GOOD-ARK GRN3, GRN7, GRN6, GRN4 Datasheet

Features

Plastic package has Underwriters Laboratory

Flammability Classification 94V-0

Ideal for surface mount automotive applications

High temperature metallurgically bonded construction

Glass passivated cavity-free junction

Capable of meeting environmental standards of

MIL-S-19500

Built-in strain relief

Easy pick and place

Fast switching for high efficiency

High temperature soldering guaranteed:

450

/5 seconds at terminals

Complete device submersible temperature of

265 for 10 seconds in solder bath

Mechanical Data

Case: SMA molded plastic over glass body

Terminals: Solder plated, solderable per

MIL-STD-750,

Polarity: Color band denotes cathode end

Mounting Position: Any

Weight: 0.004 ounce, 0.118 gram

method 2026

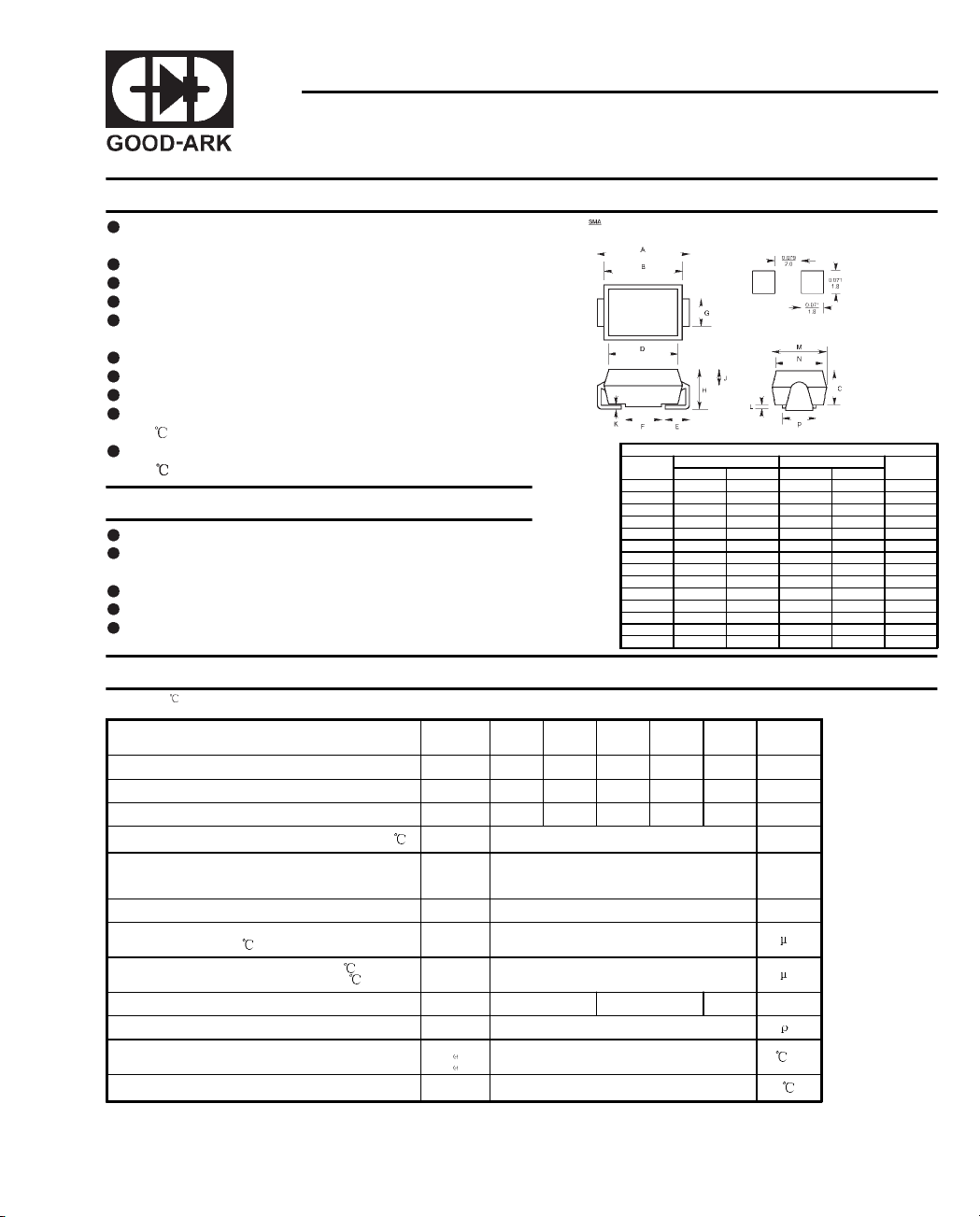

GRN3 THRU GRN7

SURFACE MOUNT GLASS PASSIVATED JUNCTION

FAST S W ITC H ING RE C T IF IER

Reverse Voltage -

Forward Current -

DIM

A 0.216 0.226 5.48 5.74

B 0.176 0.182 4.48 4.63

C 0.094 0.100 2.40 2.55

D 0.170 0.176 4.33 4.48

E 0.039 0.055 1.00 1.40

F 0.080 0.081 2.03 2.07

G 0.068 0.083 1.72 2.10

H 0 .112 0 .118 2 .85 3 .00

J 0.057 - 1.44 -

K - 0.018 - 0.45

L 0.016 - 0.40 -

M 0.109 0.115 2.77 2.93

N 0.105 0.107 2.67 2.73

P 0.078 0.081 2.00 2.05

inches mm

Min. Max. Min. Max.

50 to 600 Volts

1.0 Ampere

DIM ENSIONS

Note

Maximum Ratings and Electrical Characteristics

Ratings at 25 ambient temperature unless otherwise specified.

Symbols GRN3 GRN4 GRN5 GRN6 GRN7 Units

Maximum repetitive peak reverse voltage V

Maximum RMS voltage V

RRM

RMS

Maximum DC blocking voltage V

Maximum average forward rectified current at T

Peak forward surge current

8.3mS single half sine-wave superimposed

on rated load (MIL-STD-750D 4066 method)

=120 I

L

(AV)

I

FSM

Maximum instantaneous forward voltage at 1.0A V

Maximum full load reverse current, full cycle

average, T

Maximum DC reverse current T

at rated DC blocking voltage TA=125

A

=55

A

=25

I

R(AV)

I

Maximum reverse recovery time (Note 1) T

Typical junction capacitance (Note 2) C

Typical thermal resistance (Note 3)

Operating junction and storage temperature range T

R

R

, T

J

Notes:

(1) Reverse recovery test conditions: IF=0.5A, IR=1.0A, Irr=0.25A

(2) Measured at 1.0MHz and applied reverse voltage of 4.0 volts

(3) Thermal resistance from junction to ambient and from junction to lead P.C.B. mounted on 0.2X0.2 (5.0X5.0mm) copper pad areas

50 100 200 400 600 Volts

35 70 140 280 420 Volts

50 100 200 400 600 Volts

DC

1.0 Amp

30.0 Amps

F

1.30 Volts

50.0

R

rr

J

JA

JL

STG

150 250 500 nS

5.0

100.0

8.5

85.0

28.0

-65 to +175

1

A

A

F

/W

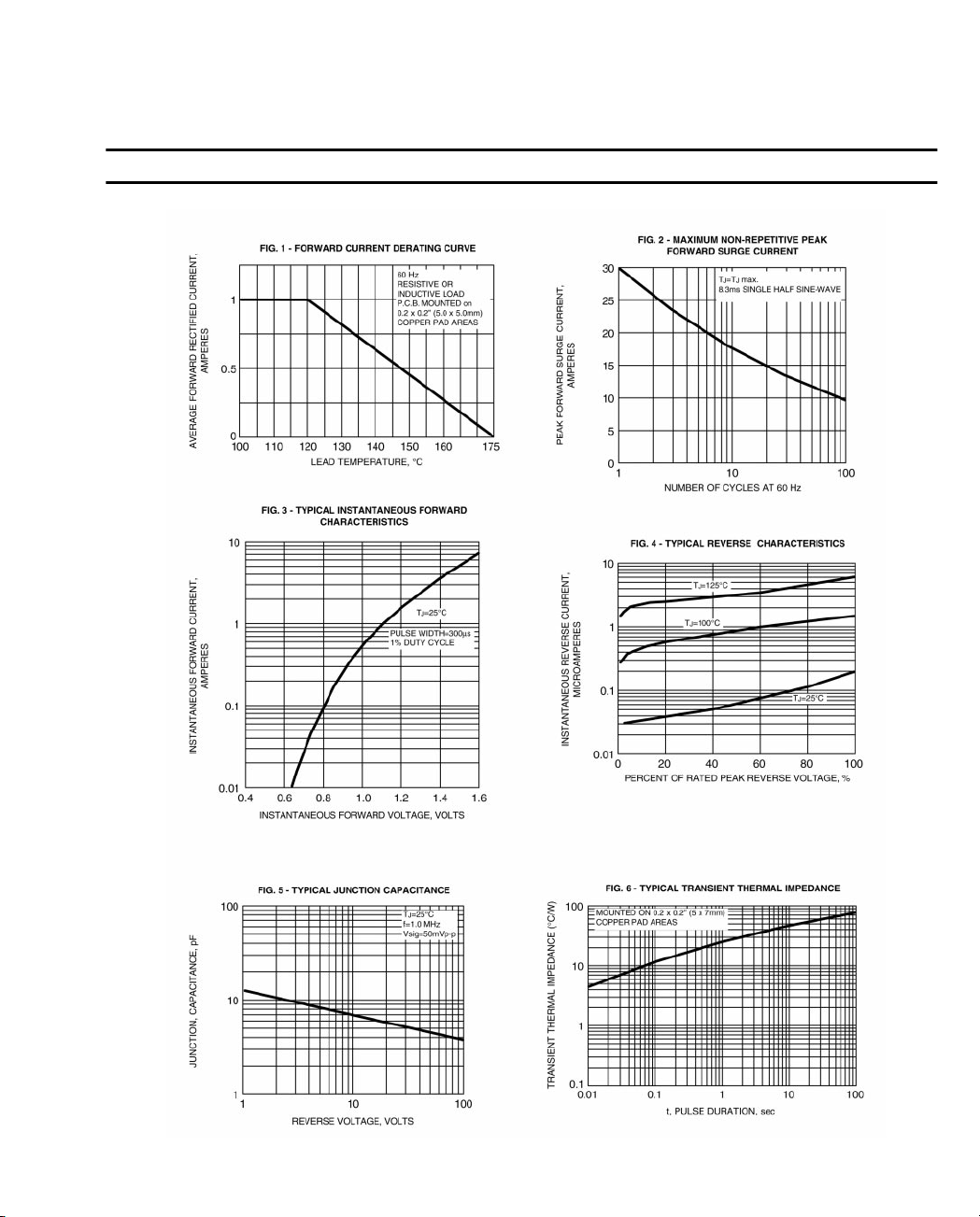

RATINGS AND CHARACTERISTIC CURVES

2

Loading...

Loading...