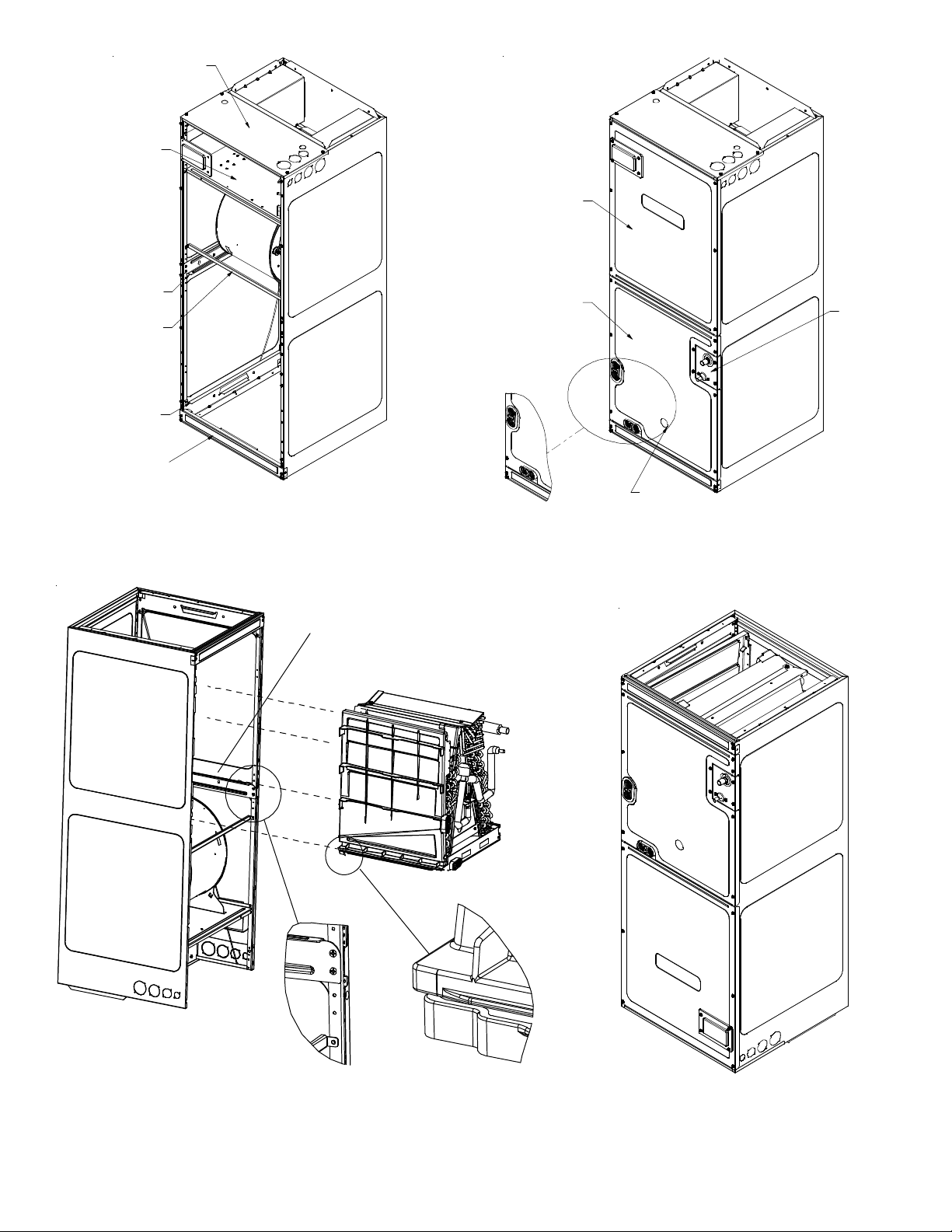

1. Before inverting the air handler, remove blower access panel and coil access panel. The coil access panel

and tubing panel may remain screwed together during

this procedure. Remove and retain the seven (7) screws

securing the coil access panel to the cabinet and the

six (6) screws securing the blower access panel to the

cabinet.

DFK-C

DOWNFLOW KIT

DFK-D

DOW NFLOW KIT

ASPT49C14** ASPT49D14**

ASPT59C14**

DOWNFLOW KIT

Table 2

4

2. Slide the coil assembly out from the cabinet. Use the

drain pan to pull the assembly from the cabinet.

NOTE: DO NOT USE MANIFOLDS OR FLOWRATOR TO

PULL THE COIL ASSEMBLY OUT. FAILURE TO DO SO

MAY RESULT IN BRAZE JOINT DAMAGE AND LEAKS.

3. Removal of the center support is required on units with

21" wide cabinet. Remove and retain the two (2) screws

that secure the center support to the cabinet. Remove

the center support.

4. Position the unit in the downflow position.

5. Using the drain pan to hold the coil assembly, slide the

coil assembly back into the cabinet on the downflow

brackets as shown in Figure 8.

6. Reinstall the center support (if removed) using the two

(2) screws removed in Step 5.

7. Reinstall the coil access panels and reinstall blower

access panel removed in Step 1 as shown in Figure 9.

8. Drain Connections for Horizontal Right Installation

a. The bottom right drain connection in side drain pan

is the primary drain for this application and condensate drain line must be attached to this drain

connection. The bottom left drain connection is

for the secondary drain line (if used).

b. Remove red plugs from side drain pan before con-

necting condensate drain pipes. Use removed plug

to close drain ports on vertical drain pan.

UPFLOW

Figure 2

9. Drain Connections for Downflow Installation

a. The bottom left drain connection in the vertical

drain pan is the primary drain for this application

and condensate drain line must be attached to this

drain connection. The bottom right drain connection is for the secondary drain line (if used).

b. Remove red plugs from vertical drain pan before

connecting condensate drain pipes.

NOTE: If removing only the coil access panel from the unit,

the filter access panel must be removed first. Failure

to do so will result in panel damage.

DOWNFLOW

Figure 3

5

HORIZONTAL LEFT

Figure 4

HORIZONTAL RIGHT

Figure 5

7 Refrigerant Lines

This product i s factory-shipped with R410A and dry

nitrogen mixture gas under pressu re. Use appr opria te

service tools and follow these instructions to prevent

injury .

NOTE: Refrigerant tubing must be routed to allow adequate

access for servicing and maintenance of the unit.

7.1 Tubing Size

For the correct tubing size, follow the specification for

the condenser/heat pump.

7.2 Tubing Preparation

All cut ends are to be round, burr free, and clean. Failure to follow this practice increases the chances for

refrigerant leaks. The suction line is spun closed and

requires tubing cutters to remove the closed end.

NOTE: To prevent possible damage to the tubing joints,

do not handle coil assembly with manifold or flowrator

tubes. Always use clean gloves when handling coil assemblies.

7.3 Special Instructions

Units without a factory installed TXV come equipped

with a flowrator piston for refrigerant expansion. For

most installations with matching applications, no

change to the flowrator piston is required. However,

in mix-matched applications, a flowrator piston

change may be required. See the piston kit chart (provided in the literature packet) or consult your local

distributor for details regarding mix-matched

flowrator piston sizing. If the mix-match application

requires a different flowrator piston size, change the

flowrator piston in the flowrator body on the indoor

coil before installing the coil and use the procedure

in section 7.4.

NOTE: The use of a heat shield is strongly recommended

when brazing to avoid burning the serial plate or the

finish of the unit. Heat trap or wet rags must be used

to protect heat sensitive components such as service

valves and TXV valves sensing bulb.

Do not install the air handler in a location that violates the

instructions provided with the condenser. If the unit is

located in an unconditioned area with high ambient

temperature and/or high humidity, the air handler may be

subject to nuisance sweating of the air handler cabinet.

On these installations, a wrap of 2" fiberglass insulation

with a vapor barrier is recommended.

A quenching cloth is strongly recommended to prevent

scorching or marring of the equipment finish when

brazing close to the painted surfaces. Use brazing

alloy of 5% minimum silver content.

CAUTION

Applying too much heat to any tube can melt the tube. Torch

heat required to braze tubes of various sizes must be

proportional to th e s ize of th e tube. S er vice p er sonn el mu st

use the appropriate heat level for the size of the tube being

brazed.

6

Upper Tie Plate

Control

Deck

Blower

Access

Panel

Downflow

Bracket

Center

Support

Filter

Bracket

Filter

Access

Panel

INTERNAL PART TERMINOLOGY

Figure 6

Coil slides

on the downflow bracket

Coil

Access

Panel

UV

Knockout

EXTERNAL PART TERMINOLOGY

Figure 7

Tubing

Panel

IMPORTANT NOTE:

Ensure coil slides on the rails along the groove provided on the drain pan side

walls. Failure to do so will result in improper condensate drainage.

COIL INSTALLATION FOR DOWNFLOW

Figure 8

7

ACCESS PANEL CONFIGURATION FOR DOWNFLOW

OR HORIZONTAL RIGHT

Figure 9

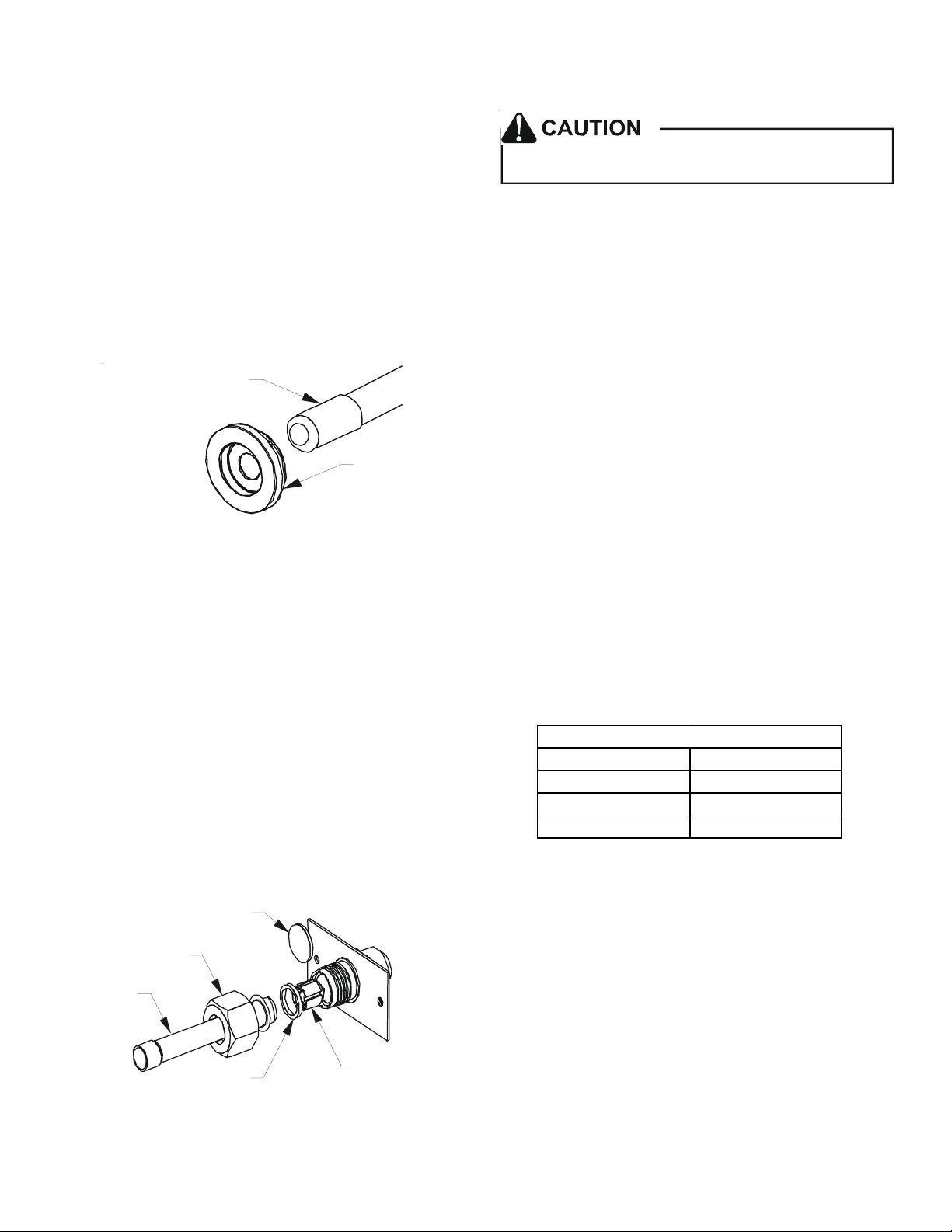

7.4 Tubing Connections for Flowrator Model

1. Loosen the 13/16 nut 1 TURN ONLY to allow high pressure tracer gas to escape. No gas indicates a possible

leak.

9. Torque the 13/16 nut to 7-25 ft-lbs. or tighten 1/6

turn.

2. After the gas has been expelled, remove the nut and

discard the black or brass cap plastic seal.

3. Remove the flowrator piston to verify it is the correct

size for the outdoor unit being installed and then replace the piston (changing size, if needed). See piston

kit chart in the literature kit for appropriate piston

size.

4. Remove the spin closure on the suction line using a

tube cutter and deburr the tube.

SUCTION LINE

WITH SPIN CLOSURE

RUBBER

GROMMET

SUCTION SPUN END AND GROMMET

Figure 10

5. Insert the suction line into the connection, slide the

insulation and the rubber grommet at least 18" away

from the braze joint.

6. Remove the tailpiece clamped to the exterior of the

cabinet or in the literature kit packet and slide the

13/16 nut into place.

Excessive torque can cause orifices to stick. Use the

proper torque settings when tightening orifices.

7.5 Tubing Connections for TXV Models

TXV models come with factory installed TXV with the

bulb pre-installed on the vapor tube.

1. Remove refrigerant tubing panel or coil (lower) access

panel.

2. Remove access valve fitting cap and depress the valve

stem in access fitting to release pressure. No pressure

indicates possible leak.

3. Replace the refrigerant tubing panel.

4. Remove the spin closure on both the liquid and suction

tubes using a tubing cutter.

5. Insert liquid line set into liquid tube expansion and

slide grommet about 18" away from braze joint.

6. Insert suction line set into suction tube expansion and

slide insulation and grommet about 18" away from braze

joint.

7. Braze joints. Quench all brazed joints with water or a

wet rag upon completion of brazing.

7.6 ASPT**14** Models with Non-Adjustable TXV

ASPT air handlers equipped with Parker non-adjustable TXV

should be charged by subcooling only.

7. Braze tailpiece to the line set liquid tube and braze

suction line connection. Quench all brazed joints with

a damp rag upon completion of brazing. Do not allow

water to enter the inside of the tubing.

8. AFTER THE TAILPIECE HAS COOLED, confirm position

of the white Teflon® seal and hand tighten the 13/16

nut.

PLASTIC or BRASS CAP

13/16” NUT

TAILPIECE

WHITE

TEFLON SEAL

TAILPIECE JOINT

Figure 11

PISTON

Models

ASPT25B14** ASPT47D14**

ASPT29B14** ASPT47C14**

ASPT37B14** ASPT49D14**

ASPT37C14** ASPT59C14**

Table 3

See section 7.7 for detailed information on adjusting the

thermal expansion valve.

8

7.7 Thermal Expansion Valve System Adjustment

Run the system at Cooling for 10 minutes until refrigerant

pressures stabilize. Use the following guidelines and methods to check unit operation and ensure that the refrigerant

charge is within limits. Charge the unit on low stage.

1. Purge gauge lines. Connect service gauge manifold to

base-valve service ports.

2. Temporarily install a thermometer on the liquid line

at the liquid line service valve and 4-6" from the compressor on the suction line. Ensure the thermometer

makes adequate contact and is insulated for best possible readings. Use liquid line temperature to determine subcooling and vapor temperature to determine

superheat.

3. Check subcooling and superheat. Systems with TXV application should have a subcooling of 7 to 9ºF and superheat of 7 to 9 ºF.

a. If subcooling and superheat are low, adjust TXV to

7 to 9 ºF superheat, then check subcooling.

NOTE: To adjust superheat, turn the valve stem clockwise

to increase and counter clockwise to decrease.

b. If subcooling is low and superheat is high, add charge

to raise subcooling to 7 to 9ºF then check superheat.

c. If subcooling and superheat are high, adjust TXV

valve to 7 to 9 ºF superheat, then check subcooling.

d. If subcooling is high and superheat is low, adjust

TXV valve to 7 to 9 ºF superheat and remove charge to

lower the subcooling to 7 to 9ºF.

NOTE: Do NOT adjust the charge based on suction pressure

unless there is a gross undercharge.

4. Disconnect manifold set, installation is complete.

NOTE: Check the Schrader ports for leaks and tighten valve

cores if necessary. Install caps finger-tight.

SUBCOOL FORMULA =

SAT. LIQUID LINE TEMP. - LIQUID LINE TEMP.

SUPERHEAT FORMULA =

SUCT. LINE TEMP. - SAT. SUCT. TEMP.

NOTE: Expansion valve system in ASPT models are already

tuned for 16 SEER single stage Heat Pump, adjustment of

Expansion valve system is required in case subcool, superheat

does not match to Section 7.6.3 above or when these models

are installed with any other outdoor models.

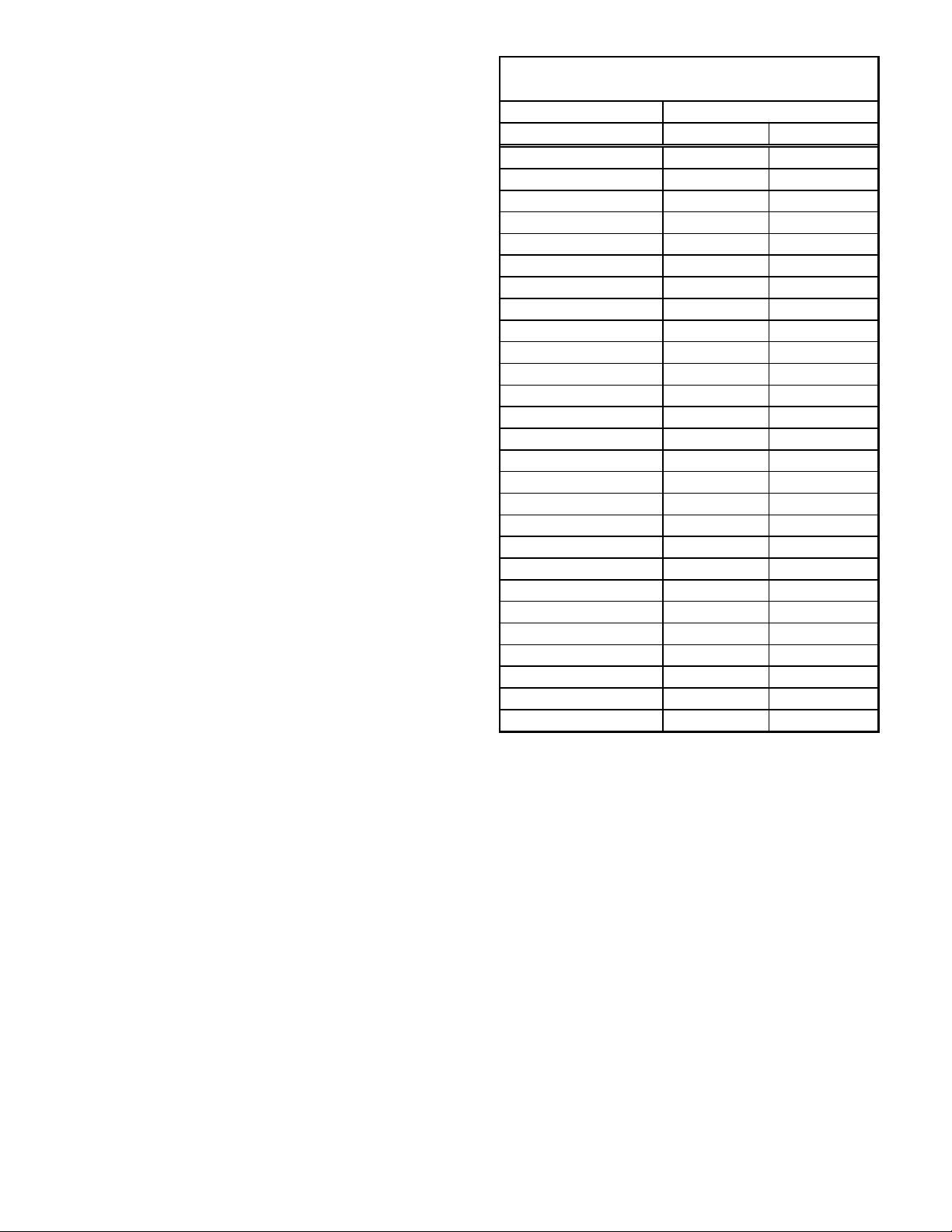

SATURATED SUCTION PRESSURE

TEMPER AT UR E CH AR T

SUCTION PRESSURE

PSIG R- 22 R- 410A

50 26 1

52 28 3

54 29 4

56 31 6

58 32 7

60 34 8

62 35 10

64 37 11

66 38 13

68 40 14

70 41 15

72 42 16

74 44 17

76 45 19

78 46 20

80 48 21

85 50 24

90 53 26

95 56 29

100 59 31

110 64 36

120 69 41

130 73 45

140 78 49

150 83 53

160 86 56

170 90 60

SATURATED SUCTION

9

Loading...

Loading...