Gonnheimer elektronic F840 User Manual

l

Instruction manua

Pressurized enclosure system

F840

FS840 Seite 2

Content

1

Safety indication for explosion-proof devices ........................................................................................ 4

2 General requirements to pressuri zed enclosur e system F830/840 ...................................................... 5

2.1 General requirements .................................................................................................................... 5

2.2 Mechanical requirements to the Ex pzc- housing .......................................................................... 5

2.3 Determination of pre- purging phase ............................................................................................. 6

2.4 Purge medium requirements .......................................................................................................... 7

2.5 Temperature class of the Ex pzc- housing .................................................................................... 7

2.6 Particular requirements in Zone 22 (Dust - Ex) ............................................................................. 7

2.6.1 Purging-phase / Cleaning of the housing ............................................................................... 7

2.6.2 Marking in the housing ............................................................................................................ 8

2.6.3 Special conditions in the manual of the Ex pzc- system (Zone 22) ........................................ 8

2.7 Introduction: Pressurized enclosure system F840 with protection pzc .......................................... 8

2.8 Relation between FS830 and FS840 ............................................................................................. 9

2.9 Purging phase ................................................................................................................................ 9

2.9.1 Pressurized enclosure system without pre- purging ............................................................... 9

2.9.2 Pressurized enclosure system with pre- purging .................................................................. 10

2.10 Operation mode Leakage compensation ................................................................................. 11

2.11 Conformity with Standards ....................................................................................................... 11

3 Mounting and connection .................................................................................................................... 12

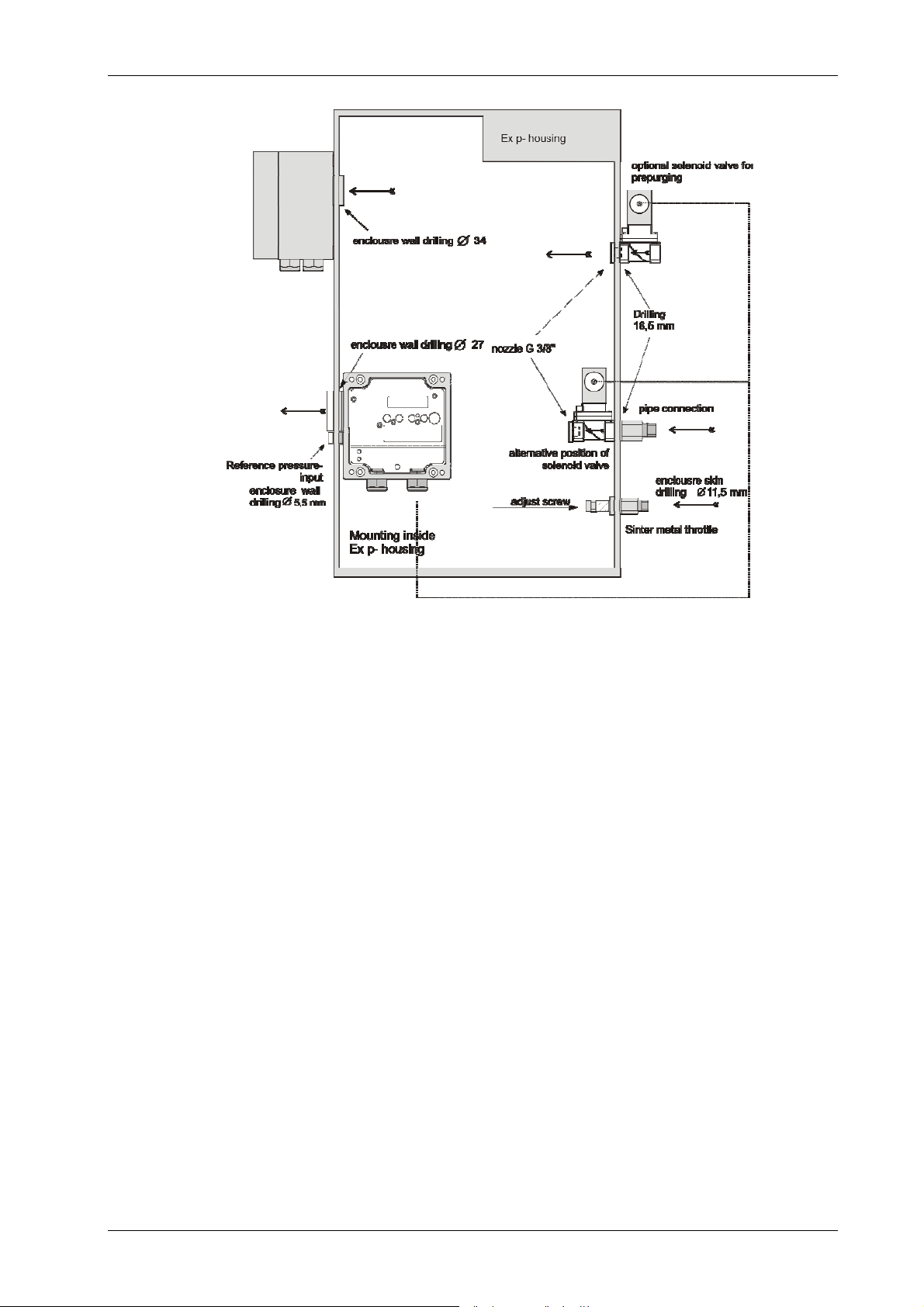

3.1 Mounting ...................................................................................................................................... 12

3.1.1 Control unit FS840 ................................................................................................................ 12

3.1.2 Sinter metal throttle SD840 ................................................................................................... 13

3.1.3 Optional solenoid valve for purging ...................................................................................... 13

3.2 Connection and Startup ............................................................................................................... 13

3.2.1 Connection details ................................................................................................................ 13

3.2.2 Terminals of the FS840 ........................................................................................................ 14

3.2.3 Place and exchange of valve fuse ........................................................................................ 14

3.2.4 Power off relays .................................................................................................................... 14

3.2.5 Switch input for passive contacts .......................................................................................... 15

3.2.6 Electrical diagram of the FS840 ............................................................................................ 15

4 Operation ............................................................................................................................................. 16

4.1 Display ......................................................................................................................................... 16

4.2 Alarm- signal- lamp ...................................................................................................................... 16

4.3 Buttons ......................................................................................................................................... 16

4.4 Indication modes during normal operation ................................................................................... 17

4.5 Bypass, activate and deactivate .................................................................................................. 17

4.6 Configuration ................................................................................................................................ 17

4.7 Menu structure ............................................................................................................................. 18

5 Annex ......................................................................................................................... ......................... 21

5.1 Terminals and terminals Ex- limits ............................................................................................... 21

5.2 Technical details .......................................................................................................................... 21

5.3 Air pressure values ...................................................................................................................... 22

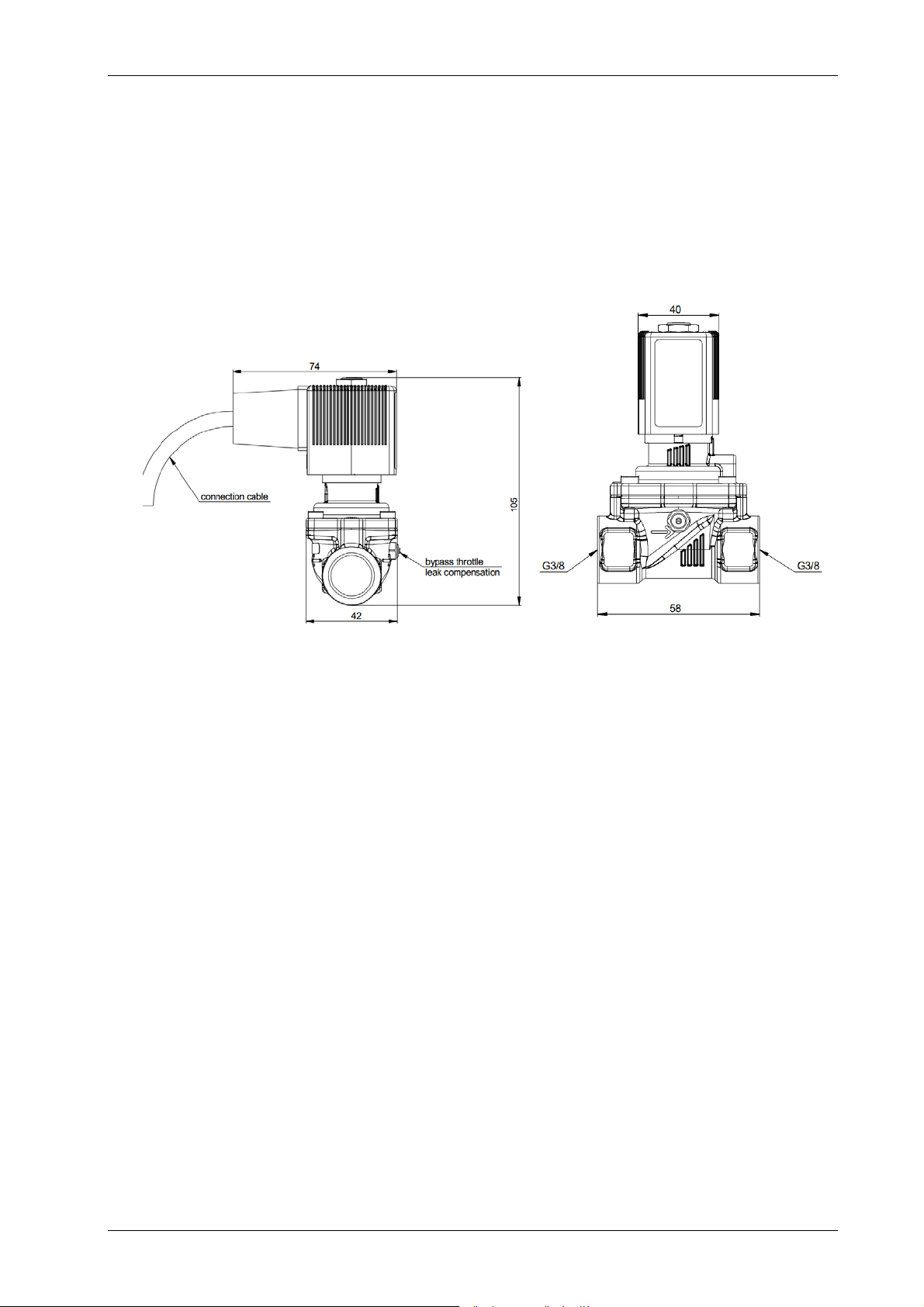

5.4 Dimensions .................................................................................................................................. 22

5.5 Flow chart ..................................................................................................................................... 24

5.6 Flow rate table .............................................................................................................................. 25

5.7 Type designation .......................................................................................................................... 25

5.8 Problems and solutions ................................................................................................................ 26

5.9 Transport, Storing, Disposal and Repairs .................................................................................... 26

5.10 Marking ..................................................................................................................................... 26

5.11 List of parameters ..................................................................................................................... 27

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

FS840 Seite 3

The symbols DANGER, WARNING, ATTENTION

The signal word calls a danger with a high risk degree which if it is not avoided

can cause death or heavy injury.

DANGER

The signal word calls a danger with a middle risk degree which if it is not avoided

can cause death or heavy injury.

WARNING

The signal word calls a danger with a low risk degree which if it is not avoided can

cause slight or moderate injury.

ATTENTION

This symbol refers to the danger of electric tension which can cause heavy injury

or death.

DANGER

Safety measures: Absolutely read and follow

Warning! With the use of this device special care is required. A high electric discharging is possible and can be deadly.

Work at electrical installations and equipment, which are energized are

DANGER

basically forbidden in explosive areas. Work at intrinsically safe circuits

(Ex i) are excluded. In special cases work at non intrinsically safe circuits

can be carried out if it is ensured that no explosive atmosphere is present

during the whole work. The check of the presence of electrical tension

should only be done using explosion protected and certified measuring

instruments. Grounding and short-circuiting should only be carried out if it

is ensured that no hazardous atmosphere is present.

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

FS840 Seite 4

1 Safety indication for explosion-proof devices

Application and Standards

The instructions and warnings given in this instruction manual must be observed in order to ensure safe and proper operation. The equipment should only be used for its intended purpose.

The relevant provisions of the standards IEC/EN 60079 particularly IEC/EN 60079-14 "electrical

apparatus for potentiality explosive atmospheres" apply. The use of the equipment is permitted

in potentially explosive atmospheres due to gases or vapours. The data provided at the type

plate must be observed. When constructing and operating explosion-proof systems and facilities, the applicable national regulations, provisions and valid standards must be observed.

General Instructions

Work on electrical installations and apparatus in operation is generally forbidden in hazardous

locations, with the exception of intrinsically safe circuits. In special cases work can be done on

non-intrinsically safe circuits, on the condition that during the duration of such work no explosive

atmosphere exists.

Proper and safe operation of this device requires appropriate transport, correct storage and assembly as well as careful service and maintenance. Any work at the device may only be carried

out by technically trained personnel.

The electrical characteristics shown at the type plate and within the certificates BVS 15 ATEX E

048 X and IECEx BVS 15.0037 X, and, if applicable, their special conditions, have to be considered.

For outdoor installation it is recommended to protect the explosion protected distribution and

control panel against direct climatic influence, e.g. with a protective roof. The maximum ambient

temperature is 40°C, if not stipulated otherwise.

Terminal compartment in Increased Safety

When closing, it is to be ensured that the gaskets of the terminal compartment remain effective,

thus maintaining degree of protection IP 54. Close unused entries by impact-proof stopping

plugs, which are secured against self-loosening and turning.

Maintenance Work

The gaskets of Ex e enclosures are to be checked for damages and replaced, if required. Terminals, especially in the Ex e chamber are to be tightened. Possible changes in colour point to

increased temperature. Cable glands, stopping plugs and flanges are to be tested for tightness

and secure fitting.

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

FS840 Seite 5

2 General requirements to pressurized enclosure system F830/840

The control unit (FS840) for pressurized enclosure systems can be combined with every Ex

pzc- housing that fulfils the following requirements.

2.1 General requirements

1 The Ex pzc- system must be inspected by a skilled person of accordance to

IEC/EN 60079 –2, IEC/EN 60079 –14 and this manual.

2 Mount the solenoid valve (purging medium input) and control unit FS840 to a

maximum of distance (optimal arrangement is diagonal).

3 The operator must not do any technical changes to the control unit FS840. Any

change will invalidate the type examination certificate.

4 Only Gönnheimer Elektronic GmbH is allowed to repair the FS840.

5 Harmed Ex p-pipes and connections have to be repaired/replaced immediately.

6 Discharging of flammable gases into the Ex pzc-housing, e.g. for gas analyser

applications is prohibited.

7 It is necessary to create an instruction manual for the complete system.

2.2 Mechanical requirements to the Ex pzc- housing

1 Regard particularly IEC/EN 60079- 0 + 2.

2 The Ex pzc- housing must hold the 1,5 – fold of the maximum pressure, which

can be reached inside of the cabinet, 2 mbar at least. The operator has to define

the maximum pressure of the housing and has to program this pressure value as

monitored max. pressure into the FS840 and has to ensure, that the housing

holds this maximum pressure by 1,5 times.

3 The Ex pzc- housing must pass an impact test according IEC/EN 60079-0.

4 The protection class of the Ex pzc- housing must be greater than IP54.

5 Cable glands must have a protection class greater than IP54.

6 If the Ex pzc- housing has surfaces made of synthetics (e.g. windows), the maxi-

mum limits for area and thickness must be complied with IEC/EN 60079-0.

WARNING – DANGER THROUGH ELECTROSTATIC DISCHARGE – SEE INSTRUCTION

MANUAL

7 There is no danger of static discharge, if the synthetic surface has a thickness of

≤ 0,2 mm (Group IIC) respectively 2 mm (Group IIB) or less and it is mounted on

a metallic ground.

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

FS840 Seite 6

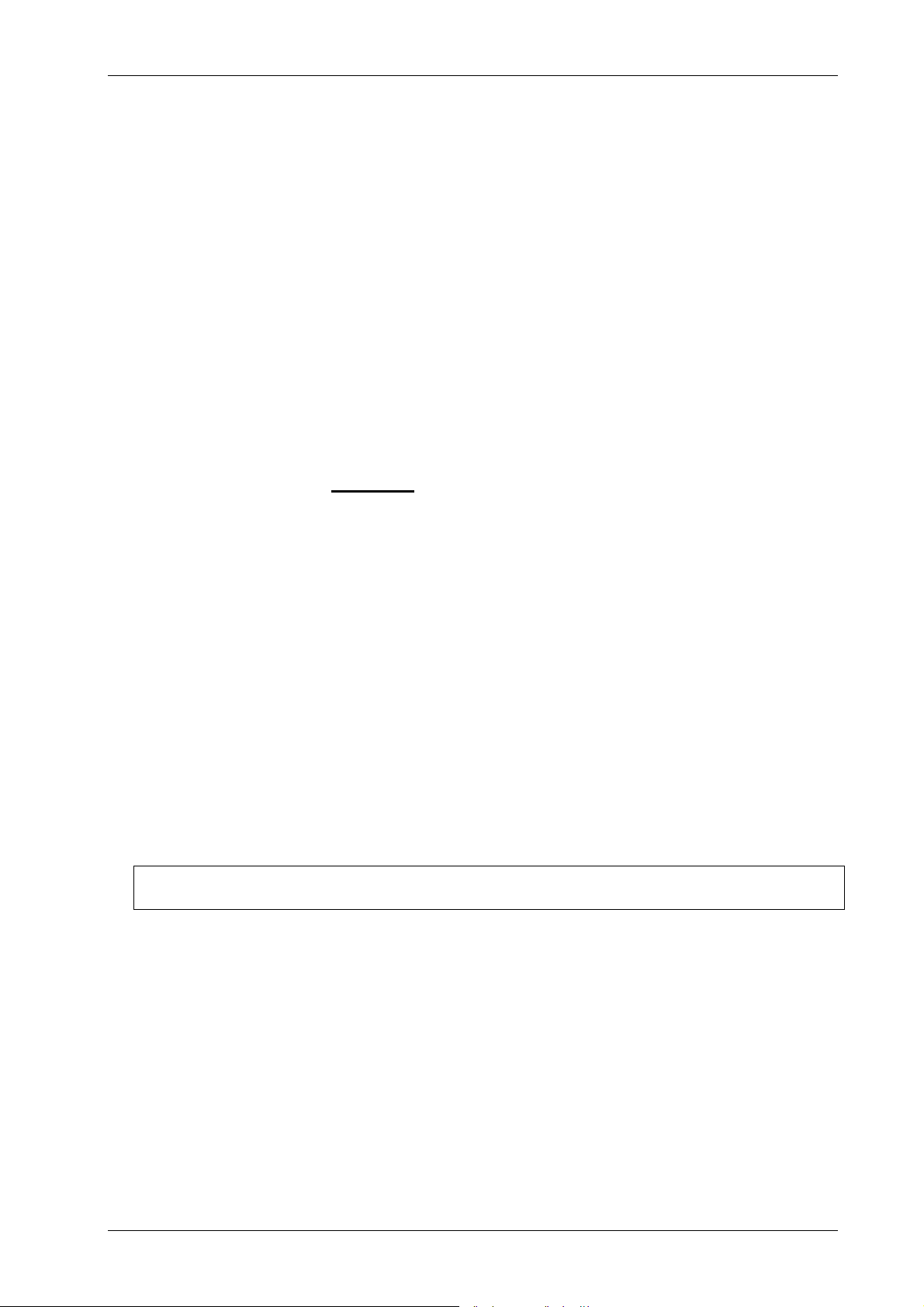

8 If the Ex pzc- housing posses internal compartments (closed rooms, compart-

ments that are not purged), the following rules have to be observed:

a) Components with a free internal volume less than 20 cm³ are not considered

to be internal compartments requiring purging as long as the total volume of all

such components is not more than 1% of the free internal volume of the pressurized apparatus.

b) Provide not less than 1 cm² of vent area for each 1000 cm³, (IEC/EN 60079 –

2; Abs. 5.5.2).

c) Place the vents in a diagonal order, as shown on the picture below, with a

minimum vent size of 6,3 mm diameter

drillings

drillings

d) Installer can also remove covers or doors of internal housings if they provide

adequate vent diameters alternatively.

e) If the topics above are not applicable, a separate piping must be added to the

internal compartment. The purge medium flow through the compartment must

be high enough to make sure that the air in the compartment is exchanged at

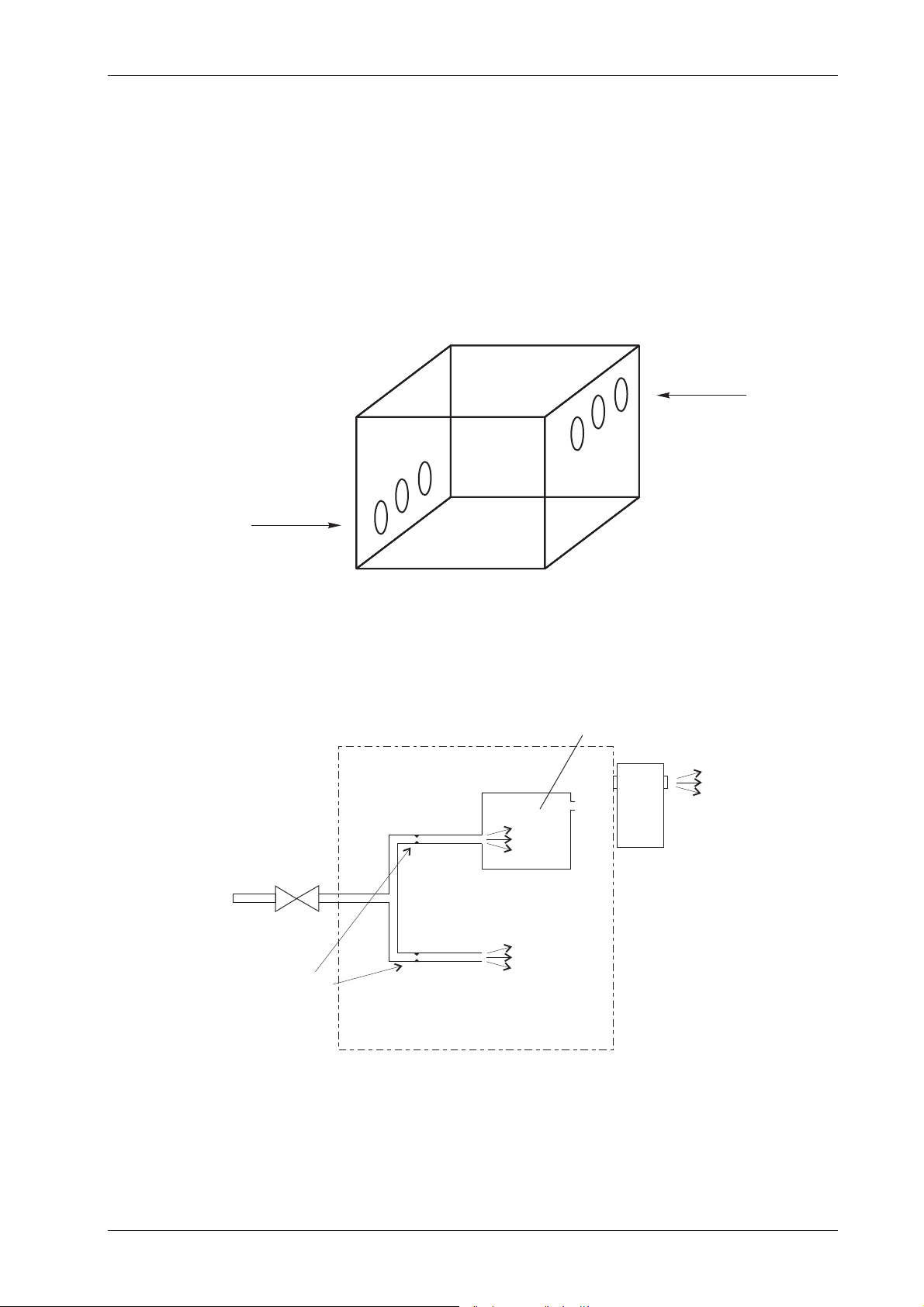

least 10 times higher. For instance:

Inner volume

FS840

Valve

Nozzles for air

distribution

Ex pzc- housing

2.3 Determination of pre- purging phase

In (Gas- ) Ex- Zone 2 it is possible to resign to a purging phase, if the atmosphere in the

housing and in the corresponding pipes is much lower than the lower explosive limit (e.g.

25% LEL). Additionally gas detectors can be used to check, if the Gas in the Ex pzc housing is ignitable. (See IEC/EN 60079-14)

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

FS840 Seite 7

2.4 Purge medium requirements

1 The purging medium must not be derived from hazardous area, it must be con-

tamination free (dry, free of oil and dust). The air quality must be class 533 ac-

cording ISO 8573-1, Solids 40µm (Class 5); Dew point -20°C (Class 3); Oil quality

1mg/m³ (Class 3).

2 If another purge medium than air is used, it is important to regard the minimum

oxygen content of the ambient. Maybe it is necessary to install an exhaust pipe

from the outlet of the Ex pzc- housing to out-of-door.

3 The inlet of the purging gas into the Ex pzc- housing and the pressurized enclo-

sure control unit FS840 should be located as far away to each other as possible

(body diagonal), to achieve a proper purging of the complete housing.

4 The pressure loss at the solenoid valve must not be higher than 500 mbar, while

pre- purging phase.

2.5 Temperature class of the Ex pzc- housing

The installer has to define the maximum ambient temperature and the resulting maximum

temperature class of the Ex pzc- housing.

To determine the temperature class, measure, on worst conditions, the hottest point on the

surface of the Ex pzc- housing and recalculate it to the maximum ambient temperature. The

minimum temperature class is the one of the FS840 and its surface temperature.

If some parts inside of the housing get hotter than the temperature class, the installer has to

determine the time in which the temperature of those parts falls below the temperature

class. He has to place a sign on the Ex pzc- housing with the following sentence:

ATTENTION – ALL DOORS AND WINDOWS SHALL NOT BE OPENED UNTIL X

MINUTES AFTER DEENERGIZING.

X is the determined cooling-time that is needed to cool down hot surfaces lower than the

temperature limit for the corresponding temperature class.

2.6 Particular requirements in Zone 22 (Dust - Ex)

2.6.1 Purging-phase / Cleaning of the housing

For the application in the zone 22 the FS840 must not initialize a pre purging phase. Therefore, the automatic purging at the controller FS840 has to be deactivated (Purging = No).

The purging phase before the start-up of the inserted, electrical non-ex equipment, upstream within the gas ex range, is replaced in the zone 22 by inside cleaning the hous-

ing.

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

FS840 Seite 8

2.6.2 Marking in the housing

On the housing has to be the following marking in a well visible place:

WARNING – REMOVE ALL DUST FROM INSIDE OF THE ENCLOSURE BEFORE CON-

NECTING OR RESTORING THE ELECTRICAL SUPPLY!

2.6.3 Special conditions in the manual of the Ex pzc- system (Zone 22)

In the manual for Ex p- applications for the zone 22 the following items are supplemented:

The use of the Ex p- application within the zone 22 must take place without pre purging

phase. The automatic purging at the controller FS840 has to be therefore always deactivated.

The system may be operated not with a single solenoid valve, but only with a leakage balance mechanism without flushing attitude, e.g. SD840 throttle.

Before start-up of the ignition capable apparatus, the inside of the housing has to be

cleaned completely.

The protective class of the Ex pzc- housing in dust explosive area with not leading-capable

dust has to be at least to IP5X, with leading-capable dust at least IP6X.

2.7 Introduction: Pressurized enclosure system F840 with protection pzc

The use of simplified pressurized enclosures allows the operation of ‘non explosion protected’ devices in hazardous areas inside zones 2 + 22. The protection type ‘pressurization’ is

based on the principle of maintaining a constant pressure using air or a protective gas to

prevent an explosive mixture forming near the apparatus inside the pressurized enclosure.

This is achieved by operating the unit in a pressurized enclosure (Ex pzc- enclosure) and

protecting it from the ingress of explosive gas mixtures by a continuous overpressure with

air or an inert gas.

The control unit FS840 provides all necessary functions to install a pressurized enclosure

system according IEC/EN 60079-14 and IEC/EN 60079-2 „pzc“: The FS840 measures the

internal pressure and alarms or powers off, if the pressure is below the pre- defined minimum pressure.

Optional the FS840 can also pre purge the housing before automatic powering on the housing. In this case connect a digital working 2/2 way solenoid valve to the appropriate terminals. The solenoid must have a separate certification for zone 2.

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

FS840 Seite 9

The purge medium that flows in through the valve is blown through the air outlet in the

FS840 into the ambient Ex atmosphere. The air outlet is conform to IEC/EN 60079-2 designed and contains the needed spark barrier.

2.8 Relation between FS830 and FS840

The pressurized enclosure system control units are certified in the same type examination

certificate. The special conditions are written in the type examination certificate.

2.9 Purging phase

2.9.1 Pressurized enclosure system without pre- purging

If the operator is sure, that the atmosphere inside of the enclosure and the appropriate pipe

infrastructure is below 25% of the lower explosive limit (LEL) at power up, he can abandon

the pre- purging of the enclosure in zone 2. In that case the FS840 monitors only the pressure inside of the enclosure of 0.8 mbar at minimum and maximal 22 or 27 mbar at maximum. If any limit is exceeded, the FS840 changes the state on the potential free relay contacts.

The purge medium flows through an adjustable sinter metal throttle into the Ex pzc- housing

while reducing its pressure.

The FS840 has a mechanical output valve which opens at approximately 5 mbar to let the

purge medium out. Before this valve is a spark barrier located thus the purge medium can

be exhausted directly to the hazardous area.

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

FS840 Seite 10

+

2.9.2 Pressurized enclosure system with pre- purging

To pre- purge the Ex pzc- housing connect a digital working 2/2 way solenoid valve to the

control unit that switches between purging and pressure maintenance. In the valve is a

nozzle integrated to reduce the pre- pressure and also an adjustable bypass-throttle. For

purging, the valve opens and purge air flows through the nozzle into the Ex pzc- housing.

After pre- purging the valve closes automatically and the adjustable throttle of the SVD.L

lets a small amount of purge medium into the housing to hold the pressure.

The installer can determine the pre- purging time once by doing the attenuation test according IEC/EN 60079-2.

As an alternative he can calculate the purging time without the elaborate attenuation test

see below:

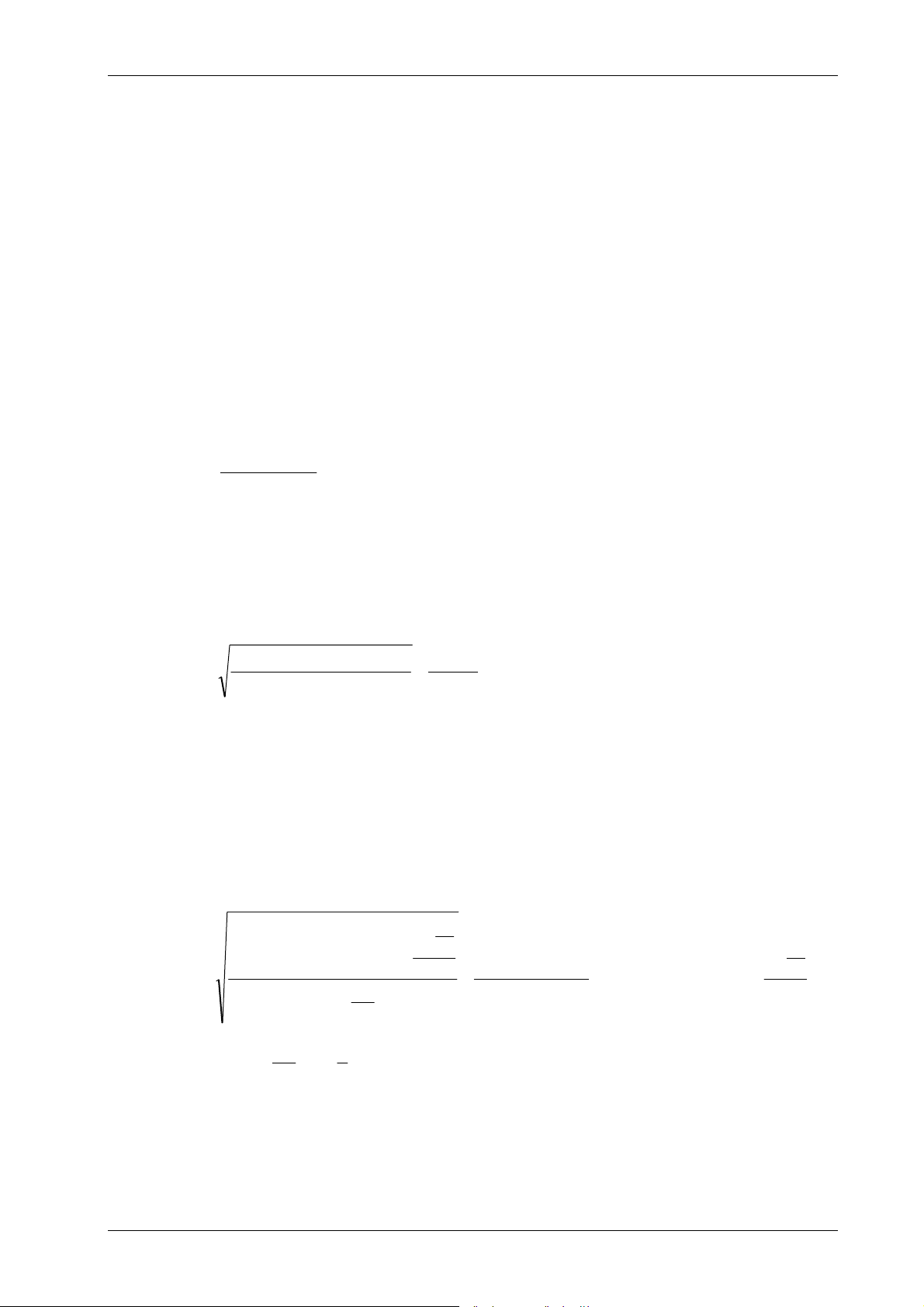

The purging time depends on minimum flow (Q

), free internal volume (V) and the free

min

volume of the connected pipes (Va). Final the calculated time must be multiplied by 10. The

purging time t

purge

is:

)(10

Q

min

VaV

t

purge

×

=

The minimum flow (Q

at the valve (P

Valve

(d). The pressure lost at the valve (P

) depends on the minimum pre pressure (P

min

), internal pressure of the Ex pzc- housing (P

) should not exceed 500 mbar. The maximum in-

Valve

) and the nozzle diameter

Int

ternal pressure of the housing is defined to be less than 25 mbar. The minimum flow Q

), the pressure lost

premin

min

can be calculated by:

PPP

=

Q

min

min

ρ

IntValvepre

×

π

×

d

4

2

)(2

−−×

3

ρ is the density of the purging medium. The density of air is ρ =1,293 kg/m

nitrogen is 1,25 kg/m

3

. We calculate the ρ of air for all gases, because the difference is only

, the density of

3%.

The installer can calculate the purging time of his own or he can use the automatic calcula-

tion in the menu of the FS840 (see 4.7)

Example:

m

kg

Q

Q

Beispiel

Beispiel

2

5

m

s

2

002,0

×

m

22

××

π

barmit

101,

=

4

10)025,05,02(2

×−−×

=

3

m

≈≈

s

kg

293,1

3

m

l

5,10015,0

s

m

kg

2

5

s

2

m

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

FS840 Seite 11

2.10 Operation mode Leakage compensation

The FS840 works after the pre- purging phase or without pre purging phase immediately after the voltage supply in the mode of operation "leakage compensation ".

In this mode of operation will maintain after an overpressure (at least 0.8 mbar) within the

Ex pzc- cabinet. This cabinet minimum pressure as well as also a cabinet maximum pressure are programmable and are monitored constantly.

Leakage losses are compensated by a small bypass. This bypass is integrated in the valve

and mechanically adjustable (diameter 0,3 ... 1 mm).

2.11 Conformity with Standards

The Ex certified control unit FS840 fulfills the requirements of listed standards in the attachment (Declaration of conformity). It is developed, manufactured and tested in accordance with state-of-the-art engineering practice and ISO9001:2015.

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

FS840 Seite 12

3 Mounting and connection

3.1 Mounting

3.1.1 Control unit FS840

The control unit FS840 is suitable for mounting in hazardous area zones 2 / 22. The installer can place it at the outside of the Ex pzc- housing, the position is arbitrary.

The installer can mount the control unit using the 4 mounting holes in the housing rear, but

the fixing on the air in- or outlet is sufficient.

While mounting, observe local safety guidelines and

the regulative: IEC/EN 60079-14.

CAUTION!

The reference output (=M5 internal thread at the left

side of the control unit) must have contact to the

ambient pressure.

If the control unit is placed into the Ex pzc- housing, the reference output

CAUTION!

must be connected to the ambient with a pipe or tube.

Additional see general requirements to pressurized

enclosure system F830/840 (Chapter 2).

Additional regulations for mounting in Gas- Ex- Zone

When the FS840 is used as a device of Gas Ex Group

IIC, the pressurized enclosure must have at least degree

of protection IP54.

CAUTION!

Additional regulations for mounting in Dust- Ex- Zone

When the FS840 is used as a device of Dust Ex Group

IIIB, the pressurized enclosure must have at least degree of protection IP5X.

CAUTION!

When the FS840 is used as a device of Dust Ex Group

IIIC, the pressurized enclosure must have at least degree of protection IP6X.

CAUTION!

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

FS840 Seite 13

3.1.2 Sinter metal throttle SD840

While operation mode “leakage compensation” a small amount of purging gas enters

through the sinter metal throttle SD840 into the Ex pzc- housing to provide the desired

overpressure. Dispensable purge gas will be exhausted at an overpressure of about 5 mbar

through the integrated outlet valve of the control unit FS840.

3.1.3 Optional solenoid valve for purging

The installer can mount the solenoid valve SVD.L.x-AIxx in or outside of the Ex pzc- housing, see details from manufacturer documentation.

3.2 Connection and Startup

3.2.1 Connection details

When connecting the Ex e terminals, the following limits must be observed

Min. and Max. clamping torque Min. 0,4 Nm

Max. 0,5 Nm

Min. and Max. wire cross-section Stiff: 0,2 – 2,5 mm²

Flexible: 0,2 – 2,5 mm²

When connecting and commissioning, the following points should be observed

Mains VOLTAGE! Extreme caution is advised when

handling this device. High electrical discharge is

possible and can be fatal.

See installation regulative and the conformity

statements BVS 15 ATEX E 048 X and IECEx BVS

15.0037 X.

Do not exceed terminal safety limits of each termi-

CAUTION!

nal.

See limits in technical details or conformity statements.

The internal valve fuse must be adapted to the solenoid valve that is used.

Gönnheimer Elektronic GmbH Tel.: +49 (6321) 49919-0 Fax: +49 (6321) 49919-41

Loading...

Loading...