Goodman ASAS-10ASC, ASAS-11ASC, ASAS-12ASC, ASAS-18ASC, GSAS-10ASC Installation, Operation And Service Instructions

...

INSTALLATION, OPERATION AND

SERVICE INSTRUCTIONS

MODELS

ASAS-10ASC, ASAS-1 1ASC, ASAS-12ASC, ASAS-18ASC

GSAS-10ASC, GSAS-11ASC, GSAS-12ASC, GSAS-18ASC

ELECTRONIC AIR CLEANERS

IMPORTANT: PLEASE READ MANUAL BEFORE OPERATING UNIT

Features

•

Lifetime Filter System never needs replacing

• Electronically removes dust, mites, pollen, pet dander, tobacco smoke, cooking smoke

and grease, mold, fungi, bacteria, and more down to 0.01 micron

• Light Weight Aluminum Collecting Cells are durable and easy to maintain

• Cell Guides ensure proper placement of collecting cells

• Activated Carbon Filters remove unpleasant odors

• Galvanized Steel Cabinet for solid vertical or horizontal installation

• Durable Scratch-Resistant powder coat paint finish resists corrosion

• Electronic Air Proving Switch for quick wiring

• Dual Indicator Lights show Air Cleaner is working properly at a glance

FOR QUESTIONS REGARDING INSTALLATION, OPERATION & SERVICE,

CALL THE AIR CLEANER HOTLINE TOLL-FREE

1-800-267-8305

IMPORTANT: Please read entire instructions before

installing the Electronic Air Cleaner.

CONTENTS

SAFETY CONSIDERATIONS 2

WHAT THE ELECTRONIC AIR CLEANER DOES 2

BENEFITS 2

HOW IT WORKS 2

COMPONENTS 2

INSTALLATION 3-5

Location 3

Installation Location With Humidifier 3

Installation Location With Air Conditioner 3

Electronic Air Cleaner Installation 3

Wiring 5

SYSTEM CHECK 5

OPERATION 5

WHITE DUST 5

MAINTENANCE 5

Cell and Prefilter Cleaning 5

Activated Carbon Filter Replacement 6

SERVICE 6-10

Testing Air Proving Switch (APS) 6

Replacing An Air Proving Switch (APS) 7

Testing For High Voltage AT Power Board 7

Replacing Performance Light 7

Replacing A Power Board 7

Testing The 24 V Transformer 7

Replacing The 24 V Transformer 8

Testing Voltage Of Power Board 8

Testing Voltage At Cell 9

Setting Approx. Voltage With High Voltage Meter 9

Testing Cell For Bad Contacts 9

Removing Power Box 9

Removing High Voltage Contact Tray 9

Replacing A Tungsten Ionizing Wire 10

TROUBLESHOOTING GUIDE 11

WARRANTY 12

SAFETY CONSIDERATIONS

Read and follow instructions carefully. Follow all

local electrical codes during installation. All wiring must

conform to local and national electrical codes. Improper

wiring or installation may damage Air Cleaner.

Understand the signal words WARNING and

CAUTION which are present in the Installation,

Operation & Service Instructions.

WARNING and CAUTION signifies a hazard which

could result in property damage, personal injury or

death.

Note: This unit is Certified for Shock and Electrical

Fire Hazard only.

WARNING

Before beginning any installation or modification,

be certain that the main line electrical disconnect

switch is in OFF position. Electric shock could

result. Tag disconnect switch with suitable

warning labels.

Installation and servicing of Electronic Air

Cleaners can be hazardous. Only trained and

qualified service personnel should install, repair, or

service Electronic Air Cleaners.

Homeowners or untrained personnel can

perform the basic maintenance functions of

cleaning and replacing filters.

When working on air cleaning equipment,

observe precautions in the manual, labels attached

to the unit, and other safety precautions that may

apply. Follow all safety codes. Wear safety glasses

and work gloves.

WHAT THE ELECTRONIC AIR CLEANER DOES

Your High Efficiency Electronic Air Cleaner has

been designed to remove atmospheric and household

dust, coal dust, insecticide dust, mites, pollen, mold

spores, fungi, bacteria, pet dander, cooking smoke and

grease, tobacco smoke particles, and more down to

0.01 micron (.01 micron = 1/2,540,000 of an inch).

• Helps provide relief for allergy or asthma suffering.

• Helps prevent damaging black dust from staining

walls and furnishings, reducing the amount of time

and money spent cleaning and redecorating.

• Helps eliminate unpleasant odors (with use of

optional Carbon Filters).

• Helps protect heating/cooling equipment,

prolonging the operating efficiency.

The High Efficiency Electronic Air Cleaner operates

on the principle of electrostatic precipitation. Millions of

airborne pollutants are carried through the return air

ducts of the heating/cooling system and treated

through four stages of filtration.

The prefilters (2) remove all large visible particles

such as lint. Smaller particles then pass through a two-

stage electrostatic collecting cell (2). First, particles are

given a powerful positive electrical charge by the

ionizing wires. Second, charged particles move into the

collecting area where they are attracted to a series of

grounded plates. Pollutants are held in this section like

a magnet until washed away during cleaning. Lastly,

clean air passes over

odor removal (optional).

The Electronic Air Cleaner, available in four models

with air flow capacities of up to 1200, 1400 and 2000

CFM (2040, 2380 and 3400 m³/hr), is adaptable to all

residential forced air heating or cooling systems.

BENEFITS

HOW IT WORKS

activated carbon filters (3) for

MODEL A/ GSAS-10ASC A/ GSAS-11ASC A/ GSAS-12ASC A/ GSAS-18ASC

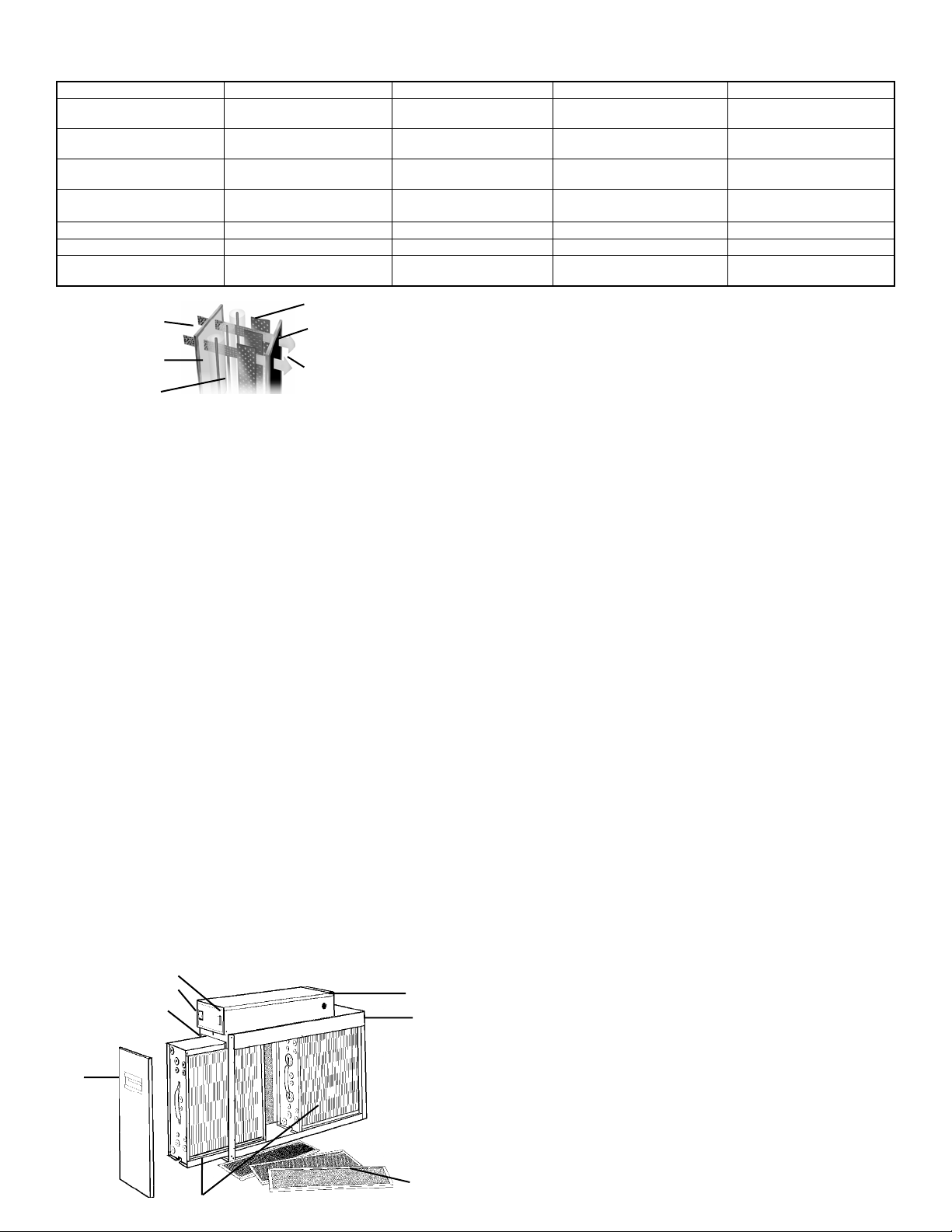

Fig. 1

House Size Area <2400 ft²

Airflow up to 1200 cfm

Duct Size 16 x 20 in

Unit Weight 28.0 lbs

Input Voltage 120 v 60 hz 120 v 60 hz 120 v 60 hz 120 v 60 hz

Power Consumption 30 Watts 30 Watts 30 Watts 30 Watts

Upgrades Included Carbon Filters (C)

1 Dirty Air

3 Ionizing

Section

2 Prefilter

<222.96 m²

up to 2039 m³/hr

40.5 x 51.0 cm

12.9 kg

Air Switch (AS)

4 Collecting Cell Plates

5 Carbon Filters (3)

6 Clean Air to Heating/Cooling

System

COMPONENTS

Cabinet: Constructed of heavy gauge galvanized

steel to resist corrosion and provide trouble-free

installation. Holes are provided to facilitate mounting to

the ductwork or air handling equipment.

Power Box: Removable. Contains the power switch,

performance indicator light, safety interlock switch,

high voltage power board and air proving switch.

The power board is uniquely equipped with a variable

resistor (potentiometer) to adjust high voltage output.

Output has been pre-set for optimum efficiency. As

voltage varies in extreme conditions of dryness,

humidity or proximity to hydro towers, raising or

lowering potentiometer allows for proper voltage

output.

Air Proving Switch (APS): Integrated. Automatically

cycles Air Cleaner on and off with the system fan. The

APS will detect airflow (fan on) and energize Air

Cleaner.

High Voltage Tray: Contains the contacts and wi res to

supply high voltage to the collecting cells.

Collecting Cells: Consist of an ionizing section and a

plate section. The arrow on the cell must point toward

the system fan.

Prefilters: Constructed of aluminum mesh, to prevent

lint and large particles from entering the collecting

cells.

Carbon Filters: Remove odors. Must be replaced

every six months - not washable. Maximum of (3)

carbon filters can be used at same time.

Performance Indicator Light

ON/OFF Switch

Prefilters (2)

Door

Fig. 2

Collecting Cells (2)

Table 1 — SPECIFICATIONS

<3000 ft²

<278.70 m²

up to 1400 cfm

up to 2379 m³/hr

16 x 25 in

40.5 x 63.5 cm

30.0 lbs

13.5 kg

Carbon Filters (C)

Air Switch (AS)

Location

The Air Cleaner must be installed in the return air

duct, as close to the fan compartment as possible. This

location provides the most even airflow across the

collecting cells and allows the Air Cleaner to keep the

system motor and blower clean. When choosing

location, there must be adequate room to wire the Air

Cleaner and remove prefilters, collecting cells and

power box.

Note: Once Air Cleaner has been installed, do not

allow the placement of any device such as a new hot

water heater, water softener, gas pipe, or electrical

cable to be put 2 ft. in front of or within 6 in. (15 cm)

from top of Air Cleaner, in order to allow removal of

filters and Air Cleaner parts, which are necessary for

maintenance or servicing.

Installation Location With Humidifier

A humidifier should be installed in the furnace

warm air duct. However, it may be installed in the

return duct without causing problems to the Air

Cleaner. Care must be taken to ensure that the

humidifier does not leak, as this may cause arcing and

a mineral deposit to build up on the collecting cells.

An atomizing type humidifier should be installed

downstream from the Air Cleaner. If the atomizing type

humidifier is installed upstream, high humidity, salts

and minerals may decrease the efficiency of the

collecting cells and cause service problems.

If the atomizing type humidifier must be installed

upstream, the following precautions should be taken:

1. Atomizing type humidifier must be installed as far

from the Air Cleaner as possible.

2. Collecting cells must be washed frequently to

prevent a mineral deposit build-up.

Installation Location With Air Conditioner

Power Box

Whenever possible, the Air Cleaner should be

installed upstream of the cooling coil. This location will

Cabinet

clean the air before it reaches the evaporator coil.

Electronic Air Cleaner Installation

1. Remove existing equipment filter. Thoroughly

clean fan compartment and ductwork where Air

Cleaner is to be installed.

2. Open access door. Slide prefilters and collecting

cells out of cabinet.

Activated

Carbon Filters

<3000 ft²

<278.70 m²

up to 1400 cfm

up to 2379 m³/hr

20 x 20 in

51.0 x 51.0 cm

33.0 lbs

15.3 kg

Carbon Filters (C)

Air Switch (AS)

INSTALLATION

>3000 ft²

>278.70 m²

up to 2000 cfm

up to 3398 m³/hr

20 x 25 in

51.0 x 63.5 cm

38.0 lbs

17.5 kg

Carbon Filters (C)

Air Switch (AS)

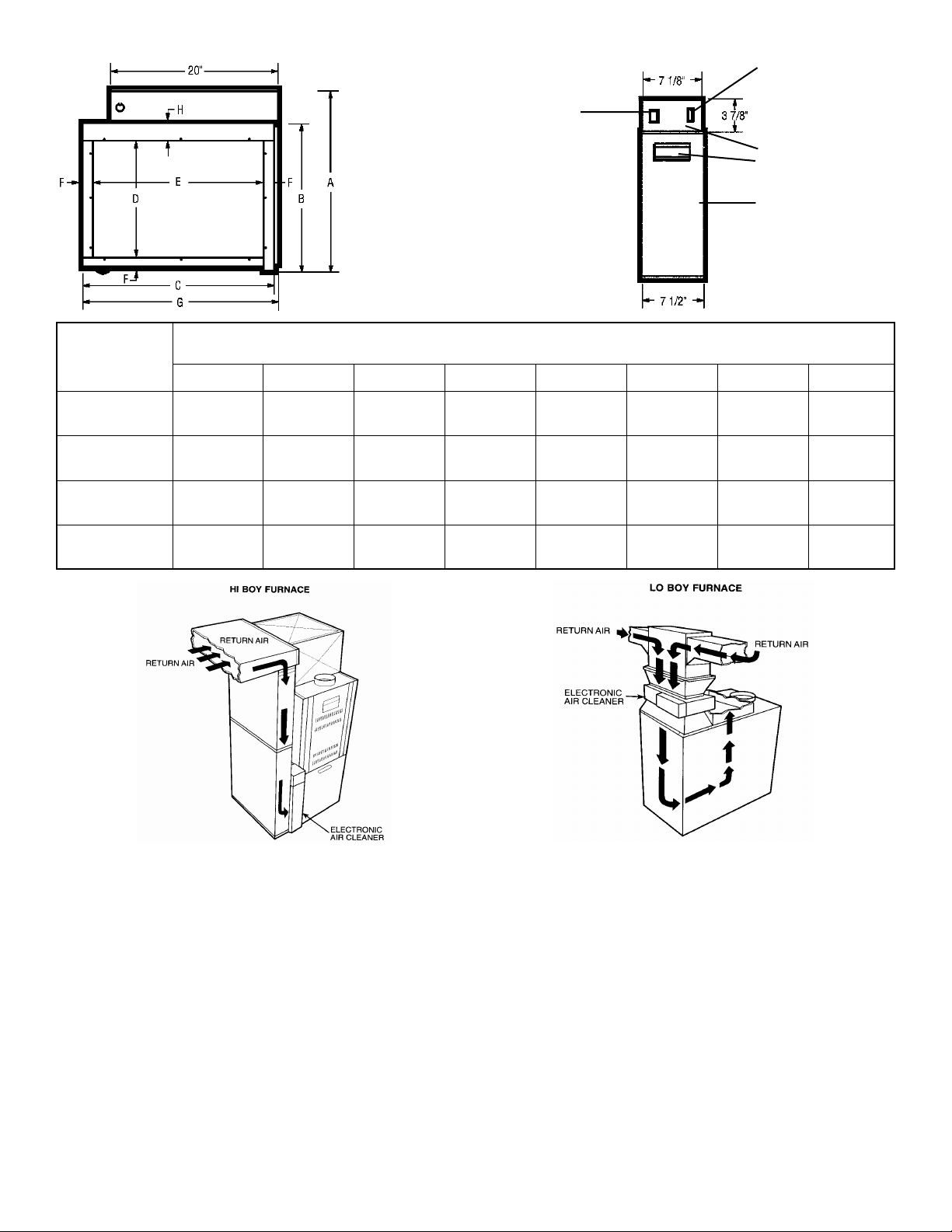

Fig. 3 — DIMENSIONS

Power Switch

AIR FLOW

Left to Right or

Right to Left

Î

Performance I ndicator

Light

Air Proving Switch

Handle

Door

DIMENSIONS — in (cm)

UNIT A B C D E F G H

ASAS-10ASC

GSAS-10ASC

ASAS-11ASC

GSAS-11ASC

ASAS-12ASC

GSAS-12ASC

ASAS-18ASC

GSAS-18ASC

21

(53.0)

21

(53.0)

25 7/8

(66.0)

25 7/8

(66.0)

17

(43.5)

17

(43.5)

22

(56.0)

22

(56.0)

23 1/4

(59.0)

26

(66.0)

21 1/4

(54.0)

26

(66.0)

13 1/8

(33.5)

13 5/8

(34.5)

18

(46.0)

18

(46.0)

20 3/4

(53.0)

24

(61.0)

18 3/4

(47.5)

23 1/2

(59.5)

1 1/4

(3.0)

1

(2.5)

1 1/4

(3.0)

1 1/4

(3.0)

23 3/4

(60.5)

26 1/2

(67.5)

21 3/4

(55.0)

26 1/2

(67.5)

2 3/8

(6.0)

2 1/8

(5.5)

2 3/8

(6.0)

2 3/8

(6.0)

Allow 24 in (600 mm) clearance for cleaning air cleaner. Allow 6 in. (150 mm) clearance for power box removal.

Fig. 4 — AIR CLEANER INSTALLATION LOCATION

3. Place cabinet in ductwork. Holes are provided to

attach cabinet to ductwork or equipment. If

adjoining ductwork is flanged, install the screws so

that screw heads are inside cabinet. This will help

prevent damage to prefilter and carbon filters

during removal for cleaning. NEVER put screws or

rivets into the removable power box.

When the air duct does not fit Air Cleaner opening,

a gradual transition is recommended to reduce air

turbulence through Air Cleaner and to increase its

efficiency. There should not be more than 20º of

expansion used on each side of transition fitting.

Do not reduce ductwork to a smaller Air Cleaner or

it will increase velocity of airflow.

4. If Air Cleaner is installed adjacent to an elbow or

angle fitting, turning vanes are recommended to

improve air distribution across the collecting cells.

5. After Air Cleaner has been secured, seal seams

airtight with duct tape or caulking to prevent dust

from entering the system.

6. Replace prefilters, collecting cells and carbon

filters. Make sure arrow on cell is pointing towards

the fan. The cell handle may need to be

repositioned if the airflow is in a different direction

than the left to right set up. The handle should face

the door. Close access door.

Loading...

Loading...