Page 1

ARUF**14** / ASPT**14**

AIR HANDLERS INSTALLATION & OPERATING INSTRUCTIONS

Contents

1 Important Safety Instructions................................... 1

2 Shipping Inspection ............................................... 3

2.1 Parts.............................................................3

2.2 Handling ........................................................3

3 Codes & Regulations .............................................. 3

4 Replacement Parts ................................................ 3

5 Pre-Installation Considerations ................................ 3

5.1 Preparation.....................................................3

5.2 System Matches................................................3

5.3 Interconnecting Tubing .......................................3

5.4 Clearances......................................................3

5.5 Horizontal Applications ......................................3

6 Installation Location ............................................. 4

6.1 Upflow Installation ...........................................4

6.2 Horizontal Left Installation .................................4

6.3 Horizontal Right Installation / Downflow Installation ..4

7 Refrigerant Lines .................................................. 6

7.1 Tubing Size .....................................................6

7.2 Tubing Preparation ............................................6

7.3 Special Instructions ...........................................6

7.4 Tubing Connections for Flowrator Model ..................8

7.5 Tubing Connections for TXV Models ........................8

7.6 ASPT**14** Models with Non-Adjustable TXV .............8

7.7 Thermal Expansion Valve System Adjustment ............9

8 Condensate Drain Lines ......................................... 10

9 Ductwork........................................................... 11

9.1 Return Ductwork ............................................ 11

10 Return Air Filters ............................................... 11

11 Electric Heat..................................................... 11

12 Electrical and Control Wiring ................................ 12

12.1 Building Electrical Service Inspection .................. 12

12.2 Wire Sizing .................................................. 12

12.3 Maximum Overcurrent Protection (MOP) .............. 12

12.4 Electrical Connections – Supply Voltage................ 12

12.4.1 Air Handler Only (Non-Heat Kit Models) ...... 14

12.4.2 Air Handler - Non-Circuit Breaker Heat Kits . 14

12.4.3 Air Handler With Circuit Breaker Heat Kit ... 14

12.5 Low Voltage Connections ................................. 14

12.5.1 Thermostats ....................................... 14

12.6 Speed Tap Adjustment .................................... 14

13 Achieving 1.4% Low Leakage Rate .........................14

14 Start-Up Procedure............................................. 15

15 Regular Maintenance........................................... 15

16 Airflow Data ..................................................... 16

17 Air Handler Low Voltage Connections ...................... 18

18 Wiring Diagrams................................................. 19

Only personnel that have been trained to install,

adjust, service or repair (hereinafter, “service”) the

equipment specified in this manual shou ld service

the equipment. The man u fa cturer will not be

responsible for any injury or property damage aris ing

from improper service or service procedures. If you

service this un it, you assume responsibility for any

injury or property damage which may result. In

addition, in jurisdictions that require one or more

licenses to service the equipment specified in this

manual, only licensed personnel should service the

equipment. Improper installation, adjustment,

servicing or repair of the equipment specified in this

manual, or attempting t o install, adjust, service or

repair the equipment specified in this manual without

proper t raining may result in product damage,

propert y damage, personal injury or death.

IO-901G

12/2017

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION.

Keep this literature in a safe place for future reference.

ATTENTION INSTALLING PERSONNEL

Prior to installation, thoroughly familiarize yourself with this Installation Manual.

Observe all safety warnings. During installation or repair, caution is to be observed.

It is your responsibility to install the product safely and to educate the customer on its safe use.

Page 2

HIGH VOLTAGE!

Disconnect ALL power before ser vicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injur y or death.

To prevent the risk of property damage, personal

injury , or dea th, do not store comb ustible m aterials or

use gasoline or other flammable liquids or vapors in

the vicin ity of this unit.

This product is factory-shipped for use with

208/240/1/60 electrical power supply.

DO NOT

reconfigure this air handler to operate with any other

power supply.

When installing or servicing this equipment, safety

clothing, including hand and eye protection, is

strongly recommended. If installing in an area that has

special safety requirements (hard hats, etc.), bserve

o

these requirements.

To avoid property damage, personal injury or death

due to electrical shock, this unit MUST have an

uninterrupted, unbroken

electrical ground. The

electrical ground circuit may consist of an

appropriately sized electrical wire connecting the

ground lug in the unit control box to the building

electrical service panel.

Other meth ods of gro unding ar e p ermit te d i f pe rfo rmed

in accordance with the National Electric Code

(NEC) /Amer ican National Stan dards I nsti tute

(ANSI)/ Nati onal Fire P rotec tion A ssocia tion (NFP A) 70

and local /s ta te c ode s. I n Canada, e le ctr ica l gro undi ng

is to be in accordance with t he Cana di an El ec tri c C ode

(CSA) C22.1.

1 Important Safety Instructions

The following symbols and labels are used throughout this

manual to indicate immediate or potential safety hazards.

It is the owner’s and installer’s responsibility to read and

comply with all safety information and instructions accompanying these symbols. Failure to heed safety information

increases the risk of personal injury, property damage, and/

or product damage.

CO can cause serious illness including perm anent bra in

damag e or death.

B10259-216

Advertenci a e spe cia l p ara la instalación de calentadores ó ma nejadoras

de aire en áreas cerradas como estacionamientos ó cuartos de servic io.

Las emis ion es de monóxido de carbono puede n c irc ula r a través

del aparat o c uando se opera en cualquier modo.

El monóx i do de carbono pued e causar enfermedades severas

como daño cerebral permanente ó muerte.

B10259-216

2

RISQUE D'E MPO ISO N NEM EN T AU

Cett e v entilation est nécessaire pour év iter le danger d'intoxication

au CO pouvant survenir si un appareil produisant du monoxyde

de carbon e continue de fonctionner au sei n de l a zone confin é e .

Le monoxyde de

des

dommages permanents au cerveau et meme la mort.

carbone peut causer des maladies graves telles que

MONOXYDE DE CARBONE

B10259-216

Page 3

2 Shipping Inspection

Always transport the unit upright; laying the unit on its side

or top during transit may cause equipment damage. The

installer should inspect the product upon receipt for shipping damage and subsequent investigation is the responsibility of the carrier. The installer must verify the model

number, specifications, electrical characteristics, and accessories are correct prior to installation. The distributor

or manufacturer will not accept claims from dealers for

transportation damage or installation of incorrectly shipped

units.

2.1 Parts

Also inspect the unit to verify all required components

are present and intact. Report any missing components

immediately to the manufacturer or to the distributor.

Use only factory authorized replacement parts (see Section 5). Make sure to include the full product model

number and serial number when reporting and/or obtaining service parts.

2.2 Handling

Use caution when transporting/carrying the unit. Do not

move unit using shipping straps. Do not carry unit with

hooks or sharp objects. The preferred method of carrying the unit after arrival at the job site is to carry via

a two-wheel hand truck from the back or sides or via

hand by carrying at the cabinet corners.

3 Codes & Regulations

This product is designed and manufactured to comply with

applicable national codes. Installation in accordance with

such codes and/or prevailing local codes/regulations is the

responsibility of the installer. The manufacturer assumes

no responsibility for equipment installed in violation of any

codes or regulations.

The United States Environmental Protection Agency (EPA)

has issued various regulations regarding the introduction

and disposal of refrigerants. Failure to follow these regulations may harm the environment and can lead to the

imposition of substantial fines. Should you have any ques-

tions please contact the local office of the EPA and/or refer to EPA’s website www.epa.gov.

4 Replacement Parts

When reporting shortages or damages, or ordering repair

parts, give the complete product model and serial numbers

as stamped on the product. Replacement parts for this

product are available through your contractor or local distributor. For the location of your nearest distributor consult the white business pages, the yellow page section of

the local telephone book or contact:

5 Pre-Installation Considerations

5.1 Preparation

Keep this document with the unit. Carefully read all

instructions for the installation prior to installing product. Make sure each step or procedure is understood

and any special considerations are taken into account

before starting installation. Assemble all tools, hardware and supplies needed to complete the installation.

Some items may need to be purchased locally. Make

sure everything needed to install the product is on hand

before starting.

5.2 System Matches

The entire system (combination of indoor and outdoor

sections) must be manufacturer approved and Air-Conditioning, Heating, and Refrigeration Institute (AHRI)

listed. NOTE: Installation of unmatched systems is not

permitted.

5.3 Interconnecting Tubing

Give special consideration to minimize the length of

refrigerant tubing when installing air handlers. Refer

to Remote Cooling/Heat Pump Service Manual

RS6200006, and TP-107 Long Line Set Application R410A for tubing guidelines. If possible, allow adequate

length of tubing such that the coil may be removed (for

inspection or cleaning services) from the cabinet without disconnecting the tubing.

5.4 Clearances

The unit clearance from a combustible surface may be

0". However, service clearance must take precedence.

A minimum of 24" in front of the unit for service clearance is required. Additional clearance on one side or

top will be required for electrical wiring connections.

Consult all appropriate regulatory codes prior to determining final clearances. When installing this unit in

an area that may become wet (such as crawl spaces),

elevate the unit with a sturdy, non-porous material. In

installations that may lead to physical damage (i.e. a

garage) it is advised to install a protective barrier to

prevent such damage. Always install units such that a

positive slope in condensate line (1/4" per foot) is allowed.

5.5 Horizontal Applications

If installed above a finished living space, a secondary

drain pan (as required by many building codes), must

be installed under the entire unit and its condensate

drain line must be routed to a location such that the

user will see the condensate discharge.

HOMEOWNER SUPPORT

GOODMAN MANUFACTURING COMPANY, L.P.

19001 KERMIER ROAD

WALLER, TEXAS 77484

(877) 254-4729

3

Page 4

6 Installation Location

D

E

NOTE: These air handlers are designed for indoor installa-

tion only.

The ARUF**14** and ASPT**14** product lines may be installed

in one of the upflow, downflow, horizontal left or horizontal right orientations as shown in Figures 2, 3, 4 and 5. The

unit may be installed in upflow or horizontal left orientation as shipped (refer to specific sections for more information).

No field modifications are mandatory. However, to obtain

maximum efficiency, the horizontal drip shield, side drain

pan and drain pan extension can be removed.

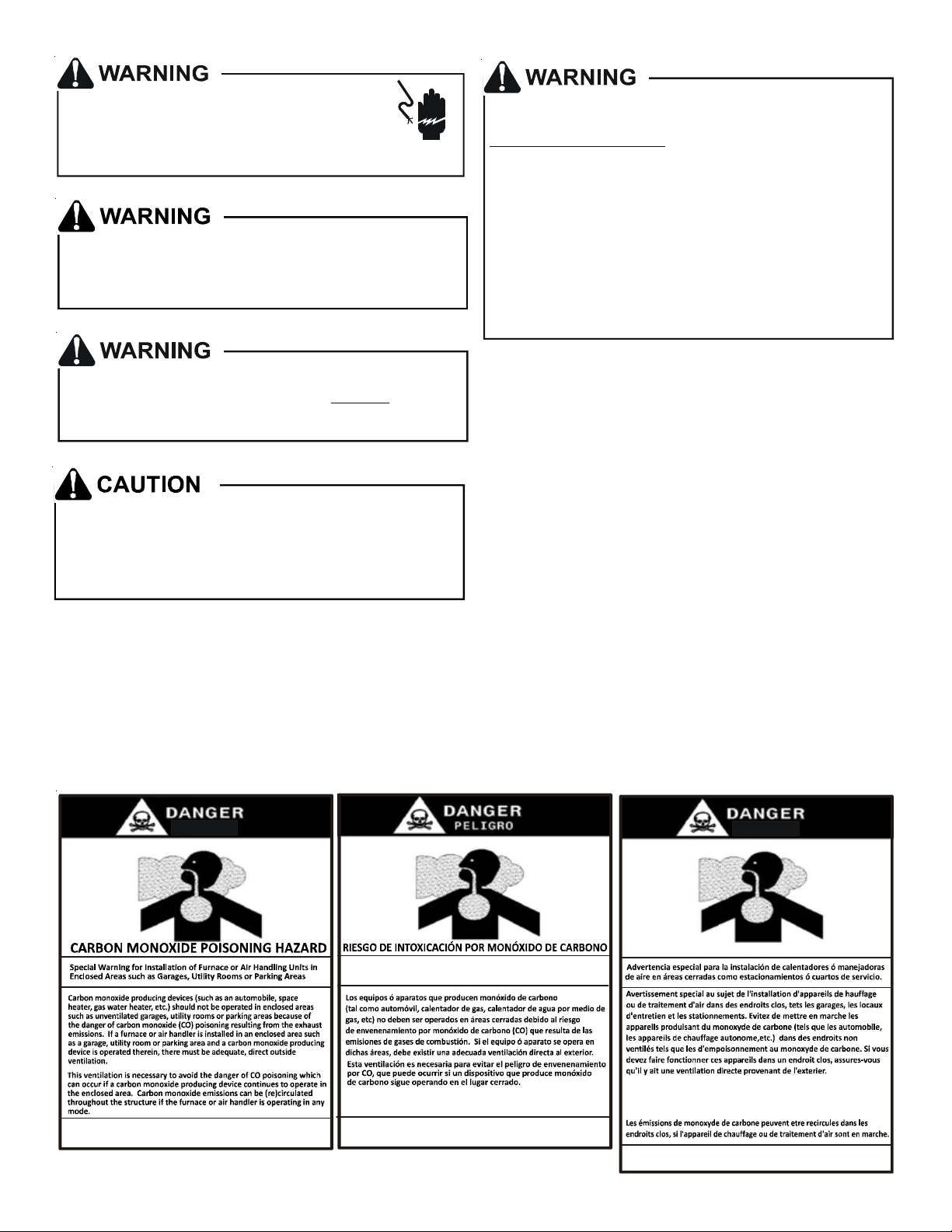

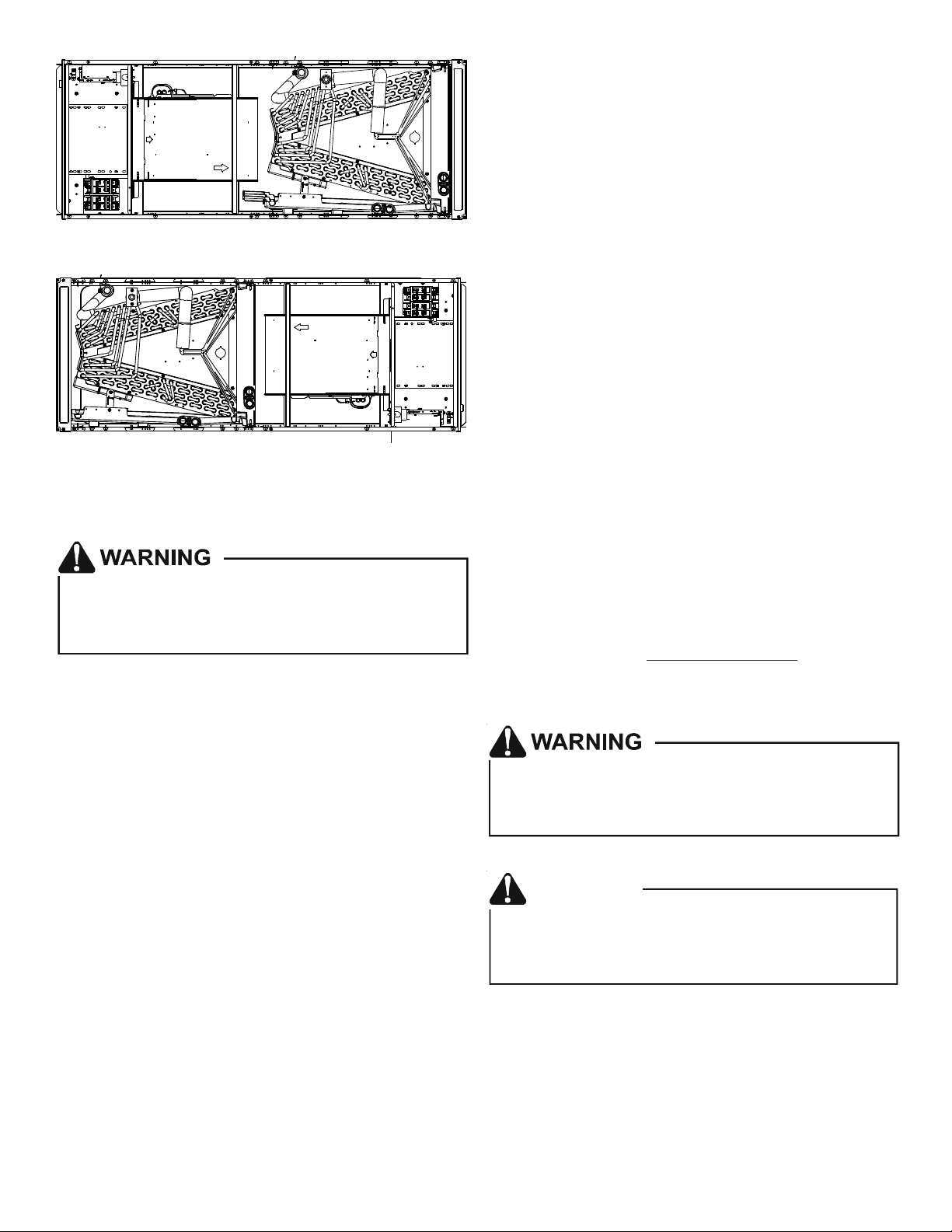

Side Drain Pan and Extension Removal: Refer to Figure 1,

remove the two (2) screws that secure the drip shield support brackets to the condensate collectors (front and back).

Unsnap the side drain pan from the bottom drain pan using

a screw driver or any small lever. The side drain pan, drip

shield brackets and the drain pan extension may now be

removed. From Figure 1, drain port labeled (A) is the primary drain for this application and condensate drain line

must be attached to this drain port. Drain port (a) is for the

secondary drain line (if used).

rip Pan

xtension

Side

Drain

Pan

Screw

Drip Shield Bracket

Drip Shield

In applications where the air handler is installed in the horizontal left position, and the return air environment see

humidity levels above 65% relative humidity coupled with

total external static levels above 0.5” e.s.p., a condensate

kit is available for field application. Kit nomenclature can

be found in Table 1.

Kit

CMK0014

Condensate

Kit

CMK0008

Condensate

ARUF25B14 ARUF31B14 ARUF37C14 ARUF47D14 ARUF61D14 ASPT33C14 ASPT49C14

ARUF29B14 ASPT29B14 ARUF37D14 ASPT49D14 ASPT39C14

ASPT25B14 ASPT37B14 ARUF43C14 ASPT61D14

CMK0009

Condensate

Kit

CMK0010

Condensate

Kit

ARUF43D14

ARUF49C14

ARUF49D14

ASPT37C14

ASPT47C14

ASPT47D14

ASPT59C14

CMK0011

Condensate

Kit

CMK0012

Condensate

Kit

CMK0013

Condensate

Kit

CONDENSATE KIT

Table 1

6.3 Horizontal Right Installation / Downflow

Installation

When installing unit in the downflow position the appropriate (DFK) downflow kit is required to prevent “coil pan

sweating”. The DFK kit is not supplied with the air handler

and is available through your local distributor. See Table 2

for the correct DFK and follow the instructions provided for

installation.

Side drain pan extension must be removed in the downflow

and horizontal right applications for all models except:

ARUF47D14**, ARUF61D14**, ASPT61D14**, ASPT49D14**.

b

B

A

Pna

Main Drain Pan

SIDE DRAIN PAN REMOVAL

Figure 1

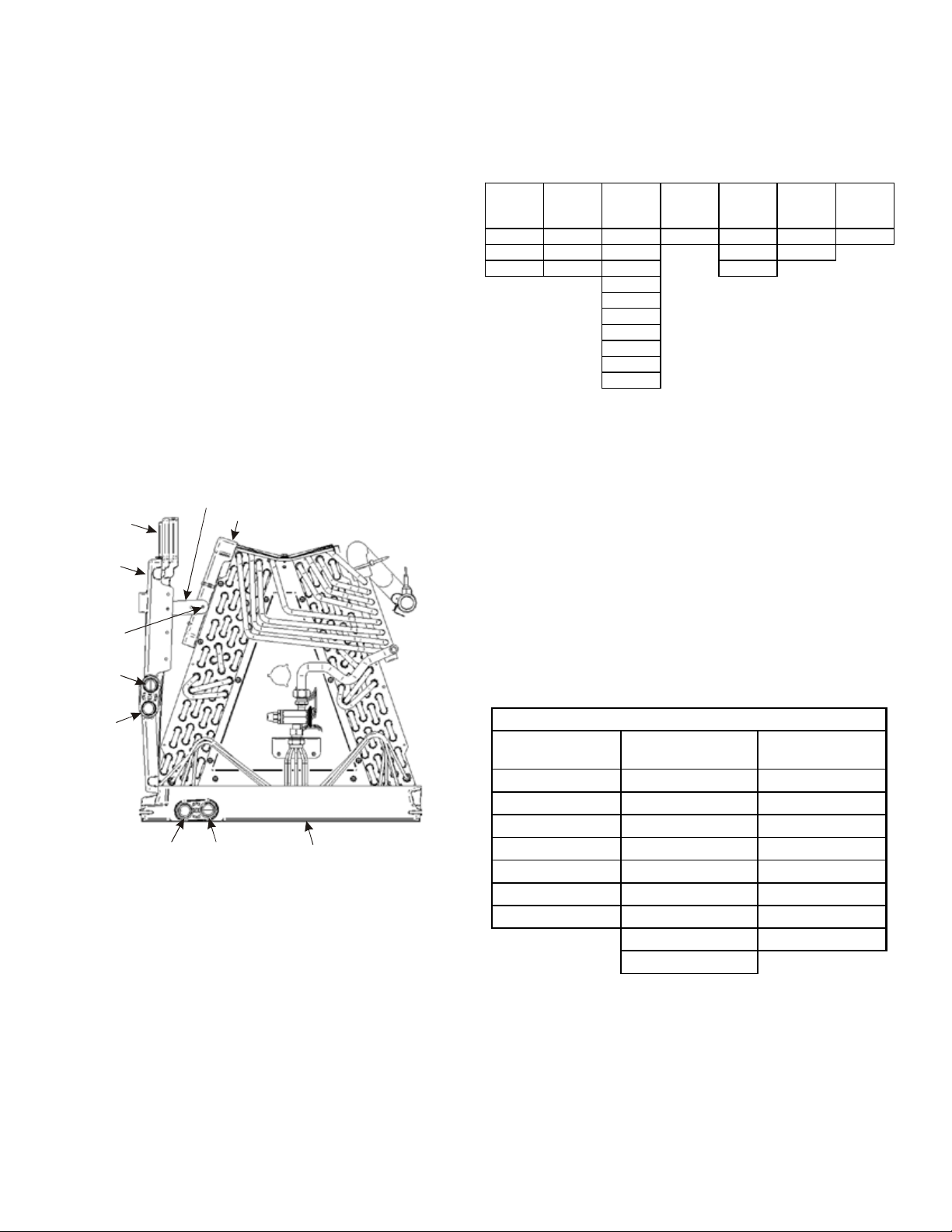

6.1 Upflow Installation

No field modifications are mandatory.

6.2 Horizontal Left Installation

No field modifications are permissible for this application.

Install unit as shown in Figure 4.

Remove red plugs from side drain pan before connecting

condensate drain pipes. Use removed plug to close drain

ports on vertical drain pan. The bottom right drain connection in side drain pan is the primary drain for this application and condensate drain line must be attached to this

drain connection. The bottom left drain connection in side

drain pan is for the secondary drain line (if used).

Refer to Figure 6 and 7 for the location of the components referenced in the following steps.

MODEL LIST FOR DOWNFLOW KIT

DFK-B

DOWNFLOW KIT

ARUF25B14** ARUF37C14** ARUF37D14**

ARUF29B14** ARUF43C14** ARUF43D14**

ARUF31B14** ARUF49C14** ARUF47D14**

ASPT25B14** ASPT33C14** ARUF49D14**

ASPT29B14** ASPT37C14** ARUF61D14**

ASPT35B14** ASPT39C14** ASPT61D14**

ASPT37B14** ASPT47C14** ASPT47D14**

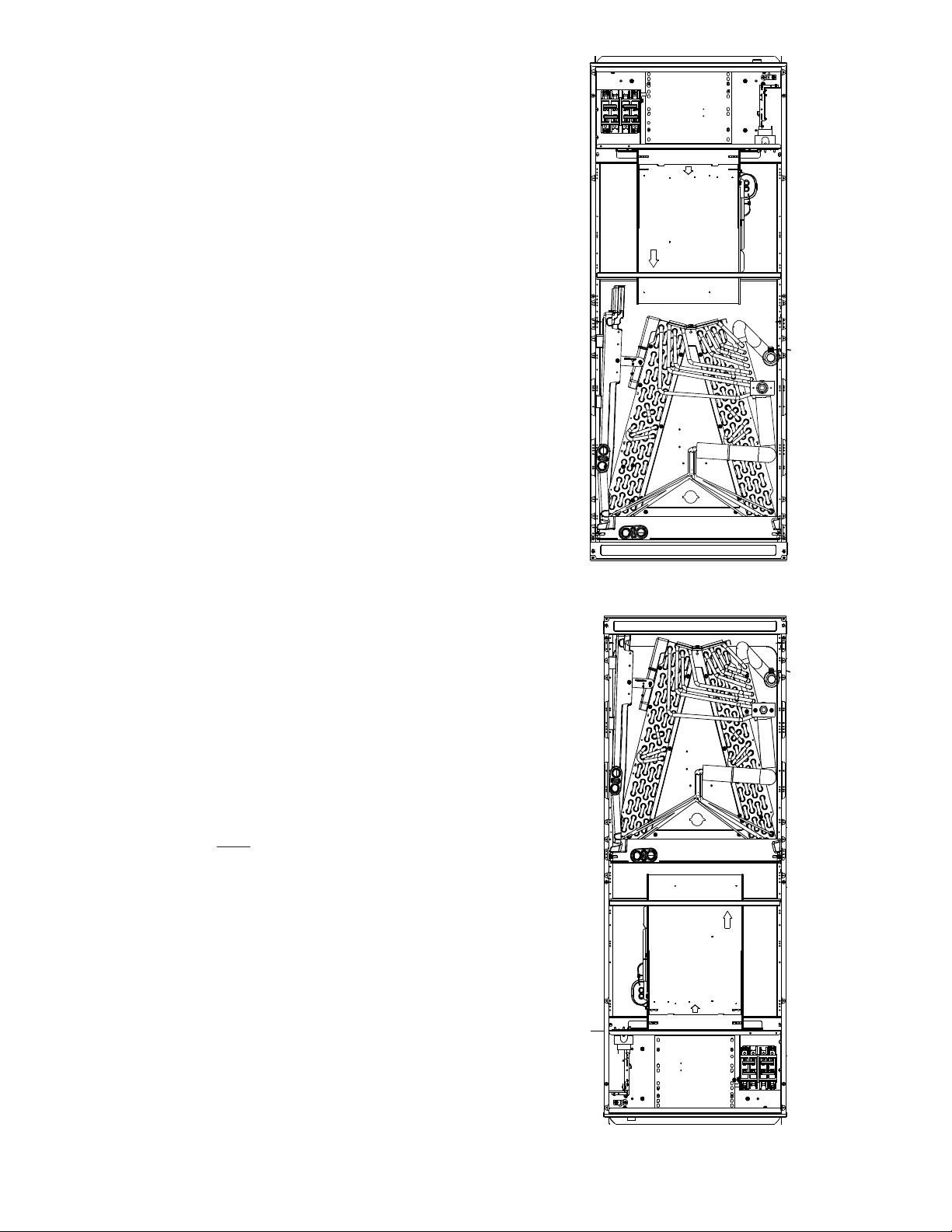

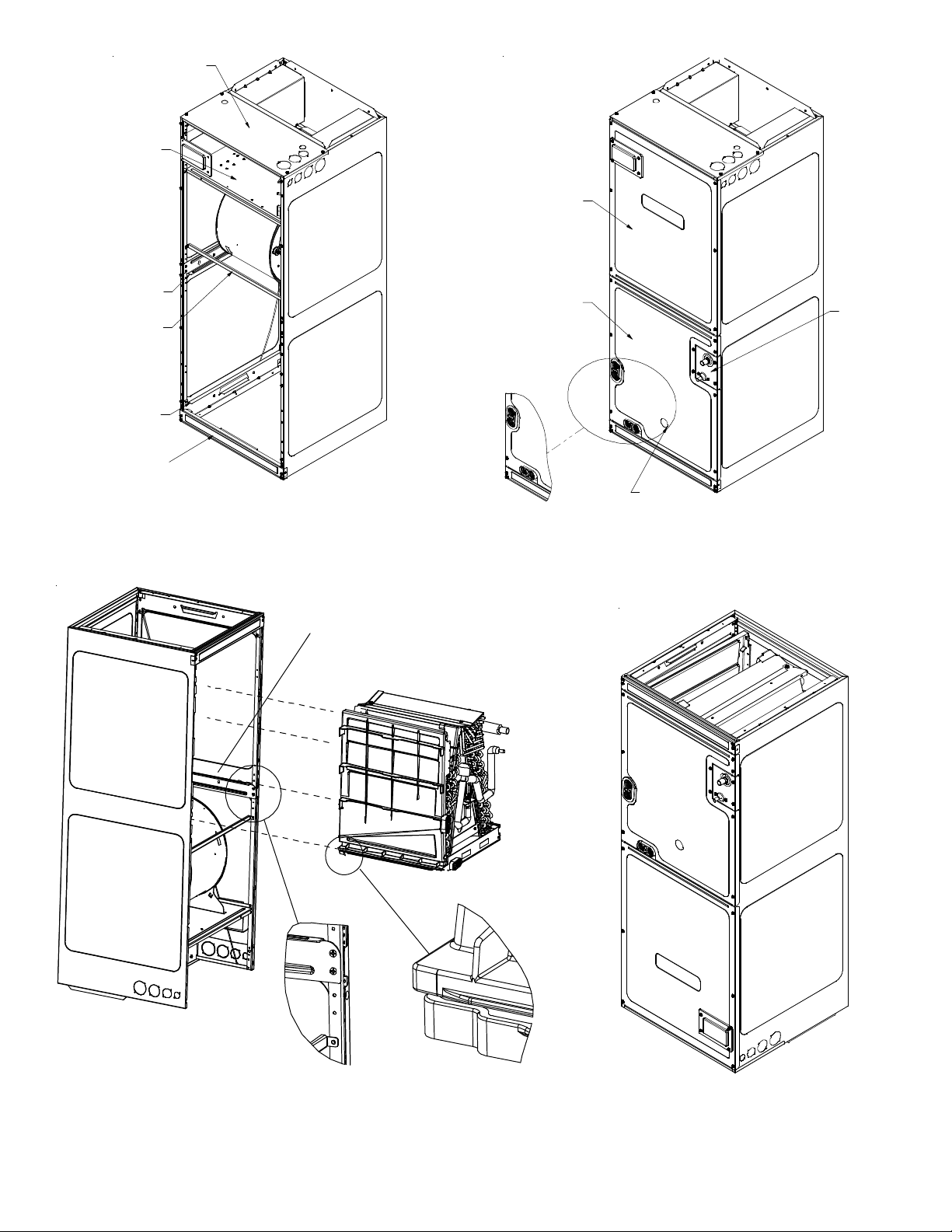

1. Before inverting the air handler, remove blower access panel and coil access panel. The coil access panel

and tubing panel may remain screwed together during

this procedure. Remove and retain the seven (7) screws

securing the coil access panel to the cabinet and the

six (6) screws securing the blower access panel to the

cabinet.

DFK-C

DOWNFLOW KIT

DFK-D

DOW NFLOW KIT

ASPT49C14** ASPT49D14**

ASPT59C14**

DOWNFLOW KIT

Table 2

4

Page 5

2. Slide the coil assembly out from the cabinet. Use the

drain pan to pull the assembly from the cabinet.

NOTE: DO NOT USE MANIFOLDS OR FLOWRATOR TO

PULL THE COIL ASSEMBLY OUT. FAILURE TO DO SO

MAY RESULT IN BRAZE JOINT DAMAGE AND LEAKS.

3. Removal of the center support is required on units with

21" wide cabinet. Remove and retain the two (2) screws

that secure the center support to the cabinet. Remove

the center support.

4. Position the unit in the downflow position.

5. Using the drain pan to hold the coil assembly, slide the

coil assembly back into the cabinet on the downflow

brackets as shown in Figure 8.

6. Reinstall the center support (if removed) using the two

(2) screws removed in Step 5.

7. Reinstall the coil access panels and reinstall blower

access panel removed in Step 1 as shown in Figure 9.

8. Drain Connections for Horizontal Right Installation

a. The bottom right drain connection in side drain pan

is the primary drain for this application and condensate drain line must be attached to this drain

connection. The bottom left drain connection is

for the secondary drain line (if used).

b. Remove red plugs from side drain pan before con-

necting condensate drain pipes. Use removed plug

to close drain ports on vertical drain pan.

UPFLOW

Figure 2

9. Drain Connections for Downflow Installation

a. The bottom left drain connection in the vertical

drain pan is the primary drain for this application

and condensate drain line must be attached to this

drain connection. The bottom right drain connection is for the secondary drain line (if used).

b. Remove red plugs from vertical drain pan before

connecting condensate drain pipes.

NOTE: If removing only the coil access panel from the unit,

the filter access panel must be removed first. Failure

to do so will result in panel damage.

DOWNFLOW

Figure 3

5

Page 6

HORIZONTAL LEFT

Figure 4

HORIZONTAL RIGHT

Figure 5

7 Refrigerant Lines

This product i s factory-shipped with R410A and dry

nitrogen mixture gas under pressu re. Use appr opria te

service tools and follow these instructions to prevent

injury .

NOTE: Refrigerant tubing must be routed to allow adequate

access for servicing and maintenance of the unit.

7.1 Tubing Size

For the correct tubing size, follow the specification for

the condenser/heat pump.

7.2 Tubing Preparation

All cut ends are to be round, burr free, and clean. Failure to follow this practice increases the chances for

refrigerant leaks. The suction line is spun closed and

requires tubing cutters to remove the closed end.

NOTE: To prevent possible damage to the tubing joints,

do not handle coil assembly with manifold or flowrator

tubes. Always use clean gloves when handling coil assemblies.

7.3 Special Instructions

Units without a factory installed TXV come equipped

with a flowrator piston for refrigerant expansion. For

most installations with matching applications, no

change to the flowrator piston is required. However,

in mix-matched applications, a flowrator piston

change may be required. See the piston kit chart (provided in the literature packet) or consult your local

distributor for details regarding mix-matched

flowrator piston sizing. If the mix-match application

requires a different flowrator piston size, change the

flowrator piston in the flowrator body on the indoor

coil before installing the coil and use the procedure

in section 7.4.

NOTE: The use of a heat shield is strongly recommended

when brazing to avoid burning the serial plate or the

finish of the unit. Heat trap or wet rags must be used

to protect heat sensitive components such as service

valves and TXV valves sensing bulb.

Do not install the air handler in a location that violates the

instructions provided with the condenser. If the unit is

located in an unconditioned area with high ambient

temperature and/or high humidity, the air handler may be

subject to nuisance sweating of the air handler cabinet.

On these installations, a wrap of 2" fiberglass insulation

with a vapor barrier is recommended.

A quenching cloth is strongly recommended to prevent

scorching or marring of the equipment finish when

brazing close to the painted surfaces. Use brazing

alloy of 5% minimum silver content.

CAUTION

Applying too much heat to any tube can melt the tube. Torch

heat required to braze tubes of various sizes must be

proportional to th e s ize of th e tube. S er vice p er sonn el mu st

use the appropriate heat level for the size of the tube being

brazed.

6

Page 7

Upper Tie Plate

Control

Deck

Blower

Access

Panel

Downflow

Bracket

Center

Support

Filter

Bracket

Filter

Access

Panel

INTERNAL PART TERMINOLOGY

Figure 6

Coil slides

on the downflow bracket

Coil

Access

Panel

UV

Knockout

EXTERNAL PART TERMINOLOGY

Figure 7

Tubing

Panel

IMPORTANT NOTE:

Ensure coil slides on the rails along the groove provided on the drain pan side

walls. Failure to do so will result in improper condensate drainage.

COIL INSTALLATION FOR DOWNFLOW

Figure 8

7

ACCESS PANEL CONFIGURATION FOR DOWNFLOW

OR HORIZONTAL RIGHT

Figure 9

Page 8

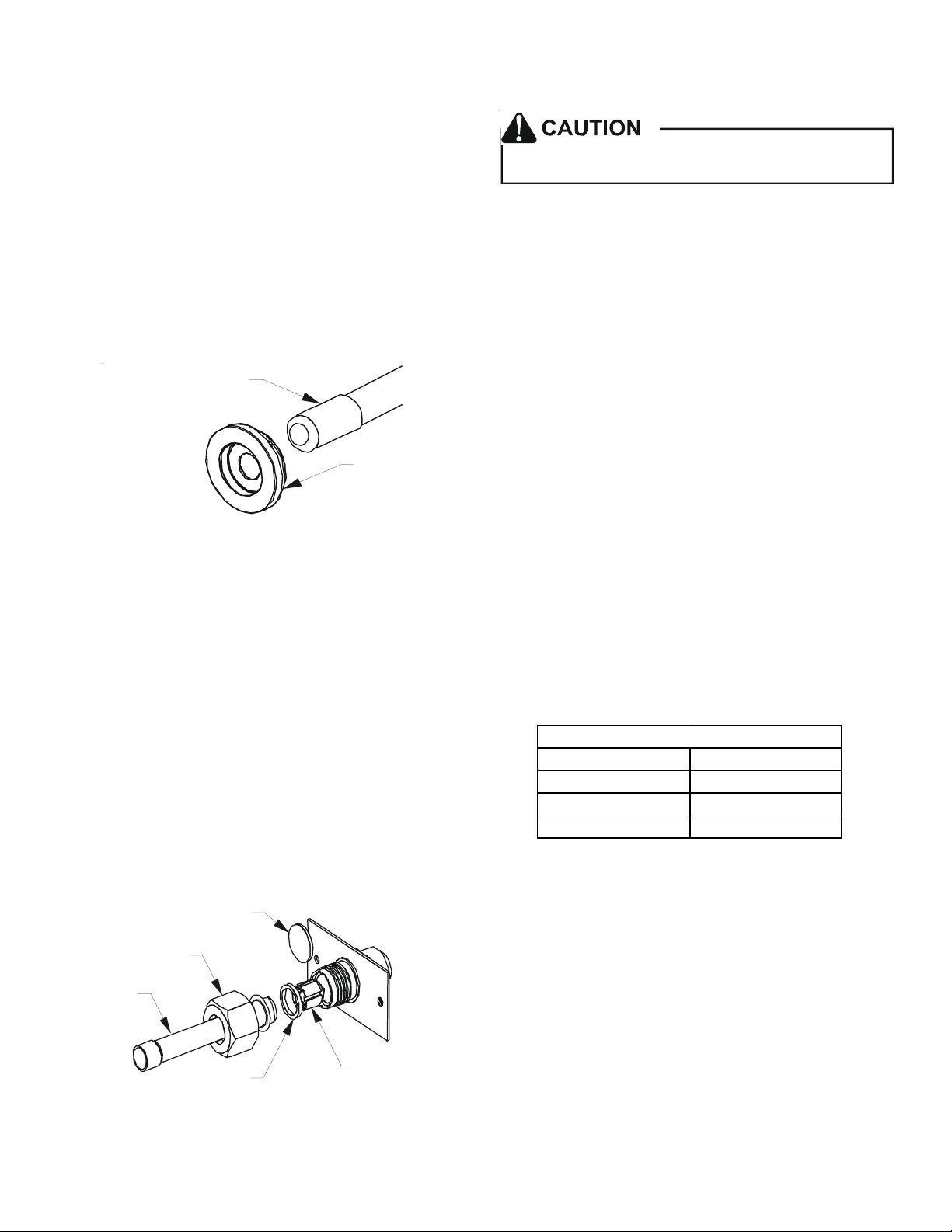

7.4 Tubing Connections for Flowrator Model

1. Loosen the 13/16 nut 1 TURN ONLY to allow high pressure tracer gas to escape. No gas indicates a possible

leak.

9. Torque the 13/16 nut to 7-25 ft-lbs. or tighten 1/6

turn.

2. After the gas has been expelled, remove the nut and

discard the black or brass cap plastic seal.

3. Remove the flowrator piston to verify it is the correct

size for the outdoor unit being installed and then replace the piston (changing size, if needed). See piston

kit chart in the literature kit for appropriate piston

size.

4. Remove the spin closure on the suction line using a

tube cutter and deburr the tube.

SUCTION LINE

WITH SPIN CLOSURE

RUBBER

GROMMET

SUCTION SPUN END AND GROMMET

Figure 10

5. Insert the suction line into the connection, slide the

insulation and the rubber grommet at least 18" away

from the braze joint.

6. Remove the tailpiece clamped to the exterior of the

cabinet or in the literature kit packet and slide the

13/16 nut into place.

Excessive torque can cause orifices to stick. Use the

proper torque settings when tightening orifices.

7.5 Tubing Connections for TXV Models

TXV models come with factory installed TXV with the

bulb pre-installed on the vapor tube.

1. Remove refrigerant tubing panel or coil (lower) access

panel.

2. Remove access valve fitting cap and depress the valve

stem in access fitting to release pressure. No pressure

indicates possible leak.

3. Replace the refrigerant tubing panel.

4. Remove the spin closure on both the liquid and suction

tubes using a tubing cutter.

5. Insert liquid line set into liquid tube expansion and

slide grommet about 18" away from braze joint.

6. Insert suction line set into suction tube expansion and

slide insulation and grommet about 18" away from braze

joint.

7. Braze joints. Quench all brazed joints with water or a

wet rag upon completion of brazing.

7.6 ASPT**14** Models with Non-Adjustable TXV

ASPT air handlers equipped with Parker non-adjustable TXV

should be charged by subcooling only.

7. Braze tailpiece to the line set liquid tube and braze

suction line connection. Quench all brazed joints with

a damp rag upon completion of brazing. Do not allow

water to enter the inside of the tubing.

8. AFTER THE TAILPIECE HAS COOLED, confirm position

of the white Teflon® seal and hand tighten the 13/16

nut.

PLASTIC or BRASS CAP

13/16” NUT

TAILPIECE

WHITE

TEFLON SEAL

TAILPIECE JOINT

Figure 11

PISTON

Models

ASPT25B14** ASPT47D14**

ASPT29B14** ASPT47C14**

ASPT37B14** ASPT49D14**

ASPT37C14** ASPT59C14**

Table 3

See section 7.7 for detailed information on adjusting the

thermal expansion valve.

8

Page 9

7.7 Thermal Expansion Valve System Adjustment

Run the system at Cooling for 10 minutes until refrigerant

pressures stabilize. Use the following guidelines and methods to check unit operation and ensure that the refrigerant

charge is within limits. Charge the unit on low stage.

1. Purge gauge lines. Connect service gauge manifold to

base-valve service ports.

2. Temporarily install a thermometer on the liquid line

at the liquid line service valve and 4-6" from the compressor on the suction line. Ensure the thermometer

makes adequate contact and is insulated for best possible readings. Use liquid line temperature to determine subcooling and vapor temperature to determine

superheat.

3. Check subcooling and superheat. Systems with TXV application should have a subcooling of 7 to 9ºF and superheat of 7 to 9 ºF.

a. If subcooling and superheat are low, adjust TXV to

7 to 9 ºF superheat, then check subcooling.

NOTE: To adjust superheat, turn the valve stem clockwise

to increase and counter clockwise to decrease.

b. If subcooling is low and superheat is high, add charge

to raise subcooling to 7 to 9ºF then check superheat.

c. If subcooling and superheat are high, adjust TXV

valve to 7 to 9 ºF superheat, then check subcooling.

d. If subcooling is high and superheat is low, adjust

TXV valve to 7 to 9 ºF superheat and remove charge to

lower the subcooling to 7 to 9ºF.

NOTE: Do NOT adjust the charge based on suction pressure

unless there is a gross undercharge.

4. Disconnect manifold set, installation is complete.

NOTE: Check the Schrader ports for leaks and tighten valve

cores if necessary. Install caps finger-tight.

SUBCOOL FORMULA =

SAT. LIQUID LINE TEMP. - LIQUID LINE TEMP.

SUPERHEAT FORMULA =

SUCT. LINE TEMP. - SAT. SUCT. TEMP.

NOTE: Expansion valve system in ASPT models are already

tuned for 16 SEER single stage Heat Pump, adjustment of

Expansion valve system is required in case subcool, superheat

does not match to Section 7.6.3 above or when these models

are installed with any other outdoor models.

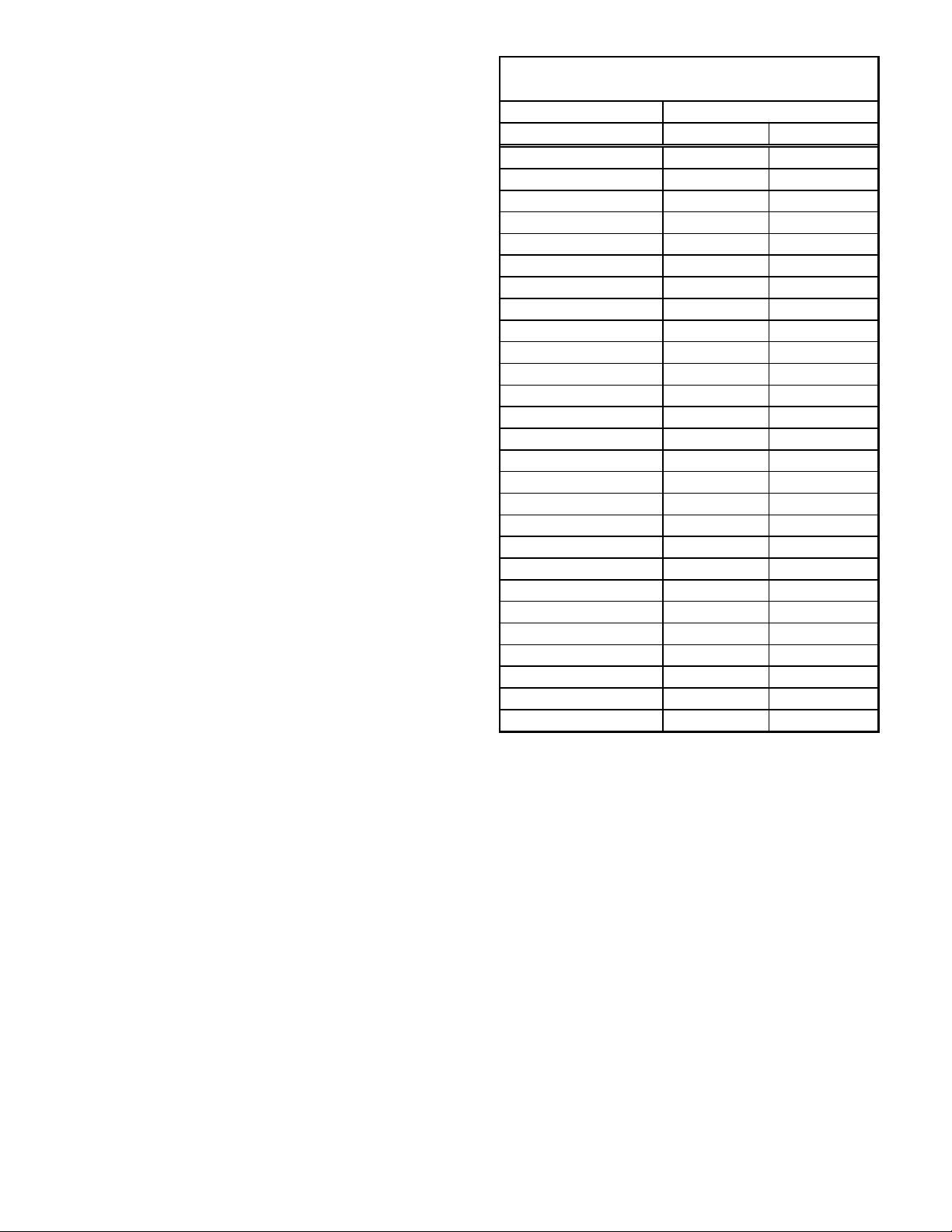

SATURATED SUCTION PRESSURE

TEMPER AT UR E CH AR T

SUCTION PRESSURE

PSIG R- 22 R- 410A

50 26 1

52 28 3

54 29 4

56 31 6

58 32 7

60 34 8

62 35 10

64 37 11

66 38 13

68 40 14

70 41 15

72 42 16

74 44 17

76 45 19

78 46 20

80 48 21

85 50 24

90 53 26

95 56 29

100 59 31

110 64 36

120 69 41

130 73 45

140 78 49

150 83 53

160 86 56

170 90 60

SATURATED SUCTION

9

Page 10

SATURATED LIQUID PRESSURE

TEMPER ATURE CHART

LIQUID PRESSURE

PSIG R-22 R- 410A

200 101 70

210 105 73

220 108 76

225 110 78

235 113 80

245 116 83

255 119 85

265 121 88

275 124 90

285 127 92

295 130 95

305 133 97

325 137 101

355 144 108

375 148 112

405 155 118

415 157 119

425 n/a 121

435 n/a 123

445 n/a 125

475 n/a 130

500 n/a 134

525 n/a 138

550 n/a 142

575 n/a 145

600 n/a 149

625 n/a 152

SATURATED LIQUID

TEMPER ATURE ºF

separately from the primary drain and end it where condensate discharge can be easily seen.

NOTE: Water coming from secondary line means the coil

primary drain is plugged and needs immediate attention.

CAUTION

If secondary drain is not installed, the secondary

access must be plugged.

Insulate drain lines located inside the building or above a

finished living space to prevent sweating. Install a condensate trap to ensure proper drainage.

NOTE: When units are installed above ceilings, or in other

locations where damage from condensate overflow may

occur, it is MANDATORY to install a field fabricated auxiliary

drain pan under the coil cabinet enclosure.

The installation must include a “P” style trap that is located as close as is practical to the evaporator coil. See

Figure 12 for details of a typical condensate line “P” trap.

NOTE: Units operating in high static pressure applications

may require a deeper field constructed “P” style trap than

is shown in Figure 12 to allow proper drainage and prevent

condensate overflow.

Drain

Connection

Air Handler

POSITI VE LIQUID

SEAL REQUIRED

AT TRAP

2" MIN.

3" MIN.

NOTE: Units matched with indoor coils equipped with nonadjustable TXV should be charged by subcooling only.

8 Condensate Drain Lines

The coil drain pan has a primary and a secondary drain with

3/4" NPT female connections. The connectors required are

3/4" NPT male, either PVC or metal pipe, and should be

hand tightened to a torque of no more than 37 in-lbs. to

prevent damage to the drain pan connection. An insertion

depth of approximately 3/8” to 1/2” (3-5 turns) should be

expected at this torque.

1. Ensure drain pan hole is not obstructed.

2. To prevent potential sweating and dripping on to finished space, it may be necessary to insulate the condensate drain line located inside the building. Use

Armaflex® or similar material.

A secondary condensate drain connection has been provided

for areas where the building codes require it. Pitch all drain

lines a minimum of 1/4" per foot to provide free drainage.

Provide required support to the drain line to prevent bowing. If the secondary drain line is required, run the line

Figure 12

NOTE: Trapped lines are required by many local codes. In

the absence of any prevailing local codes, please refer to

the requirements listed in the Uniform Mechanical Building

Code.

A drain trap in a draw-through application prevents air from

being drawn back through the drain line during fan operation thus preventing condensate from draining, and if connected to a sewer line to prevent sewer gases from being

drawn into the airstream during blower operation.

Use of a condensate removal pump is permitted when necessary. This condensate pump should have provisions for

shutting off the control voltage should a blocked drain occur. A trap must be installed between the unit and the condensate pump.

IMPORTANT NOTE: The evaporator coil is fabricated with

oils that may dissolve styrofoam and certain types of plastics.

Therefore, a removal pump or float switch must not contain

any of these materials.

10

Page 11

Tip: Priming the “P” trap may avoid improper draining at

the initial installation and at the beginning of the cooling

season.

9 Ductwork

This air handler is designed for a complete supply and return ductwork system.

Do not operate this product without all the ductwork

attached.

NOTE: For installations not indicated above the following

formula is to be used:

TR = (kW x 3412) x (Voltage Correction) / (1.08XCFM)

Where: TR = Temperature Rise

kW = Heater Kit Actual kW

3412 = Btu per kW

VC* = .96 (230 Supply Volts)

= .92 (220 Supply Volts)

= .87 (208 Supply Volts)

1.08 = Constant

CFM = Measured Airflow

To ensure correct system performance, the ductwork is to

be sized to accommodate 350-450 CFM per ton of cooling

with the static pressure not to exceed 0.5" in w.c. Refer to

ACCA Manual D, Manual S and Manual RS for information on

duct sizing and application. Flame retardant ductwork is

to be used and sealed to the unit in a manner that will

prevent leakage.

NOTE: A downflow application with electric heat must have

an L-shaped sheet metal supply duct without any outlets or

registers located directly below the heater.

9.1 Return Ductwork

DO NOT LOCATE THE RETURN DUCTWORK IN AN AREA

THAT CAN INTRODUCE TOXIC, OR OBJECTIONABLE

FUMES/ODORS INTO THE DUCTWORK. The return

ductwork is to be connected to the air handler bottom (upflow configuration).

10 Return Air Filters

Each installation must include a return air filter. This filtering may be performed at the air handler using the factory filter rails or externally such as a return air filter grille.

When using the factory filter rails, a nominal 16x20x1”,

20x20x1” or 24x20x1” (actual dimension must be less than

23-½”x20”) filter can be installed on a B, C and D cabinet

respectively (the cabinet size is the seventh letter of the

model number).

11 Electric Heat

Refer to the installation manual provided with the electric

heat kit for the correct installation procedure. All electric

heat must be field installed. If installing this option, the

ONLY heat kits that are permitted to be used are the HKS

series. Refer to the air handler unit’s Serial and Rating plate

or the HKS specification sheets to determine the heat kits

compatible with a given air handler. No other accessory

heat kit besides the HKS series may be installed in these air

handlers.

The heating mode temperature rise is dependent upon the

system airflow, the supply voltage, and the heat kit size

(kW) selected. Use data provided in Tables 4, 5, AND 6 to

determine the temperature rise (°F).

*VC (Voltage Correction)

NOTE: The Temperature Rise Tables can also be used to

estimate the air handler airflow delivery. When using these

tables for this purpose set the room thermostat to maximum

heat and allow the system to reach steady state conditions.

Insert two thermometers, one in the return air and one in

the supply air. The temperature rise is the supply air

temperature minus the room air temperature. Using the

temperature rise calculated, CFM can be estimated from

the TR formula above. See Service Manual for more

information.

HEAT KIT NOMINAL kW

CFM

3568101519/2025

800 1219233137

1000 9 1519253044

1200 8 12152125374962

1400 7 11131821324253

1600 6 9 12 15 19 28 37 46

1800 5 8 10 14 16 25 33 41

2000 5 7 9 12 15 22 30 37

230/1/60 SUPPLY VOLTAGE - TEMP. RISE °F

Table 4

HEAT KIT NOMINAL kW

CFM

3568101519/2025

800 1118223035

1000 9 14 18 24 28 42

1200 7 12 15 20 24 35 47 59

1400 6 10 13 17 20 30 40 51

1600 6 9 111518273544

1800 5 8 101316243139

2000 4 7 9 12 14 21 28 35

11

220/1/60 SUPPLY VOLTAGE - TEMP. RISE °F

Table 5

Page 12

CFM

HEAT KIT NOMINA L k W

3568101519/2025

800 1017212833

1000 8 13 17 22 27 40

1200 7 11 14 19 22 33 45 56

1400 6 10 12 16 19 29 38 48

1600 5 8 101417253342

1800 5 7 9 12 15 22 30 37

2000 4 7 8 11 13 20 27 33

208/1/60 SUPPLY VOLTAGE - TEMP. RISE °F

Table 6

12 Electrical and Control Wiring

IMPORTANT: All routing of electrical wiring must be made

through provided electrical knockouts. Do not cut, puncture or alter the cabinet for electrical wiring.

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

12.1 Building Electrical Service Inspection

This unit is designed for single-phase electrical supply

only. DO NOT OPERATE ON A THREE-PHASE POWER

SUPPLY. Measure the power supply to the unit. The

supply voltage must be measured and be in agreement

with the unit nameplate power requirements and within

the range shown.

12.2 Wire Sizing

Wire size is important to the operation of your equipment. Use the following check list when selecting the

appropriate wire size for your unit.

• Wire used must carry the Minimum Circuit Ampac-

ity (MCA) listed on the unit’s Series and Rating Plate.

• Refer to the NEC (USA) or CSA (Canada) for wire sizing. The unit MCA for the air handler and the optional electric heat kit can be found on the unit Series and Rating Plate.

• Wire must be sized to allow no more than a 2% volt-

age drop from the building breaker/fuse panel to

the unit.

• Wires with different insulation temperature rating

have varying ampacities - be sure to check the temperature rating used.

HIGH VOLTAG E!

T o avoid prope rty dama ge , persona l injury or death

due to el ect rical shock, this unit MU S T have an

uninterrupted, unbroken

electrical ground circuit may consist of an

appro pri at ely sized electrical wire co nnecting the

ground lug in the unit control box to the building

electrical service panel.

Other methods of grounding are permit ted if perform ed

in accordance with the National Electric Code

(NEC) /Americ an Nation al Standar ds Institut e

(ANSI)/National Fire Protection Association (NFP A) 70

and local/state codes. In Canada, electrical grounding

is to be in ac co rda nce w ith th e C ana dian Elec tric Cod e

(CSA) C22.1.

electrical ground. The

Refer to the latest edition of the National Electric

Code or in Canada the Canadian Electric Code when

determining the correct wire size.

12.3 Maximum Overcurrent Protection (MOP)

Every installation must include an NEC (USA) or CEC

(Canada) approved overcurrent protection device.

Also, check with local or state codes for any special

regional requirements.

Protection can be in the form of fusing or HACR style

circuit breakers. The Series and Rating Plate provides the maximum overcurrent device permissible.

NOTE: Fuses or circuit breakers are to be sized larger

than the equipment MCA but not to exceed the MOP.

12

Page 13

MODEL

3 5 6 8 10 15 19 20 25

ARU F25B 14 715 715 715 715 950

ARU F29B 14 715 715 715 715 950

ARU F31B 14 715 715 715 715 875

ARUF37C14 1170 1170 1170 1170 1345 1345

ARUF43C14 1170 1170 1170 1170 1345 1345

ARUF49C14 1170 1170 1170 1170 1340 1430

ARUF37D14 1 170 1170 1170 1170 1345 1345

ARUF43D14 1 170 1170 1170 1170 1345 1345

ARUF47D14 1 170 1170 1170 1170 1345 1345

ARUF49D14 1 240 1240 1240 1240 1520 1520

ARUF61D14 1 590 1590 1590 1590 1715 1715 1715

HEATER KIT (KW)

MINIMUM CFM REQUIRED FOR HEATER KITS

Table 7

Model

HEATER KIT (KW)

3 5 6 8 10 15 19 20 25

ASPT2 5B14 715 715 715 715 850

ASPT2 9B14 715 715 715 715 875 1050

ASPT3 5B14 715 715 715 715 875 1050

ASPT3 7B14 715 715 715 715 875 1050

ASPT3 3C14 715 715 715 715 875 875

ASPT3 7C14 1170 1170 1170 1170 1345 1345

ASPT3 9C14 1170 1170 1170 1170 1345 1345

ASPT4 7C14 1170 1170 1170 1170 1345 1345

ASPT4 9C14 1170 1170 1170 1170 1345 1345

ASPT5 9C14 1170 1170 1170 1170 1345 1345

ASPT4 7D14 1240 1240 1240 1240 1520 1520

ASPT4 9D14 1590 1590 1590 1590 1715 1715 1715

ASPT6 1D14 1590 1590 1590 1590 1715 1715 1715

MINIMUM HEATER KIT AIRFLOW

Table 8

Nominal Input Minimum Voltage Maximum Voltage

208-240 197 253

ELECTRICAL VOLTAGE

Table 9

13

Page 14

12.4 Electrical Connections – Supply Voltage

FIRE HAZARD!

To avoid the risk of property damage, personal injury

or fire, use only copper conductors.

IMPORTANT NOTE: USE COPPER CONDUCTORS ONLY.

Knockouts are provided on the air handler top panel and

sides of the cabinet to allow for the entry of the supply

voltage conductors, as shown in Figure 13. If the knockouts

on the cabinet sides are used for electrical conduit, an

adapter ring must be used in order to meet UL1995 safety

requirements. An NEC or CEC approved strain relief is to be

used at this entry point. Some codes/municipalities require

the supply wire to be enclosed in conduit. Consult your

local codes.

Top of

Cabinet

Side of

Cabinet

12.5 Low Voltage Connections

Several combinations of low voltage schemes are possible, depending on the presence of a heat kit and

whether the heat kit is single-stage or multi-stage,

whether the outdoor section is an air conditioner or

heat pump, and whether the outdoor section is singlestage or two-stage. The 24V-control voltage connects

the air handler to the room thermostat and condenser.

Low voltage wiring must be copper conductors. A minimum of 18AWG must be used for installations up to

100 feet. Low voltage wiring must be connected

through the top of the cabinet or either side. See the

“Thermostat Wiring” section of this manual for typical low voltage wiring connections.

12.5.1 Thermostats

Second-stage heat can be accomplished by a multistage heating thermostat or the addition of an outdoor thermostat as shown in wiring schematics on page

19. Follow the thermostat manufacturer’s instructions for installation.

12.6 Speed Tap Adjustment

ARUF**14** air handlers have multi-speed PSC motors.

The color of the wire coming from the motor to the

“COM” terminal on the control board defines at which

speed the motor will operate. Black wire is high speed,

blue wire is medium speed and red wire is low speed.

To change speeds, remove the wire attached to the

“COM” terminal on the control board, and swap it

with the wire (on terminal “M1” or “M2”) with the

color that will give the desired speed.

KNOCK-OUT FOR ELECTRICAL CONNECTIONS

Figure 13

12.4.1 Air Handler Only (Non-Heat Kit Models)

The building supply connects to the stripped black

and red wires contained in the air handler electrical

compartment cavity. A ground screw is also contained

in this area. Attach the Supply wires to the air handler conductors as shown in the unit wiring diagram

using appropriately sized solderless connectors or

other NEC or CEC approved means.

12.4.2 Air Handler - Non-Circuit Breaker Heat

Kits

A terminal block is provided with the HKS kit to attach the power supply and air handler connections.

Follow the HKS Installation Manual and wiring diagram

for complete wiring details.

12.4.3 Air Handler With Circuit Breaker Heat Kit

The air handler has a plastic cover on the upper access panel that will require either one or both sections to be removed to allow the heat kit circuit

breaker(s) to be installed. The circuit breakers have

lugs for power supply connection. See the HKS Installation Instructions for further details.

ASPT**14** air handlers feature energy efficient blower

motors. The motors run at a constant torque with very

low power consumption and are energized by 24 VAC.

Adjust the CFM by changing the 24 VAC leads to the

desired speed tap on the terminal block. The ASPT

blower motor speeds are programmed to deliver adequate airflow at rated external static pressure and

with 60 second off time delay. For details, refer to

the specification sheet applicable to your model.

NOTE: In some models, not all speed taps are allowable for

certain electric heat applications. Refer to Table 5 for

minimum speed.

14

Page 15

13 Achieving 1.4% Low Leakage Rate

Ensure all the gaskets remain intact on all surfaces as shipped

with the unit. These surfaces are areas between the upper

tie plate and blower access panel, blower access and coil

access panels, and between the coil access and filter access

panels. Ensure upon installation, that the plastic breaker

cover is sitting flush on the blower access panel and all access panels are flush with each other and the cabinet. With

these requirements satisfied, the unit achieves less than 1.4%

airflow leakage when tested in accordance with ASHRAE Standard 193.

14 Start-Up Procedure

15 Regular Maintenance

The only item required to be maintained on a regular basis

by the user is the circulating air filter(s). Filter should be

cleaned or replaced regularly, typically once per month. A

certified service technician must perform all other services.

IMPORTANT NOTE: If thumb screws are used to access the

filter, ensure the washer installed on the screw behind the

access panel remains in place after re-installation.

HIGH VOLTAGE!

Disconnect ALL power before servicing or

installing this unit. Multiple power sources may

be present. Failure to do so may cause property

damage, personal injury or death.

• Prior to start-up, ensure that all electrical wires are

properly sized and all connections are properly tightened.

• All panels must be in place and secured. For Air Tight

application, gasket must be positioned at prescribed

locations to achieve 1.4% leakage.

• Tubing must be leak free.

• Condensate line must be trapped and pitched to allow for drainage.

• Low voltage wiring is properly connected.

• Auxiliary drain is installed when necessary and pitched

to allow for drainage.

• Unit is protected from vehicular or other physical damage.

• Return air is not obtained from, nor are there any return air duct joints that are unsealed in, areas where

there may be objectionable odors, flammable vapors

or products of combustion such as carbon monoxide

(CO), which may cause serious personal injury or death.

15

Page 16

16 Airflow Data

Model

ARUF25B14

ARUF29B14

ARUF31B14

ARUF37C14

ARUF43C14

ARUF49C14

ARUF37D14

ARUF43D14

ARUF47D14

ARUF49D14

ARUF61D14

Notes

1. Airf low data indicated is at 230V without air filter in place.

2. The ch ar t is for i nfor mat io n on l y . F o r sat isf ac to r y o p er ati on , ex ter n al stat ic pr e ssur e m u st n o t ex c eed v alu e sho w n o n

3. Use the CFM adjustment factors of 0.98 for horizontal left and 0.96 f or horizontal rig ht & downflow orientations

Blower

Speed

LOW 650 620 595 540 490 420 275

MED 885 865 825 815 750 690 560

HIGH 1255 1225 11 30 1090 965 925 800

LOW 650 620 595 540 490 420 275

MED 885 865 825 815 750 690 560

HIGH 1255 1225 11 30 1090 965 925 800

LOW 660 625 595 560 500 430 330

MED 930 905 865 820 765 700 590

HIGH 1235 1185 11 30 1060 990 910 825

LOW 1120 1085 1040 1000 940 875 800

MED 1425 1385 13 45 1285 1220 1145 1060

HIGH 1625 1575 15 20 1460 1375 1295 1200

LOW 1120 1085 1040 1000 940 875 800

MED 1425 1385 13 45 1285 1220 1145 1060

HIGH 1625 1575 15 20 1460 1375 1295 1200

LOW 1295 1255 1225 1175 1120 1055 970

MED 1535 1485 14 20 1370 1295 1215 1130

HIGH 1755 1680 15 90 1515 1425 1340 1250

LOW 1155 1115 1070 1015 955 89 5 840

MED 1505 1470 14 30 1375 1300 1210 1105

HIGH 1785 1735 16 80 1625 1555 1440 1330

LOW 1410 1360 1290 1210 1120 1010 920

MED 1610 1540 14 70 1390 1300 1190 1060

HIGH 1900 1830 17 40 1645 1540 1420 1280

LOW 1420 1370 1310 1240 1125 1045 960

MED 1625 1585 15 15 1435 1350 1235 1095

HIGH 1930 1890 18 20 1735 1635 1505 1355

LOW 1410 1360 1290 1210 1120 1010 920

MED 1610 1540 14 70 1390 1300 1190 1060

HIGH 1900 1830 17 40 1645 1540 1420 1280

LOW 1530 1500 1460 1405 1350 1280 115 5

MED 1950 1885 18 30 1785 1745 1670 1595

HIGH 2235 2170 21 00 2030 1965 1915 1825

0.1 0.2 0.3 0.4 0.5 0.6 0.7

Static Pressure (i n w.c) Airfl o w (CFM)

AIRFLOW DATA (CFM) - Table 10

16

Page 17

j

p

y

Model Blower Speed

T1 640 585 580 545 510 490 410 340 280

A SP T25B 14A A

A SP T29B 14A A

A SP T35B 14A A

A SP T37B 14A A

A SP T33C 14A A

A SP T37C 14A A

A SP T39C 14A A

A SP T47C 14A A

A SP T49C 14A A

A SP T59C 14A A

A SP T47D 14A A

A SP T49D 14A A

A SP T61D 14A

T2 800 765 725 700 670 645 595 565 490

T3 840 805 800 760 740 700 670 625 580

T4 985 950 920 885 850 815 800 760 725

T5 1475 1440 1400 1375 1335 1305 1270 1240 1150

T1 595 590 565 530 505 455 380 305 260

T2 790 775 745 705 665 625 585 515 445

T3 865 820 790 770 735 695 645 595 530

T4 1015 980 955 925 880 840 795 770 720

T5 1505 1465 1430 1410 1385 1350 1315 1285 1220

T1 875 845 845 825 795 780 730 680 630

T2 985 945 925 915 905 880 845 795 760

T3 1070 1025 990 985 980 960 940 905 860

T4 1245 1205 1170 1135 1115 1115 1100 1090 1035

T5 1310 1275 1230 1190 1155 1135 1085 1080 1040

T1 1025 985 945 910 875 830 795 735 690

T2 1150 1105 1065 1025 995 950 915 870 825

T3 1240 1200 1160 1120 1085 1050 1010 970 925

T4 1425 1400 1355 1320 1290 1250 1215 1180 1145

T5 1490 1455 1415 1390 1355 1320 1285 1250 1205

T1 865 685 615 540 480 410 335 270 215

T2 935 880 820 785 720 660 600 550 490

T3 1110 1050 1000 955 905 855 795 760 710

T4 1360 1310 1260 1220 1180 1135 1095 1055 1010

T5 1560 1515 1475 1435 1395 1370 1330 1295 1260

T1 980 935 895 860 825 800 755 710 665

T2 1125 1075 1045 1000 965 930 880 845 820

T3 1235 1190 1155 1120 1085 1045 1005 965 920

T4 1485 1450 1425 1390 1355 1315 1275 1230 1190

T5 1565 1535 1510 1480 1240 1390 1365 1320 1280

T1 865 685 615 540 480 410 335 270 215

T2 935 880 820 785 720 660 600 550 490

T3 1110 1050 1000 955 905 855 795 760 710

T4 1360 1310 1260 1220 1180 1135 1095 1055 1010

T5 1560 1515 1475 1435 1395 1370 1330 1295 1260

T1 955 895 855 840 780 735 675 615 560

T2 1100 1050 1005 965 925 870 815 770 705

T3 1205 1160 1120 1075 1035 990 940 885 830

T4 1445 1410 1365 1320 1275 1235 1190 1140 1095

T5 1525 1480 1435 1400 1360 1320 1275 1230 1180

T1 1325 1280 1240 1200 1160 1115 1065 1025 990

T2 1465 1420 1380 1355 1315 1280 1245 1195 1155

T3 1510 1470 1430 1395 1355 1330 1290 1250 1210

T4 1600 1565 1530 1490 1460 1425 1390 1365 1295

T5 1690 1660 1625 1590 1555 1525 1490 1400 1255

T1 1370 1330 1295 1255 1215 1180 1140 1100 1060

T2 1535 1500 1465 1430 1405 1370 1335 1300 1210

T3 1680 1645 1615 1575 1545 1510 1440 1330 1205

T4 1905 1855 1780 1690 1605 1515 1425 1330 1205

T5 1940 1855 1775 1700 1605 1505 1420 1320 1205

T1 1055 1015 950 895 830 785 730 680 620

T2 1210 1165 1110 1070 1015 960 900 840 785

T3 1335 1290 1250 1205 1145 1100 1050 980 910

T4 1625 1580 1530 1495 1455 1405 1350 1295 1230

T5 1720 1670 1625 1580 1540 1490 1435 1390 1325

T1 1485 1435 1380 1320 1265 1200 1230 1015 930

T2 1570 1525 1480 1430 1370 1315 1235 1155 1035

T3 1680 1600 1570 1555 1475 1430 1360 1280 1185

T4 1800 1765 1715 1670 1625 1590 1510 1465 1390

T5 2215 2160 2120 2085 2040 2000 1970 1930 1865

T1 1545 1495 1440 1390 1335 1260 1180 1105 1045

T2 1705 1655 1605 1555 1505 1445 1380 1330 1275

A

T3 1850 1805 1760 1710 1665 1615 1555 1500 1445

T4 2095 2055 2020 1980 1935 1890 1845 1800 1755

T5 2260 2205 2195 2160 2120 2075 2030 1990 1945

Static P ressure (in w.c.) A irflow (C FM)

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

Notes

1. Airflow data indicated is at 230V without air fi lter in

2. The chart is for informa tion onl

3. U se the CFM ad

ustment fac tors of 0.98 for horizontal left and 0.96 for horizontal right & downflow orientations.

. For satisfactory operation, external static pressure must n ot exceed value sh own on rating plate. Th e shaded area

lace.

ASPT AIRFLOW DATA (CFM) - Table 11

17

Page 18

17 Air Handler Low Voltage Connections

The following composite wiring diagrams detail various configurations in which the air handlers can be used. Examples

include single-stage cooling and heat pump with single or two-stage electric heating. All these configurations can be

applied with convenient connections to outdoor thermostat applications.

The following sections are detailed:

• Single-Stage Cooling

• Heat Pump

Each diagram details the connections between room thermostat and the air handlers, and the connections between the

air handlers and the Condensing Unit (or Heat Pump) with optional connections to Outdoor Thermostats. For each

configuration, refer to the explanation of the proper jumper(s) to remove for the corresponding blower speed that will

result in the programmed fixed speed ECM motor.

IMPORTANT: WHEN MATCHING THE ASPT AIR HANDLERS TO A SINGLE SPEED COOLING OR HEAT

PUMP UNIT, REMEMBER TO CONNECT “Y” FROM THE THERMOSTAT TO THE “Y2” ON THE LOW

VOLTAGE TERMINAL BOARD.

Any equivalent thermostat can be used in place of the manufacturer’s thermostat part number.

18

Page 19

WARNING

HIGH VOLTAGE!

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

DISCO NNECT ALL POWER BEFORE SERVICING.

Low Voltage Wiring for ARUF Air Handlers

ROOM THERMOSTAT

WY

GR

#18 GA. 4 WIRES WITH

COOLING 3 WIRES WITHOUT

ARUF UNIT

R

G

W

Y

CONTACTOR

COIL

TO CON DENSING

UNIT 2 4 V. CONNE CTIONS

#18 GA. 2 WIRES

Low Voltage Wiring Diagram for Cooling Unit with optional heat kit 10KW and below

RED

GREEN

WHITE

BLUE

W2

ARUF UNIT

#18 GA. 4 WIRE WI TH

COO LING 3 WI R E WITHO UT

RED

GREEN

WHITE

#18 GA. 2 WIRES

CONTACTOR

COIL

CONDENSING

UNIT 2 4V. CONNEC TIO N S

BROWN

BLUE

Low Voltage Wiring Diagram for Cooling Unit with optional heat kit 15KW and above

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

19

Page 20

WARNING

ARUF

10 KW & BELOW

HEAT PUMP

CW2OYR

B

R

I

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERVICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

Low Voltage Wiring for ARUF Air Handlers

TYPICAL H/P

ROOM THERMOSTAT

YOC GRE

R

W2

R

R

#18 GA. 7 WIRE

AR UNIT

R

RED

#18 GA. 5 WIRE

(OPTIONAL)

OUTDOOR THERMOST AT

CLOSE ON TEMPERATURE FALL

ARUF

ABOVE 10 KW

HEAT PUMP

W2

C

B

YO R

R

R

I

Y

O

W

BL

ROOM THERMOSTAT

Y CO

R

Y

O

W

NOTE

TYPICAL H/P

W2

NOTE

RGE

BR

G

BR

W

BL

R

G

NOTE

G

GREEN

W

WHITE

BL

BLUE

#18 GA. 6 WIRE NEEDED WHEN OT IS USED

#18 GA. 7 WIRE

AR UNIT

RED

R

GREEN

G

WHITE

W

BROWN

BR

BL

BL

#18 GA. 5 WIRE

(OPTIONAL)

OUTDOOR THERMOST AT

CLOSE ON TEMPERATURE FALL

BL

#18 GA. 7 WIRE NEEDED WHEN TWO OT'S ARE USED

BLUE

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

20

Page 21

WARNING

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERVICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

#18 GA. 4 WIRES WITH COOLING

3 WIRES WITHOUT

YW

GR

AIR HANDLER

C

RD

GR

WH

R

G

W1

W2

Y1

Y2

O

TB

YL

BL

TO CONDENSING UNIT

24V CONNECTION

YL

YL

BL

COOLING UNIT WITH OPTIONAL HEAT KITS OF 10 kW AND BELOW

#18 GA. 5 WIRES WI T H COOLING

4 WIRES WITHOUT

W2

BR

YL

BL

YGW

YL

CONDENSING UNIT

24V CONNECTION

R

BR

RD

GR

WH

BR

YL

YL

BL

AIR HANDLER

C

R

G

W1

W2

Y1

Y2

O

TB

COOLING UNIT WITH OPTIONAL HEAT KITS OF 15 kW AND ABOVE

AND ROOM TH E RMOST AT WITH TWO ST A GES OF H EAT

NOTES:

1) OUTDOOR THERMOSTAT (OT-1) SHOULD BE THE FIRST

TO CLOSE AND THE LAST TO OPEN.

2) JUMPER W1 AND W2 TOGETHER IF OT-2 IS NOT USED.

3) REMOVE WIRE WHEN USING OUTDOOR THERMOSTAT.

NOMENCLATURE:

OT - OUTDOOR THERMOSTAT (OPTIONAL)

EHR - EMERGENCY HEAT RELAY (OPTIONAL)

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

21

COLOR CODES

RD - RED

YL - YELLOW

BL - BLUE

BR - BROWN

OR - ORANGE

WH - WHITE

Page 22

WARNING

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERVICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

#18 GA. 7 WIRE

W2

YC

O

R Y O

W2

GC R

E

AIR HANDLER

GR

BR

BR

RD

WH

YL

OR

BL

BL

YL

C

R

G

W1

W2

Y1

Y2

O

TB

RD

YL

OR

WH

BL

YL

BL

WH

WH

HEAT PUMP UNIT WITH OPTIONAL HEAT KITS OF 10 kW AND BELOW

#18 GA. 7 WIRE

W2

YC

O

R Y O

W2

GC R

E

AIR HANDLER

BR

RD

GR

YL

WH

OR

RD

BL

RD

WH

C

R

G

W1

W2

Y1

Y2

O

TB

WH

RD

YL

OR

BL

YL

OR

OR

GR

WH

BL

WH

OR

BR

HEAT PUMP UNIT WITH OPTIO NA L HEAT KITS O F 15 kW AND A B O VE

NOTES:

1) OUTDOOR THERMOSTAT (OT-1) SHOULD BE THE FIRST

TO CLOSE AND THE LAST TO OPEN.

2) JUMPER W1 AND W2 TOGETHER IF OT-2 IS NOT USED.

3) REMOVE WIRE WHEN USING OUTDOOR THERMOSTAT.

NOMENCLATURE:

OT - OUTDOOR THERMOSTAT (OPTIONAL)

EHR - EMERGENCY HEAT RELAY (OPTIONAL)

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

22

COLOR CODES

RD - RED

YL - YELLOW

BL - BLUE

BR - BROWN

OR - ORANGE

WH - WHITE

Page 23

WARNING

C

T

P

R

C

P

C

R R

M

L

L

G

T

R

ELECTRONIC BLOWER TIME DELAY RELAY

HIGH VOLTAGE!

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

DISCO NNECT ALL POWER BEFORE SERVICING.

SYSTEM

TRANSFORME

24 VAC

OPTIONAL

SPEEDU

TSTA

XFMR-

K1

PARK TER M INA

M1

120/240VA

MOTO

B13707-35

XFMR-

WIRING DIAGRA

K1

FOR USE WITH

HEAT KI

SPEEDU

The Electronic Blower Time Delay Relay provides power to the blower motor with a delay of 7

seconds after 24VAC is applied to “G”. After 24VAC is removed from “G”, the blower motor

output is de-energized after a delay of 65 seconds.

Normal Time Delays 60Hz 50Hz

Turn On Delay 7.0 SEC.±1% 8.4 SEC. .±1%

Turn Off Delay 65.0 SEC.±1% 78.0 SEC. .±1%

N E UTRA

Field test mode: Shorting the “speedup” quick connect to “C” decrease times as follows:

Speedup Time s 60Hz 50Hz

Turn On Delay 3.0 SEC.±1% 3.6 SEC. .±1%

Turn Off Delay 5.0 SEC.±1% 6.0 SEC. .±1%

Field test mode is cancelled when the “speedup” quick connect to “C” short is removed.

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

23

Page 24

18 Wiring Diagrams

COPPER POWERSUPPLY

(USERATING PLATE)

USE MIN.75° C FIELD WIRE

0140A00630-A

PLM

PLF

TR

FACTOR YWIRIN G

FIELD WIRING

NOTE

S:

1. RED WIRES TO BE ON TRANSFORMER TER MINAL"3" FOR 240 VOLTS ANDON

TERMINAL "2" FOR 208 VOLTS.

2.SEE C OMPL ETEWIRING DIAG R AMS ININSTALLATION INSTRUCTIONSFOR

PRO PERLO W VOLTAGE WIRING CON NECTION S.

3. "CONFIRM SPEED TAPSELECTION ISAPPROPRIATE FOR APPLICATION. IF

SPEED TAP NEEDS T O BE CHAN GED, CONNECT PURPLEW IRE FROM TERMINAL7

OF CR (TERMINAL 4 OF ALTERN ATE) R ELAY TO APPROPRIATE TAP AT TB”

4. BROWN AND WHITEWIRES ARE USED FOR HEAT KITS ONLY.

5. FUSE: 3A,250V, 3AG AT OSTYLE FUSE. OPTIONAL FUSE 3 AMP CARTRIDGE.

6. LOW VOLTAGE FIELD WIRING TO BEN.E.C CLASS 2WIRES.

RELAY

EVAPORATOR MOTOR

TERMINAL BOARD

R

EM

TB

BK

RD

BLYLBLUE

BLACK

RED

YELLOW

COMPONENT COD E

BROWN

PURPLE

GREEN

PU

BR

GR

FEMALE PLUG CONNECTOR

MALE PLUG CONNECTO R

TRANSFORMER

HIGH VOLTAGE

LOW VOLTA GE

HIGH VOLTA GE

LOW VOLTA GE

PLF

2

COLOR CODE

TR

65 PLM

4

4

24V

5

1

23

EM

W

IRING COD E

208/240 VOLTS

1

1

PLF

PLM

L1

PLM

2

L2

IF REPLACEMENT OF T HE ORI GINALWIRES

SUPPLIEDW ITH THIS ASSEMBLY IS NECESSARY,

USE WIRE THA T CONFORMS T O THE NATIONAL

ELECTRIC C ODE.

FL

FUSE LINK

TL

THERMAL LIMIT

CR

CONTROL RELAY

WHITEWH

LG

N

W2R W1C G 4Y1 OY2 1DH 325

A

B

1

C

EM

2

4

3

5

4

7

CR

1

SEE NOTE 1

U

S

E

C

O

P

P

E

R

W

I

R

E

E

Q

U

I

P

M

E

N

T

G

R

O

U

N

D

B

L

E

M

Y

L

B

L

5

B

K

C

B

K

P

L

F

B

K

1

R

D

2

3

2

4

0

2

4

V

4

123

T

R

R

D

B

L

B

R

4

5

W

H

6

7

8

9

P

L

M

G

R

D

1

2

3

4

5

6

7

8

9

A

B

1

7

4

C

R

S

E

E

N

O

T

E

S

2

&

6

21435

NCG

L

R

D

P

U

B

L

B

R

W

H

B

L

R

D

G

R

R

D

o

r

B

K

B

L

R

D

B

K

R

D

W

2

R

W

1

C

G4Y1O

Y

2

1

D

H

325

R

D

o

r

B

K

P

U

B

R

W

H

O

R

W

H

W

H

B

L

G

R

R

D

o

r

B

K

B

L

L

2

L

1

SEE

NOTE 1

SEE

NOTE 4

1

3

542

ALTERNATE CONTROL RELAY

B

L

P

U

R

D

G

R

W

H

B

L

1

3

2

4

CR

5

ALTERNATE HEAT RELAY

GRND

GROUND

S

E

E

N

O

T

E

S

2

&

6

F

U

S

E

F

U

S

E

TB

TB

ARUF**14**

IF REPLACEMENT OF THE ORIGINAL WIRES

SUPPLIED WITH THIS ASSEMBLY IS NECESSARY

USE WIRE THAT CONFORMS TO THE

NATIONAL ELECTRIC CODE.

NOTES:

1) RED WIRES TO BE ON TRANSFORMER TERMINAL "3" FOR 240 VOLTS

AND ON TERMINAL "2" FOR 208 VOLTS.

2) SEE COMPOSITE WIRING DIAGRAMS IN INSTALLATION INSTRUCTIONS

FOR PROPER LOW VOLTAGE WIRING CONNECTIONS.

3) CONFIRM SPEED TAP SELECTED IS APPROPRIATE FOR APPLICATION.

IF SPEED TAP NEEDS TO BE CHANGED, CONNECT APPROPRIATE

MOTOR WIRE (RED FOR LOW, BLUE FOR MEDIUM, AND BLACK FOR

HIGH SPEED) ON "COM" CONNECTION OF THE EBTDR.

INACTIVE MOTOR WIRES MUST BE CONNECTED TO "M1 OR M2"

ON EBTDR.

4) BROWN AND WHITE WIRES ARE USED WITH HEAT KITS ONLY.

5) EBTDR HAS A 7 SECOND ON DELAY WHEN "G" IS ENERGIZED

AND A 65 SECOND OFF DELAY WHEN "G" IS DE-ENERGIZED.

6) LOW VOLTAGE FIELD WIRING TO BE N.E.C CLASS 2 WIRES.

WARNING

SEE NOTES 2 & 6

WH

BL

RD GR

GR

RD

BL

XFMR-R

RD

XFMR-C

BL

COPPER POWER SUPPLY

(SEE RATING PLATE)

USE MIN. 75C FIELD WIRE

THREE SPEED MOTOR WIRING

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERVICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

TERMINAL BLOCK SHOWN

FOR 50HZ MODELS ONLY

BR

SR

BR

WH

SEE NOTE 5

G

EBTDR

R

K1

K1

C

M1

SPEEDUP

BK

(SELECT MODELS ONLY)

SEE NOTE 3

COM

M2

NO

NC

SEE

NOTE 3

PLF

PLM

PU

(COM) RD

(M2)

(M1)

(TR 1)

PU

L1

L2

RD

BK

2

1

23

1

PU

BK

RD

BK

RD

PU

RD

LOW

BL

MEDIUM

BK

HIGH

PU

BR

3 SPEED

RC

GRD

3

C

EM

4

4

BL

12

24V

5

BL

EQUIPMENT GROUND

USE COPPER WIRE

5 67

5WH67

BR

NOTE 4

RD

SEE NOTE 1

3

240

TR

4

BL

RD

RD

RC

BR

BR

SEE

8 9

89

PU

BK

EM

EBTDR

BK

RD

YL

BL

EM

RC

SR

R

EBTDR

COLOR COD

COMPONENT

L1

PLF

1

PLM

1

RC

1

TR

R

4

RD

E

BLACK

GR

RED

YELLOW

BLUE

GREEN

PU

PURPLE

BROWN

BR

WHITEWH

CODE

EVAPORATOR MOTOR

RUN CAPACITOR

STRAIN RELIEF

RELAY

ELECTRONIC BLOWER

TIME DELAY RELAY

EM

2

24V

WH6BR

3

5

5

208/240

VOLTS

4

PLF

3

NC

M1

HI

M2

LO

SEE NOTE 1

BL

CODE

W

IRING

FACTORY WIRING

HIGH VOLTAGE

LOW VOLTAGE

FIELD WIRING

HIGH VOLTAGE

LOW VOLTAGE

TRANSFORMER

TR

FEMALE PLUG CONNECTOR

PLF

PLM

MALE PLUG CONNECTOR

FL

FUSE LINK

TL

THERMAL LIMIT

EBTDR

COM

EBTDR

PLF

PLM

NO

L2

2

2

GC

GR

0140A00242-A

ASPT**14**

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

24

Page 25

WARNING

3-Phase Heat Kit

HIGH VOLTAGE!

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

DISCO NNECT ALL POWER BEFORE SERVICING.

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

25

Page 26

AIR HANDLER

AIR HANDLER HOMEOWNER’S ROUTINE MAINTENANCE RECOMMENDATIONS

REPLACE OR CLEAN FIL TER

IMPORTANT NOTE: Never operate unit without a filter installed as dust and lint will build up on internal parts resulting in

loss of efficiency, equipment damage and possible fire.

An indoor air filter must be used with your comfort system. A properly maintained filter will keep the indoor coil of your

comfort system clean. A dirty coil could cause poor operation and/or severe equipment damage.

Your air filter or filters could be located in your furnace, in a blower unit, or in “filter grilles” in your ceiling or walls. The

installer of your air conditioner or heat pump can tell you where your filter(s) are, and how to clean or replace them.

Check your filter(s) at least once a month. When they are dirty, replace or clean as required. Disposable type filters

should be replaced. Reusable type filters may be cleaned.

You may want to ask your dealer about high efficiency filters. High efficiency filters are available in both electronic and

non-electronic types. These filters can do a better job of catching small airborne particles.

MOTORS

Indoor and outdoor fan motors are permanently lubricated

and do not require additional oiling.

ALUMINUM INDOOR COIL CLEANING

(QUALIFIED SERVICER ONLY)

This unit is equipped with an aluminum tube evaporator

coil. The safest way to clean the evaporator coil is to simply flush the coil with water. This cleaning practice remains as the recommended cleaning method for both copper tube

and aluminum tube residential evaporator coils.

It has been determined that many coil cleaners and drain pan tablets contain corrosive chemicals that can be harmful to

aluminum tube and fin evaporator coils. Even a one-time application of these corrosive chemicals can cause premature

aluminum evaporator coil failure. Any cleaners that contain corrosive chemicals including, but not limited to, chlorine

and hydroxides, should not be used.

An alternate cleaning method is to use one of the products listed in TP-109* to clean the coils. The cleaners listed are the

only agents deemed safe and approved for use to clean round tube aluminum coils. TP-109 is also available on the web

site in Partner Link > Service Toolkit.

NOTE: Ensure coils are rinsed well after use of any chemical cleaners.

BEFORE YOU CALL YOUR SERVICER

• Check the thermostat to confirm that it is properly

set.

• Wait 15 minutes. Some devices in the outdoor unit or

in programmable thermostats will prevent compressor operation for awhile, and then reset automatically. Also, some power companies will install devices which shut off air conditioners for several minutes on hot days. If you wait several minutes, the

unit may begin operation on its own.

• Check the electrical panel for tripped circuit breakers or failed fuses. Reset the circuit breakers or replace fuses

as necessary.

• Check the disconnect switch near the indoor furnace or blower to confirm that it is closed.

• Check for obstructions on the outdoor unit . Confirm that it has not been covered on the sides or the top. Remove

any obstruction that can be safely removed. If the unit is covered with dirt or debris, call a qualified servicer to

clean it.

• Check for blockage of the indoor air inlets and outlets. Confirm that they are open and have not been blocked by

objects (rugs, curtains or furniture).

• Check the filter. If it is dirty, clean or replace it.

• Listen for any unusual noise(s), other than normal operating noise, that might be coming from the outdoor unit. If

you hear unusual noise(s) coming from the unit, call a qualified servicer.

26

Page 27

This page left blank intentionally.

27

Page 28

CUSTOMER FEEDBACK

We are very interested in all product comments.

Please fill out the feedback form on one of the following links:

Daikin Products: (https://daikincomfort.com/contact-us)

Goodman® Brand Products: (http://www.goodmanmfg.com/about/contact-us).

Amana® Brand Products: (http://www.amana-hac.com/about-us/contact-us).

You can also scan the QR code on the right for the product brand you purchased

to be directed to the feedback page.

PRODUCT REGISTRATION

Thank you for your recent purchase. Though not required to get the protection of the

standard warranty, registering your product is a relatively short process, and entitles you to

additional warranty protection, except that failure by California and Quebec residents to

register their product does not diminish their warranty rights.

For Product Registration, please register as follows:

Daikin Products:

(https://daikincomfort.com/owner-support/product-registration).

Goodman® Brand products: (https://www.goodmanmfg.com/product-registration).

Amana® Brand products: (http://www.amana-hac.com/product-registration).

You can also scan the QR code on the right for the product brand you purchased

to be directed to the Product Registration page.

NOTE: SPECIFICATIONS AND PERFORMANCE DATA LISTED HEREIN ARE SUBJECT TO CHANGE WITHOUT NOTICE

Visit our website at www.daikincomfort.com, www.goodmanmfg.com or www.amana-hac.com for information on:

• Products

• Warranties

• Customer Services

• Parts

• Contractor Program and Training

• Financing Options

5151 San Felipe, Suite 500, Houston, TX 77056

© 2014-2017 Goodman Manufacturing Company, L.P.

is a registered trademark of Maytag Corporation or its related companies and is used under license. All rights reserved.

DAIKIN

GOODMAN® BRAND

AMANA® BRAND

GOODMAN® BRAND

DAIKIN

AMANA® BRAND

28

Loading...

Loading...