Page 1

Air-Cooled Scroll Compressor Units

ACZ010BS – ACZ 039BS Condensing Units

AGZ010BS – AGZ 034BS Chillers

AGZ010BM – AGZ 034BM Chillers with Remote Evaporators

10 to 40 Tons (35 to 140 kW)

60 Hertz

R-407C

Catalog

CAT 616

Page 2

Table of Contents

y

Introduction. .............................................................................3

Features and Benefits ..............................................................4

Design Features . .......................................................................5

ACZ Condensing Unit Performance . ...................................11

AGZ Chiller Selection Procedure .........................................15

AGZ Chiller Performance Data ...........................................21

Pressure Drop Curves............................................................24

Sound Data .............................................................................25

Electrical Data........................................................................29

Physical Data . .........................................................................36

Dimensions & Weights...........................................................42

Application Data ....................................................................47

Optional Features...................................................................52

Product Specification.............................................................54

Manufactured in an ISO certified facilit

Document Number: Catalog ACZ-AGZB1-1

Initial Issue: October 2007

Revision Date: March 2012

Replaces: June 2011

© 2013 Daikin Applied. Illustrations and data cover the Daikin product at the time of publication and we reserve the right to make

changes in design and construction at anytime without notice. ™® The following are trademarks or registered trademarks of

their respective companies: BACnet from ASHRAE; LONMARK, LonTalk, LONWORKS, and the LONMARK logo are managed,

granted and used by LONMARK International under a license granted by Echelon Corporation; Compliant Scroll from Copeland

Corporation; ElectroFin from AST ElectroFin Inc.; Modbus from Schneider Electric; FanTrol, MicroTech II, Open Choices, and

SpeedTrol from Daikin.

2 Catalog 616

Page 3

Introduction

This catalog covers air-cooled, single circuit, R-407C, scroll compressor chillers and

condensing units as follows:

ACZ 010BS – ACZ 039BS condensing units, 10 to 39 tons

AGZ 010BS – AGZ 034BS packaged chillers, 10 to 34 tons

AGZ 010BM – AGZ 034BM chiller with remote, 10 to 34 tons, matching water cooler, shipped

separately for field installation, usually indoors

These units utilize a single refrigerant circuit using a set of tandem scroll compressors. They

continue Daikin’s legacy of high quality, high efficiency, latest technology and quiet operation.

These features make the ACZ and AGZ the best overall value in air-cooled units available today.

Latest Control Technology

These units have the latest control technology through utilization of Daikin’s MicroTech II

microprocessor. Integrating with your building automation system is easy with the Daikin’s Open

Choices feature using LONMARK, BACnet or Modbus network communication, requiring only

the addition of a small communication module to the unit controller.

Compact Size

Our reputation for compact designs with small footprints to minimize space requirements continues to be

a primary feature.

Quiet Operation

The ACZ and AGZ units further enhance Daikin’s reputation for low operating sound levels to

make these units “neighborhood friendly”.

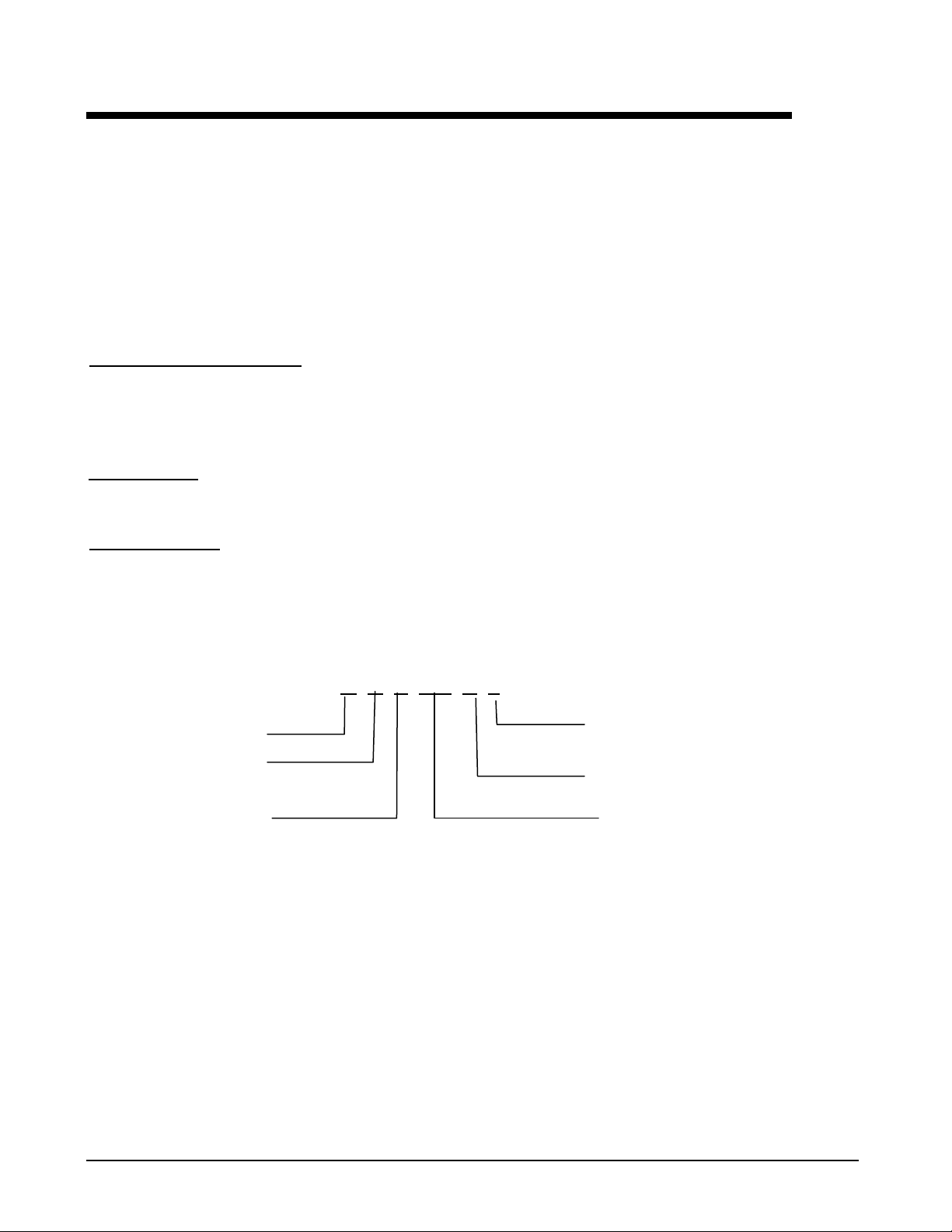

NOMENCLATURE

A C Z 010 B S

Air-cooled

C = Condensing Unit

G = Packaged Chiller

Scroll Compressor Nominal Capacity (Tons)

S = Standard Unit

M = Remote Evaporator

Vintage

Catalog 616

3

Page 4

Features and Benefits

ACZ-AGZ, Single Circuit Units

Great values also come in small packages. The ACZ and AGZ units have a single refrigerant circuit with

capacities from 10 to over 34 tons. Customer benefits include high efficiency operation, low sound levels,

efficient and reliable scroll compressor technology, and MicroTech II controls.

High Efficiency Operation

These units operate at high efficiency with IPLVs up to 14.6 EER. Through the use of tandem scroll

compressors and the latest control technology, excellent part load performance occurs. With a single

compressor running, the entire unit’s condenser surface is utilized, lowering condenser pressure and

reducing power input.

Quiet Operation

ACZ and AGZ units have low sound ratings through the use of scroll compressors. These compressors are

housed in a sheet metal enclosure to further reduce the levels. All units have a sound power rating of 90

dBA or less. For additional sound attenuation, optional acoustic blankets are also available. See page 25

re information regarding our low sound levels.

o

for m

Superior Control with MicroTech II

They have the MicroTech II controller providing control strategies expected of much larger units.

Building Automation System Integration

The MicroTech II controller allows for easy BAS integration through our Open Choice feature using

ONMARK, BACnet or Modbus communications. This is another advanced feature typical of larger units.

L

Figure 1, Model ACZ 033, 30-ton Condensing Unit

4 Catalog 616

Page 5

Design Features

The Daikin air-cooled, scroll compressor units are a product of Daikin’s commitment to offer

quiet, reliable, energy efficient equipment. These units incorporate high quality compressors,

state-of-the-art coil design, and innovative packaging.

Construction

Factory assembled and mounted on a heavy-gauge steel channel base. The base rails, supports and cabinetry are

powder-coat painted. The base distributes the unit weight for roof loading. Varied and convenient installation is

possible by virtue of the unit's small footprint.

Compressors

Copeland’s Compliant Scroll tandem compressors are used. These rugged hermetic compressors are

constructed with an integral cast iron frame, cast iron scrolls, three Teflon impregnated bearings, and three oil

filtration devices for each compressor.

Using Copeland's Compliant Scroll tandem compressors provides two steps of capacity modulation. One

compressor can run alone, depending on the load of the system, utilizing the entire unit’s condenser surface,

which results in excellent part-load efficiency. The refrigerant circuit has specially designed oil and gas

equalization lines to control oil migration.

The design also offers radial and axial compliance (no tip seals), a large internal volume for liquid handling, a

removable suction screen, and a rotary dirt trap and oil screen. In addition, the compressor is self-compensating

for wear, handles liquid and debris, and inherently yields the highest efficiency for its class.

This well protected compressor includes a solid-state motor protection module, 4 individual motor-winding

sensors, a patented internal discharge temperature probe, and a patented shutdown feature that prevents reverse

rotation. An internal discharge check valve helps prevent shutdown noise and comes standard with high and

low pressure taps with Schrader valves, a sight glass, an oil level adjustment valve, and an off cycle crankcase

heater.

Units are available in 60 Hertz electrical voltage configurations from 208 to 575 volt operating at 3500 rpm.

Condenser Coils

Condenser coils have internally enhanced seamless copper tubes arranged in a staggered row pattern. The

coils are mechanically expanded into Daikin lanced and rippled aluminum fins with full fin collars. A variety

of optional coil material and coatings are available for corrosive atmospheres. The external condenser coils are

fitted with a protective wire mesh guard as standard equipment.

Condenser Fans and Motors

Multiple direct-drive, dynamically balanced, propeller fans operate in formed venturi openings at low tip

speeds for maximum efficiency and minimum noise and vibration. A heavy-gauge vinyl-coated fan guard

protects each fan.

Each condenser fan motor is heavy-duty, 3-phase, Totally Enclosed Air Over (TEAO) with permanently

lubricated ball bearings and inherent overload protection. SpeedTrol option includes a single-phase motor with

fan speed control on the lead fan.

Evaporator

Stainless steel, brazed plate evaporators are used on the AGZ units. They have counter-flow operation and very

high efficiencies.

Catalog 616

5

Page 6

Electrical Control Center

Operating and equipment protection controls and motor starting components are separately housed in a

centrally located, weather-resistant control panel with hinged and tool-locked doors. In addition to the

MicroTech II controller described in the next sections, the following components are housed in the panel:

Standard single-point, terminal block connection

Control, input, and output terminal block

Control transformer

Phase voltage monitor with under/over voltage and phase reversal protection

Fan contactors with short circuit protective devices

The standard FanTrol head pressure control system controls refrigerant discharge pressure by fan

staging. The FanTrol system cycles condenser fans based on discharge pressure and outdoor temperature and

is designed for operation down to 35°F (1.7°C).

Optional SpeedTrol™ control using both fan cycling and fan speed control on the lead fan per circuit and

allows operation to 0°F (-18°C) outdoor temperature.

Mechanical high pressure cutout

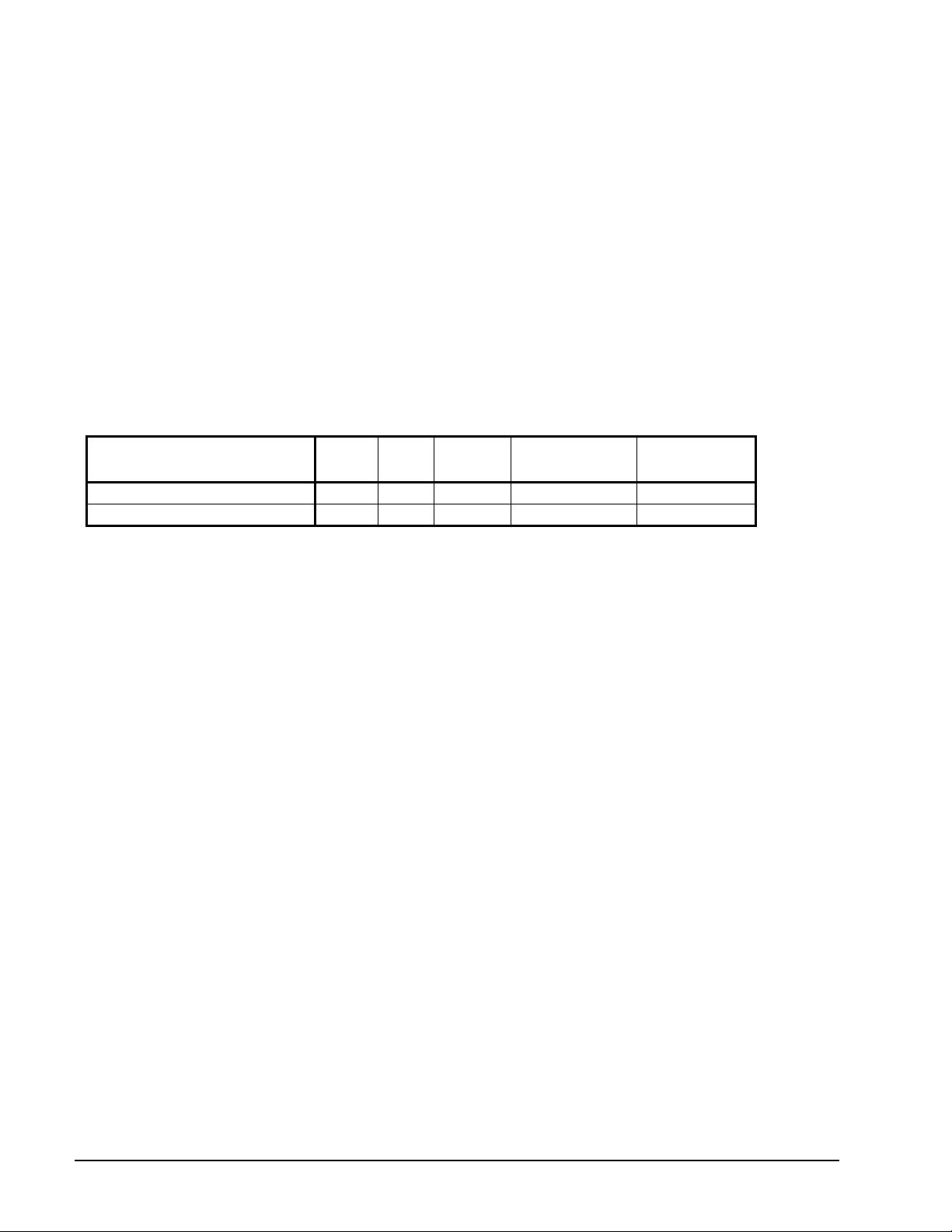

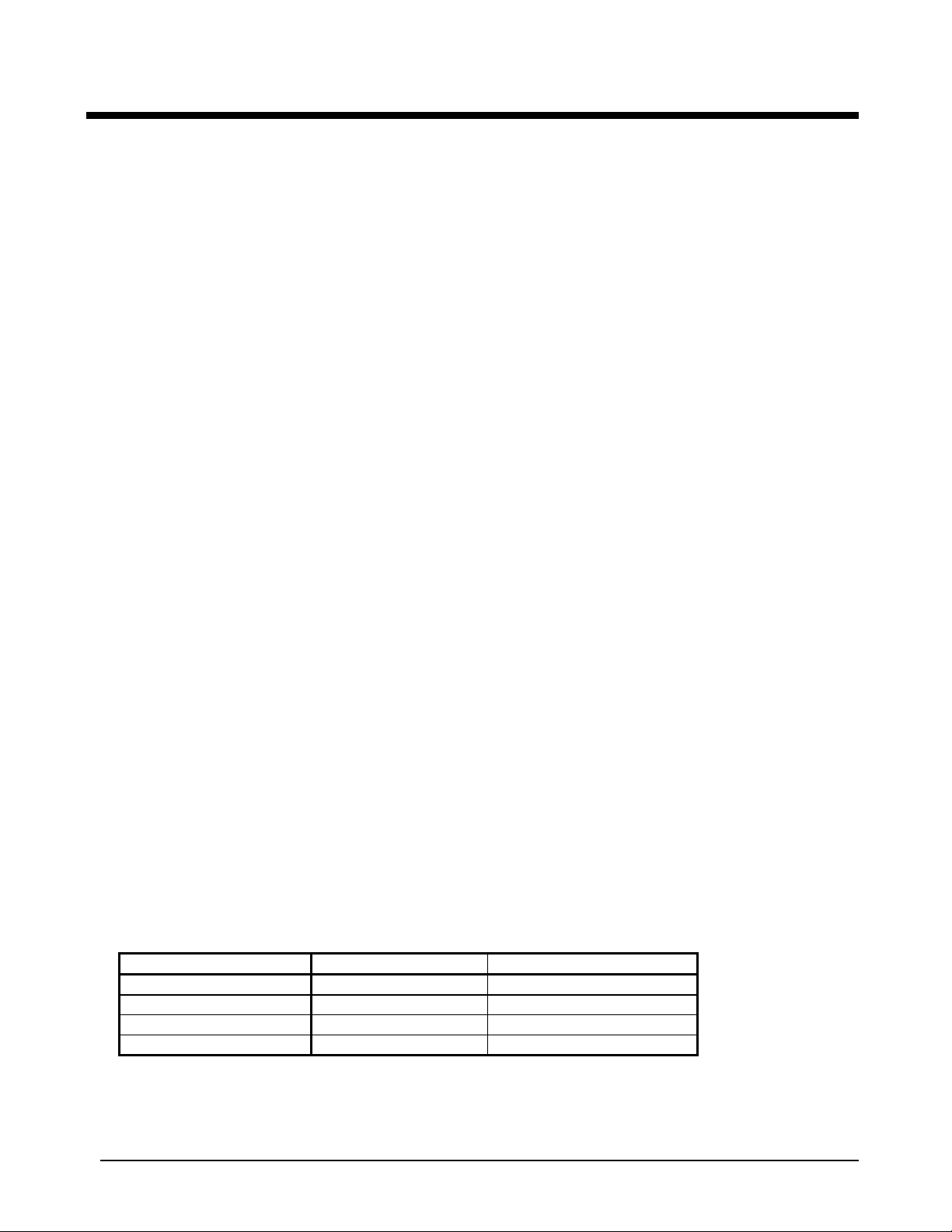

Power connections are per following table:

Power Connection

ACZ 010-039, Single-Point Connection Std. Opt Not Avail. Opt. Opt.

AGZ 010-034 Single Point Connection Std. Opt Not Avail. Opt. Opt.

Power

Block

Disc.

Swt.

Comp.

Circuit

Breakers

Definitions:

1. Power Block: An electrical device to directly accept field wiring without any disconnecting means.

2. Disconnect Switch: A molded case switch that accepts field wiring and disconnects main power to the

entire unit or each main power supply if the multi-point power supply option is selected. This option does

not provide overcurrent protection.

3. Unit Circuit Breaker with High Interrupting Capacity: A molded case circuit breaker acting as the

main disconnect switch with short circuit current rating (formally known as “withstand”). One circuit

breaker is provided. The circuit breaker provides overcurrent protection for the power supply.

4. Control Panel High Short Circuit Current Rating: (Previously known as “withstand rating”). The

entire control panel is designed for short circuit current rating. In the event of a short circuit, the damage

is contained within the control panel enclosure.

High Interr

Disconnect Switch

Current Rating

High Short Circuit

Current Rating w/

Disconnect Switch

Control System

The MicroTech II

systems available today on this class of equipment. This powerful, user-friendly control system provides

the flexibility and performance needed for either stand-alone unit operation or the controller can be easily

tied into your building automation system of choice using Daikin’s exclusive Open Choices feature that

allows you to choose from open standard protocols such as BACnet, Modbus, and LonTalk to

communicate easily with the building automation system that best meets your facility requirements. These

optional communications modules are available factory-installed or can be easily field installed.

MicroTech II’s state-of-the-art design will not only permit the unit to run more efficiently, but will also

simplify troubleshooting if a system failure occurs. Every MicroTech II controller is programmed and tested

prior to shipment.

Operator-friendly

The MicroTech II control menu structure is separated into four distinct categories that provide the operator or

service technician with a full description of current unit status, control parameters, and alarms. Security

protection helps prevent unauthorized changing of the setpoints and control parameters.

MicroTech II continuously performs self-diagnostic checks, pressures and protection devices, monitoring

system temperatures, and it will automatically shutdown a compressor, or the entire unit, if a fault occurs. The

6 Catalog 616

advanced DDC unit controller surpasses all other microprocessor-based unit control

Page 7

cause of the shutdown will be retained in memory and can be easily displayed in English or metric units for

operator review.

The MicroTech II unit controller can also retain and display the time that the fault occurred and the operating

conditions that were present at the time of the fault, an extremely useful feature for troubleshooting. In

addition to displaying alarm diagnostics, the MicroTech II controller also provides the operator with a

warning of pre-alarm conditions. Alarm notification data can also be passed on to your BAS through an

optional communications module.

Staging

On ACZ condensing units, temperature control for the system is provided by the installer through a field

supplied temperature controller. The field-supplied staging signals are provided to the MicroTech II controller

which correspondingly activates and deactivates the scroll compressors. The temperature controller is

required to close normally-open 24 volt contacts on a demand for cooling. These closure signals are field

wired to the terminal strip (TB2) in the condensing unit. Refer to the typical field wiring diagram on page 34

wo control stages are required:

for details.

Lead/lag is automatic and switched based on operating hours and compressor starts.

T

Equipment Protection

The unit is protected in two ways: (1) by alarms that shut the unit down and require manual reset to restore

unit operation and (2) by limit alarms that reduce unit operation in response to some out-of-limit condition.

Shut down alarms can activate a remote alarm signal. Limit alarms activate a signal on the controller.

Shutdown Alarms

High condenser pressure

No chilled water flow

Motor protection sy

Phase voltage protection (Optional on ACZ-B and

Outside am

Sensor failures

Limit Ala

rms

Condenser pressure stage down, unloads unit at high dischar

Low am

Low evaporator pressure hold, holds stage #1 until pressure rises

Low evaporator pressure unload, shuts off stage #2

bient temp

bient lockout, shuts off unit at low ambient temp

stem

AGZ-B)

erature

ge pressures

eratures

Unit Enable Selection

Enables unit operation from either local keypad, digital input, or BAS

Unit Mode Selection

Selects standard cooling, or test operation mode

Digital Inputs

Unit off switch

Remote start/stop

Flow switch

Digital Outputs

Shutdown alarm; field wired, activates on an alarm condition, off when alarm is cleared

Evaporator pump or air handler fan motor; field wired, starts when unit is set to start

Catalog 616

7

Page 8

Condenser fan control

The MicroTech II controller provides control of condenser fans. The controller stages condenser fans based

on discharge pressure.

Building Automation System (BAS) Interface

The following BAS standard protocols are supported through Daikin’s Open Choices option:

BACnet/IP

BACnet MS/TP

BACnet Ethernet

L

onTalk

Modbus

The following functions are generally available depending on the application and protocol in use:

Enable/disable operation

Select operating mode

Set the network limit variable

Read all digital and analog inputs and outputs

Read operating mode and status

Send a description of each alarm when it occurs

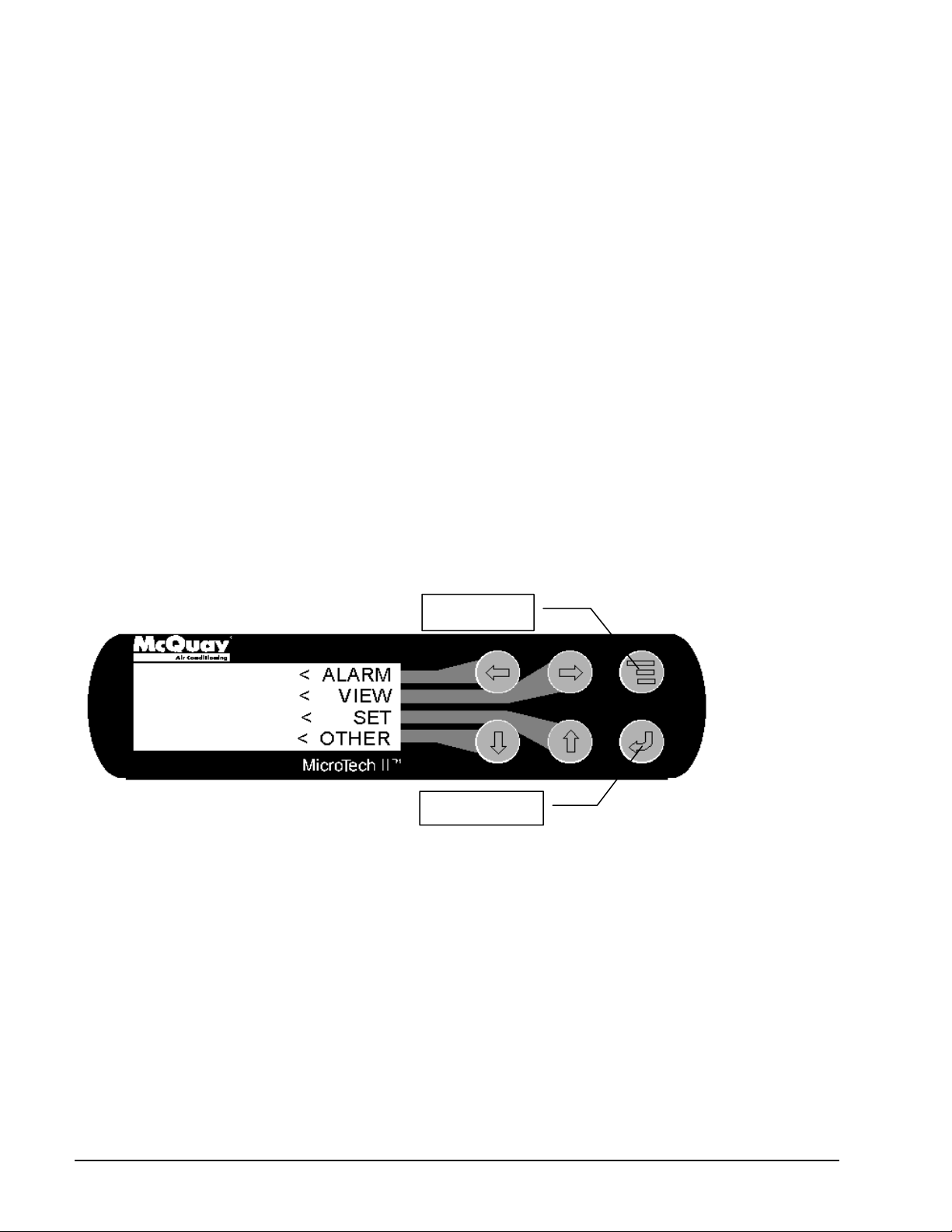

Keypad/Display

A 4-line by-20 character/line liquid crystal display and 6-key keypad is mounted on the unit controller. Its

layout is shown in

1Figure 2.

Figure 2, MicroTech II

Keypad

Menu Button

"Enter" Button

The four arrow buttons (UP, DOWN, LEFT, RIGHT) have three modes of use.

Scroll between data screens as indicated by the arrows (default mode).

Select a specific data screen in a hierarchical fashion using dynamic labels on the right side of the display

(this mode is entered by pressing the MENU button).

Change field values in edit mode.

8 Catalog 616

Page 9

Figure 3, ACZ/AGZ-B Control Panel

Optional Remote Interface Panel

The ACZ/AGZ units can be individually equipped with a

remote user interface. It provides convenient access to

unit diagnostics and control adjustments, remote from

the condensing unit panel. A separate panel is required

for each chiller on a job site.

Each remote user interface is similar to its unit-mounted

counterpart and offers the same functionality, including:

Touch-sensitive keypad with a 4 line by 20-character

display format

Digital display of messages in English language

All operating conditions, system alarms, control

parameters

Figure 4, Remote Interface Panel Dimensions

Features

Can be wired up to 1,640 feet (500 m

unit for flexibility in placing each rem

eters) from the

ote user interface

within your building.

The main control is isolated from the remote user interface

wiring so that wiring problems are less likely to damage the

unit user interface.

Can be placed on a desk or surface or recessed wall mounted.

Benefits

Allows y

ou to access the user interface for each unit from

one location, inside the building.

Users need to learn one format because the rem

ote user

interface is identical to the unit-mounted version.

No additional field commissioning is required for the remote user interface.

Can be retrofit after unit installation.

All the BAS communications options are still available with the remote interface panel.

Cable and Wiring Recommendations

No more than 1,640 feet (500 m

eters) of wiring can be used to connect the remote user interface to the unit.

Power: AWG 22 twisted pair cable.

Communications: Belden 9841 or equal AWG 22 twisted pair.

A separate small communication terminal board is used at the unit and at the remote panel.

Catalog 616

9

Page 10

Figure 5, Remote User Interface Wiring Diagram

p

D

A

r

pLAN

cable

Chiller Terminal Board

0 1 2 3 4 5 6

sc

pLAN phone style

cable to J10 of

Display Terminal Board

chiller Unit control

Note:

Maximum distance between terminal

blocks is 1640 feet (500 m)

A

0 1 2 3 4 5 6

sc

Power is supplied through

30 Vdc +

Power Common

RX+/Tx+

Rx-/Tx-

Shield

AWG22 twist ed pair cable

Communications cable is

Belden 9841 or equivalent

WG22 twisted pai

10 Catalog 616

Page 11

ACZ Condensing Unit Performance

Selection Procedure

ACZ condensing units are selected in conjunction with some kind of evaporator equipment. The ACZ ratings

are based on saturated suction temperature at the compressor inlet and on ambient air dry-bulb temperature. For

a system selection, the ACZ condensing unit is usually selected first, and then the line loss added to the

condensing unit saturated suction temperature to determine the saturated evaporating temperature. This

temperature is then used for the selection of the evaporator, whether it is a DX cooling coil or water heat

exchanger. The pipe size can be determined from procedures and data in the Refrigerant Piping Section. For

selection purposes, the tubing size is based on a pressure equivalent of a two-degree F line loss (equal to about

3-psi pressure drop).

uired job capacity by

The correction for altitude found in Table 1 is applied, if applicable, by dividing the re

the correction factor to ascertain the necessary unit capacity in the Capacity Tables.

R-407C NOTE: R-407C is an azeotrope and as such has a glide characteristic. An evaporator mid-point

temperature will be about four-degrees higher than the dew point temperature. For example, an R-22 evaporator

selected at a 40F evaporating temperature would be comparable to 44F with R-407C.

Selection example, Inch-Pound units

Given:

200 Mbh job requirement 95°F ambient temperature

40F saturated suction temperature 2,000 foot altitude

R-22

1. To select the correct size unit, correct for altitude by dividing the required capacity by

factor found in T

200 Mbh required / 0.986 factor = 202 Mbh corrected requirem

2. From Table 2 on the following page, an ACZ 020 at th

unit power input of 20.0 kW

3.

Correct for altitude:

Capacity: 202.5 Mbh x 0.986 = 200 Mbh

Power: 20.0 kW x 1.009 = 20.2 kW

EER: 10.1 EER x 0.986/1.009 = 9.9 EER

4. An evaporator would be selected at 42F saturated evaporating temperature.

able 1.

ent.

e given conditions will produce 202.5 Mbh with a

and a unit EER of 10.1.

q

the correction

Selection example-SI units

Use the same procedure as for Inch-Pounds but use SI tables and units.

Application Adjustment Factors

Altitude Correction Factors

Performance tables are based at sea level. Elevations other than sea level affect the performance of the unit.

The decreased air density will reduce condenser capacity, consequently reducing the unit's performance.

Table 1, Altitude Correction Factors

Altitude Capacity Power

Sea Level 1.000 1.000

2000 ft (610 m) 0.986 1.009

4000 ft (1220) m 0.973 1.021

6000 ft (1830) m 0.959 1.031

Catalog 616

11

Page 12

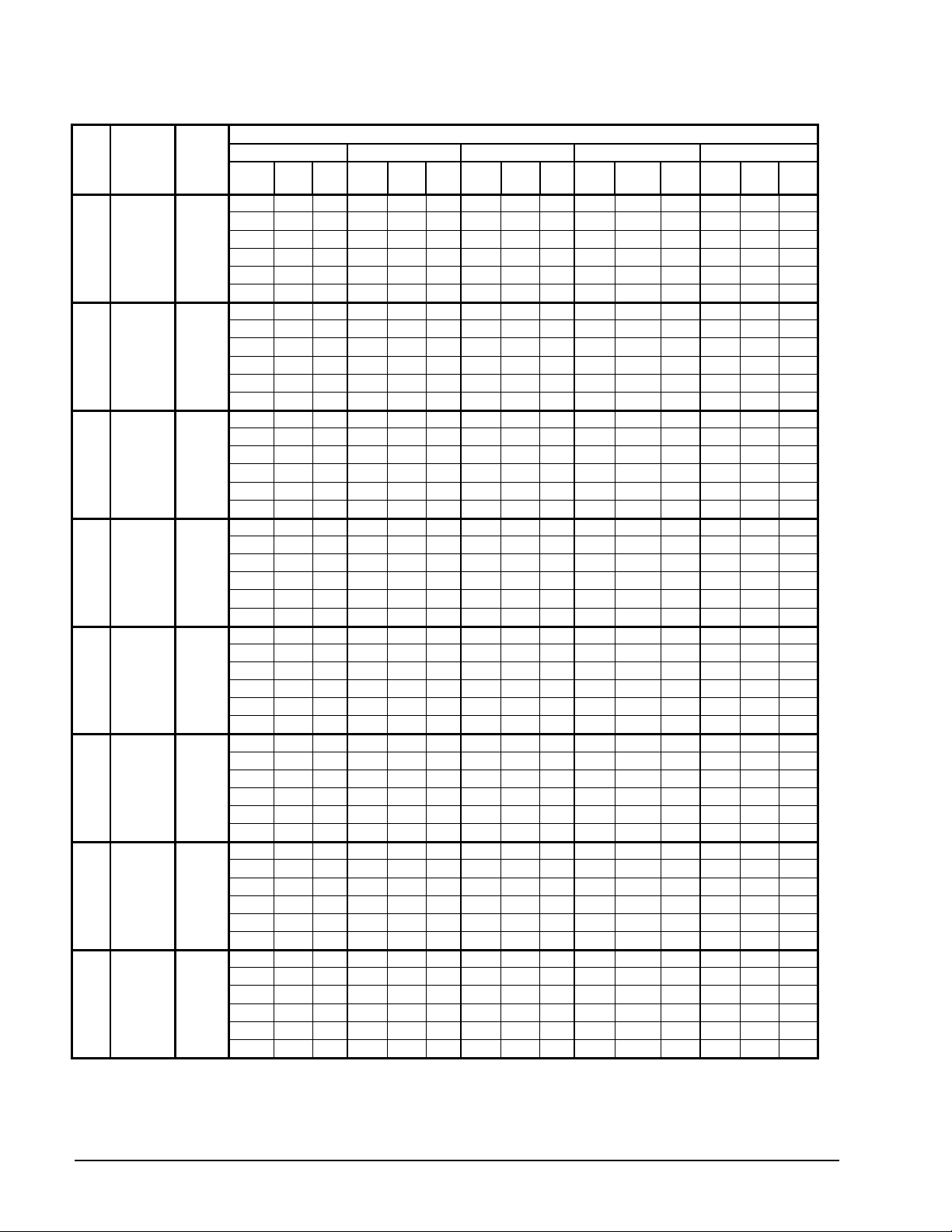

ACZ Performance Data

Table 2, R-407C, I-P Units, 60 Hz

Suction

ACZ

Dewpoint

Unit

Size

010

013

016

020

025

028

033

039

NOTES:

1. Ratings based on R-407C, and sea level altitude.

2.

3. KWi and EER are for the entire unit, including compressors, fan motors and control power.

4. Rated in accordance with ARI Standard 365-2002.

Temp

(F)

30 1.8 85.6 8.2 10.4 84.4 8.6 9.9 79.7 9.2 8.7 74.9 10.0 7.5 70.2 10.8 6.5

35 1.8 95.1 8.3 11.4 92.8 8.7 10.7 88.0 9.4 9.4 83.2 10.1 8.2 77.3 10.9 7.1

40 1.8 104.7 8.6 12.2 102.3 8.9 11.5 96.3 9.5 10.2 91.6 10.3 8.9 85.6 11.1 7.7

45 1.8 114.2 8.7 13.2 111.8 9.0 12.5

50 1.8 124.9 8.9 14.1 122.5 9.2 13.4 116.5 9.9 11.8 109.4 10.6 10.3 103.5 11.5 9.0

55 1.8 135.6 9.2 14.8 133.2 9.5 14.0 126.1 10.1 12.5 120.1 10.9 11.0 113.0 11.7 9.6

30 1.8 112.4 11.1 10.2 108.8 11.6 9.4 103.9 12.5 8.3 97.9 13.7 7.1 91.9 15.0 6.1

35 1.8 125.7 11.4 11.1 122.1 11.8 10.3 116.0 12.9 9.0 110.0 14.0 7.8 102.7 15.3 6.7

40 1.8 140.2 11.6 12.1 136.6 12.1 11.3 130.5 13.1 10.0 123.3 14.2 8.7 116.0 15.6 7.4

45 1.8 155.9 12.0 13.0 152.3 12.4 12.2

50 1.8 171.6 12.3 13.9 168.0 12.8 13.2 159.5 13.8 11.5 152.3 15.0 10.2 142.6 16.3 8.8

55 1.8 188.6 12.6 14.9 184.9 13.2 14.0 176.5 14.1 12.5 166.8 15.3 10.9 157.1 16.7 9.4

30 1.8 154.7 16.1 9.6 150.9 16.8 9.0 143.4 18.3 7.8 136.0 20.1 6.8 128.5 21.9 5.9

35 1.8 170.9 16.4 10.4 165.9 17.1 9.7 158.4 18.5 8.5 149.7 20.3 7.4 140.9 22.2 6.3

40 1.8 187.1 16.7 11.2 183.3 17.4 10.6 174.6 18.9 9.2 165.9 20.7 8.0 155.9 22.6 6.9

45 1.8 205.8 17.0 12.1 200.8 17.7 11.3

50 1.8 225.8 17.4 13.0 220.8 18.1 12.2 209.5 19.6 10.7 199.6 21.4 9.3 187.1 23.3 8.0

55 1.8 247.0 17.8 13.8 242.0 18.5 13.0 229.5 20.1 11.4 218.3 21.9 10.0 205.8 23.7 8.7

30 1.8 178.1 17.3 10.3 174.5 18.0 9.7 165.0 19.7 8.4 155.4 21.5 7.2 145.8 23.4 6.2

35 1.8 196.0 17.7 11.1 191.3 18.4 10.4 181.7 20.1 9.0 170.9 21.9 7.8 160.2 23.9 6.7

40 1.8 215.2 18.1 11.9 210.4 18.8 11.2 198.4 20.6 9.6 187.7 22.5 8.4 175.7 24.4 7.2

45 1.8 235.5 18.5 12.7 229.5 19.4 11.9

50 1.8 255.8 19.1 13.4 249.8 19.9 12.6 236.7 21.5 11.0 223.5 23.4 9.6 210.4 25.4 8.3

55 1.8 278.5 19.6 14.2 271.4 20.4 13.3 257.0 22.0 11.7 242.7 24.0 10.1 228.3 26.1 8.8

30 2.7 238.0 23.4 10.2 233.1 24.3 9.6 220.9 26.5 8.3 207.4 28.7 7.2 193.9 31.3 6.2

35 2.7 262.6 23.9 11.0 256.5 24.9 10.3 243.0 27.0 9.0 229.5 29.4 7.8 214.7 32.0 6.7

40 2.7 288.4 24.4 11.8 281.0 25.5 11.0 267.5 27.7 9.7 251.5 30.0 8.4 235.6 32.6 7.2

45 2.7 315.4 25.1 12.6 308.0 26.1 11.8

50 2.7 344.8 25.8 13.3 336.2 26.8 12.5 319.0 29.0 11.0 300.6 31.3 9.6 282.2 34.0 8.3

55 2.7 374.3 26.5 14.1 365.7 27.6 13.3 347.3 29.7 11.7 327.6 32.1 10.2 308.0 34.9 8.8

30 2.7 261.5 26.9 9.7 255.3 28.0 9.1 241.8 30.3 8.0 227.0 33.0 6.9 212.2 35.9 5.9

35 2.7 288.6 27.6 10.5 281.2 28.7 9.8 266.4 31.1 8.6 250.4 33.8 7.4 234.4 36.6 6.4

40 2.7 315.8 28.3 11.1 308.4 29.4 10.5 292.3 31.9 9.2 275.1 34.5 8.0 257.8 37.5 6.9

45 2.7 345.4 29.1 11.9 336.7 30.2 11.1

50 2.7 376.2 30.0 12.5 367.6 31.1 11.8 349.1 33.5 10.4 329.3 36.3 9.1 308.4 39.3 7.8

55 2.7 409.5 30.9 13.3 399.7 32.0 12.5 378.7 34.4 11.0 357.7 37.2 9.6 335.5 40.3 8.3

30 2.7 307.8 30.9 10.0 300.8 32.3 9.3 285.7 35.4 8.1 269.5 38.8 7.0 253.2 42.3 6.0

35 2.7 339.2 31.8 10.7 331.0 33.1 10.0 313.6 36.2 8.7 296.2 39.6 7.5 278.8 43.3 6.4

40 2.7 371.7 32.6 11.4 362.4 34.0 10.7 343.8 37.2 9.2 325.2 40.5 8.0 305.5 44.3 6.9

45 2.7 405.4 33.6 12.1 396.1 35.0 11.3

50 2.7 441.4 34.6 12.8 430.9 36.0 12.0 410.0 39.2 10.5 387.9 42.7 9.1 364.7 46.5 7.8

55 2.7 479.7 35.7 13.5 468.1 37.1 12.6 444.8 40.3 11.0 420.5 43.8 9.6 394.9 47.7 8.3

30 2.7 382.2 42.1 9.1 372.8 43.8 8.5 353.0 47.6 7.4 330.9 51.6 6.4 306.4 55.8 5.5

35 2.7 420.6 43.2 9.7 410.1 45.0 9.1 388.0 48.9 7.9 363.5 53.1 6.9 337.9 57.4 5.9

40 2.7 460.2 44.6 10.3 448.6 46.4 9.7 424.1 50.3 8.4 398.5 54.5 7.3 370.5 59.0 6.3

45 2.7 501.0 46.0 10.9 488.2 47.9 10.2

50 2.7 544.1 47.6 11.4 531.3 49.4 10.8 502.2 53.4 9.4 473.0 57.8 8.2 440.4 62.5 7.1

55 2.7 590.7 49.2 12.0 575.6 51.1 11.3 544.1 55.1 9.9 511.5 59.6 8.6 477.7 64.3 7.4

Interpolation is allowed; extrapolation is not permitted. Consult the local Daikin sales office for performance outside the cataloged

ratings.

Fan &

Control

Power

(kW)

75 85 95 105 115

Unit

PWR

Unit

Unit

Mbh

kWi

EER

PWR

Mbh

Ambient Air Temperature (F)

Unit

Unit

kWi

EER

PWR

Mbh

kWi

105.8 9.7 10.9

145.0 13.4 10.8

192.1 19.3 10.0

217.6 21.0 10.4

292.0 28.2 10.4

319.5 32.6 9.8

376.3 38.1 9.9

462.6 51.8 8.9

Unit

Unit

PWR

Unit

EER

Mbh

kWi

99.9 10.4 9.6 93.9 11.3 8.3

136.6 14.6 9.4 129.3 15.9 8.1

182.1 21.0 8.7 170.9 22.9 7.5

205.6 22.9 9.0 192.5 24.9 7.7

276.1 30.7 9.0 258.9 33.4 7.8

302.2 35.4 8.5 282.5 38.4 7.4

355.4 41.6 8.5 334.5 45.4 7.4

434.6 56.2 7.7 405.5 60.6 6.7

EER

Unit

Mbh

PWR

kWi

Unit

EER

12 Catalog 616

Page 13

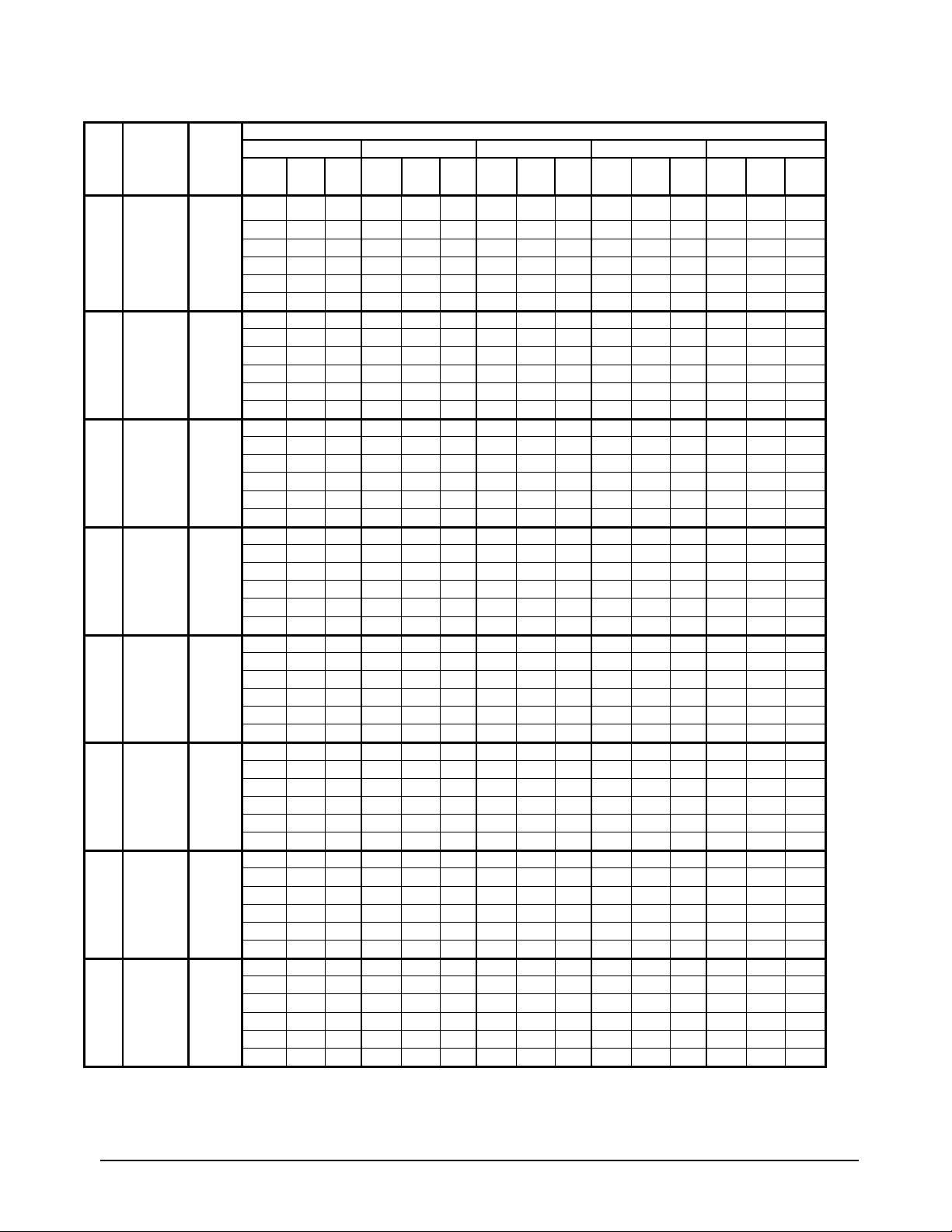

Table 3, R-407C, SI, 60 Hz

ACZ

Unit

Size

010

013

016

020

025

028

033

039

NOTES:

1.

2.

3.

Suction

Dewpoint

Temp

(C)

-1

11

13

-1

11

13

-1

11

13

-1

11

13

-1

11

13

-1

11

13

-1

11

13

-1

11

13

Fan &

Control

Power

(kW)

2

5

8

2

5

8

2

5

8

2

5

8

2

5

8

2

5

8

2

5

8

2

5

8

Ratings based on R-407C and sea level altitude.

Interpolation is allowed; extrapolation is not permitted. Consult the local Daikin sales office for performance outside the

cataloged ratings.

KWi and COP are for the entire unit, including compressors, fan motors and control power.

Unit

kW

1.8 25.1 7.6 3.3 23.9 8.3 2.9 22.7 8.8 2.6 21.3 9.6 2.2 19.8 10.5 1.9

1.8 27.9 7.8 3.6 26.6 8.4 3.2 25.3 9.0 2.8 23.8 9.8 2.4 22.2 10.7 2.1

1.8 30.9 7.9 3.9 29.5 8.6 3.4 28.0 9.2 3.0 26.4 10.0 2.6 24.7 10.9 2.3

1.8 34.1 8.1 4.2 32.5 8.8 3.7

1.8 37.5 8.4 4.5 35.7 9.0 4.0 34.1 9.6 3.6 32.2 10.4 3.1 30.2 11.3 2.7

1.8 39.9 8.5 4.7 38.0 9.1 4.2 36.3 9.7 3.7 34.2 10.6 3.2 32.1 11.5 2.8

1.8 32.8 10.2 3.2 31.1 11.2 2.8 29.7 12.1 2.5 27.9 13.3 2.1 26.0 14.7 1.8

1.8 37.1 10.5 3.5 35.3 11.4 3.1 33.7 12.4 2.7 31.7 13.6 2.3 29.5 15.0 2.0

1.8 41.7 10.8 3.8 39.7 11.8 3.4 37.9 12.7 3.0 35.8 13.9 2.6 33.4 15.3 2.2

1.8 46.6 11.2 4.1 44.4 12.2 3.6

1.8 51.8 11.6 4.5 49.4 12.5 4.0 47.2 13.4 3.5 44.6 14.6 3.0 41.8 16.0 2.6

1.8 55.3 11.9 4.7 52.8 12.8 4.1 50.5 13.6 3.7 47.7 14.8 3.2 44.8 16.3 2.7

1.8 45.4 14.9 3.0 43.0 16.4 2.6 41.2 17.6 2.3 38.8 19.5 2.0 36.3 21.4 1.7

1.8 50.5 15.3 3.3 47.9 16.6 2.9 45.8 18.0 2.5 43.2 19.8 2.2 40.5 21.7 1.9

1.8 55.9 15.6 3.6 53.2 17.0 3.1 50.8 18.3 2.8 48.0 20.1 2.4 44.9 22.1 2.0

1.8 61.9 15.9 3.9 58.7 17.3 3.4

1.8 68.3 16.3 4.2 64.9 17.8 3.7 62.1 19.1 3.2 58.6 20.9 2.8 54.9 23.0 2.4

1.8 72.7 16.6 4.4 69.2 18.1 3.8 66.2 19.3 3.4 62.5 21.3 2.9 58.4 23.2 2.5

1.8 52.5 15.9 3.3 49.7 17.5 2.8 47.3 18.9 2.5 44.3 20.8 2.1 41.3 22.8 1.8

1.8 58.1 16.3 3.6 55.1 17.9 3.1 52.5 19.4 2.7 49.3 21.3 2.3 46.0 23.3 2.0

1.8 64.2 16.8 3.8 60.8 18.4 3.3 57.9 19.9 2.9 54.4 21.8 2.5 50.8 23.8 2.1

1.8 70.6 17.3 4.1 66.9 18.9 3.5

1.8 77.4 17.8 4.3 73.3 19.4 3.8 69.9 20.9 3.3 65.6 22.8 2.9 61.3 25.0 2.4

1.8 82.0 18.1 4.5 77.8 19.8 3.9 74.1 21.3 3.5 69.6 23.2 3.0 65.0 25.4 2.6

2.7 69.9 21.7 3.2 66.4 23.6 2.8 63.3 25.5 2.5 59.3 27.9 2.1 55.0 30.5 1.8

2.7 77.6 22.2 3.5 73.7 24.2 3.0 70.2 26.1 2.7 65.9 28.5 2.3 61.3 31.3 2.0

2.7 85.9 22.8 3.8 81.5 24.9 3.3 77.7 26.7 2.9 72.9 29.2 2.5 68.0 32.0 2.1

2.7 94.6 23.5 4.0 89.8 25.5 3.5

2.7 103.7 24.2 4.3 98.4 26.2 3.8 94.0 28.1 3.3 88.3 30.6 2.9 82.4 33.4 2.5

2.7 110.1 24.8 4.4 104.5 26.7 3.9 99.6 28.6 3.5 93.7 31.2 3.0 87.5 33.9 2.6

2.7 76.8 24.9 3.1 72.9 27.2 2.7 69.4 29.3 2.4 64.8 32.0 2.0 59.9 35.0 1.7

2.7 85.1 25.7 3.3 80.8 27.9 2.9 77.0 30.1 2.6 72.1 32.8 2.2 66.8 35.9 1.9

2.7 94.0 26.4 3.6 89.3 28.7 3.1 85.1 30.8 2.8 79.8 33.7 2.4 74.1 36.8 2.0

2.7 103.4 27.3 3.8 98.2 29.5 3.3

2.7 113.5 28.2 4.0 107.7 30.5 3.5 102.6 32.6 3.1 96.3 35.5 2.7 89.7 38.7 2.3

2.7 120.3 28.9 4.2 114.1 31.1 3.7 108.8 33.2 3.3 102.1 36.1 2.8 95.2 39.3 2.4

2.7 90.5 28.5 3.2 85.8 31.4 2.7 81.9 34.1 2.4 77.1 37.5 2.1 72.0 41.2 1.7

2.7 100.2 29.4 3.4 95.2 32.3 2.9 90.8 34.9 2.6 85.5 38.4 2.2 79.9 42.2 1.9

2.7 110.6 30.2 3.7 105.1 33.2 3.2 100.3 35.9 2.8 94.3 39.5 2.4 88.2 43.3 2.0

2.7 121.5 31.2 3.9 115.5 34.2 3.4

2.7 133.1 32.3 4.1 126.4 35.2 3.6 120.8 38.1 3.2 113.6 41.7 2.7 106.2 45.7 2.3

2.7 141.0 33.1 4.3 134.0 36.1 3.7 128.0 38.8 3.3 120.4 42.5 2.8 112.6 46.6 2.4

2.7 112.4 38.9 2.9 106.7 42.5 2.5 101.4 45.8 2.2 94.5 50.0 1.9 86.9 54.3 1.6

2.7 124.4 40.1 3.1 117.9 43.8 2.7 112.2 47.1 2.4 104.8 51.4 2.0 96.6 55.9 1.7

2.7 137.0 41.5 3.3 129.9 45.3 2.9 123.6 48.7 2.5 115.5 53.1 2.2 106.7 57.7 1.8

2.7 150.4 42.9 3.5 142.5 46.8 3.0

2.7 164.4 44.6 3.7 155.7 48.5 3.2 148.1 52.0 2.8 138.5 56.5 2.4 128.4 61.3 2.1

2.7 174.0 45.7 3.8 164.8 49.6 3.3 156.7 53.1 2.9 146.6 57.7 2.5 135.9 62.7 2.2

Ambient Air Temperature (F)

24C 30C 35C 41C 47C

PWR

Unit

Unit

PWR

Unit

Unit

PWR

Unit

Unit

PWR

Unit

Unit

kWi

COP

kW

kWi

COP

kW

31.0 9.4 3.1

42.5 13.0 3.1

56.3 18.7 2.9

63.8 20.4 3.0

85.6 27.3 3.0

93.6 31.7 2.8

110.3 36.9 2.8

135.6 50.2 2.6

kWi

COP

kW

kWi

COP

29.2 10.2 2.9 27.4 11.1 2.5

40.1 14.2 2.8 37.4 15.6 2.4

53.2 20.5 2.6 49.7 22.5 2.2

59.9 22.2 2.7 55.9 24.4 2.3

80.4 29.9 2.7 75.0 32.7 2.3

87.8 34.5 2.5 81.7 37.7 2.2

103.8 40.5 2.6 97.0 44.5 2.2

126.8 54.7 2.3 117.4 59.5 2.0

kW

PWR

kWi

Unit

COP

Catalog 616

13

Page 14

ACZ Part Load Data

Table 4, IP Units, 60Hz

R-407C Part Load Data

Suct

ACZ

Unit

% Load

Size

100 95.0 45.0 105.8 9.7 10.9

010B

013B

016B

020B

025B

028B

033B

039B

NOTES:

1. Certified according to ARI Standard 365-2002.

2. The 100 percent load, 95F, performance data is for information only and is not a factor in calculating a condensing unit IPLV

100 80.0 50.0 123.7 9.0 13.8

100 95.0 45.0 145.0 13.4 10.8

100 80.0 50.0 169.8 12.5 13.6

100 95.0 45.0 192.1 19.3 10.0

100 80.0 50.0 223.3 17.7 12.6

100 95.0 45.0 217.6 21.0 10.4

100 80.0 50.0 252.8 19.4 13.0

100 95.0 45.0 292.0 28.2 10.4

100 80.0 50.0 340.5 26.4 12.9

100 95.0 45.0 319.5 32.6 9.8

100 80.0 50.0 371.9 30.5 12.2

100 95.0 45.0 376.3 38.1 9.9

100 80.0 50.0 436.2 35.2 12.4

100 95.0 45.0 462.6 51.8 8.9

100 80.0 50.0 537.7 48.4 11.1

Outdoor

Air

Temp

53 80.0 50.0 63 4.2 12.5

53 80.0 50.0 87 6.5 13.3

53 80.0 50.0 116 8.6 13.4

53 80.0 50.0 132 9.5 13.9

53 80.0 50.0 177 12.6 14.0

53 80.0 50.0 197 14.7 13.4

53 80.0 50.0 231 16.7 13.8

53 80.0 50.0 285 21.9 13.0

Dew

Point

Temp

(F)

Cap.

Mbh

Power

kWi

EER IPLV

13.0

13.4

13.0

13.5

13.6

13.0

13.2

12.2

.

14 Catalog 616

Page 15

AGZ Chiller Selection Procedure

F

Packaged Chiller, Model BS

Selection with Inch-Pound (I-P) units

Table 13 and Table 14 cover the range of leaving evaporator water temperatures and outside ambient

temperatures included under ARI Standard 550/590-2003. The tables are based on a 10 degree F (5.5 degree

C) temperature drop through the evaporator. Adjustment factors for applications having other than a 10 degree

5 degree C) drop can be found in Table 7. The minimum leaving chilled water temperature

F (5.

setpoint without glycol is 40°F (4C). For brine selections, see Table 5 through Table 6 for glycol

adjustment factors. Ratings are based on a 0.0001 ft2 x hr x F/Btu fouling factor in the evaporator at sea level

operation. For other fouling factors, different Delta-Ts, or altitude correction factors see Table 7. For

applications outside the catalog ratings contact your local Daikin sales representative.

Selection example

20 tons minimum requirement

95°F ambient temperature

48 gpm, 54F to 44°F chilled water

0.0001 evaporator fouling factor

1. From Table 13, an AGZ 020B at the given conditions will produce 21.5 tons with a unit kW

and a unit EER of 8.9.

2. Use the following formula to calculate any unknown elements.

tons

24

(water only)

gpm =

input of 29.0

3. Determine the evaporator pressure drop. Using Figure 7 on page, enter at 48 gpm and follow up to the

AGZ 020B line intersect. Read horizontally to obtain an evaporator pressure drop of 5.9 feet of water.

ote the allowable minimum and maximum flows.

N

Selection example using ethylene glycol

20 tons minimum requirement

95°F ambient air temperature

54°F - 44°F chilled water temperature

0.0001 evaporator fouling factor

Protect from freezing down to 0°F

1. From Table 5, select an ethylene glycol concentration of 40% to protect against freezing at 0°F.

2. At 40%

GPM = 1.132, pressure drop = 1.557

3. Select the AGZ 020B from Table 13 and correct with 40% ethylene glycol factors.

4. Correct capacity

5. Correct comp

6. Calculate chilled water flow:

Gly

ethylene gly

ressor kW = 0.992 X 29.0 kW = 28.8 kW

col flow (at 40% solution) = 1.132 X 48.0 gpm = 54.3 gpm

col, the adjustment factors are: Capacity =0.980, kW = 0.992,

= 0.980 X 21.5 tons = 21.1 tons

= capacity) corrected(at flowWater

tons

24×0.20

gpm 48 =

°10

F

Determine the evaporator pressure drop. Using Figure 7, enter at 20 gpm (water) and follow up to the AGZ

020B line intersect.

pressure drop for 40% solution = 1.557 x 5.9 feet = 9.2 feet for ethylene glycol.

Catalog 616

Read horizontally to obtain an evaporator pressure drop of 5.9 feet. Correct the

15

Page 16

Selection example, SI Units

The selection procedure for Metric units is identical to English except that metric data and tables are used.

Remote Evaporator, Model BM

Inch-Pound (I-P) Units

Since the AGZ-BM units always include a specific remote evaporator, packaged chiller ratings are used.

The ratings are based on leaving chilled water temperature and ambient air temperature with correction for

the effect of the interconnecting refrigerant piping.

Table 13 and Table 14 cover the range of leaving evaporator water temperatures and outside

ambient temperatures included under ARI 550/590-2003. The tables are based on a 10-degree F (5.5degree C) temperature drop through the evaporator. Adjustment factors for applications having other than

a 10-degree F (5.5-degree C) drop can be found in Table 7. The minimum leaving chilled water

temperature setpoint without glycol is 40°F (4C). For brine selections, see Table 5 or Table 6 for

glycol adjustment factors. Ratings are based on a 0.0001 ft2 x hr x F/Btu fouling factor in the evaporator

at sea level operation. For other fouling factors, different Delta-Ts, or altitude correction factors see Table

7. For applications outside the catalog ratings, contact your local Daikin sales representative.

The length and configuration of the field installed interconnecting refrigerant piping will affect the system

capacity. Derates based on equivalent length of line are given in Table 12.

The steps for selecting an AGZ-BM are as follows:

1. Add 3% to the required cooling capacity (to approximate the effect of the correction factors to be

determined) and make a preliminary unit selection from Table 13 and Table 14.

2. Divide the required capacity

Table 6, altitude, chilled water Delta T, or fouling factor from Table 7, and refrigerant piping derate

from Table 12 as explained in step 3 below.

3. Determ

summing the equivalent feet (from table 10) of

all the fittings (use a sketch of the piping

layout) and adding the sum of these fitting

losses to the actual linear feet of tubing. This

will equal the total equivalent feet. (To use the

equivalent feet table 10, start with the unit

suction connection size from table 13 and

correct if required.)

4. If the unit rated capacity in the tables is less

than the corrected required capacity, redo the

selection with the next larger unit. In most

cases the line size will be the unit connection

size. If the selection is satisfactory, correct the

power (if applicable) and determine water

pressure drop. Selection example

English Units

ine the suction line size by first

Given: 20 tons required capacity

95°F ambient temperature

Cool 48 gpm from 54F to 44°F

0.0001 evaporator fouling factor

2,000 foot altitude

by the appropriate capacity correction factors: glycols from Table 5 or

Figure 6, Sample Piping Layout

B

16 Catalog 616

Page 17

1. Add 3% to the required capacity for approximate derate: 20 x 1.03 = 20.6 tons. From Table 13 an AGZ020B at the given conditions will produce 21.5 tons with a unit kW

input of 29.0 and a unit EER of 8.9.

2. Determine derate factors:

Altitude correction from Ta

ble 7:

0.998 Capacity, 1.009 Power

3. Piping correction:

Assume 1 5/8” suction line based on line size in Tab le 11.

90 S

(3)

Plus actual linear feet 70 ft

tandard ells 3 x 4 ft =12 ft

Total Equivalent Feet 82 ft

This puts it between 1 5/8” and 2 1/8” line size.

Check Table 9 and find that 1 5/8” is maximum size for oil carry.

This m

eans that the 1 5/8 riser will be satisfactory

, but with a slightly higher pressure drop.

The capacity correction factor from Table 12 is between 0.97 and 0.98. Use 0.975.

of the

4. The corrected capacity

the 20 ton requirem

ent.

AGZ is: 21.5 tons x 0.998{altitude} x 0.98{piping} = 21.0 tons

5. Correct the unit power required: 29.0 kW x 1.009{altitude} = 29.3 kW

.

This satisfies

6. Calculate the unit EER based on the correct capacity and power:

EER = (21 tons x 12,000)/ (29.3 kW x 1,000) = 8.6

7. Determine the evaporator pressure drop. Enter the pressure drop curves, (Figure 7) at 48 gpm

and read up to

AGZ 020, read over to pressure drop of 5.9 ft.

Selection example, SI Units

The selection procedure for Metric units is identical to English except that metric data and tables are used.

Catalog 616

17

Page 18

Application Adjustment Factors

Ethylene and Propylene Glycol Factors

AGZ units can operate with a leaving chilled fluid temperature range of 20°F (-6°C) to 60°F (10°C). A

glycol solution is required when leaving chilled fluid temperature is below 40°F (4.6°C). The use of glycol

will reduce the performance of the unit depending on concentration.

Altitude Correction Factors

Performance tables are based at sea level. Elevations other than sea level affect the performance of the unit.

The decreased air density will reduce condenser capacity consequently reducing the unit's performance. For

performance at elevations other than sea level refer to Table 7.

Evaporator Temperature Drop Factors

Performance tables are based on a 10°F (5°C) temperature drop through the evaporator. Adjustment factors

for applications with temperature ranges from 6°F to 16°F (3.3°C to 8.9°C) are in Table 3. Temperature

drops outside this 6°F to 16°F (3.3°C to 8.9°C) range can affect the control system's capability to maintain

acceptable control and are not recommended.

The maximum water temperature that can be circulated through the evaporator in a non-operating mode is

100°F (37.8°C).

Table 5, Ethylene Glycol Factors

% E.G.

10

20

30

40

50

Freeze Point

°F °C

26 -3.3 0.998 0.998 1.036 1.097

18 -7.8 0.993 0.997 1.060 1.226

7 -13.9 0.987 0.995 1.092 1.369

-7 -21.7 0.980 0.992 1.132 1.557

-28 -33.3 0.973 0.991 1.182 1.791

Capacity Power Flow PD

T

able 6, Propylene Glycol Factors

% P.G.

10

20

30

40

50

NOTE: Ethylene and propylene glycol ratings are outside the scope of ARI Standard 550/590-2003 certification program.

18 Catalog 616

Freeze Point

°F °C

26 -3.3 0.995 0.997 1.016 1.100

19 -7.2 0.987 0.995 1.032 1.211

9 -12.8 0.978 0.992 1.057 1.380

-5 -20.6 0.964 0.987 1.092 1.703

-27 -32.8 0.952 0.983 1.140 2.251

Capacity Power Flow PD

Page 19

Fouling Factor

Performance tables are based on water with a fouling factor of

As fouling is increased, performance decreases. For performance at other than 0.0001 (0.0176) fouling factor

refer to Table 7. Foreign matter in the chilled water system will adversely af

the evaporator and could increase the pressure drop and reduce the water flow. Maintain proper water

treatment to provide optimum unit operation.

Table 7, Capacity and Power Derates

Chilled Water

Altitude

Sea

Level

2000 feet

4000 feet

6000 feet

Delta T

°F °C Cap. Power Cap. Power Cap. Power Cap. Power

6 3.3 0.978 0.993 0.975 0.991 0.963 0.987 0.940 0.980

8 4.4 0.989 0.996 0.986 0.994 0.973 0.990 0.950 0.983

10 5.6 1.000 1.000 0.996 0.999 0.984 0.994 0.961 0.987

12 6.7 1.009 1.003 1.005 1.001 0.993 0.997 0.969 0.990

14 7.7 1.018 1.004 1.014 1.003 1.002 0.999 0.978 0.991

16 8.9 1.025 1.007 1.021 1.006 1.009 1.001 0.985 0.994

6 3.3 0.977 1.001 0.973 1.000 0.961 0.996 0.938 0.989

8 4.4 0.987 1.006 0.984 1.004 0.971 1.000 0.948 0.993

10 5.6 0.998 1.009 0.995 1.007 0.982 1.003 0.959 0.996

12 6.7 1.007 1.011 1.004 1.010 0.991 1.006 0.967 0.998

14 7.7 1.014 1.014 1.011 1.013 0.998 1.009 0.974 1.001

16 8.9 1.022 1.016 1.018 1.014 1.005 1.010 0.981 1.003

6 3.3 0.973 1.011 0.970 1.010 0.957 1.006 0.935 0.998

8 4.4 0.984 1.014 0.980 1.013 0.968 1.009 0.945 1.001

10 5.6 0.995 1.019 0.991 1.017 0.979 1.013 0.955 1.005

12 6.7 1.004 1.021 1.000 1.020 0.987 1.016 0.964 1.008

14 7.7 1.011 1.024 1.007 1.023 0.994 1.018 0.971 1.011

16 8.9 1.018 1.027 1.014 1.026 1.002 1.021 0.978 1.014

6 3.3 0.969 1.021 0.966 1.020 0.954 1.016 0.931 1.008

8 4.4 0.980 1.026 0.977 1.024 0.964 1.020 0.942 1.013

10 5.6 0.989 1.029 0.986 1.027 0.973 1.023 0.950 1.015

12 6.7 0.998 1.033 0.995 1.031 0.982 1.027 0.959 1.020

14 7.7 1.007 1.036 1.004 1.034 0.991 1.030 0.967 1.022

16 8.9 1.014 1.037 1.011 1.036 0.998 1.031 0.974 1.024

0.0001 (0.0176) 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

22

per ARI 550/590-2003.

)/0176.0(/0001.0

kWCmorBTUFhrft

fect the heat transfer capability of

Fouling Factor

Table 8, Equivalent Feet for Fittings

Fitting Type 7/8 1 1/8 1 3/8 1 5/8 2 1/8 2 5/8 3 1/8

Elbows

90 Standard

90 Long Radius

90 Street

45 Standard

45 Street

180 Bend

Tees

Full Size

Reducing

Valves

Globe Valve, Open

Gate Valve, Open

Angle Valve, Open

Catalog 616

2.0 2.6 3.3 4.0 5.0 6.0 7.5

1.4 1.7 2.3 2.6 3.3 4.1 5.0

3.2 4.1 5.6 6.3 8.2 10 12

0.9 1.3 1.7 2.1 2.6 3.2 4.0

1.5 2.1 3.0 3.4 4.5 5.2 6.4

3.2 4.1 5.6 6.3 8.2 10 12

1.4 1.7 2.3 2.6 3.3 4.1 5.0

2.0 2.6 3.3 4.0 5.0 6.0 7.5

22 29 38 43 55 69 84

0.9 1.0 1.5 1.8 2.3 2.8 3.2

9.0 12 15 18 24 29 35

19

Page 20

Table 9, Maximum Line Size (R-407C) For Oil Carry Up a Suction Riser

Unit Size

Line Size 1 1/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8

AGZ

010

AGZ

013

AGZ

017

AGZ

020

AGZ

025

AGZ

029

AGZ

034

Table 10, Recommended Liquid Line Size, R-407C

AGZ-BM

Unit Model

AGZ 01

AGZ 013

AGZ 016

AGZ 020

AGZ 025

AGZ 029

AGZ 034

Connection

Size

At Unit

7/8" 7/8 " 7/8 " 7/8 " 7/8 " 7/8 "

7/8" 7/8 " 7/8 " 7/8 " 7/8 " 7/8 "

7/8" 7/8 " 7/8 " 7/8 " 7/8 " 7/8 "

7/8" 7/8 " 7/8 " 7/8 " 7/8 "

7/8" 7/8 " 7/8 " 7/8 "

7/8" 7/8 " 7/8 "

7/8" 7/8 "

Up to Up to Up to Up to Up to

50 Equiv. Ft 75 Equiv. Ft 100 Equiv. Ft 125 Equiv. Ft 150 Equiv. Ft

Recommended Liquid Line Size

1 1/8 " 1 1/8 "

1 1/8 " 1 1/8 " 1 1/8 "

1 1/8 " 1 1/8 " 1 1/8 " 1 1/8 "

Table 11, Recommended Suction Line Size, R-407C

Unit Model

AGZ 010AM

AGZ 013AM

AGZ 016AM

AGZ 020AM

AGZ 025AM

AGZ 029AM

AGZ 034AM

Note: For horizontal and vertical downflow only.

Connection

Size

At Unit

1 1/8”

1 1/8” 1 3/8"

1 5/8"

1 5/8"

1 5/8"

2 1/8" 2 1/8" 2 1/8" 2 1/8" 2 1/8"

2 1/8" 2 1/8" 2 1/8"

Up to Up to Up to Up to Up to

50 Equiv. Ft 75 Equiv. Ft 100 Equiv. Ft 125 Equiv. Ft 150 Equiv. Ft

1 1/8”

1 5/8" 1 5/8" 1 5/8"

1 5/8" 1 5/8"

1 5/8"

Recommended Suction Line Sizes

1 3/8" 1 3/8"

1 5/8" 1 5/8" 1 5/8" 1 5/8"

2 1/8" 2 1/8" 2 1/8"

2 1/8" 2 1/8" 2 1/8" 2 1/8"

2 5/8" 2 5/8" 2 5/8"

1 5/8" 1 5/8"

2 1/8" 2 1/8"

1 1/8 "

2 5/8"

Table 12, Refrigerant Piping Derates

Unit Capacity Loss Factor Due to Refrigerant Piping

Model At Unit 50 Equiv. Ft 75 Equiv. Ft 100 Equiv. Ft 125 Equiv. Ft 150 Equiv. Ft

AGZ 010AM

AGZ 013AM

AGZ 016AM

AGZ 020AM

AGZ 025AM

AGZ 029AM

AGZ 034AM

1.0 0.98 0.98 0.97

1.0 0.98

1.0

1.0

1.0

1.0 0.99 0.98 0.97 0.96

1.0 0.99 0.98

0.99 0.98 0.98

0.98 0.97

0.98

0.98 0.98 0.97 0.96

0.98 0.98 0.97

0.99 0.99 0.98 0.97

0.98 0.97 0.97

0.98 0.97

0.99 0.98

0.98

20 Catalog 616

Page 21

AGZ Chiller Performance Data

Table 13, Performance Data, R-407C, IP Units, 60 Hz

AGZ

Unit

Size

010 2.3

013 2.3

017 2.3

020 3.2

025 3.2

029 3.2

034 3.2

NOTES:

1. Ratings based on R-407C, evaporator fouling factor of 0.0001, evaporator water flow of 2.4 gpm/ton and sea level altitude.

2. KW input is for the entire unit including compressors, fan motors and control power.

3. Interpolation is allowed; extrapolation is not permitted. Consult the local Daikin sales office for performance outside the

4. For LWT below 40°F please refer to Application Considerations.

5. Use anti-freeze below 42.0F.

Fan &

Control

Power

(kW)

cataloged ratings.

LWT

(F)

Tons

42 10.2 10.8 11.4 9.8 11.7 10.1 9.4 12.8 8.8 9.0 14.1 7.7 8.5 15.4 6.6

44 10.7 10.9 11.8 10.2 11.8 10.4

46 11.1 11.0 12.2 10.7 11.9 10.8 10.2 13.0 9.4 9.7 14.3 8.2 9.3 15.7 7.1

48 11.5 11.1 12.5 11.1 12.0 11.1 10.6 13.1 9.7 10.1 14.4 8.4 9.6 15.8 7.3

50 12.0 11.1 13.0 11.5 12.1 11.4 11.0 13.2 10.0 10.5 14.5 8.7 10.0 15.9 7.5

42 14.0 14.7 11.5 13.5 16.0 10.1 12.9 17.5 8.9 12.3 19.2 7.7 11.7 21.0 6.7

44 14.6 14.9 11.8 14.0 16.2 10.4

46 15.2 14.9 12.2 14.5 16.3 10.7 13.9 17.8 9.4 13.3 19.5 8.2 12.6 21.4 7.1

48 15.7 15.1 12.4 15.2 16.5 11.0 14.4 18.0 9.6 13.7 19.8 8.3 13.1 21.6 7.3

50 16.3 15.2 12.8 15.7 16.6 11.3 15.0 18.1 9.9 14.2 19.9 8.6 13.5 21.7 7.5

42 16.2 17.0 11.4 15.6 18.5 10.1 14.9 20.2 8.8 14.2 22.1 7.7 13.5 24.3 6.7

44 16.9 17.1 11.8 16.2 18.7 10.4

46 17.4 17.2 12.1 16.7 18.7 10.7 16.0 20.5 9.3 15.3 22.5 8.1 14.5 24.6 7.1

48 18.0 17.4 12.4 17.4 18.9 11.0 16.6 20.7 9.6 15.8 22.7 8.3 15.0 24.9 7.2

50 18.6 17.0 13.1 17.9 18.5 11.6 17.2 20.2 10.2 16.4 22.1 8.9 15.6 24.3 7.7

42 21.2 22.2 11.5 20.4 24.2 10.1 19.5 26.4 8.9 18.6 28.9 7.7 17.7 31.7 6.7

44 22.0 22.4 11.8 21.1 24.4 10.4

46 22.7 22.5 12.1 21.9 24.5 10.7 20.9 26.8 9.3 19.9 29.4 8.1 18.9 32.2 7.0

48 23.6 22.8 12.4 22.7 24.8 11.0 21.7 27.1 9.6 20.7 29.7 8.4 19.7 32.6 7.2

50 24.4 23.1 12.7 23.4 25.1 11.2 22.4 27.5 9.8 21.4 30.1 8.5 20.3 33.0 7.4

42 23.3 24.4 11.5 22.4 26.5 10.2 21.5 29.0 8.9 20.5 31.7 7.7 19.5 34.9 6.7

44 24.2 24.6 11.8 23.2 26.8 10.4

46 25.1 25.0 12.1 24.1 27.1 10.7 23.0 29.6 9.3 21.9 32.5 8.1 20.9 35.6 7.0

48 25.9 25.2 12.4 24.9 27.5 10.9 23.8 30.0 9.5 22.7 32.8 8.3 21.6 36.0 7.2

50 27.0 25.5 12.7 26.0 27.7 11.3 24.8 30.3 9.8 23.6 33.2 8.5 22.4 36.3 7.4

42 28.5 29.9 11.5 27.4 32.4 10.1 26.2 35.5 8.9 25.0 38.7 7.8 23.8 42.6 6.7

44 29.6 30.1 11.8 28.4 32.8 10.4

46 30.7 30.5 12.1 29.4 33.2 10.6 28.1 36.2 9.3 26.9 39.6 8.1 25.5 43.5 7.0

48 31.6 30.7 12.4 30.5 33.5 10.9 29.1 36.6 9.5 27.8 40.0 8.3 26.4 44.0 7.2

50 32.7 31.1 12.6 31.4 33.8 11.2 30.1 37.0 9.8 28.7 40.5 8.5 27.3 44.4 7.4

42 35.1 37.4 11.3 33.7 40.6 10.0 32.2 44.4 8.7 30.7 48.6 7.6 29.2 53.4 6.6

44 36.3 37.7 11.5 34.9 41.1 10.2

46 37.5 38.2 11.8 36.0 41.5 10.4 34.4 45.4 9.1 32.8 49.7 7.9 31.1 54.6 6.9

48 38.8 38.5 12.1 37.3 42.0 10.6 35.6 45.9 9.3 33.9 50.2 8.1 32.2 55.2 7.0

50 40.1 39.0 12.4 38.6 42.3 10.9 36.9 46.4 9.5 35.2 50.8 8.3 33.4 55.7 7.2

75 85 95 105 115

Unit

PWR

Unit

Unit

kWi

EER

Tons

Ambient Air Temperature (F)

PWR

Unit

Unit

PWR

kWi

EER

Tons

kWi

9.8 12.9 9.1

13.4 17.7 9.1

15.5 20.4 9.1

20.2 26.6 9.1

22.2 29.3 9.1

27.2 35.8 9.1

33.3 44.9 8.9

Unit

Unit

PWR

Unit

Unit

EER

Tons

kWi

EER

Tons

9.4 14.2 8.0 8.9 15.5 6.9

12.8 19.4 7.9 12.2 21.2 6.9

14.8 22.3 8.0 14.0 24.5 6.9

19.3 29.2 7.9 18.3 32.0 6.9

21.3 32.2 7.9 20.2 35.2 6.9

25.9 39.2 7.9 24.7 43.0 6.9

31.7 49.2 7.7 30.2 53.9 6.7

PWR

kWi

Unit

EER

Catalog 616

21

Page 22

SI Units

Table 14, Performance Data, R-407C, SI Units, 60 Hz

Fan &

AGZ

Control

Unit

Power

Size

(kW)

010 2.3

013 2.3

017 2.3

020 3.2

025 3.2

029 3.2

034 3.2

NOTES:

1. Ratings based on R-407C, evaporator fouling factor of 0.0176, 5.6C evaporator delta-T, and sea level altitude.

2. KW input is for the entire unit including compressors, fan motors and control power.

Interpolation is allowed; extrapolation is not permitted. Consult the loc

3.

cataloged ratings.

4. For LWT below 5.0°C please refer to Application Considerations.

LWT

(C)

6.0 35.9 10.8 3.3 34.7 11.7 3.0 33.2 12.8 2.6 31.9 14.1 2.3 30.6 15.4 2.0

7.0 37.3 10.9 3.4 35.9 11.8 3.0

8.0 38.7 11.0 3.5 37.4 11.9 3.1 35.8 13.0 2.7 34.4 14.3 2.4 32.9 15.7 2.1

9.0 40.0 11.1 3.6 38.7 12.0 3.2 37.2 13.1 2.8 35.6 14.4 2.5 34.0 15.8 2.1

10.0 41.5 11.1 3.7 40.1 12.1 3.3 38.4 13.2 2.9 36.8 14.5 2.5 35.3 15.9 2.2

6.0 49.2 14.7 3.3 47.5 16.0 3.0 45.6 17.5 2.6 43.8 19.2 2.3 41.9 21.0 2.0

7.0 50.9 14.9 3.4 49.1 16.2 3.0

8.0 52.8 14.9 3.5 50.9 16.3 3.1 48.8 17.8 2.7 46.8 19.5 2.4 44.8 21.4 2.1

9.0 54.4 15.1 3.6 52.6 16.5 3.2 50.5 18.0 2.8 48.3 19.8 2.4 46.2 21.6 2.1

10.0 56.2 15.2 3.7 54.3 16.6 3.3 52.1 18.1 2.9 49.9 19.9 2.5 47.7 21.7 2.2

6.0 56.7 17.0 3.3 54.8 18.5 3.0 52.5 20.2 2.6 50.5 22.1 2.3 48.3 24.3 2.0

7.0 58.8 17.1 3.4 56.6 18.7 3.0

8.0 60.4 17.2 3.5 58.4 18.7 3.1 55.9 20.5 2.7 53.7 22.5 2.4 51.4 24.6 2.1

9.0 62.3 17.4 3.6 60.3 18.9 3.2 58.0 20.7 2.8 55.4 22.7 2.4 53.0 24.9 2.1

10.0 64.4 17.0 3.8 62.3 18.5 3.4 59.7 20.2 3.0 57.3 22.1 2.6 54.8 24.3 2.3

6.0 74.4 22.2 3.4 71.8 24.2 3.0 68.8 26.4 2.6 66.0 28.9 2.3 63.3 31.7 2.0

7.0 76.6 22.4 3.4 73.9 24.4 3.0

8.0 79.1 22.5 3.5 76.3 24.5 3.1 73.3 26.8 2.7 70.3 29.4 2.4 67.2 32.2 2.1

9.0 81.6 22.8 3.6 79.0 24.8 3.2 76.0 27.1 2.8 72.7 29.7 2.4 69.4 32.6 2.1

10.0 84.2 23.0 3.7 81.3 25.1 3.2 78.0 27.5 2.8 74.8 30.1 2.5 71.6 33.0 2.2

6.0 81.8 24.4 3.3 78.9 26.5 3.0 75.7 29.0 2.6 72.8 31.7 2.3 69.6 34.9 2.0

7.0 84.4 24.6 3.4 81.4 26.8 3.0

8.0 87.2 25.0 3.5 84.2 27.1 3.1 80.8 29.6 2.7 77.6 32.5 2.4 74.1 35.6 2.1

9.0 89.7 25.2 3.6 86.8 27.5 3.2 83.4 30.0 2.8 79.8 32.8 2.4 76.3 36.0 2.1

10.0 93.3 25.5 3.7 90.1 27.7 3.3 86.5 30.3 2.9 82.8 33.2 2.5 79.3 36.3 2.2

6.0 99.9 29.8 3.4 96.5 32.6 3.0 92.5 35.5 2.6 88.9 38.9 2.3 85.0 42.7 2.0

7.0 103.2 30.1 3.4 99.4 32.8 3.0

8.0 106.6 30.4 3.5 102.9 33.2 3.1 98.7 36.2 2.7 94.7 39.7 2.4 90.7 43.5 2.1

9.0 109.6 30.8 3.6 106.1 33.6 3.2 102.0 36.7 2.8 97.6 40.1 2.4 93.2 44.0 2.1

10.0 113.1 31.0 3.6 109.3 33.8 3.2 104.8 37.0 2.8 100.5 40.4 2.5 96.2 44.4 2.2

6.0 122.9 37.9 3.2 118.6 41.3 2.9 113.8 45.1 2.5 109.3 49.4 2.2 104.6 54.2 1.9

7.0 126.5 37.7 3.4 121.9 41.1 3.0

8.0 130.2 38.7 3.4 125.7 42.2 3.0 120.6 46.1 2.6 115.7 50.5 2.3 110.7 55.4 2.0

9.0 133.9 39.2 3.4 129.6 42.6 3.0 124.6 46.6 2.7 119.1 51.0 2.3 113.9 56.0 2.0

10.0 138.6 39.6 3.5 133.9 43.1 3.1 128.4 47.1 2.7 123.2 51.6 2.4 117.9 56.6 2.1

25 30 35 40 45

Unit

PWR

Unit

Unit

PWR

kW

kWi

COP

kW

kWi

Ambient Air Temperature (C)

Unit

Unit

PWR

Unit

COP

kW

kWi

COP

34.5 12.9 2.7

47.2 17.7 2.7

54.5 20.4 2.7

71.0 26.6 2.7

78.2 29.3 2.7

95.6 35.8 2.7

117.2 44.9 2.6

al Daikin sales office for performance outside the

Unit

PWR

Unit

kW

kWi

COP

33.2 14.2 2.3 31.7 15.5 2.0

45.4 19.4 2.3 43.4 21.2 2.0

52.3 22.3 2.3 50.0 24.5 2.0

68.3 29.2 2.3 65.3 32.0 2.0

75.2 32.2 2.3 71.9 35.2 2.0

91.9 39.2 2.3 87.9 43.0 2.0

112.6 49.2 2.3 107.6 53.9 2.0

Unit

kW

PWR

kWi

Unit

COP

22 Catalog 616

Page 23

AGZ Part Load Data

Table 15, R-22 and R-407C, IP Units, 60Hz

R-407C

AGZ

Unit

Size

010

013

017

020

025

029

034

NOTE: Certified according to ARI Standard 550/590-2003.

% Load

100.0 9.8 12.9 9.1

75.0 7.4 7.4 11.9

50.0 4.9 4.2 14.0

25.0 2.5

100.0 13.4 17.7 9.1

75.0 10.1 10.1 12.0

50.0 6.7 5.7 14.1

25.0 3.4

100.0 15.5 20.4 9.1

75.0 11.6 11.5 12.1

50.0 7.7 6.5 14.3

25.0 3.9

100.0 20.2 26.6 9.1

75.0 15.1 14.5 12.5

50.0 10.1 8.1 15.0

25.0 5.0

100.0 22.2 29.3 9.1

75.0 16.7 16.0 12.5

50.0 11.1 8.9 15.0

25.0 5.6

100.0 27.2 35.8 9.1

75.0 20.4 19.7 12.4

50.0 13.6 11.2 14.5

25.0 6.8

100.0 33.3 44.9 8.9

75.0 25.0 24.6 12.2

50.0 16.7 13.9 14.4

25.0 8.3

Capacity

Tons

Power

kWi

2.0

2.7

3.0

3.8

4.2

5.3

6.6

EER IPLV

13.2

15.0

13.3

15.1

13.4

15.3

14.0

16.0

14.0

16.0

13.7

15.5

13.5

15.2

Catalog 616

23

Page 24

A

A

A

A

Pressure Drop Curves

Figure 7, AGZ 010B – 034B, Evaporator Pressure Drops

AGZ 010

GZ 020

GZ 025

GZ 029

GZ 034

AGZ 017

AGZ 013

AGZ Unit

Model

AGZ 010B

AGZ 013B

AGZ 017B

AGZ 020B

AGZ 025B

AGZ 029B

AGZ 034B

Inch-Pound S.I. Inch-Pound S.I. Inch-Pound S.I.

gpm DP ft. lps DP kpa gpm DP ft. lps DP kpa gpm DP ft. lps DP kpa

15 2.3 0.9 6.9 24 5.7 1.5 17.0 39 14.8 2.5 44.1

20 1.6 1.3 4.8 32 4.0 2.0 11.9 53 10.5 3.3 31.3

24 1.7 1.5 5.1 38 4.3 2.4 12.8 64 11.2 4.0 33.4

31 2.6 1.9 7.7 49 6.2 3.1 18.5 82 16.3 5.2 48.6

34 2.0 2.2 6.0 55 4.8 3.5 14.3 91 12.7 5.7 37.8

43 2.2 2.7 6.6 68 5.3 4.3 15.8 113 14.1 7.1 42.0

51 2.2 3.2 6.6 82 5.3 5.2 15.8 136 14.2 8.6 42.3

Minimum Nominal Maximum

24 Catalog 616

Page 25

Sound Data

AGZ/ACZ Units

Table 16, Sound Pressure, w/o Sound Insulation

Model

-- 010B

010B 013B

013B 016B

017B 020B

020B 025B

025B 028B

029B 033B

034B 039B

Note: Data at:

1. 30 feet (9m) from side of unit.

2. Q=2, unit on a flat roof or ground with no adjacent wall.

3. Octave band readings are flat dB, overall is “A” weighted.

ACZ Unit

Model

63 125 250 500 1000 2000 4000 8000

52 52 52 54 48 46 44 42 55

52 52 52 54 48 46 44 42 55

53 54 54 55 48 47 45 42 56

58 56 55 53 52 50 48 48 57

58 57 56 54 52 50 48 48 58

58 58 56 55 52 50 48 48 58

59 59 61 58 54 53 51 50 61

61 62 63 59 55 54 53 51 63

Table 17, Sound Power, w/o Sound Insulation

Model

-- 010B

010B 013B

013B 016B

017B 020B

020B 025B

025B 028B

029B 033B

034B 039B

Note: Octave band readings are flat dB, overall is “A” weighted.

ACZ Unit

Model

Octave Band at Center Frequency (per ARI Standard 370) AGZ Unit

63 125 250 500 1000 2000 4000 8000

79 79 79 81 75 73 71 69 82

79 79 79 81 75 73 71 69 82

80 81 81 82 75 74 72 69 83

85 83 82 80 79 77 75 75 84

85 84 83 81 79 77 75 75 85

85 85 83 82 79 77 75 75 85

86 86 88 85 81 80 78 77 88

88 89 90 86 82 81 80 78 90

Octave Band at Center Frequency AGZ Unit

Overall

A-Weighted

Overall

A-Weighted

Table 18, Sound Pressure w/ Sound Insulation

Model

-- 010B

010B 013B

013B 016B

017B 020B

020B 025B

025B 028B

029B 033B

034B 039B

Notes: Data at:

1. 30 feet (9m) from side of unit.

2. Q=2, unit on a flat roof or ground with no adjacent wall.

3. Octave band readings are flat dB, overall is “A” weighted.

ACZ Unit

Model

63 125 250 500 1000 2000 4000 8000 A-Weighted

n/a n/a n/a n/a n/a n/a n/a n/a n/a

n/a n/a n/a n/a n/a n/a n/a n/a n/a

52 53 51 53 47 45 43 41 54

52 53 53 54 47 45 44 42 55

53 54 54 55 48 46 45 43 56

54 54 54 55 48 46 45 43 56

54 54 55 56 49 47 46 43 57

55 55 56 57 50 48 47 43 58

Octave Band at Center Frequency Overall AGZ Unit

Table 19, Sound Power w/ Sound insulation

Model

-- 010B

010B 013B

013B 016B

017B 020B

020B 025B

025B 028B

029B 033B

034B 039B

Note: Octave band readings are flat dB, overall is “A” weighted.

ACZ Unit

Model

Octave Band at Center Frequency (per ARI Standard 370) Overall AGZ Unit

63 125 250 500 1000 2000 4000 8000 A-Weighted

n/a n/a n/a n/a n/a n/a n/a n/a n/a

n/a n/a n/a n/a n/a n/a n/a n/a n/a

79 80 78 80 74 72 70 68 81

79 80 80 81 74 72 71 69 82

80 81 81 82 75 73 72 70 83

81 81 81 82 75 73 72 70 83

81 81 82 83 76 74 73 70 84

82 82 83 84 77 75 74 70 85

Catalog 616

25

Page 26

Quiet Operation

Sound levels can be as important as unit cost and efficiency, and must be addressed before the start of any

development program. Efforts by Daikin’s Design Engineers to design units that are sensitive to the sound

requirements of the market, combined with inherently quiet scroll compressors, have paid off.

Background Information

Sound is a vibration in an elastic medium and is essentially a pressure and particle displacement phenomena.

A vibrating body produces compression waves, and as the waves are emitted from the vibrating body,

molecules are ultimately compressed. These values are transmitted through gas, liquid, solidanything

which is elastic or viscous.

The sound data provided in this section is presented with both sound pressure and sound power levels. Sound

power is the total sound energy radiated by a source per unit of time integrated over the surface through

which the sound is radiated. Sound power is a calculated quantity and cannot be measured directly like sound

pressure. Sound power is not dependent on the surrounding environment or distance from the source, as is

sound pressure.

Sound pressure varies with the distance from the source and is dependent on its surroundings. For example, a

brick wall located 10 feet from a unit will affect the sound pressure measurements differently than a brick

wall at 20 feet. Sound pressure is measured in decibels (dB), which is a dimensionless ratio (on a logarithmic

scale) between measured sound pressure and a reference sound pressure level.

Sound Pressure Levels - Full Load

All sound pressure tables give the overall "A" weighted sound pressure levels which are considered typical of

what can be measured in a free field with a hand held sound meter, in the absence of any nearby reflective

surfaces. The sound pressure levels are measured at 30 feet (10 meters) from the side of the unit at 100% unit

load and ARI conditions. 95°F (35°C) ambient air temperature and 50F suction temperature.

Sound Power Levels

Acoustical consultants can require sound power octave band data to perform a detailed acoustical analysis.

The tables present sound power levels per ARI Standard 370, “Sound Rating of Large Outdoor Refrigerating

and Air Conditioning Equipment”. These standards were developed to establish uniform methods of

determining the sound power radiated by large outdoor and indoor equipment. The aforementioned methods

are based on providing sound power levels by octave band and the overall ‘A’ weighted value. Measurements

are taken over a prescribed area around the unit and the data is mathematically calculated to give the sound

power, dB. Sound power can be thought of as basic sound level emanating from the unit without

consideration of distance or obstructions.

Sound Reduction due to Distance from the Unit

The distance between a source of sound and the location of the sound measurement plays an important role in

minimizing sound problems. The equation below can be used to calculate the sound pressure level at any

distance if the sound power is known. Results for typical distances are tabulated in Table 19. Another way of

determ

dimensionless number that compensates for the type of sound reflection from the source. For example, a unit

sitting on a flat roof or ground with no other reflective surfaces or attenuation due to grass, snow, etc.,

between source and receiver: Q=2.

ining the effect of distance is to work from sound pressure only. “Q”, the directionality factor, is a

26 Catalog 616

Page 27

Figure 8, "Q" Definition, Plan View, Unit Located in Center

Uniform Spherical Radiation

Q=1 no reflecting surface

Sound pressure can be calculated at any

Uniform Hemispherical Radiation

Q=2 single reflecting surface

distance from the unit if the sound power is known.

Uniform Radiation over ¼ of sphere

Q=4 two reflecting surfaces

Lp=Lw-(20 log r) + (10 log Q) - .5

Lp = sound pressure r = distance from unit in feet

Lw = sound power Q = directionality factor

With Q=1

, Unit suspended in space (theoretical condition), the equation simplifies to:

Lp = Lw – (20)(log r) –0.5

With Q=2

, for a unit sitting on a flat roof or ground with no adjacent vertical wall as a reflective surface,

the equation simplifies to:

Lp = Lw – (20)(log r) + 2.5

With Q=4

for a unit sitting on a flat roof or ground with one adjacent vertical wall as a reflective surface,

the equation simplifies to:

Lp = Lw – (20)(log r) + 5.5

The equations are reduced to table form in Table 19 for various distances and the two most usual cases of

“Q” type of location.

able 20, dB Conversion of Sound Power to Pressure for Distance

T

Distance from Sound

Source

ft. (m)

30 (9) 27.1 24.0

50 (15) 31.6 28.5

75 (23) 35.1 32.0

100 (30) 37.6 34.5

150 (46) 41.1 38.0

200 (61) 43.6 40.5

300 (91) 47.6 44.0

dB Reduction from Sound Power at the Source to

Sound Pressure at Referenced Distance

Q=

2 Q=4

Catalog 616

27

Page 28

Figure 9, Sound Pressure Attenuation Due to Distance from Unit

Sound Pressure Reduction - Low Ambient Conditions

Unit operation at a lower ambient temperature than 95°F (35C) will also result in lower sound pressure

levels. The sound pressure level will decrease 1 dBA for ambient temperatures between 85F and 94°F

(29.4C and 34.4C), 2 dBA for ambient temperatures between 75F and 84°F (23.9C and 28.9C), and 3

dBA for ambient temperatures between 65F and 74°F (18.3C and 23.3C).

Optional Acoustic Packages

For sound-critical applications, optional acoustical blankets can be factory-installed on each compressor.

They are also available for retrofit field installation.

28 Catalog 616

Page 29

Electrical Data

Field Wiring

Wiring must comply with all applicable codes and ordinances. Warranty is void if wiring is not in accordance

with specifications. Copper wire is required for all power lead terminations at the unit.

ACZ-B and AGZ-B units have single-point power connection. A single field supplied fused disconnect is

required or it can be supplied as a factory-mounted option. The control transformer is factory mounted.

ACZ/AGZ-B units are rated to 115F (46C) maximum operating ambient air temperature as standard. There

is no high ambient option of vents or fans.

Electrical Data, R-407C

Table 20, AGZ/ACZ-B, Electrical Data, R-407C

AGZ

Unit

Size

-- 010B

010B 013B

013B

017B 020B

020B 025B

025B 028B

029B 033B

034B 039B

NOTE: See page 533for all Electrical Data notes.

ACZ

Unit

Size

016B

Volts

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

Minimum

Circuit

Ampacity

(MCA)

45

45

22

19

58

54

27

22

77

77

39

30

82

80

41

33

113

113

51

41

129

129

61

51

148

139

72

58

187

182

85

73

Quantity

Power Supply

Field Wire

Wire

Gauge

75C

3 8 AWG 1 1.00 (25)

3 8 AWG 1 1.00 (25)

3 10 AWG 1 1.00 (25)

3 10 AWG 1 1.00 (25)

3 6 AWG 1 1.00 (25)

3 6 AWG 1 1.00 (25)

3 10 AWG 1 1.00 (25)

3 10 AWG 1 1.00 (25)

3 4 AWG 1 1.00 (25)

3 4 AWG 1 1.00 (25)

3 8 AWG 1 1.00 (25)

3 10 AWG 1 1.00 (25)

3 4 AWG 1 1.00 (25)

3 4 AWG 1 1.00 (25)

3 8 AWG 1 1.00 (25)

3 10 AWG 1 1.00 (25)

3 2 AWG 1 1.25 (32)

3 2 AWG 1 1.25 (32)

3 6 AWG 1 1.00 (25)

3 8 AWG 1 1.00 (25)

3 1 AWG 1 1.25 (32)

3 1 AWG 1 1.25 (32)

3 6 AWG 1 1.00 (25)

3 6 AWG

3 1/0 AWG 1 1.50 (38)

3 1/0 AWG 1 1.50 (38)

3 4 AWG 1 1.00 (25)

3 6 AWG 1 1.00 (25)

3 3/0 AWG 1 2.00 (51)

3 3/0 AWG 1 2.00 (51)

3 4 AWG 1 1.00 (25)

3 4 AWG

Hub (Conduit

Connection)

Quantity

Nominal

Size

In. (mm)

1 1.00 (25)

1 1.00 (25)

Recommended Maximum

Field Fuse

or Breaker Size

50 50

50 50

25 25

20 20

70 70

60 70

30 35

25 25

90 100

90 100

45 50

35 40

110 110

90 100

50 50

40 40

125 150

125 150

60 60

50 50

150 175

150 175

70 80

60 60

175 200

175 175

80 100

80 80

250 250

250 250

100 110

100 100

Catalog 616

29

Page 30

Table 21, AGZ/ACZ-B, Compressor & Condenser Fan Motor Amp Draw, R-407C

Rated Load Amps Locked Rotor Amps

AGZ

ACZ

Unit

Size

010B 013B

013B 016B

017B 020B

020B 025B

025B 028B

029B 033B

034B 039B

NOTE: See page 533 for all Electrical Data notes.

Unit

Size

-- 010B

Volts

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

Compressors Compressors

No. 1 No. 2

14.8 14.8

14.8 14.8

7.1 7.1

5.8 5.8

20.3 20.3

18.6 18.6

9.2 9.2

7.4 7.4

28.8 28.8

28.8 28.8

14.7 14.7

10.8 10.8

31.2 31.2

30.1 30.1

15.5 15.5

12.1 12.1

42.3 42.3

42.3 42.3

18.6 18.6

14.6 14.6

49.4 49.4

49.4 49.4

23.1 23.1

19.2 19.2

57.9 57.9

53.8 53.8

28.2 28.2

22.4 22.4

75.0 75.0

73.1 73.1

34.0 34.0

28.8 28.8

F.L. Amps

Fan

Motor

(Each)

5.8 2 21.4 91 91

5.8 2 23.7 91 91

2.8 2 10.7 50 50

2.5 2 11.0 37 37

5.8 2 21.4 156 156

5.8 2 23.7 156 156

2.8 2 10.7 75 75

2.5 2 11.0 54 54

5.8 2 21.4 195 195

5.8 2 23.7 195 195

2.8 2 10.7 95 95

2.5 2 11.0 80 80

5.8 2 21.4 225 225

5.8 2 23.7 225 225

2.8 2 10.7 114 114

2.5 2 11.0 80 80

5.8 3 21.4 245 245

5.8 3 23.7 245 245

2.8 3 10.7 125 125

2.5 3 11.0 100 100

5.8 3 21.4 300 300

5.8 3 23.7 300 300

2.8 3 10.7 150 150

2.5 3 11.0 109 109

5.8 3 21.4 340 340

5.8 3 23.7 340 340

2.8 3 10.7 173 173

2.5 3 11.0 132 132

5.8 3 21.4 505 505

5.8 3 23.7 505 505

2.8 3 10.7 225 225

2.5 3 11.0 180 180

No. of

Fan

Mtrs

L.R.Amps

Fan

Motor

(Each) No. 1 No. 2

Across-The-Line

30 Catalog 616

Page 31

Table 22, AGZ/ACZ-B, Field Wiring Data, R-407C

AGZ

Unit

Size

ACZ

Unit

Size

Volts

Standard Power Block Terminal

Maximum

Terminal Amps

208 175 14 AWG – 2/0

-- 010B

230 175

460 175

575 175

208 175

010B 013B

230 175

460 175

575 175

208 175

013B 016B

230 175

460 175

575 175

208 175

017B 020B

230 175

460 175

575 175

208 175

020B 025B

230 175

460 175

575 175

208 175

025B 028B

230 175

460 175

575 175

208 175

029B 033B

230 175

460 175

575 175

208 335 6 AWG – 400 kcmil

034B 039B

230 335 6 AWG – 400 kcmil

460 175 14 AWG – 2/0

575 175 14 AWG – 2/0

NOTES:

1.

High Interruptor or HSCCR Circuit Breakers are not available in these sizes.

2. See page

533 for all Electrical Data notes.

Wiring to

Connector Wire

Range

Disconnect

(Copper Wire Only)

14 AWG – 2/0 60 14 AWG – 1 AWG 70 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 35 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 30 10 AWG - 1/0

14 AWG – 2/0 60

14 AWG – 2/0 60 14 AWG – 1 AWG 80 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 40 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 35 10 AWG - 1/0

14 AWG – 2/0 100

14 AWG – 2/0 100

14 AWG – 2/0 60 14 AWG – 1 AWG 60 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 50 10 AWG - 1/0

14 AWG – 2/0 100

14 AWG – 2/0 100

14 AWG – 2/0 60 14 AWG – 1 AWG 70 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 50 10 AWG - 1/0

14 AWG – 2/0 125

14 AWG – 2/0 125

14 AWG – 2/0 60 14 AWG – 1 AWG 80 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 70 10 AWG - 1/0

14 AWG – 2/0 225

14 AWG – 2/0 225

14 AWG – 2/0 100

14 AWG – 2/0 60

14 AWG – 2/0 225

14 AWG – 2/0 225

14 AWG – 2/0 100

14 AWG – 2/0 100

Optional Disconnect Switch

Wiring to

Connector Wire

Size

60

Range

(Copper Wire Only)

14 AWG – 1 AWG

14 AWG – 1 AWG

8 AWG - 1/0

8 AWG - 1/0

8 AWG - 1/0

8 AWG - 1/0

3 AWG – 3/0

3 AWG - 3/0

2 AWG - 4/0

2 AWG - 4/0

8 AWG - 1/0

14 AWG – 1 AWG

2 AWG - 4/0

2 AWG - 4/0

8 AWG - 1/0

8 AWG - 1/0

225

225

100

100

2 AWG - 4/0

2 AWG - 4/0

8 AWG - 1/0

8 AWG - 1/0

Wiring to High Interrupt

or HSCCR Circuit Breaker

Max.

Amps

Connector Wire

Range

(Copper Wire Only)

70 10 AWG - 1/0

90 10 AWG - 1/0

125 3 AWG - 3/0

125 3 AWG - 3/0

125 3 AWG - 3/0

125 3 AWG - 3/0