GoNet Systems GB8000F-000 Assemply Instructions

Proprietary Information - Confidential

DO001152

GoBeam-8000

Assembly Instruction

Revision:

1.1

Page: 1 out of 16

Approval Date:

16.12.2013

Effective

Date:

16.12.2013

Update by:

Approved by:

Oleg Einem

Nimrod Tenne

Sharon Ashkenazi

Page 1 of 16

DO001152 REV 1.1

Printed version are uncontrolled

Revision

Date

Changes

Modified By

Approved By

1.0

09.12.13

Release Work Procedure

Oleg Einem

Nimrod Tenne

1.1

06.01.14

Fixed

Oleg Einem

Sharon

Ashkenazi

Revision History

Proprietary Information - Confidential

DO001152

GoBeam-8000

Assembly Instruction

Revision:

1.1

Page: 2 out of 16

Approval Date:

16.12.2013

Effective

Date:

16.12.2013

Update by:

Approved by:

Oleg Einem

Nimrod Tenne

Sharon Ashkenazi

Page 2 of 16

DO001152 REV 1.1

Printed version are uncontrolled

Table of Content

Revision History ................................................................................................................................ 1

1. Introduction ................................................................................................................................ 3

2. Required Tools ........................................................................................................................... 3

3. General Instructions ................................................................................................................... 3

4. Mechanical Assembly ................................................................................................................ 4

4.1. Heat Conductive Gap Fillers Gluing 4

4.2. Light pipes 5

4.3. Sealing Gasket. 5

4.4. Adhesive Membrane Vent Gluing 6

4.5. CPU board. 6

4.6. PS board. 7

4.7. Wireless mini PCI Boards 2.4GHz, 5GHz. 8

4.8. Mechanical Assembly. 10

4.9. Beam Forming. 11

4.10. Antennas. 13

4.11. Radom. 14

4.12. Sealing screw. 15

4.13. Ground Screw 15

4.14. Plug for ETH2 16

4.15. Labels Sticking 16

Proprietary Information - Confidential

DO001152

GoBeam-8000

Assembly Instruction

Revision:

1.1

Page: 3 out of 16

Approval Date:

16.12.2013

Effective

Date:

16.12.2013

Update by:

Approved by:

Oleg Einem

Nimrod Tenne

Sharon Ashkenazi

Page 3 of 16

DO001152 REV 1.1

Printed version are uncontrolled

Screw Size

M2

M3

M3 Nylon

M4

M5

Bit size

1

2

Required Torque

4 kg-cm

3.5 lb-In

6.9 kg-cm

6 lb-In

3.5 kg-cm

3 lb-In

17 kg-cm

14.8 lb-In

30 kg-cm

26 lb-In

1. Introduction

This document describes in detail the assembly process of the GoBeam-8000 Top level Systems.

2. Required Tools

Automatic screw drivers with torque (for example “Delvo” DLV-7333 and DLV-7140).

Philips screw head bits size 1 and 2.

Hexagon head bit size 5mm.

PLCC Instructor.

3. General Instructions

3.1. Before assembling verify that all required items are in following conditions:

3.1.1. Parts are in correspondence with proper part numbers and revisions.

3.1.2. All items are in good condition, not damaged and fully clean.

3.1.3. Each component has relevant certificate, test report and approval.

3.1.4. Tools are calibrated, tested in time and approved for use.

3.1.5. Working place is properly equipped, clean and free of extraneous objects.

3.2. All assembly executors must carefully follow these instructions.

3.3. Unless otherwise specified use Soudure NET 9418 (Go P/n: MS000010) for cleaning and

degreasing.

3.4. Unless otherwise specified screws bit size and closing torque should be in accordance with the

following table:

Proprietary Information - Confidential

DO001152

GoBeam-8000

Assembly Instruction

Revision:

1.1

Page: 4 out of 16

Approval Date:

16.12.2013

Effective

Date:

16.12.2013

Update by:

Approved by:

Oleg Einem

Nimrod Tenne

Sharon Ashkenazi

Page 4 of 16

DO001152 REV 1.1

Printed version are uncontrolled

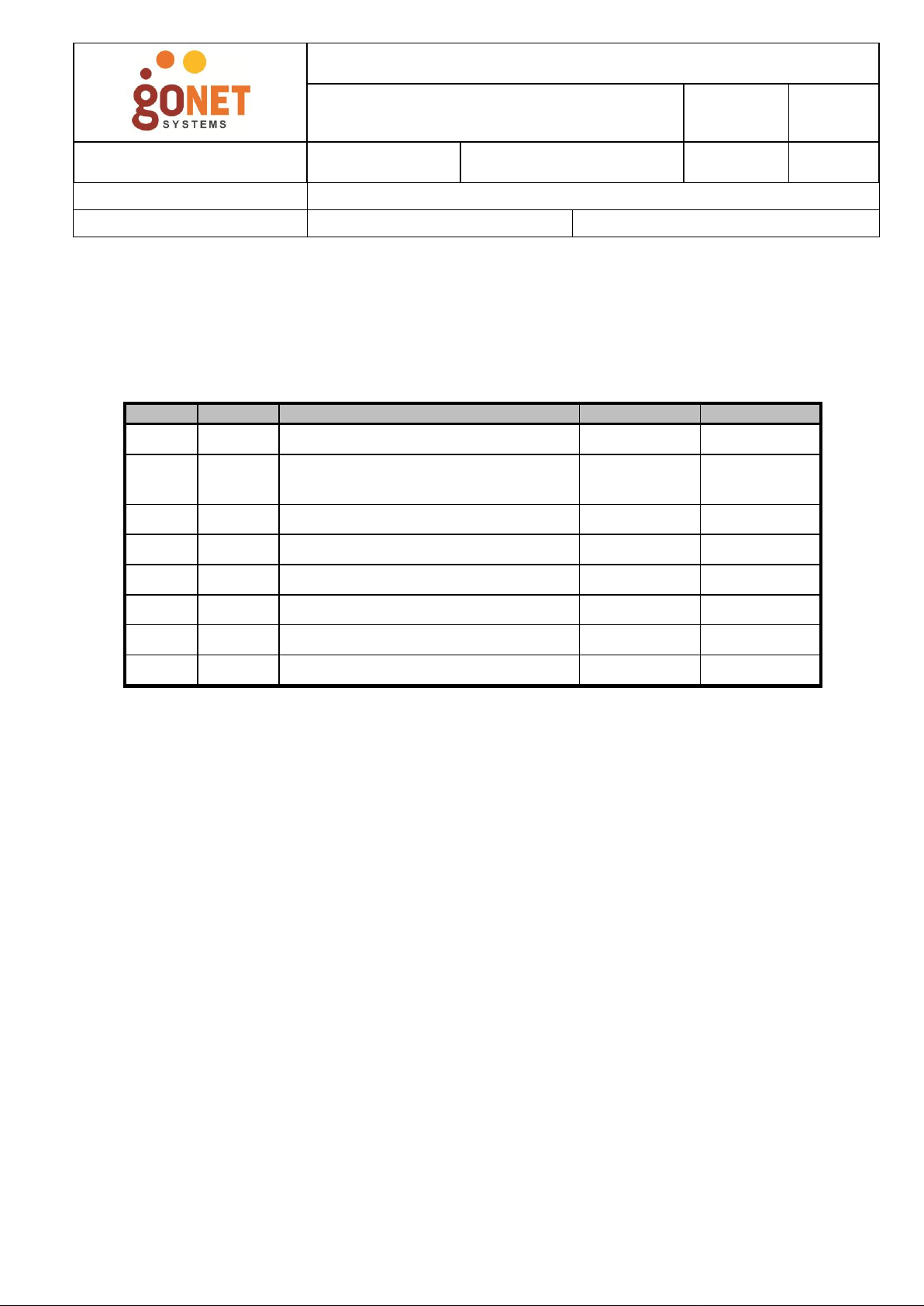

Item

Description

Part No

QTY

1

Base

MC000471

1

2

Thermal Pad 50x25x2 mm

MC000500

2

3

Thermal PAD(45*7*1t)

MC000477

1

4

Thermal PAD(26*26*1t)

MC000478

1

5

Thermal PAD(7.5*6.5*1t)

MC000479

4

6

Thermal PAD(8*8*1t)

MC000480

2

4. Mechanical Assembly

4.1. Heat Conductive Gap Fillers Gluing

4.1.1. Stick items 2…6 to item 1 after previously cleaning related surfaces of

item 1.

Proprietary Information - Confidential

DO001152

GoBeam-8000

Assembly Instruction

Revision:

1.1

Page: 5 out of 16

Approval Date:

16.12.2013

Effective

Date:

16.12.2013

Update by:

Approved by:

Oleg Einem

Nimrod Tenne

Sharon Ashkenazi

Page 5 of 16

DO001152 REV 1.1

Printed version are uncontrolled

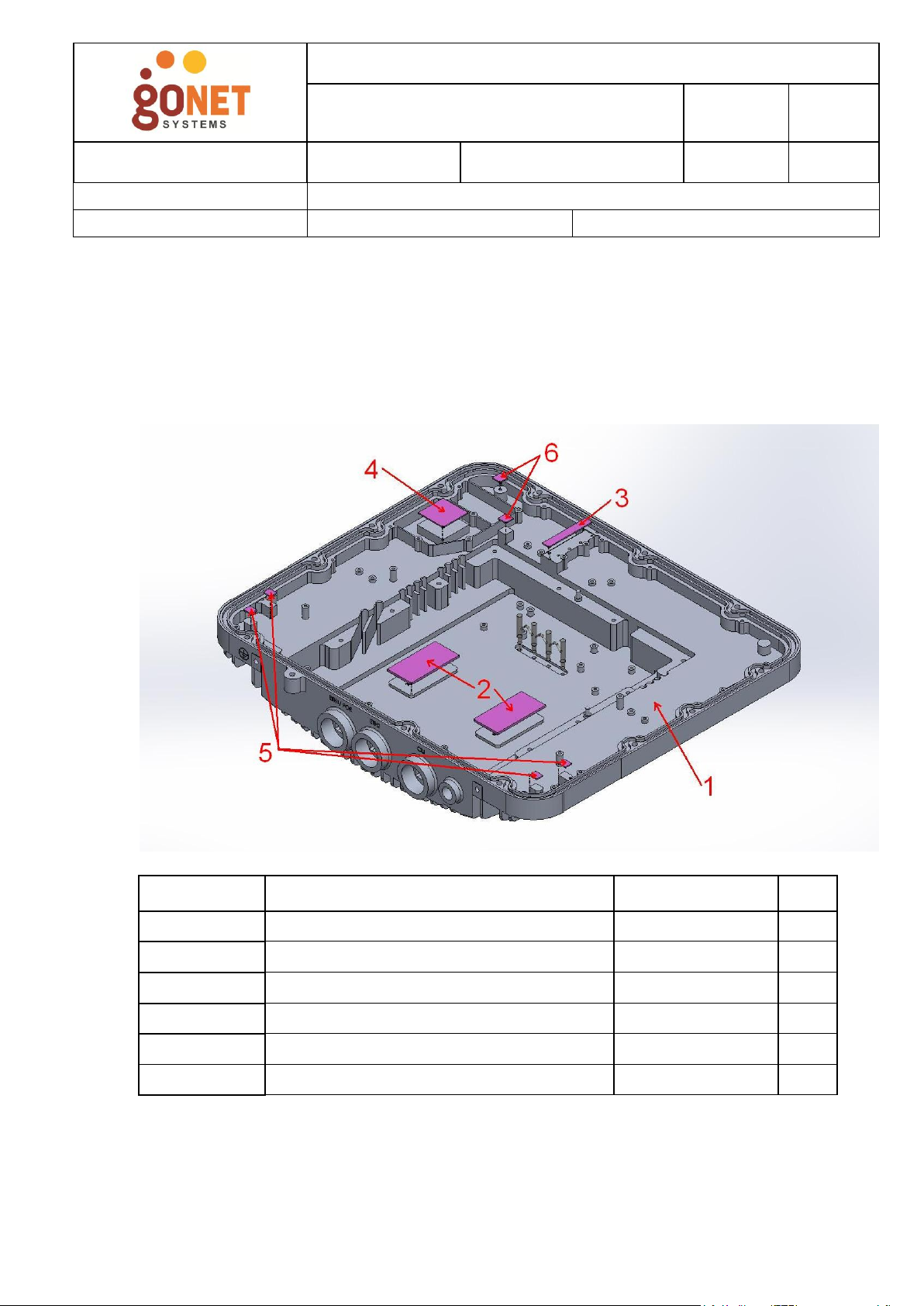

Item

Description

Part No

QTY

1

Base

MC000471

1

2

Silicon

MS000022

0.08mL

3

Light Pipe

MC000483

1

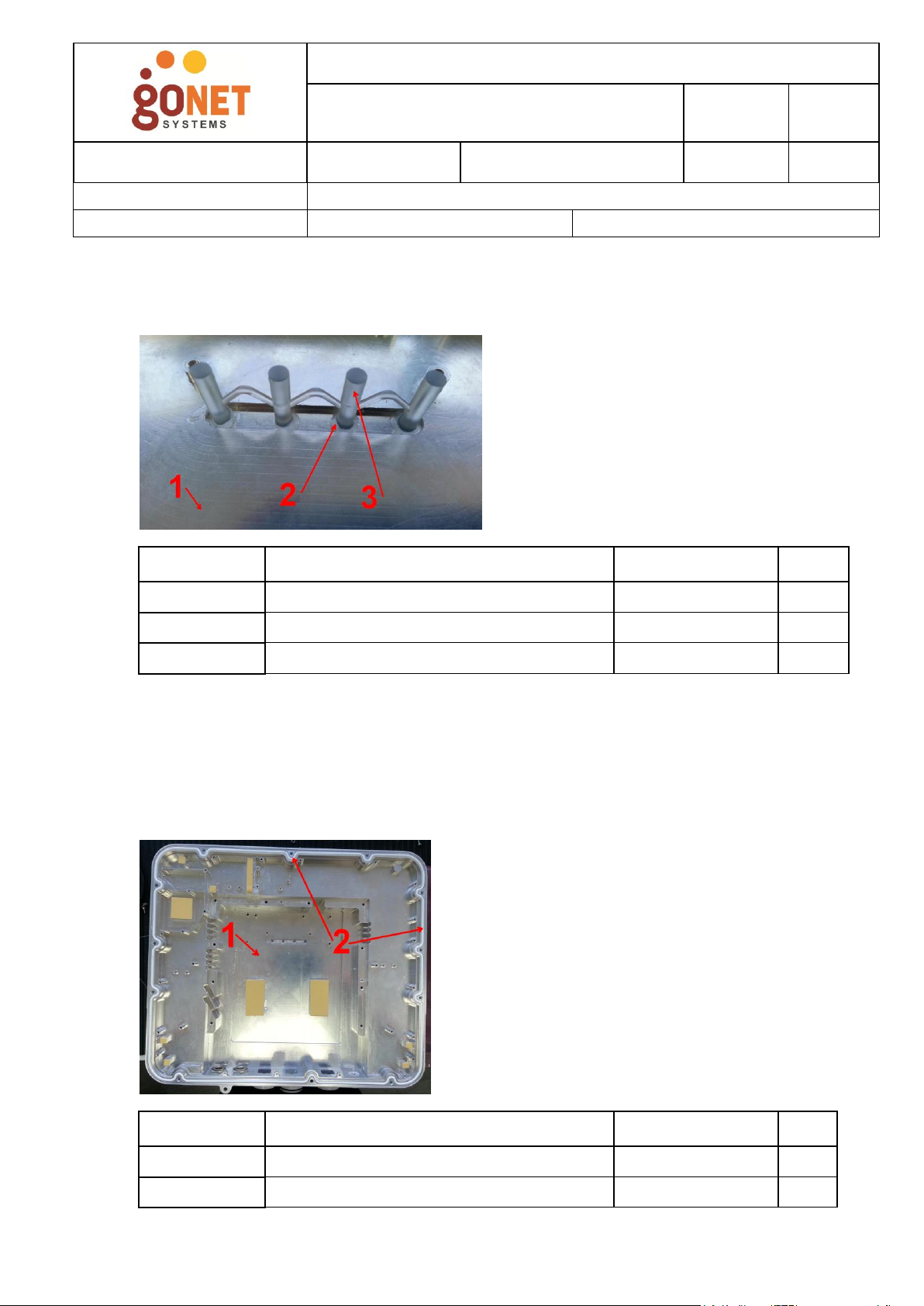

Item

Description

Part No

QTY

1

Base

MC000471

1

2

O-Ring

MC000495

1

4.2. Light pipes

4.2.1. Paste the light pipes (item 3) to the item 1 by item 2 without holes

between body and light pipes.

4.3. Sealing Gasket.

Fit the Sealing Gasket (item 2) into the Body’s groove after previously applying

Grease MS000008.

Ensure that the gasket seats proper along the groove and any of its particles do

not get out.

Loading...

Loading...