Page 1

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 1-

5007090-00

BA-E

®

Tile cutting machine

TS 200 / TS 250

ZN der Bedienungsanleitung: 5007090-00

Erstellt am: 05 / 2014

Erstellt von: Sabrina Linden

Datei: K:\KDV\5007xxx\5007090-Bedienungsanleitung\

5007090-00-Bedienungsanleitung-E.doc

GÖLZ® GmbH

Dommersbach 51

D-53940 Hellenthal

Telefon: +49 (0) 2482 12 200 / Telefax: +49 (0) 2482 12 222

E-Mail: info@goelz.de / Internet: www.goelz.de

Page 2

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 2-

5007090-00

BA-E

®

Page 3

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 3-

5007090-00

BA-E

®

All rights reserved according to DIN ISO 16016.

No part of this document (instruction manual and spare parts list) may be reproduced, adapted,

transmitted, transcribed, stored on a data medium or be translated into another language without prior

written approval of

GÖLZ® GmbH

Dommersbach 51

D-53940 Hellenthal

Guarantee

We reserve the right to amend any information included in this document (manual instruction and

spare parts list) at any time and without prior notice.

GÖLZ® assumes no warranty for these documents.

GÖLZ® shall not be liable for errors in this document (manual instruction and spare parts list) or for any

collateral or consequential damage in connection with shipment, performance or use of the material.

Page 4

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 4-

5007090-00

BA-E

®

EC-DECLARATION OF CONFORMITY

Manufacturer

GÖLZ® GmbH

Dommersbach 51, D-53940 Hellenthal

Tel.: +49 (0) 2482 12 200 / Fax: +49 (0) 2482 12 222

Declare hereby certifies on its sole responsibility that the following product:

TS200 / TS250

Tile cutting machine

Serial number:____________________

which is explicitly referred to by this declaration meet the following directives:

2006/42/EG Safety and health requirement

2004/108/EG Electromagnetic compatibility

2006/95/EG Low Voltage Directive

meet the following standards:

EN 12418

Documented evidence conforming to the requirements of the directives is kept available for inspection

at the above manufacturer’s address.

Hellenthal, den 06.05.2014 …………………………………

General Manager

Page 5

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 5-

5007090-00

BA-E

®

Contents

Preface ....................................................................................................................... 7

Warning signs and symbols .................................................................................... 7

1.

Technical data and accessory ...................................................................... 8

1.1 Technical data of the machine...................................................................... 8

1.2 Provided accessory ...................................................................................... 8

2.

Description ..................................................................................................... 9

2.1 Main parts .................................................................................................... 9

3.

Basic safety instructions ............................................................................ 10

3.1 Intended use............................................................................................... 10

3.2 Operating range ......................................................................................... 10

3.3 Organisational measures ........................................................................... 11

3.4 Selection and qualification of person .......................................................... 12

3.5 Safety instructions governing specific operational phases ......................... 12

3.6 Special work related to the maintenance and repair of the machine .......... 13

3.7 Information about special risks with electrical energy ................................. 14

3.8 Gas, dust, steam, smoke ............................................................................ 14

3.9 Noise .......................................................................................................... 14

3.10 Illumination ................................................................................................. 15

3.11 Oils, greases and other chemical substances ............................................ 15

3.12 Transport .................................................................................................... 15

3.13 Store ........................................................................................................... 16

4.

Bringing into service ................................................................................... 17

4.1 Export checking .......................................................................................... 17

4.2 Assembling ................................................................................................. 17

4.3 Engine ........................................................................................................ 18

4.4 Setting up the machine ............................................................................... 18

4.5 Mounting / changing the blade ................................................................... 18

4.6 Electrical connections ................................................................................. 20

5.

Operation ...................................................................................................... 21

5.1 Before starting the machine ....................................................................... 21

5.2 Starting the machine .................................................................................. 21

5.3 Cutting operation ........................................................................................ 21

5.3.1

Cutting method: Fixed depth cutting ............................................................................ 22

5.3.2

Cutting method: Free depth cutting for multiple steps cutting ..................................... 24

5.3.3

Cutting method: 45° bevel cuts ................................................................................... 25

5.4 Stop cutting operation ................................................................................ 28

5.5 Changing the blade .................................................................................... 28

Page 6

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 6-

5007090-00

BA-E

®

6.

Maintenance and care ................................................................................. 29

6.1 Machine ...................................................................................................... 29

6.2 Blade .......................................................................................................... 29

7.

Troubleshooting ........................................................................................... 30

8.

Spare parts list ............................................................................................. 31

8.1 Using the spare parts list ............................................................................ 31

8.1.1

Safety regulation .......................................................................................................... 31

8.1.2

Ordering information .................................................................................................... 31

8.1.3

Distribution agencies ................................................................................................... 32

8.2 Wearing parts ............................................................................................. 33

9.

Exploded view and spare parts list ............................................................ 34

9.1 Machine ...................................................................................................... 34

9.2 Frame ......................................................................................................... 36

9.3 Cutter head ................................................................................................ 38

9.3.1

Cutter head bracket ..................................................................................................... 42

9.3.2

Engine ......................................................................................................................... 43

9.3.3

Blade guard ................................................................................................................. 44

9.4 Guiding rail ................................................................................................. 46

9.5 Transport wheel .......................................................................................... 48

9.6 Back square ............................................................................................... 49

9.7 Water tank .................................................................................................. 50

9.7.1

Stopple with rope ......................................................................................................... 51

9.8 Main pillar ................................................................................................... 52

9.9 Extension table ........................................................................................... 53

9.10 Transport handle ........................................................................................ 54

10. Wiring diagram ............................................................................................. 55

Page 7

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 7-

5007090-00

BA-E

®

Preface

This operating manual is designed to familiarize the user with the masonry bench saw, hereinafter

referred to as the machine, and to use its intended applications.

The operating manual contains important information on how to operate the machine safely, properly

and most efficiently. Observing these instructions helps to avoid danger, to reduce repair costs and

downtimes and to increase the reliability and the life of the machine.

This operating manual is to be supplemented by the respective national rules and regulations for

accident prevention and environmental protection.

The operating manual must always be available wherever the machine is in use.

It is to be read and applied by any person in charge of work with or on the machine, such as:

• Operation including setting up, troubleshooting in the course of work, elimination of

manufacturing waste, care and disposal of fuels and consumables.

• Servicing (maintenance, inspection, repair) and/or

• Transport

In addition to the operating manual and to the mandatory rules and regulations for accident

prevention of the country and place of use of the machine, the recognized technical rules for safe and

proper working conditions and procedures are also to be observed.

In this manual all the information required for the intended use of the unit is included. If though you

have any specific questions, please refer to your representative, to one of our sales representatives or

directly to us:

GÖLZ® GmbH

Dommersbach 51, D-53940 Hellenthal

Telefon: +49 (0) 2482 12 200 / Telefax: +49 (0) 2482 12 222

E-Mail: info@goelz.de / Internet: www.goelz.de

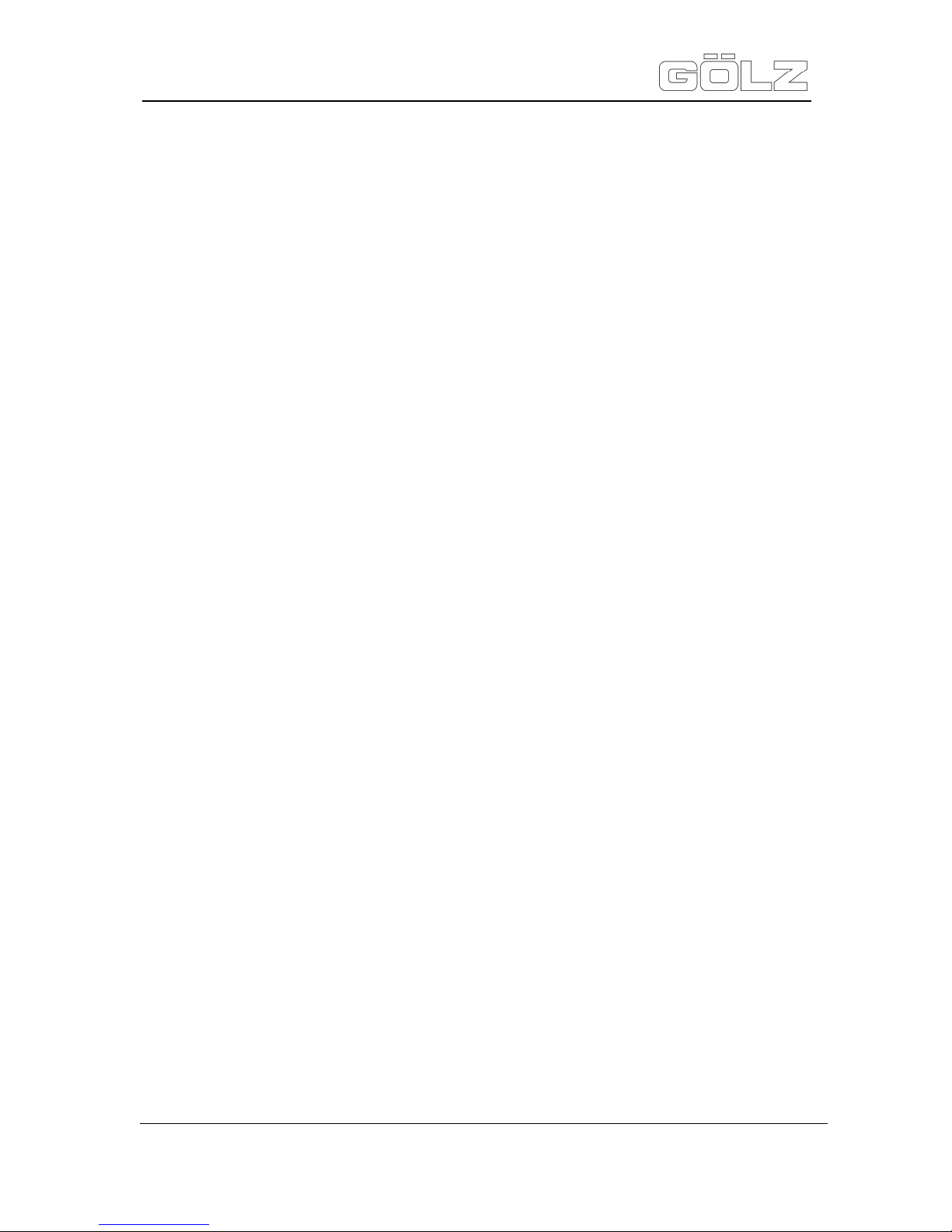

Warning signs and symbols

Wear safety glasses!

Wear hard hat!

Wear ear muffs!

Wear safety boots!

Wear safety clothes!

Wear protective gloves!

Read owner’s manual

before first initiation!

Important advice!

Danger exists to cut oneself!

General danger!

Wear dust protection!

Never touch!

Page 8

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 8-

5007090-00

BA-E

®

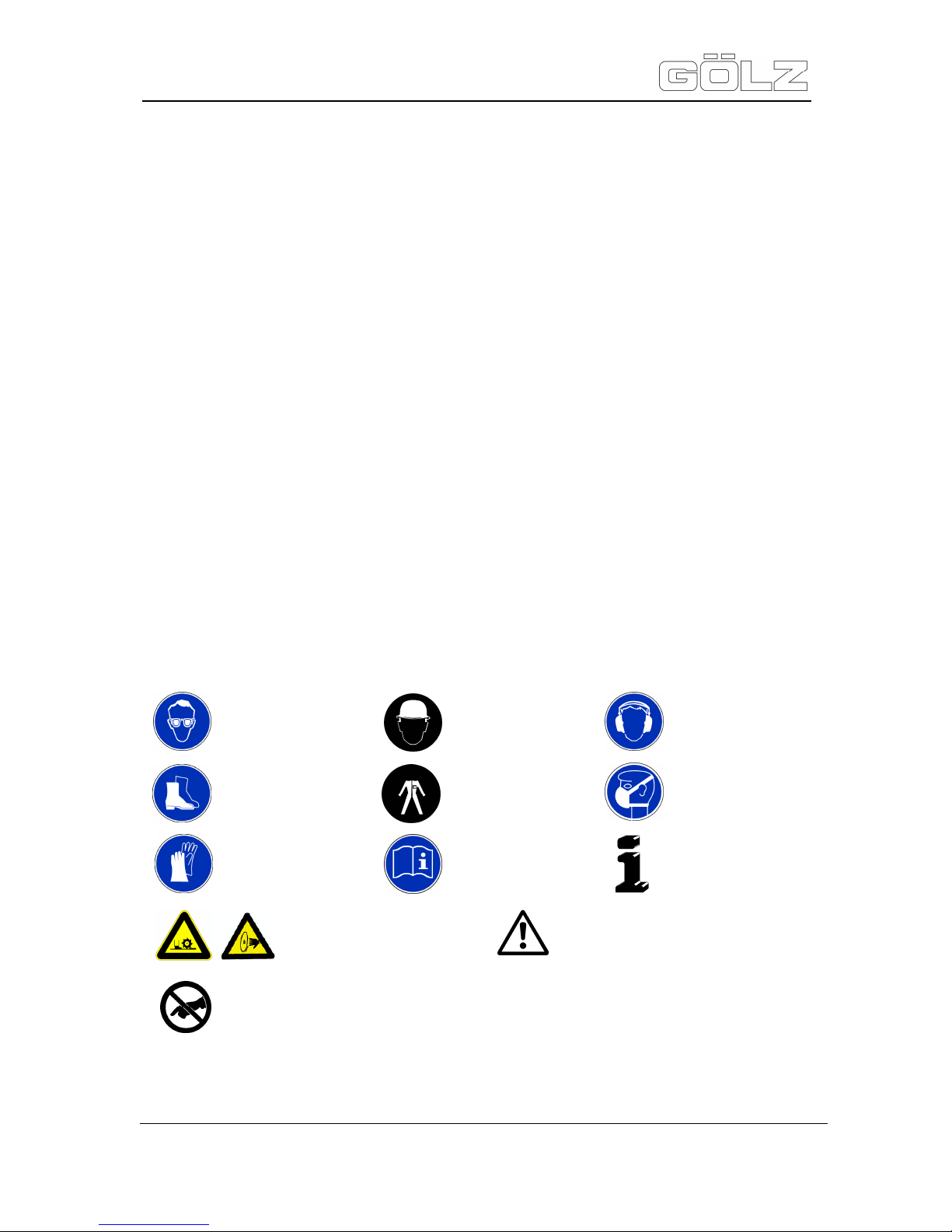

1. Technical data and accessory

1.1 Technical data of the machine

Type TS 200 TS 250

Max. cutting depth 40 mm - 1,6 in. 65 mm - 2,6 in.

Max. cutting length 720 mm - 28,3 in. 1000 mm - 3,9 in.

Blade shaft size 25,4 - 1 in.

Max. blade-Ø 200 mm – 7,9 in. 250 - 9,8 in.

Engine

Electric Engine

1,3 kW, 230 V, 50 Hz IP54, P1

Speed 2800 rpm

Water supply tank 20 l

Dimensions (L x B x H)

1000 x 520 x 1250 mm -

3,9 x 20,5 x 49,2 in.

1280 x 520 x 1250 mm -

50,4 x 20,5 x 49,2 in.

Weight 56 kg – 123,2 lbs. 74 – 162,8 lbs.

Sound power level after ISO EN 3744 92 dB(A)

Sound pressure level after ISO EN 11201 80 dB(A)

Vibration 2,3 m/s²

1.2 Provided accessory

• Operating instruction

• Spare parts list

For the item number of accessories, please refer to the current catalogue of GÖLZ®

If accessories are used which do not correspond to GÖLZ® specifications, no liability is assumed for

any damage resulting hereof.

For details regarding the selection of the right GÖLZ® diamond blades, please refer to the current

GÖLZ® catalogue for diamond tools.

Page 9

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 9-

5007090-00

BA-E

®

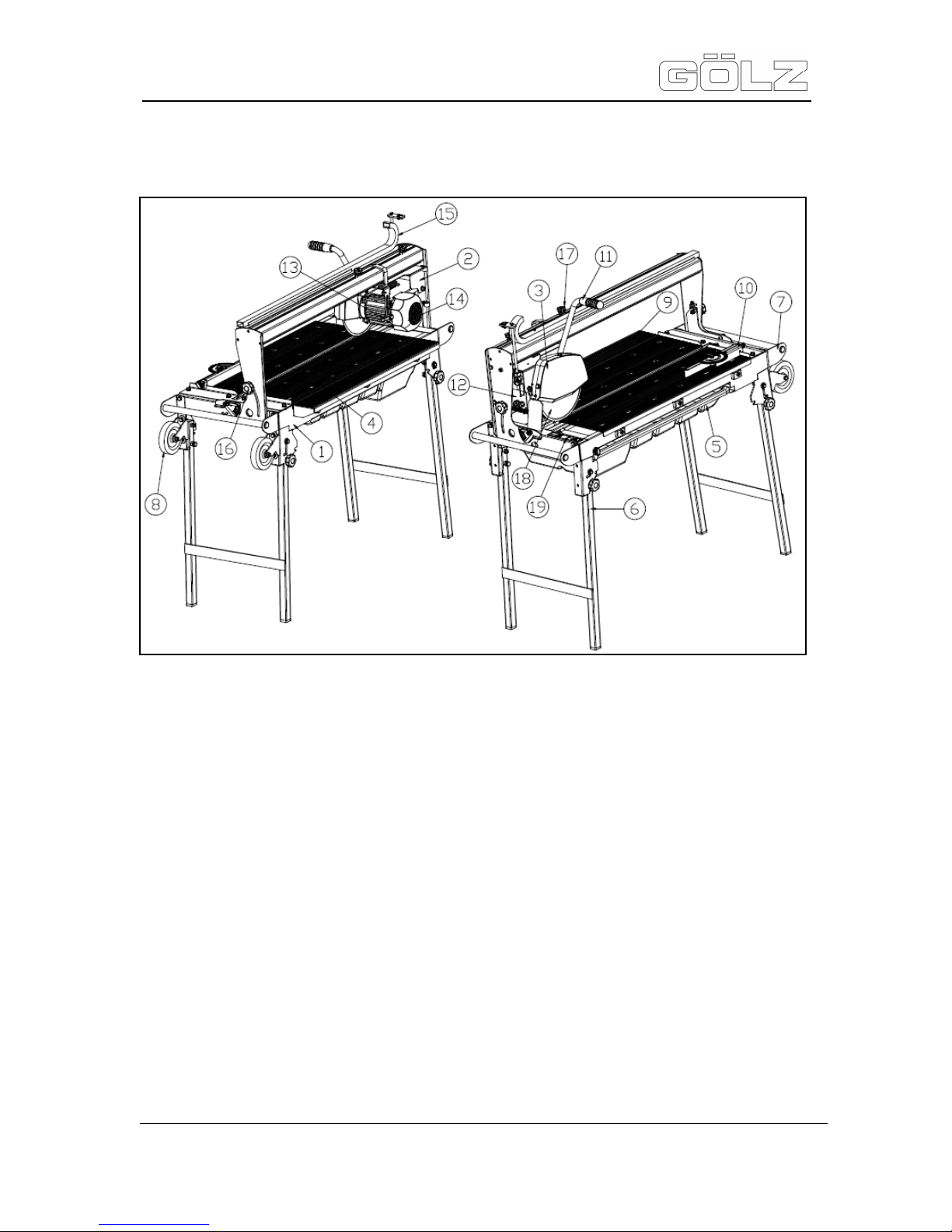

2. Description

2.1 Main parts

1) Frame 8) Transport wheel 15) Cable protector

2) Cutter head 9) Cutting table 16) Adjusting angle grip knob

3) Blade guard 10) Back square 17) Transport lock

4) Extension table 11) Cutter head handle 18) Blade

5) Water tank 12) Switch 19) Machine plate

6) Main pillar 13) Adjusting handle

7) Transport handle 14) Engine

Page 10

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 10-

5007090-00

BA-E

®

Note / Important: Contains important information which stands out from the other

text!

3. Basic safety instructions

In this manual the following terms and symbols are used for particular important information:

Important text passages are highlighted in italics or bold or can be found in a grey highlighted text

field.

3.1 Intended use

The machine has been built in accordance with state-of-the-art standards and the recognized safety

rules. Nevertheless, its use may constitute a risk to life and limb of the user or of third parties, or cause

damage to the machine and to other material property.

The machine must only be used in technical perfect condition in accordance with its designated use

and the instructions set out in the operating manual, and only by safety-conscious persons who are

fully aware of the risks involved in operating the machine. Any functional disorders, especially those

affecting the safety of the machine, should therefore be rectified immediately!

The machine is designed exclusively for cutting in concrete, reinforced concrete, natural stone, cast

stone and brickwork. Using the machine for purposes other than mentioned above (such as cutting in

wood and so on) is considered contrary to its designated use. The GÖLZ® GmbH cannot be held liable

for any damage resulting from such use. The risk of such misuse lies entirely with the user.

Only use gear drives and motors, which are provided by GÖLZ® GmbH. Also attend those operating

manuals.

Operating the machine within the limits of its designated use also involves observing the instructions

set out in the operating manual and complying with the inspection and maintenance directives

3.2 Operating range

The operating range of the unit can be extended due its wide range of accessories allowing easy

retrofitting which can be carried out by the operating personnel themselves.

Do not modify, add components to or retrofit the unit in a way which could affect its safety and do not

use non-official accessories! This is not allowed without prior approval of GÖLZ® GmbH!

Attention: Contains instructions which must be strictly observed to prevent

damage from the unit and the operator!

Attention: Read and observe all the operating instructions which belong to this

unit!

Note: Read and observe the operating instructions to the accessories!

Page 11

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 11-

5007090-00

BA-E

®

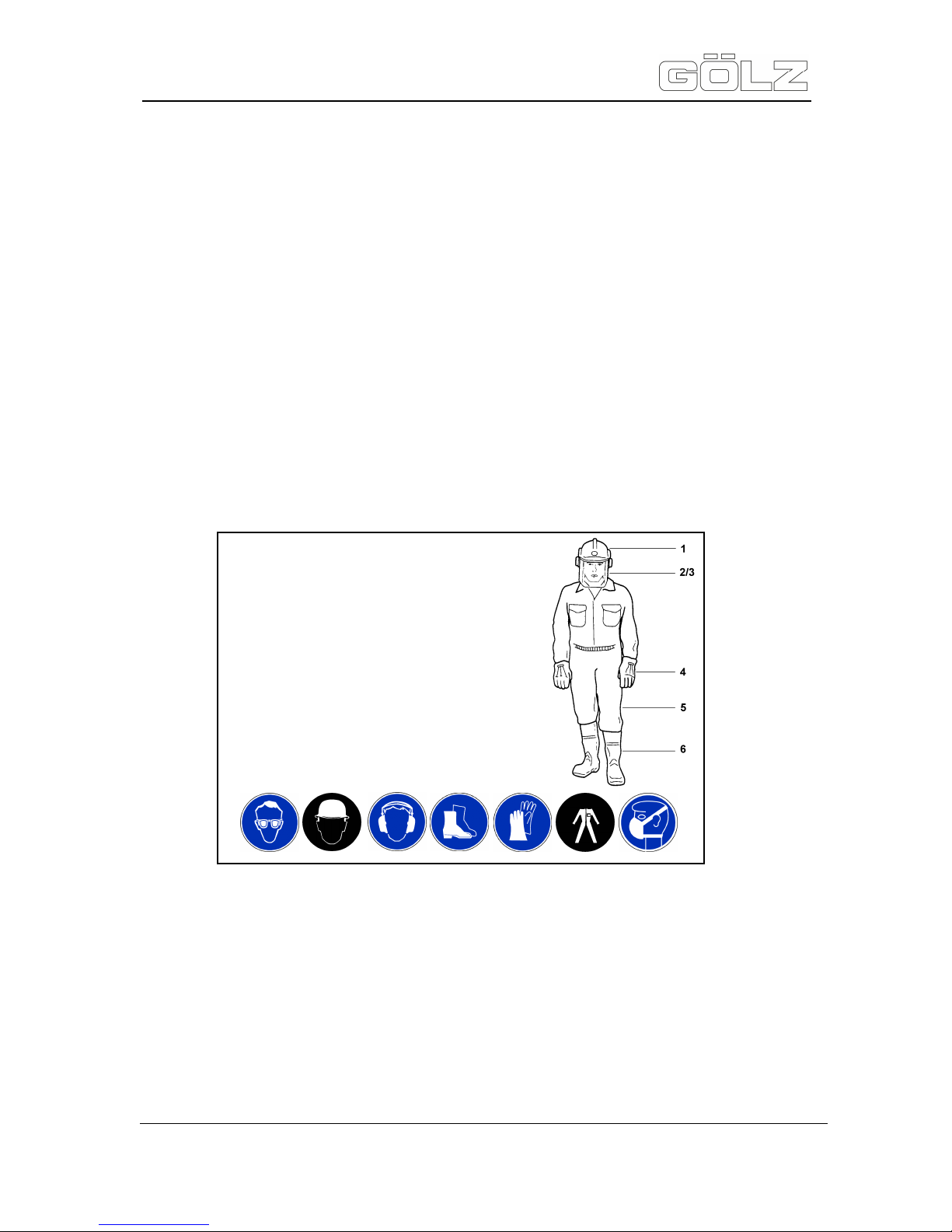

3.3 Organisational measures

This operating manual must always be at hand at the place of use of the machine and must be

accessible to the person operating the machine!

In addition to this operating manual, all other generally applicable legal and other mandatory

regulations relevant to accident prevention and environmental protection must be observed! Such

obligations may also comprise the handling of hazardous materials, provisioning and/ or wearing of

personal protective equipment, or road traffic regulations.

This operating manual must be supplemented by instructions covering the duties involved in

supervising and notifying special organizational features, such as job organization, work flows or the

person entrusted with the work. Person entrusted with work on the machine must have read the

operating manual prior to taking up work. This applies especially to persons working only occasionally

on the machine, e.g. during set-up or maintenance activities.

Check - at least from time to time - whether the personnel is carrying out the work in compliance with

the operating manual and paying attention to risks and safety-relevant factors.

For reasons of safety, long hair must be tied back or otherwise secured, garments must be close-fitting

and no jewellery - including rings - may be worn.

Severe injury may result from being caught by moving parts of the machine. Personal protective

equipment must be used wherever required by the circumstances or by law (e.g. safety glasses, ear

protectors, safety boots, suitable safety clothing). Observe the regulations for prevention of accidents!

Observe all safety precautions and warnings attached to the machine and always keep them in good

and perfectly legible condition.

The personal protection equipment should consist of the following parts:

In case event of safety-relevant modifications or changes in the behaviour of the machine, stop the

machine immediately and report the malfunction to the competent authority/ person. Do not remove or

make inoperative any safety devices the machine is equipped with.

Never make any modifications, additions or conversions which might affect safety without GÖLZ

®

GmbH prior approval! This also applies to the installation and adjustment of safety devices as well as

to welding and cutting work on supporting structures.

Damaged or worn parts of the product must be replaced immediately. Use genuine spare parts only.

All spare parts and tools must comply with the technical requirements specified by the manufacturer/

distributor. Adhere to the legally prescribed preventive maintenance and inspection intervals or those

specified in this operating manual!

Hydraulic hose pipes must be changed within the specified or appropriate intervals, even if no safetyrelevant defects are visible.

1) Hard hat with ear muff

2) Visor or safety glasses

3) Dust mask

4) Protective gloves

5) Safety clothes

6) Safety boots

Page 12

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 12-

5007090-00

BA-E

®

All maintenance and repair activities must be performed by qualified personnel using suitable tools

and other suitable workshop equipment. Observe the fire alarm and fire fighting measures. The

personnel must be made familiar with the location and handling of fire extinguishers!

3.4 Selection and qualification of person

Only permitted personnel is allowed to work on and with the machine! The legal minimum age is to be

observed!

Only assign trained and instructed personnel! Clearly define the responsibilites of the personnel with

regard to operating, setting-up, maintaining and repairing the machine! The GÖLZ® GmbH can assist

you in training your personnel.

Make sure that only instructed and competent personnel works on the machine. Define the

responsibility of the machine operator, also in terms of traffic regulations and enable him to refuse

instructions of third parties which breach safety regulations.

Personnel that is to be trained or to be instructed or that is serving a general training is only to be

permitted to operate the machine under the supervision of an experienced person.

To operate the machine you must be rested, in good physical condition and mental health. If you have

any condition that might be aggravated by strenuous work, check with your doctor before operating

with the machine. Do not operate the machine if you are under the influence of any substance (drugs,

alcohol) which might impair vision, dexterity or judgment.

Works on electrical, pneumatic, combustion and hydraulic fittings and equipment are only to be carried

out by qualified personnel or instructed people being directed and supervised by qualified personnel in

compliance with the respective rules!

3.5 Safety instructions governing specific operational phases

Before work

Avoid any operational mode that might be prejudicial to safety!

Before beginning work, familiarize yourself with the surroundings and circumstances of the site, such

as obstacles in the working and travelling area, the soil bearing capacity and any barriers separating

the construction site from public roads.

Take the necessary precautions to ensure that the machine is used only when in a safe and reliable

state. Operate the machine only if all protective and safety-oriented devices, such as removable safety

devices, emergency shut-off equipment, sound-proofing elements and exhausters, are in place and

fully functional.

Regard all safety specifications!

Check the machine at least once per working shift for obvious damage and defects. Report any

changes (incl. changes in the machine’s working behaviour) to the competent organization/ person

immediately. If necessary, stop the machine immediately and lock it. Have any defects rectified

immediately. At any time, ensure the operator has sufficient view to his working area, in order to have

intervention to the working process.

Wet cutting is to be accomplished while working. This prevents the appearance of particulate matter

and increases the life-time of the diamond tool. During start-up and shut-down procedures always

watch the indicators in accordance with the operating instructions!

Before starting or setting the machine in motion, make sure that nobody is at risk. Keep children and

unauthorized persons away from the work area.

Noise protection equipment on the unit must be in protective position during operation. Wear the

required individual ear protection!

Always keep at a distance from the edges of building pits and slopes. Avoid any operation that might

be a risk to machine stability! Keep the work area clean. Cluttered areas and benches invite injuries!

Do not operate when you are tired! Watch what you are doing! Risk of stumbling! Cables and hoses

must complete rolling up. After assembly do not leave any tools, a wrench for example, on the unit.

Check to see that the tools are removed from the machine before operating! Damaged blades have to

be changed immediately. Use only recommended blades from the GÖLZ

®

GmbH.

Page 13

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 13-

5007090-00

BA-E

®

Important: Wet cutting is to be accomplished while working! This prevents the

appearance of particulate matter and increases the life-time of the diamond tool!

Control the working area for water-, gas- and electrical lines!

During work

Make sure, that the machine is well fastened before and while cutting!

Never touch rotating parts like blade shaft or blade!

After work

Before leaving the machine always secure it against unauthorized use!

3.6 Special work related to the maintenance and repair of the machine

Observe the adjustment, maintenance and inspection activities and intervals set out in the operating

instructions, including information on the replacement of parts and equipment! These activities may be

executed by skilled personnel only.

Brief operating personnel before beginning special operations or maintenance work, and appoint a

person to supervise the activities.

In any work concerning the operation, conversion or adjustment of the machine and it’s safety-oriented

devices or any work related to maintenance, inspection and repair, always observe the start-up and

shut-down procedures described in the operating instructions and the information on maintenance

work. Ensure that the maintenance area is adequately secured.

Carry out maintenance and repair work only of the machine is positioned on stable and level ground

and has been secured against inadvertent movement and buckling. If the machine is completely shut

down for maintenance and repair work, it must be secured against inadvertent starting.

To avoid the risk of accidents, individual parts and large assemblies being moved for replacement

purposes should be carefully attached to lifting tackle and secured. Use only suitable and technically

perfect lifting gear and suspension systems with adequate lifting capacity. Never work or stand under

suspended loads.

The fastening of loads and the instructing of crane operators should be entrusted to experienced

persons only. The marshaller giving the instructions must be within sight or sound of the operator.

For carrying out overhead assembly work always use specially designed or otherwise safety-oriented

ladders and working platforms. Never use machine parts as a climbing aid. Wear safety harness when

carrying out maintenance work at greater heights.

Clean the machine, especially connections and threaded unions, of any traces of oil, fuel or

preservatives before carrying out maintenance / repair. Never use aggressive detergents. Use lint-free

cleaning rags.

Before cleaning the machine with water, steam jet or detergents, cover or tape up all openings which for safety and functional reasons - must be protected against water, steam or detergent penetration.

Do not clean the machine with a high-pressure cleaner. The hard water jet can put damage to parts of

the machine. After cleaning, remove all covers and tapes applied for that purpose.

After cleaning check the machine for loose connections, chafe marks and damage! Have identified

defects repaired immediately!

Always tighten any screwed connections that have been loosened during maintenance and repair.

Any safety devices removed for set-up, maintenance or repair purposes must be refitted and checked

immediately upon completion of the maintenance and repair work. Ensure that all consumables and

replaced parts are disposed of safely and with minimum environmental impact.

Page 14

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 14-

5007090-00

BA-E

®

3.7 Information about special risks with electrical energy

Observe the relevant national regulations or standards. Electrical connections must always be kept

free from dirt and moisture.

Use only original fuses with the specified rating! Switch off the machine immediately, if trouble occurs

in the electric power supply!

If your machine comes into contact with a live wire:

• warn others against approaching and touching the machine

• have the live wire de-energized

When working with the machine, maintain a safe distance from overhead electric lines. If work is to be

carried out close to overhead lines, the working equipment must be kept well away from them.

Caution, danger to life!

• Check out the prescribed safety distances.

• Work on the electrical system or equipment may only be carried out by a skilled electrician

himself or by specially instructed personnel under the control and supervision of such electrician

and in accordance with the applicable engineering rules.

• If provided for in the regulations, the power supply to parts of machines and plants, on which

inspection, maintenance and repair work is to be carried out must be cut off.

• Before starting work, check the de-energized parts for the presence of power and ground or

short-circuit them in addition to insulating adjacent live parts and elements.

The electrical equipment of machines is to be inspected and checked at regular intervals. Defects

such as loose connections or scorched cables must be rectified immediately.

Necessary work on live parts and elements must be carried out only in the presence of a second

person who can cut off the power supply in case of danger by actuating the emergency shut-off or

main power switch. Secure the working area with a red-and white safety chain and a warning sign.

Use insulated tools only.

If mobile electrical equipment, connecting cables and/ or extension/ appliance cords with plug

connectors are used, ensure that such equipment, cables and cords are checked for correct function

at least once every six months by a qualified electrician or - if suitable testing equipment is available by a properly instructed person.

Protective installations with fault-current protection units used in non-stationary equipment must be

checked for correct operation at least once a month by a properly instructed person.

Fault-current and fault-voltage protection units must be checked for correct operation by actuating the

testing facility:

• once on every working day in the case of mobile equipment,

• at least once every six months in the case of stationary equipment.

3.8 Gas, dust, steam, smoke

Operate combustion engines only in well-ventilated rooms! Before starting the unit in closed rooms,

make sure that the room is sufficiently ventilated and use the exhaust gas hose!

Welding, burning and grinding operations on the machine are only to be carried out if this is explicitly

authorized (there is the danger of fire and explosion)!

Before welding, burning and grinding operations clean the machine and its surrounding area from dust

and flammable substances and care for sufficient ventilation (danger of explosion)!

When working in confined spaces observe any existing national regulations!

3.9 Noise

During operation sound protection devices on the machine must be in safe position. Wear the

prescribed personal ear protection! (UVV 29 § 10, Article 29 of the Accident Prevention regulations).

The use of noise emitting machines may be restricted to certain times by national or local regulations.

Page 15

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 15-

5007090-00

BA-E

®

3.10 Illumination

The machine is designed for use in daylight! The machine operator / owner must ensure sufficient

workplace lighting for non-illuminated work sites!

3.11 Oils, greases and other chemical substances

When handling hydraulic fluids, lubricants, greases or preservatives (referred to hereinafter as fuels

and lubricants), the safety regulations which apply to the respective machine are to be observed!

Avoid long contact of the fuels and lubricants with your skin! Careful cleaning of the skin from adhering

fuels and lubricants is necessary.

Be careful when handling hot consumables (risk of burning or scalding) particularly at liquid temperatures above 60°C, avoid any skin contact with these liquids!

If you get fuels or lubricants in your eyes, rinse them immediately and carefully with potable water.

Then consult a doctor.

Remove flown out fuels and lubricants immediately! Therefore use a binder.

Fuels and lubricants must not seep into the soil or into the public sewage system! Fuels and lubricants

which can no longer be used are to be collected, properly stored and to be properly disposed of.

The respective regulations and laws for handling fuels and lubricants which are valid in the country of

use are to be observed and adhered to. This also applies to the disposal of such fuels and lubricants.

To inform yourself turn to the responsible authorities.

3.12 Transport

Use only suitable means of transport and lifting gear of sufficient capacity when loading or transporting

the machine! Appoint an experienced instructor for the lifting operation!

Always observe the instructions given in the operating manual when lifting the machine (use only the

prescribed lifting eyes for attaching the lifting gear)!

Use only suitable transport vehicles with sufficient load capacity! Secure the load carefully. Use

suitable fastening points for securing!

Before loading the machine or parts of it, secure the machine against inadvertent movement! Attach a

suitable warning sign!

The blade must be removed for transport. Even in case of a minor change of location, the engine must

be stopped!

Before using the machine again, make sure that such protection material or devices are properly

removed! Parts which had to be removed for transporting of the machine must be refitted and secured

carefully before the machine is used again!

Before setting the machine in motion always check that all accessories are safely stowed.

The recommissioning procedure must be strictly in accordance with the operating instruction! Observe

the instructions given in the operating instruction when reassembling and operating the machine.

The machine can be transported by two persons using the transport handles or one person using the

transport wheels. The machine is not designed to be transported by crane!

Before transporting the machine always do the following instructions:

• Remove the blade

• Empty the water tray,

• Lock the table

• Fold and tight the legs with the locking screws

• Make sure the transport handles and wheels are mounted correctly and well tighten.

Page 16

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 16-

5007090-00

BA-E

®

3.13 Store

Store the machine in a dry, high or locked place, out of the reach of children or unauthorized persons.

Clean and preserve the machine with corrosion preventive if storing over a longer time like winter time!

Note: Store dismounted blades so, that the blades not exposed to mechanical damages and harmful

environmental conditions (UV radiation, temperature, humidity, etc.).

Before storing always do the following instructions:

• Clean the machine

• Empty and clean the water tray

• Clean the water pump

• In case of frost, empty all water cooling system from its water.

Attention: Store blades just standing or hanging!

Page 17

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 17-

5007090-00

BA-E

®

4. Bringing into service

4.1 Export checking

Remove the transport packaging and place the unit vertically on a horizontal, flat and stable surface.

Dispose of the transport packaging according to environmental regulations. Since the unit is delivered

completely assembled, you need only check if it is complete and intact.

For the scope of delivery, see "Technical Data and Accessories".

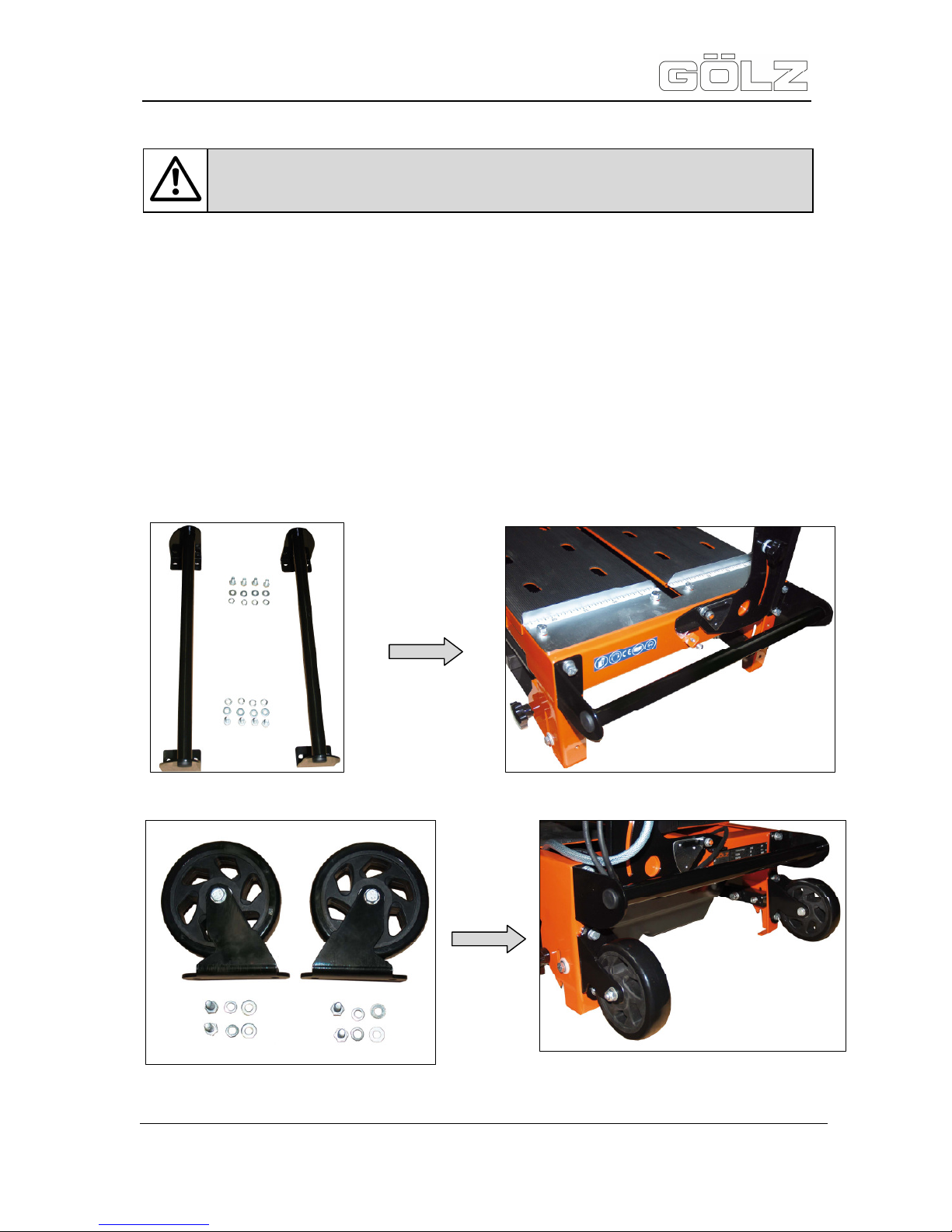

4.2 Assembling

Some components must be mounted on the machine. Look at the following pictures.

Attention: Do not yet turn the engine on! The following work is to be done with the

engine being stopped!

Page 18

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 18-

5007090-00

BA-E

®

4.3 Engine

4.4 Setting up the machine

Loosen the star knob screws on the legs to close this out. Set up the machine on a solid level and

stable surface.

4.5 Mounting / changing the blade

To mount a new blade, always do the following instructions:

• Switch off the machine and unplug the supply cable.

Attention: The cutting head must be set and detected with the control handle in a

raised position!

Attention: The cutting table must be saved with the transport lock.

Note: Read and observe the instructions to the engine!

Page 19

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 19-

5007090-00

BA-E

®

• Loose the 3 screws (front-up-back) of the blade guard. Then remove the mobile part of the

blade guard.

• Loose the left threaded hexagonal nut on the motor shaft and remove the outer flange and the

tool.

•

Clean the tool shaft and flanges and inspect for wear

.

• Mount the new blade. Make sure the tool rotation is correct and the bore corresponds to the

shaft diameter.

Page 20

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 20-

5007090-00

BA-E

®

• Mount back the outer flange.

• Tighten the left threaded hexagonal nut on the motor shaft.

• Put back the mobile part of the blade guard in place. Tighten the 3 screws (front-up-back).

4.6 Electrical connections

Before connecting the machine to a power supply, make sure:

• The voltage/phase supply corresponds to the information indicated on the motor plate and

machine plate.

• Available power supply must have ground connection in conformity with safety regulations.

• The size of the electric cable of the extended lead is sufficient (H07RNF 3x2.5mm2 up to 50m for

230V)

Page 21

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 21-

5007090-00

BA-E

®

Important: Observe all the previous chapters in this manual, in particular the safety

and warning instructions!

5. Operation

5.1 Before starting the machine

Before starting observe the following points:

• Make sure that the blade is correct installed and the blade guard is closed. The blade guard must

always be fitted when cutting.

• Defective or worn blades must be replaced immediately.

• Make sure that the blade is not touching the cutting table at any position of the cutting table or

cutting head.

• Fill the water tank with clean water and make sure the water pump in completely immersed in the

water. The water pump doesn't run without water refill the water tank with clean water if

necessary.

• Supply cooling water to the blade by the water pump.

• The material to be cut must not exceed the following:

Weight < 10 kg - 22 lbs.

Max. Dimensions TS200: 720 x 480 x 40 mm - 28,3 x 18,9 x 1,6 in.

Max. Dimensions TS250: 1140 x 480 x 65 mm - 44,9 x 18,9 x 2,6 in.

The machine only is operated in safe operating condition!

Pay attention to the dispositions of cooling water and flushing water as well as cutting muds. Cutting

muds must be absorbed, filtered and disposed of.

5.2 Starting the machine

To start the machine, open the cover of the switch and press the green button.

After starting the machine check immediately the following points:

• The cooling water must be transported in sufficient quantity from the water pump to the blade.

The water should drain on both sides of the blade.

• The water nozzles and water hoses should not clog.

If one of these conditions is not correct, stop immediately the machine!

The motor is equipped with a thermal protection to prevent high temperature rises, if the thermal

protection triggers, wait until the motor has cooled down before starting the machine again.

5.3 Cutting operation

Warning: Never touch rotating parts!

Attention: Location rid of anything that might interfere with the operation! Ensure

correct installation of the blade! With the exception of the operator, should be no

other persons present in the work area!

Page 22

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 22-

5007090-00

BA-E

®

5.3.1 Cutting method: Fixed depth cutting

In fixed depth cutting, the cutting head is locked in a fixed position. To do fixed depth cutting, please

follow this procedure:

• Switch off the machine and make sure the blade is not rotating.

• Loosen the adjusting handle

and adjust the cutting head

to the desired position.

• Make sure that the blade is not touching the cutting table at any

position of the cutting table or cutting head.

Warning: Never touch rotating parts!

Attention: Transport the unit only when the engine is stopped! This applies also to

a short change of location!

Attention: Wear appropriate individual protective equipment!

Page 23

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 23-

5007090-00

BA-E

®

• Tighten strongly the adjusting handle and make sure the

cutting head is well fixed and cannot move.

• Put the material on the cutting table. By using the back square

control the position of the material.

• Start the machine.

• Put your hand on the cutting handle.

• Push the cutting table slowly and without undue pressure

towards the rotating blade. The blade cuts the applied

material.

Page 24

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 24-

5007090-00

BA-E

®

5.3.2 Cutting method: Free depth cutting for multiple steps cutting

In free depth cutting, the cutting head is not locked in a fixed position. This cutting method enables

multiple steps cutting which consists of moving the table back and forth with the material to be cut

under the rotating blade. For hard material, it is recommended to use this cutting method (e.g. by

doing many shallow cuts).

To do free depth cutting, please follow this procedure:

• Switch off the machine and make sure the blade is not

rotating.

• Loosen the adjusting handle.

• Make sure that the blade is

not touching the cutting

table at any position of the

cutting table when the

cutting head is at the lowest

position.

• Put the material on the

cutting table. By using the

back square control the

position of the material.

Page 25

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 25-

5007090-00

BA-E

®

• Start the machine.

• Put your hand on the cutting handle.

• Push the cutting table slowly and without undue pressure

towards the rotating blade. The blade cuts the applied

material.

• During the cutting process set the cutting depth manual about

the cutter head handle. Push about the table handle the

cutting table to the front and back again.

5.3.3 Cutting method: 45° bevel cuts

The machine enables to make fixed or multiple steps 45° bevel cuts.

To do 45° bevel cuts, please follow this procedure:

• Switch off the machine and make sure the blade is not

rotating.

• Loosen the two grip knobs on each side of the machine.

Page 26

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 26-

5007090-00

BA-E

®

• Rotate the complete cutting head and rail to the required

angle.

• Tighten well the two grip knobs on each side of the machine.

• Loosen the adjusting handle.

• Adjust the depth stop and tighten it well.

• Make sure that the blade is not touching the cutting table at

any position of the cutting table when the cutting head is at

the lowest position.

• Put the material on the cutting table. By using the back

square control the position of the material.

Page 27

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 27-

5007090-00

BA-E

®

• Start the machine.

• Put your hand on the cutting handle.

• Push the cutting table slowly and without undue pressure towards the rotating blade. The blade

cuts the applied material.

To put the cutting head back in the normal position, please follow this procedure:

• Switch off the machine and make sure the blade is not

rotating.

• Tighten well the two grip knobs on each side of the machine.

• Rotate the cutting head until it stops at 0°.

• Tighten well the two grip knobs on each side of the machine.

Page 28

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 28-

5007090-00

BA-E

®

• Make sure that the blade is not

touching the cutting table at any

position of the cutting table

when the cutting head is at the

lowest position.

5.4 Stop cutting operation

To stop the machine, press the red button or directly the emergency switch to stop the machine.

The motor and the water pump shut off.

Carry out the maintenance and care work according to the chapter "maintenance and care".

5.5 Changing the blade

The blade must be changed if:

• the diamond segments of the blade are completely worn

• the material to be cut changes

• the blade turns irregularly

• the diamond segments are damaged or broken

For fitting a new blade, proceed as described in the chapter "Mounting / changing the blade".

Page 29

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 29-

5007090-00

BA-E

®

6. Maintenance and care

Spare parts must comply with the technical requirements specified by the manufacturer. Spare parts

from GÖLZ® can be relied to do so! Observe the following indications:

In accordance to the given cycles, the subsequently described maintenance work has to be enforced.

Also the wearing parts subject to no certain maintenance-intervals have to be checked regularly for

wear and to adjust if necessary or to exchange.

Vor jeder

Inbetrieb-

nahme

Nach

Arbeits-

ende

Wöchent-

lich

Bei

Störung

Bei

Beschädigung

Gesamte Maschine

Kontrolle

x

x x

Säubern

x

Schneidflansch

Säubern

x

Austauschen

x

Motorwelle Säubern

x

Motor (Gehäuse und

Lüfter)

Säubern

x

Wasserbehälter Säubern

x

Wasserpumpe

Kontrolle

x x

Säubern

x

Wasserschläuche Leeren

x

Wasserdüsen Säubern

x

Führungsschienen

und -rollen

Säubern

x

Schraubenverbindungen

Kontrolle

x

6.1 Machine

Clean the machine after each duty and check all functions. Replace all necessary parts that are out of

order or worn out immediately.

6.2 Blade

When ending a cutting job - check blade as follows:

Check segments for cracks or break-outs, Cracks between segment and core barrel,

Deformation and out of round wear.

In case of doubt, send the blade for repair.

Attention: All maintenance, repair and care work is only to be done if the motor

being stopped and the power supply is disconnected!

Page 30

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 30-

5007090-00

BA-E

®

7. Troubleshooting

Cause Remedy

Machine doesn’t work

No electrical power supply

Check the power cable. Check the power

connection.

Defective power cable

Change the power cable

Defective switch

Change the switch

Defective engine

Change the engine

No water on the blade

Not enough water in the water tank

Refill with clean water

Closed water tap

Open the water tap

Clogged water system

Clean the water system and refill the water tank

with clean water

Defective water pump

Clean the water pump.

Replace the water pump if cleaning does not

improve

Water pump is off

Check the electrical power supply

Engine stops during cutting

Wrong blade for the application

Change the blade

Defective blade

Change the blade

Worn blade

Change the blade

Cutting advance too fast

Cut slowly

Undue pressure on the blade

Cut slowly

Attention: Only qualified personnel or personnel that is supervised and guided by

qualified personal are allowed to work on electrical equipment based to applicable

rules.

Page 31

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 31-

5007090-00

BA-E

®

GÖLZ® GmbH

D - 53940 Hellenthal Tel. (02482) 120

Typ

Baujahr Maschinen-Nr.

Gew. kg kW

TS 200

XXXXX

20XX

XXXXX

XX

Note: In order to avoid wrong deliveries the information the ordering information

should be checked for accuracy and completeness before sending it! Completely

indicate the delivery address!

8. Spare parts list

8.1 Using the spare parts list

The spare parts list is not a mounting or dismounting instruction. The only purpose of the spare parts

list is to easily and quickly find spare parts which can be ordered with distribution agencies, see

chapter 8.1.3 "Distribution agencies".

8.1.1 Safety regulation

Using this spare parts list for mounting or dismounting purposes is not permitted. For assembly and

disassembly work exclusively the corresponding descriptions in this operating manual are to be

followed.

8.1.2 Ordering information

Danger: Non-observance of this instruction can result in injury which, in the worst

case, can result in death!

Danger: Mounting or dismounting assembly groups can give rise to risks which are

not mentioned in the spare parts list!

Page 32

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 32-

5007090-00

BA-E

®

So bekommen Sie schnell und

richtig Ihr Ersatzteil

Always indicate

Pour obtenir rapidement les

pièces de rechange indiquer

• Maschinentyp gemäß

Typenschild

• Baujahr gemäß Typenschild

• Artikelnummer gemäß

Ersatzteilliste

• Maschinennummer gemäß

Typenschild

• machine type according to

nameplate

• year of manufacture

according to nameplate

• order number according to

spare part list

• serial number according to

nameplate

• type de la machine conforme

de plaque d'identification

• Année de construction selon

plaque d'identification

• Numéro de l'article selon la

liste des pièces de rechange

• numéro de la machine conforme de plaque d'identification

Für Bestellungen, Fragen und

Informationen wenden Sie sich

bitte an die zuständigen Stellen.

For orders, questions and

information, please contact the

competent departments.

Pour les commandes, questions

et informations, veuillez-vous

adresser aux points de ventes

correspondants.

8.1.3 Distribution agencies

Deutschland – Germany - Allemagne

GÖLZ® GmbH

Dommersbach 51

DE-53940 Hellenthal

Tel: +49 (0)2482-12 200

Fax: +49 (0)2482-12 222

E-Mail: info@goelz.de / Internet: www.goelz.de

Österreich - Austria - Autriche

GÖLZ® Ges.m.b.H

Samstraße 52

A-5020 Salzburg

Tel: +43 (0) 662 - 43 81 75

Fax: +43 (0) 662 - 43 07 34

E-Mail: info@goelz.at / Internet: www.goelz.at

Frankreich - France - France

GÖLZ® S.A.S.

1, rue de la Mairie

F-67370 Berstett

Tel: +33 (0)3.88.59.43.00

Fax: +33 (0)3.88.59.47.77

E-Mail: info@golz.fr / Internet: www.golz.fr

Großbritannien - Great Britain - Grande-Bretagne

GÖLZ® (UK) Ltd.

Unit A5, Springhead, Enterprise Park

Northfleet

Kent DA11 8HB

Tel: +44 1 474321679

Fax: +44 1 474321477

E-Mail: info@goelz.co.uk / Internet: www.goelz.co.uk

Benelux

GÖLZ® Benelux

Eupener Straße 61

BE-4731 Raeren-Eynatten

Tel: +49 (0)2482-12 200

Fax: +49 (0)2482-12 222

E-Mail: benelux@goelz.de / Internet: www.goelz-online.com

Australien - Australia - Australie

GOLZ® Pty Ltd.

44 Stanley Street

Peakhurst, NSW 2210

Tel: +61 (0) 2 9534 5599

Fax: +61 (0) 2 9534 5588

E-mail: info@golz.com.au / Internet: www.golz.com.au

USA

GOLZ® L.L.C.

5860 East Osage Ridge Lane

Columbia MO 65203-6018

Tel: +1 573 474 4961

E-Mail: info@golzusa.com / Internet: www.goelz-online.com

Page 33

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 33-

5007090-00

BA-E

®

8.2 Wearing parts

Wearing parts for construction devices mentioned in the operating manual such as drilling and

sawing machines.

Wearing parts are the parts subject to operation-related (natural) wear during proper use of the device.

The wearing time cannot be uniformly defined, and differs according to the intensity of use. The

wearing parts must be adjusted, maintained and, if necessary, replaced for the specific device in

accordance with the manufacturer’s operating manual. Operation-related wear is not a reason for

defect claims.

Wearing parts of this machine are grey marked in the spare parts list.

• Feed and drive elements such as toothed racks, gearwheels, pinions, spindles, spindle nuts,

spindle bearings, cables, chains, sprockets, belts

• Seals, cables, hoses, packings, connectors, couplings and switches for pneumatic, hydraulic,

water, electrical and fuel systems

• Guide elements such as guide strips, guide bushes, guide rails, rollers, bearings, sliding

protection supports

• Clamping elements for quick-separating systems

• Flushing head seals

• Slide and roller bearings that do not run in an oil bath

• Shaft oil seals and sealing elements

• Friction and safety clutches, braking devices

• Carbon brushes, commutators / armatures

• Easy-release rings

• Control potentiometers and manual switching elements

• Securing elements such as plugs, anchors, screws and bolts

• Fuses and lamps

• Auxiliary and operating materials

• Bowden cables

• Discs

• Diaphragms

• Spark plugs, glow plugs

• Parts of the reversing starter such as the starting rope, starting pawl, starting roller and

starting spring

• Sealing brushes, rubber seals, splash protection cloths

• Filters of all kinds

• Drive rollers, deflection rollers and bandages

• Cable anti-twist elements

• Running and drive wheels

• Water pumps

• Cut-material transport rollers

• Drilling, parting and cutting tools

• Energy storage

Page 34

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 34-

5007090-00

BA-E

®

9. Exploded view and spare parts list

9.1 Machine

Page 35

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 35-

5007090-00

BA-E

®

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

1

-

TS200

Rahmen kpl. Frame complete Châssis complète

-

TS250

2

-

TS200

Schneidkopf kpl. Cutter head complete

Couteau en-tête

complète

-

TS250

3

-

TS200

Führungsschiene kpl. Guiding rail complete Glissière complète

-

TS250

4

-

TS200

Schnittguttisch kpl. Cutting table complete

Table de travail

complète

-

TS250

5

-

TS200

Auffangblech Plate Tôle attraper

-

TS250

6

-

Anschlagwinkel kpl. Back square complete Équerre complète

7

-

Wasserbehälter kpl. Water tank complete Tank complète

8

-

Standbein kpl. Main pillar complete

Jambe de pivot

complète

9

-

Standbein kpl. Main pillar complete

Jambe de pivot

complète

10

-

TS200

Tischverlängerung kpl.

Table extension

complete

Table de travail

rallonge complète

-

TS250

11

-

Transportgriff kpl.

Transport handle

complete

Poignée de transport

complète

12

-

Transporträder kpl.

Transport wheel

complete

Roue de transport

complète

13

5007093

Bedienungsanleitung Operating instruction Mode d’emploi

Page 36

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 36-

5007090-00

BA-E

®

9.2 Frame

Page 37

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 37-

5007090-00

BA-E

®

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

TS200

Rahmen kpl. Frame complete Châssis complète

-

-

TS250

1

-

TS200

Rahmen Frame Châssis

-

TS250

2

-

Anschlagblech Stop plate Lame d’arrêt

3

-

DIN EN

ISO 4017

M 8 x 16 Schraube Screw Vis

4

-

DIN 127

A 8 Federring Spring washer Rondelle-ressort

5

-

DIN EN

ISO 7089

A 8,4 Scheibe Washer Rondelle

6

-

M 8 x 25 Sterngriffschraube Star grip screw Poignée-étoile

7

-

GN 615 M 8 Druckstück Thrust piece Patin de serrage

8

-

DIN EN

ISO 7040

M 8 Mutter Nut Écrou

9

-

Tiefenanzeiger Depth finder Indicateur de la gravité

10

-

DIN EN

ISO 4032

M 8 Mutter Nut Écrou

11

-

Behältersicherung Water tray lock Sécurité tank

12

-

GN 531 M 8 Flügelschraube Wing screw Vis à ailettes

13

-

DIN EN

ISO 4017

M 6 x 25 Schraube Screw Vis

14

-

DIN EN

ISO 4032

M 6 Mutter Nut Écrou

15

-

M 8 x 30 Sterngriffschraube Star grip screw Poignée-étoile

16

-

Ø 25 x 8,5 x 3 Scheibe Washer Rondelle

Page 38

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 38-

5007090-00

BA-E

®

9.3 Cutter head

Page 39

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 39-

5007090-00

BA-E

®

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

TS200

Schneidkopf kpl. Cutter head complete

Couteau en-tête

complète

-

-

TS250

1

-

DIN EN

ISO 4762

M 8 x 20 Schraube Screw Vis

2

-

DIN EN

ISO 7089

A 8,4 Scheibe Washer Rondelle

3

-

Achse Axis Arbre

4

-

Motoraufnahme Motor acceptance Levé moteur

5

-

Feder Spring Languette

6

-

Führungsleiste Support guide Liston guidage

7

-

Längenanzeige Length indicator

Indicateur de la longueur

8

-

DIN EN

ISO 4017

M 5 x 20 Schraube Screw Vis

9

-

DIN 127

A 5 Federring Spring washer Rondelle-ressort

10

-

DIN EN

ISO 4032

M 5 Mutter Nut Écrou

11

-

Schneidkopfaufnahme

kpl.

Cutter head acceptance

complete

Levé couteau en-tête

complète

12

-

Schneidkopfgriff Cutter head handle

Couteau en-tête

poignée

13

-

DIN EN

ISO 4017

M 8 x 20 Schraube Screw Vis

14

-

Kabelschutzhalter Cable protection holder Protection du câble

15

-

Kabelschutzführung Cable protection guide Protection du câble

16

-

Griff einstellbar Handle adjustable Poignée ajustable

17

-

DIN EN

ISO 4017

M 6 x 20 Schraube Screw Vis

18

-

DIN EN

ISO 7045

M 4 x 12 Schraube Screw Vis

19

-

DIN EN

ISO 4762

M 5 x 20 Schraube Screw Vis

20

-

DIN EN

ISO 4762

M 5 x 15 Schraube Screw Vis

21

-

DIN 6921 M 5 x 20 Schraube Screw Vis

22

-

TS200

Schutzhaube kpl. Blade guard complete

Capot protecteur

complète

-

TS250

23

-

DIN 6921 M 8 x 20 LH Schraube Screw Vis

24

-

Griff Handle Poignée

25

-

Außenflansch Outer flange Bride extérieur

26

-

DIN 127

A 8 Federring Spring washer Rondelle-ressort

27

-

Innenflansch Inner flange Bride intérieur

28

-

Motor kpl. Motor complete Moteur complète

29

-

Motorführung Motor guide Guidage moteur

30

-

M 8 x 15 Klemmhebel Clamp lever Levier de serrage

31

-

DIN EN

ISO 7045

M 4 x 8 Schraube Screw Vis

32

-

Lüfterhaube Fan cover Capot

Page 40

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 40-

5007090-00

BA-E

®

Page 41

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 41-

5007090-00

BA-E

®

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

33

-

Distanzplatte Distance plate Plaque de distance

34

-

Gleitlager Bush bearing Roulement coulissant

35

-

DIN 127

A 6 Federring Spring washer Rondelle-ressort

36

-

DIN EN

ISO 7089

A 6,4 Scheibe Washer Rondelle

37

-

DIN EN

ISO 4032

M 4 Mutter Nut Écrou

Page 42

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 42-

5007090-00

BA-E

®

9.3.1 Cutter head bracket

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

Schneidkopfaufnahme

kpl.

Cutter head bracket

complete

Levé couteau en-tête

complète

1

-

DIN 625 608-2RS1 Kugellager Ball bearing Roulement à billes

2

-

Exzenterwelle Eccentric shaft Arbre excentrique

3

-

DIN EN

ISO 7089

A 8,4 Scheibe Washer Rondelle

4

-

DIN EN

ISO 7040

M 8 Mutter Nut Écrou

5

-

Schneidkopfaufnahme Cutter head bracket Levé couteau en-tête

6

-

Welle Shaft Arbre

Page 43

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 43-

5007090-00

BA-E

®

9.3.2 Engine

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

Motor kpl. Motor complete Moteur complète

1

-

1,3 kW Motor Motor Moteur

2

-

Dichtung Gasket Joint

3

-

Schaltkasten Switch box Combinateur

4

-

Dichtung Gasket Joint

5

-

Deckel Cover plate Couvercle

6

-

Schalter Switch Interrupteur

7

-

Kondensator Capacitor Condensateur

8

-

DIN EN

ISO 7045

M4x8 Schraube Screw Vis

9

-

Kabelverschraubung Cable connection Branchement

10

-

DIN EN

ISO 7049

St2.9x16 Schraube Screw Vis

11

-

DIN EN

ISO 7045

M4x6 Schraube Screw Vis

12

-

DIN 6797 JJ 4.3 Scheibe Washer Rondelle

Page 44

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 44-

5007090-00

BA-E

®

9.3.3 Blade guard

Page 45

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 45-

5007090-00

BA-E

®

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

TS200

Schutzhaube kpl. Blade guard complete

Capot protecteur

complète

-

TS250

1

-

TS200

Schutzhaube Seitenteil Blade guard side frame

Capot protecteur pièce

latérale

-

TS250

2

-

TS200

Schutzhaube Seitenteil Blade guard side frame

Capot protecteur pièce

latérale

-

TS250

3

-

DIN 6921 M 8 x 20 Schraube Screw Vis

4

-

Spritzschutz Splash guard Bavette anti-projection

5

-

DIN EN

ISO 7945

M 4 x 12 Schraube Screw Vis

6

-

DIN EN

ISO 7089

Scheibe Washer Rondelle

7

-

DIN EN

ISO 7040

M 8 Mutter Nut Écrou

8

-

DIN EN

ISO 7040

M 4 Mutter Nut Écrou

10

-

Aufkleber Label Macaron

11

-

Aufkleber Label Macaron

12

-

Y-Verteiler Y-Distribution Y-Distributeur

13

-

Schelle Clamp Collier

14

-

Schlauch Hose Tuyau

15

-

DIN EN

ISO 7045

M 4 x 4 Schraube Screw Vis

16

-

1/4" Schlauchtülle Hose clip Tétine (Tuyau)

17

-

1/4" Doppelnippel Double nipple Raccord double

18

-

1/4" Kugelhahn Ball valve Robinet à rotule

19

-

Schlauch Hose Tuyau

Page 46

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 46-

5007090-00

BA-E

®

9.4 Guiding rail

Page 47

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 47-

5007090-00

BA-E

®

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

TS200

Führungsschiene kpl. Guiding rail complete Glissière complète

-

TS250

1

-

DIN EN

ISO 4762

M 8 x 25 Schraube Screw Vis

2

-

DIN EN

ISO 7040

M 8 Mutter Nut Écrou

3

-

TS200

Seitenteil Führungsschiene

Side frame guiding rail Pièce latérale glissière

-

TS250

4

-

DIN EN

ISO 4017

M 6 x 25 Schraube Screw Vis

5

-

DIN EN

ISO 4032

M 6 Mutter Nut Écrou

6

-

Schelle Clamp Collier

7

-

DIN EN

ISO 4017

M 8 x 16 Schraube Screw Vis

8

-

Gummipuffer Rubber stop Patin

9

-

TS200

Führungsschiene Guiding rail Glissière

-

TS250

10

-

TS200

Seitenteil Führungsschiene

Side frame guiding rail Pièce latérale glissière

-

TS250

11

-

DIN EN

ISO 7089

A 8,4 Scheibe Washer Rondelle

12

-

Anschlag Platte 1 Limitation plate 1 Limitation plaque 1

13

-

Anschlag Platte 2 Limitation plate 2 Limitation plaque 2

14

-

M 6 Griff Handle Poignée

15

-

TS200

Kabelschutz Cable protector Câble protecteur

-

TS250

16

-

Kabelführung Cable guidance Câble de guidage

17

-

DIN EN

ISO 7045

M 4 x 4 Schraube Screw Vis

18

-

Winkelskala Angle scale Cadran de jarret

19

-

DIN EN

ISO 8746

2 x 4 Niet Rivet Rivet

20

-

Skala Scale Cadran

21

-

Winkelskala Angle scale Cadran de jarret

Page 48

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 48-

5007090-00

BA-E

®

9.5 Transport wheel

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

Transporträder kpl.

Transport wheel

complete

Roue de transport

complète

1

-

Aufnahme Acceptance Levé

2

-

Pos. 2.1-2.3 Rad kpl. Wheel complete Roue complète

2.1

-

Ø 125 Rad Wheel Roue

2.2

-

DIN 625 6001-2RS1 Kugellager Ball bearing Roulement à billes

2.3

-

Ø 10 x Ø 8

x 27,5

Distanzhülse Distance sleeve Douille de distance

3

-

DIN EN

ISO 4017

M 8 x 60 Schraube Screw Vis

4

-

DIN EN

ISO 7040

M 8 Mutter Nut Écrou

5

-

DIN EN

ISO 4017

M 8 x 20 Schraube Screw Vis

6

-

DIN EN

ISO 7089

A 8,4 Scheibe Washer Rondelle

7

-

DIN 127

A 8 Federring Spring washer Rondelle-ressort

Page 49

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 49-

5007090-00

BA-E

®

9.6 Back square

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

Anschlagwinkel kpl. Back square complete Équerre complète

1

-

Aufnahme Acceptance Levé

2

-

Anschlagwinkel Back square Équerre

3

-

DIN EN

ISO 4017

M 8 x 20 Schraube Screw Vis

4

-

GN 531 M 8 x 30 Flügelschraube Wing screw Vis à ailettes

5

-

Exzentergriff Eccentric handle Poignée excentrique

6

-

DIN EN

ISO 7040

M 8 Mutter Nut Écrou

7

-

DIN EN

ISO 7089

A 8,4 Scheibe Washer Rondelle

8

-

DIN 6799

Sicherungsscheibe Lock washer Rondelle d’arrêt

Page 50

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 50-

5007090-00

BA-E

®

9.7 Water tank

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

Wasserbehälter kpl. Water tank complete Tank complète

1

-

Wasserbehälter Water tank Tank

2

-

25 W Wasserpumpe Water pump Pompe d’eau

3

-

Ablaufstopfen kpl.

Stopple with rope

complete

Bouchon avec

prolonge complète

4

-

TS200

Schlauch Hose Tuyau

-

TS250

5

-

DIN EN

ISO 7089

A 4,3 Scheibe Washer Rondelle

6

-

DIN EN

ISO 7040

M 4 Mutter Nut Écrou

7

-

DIN EN

ISO 7045

M 4 x 12 Schraube Screw Vis

8

-

Schlauchschelle Hose clamp Collier

9

-

Kupplung Clutch Raccord

10

-

Kupplung Clutch Raccord

11

-

1/4“ Schlauchtülle Hose fitting

Raccord à queue

crantée

Page 51

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 51-

5007090-00

BA-E

®

9.7.1 Stopple with rope

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

Ablaufstopfen kpl.

Stopple with rope

complete

Bouchon avec

prolonge complète

1

-

Seil Rope Prolonge

2

-

Stopfen Stopple Bouchon

3

-

Seilklemme Rope clip Prolonge clip

4

-

DIN EN

ISO 7089

A 4,3 Scheibe Washer Rondelle

5

-

DIN EN

ISO 7049

4,2 x 16 Schraube Screw Vis

Page 52

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 52-

5007090-00

BA-E

®

9.8 Main pillar

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

Standbein kpl. Main pillar complete

Jambe de pivot

complète

1

-

Standbein Main pillar Jambe de pivot

2

-

30 x 30 Stopfen Stopple Bouchon

3

-

DIN EN

ISO 4014

M 8 x 55 Schraube Screw Vis

4

-

DIN EN

ISO 4017

M 10 x 60 Schraube Screw Vis

5

-

M 10 Sterngriff Star grip Poignée-étoile

6

-

DIN EN

ISO 7040

M 8 Mutter Nut Écrou

7

-

DIN EN

ISO 7089

A 8,4 Scheibe Washer Rondelle

8

-

Ø 22 x Ø 8,5 Scheibe Washer Rondelle

9

-

DIN 127 A 10 Federring Spring washer Rondelle-ressort

Page 53

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 53-

5007090-00

BA-E

®

9.9 Extension table

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

TS200

Tischverlängerung kpl.

Table extension

complete

Table de travail

rallonge complète

-

TS250

1

-

TS200

Tischverlängerung Table extension

Table de travail

rallonge

-

TS250

2

-

TS200

Gummiauflage Rubber support plate Support élastique

-

TS250

3

-

Stopfen Stopple Bouchon

4

-

DIN EN

ISO 4017

M 8 x 40 Schraube Screw Vis

5

-

DIN EN

ISO 4032

M 8 Mutter Nut Écrou

Page 54

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 54-

5007090-00

BA-E

®

9.10 Transport handle

Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation

-

-

Transportgriff kpl.

Transport handle

complete

Poignée de transport

complète

1

-

Transportgriff Transport handle Poignée de transport

2

-

Stopfen Stopple Bouchon

3

-

DIN EN

ISO 4017

M 8 x 20 Schraube Screw Vis

4

-

DIN EN

ISO 7089

A 8,4 Scheibe Washer Rondelle

Page 55

TS200 / TS250

Translation of the original operating instruction and spare parts list

- 55-

5007090-00

BA-E

®

10. Wiring diagram

Loading...

Loading...