INDEX

to

GENERAL INFORMATiON

2.0 SPECIFICATIONS

3.0 SET-UP

4.0 OPERATING PROCEDURE

5.0 OPERATING PRINCIPLE

6.0 MAINTENANCE AND SERVICE

7.0 ILLUSTRATIONS

8.0

TROUBLESHOOTING

9.0 REPLACEMENT PARTS

LIST

1.0 GENERAL

1.1 Purpose:

Gomco

suction for specialized

and fistula drainage following prostatectomy. The suction system includes two preset

drainage levels of 90mm and 120mm of mercury vacuum.

1.2

Features — Model

Supplied

1. One (1) 1200 ml glass collection container

2.

One (1) wire formed

3.

Bacteria

4.

One disposable tubing

5.

Compact

1.2.1

Overflow

INFORMATION:

Models 270 and 2701 are portable drainage pumps designed to assure gentle

uses

as gastric lavage, abdominal decompression, doudenal

270:

with

model 270 as standard equipment are:

with

overflow protection cap

assembly.

bottle

filter

to prevent fluid and aerosol contamination.

PVC

tubing.

case

with

lighted selector switch, pump cycle

plug.

Protection:

The 1200 ml coiiection

and

float

assembly (See

predetermined

cap

and float.

level,

the vacuum supply to the collection

holder.

pacltage

bottle

assembly supplied

Illustration

containing 2-six

No. 4). When collected patient fluids reach a

foot

iengths of clear flexible

light

and hospital grade

with

this pump includes a cap

bottle

is shut off by the

1.2.2

Bacteria

The high efficiency bacteria

aerosoi

hydrophobic, microporous membrane which filters air

(0.3 micron particles in air), while

aerosoi

pump contamination in the

overflow from reaching the pump.

1.3

Features — iViodel

Supplied

1. One 1100 ml disposable collection container

2.

One wire formed container holder.

3.

Bacteria

4.

One disposable tubing

5.

Compact

1.3.1

with

PVC

tubing.

plug.

Overfiow

The 1100 ml disposable collection container supplied

multi-stage

(acts as overflow protection), (2) giass prefilter allows

laser/electrocautery

Fiiter:

filter

is custom engineered to prevent fluid and

contamination of portable suction

blocl^ing

contaminants. The Gomco high efficiency

case

of canister overflow as it helps prevent the

2701:

modei 2701 as standard equipment are:

filter.

case

with

lighted selector switch, pump cycle

protection:

filter

(1) hydrophobic membrane stops flow of aqueous solutions

applications.

paci<age

containing 2-six

units.

the

floW

with

This

filter

features a

with

maximum efficiency

of aqueous fluids and

fiiter

protects against suction

overflow protection cap.

foot

lengths of clear flexible

light

and hospita! grade

with

this pump includes a

filter

to handle most

1.3.2

Bacteria

Fiiter:

The high efficiency bacteria

aerosol

hydrophobic, microporous membrane which filters air

(0.3 micron particles in air), while

aerosol

pump contamination in the

overfiov\(

contamination of portable suction units. This

contaminants. The Gomco high efficiency

from reaching the pump.

filter

is custom engineered to prevent fluid and

bloci^ing

case

of canister overflow as it helps prevent the

'"\

the flow of aqueous

filter

filter

features a

with

maximum efficiency

flujds

protects against suction

and

2.0 SPECIFICATIONS:

2.1 Vacuum:

* At 90mm setting: 90mm to 99mm Hg.

at 120mm setting: 120mm to 132mm Hg.

2.2

Flow

Rate

(Air):

At 90mm setting: .25 iiters/minute

At 120mm setting: .30 liters/minute

2.3 Electrical

115

volts 50/60 Hz. (1.5 amps max.)

230 volts 50/60 Hz. (1.3 amps max.)

2.4 Pump Cylinder:

155

to 160

2.5 Dimensions:

Case

Only - (D) 8" x (w) 8" x (H) 7"

2.6

2.7

*

NOTE;

Overall

Weight:

Shipping

Net - 10 pounds

Duty:

Continuous

Vacuum should be measured after the pump has been running for 15 minutes to normalize the

pump cylinder temperature.

-(D) 8" x

Requirements:

OHMS

-15

resistance

(V\/)

pounds

11" x (H) 7"

3.0 SET-UP:

3.1 Collection

(See

Illustration No. 4)

1. Check the bottie top edges for nicks. If the bottle top is nicked, it will not

2.

Check

3.

Check

4.

Screw the cover assembly securely onto the bottle, making sure

5.

Place

6. Connect one length of tubing, enclosed in the tubing package, to the bacteria

7. Connect the other length of tubing to the long bent metal tube of the cap

3.2 Collection

1.

Make sure

2.

Place

3.

Place

4.

Connect one length of

5.

Connect't'he

Bottle

seals.

filter

pump".

assembly.

Bottle

to snap lid to bottle.

filter

Assembly — Glass

that

the cap gasket Is properly positioned inside the cover.

that

the float moves freely.

the bottle assembly into the wire form bottle holder.

and to the vertical

Assembly — DCU:

filter

shut-off is in place in under side of lid.

bottle on a

bottle into wire form bottle holder.

and to the vertical

flat

other length of tubing to the elbow

fitting

surface and lay cap assembly on bottle.

tubing.-enclosed

fitting

Bottle:

on the bottle cap and float assembiy marked "to

in the tubing package, to the bacteria

of the cap marked vacuum.

marked

that

Push

"patient".

seal.

the gasket

down on cap

4.0 OPERATING PROCEDURE:

{See Illustration No. 3)

1.

Tiie

2.

Plug

3.

Be sure the collection bottle is assembled properly, see

4.

Push

5.

During operation, the amber "pump

6. Prior to using your pump on a patient, insure the vacuum by submerging the end of the

7. The pump is now ready for use.

8. During patient use, the level of the collected contents within the collection bottle

selector switcli stiouid be in the center "off" position.

the line cord into a grounded electrical outlet, making sure

voltage as indicated on the

ing from the bottle to the bacteria

the selector switch on the

120mm Hg and down for 90mm Hg. The red light within the switch will remain lit in-

dicating the

intermittent

vacuum

patient tube into a container of water. Aspiration of water into the collection bottle

should

should

unit

is on.

pumping action. After four or five minutes of operation, the selected

levei will be reached.

be noticed.

be frequently checked and emptied.

unit

nameplate.

filter

front

3,0,

is dry.

control panel to the desired vacuum range, up for

cycle"

lamp will blink intermittently to indicate the

and

that

it is the same

that

the length of tub-

5.0 OPERATING

The

mild negative pressure of this

within an airtight cylinder. The expansion and contraction of the air in the cylinder is

trolled by pressure and suction valves and a solid state timing device to produce a mild

tion. Contained within the air

resistance

of 2 to 3.5

timer. The resistance wire heats the air within the cylinder and expanded air is expelled into

atmosphere through the pressure (check) valve. The amber pump cycle lamp in the

trol

panel (See Illustration No. 3) is lit during this time. During the "off" time, voltage to the

heating element is interrupted by the solid state timer for a period of 19 to 22

pressure

contracts causing a partial vacuum which opens the suction (check) valve. Air from within the

collection bottle is drawn into the cylinder to

pump cycle lamp in the

6.0

IVIAINTENANCE

6.1 Pump:

valve

The

event flooding of the pump occurs, the element in the pump cylinder and the valves will

need

control circuit.

PRINCIPLE:

unit

is induced by the expansion and contraction of air

tight

pump cylinder is a heating element wound

wire. During the "on" time 120 volts is applied to the heating element for a period

seconds,

depending upon the selected vacuum range, controlled by the solid state

closes

during this period and the remaining air. within the cylinder cools and

fill

the vacuum. During this "off" time, the amber

front

control panel remains off and this is when suction actually occurs.

with

a

front

seconds.

AND SERVICE

pump of this

replacing. Attempting to continue to run a flooded pump may cause damage to the

unit

has no moving parts and therefore requires no maintenance. In the

con-

suc-

con-

The

6.2 Pump Cylinder

1. Disconnect the

2.

Remove the

3.

Disconnect the valve and manifold assembly from the cylinder tubing connector.

4.

Remove the power cord ground wire from the

5.

Remove the cylinder ground wire from the ground screw.

6. Remove the

7. Unsolder the two cylmder wires at the cylinder cover terminals

8.

Install the new cylinder in reverse order.

Replacement:

unit

from Its power source.

case

top cover by removing the four self tapping screws.

two

cylinder mounting screws from the bottom side of the

case

ground screw.

anjd

case.

remove.

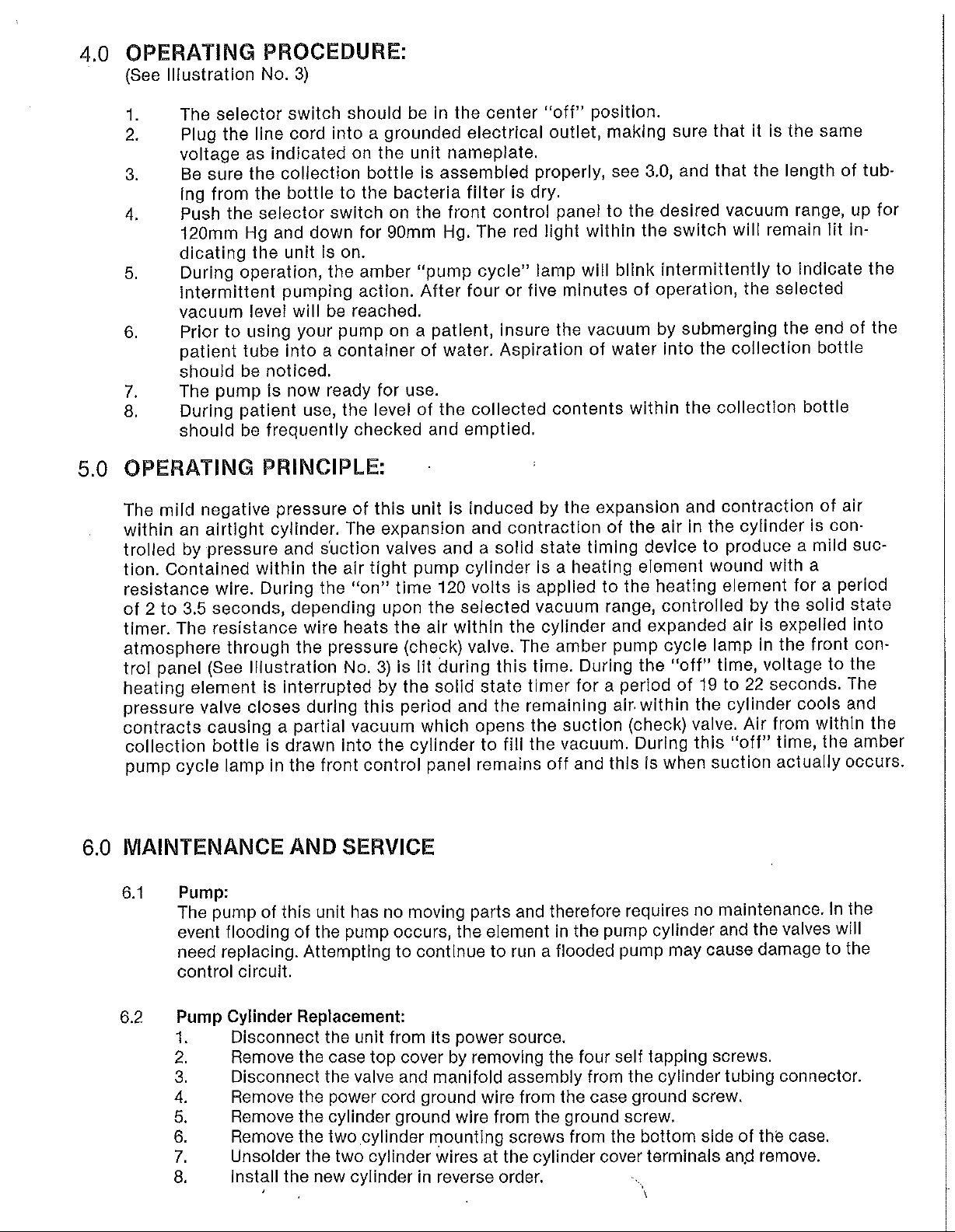

Air

Tight

Cylinder

To Atmosphere

Pressure (Check)

Valve

Suction (Check)

Valve

Bacteria Filter

SUCTION

SYSTEM

Collection

Bottle

6.2.1

Element

Replacement

1. Remove pump cylinder as described

2.

Remove the six slotted head machine screws fastening the cylinder cover to the

cylinder.

3.

Tap the edge of the pump cover

4.

Lift the cover off

5.

Remove the two eiement leads running

them from the top side of the cover. Pry-up the two small tabs securing the wire

to the terminals. The center terminal holes should be clear of solder.

6. Loosen the hex nut locking the element rod to the cover and unscrew the element

from the cover.

7. Screw the new element into cover center hole approximately flush

surface

8.

Pass

the small terminal tabs and bend both tabs down to secure the wires. Solder the

two leads and solder closed the center terminal holes.

9.

Check resistance to make sure of proper contact — 155 to 160

10.

Piace

sealant

prevent any leaks.

11.

Insert the element into the cylinder and place the cover onto the cylinder while

aligning screw holes. Replace the six cover mounting screws and tighten. Note —

care

damage

12.

Install cylinder as described in pump cylinder

of the cover. Tighten the element lock nut against cover.

the two element leads

gasket to the seal surface of the cylinder. Apply a small drop of RTV

on top side of the cylinder cover at the center element rod hole to

must be taken when handling the element and cover assembly to prevent

to the fragile element.

(See Illustration No. 6)

In

with

a piastic mallet to break it free.

with

heating element attached.

thru

the cover terminals and wind each lead around

6.2.

thru

the cover terminals by unsoldering

with

OHMS.

replacement—6.2.

the top

6.3 Suction and Pressure Valves:

The

check valves used in this

(See

Illustration No. 8)

6.3.1 Suction and Pressure

6.4

Bacteria

The

of the air flow rate is noticed. It must be replaced in the event fluids have entered it, such

as

1. Disconnect the

2.

Remove the

3.

Disconnect the white silicone rubber tubing from the pump cylinder tubing

connector.

4.

Disconnect the rubber tubing from the suction valve.

5.

Unscrew both valves from the valve manifold.

6. Lightly lubricate the threads of the new valves

equivalent and screw the valves into the manifold.

when replacing valves to prevent thread damage due to cross threading and

overtightening. Valves should only be installed finger

7. Install the valve and manifold assembly in reverse order.

Filter:

bacteria

in collection bottle overflow.

filter

should be replaced after one month of patient use or when a reduction

unit

case

unit

are factory

Valve

top cover by removing the four self tapping screws.

Replacement:

from its power source.

sealed,

therefore require no maintenance

with

petroleum jelly or

Note:

Care

tight.

must be taken

6.4.1

Bacteria

Filler

Repiacement:

1. Unscrew the

No.

1 or No. 2) by hand turning in a

2.

Screw a new

clockwise

Note:

Care

damage due to cross threading and overtightening.

filter

from the vacuum and

counter-cloci<wise

filter

into

the vacuum and

direction finger

must be taken when replacing the

tight.

filter

filter

connection (See

direction.

connection by turning in a

filter

to prevent thread

Illustration

6,5 Glass Collection

1. Remove the cap assembly from the bottle.

2.

Dispose of drainage fluids and materials in the bottle.

3.

4.

6.6

Control

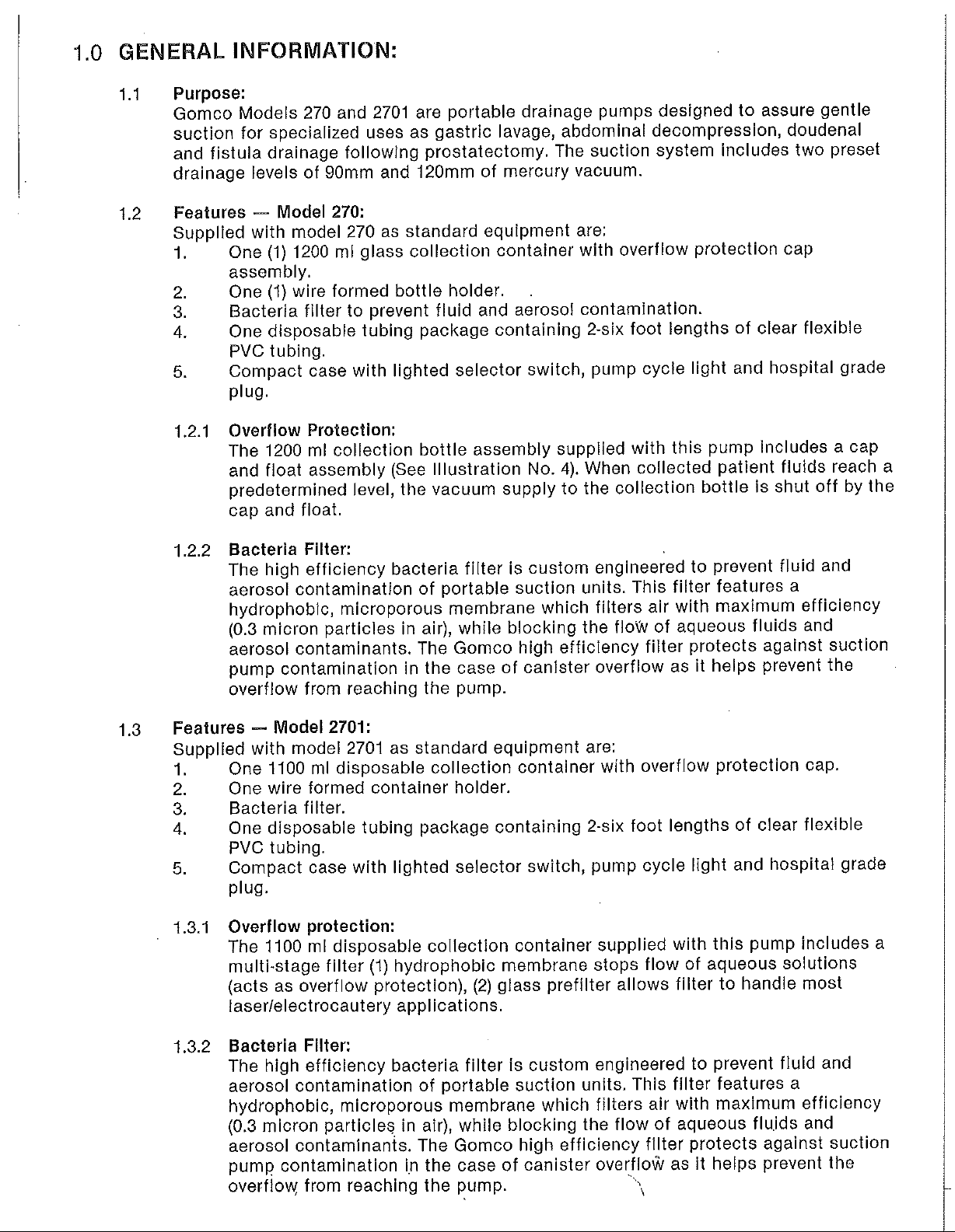

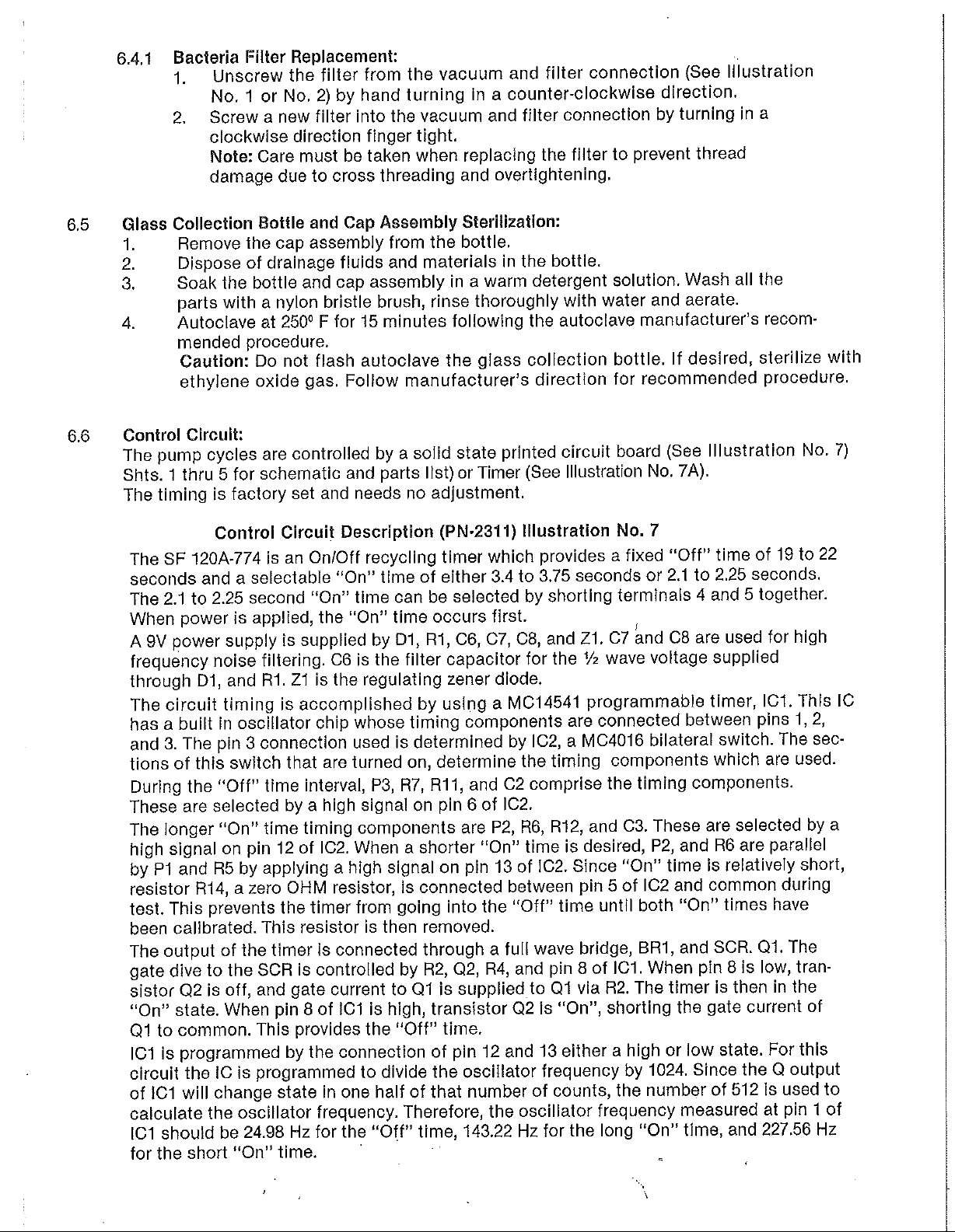

The pump cycles are controlled by a solid state printed circuit board (See

Shts. 1 thru

The timing is factory set and needs no adjustment.

Soak

Autoclave at 250° F for 15 minutes following the autoclave manufacturer's recom-

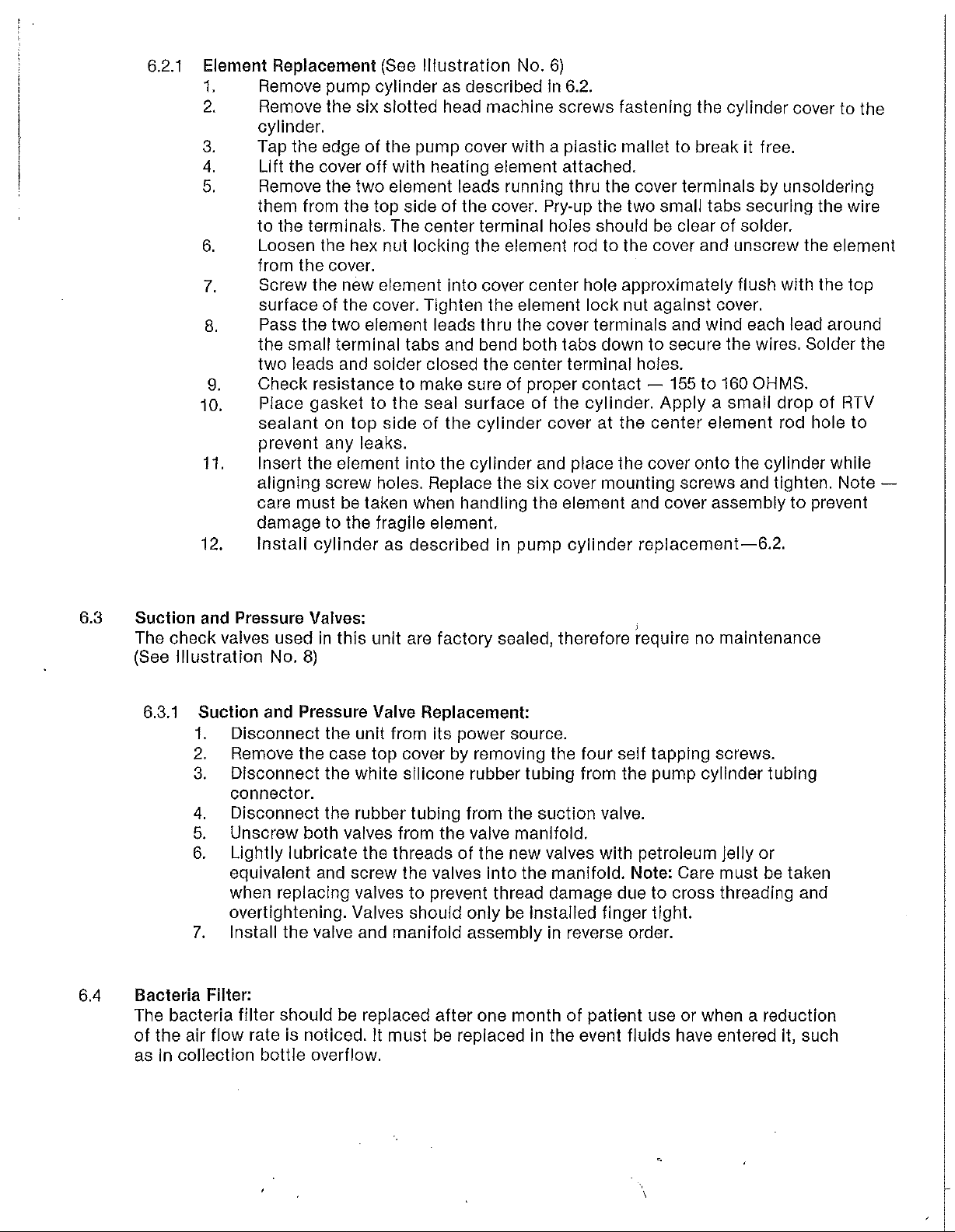

The SF 120A-774 is an On/Off recycling timer which provides a fixed "Off" time of 19 to 22

seconds

The 2.1 to 2.25 second "On" time can be selected by shorting terminals 4 and 5 together.

When power is applied, the "On" time occurs

A

9V power supply is supplied by

frequency noise filtering. C6 is the

through D1, and

The circuit timing is accomplished by using a MC14541 programmable timer, IC1. This IC

has a built

and 3. The pin 3 connection used is determined by

tions of this switch

During the "Off" time interval, P3, R7,

These

The longer "On" time timing components are P2, R6,

high signal on pin 12 of

by P1 and R5 by applying a high signal on pin 13 of

resistor R14, a zero OHM resistor, is connected between pin 5 of IC2 and common during

test. This prevents the timer from going

been

calibrated. This resistor is then removed.

The

output

gate dive to the SCR is controlled by

sistor Q2 is off. and gate current to

"On"

state. When pin 8 of

Ql

to common. This provides the "Off"

IC1 is programmed by the connection of pin 12 and 13 either a high or low state. For this

circuit the IC is programmed to divide the oscillator frequency by 1024.

of 1C1 will change state in one half of

calculate the oscillator frequency. Therefore, the oscillator frequency measured at pin 1 of

ICI

should be 24.98 Hz for the "Off" time, 143.22 Hz for the long "On"

for

the short "On" time.

the

parts

with

mended procedure.

Caution:

ethylene oxide gas. Follow manufacturer's direction for recommended procedure.

Circuit:

5 for schematic and parts

Control

and a selectable "On" time of either 3.4 to 3.75 seconds or 2.1 to 2.25

in oscillator chip whose timing components are connected between pins 1, 2,

are selected by a high signal on pin 6 of

of the timer

Bottle

bottle

a nylon bristle brush, rinse thoroughly

Do not flash autoclave the glass collection bottle. If desired, sterilize

Rl.

and Cap Assembly

and cap assembly in a warm detergent solution. Wash all the

Circuit

Zl

that

Description

Dl,

filter

is the regulating zener diode.

are turned on, determine the timing components which are

102,

When a shorter "On" time is desired, P2, and R6 are parallel

Is

connected through a

Ql

101

is high, transistor

Steriiization:

with

water and aerate.

Illustration

list)

or Timer (See

(PN-2311)

first.

Rl,

C6, C7,

capacitor for the Vz wave voltage supplied

Rll,

and

into

R2.

Q2, R4, and pin 8 of

is supplied to

time.

that

number of counts, the number of 512 is used to

08,

02

102.

the "Off" time

full

Q2

Illustration

Illustration

and

Zl.

102, a MC4016

comprise the timing components.

R12,

and C3. These are selected by a

102.

Since

until

wave bridge, BR1, and SCR.

01

via R2. The timer is then In the

Is

"On", shorting the gate current of

No, 7A).

No. 7

07

and

08

are used for high

bilateral switch. The

"On" time is relatively short,

both "On" times have

ICI.

When pin 8 is low, tran-

Since

time,

the Q

and 227.56 Hz

No. 7)

seconds.

used.

01.

The

output

with

sec-

6.6.1 Control Circuit Specifications:

1. Mode of operation — continuous On-Off recyciing

input terminals. The load is energized during the "On" time period (See Illustration No. 7).

2.

Input

3.

Time Delays —

4.

Load 160

6,6.2

Control Circuit

1. Disconnect the

2.

Remove the

3.

Disconnect all the wires from the P.C. board by pulling off the

4.

Remove the two P.C. board mounting screws from the bottom side of the

5.

Install the new P.C. board in reverse order. (See Illustration No. 1 for wiring

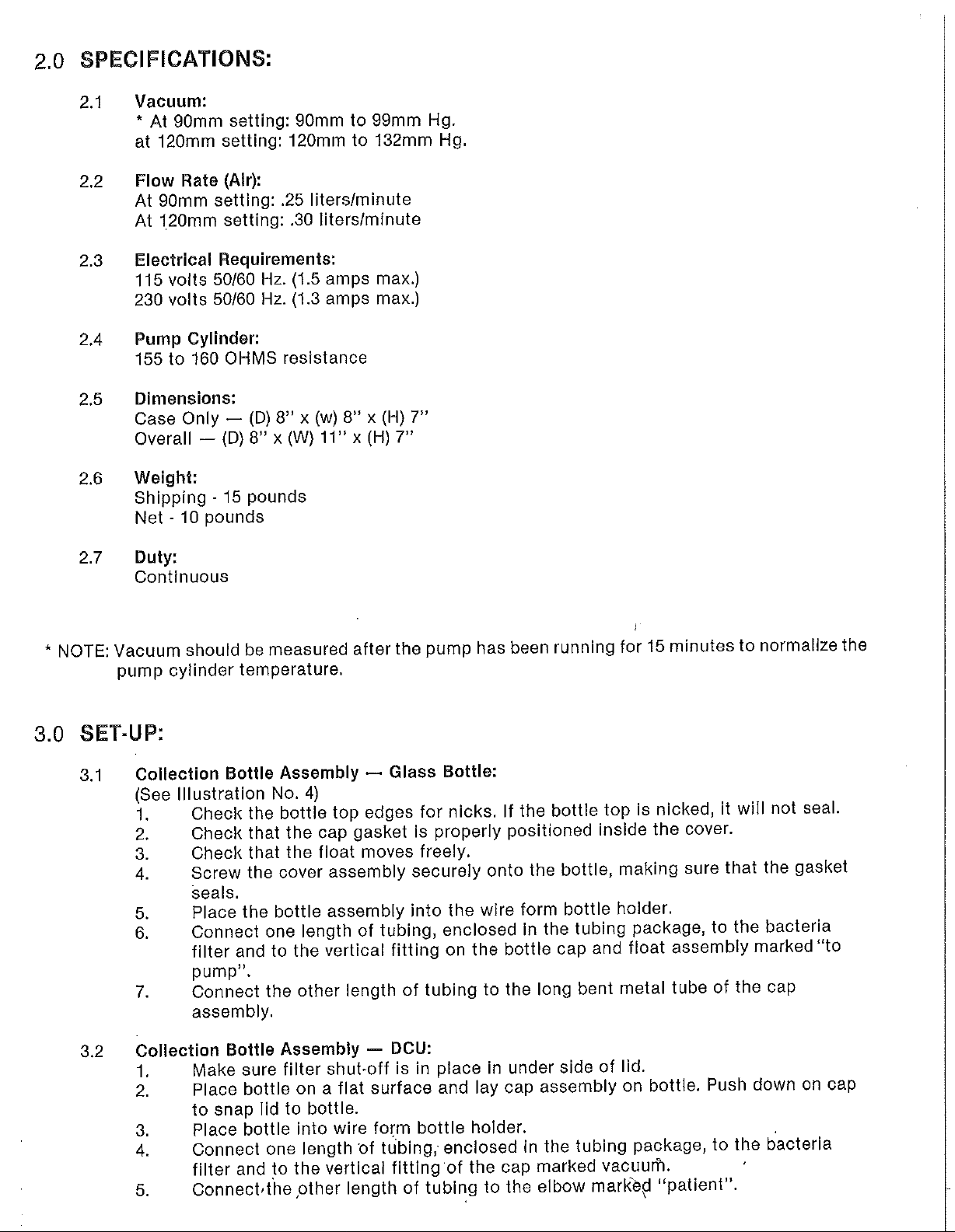

6. NOTE: On 10/18/04 the P.C. board was replaced

voltage — 120 Volts ± 15%, 50/60 Hz.

OHMS

ON

OFF

terminals (Do not

minal).

case.

detail.)

To

install the encapsulated circuit package, install one mounting screw into an existing

mounting hole In the bottom

package

terminals (See Illustrations No. 2 for wiring detail).

resistive.

AT120

TIME

TIME

Replacement:

unit

from its power source.

case

top cover by removing the four self tapping screws.

pull

on wires.

witti

power appiied to the

AT

MM

SETTING

3.4 to 3.75 sec. 2.1 to 2.25 sec.

19

to

22 sec.

Mal^e

sure you have a

side

of the

case,

90 MM

19

connect all wires to the proper circuit

SETTING

to 22 sec.

firm

hold on the ter-

with

a encapsulated circuit

quicl<

connect

pacl<age.

7.0 ILLUSTRATIONS

No. 1 No.

No.

No.

No.

No. 6 -

No. 7 No.

No.

Final Assembly & Wiring Detail

2 - Final Assembly & Wiring Detail

3 - Front

4 - Collection Bottle Assembly

5 - DCU

Pump Cylinder Assembly

Control Circuit (P.C. BD.)

7A - Control Circuit (Timer)

8 - Valve and Manifold Assembly

Panel

Assembly

w/RC.

w/Tlmer

BD.

ILLUSTRATION

NO. 2

I

a

I

Pi"

\

\

'0

\

\

\

\

\

4^

Vi

Vj

V5

K

\

S>rs

1.

X^ooa

OF

OpHRATiOKJ 1 COMTi'-O^JS

IMpJT

z.

ivipoT

Voi.TA<:ie,

2.2.

SF250A-'>74 = 23o

3.

Ti-ie.

Osi-Art

J 1 OFT

Ti»«e.

3.2 OJ

-r-fl&

5F'2*

ft . pi c AT'o

TEBM

MALS.

rXLAiS

r;c.i-A-<i

A-77-4-

nEVI8<ON$

S

Th£

LOAC

AC

•-

sFizsA-774. : 1^

M'^H

I

<*5

ie<:-.*io%

0>0 - OFF

.-^

i^-^C

.5<i/(-o

T.

J-i

T.

z.zS

-O

i.liec.,*'0%,-0

APP.

fli,

zz

atna-iDs

Sec

BV

ILLUSTRATION NO. 7 SHEET

NO.

1

OWN BY

cpS

CMK.

9Y

DATE:

APP

BY

DATE:

SCALE

fJt-U

00

OATE-

MOT

'?.lC-ao

/a

SCALE

DtUENStONS:

I.OK)

FftACTlONS = -A

2 PLACE

3

PLAC^

AMGLES

IN

IN.

TOlERANCES

S

- UW

=

H«0

D£C. = .01 - .25

DEC. I .005 - ,13

T

MM.

TITLE:

SOL

STATE

PART

PdO:

DWQ- I C?

T...ieC5

?>

4.,

W J o O '

UJ

^

O

i(

K

H H

3 U O

S. .

Ul

UJ

UJ

In Q •

O O

UJ UJ

U.

[M

f)

<

o

ff-

lij

<

•

l/l

'3

>

m

If

r

u

M

o

•J

UJ

<

o

U

>•'

to

0.

fl.

<

N.

CO

01

R I V

PAHT

KO:

REVISIONS

•

APP,

BV

ILLUSTRATION

TC

/

Zi-

—

NO, 7

SHEET

NO. 3

DWN.

CMK.

BY:

APP.

APP.

SCALE;

BY:

SfT.

J-'if'*.

BY:

i{.^4

BY:

i{.^4

r\y 1 DO

DATEi'l'l-^-S-'

DATE:

»0T

<}

•^•If-fx^

•^•If-fx^

SCALE

DWG-

DATE.

DATE.

TOLEPIANCES

FE5ACT10NS = t

2

PLACE

oec. = .01

2

PLACE

oec. = .01

2

PLACE

oec. = .01

3

PLACE

DEC. = .CBK

3

PLACE

DEC. = .CBK

3

PLACE

DEC. = .CBK

ANGLES

=

ANGLES

=

ANGLES

=

T

T

T

TtTLE:e\t;CUiT

PAHT

NO

PAHT

NO

DWG. I OF

DWG. I OF

1

1

B

^

BILL

OF

MATERIALS

REF NO

BRl

Cl

C2

C5

C4

C5

C6

C7,C8

Dl

ICI

IC2

QTY,

1

1

1

1

1

1

1

2

1

•

1

1

BRIDGE

CAPACITOR

CAPACITOR

CAPACITOR

CAPACITOR

CAPACITOR

CAPACITOR

CAPACITOR

RECTIFIER

W04MA

.lufd

.lufd

.Oluf'd

.Olufd

.Olufd

^^uf-d

.00lufd

DIODE

250

250

25

1N4001|

INTEGRATED CIRCUT

INTEGRATED CIRCUT

DESCRIPTION

VDC

VDC

250

VDC

250

VDC

250

VDC

VDC MSR

500

MC

MC

VDC

l45Hl

l40l6

B

B

Pl

P2

P3

Ql

Q2

Rl

R2

R5

r4

R5

r6

R7

r8

1

1

1

1

1

1

1

1

1

1

1

1

1

TRIMPOT

TRIMPOT

TRIMPOT

SCR

TRANSISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR 270K

RESISTOR 120K

RESISTOR

1 MEG. OHM

lOOK

lOOK

C 106 D

2^15172

22K

lOK

4.7K

27IC

47K

27K

'

OHM

OHM

OHM

1^2

WATT

OHM i WATT

OHM ^ V7ATT

OHM h WATT

OHM ^ WATT

OHM ^ WATT

OHM ^ WATT

OHM i WATT

R9

1

RESISTOR

lOKOHM i WATT

iL|„USTRATiON

NO. 7 SHEET

4

REF

RIO

NO

QTY.

1

BILL

RESISTOR

OF

33K

MATERIALS

DESCRIPTION

OHM i WATT

Rll

R12

R13

Rll|

R15,16,17

1

1

1

I

1

1

5

1

1

3

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

ZENER

PRINTED CIRCUT

i

IN. TERMINAL

COVER

LABEL

SPACER

390K

390K

27K

0 OHM i WATT

0 OHM f WATT

9V

1N5239B

OHM i WATT

OHM i WATT

OHM J WATT

BOARD

ILLUSTRATION

NO. 7 SHEET

5

2.0

2311-1

INPUT

120

3

VAC

2

L_.^

;._J

1

REV.

ITR.

REVISIONS

E.C.O.

NUMBER

DATE

OCP

4i.

F3

BY

-

2.0

1.2

us

07CB13S

MAX.

3

2

(-)

PATENT

1

00.250

THRU

THS

PRINT

IS

AUJEO

ANO

PRODUCED.

POSED

INDIRECTLY. NOR USED FOR ANY

PURPOSE

FOR

FURNISHED EXCEPT BY

PERMISSION OF ALUEO HEALTHCARE

DRAW

PLOTSCALE:-

THE PROPERTY OF

HEALTHCARE PROOUCTS

SH^

NOT BE

COPIED.RE-

LOANED.OR

OF EITHER DIRECTLY OR

OWER

TMAM

iS

SPEOHCALLY

WRITTEN

1:1

THAT

WHICH

IT

PRODUCTS.

SCALE:

1:1

DIS-

0.25 INCH

uMi£ss

onoviiEE

SPEoreo

25/^

«

\J

B*fl.1

SACHINOX

ajRFACi^

SYUBOLS

PER

Y14.5

EDGES

ANSI

ALL SHARP

.0DS/-ai5

.015 R. WAX.

ALL

BURRS

ORAViINC

STO.

BREAK

nU£TS

REUO^

DO NOT SCALE

us

PAIEMT f CPl]

ri!rt=>-

CONNECTIOM

OlACRAM

MALE

PLACE

LABEL

THE

CUSTOMER

TIME

CURRENT

QUICK

LABEL

IS

CONNECT

AS SHOWN

TO BE

MARKED

TERMINALS

WITH

FOLLOWING INFORMATION:

PART

DELAYS.

NUMBER

VOLTAGE

AND

RATING.

wiEES

otMOnKE

DIUEN30HS

ARC

TOLERANCES

ANCL£S±

XL

.1

-XXt

.02

.m«±

.005

niAcnoNSi

T

atortti

IM

INC»[S

ARE:

1/32"

DRAWN

CHECK

DESIGN

APPROVED

APPROVED

CATALOG

iNlllAL

ft£L£ASt;

SIGNATURE

Vl

NO,

AG

NO.

DATE

01 /05

9847

AND DATE

swwot's

OUAUTY

Oft

PRODUCTS.

APPROVAI.

or

4i£,J

4i£,J

4i£,J

/A

ULLvVL

/A

ULLvVL

/A

ULLvVL

««.i>iii™;i«tiuoni-1

««.i>iii™;i«tiuoni-1

««.i>iii™;i«tiuoni-1

TiTLz

ENCAPSULATED

TiTLz

ENCAPSULATED

GOMCO

GOMCO

3IE

g

3IE

g

SCALE

1:1

(5

PLACES)

CODE

NOTE; ANY CHANCE M MATERIAL

USE

OF

JUd

PARTS UUST

BE

NO

5KPUENI

EUSODWJC

AOIEO

HEALlHCARE PROOUCIS.

Allied

Allied

Allied

SL

Louia

uo

SL

Louia

uo

SL

Louia

uo

PHONE

C31«)

PHONE

C31«)

PHONE

C31«)

T1MER-120V

T1MER-120V

DRAWING

DRAWING

SUBUinCD

SUCH A CHANCE

Healthcare Products,

Healthcare Products,

Healthcare Products,

eino

eino

eino

771-2*00

771-2*00

771-2*00

Na

\

Na

\

REV. NEW

mm

ON AHP

FAX

FAX

FAX

OR

CLOSE

ON

(31*)

(31*)

(31*)

ON

LOW

TWE

DELAYS

PROCESS

BY

THE

PROUPTLY

FOU

iS

TO BE

771-3465

771-3465

771-3465

~\

~\

2/27/98

SHEET 1 OF

AUIOCM)

STSOl

SUPPUEH

WWCM

APPHOVAL

UAOE

AFFECTS

TO ALUED

HEALTOCARC

WITHOUT

PRIOR

WWTTEH

(G;\DE3CNV000\ZJ1l-li)M;)

IKE

Ina

Ina

Ina

1

ILLUSTRATION

NO.

7A

8.0

TROUBLE

SHOOTING

PROBLEM

NO SUCTION BUT PUMP

NO SUCTION BUT PUMP

NO SUCTION BUT PUMP

CYCLING PROPERLY

CYCLING PROPERLY

CYCLING PROPERLY

LOW SUCTION

LOW SUCTION

LOW SUCTION

LOW SUCTION

LOW SUCTION

CYCLE

REMAINS ON

CYCLE

CYCLE

CYCLE

CYCLE

CYCLE

NOT

NOT

NOT

NOT

NOT

LAMP

LAMP DOES

LAMP DOES

LAMP DOES

LAMP DOES

LAMP DOES

COME

COME

COME

COME

COME

ON

ON

ON

ON

ON

PROBABLE

1.

SUCTION OR PRESSURE

VALVE BAD.

2. LOOSE OR OPEN

TUBING CONNECTION

3. COLLECTION BOTTLE

TOP LEAKING

1. SUCTION OR PRESSURE

VALVE LEAKING

2. LOOSE TUBING

CONNECTION

3. COLLECTION BOTTLE

TOP LEAKING

4. HEATING ELEMENT

SHORTENED OR

BURNED

5. CONTROL CIRCUIT

MALFUNCTIONING

1. CONTROL CIRCUIT

BURNED OUT

1. CYCLE LAMP BURNED

2. CONTROL CIRCUIT

BURNED OUT

3. POWER SOURCE BAD

4. SELECTOR SWITCH BAD

5.

V\/IRING

CAUSES

INCORRECT

REMEDY

REPLACE,

CHECK

CONNECTIONS

CHECK

3.0

REPLACE,

CHECK

CONNECTIONS

CHECK

3.0

SEE

SPECS.

SEE

SEE

REPLACE

SEE

CHECK

REPLACE

CHECK

(SEE ILL. NO. 1 OR NO. 2)

SEE 6.3.1

ALL

SET

UP-SEE

SEE 6.3.1

ALL

SET

UP-SEE

- 2.4

SPECS.

SPECS. — 6.6.1

SPECS — 6.6.1

- 6.6.1

POWER OUTLET

WIRING

.0

lil No.

01-90-3451

Cylinder

Cover

Element

Elbow

Gasket

01-90-3477

Pressure

Suction Valve

Manifoid

Silicone

Suction Valve Tube

01-90-3489

1200 ML

Cap

01-90-3487

Cap

Cap

Float Gasket

Float Assembiy

Assembly

(Fitting)

Valve

Cylinder Tube

Bottle

and Float Assembly

(Includes

Gasket

{6/Gase)

Gasket)

(Only)

Pump

Cylinder

Valve

1200

Bottle

Cap and

Assembly

01-90-2715

01-90-3449

01-90-2713

01-90-3450

01-90-3731

and

Manifold

Assembly

01-90-3432

01-90-3433

01-90-2722

01-90-3475

01-90-3476

ML

Collection

Assembly

01-90-3497

01-90-3487

Float

01-90-2393

01-90-2394

01-90-2395

01-90-3486

Assembly

6

6

6

6

6

6

8

8

8

8

8

8

4

4

4

4

4

4

4

4

01-90-2986

01-90-3478

01 -90-3403

01-90-3400

01-90-2271

01-90-2270 Handle Spacer

01-90-2309 Switch

01-90-2310 Cycle Lamp

01-90-2311-1 Timer

01-90-2312-1 Timer (230 v)

01-90-3100 Bacteria Filter Package

01-90-3491

01-90-2737 Power Cord Assembly

01

-90-3109

01-90-3443

01-90-3479 Vacuum and Filter

01-90-3480

01-90-2345 Rubber Foot

01-90-3695

01-90-3696 1100

Case

Case

Case

Case

Handie

Tubing Package

Power Cord Assembly

Bottle

Elbow

1100

Top Cover

Bottom

Rear Panel

Front Panel

(115

v)

(3 each)

(2 each, 6 ft.)

(115v)

(230v)

Holder

Connection

(Fitting

ML DCU 12/Case

fVlL

for 3479)

DCU 46/Case

1-2

1-2

1-2

3

1-2

1-2

3

3

7A

7A

1-2

Not Shown

1-2

1-2

1-2

1-2

1-2

1-2

5

5

Loading...

Loading...