Page 1

KB300 / KB350 with FS560

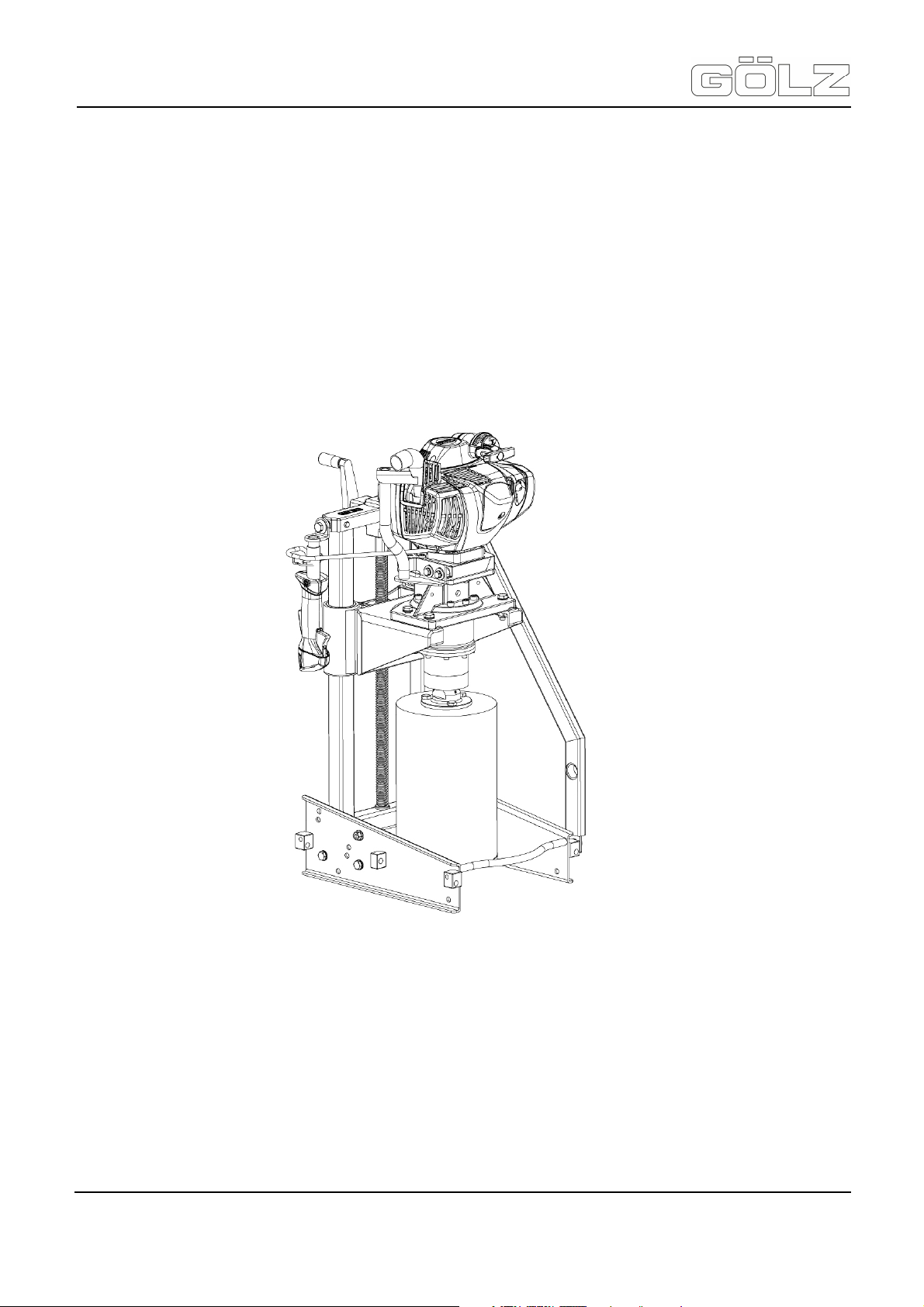

Translation of the original operating instruction and spare parts list

Drill rig

KB 300 - KB 350

with STIHL® Petrol-Engine

FS 560

ZN der Bedienungsanleitung: 5006892-01

Erstellt am: 05 / 2014

Erstellt von: Sabrina Linden

Datei: K:\KDV\5006xxx\5006892-Bedienungsanleitung\

5006892-01-Bedienungsanleitung-E.doc

GÖLZ® GmbH

Dommersbach 51

D-53940 Hellenthal

Telefon: +49 (0) 2482 12 200 / Telefax: +49 (0) 2482 12 222

E-Mail: info@goelz.de / Internet: www.goelz.de

®

- 1-

5006892-01

BA-E

Page 2

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

®

- 2-

5006892-01

BA-E

Page 3

KB300 / KB350 with FS560

shall not be liable for errors in this document (manual instruction and spare parts list) or for

Translation of the original operating instruction and spare parts list

All rights reserved according to DIN ISO 16016.

No part of this document (instruction manual and spare parts list) may be reproduced, adapted, transmitted,

transcribed, stored on a data medium or be translated into another language without prior written approval of

GÖLZ® GmbH

Dommersbach 51

D-53940 Hellenthal

Guarantee

We reserve the right to amend any information included in this document (manual instruction and spare parts

list) at any time and without prior notice.

GÖLZ® assumes no warranty for these documents.

®

GÖLZ

any collateral or consequential damage in connection with shipment, performance or use of the material.

®

- 3-

5006892-01

BA-E

Page 4

KB300 / KB350 with FS560

H. Schulte

Translation of the original operating instruction and spare parts list

EC-DECLARATION OF CONFORMITY

Manufacturer

GÖLZ® GmbH

Dommersbach 51, D-53940 Hellenthal

Tel.: (02482) 12 200 / Fax: (02482) 12 222

Declare hereby certifies on its sole responsibility that the following product:

KB 300 / KB 350

Drill rig

with

FS560

STIHL® Petrol-Engine

Serial number:____________________

which is explicitly referred to by this declaration meet the following directives:

2006/42/EG Safety and health requirement

2004/108/EG Electromagnetic compatibility

97/68/EG i.d.F. 2002/88/EG Exhaust emission directive

2000/14/EG Noise emission

meet the following standards:

EN 12100-1 / EN 12100-2, EN 12348:2000, EN 13309:2000, EN 61000, DIN EN ISO 3744-1995

Documented evidence conforming to the requirements of the directives is kept available for inspection at the

above manufacturer’s address.

Hellenthal, den 08.05.2014 ……………………………………….. ………………………………………..

General Manager

B. Schmitz

Chief of Design

®

- 4-

5006892-01

BA-E

Page 5

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

Contents

®

Preface ................................................................................................................................... 8

General description ............................................................................................................... 8

1.

Technical data and accessory ................................................................................... 9

1.1 Technical data of the machine .............................................................................................. 9

1.1.1

KB300 / KB350 .............................................................................................................................. 9

1.1.2

Motor STIHL® ................................................................................................................................. 9

1.2 Provided accessory ............................................................................................................ 10

1.3 Optional accessory ............................................................................................................. 10

2.

Description ................................................................................................................ 11

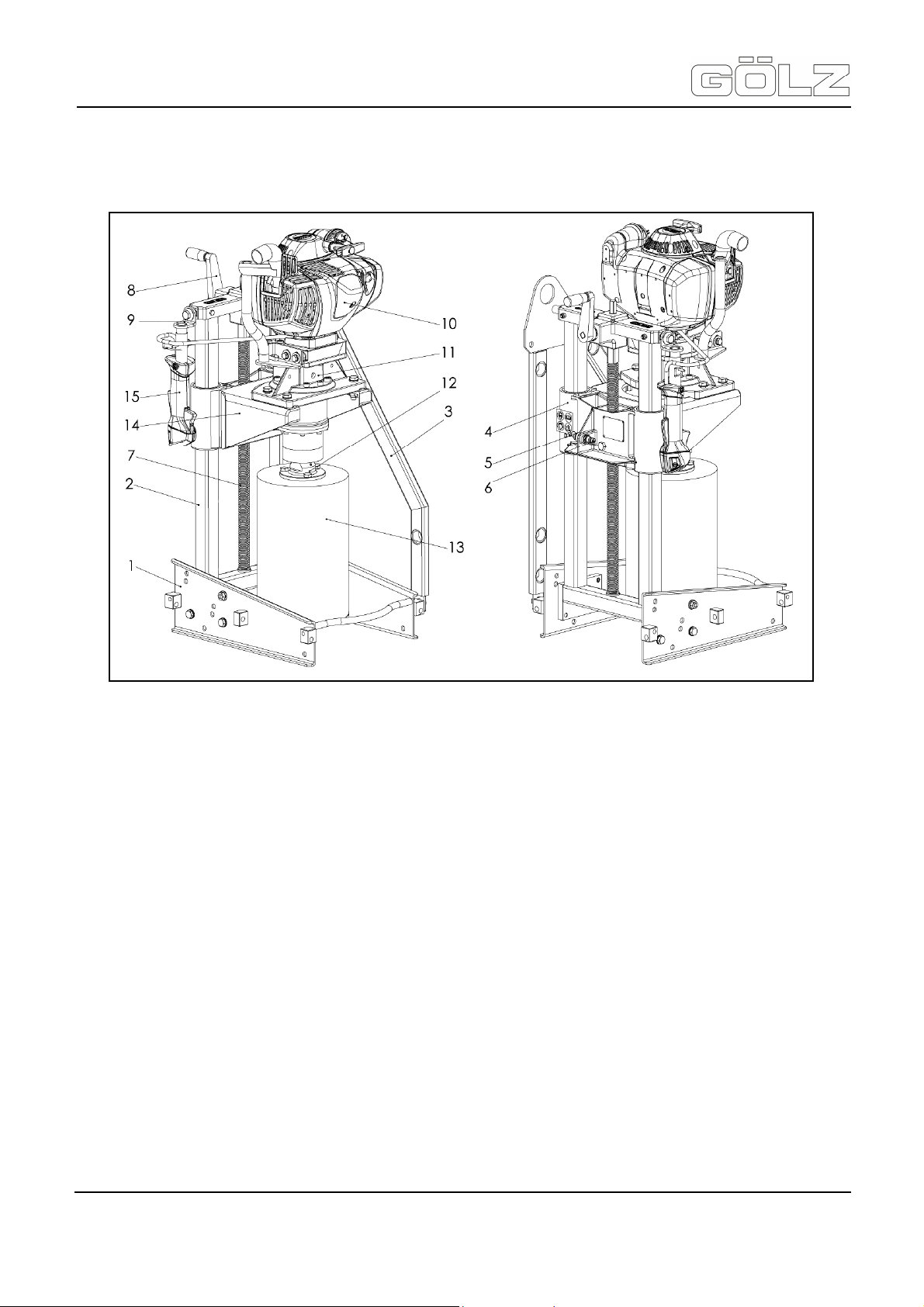

2.1 Main parts .......................................................................................................................... 11

2.2 Functional description ........................................................................................................ 11

3.

Basic safety instructions ......................................................................................... 13

3.1 Intended use ...................................................................................................................... 13

3.2 Operating range ................................................................................................................. 13

3.3 Organisational measures .................................................................................................... 14

3.4 Selection and qualification of person .................................................................................. 15

3.5 Safety instructions governing specific operational phases .................................................. 15

3.6 Special work related to the maintenance and repair of the machine ................................... 16

3.7 Information about special risks with electrical energy ......................................................... 17

3.8 Gas, dust, steam, smoke .................................................................................................... 17

3.9 Noise .................................................................................................................................. 17

3.10 Illumination ......................................................................................................................... 18

3.11 Oils, greases and other chemical substances ..................................................................... 18

3.12 Transport ............................................................................................................................ 18

3.13 Store .................................................................................................................................. 19

4.

Bringing into service ................................................................................................ 20

4.1 Export checking .................................................................................................................. 20

4.2 Petrol drill motor FS560 ...................................................................................................... 20

4.2.1

M-Tronic ....................................................................................................................................... 20

4.2.2

Fuel .............................................................................................................................................. 21

4.2.3

Air filter ......................................................................................................................................... 22

4.2.4

Winter operation .......................................................................................................................... 22

4.2.5

Spark plug .................................................................................................................................... 23

4.2.6

Adjusting the throttle cable .......................................................................................................... 23

4.3 Fixing the machine ............................................................................................................. 24

4.3.1

Placed on the ground secured by spikes..................................................................................... 24

4.3.2

By strap and ratchet at exposed pipe .......................................................................................... 25

4.3.3

Combination of ground spikes and strap ..................................................................................... 25

4.3.4

Fixing with dowels ........................................................................................................................ 26

4.3.5

Fixing with vacuum hold down ..................................................................................................... 26

4.3.6

Frame extension .......................................................................................................................... 27

4.4 Assembling a drill motor ..................................................................................................... 27

- 5-

5006892-01

BA-E

Page 6

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

4.4.1

Assembling a drill motor with gear box ........................................................................................ 27

4.4.2

Changing a drill motor with gear box ........................................................................................... 28

4.5 Water supply ...................................................................................................................... 28

4.5.1

With water tank-pressurzied type ................................................................................................ 28

4.5.2

Public water mains ....................................................................................................................... 29

4.6 Angle-drilling ...................................................................................................................... 29

4.7 Drill bit ................................................................................................................................ 30

4.7.1

With UNC-Adapter ....................................................................................................................... 30

4.7.2

With 3-hole flange ........................................................................................................................ 30

5.

Operation ................................................................................................................... 31

5.1 Before starting .................................................................................................................... 31

5.2 Starting the engine ............................................................................................................. 31

5.3 Operating instructions engine ............................................................................................. 33

5.4 Start drilling ........................................................................................................................ 33

5.5 Stop drilling ........................................................................................................................ 34

5.6 Changing the drill bit ........................................................................................................... 34

6.

Maintenance and care .............................................................................................. 35

6.1 Drill rig ................................................................................................................................ 35

6.2 Drill bit ................................................................................................................................ 35

6.3 Replacing the air filter ......................................................................................................... 35

6.4 Cleaning the air filter .......................................................................................................... 36

6.5 Changing the spark plug ..................................................................................................... 36

6.6 Replacing the starter rope and rewind spring ..................................................................... 37

6.7 Fuel pickup body in tank ..................................................................................................... 40

6.8 Spark arrestor in muffler and spacer................................................................................... 40

6.9 Maintenance and care engine ............................................................................................ 40

7.

Troubleshooting ....................................................................................................... 42

8.

Spare parts list .......................................................................................................... 44

8.1 Using the spare parts list .................................................................................................... 44

8.1.1

Safety regulation .......................................................................................................................... 44

8.1.2

Ordering information .................................................................................................................... 44

8.1.3

Distribution agencies ................................................................................................................... 45

8.2 Wearing parts ..................................................................................................................... 46

9.

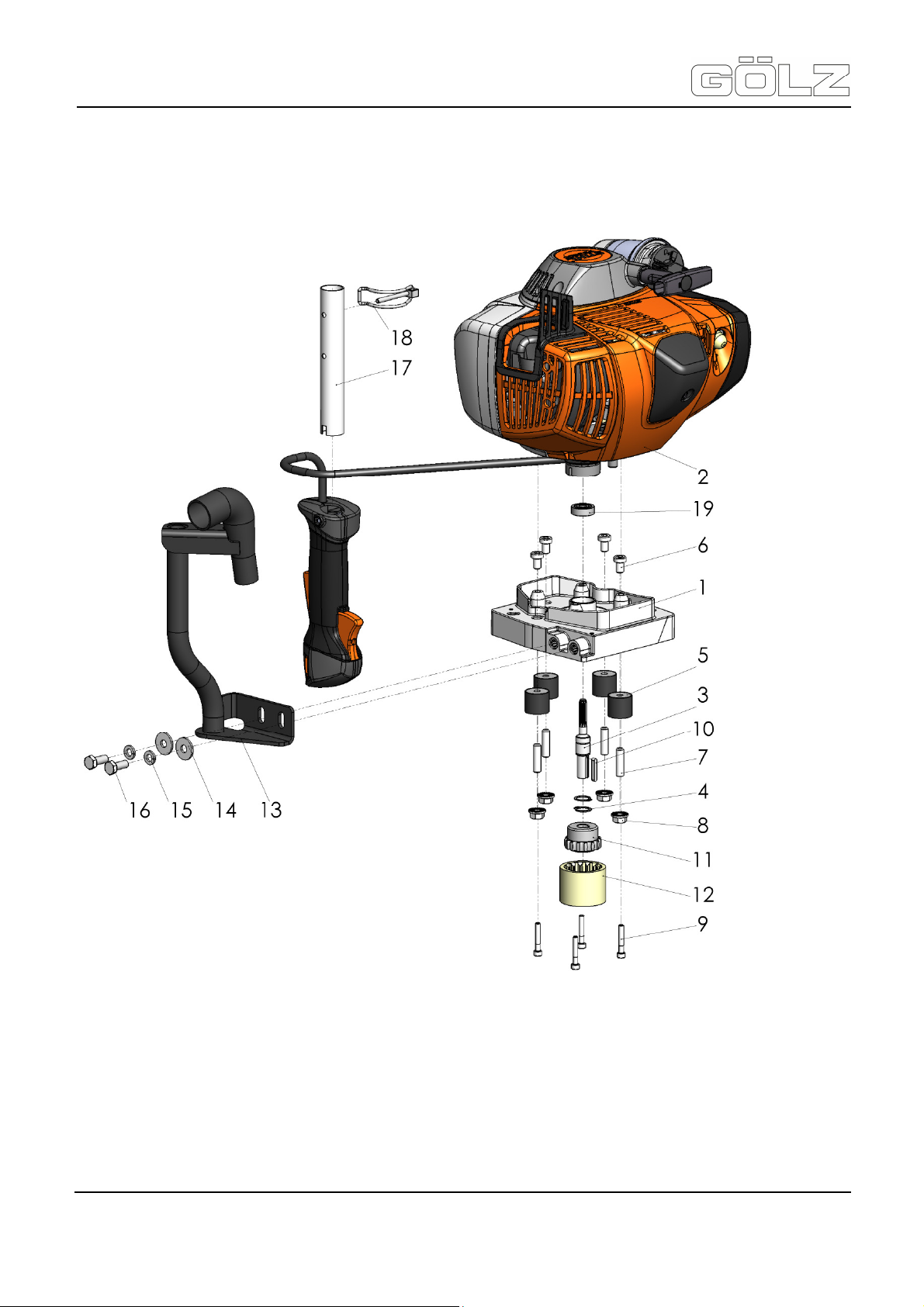

Exploded view and spare parts list ......................................................................... 47

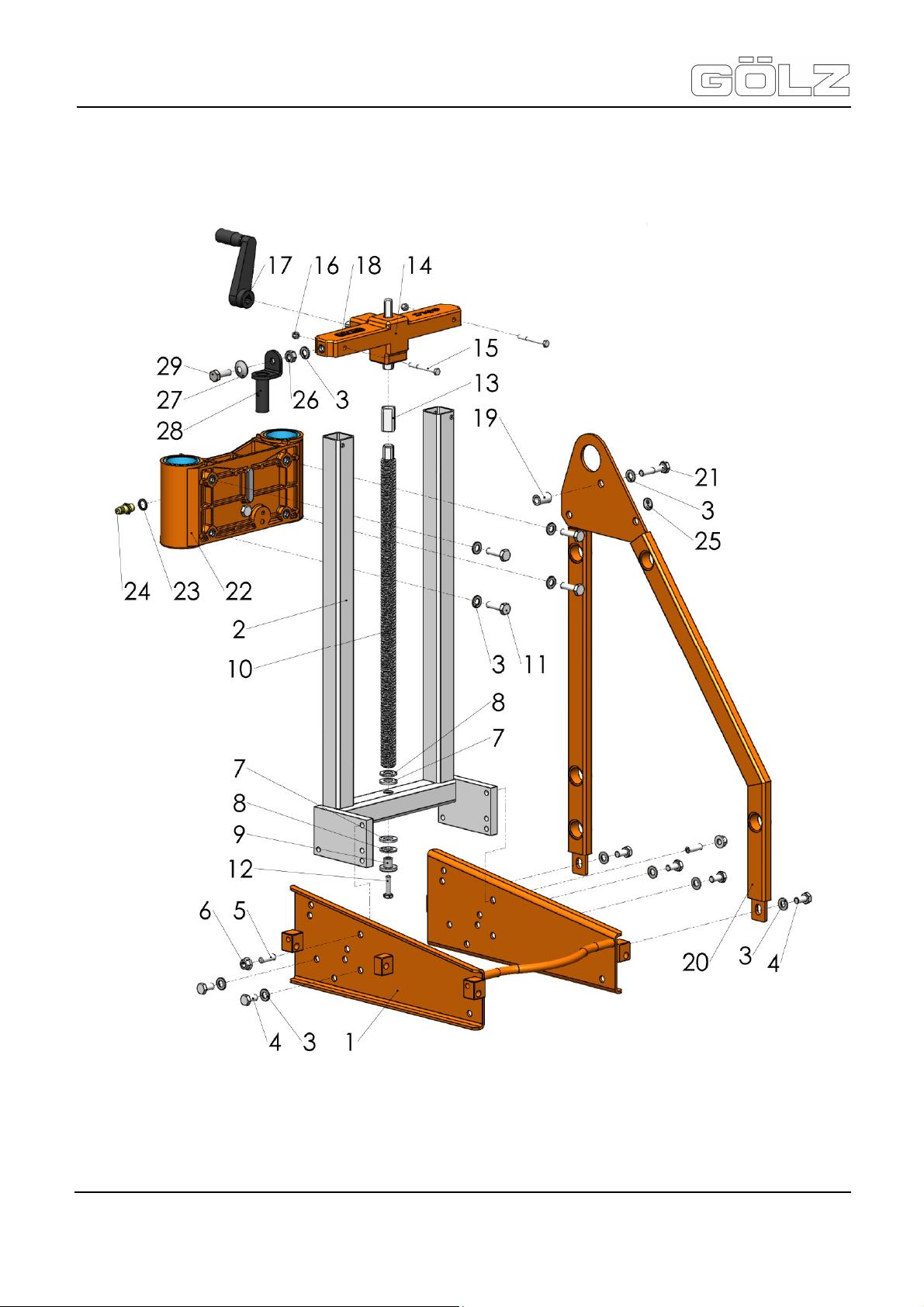

9.1 Drill rig ................................................................................................................................ 49

9.1.1

Drill rig KB300 .............................................................................................................................. 49

9.1.2

Drill rig KB350 .............................................................................................................................. 53

9.1.3

Carriage ....................................................................................................................................... 57

9.1.4

Crankcase .................................................................................................................................... 58

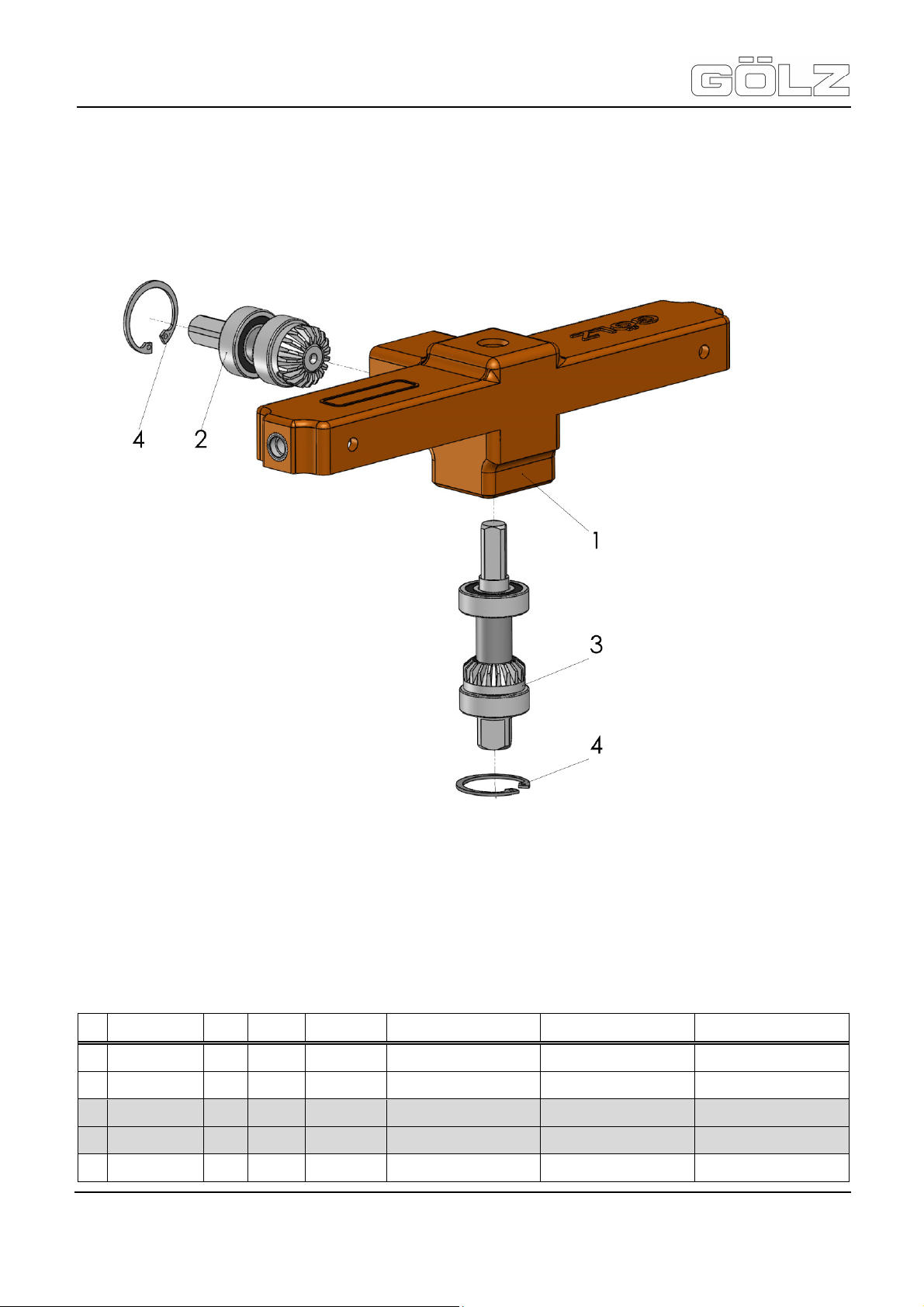

9.2 Gear box carrier ................................................................................................................. 59

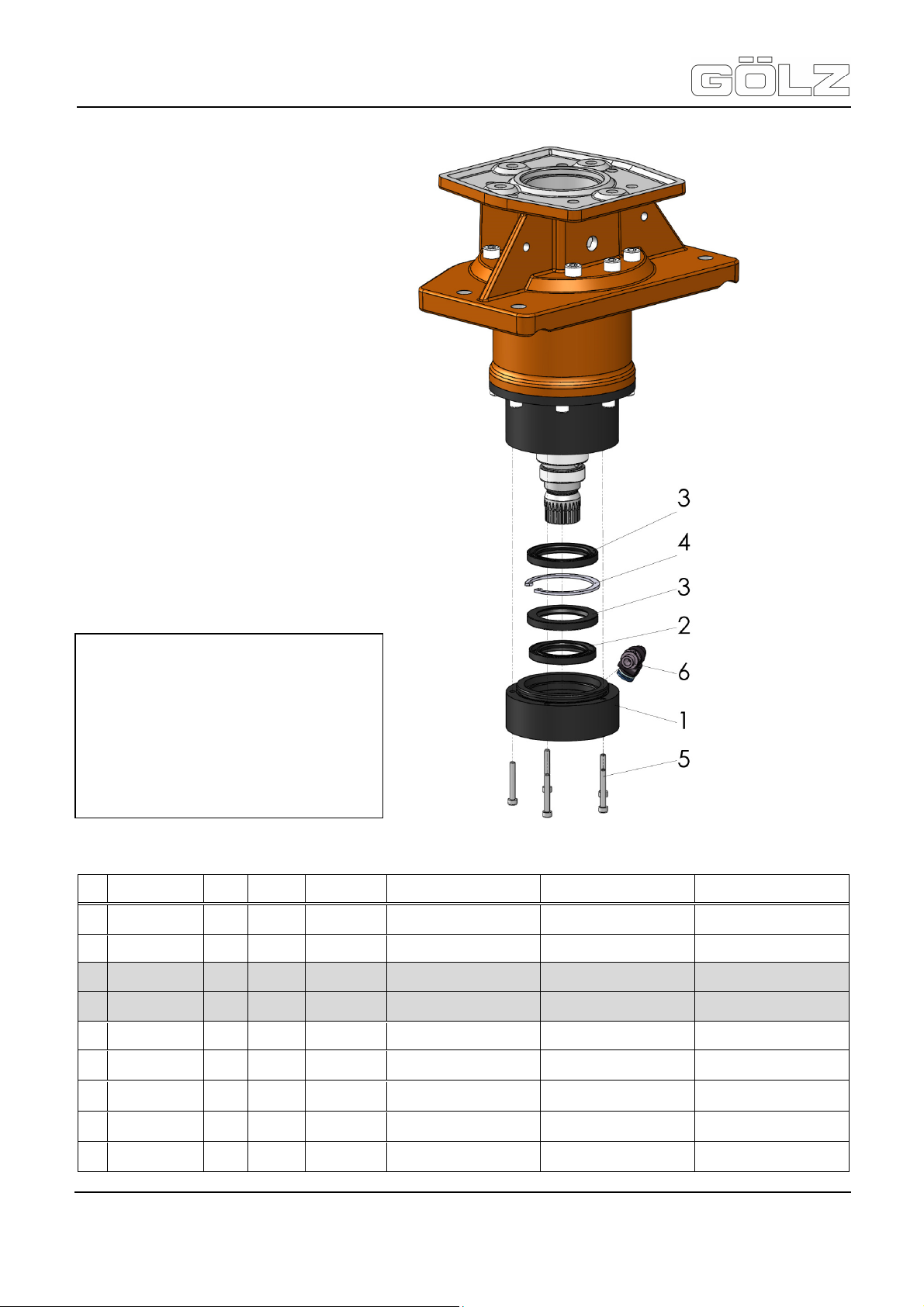

9.3 Planetary gear .................................................................................................................... 60

9.4 Drive motor ......................................................................................................................... 61

9.5 Tool acceptance ................................................................................................................. 63

9.6 Motor .................................................................................................................................. 65

®

- 6-

5006892-01

BA-E

Page 7

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

9.6.1

Motor - Crankcase, Cylinder ........................................................................................................ 65

9.6.2

Motor - Rewind starter ................................................................................................................. 67

9.6.3

Motor - Muffler, Shroud ................................................................................................................ 69

9.6.4

Motor - Fuel tank .......................................................................................................................... 71

9.6.5

Motor - Spacer flange, Air filter, Filter housing ............................................................................ 73

9.6.6

Motor - Carburetor ....................................................................................................................... 75

9.6.7

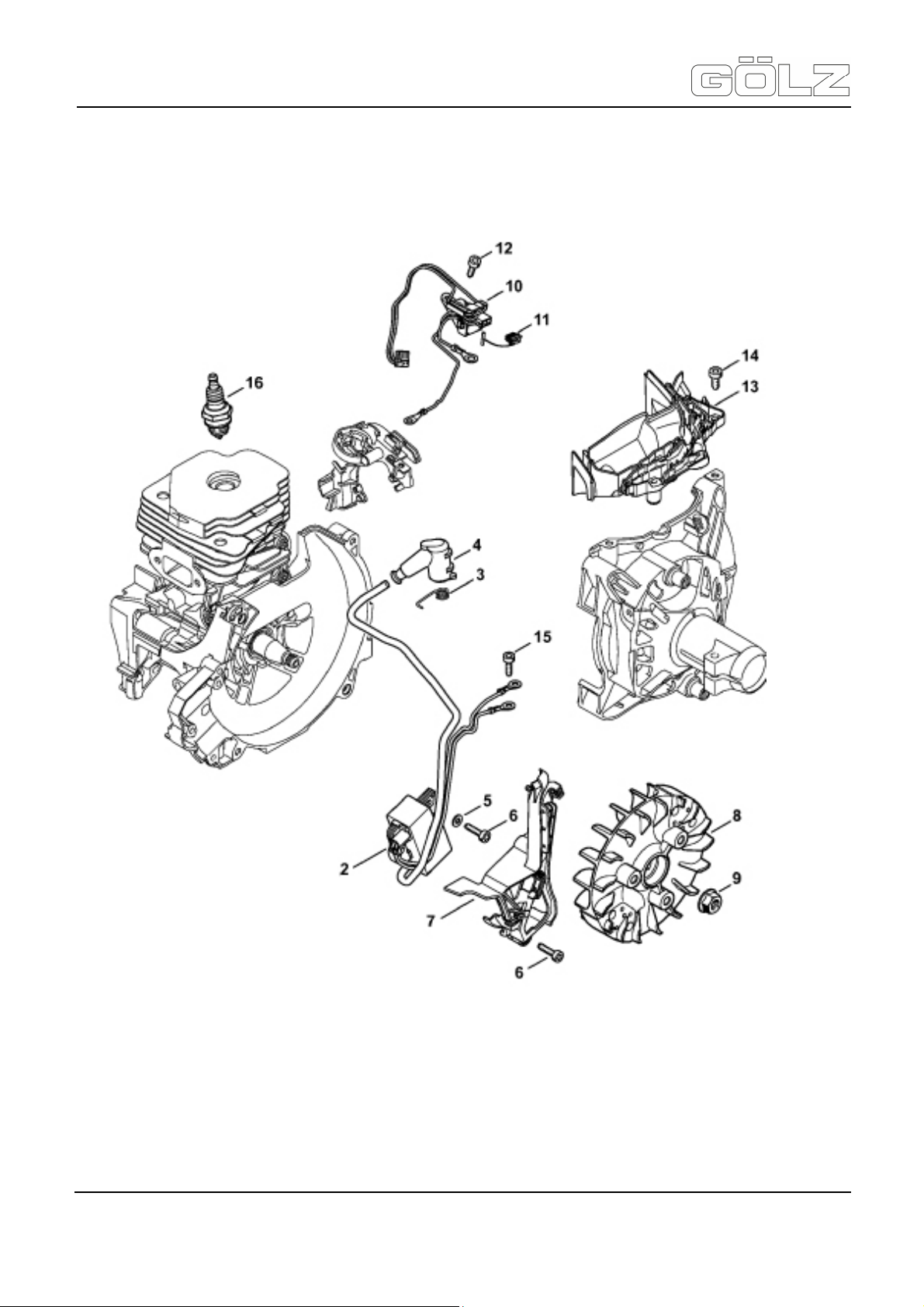

Motor - Ignition system ................................................................................................................ 77

9.6.8

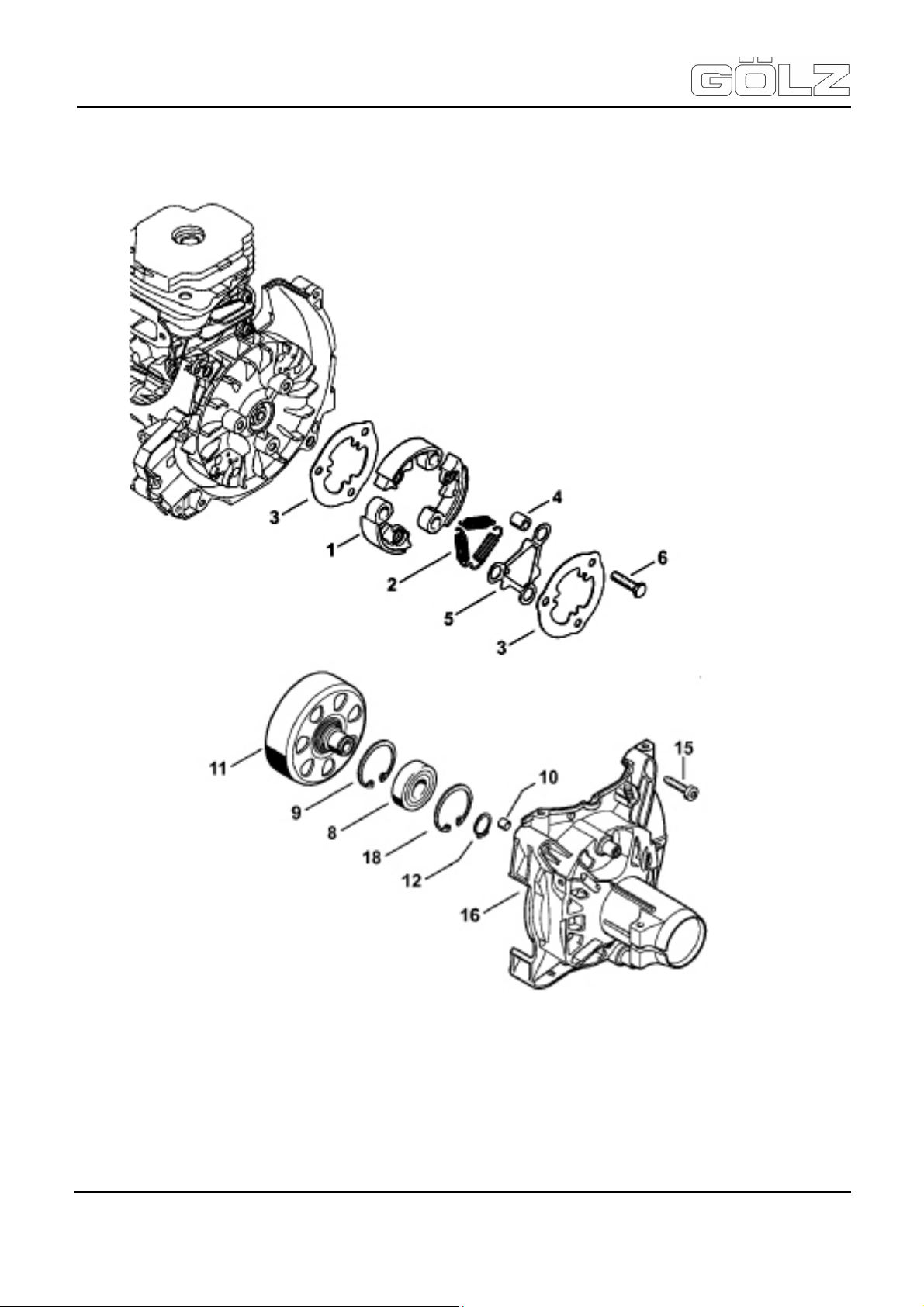

Motor - Clutch, Clutch housing .................................................................................................... 79

9.6.9

Motor - Handlebar ........................................................................................................................ 81

®

- 7-

5006892-01

BA-E

Page 8

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

Preface

This operating manual is designed to familiarize the user with drill rig, hereinafter referred to as the machine,

and to use its intended applications.

The operating manual contains important information on how to operate the machine safely, properly and most

efficiently. Observing these instructions helps to avoid danger, to reduce repair costs and downtimes and to

increase the reliability and the life of the machine.

This operating manual is to be supplemented by the respective national rules and regulations for accident

prevention and environmental protection.

The operating manual must always be available wherever the machine is in use.

It is to be read and applied by any person in charge of work with or on the machine, such as:

• Operation including setting up, troubleshooting in the course of work, elimination of manufacturing waste,

care and disposal of fuels and consumables.

• Servicing (maintenance, inspection, repair) and/or

• Transport

In addition to the operating manual and to the mandatory rules and regulations for accident prevention of the

country and place of use of the machine, the recognized technical rules for safe and proper working conditions

and procedures are also to be observed.

In this manual all the information required for the intended use of the unit is included. If though you have any

specific questions, please refer to your representative, to one of our sales representatives or directly to us:

GÖLZ® GmbH

Dommersbach 51, D-53940 Hellenthal

Telefon: +49 (0) 2482 12 200 / Telefax: +49 (0) 2482 12 222

E-Mail: info@goelz.de / Internet: www.goelz.de

General description

Wear safety glasses!

Wear hard hat!

Wear ear muffs!

®

Wear safety boots!

Wear protective gloves!

Never touch!

Danger exists to cut oneself!

Wear safety clothes!

Read owner’s manual

before first initiation!

General danger!

With water spraying forbidden!

- 8-

Wear dust protection!

Important advice!

Warning! Hot surface!

Risk of injuries !

5006892-01

BA-E

Page 9

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

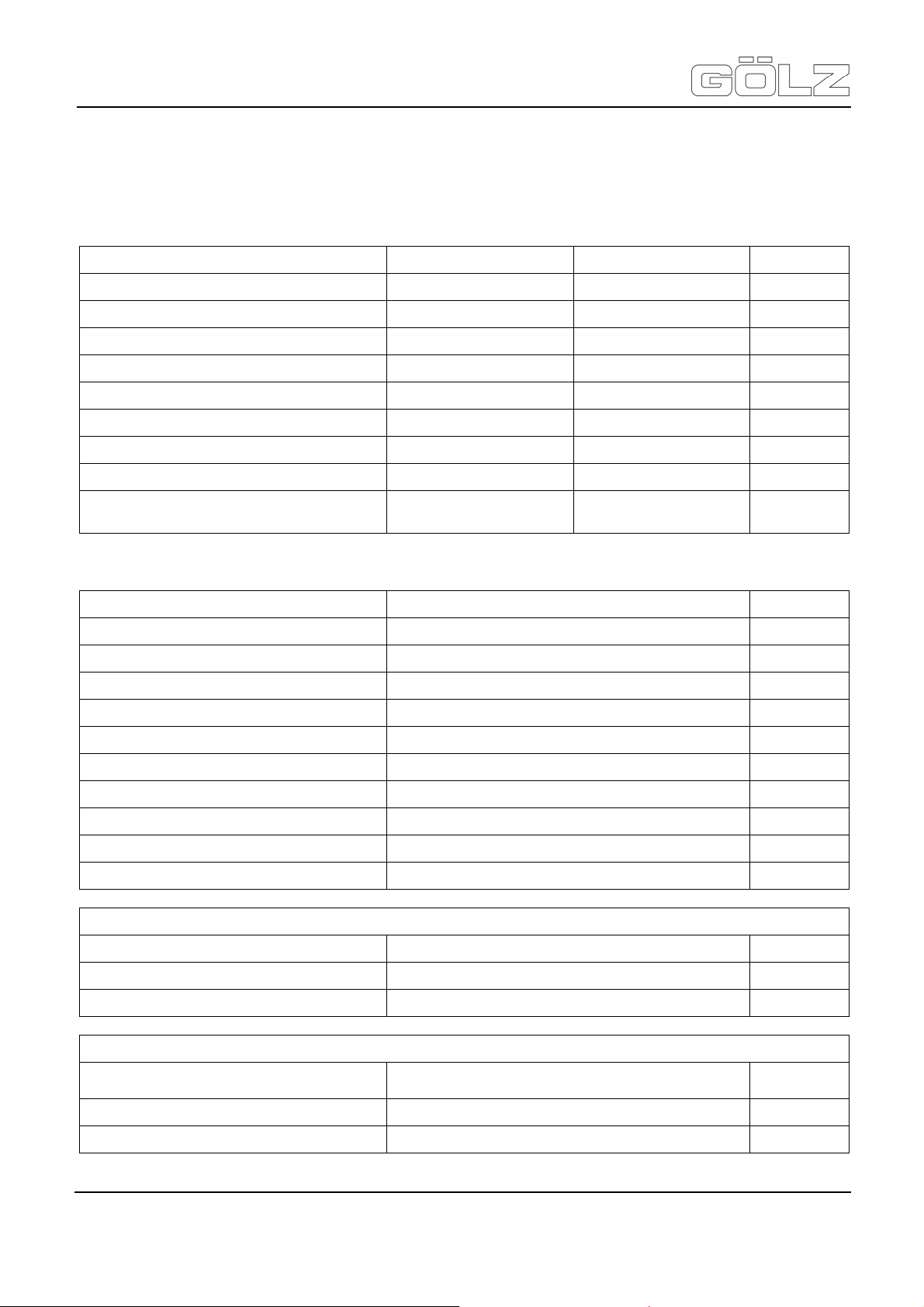

1. Technical data and accessory

1.1 Technical data of the machine

1.1.1 KB300 / KB350

Type KB 300 KB 350

Stroke 450 - 17.7 450 - 17.7 mm - in.

Feed Manual Manual

Angle drilling up to 45° up to 45°

Weight 21 - 46.3 24 - 53 kg - lbs.

Weight with motor 41 - 90.4 44 - 97 kg - lbs.

Length 440 - 17.3 550 - 21.6 mm - in.

Breadth 340 - 13.4 410 - 16.1 mm - in.

Height 800 - 31.5 800 - 31.5 mm - in.

Drilling range

Ø 110 - Ø 290

Ø 4.4 - Ø 11.4

Ø 110 - Ø 354

Ø 4.4 - Ø 13.9

1.1.2 Motor STIHL®

Type FS560

mm - in.

®

Driving mechanism STIHL® - single cylinder - two-stroke-engine

Capacity 57,1 cm³

Cylinder bore 47 - 1.85 mm - in.

Piston stroke 32,9 - 1.3 mm - in.

Power 2,8 (3,8) kW (PS)

Max. operating speed of the spindle 100 / 300 / 600 RPM

Weight with drilling gear 20 - 44.1 kg - lbs.

Continuous sound level Lpeq 101 dB(A) according to ISO 22868

Sound power level Lweq 114 dB(A) according to ISO 22868

Vibration measurement a 3,3 m/s² according to ISO 22867

Ignition system (with electronic speed limit)

Principle Electronically controlled magneto

Spark plug

Electrode gap 0,5 - 0,02 mm - in.

Fuel system

Carburettor

Air filter Paper

(interference-suppressed)

NGK BPMR7A

Non position sensitive diaphragm carburettor with

integrated fuel pump

Fuel tank capacity 0,99 (990) L (cm³)

- 9-

5006892-01

BA-E

Page 10

KB300 / KB350 with FS560

Fine dust vacuum cleaner, dry vacuum cleaner, wet vacuum

Translation of the original operating instruction and spare parts list

Mixing ratio

with STIHL® 1:50 two-stroke engine oil 1:50 = 1 part oil + 50 parts petrol

®

with other branded two-stroke engine oils

classification TC

1:25 = 1 part oil + 25 parts petrol

1.2 Provided accessory

• Strap; 2,1 m, Clamping ratchet, Linch pin

• Ground spike

• Exhaust hose; 4 m

• Pressure tank 10l with hose

• 3-hole-flange or UNC-adapter

• Tool kit

• Wrench SW 17

• Wrench

• Operating instruction

• Spare parts list

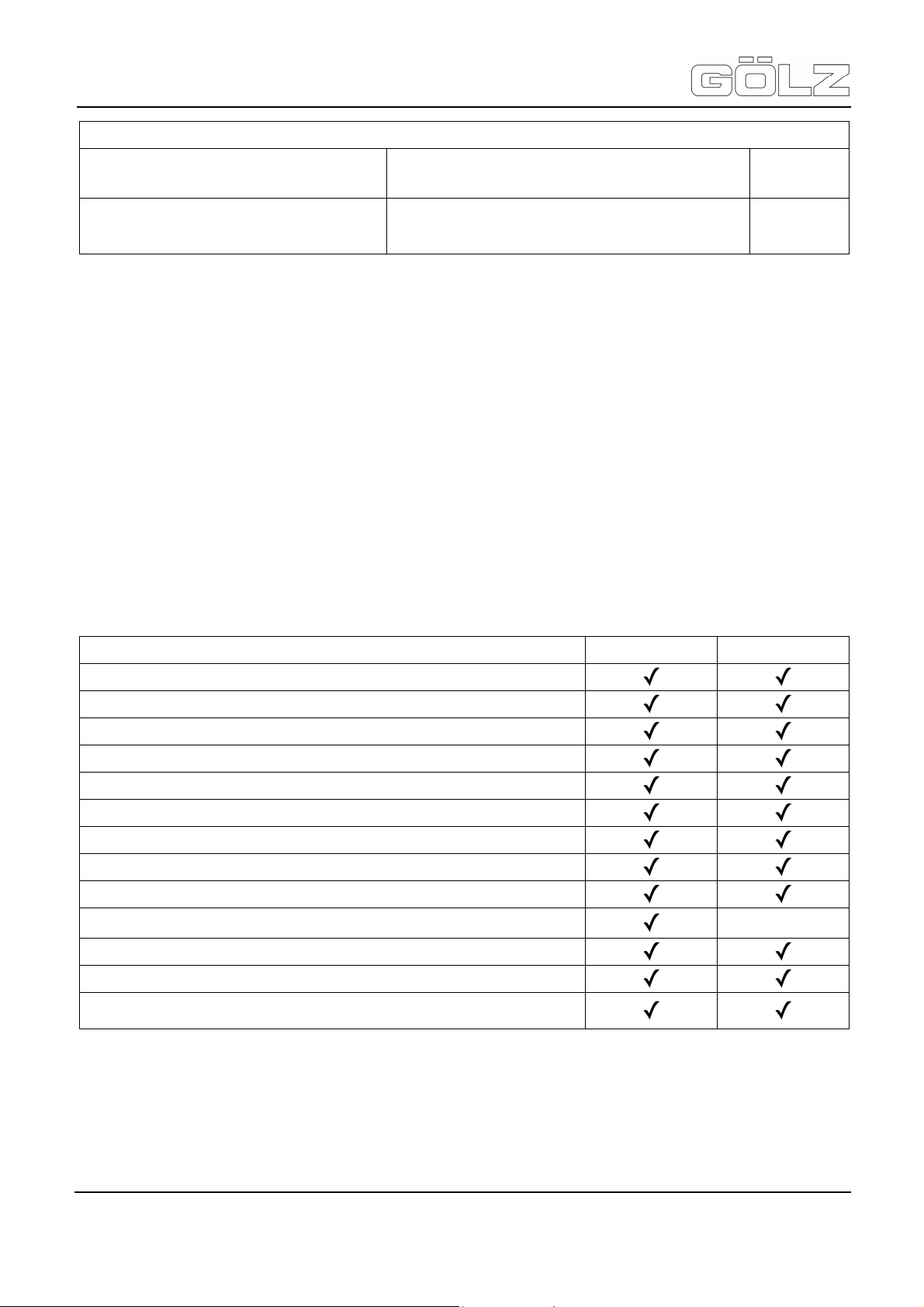

1.3 Optional accessory

KB 300 KB 350

Work with electric motor

Work with pneumatic motor

Work with hydraulic motor

Suction plate kit (Suction of smooth pipes)

Vacuum pump C10

Base plate kit (sample coring)

Roller guide kit (base plates)

Frame extension (pipes < Ø 300)

Support (drill holes in the pipe Ø 1000 or more)

Dowel plate kit (dowels and screws)

Backhoe attachment kit

Sharpening plate (drill bits)

cleaner

For the item number of accessories, please refer to the current catalogue of GÖLZ®

If accessories are used which do not correspond to GÖLZ® specifications, no liability is assumed for any

damage resulting hereof.

For details regarding the selection of the right GÖLZ® diamond drill bits, please refer to the current GÖLZ

catalogue for diamond tools.

xxxx

®

- 10-

5006892-01

BA-E

Page 11

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

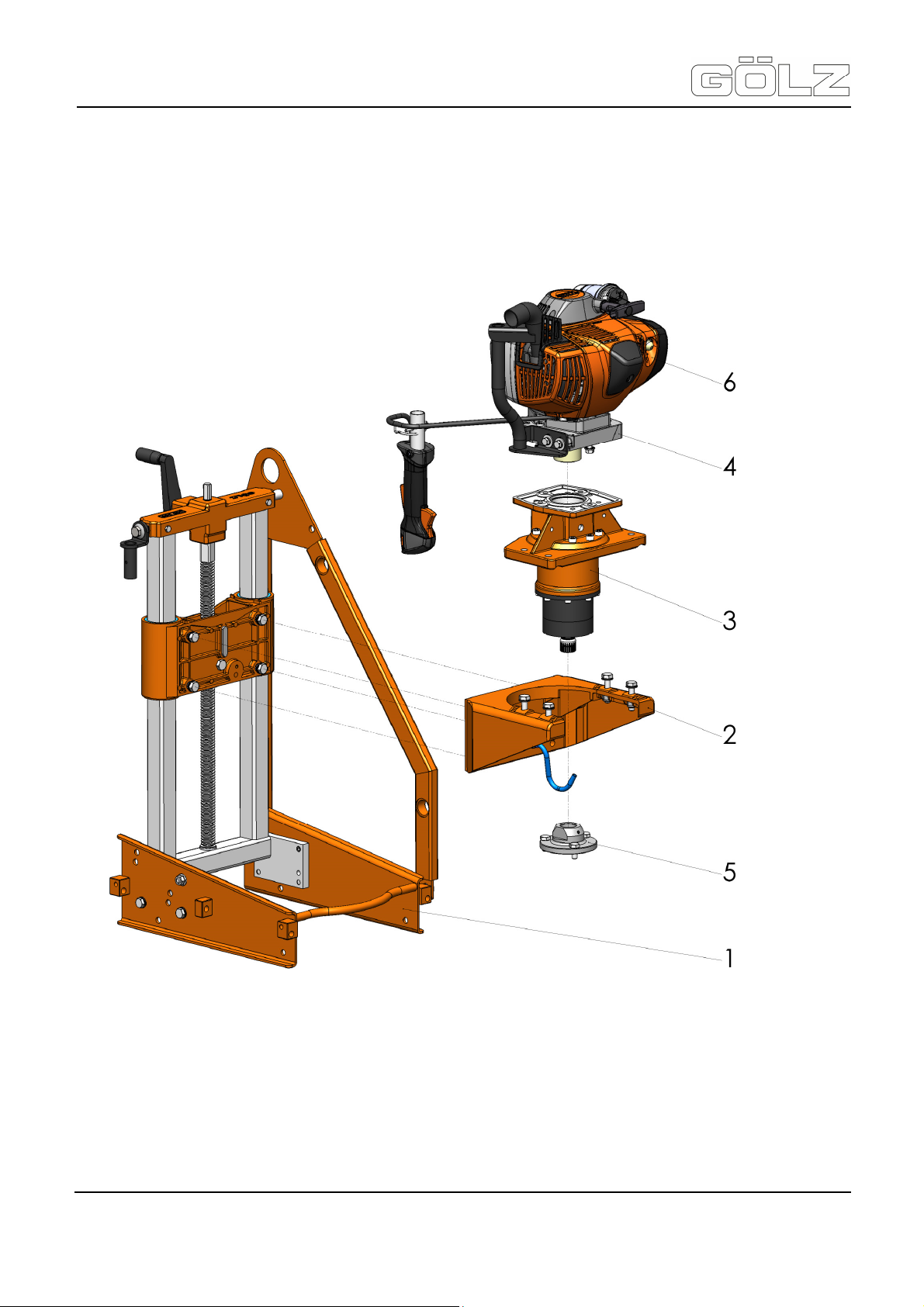

2. Description

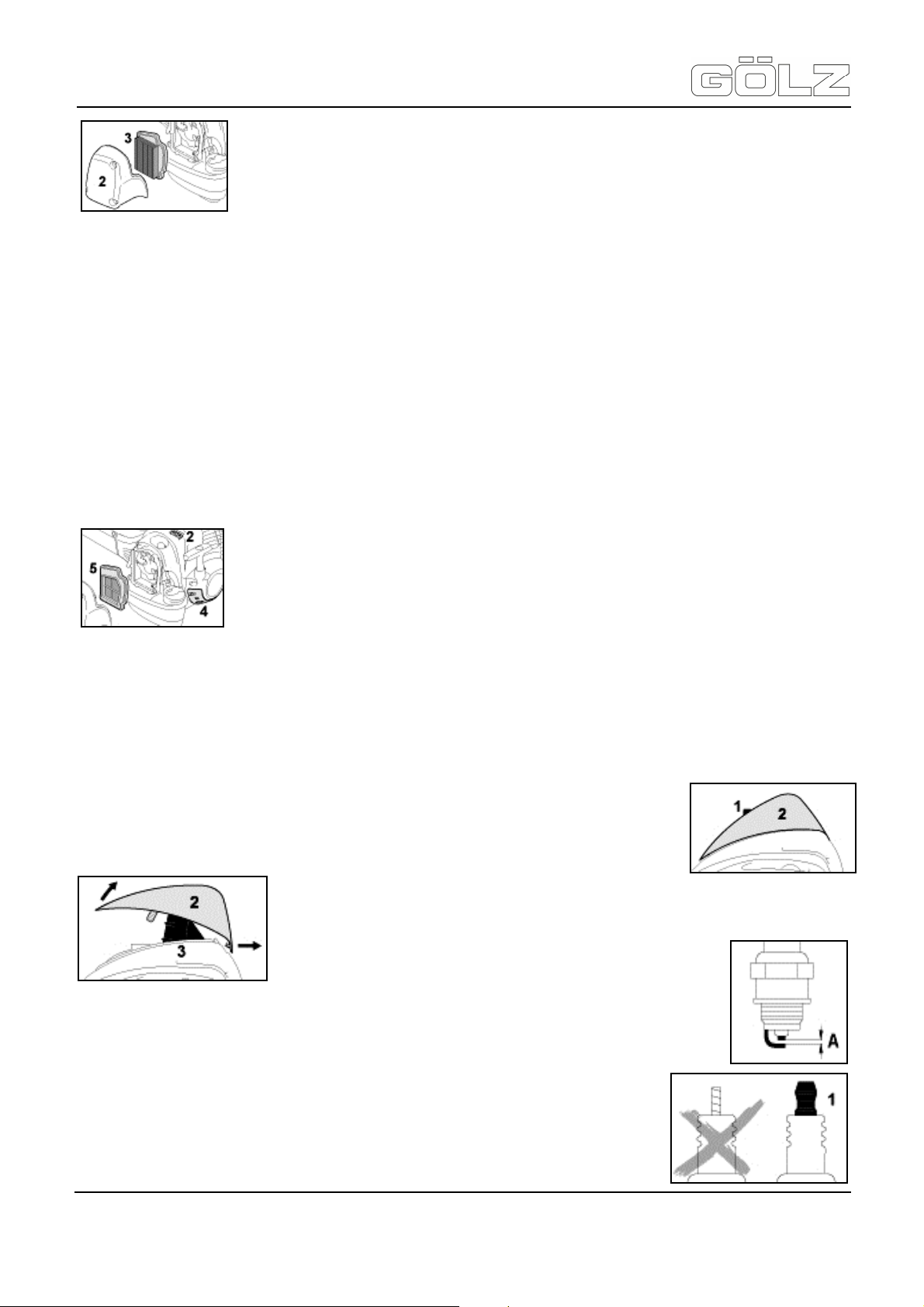

2.1 Main parts

2.2 Functional description

Due to its compact design and its lightweight construction, the KB300/350 unit with FS560 offers a practiceoriented use in a tight space. The proven STIHL®-Drive and the GÖLZ®-System-Technology ensure highest

operational safety and economic efficiency.

The KB300/350 with FS560 is used as a channel core drill for drills up to Ø 300 respectively Ø 350 mm for

manufacturing sewer pipes and manholes, for manufacturing new channels on the construction site as well as

for manufacturing later channel house connections.

Due to the fact that this unit is operated by the STIHL® FS560 gasoline-combustion engine the unit can be used

independently of power supply networks and irrespectively of its position.

To be able to operate this combustion engine also in a tight space, the supplied exhaust gas hose is fixed to the

motor so that exhaust gases can be discharged.

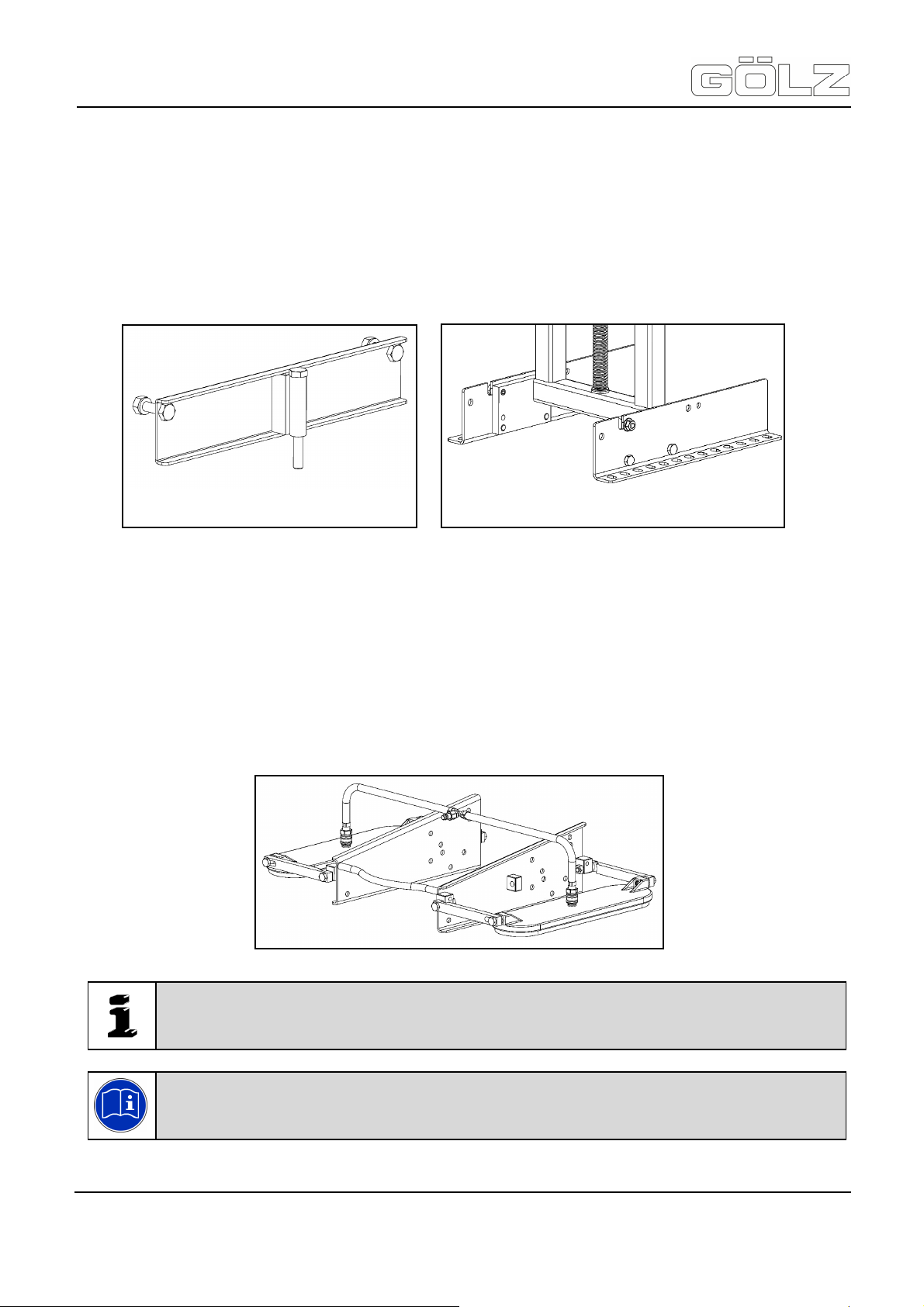

1) Pipe base 6) Water coupler 11) Planetary gear

2) Column 7) Spindle 12) 3-hole-flange

3) Floor frame with 8) Handle 13) Drill bit

lifting eye

4) Carriage 9) Control holder 14) Gear box carrier

5) Water tap 10) Petrol engine 15) Handlebar

®

- 11-

5006892-01

BA-E

Page 12

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

The exhaust of the motor as well as the exhaust gas hose were fitted with a protection against accidental

contact in order to avoid direct skin contact with hot surfaces.

The operating handle of the motor can be kept in the hand but also be positioned via the grip-adaption to the

unit.

On the gear box, either a drill bit flange or an adapter for the different tool sizes can be fitted. The

assembly of the tool is simple and easy. Regarding the flange the drill bit is fixed via a screw connection,

regarding the adapter via a threaded bolt.

The safe and easy assembly allows a quick exchange of the tools.

Water is supplied either via the supplied pressurized water container or via an external water connection. The

water hose of the pressurized water container is fitted via a coupling on the connection of the drill carriage. Thus

the water is directly routed via the gearbox into the drill bit and provides a sufficient cooling of the tool and binds

the cutting material.

The drill carriage moves on a double-guide column by means of a trapezoidal spindle. The trapezoidal spindle

allows an easy and smooth movement of the drill carriage on the column.

The drive is provided manually by default via the hand crank which can be fixed to the unit in two different ways.

Due to its special form, the pipe base can be set up with sewer junctions having different pipe diameters but

also at ground level. The base frame is fitted on the left by default, but can also be fitted on the right side. The

base frame provides the optimal support for working with the unit sidewise.

The KB300/350 offers the possibility of angle adjustment. Via the guide column, drill cuttings can be adjusted at

angles of 90°, 55° and 45°. This requires only a few screws to be loosened and the base frame to be rotated.

Due to its variable tension belt fastening or by using pegs, the unit can be used in different operative positions.

The wide range of accessories allows opening up additional working areas and additional drive systems.

Due to its compact design, the unit is easy to transport. The motor with gearbox can be easily and quickly

removed for transport. Via the crane eye which is attached to the base frame the KB300/350 with FS560 can

also be lifted with a crane.

The operator's station is behind the guide column or on the left or right next to it.

For working with this unit we recommend GÖLZ® diamond tools.

®

- 12-

5006892-01

BA-E

Page 13

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

3. Basic safety instructions

In this manual the following terms and symbols are used for particular important information:

Important text passages are highlighted in italics or bold or can be found in a grey highlighted text field.

3.1 Intended use

The machine has been built in accordance with state-of-the-art standards and the recognized safety rules.

Nevertheless, its use may constitute a risk to life and limb of the user or of third parties, or cause damage to the

machine and to other material property.

The machine must only be used in technical perfect condition in accordance with its designated use and the

instructions set out in the operating manual, and only by safety-conscious persons who are fully aware of the

risks involved in operating the machine. Any functional disorders, especially those affecting the safety of the

machine, should therefore be rectified immediately!

The machine is designed exclusively for drilling in concrete, reinforced concrete, natural stone, cast stone and

brickwork. Using the machine for purposes other than mentioned above (such as drilling in wood and so on) is

considered contrary to its designated use. The GÖLZ® GmbH cannot be held liable for any damage resulting

from such use. The risk of such misuse lies entirely with the user.

Only use gear drives and motors, which are provided by GÖLZ® GmbH. Also attend those operating manuals.

Operating the machine within the limits of its designated use also involves observing the instructions set out in

the operating manual and complying with the inspection and maintenance directives.

3.2 Operating range

The operating range of the unit can be extended due its wide range of accessories allowing easy retrofitting

which can be carried out by the operating personnel themselves.

Do not modify, add components to or retrofit the unit in a way which could affect its safety and do not use nonofficial accessories! This is not allowed without prior approval of GÖLZ® GmbH!

Note / Important: Contains important information which stands out from the other text!

Attention: Contains instructions which must be strictly observed to prevent damage from

the unit and the operator!

Attention: Read and observe all the operating instructions which belong to this unit!

Note: Read and observe the operating instructions to the accessories!

®

- 13-

5006892-01

BA-E

Page 14

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

3.3 Organisational measures

This operating manual must always be at hand at the place of use of the machine and must be accessible to the

person operating the machine!

In addition to this operating manual, all other generally applicable legal and other mandatory regulations

relevant to accident prevention and environmental protection must be observed! Such obligations may also

comprise the handling of hazardous materials, provisioning and/ or wearing of personal protective equipment, or

road traffic regulations.

This operating manual must be supplemented by instructions covering the duties involved in supervising and

notifying special organizational features, such as job organization, work flows or the person entrusted with the

work. Person entrusted with work on the machine must have read the operating manual prior to taking up work.

This applies especially to persons working only occasionally on the machine, e.g. during set-up or maintenance

activities.

Check - at least from time to time - whether the personnel is carrying out the work in compliance with the

operating manual and paying attention to risks and safety-relevant factors.

For reasons of safety, long hair must be tied back or otherwise secured, garments must be close-fitting and no

jewellery - including rings - may be worn.

Severe injury may result from being caught by moving parts of the machine. Personal protective equipment

must be used wherever required by the circumstances or by law (e.g. safety glasses, ear protectors, safety

boots, suitable safety clothing). Observe the regulations for prevention of accidents! Observe all safety

precautions and warnings attached to the machine and always keep them in good and perfectly legible

condition.

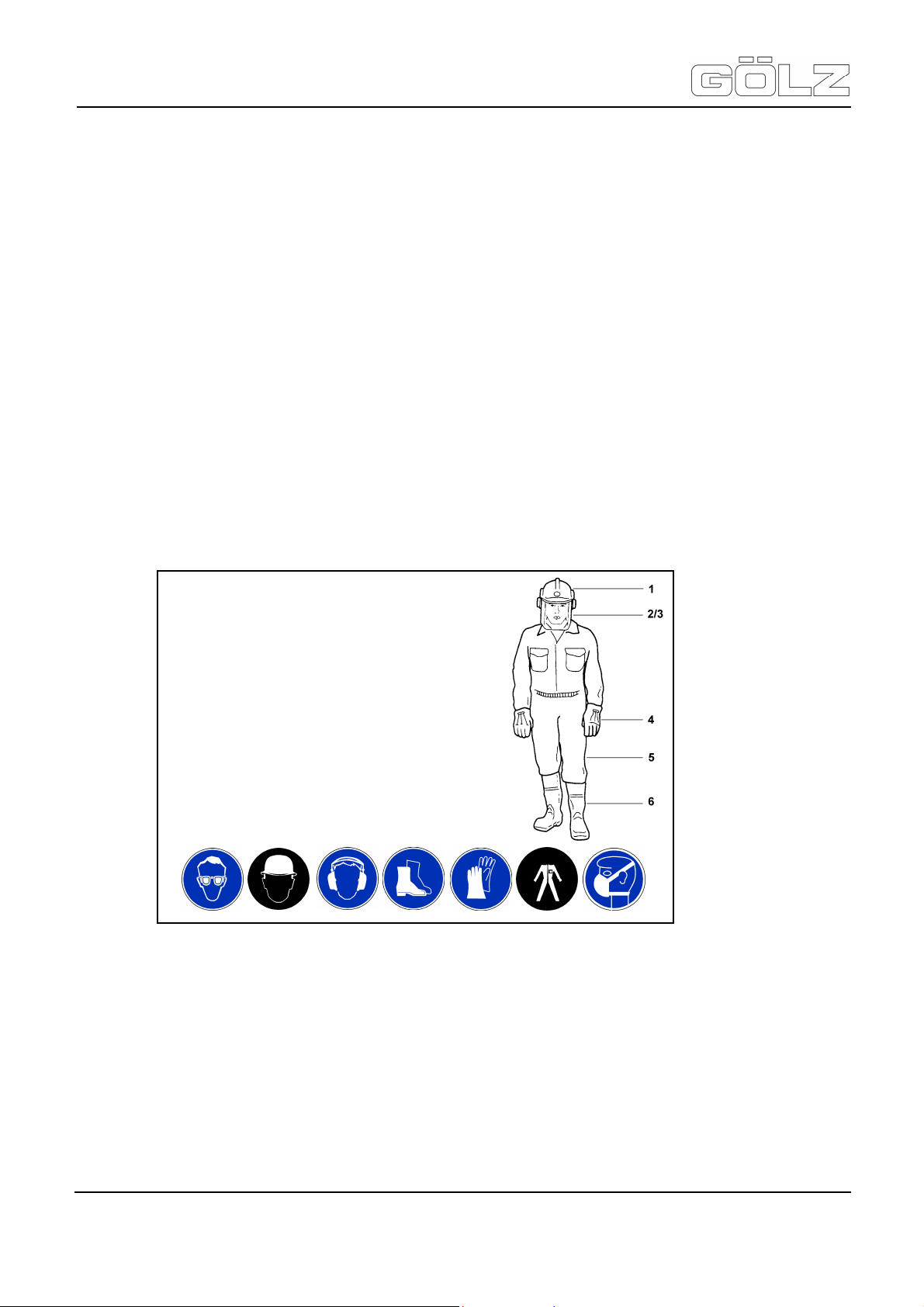

The personal protection equipment should consist of the following parts:

1) Hard hat with ear muff

2) Visor or safety glasses

3) Dust mask

4) Protective gloves

5) Safety clothes

6) Safety boots

®

In case event of safety-relevant modifications or changes in the behaviour of the machine, stop the machine

immediately and report the malfunction to the competent authority/ person. Do not remove or make inoperative

any safety devices the machine is equipped with.

Never make any modifications, additions or conversions which might affect safety without GÖLZ® GmbH prior

approval! This also applies to the installation and adjustment of safety devices as well as to welding and drilling

work on supporting structures.

Damaged or worn parts of the product must be replaced immediately. Use genuine spare parts only.

All spare parts and tools must comply with the technical requirements specified by the GÖLZ® GmbH. Adhere to

the legally prescribed preventive maintenance and inspection intervals or those specified in this operating

manual!

All maintenance and repair activities must be performed by qualified personnel using suitable tools and other

suitable workshop equipment.

- 14-

5006892-01

BA-E

Page 15

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

Observe the fire alarm and fire fighting measures. The personnel must be made familiar with the location and

handling of fire extinguishers!

3.4 Selection and qualification of person

Only permitted personnel is allowed to work on and with the machine! The legal minimum age is to be observed!

Only assign trained and instructed personnel! Clearly define the responsibilites of the personnel with regard to

operating, setting-up, maintaining and repairing the machine! The GÖLZ® GmbH can assist you in training your

personnel.

Make sure that only instructed and competent personnel works on the machine. Define the responsibility of the

machine operator, also in terms of traffic regulations and enable him to refuse instructions of third parties which

breach safety regulations.

Personnel that is to be trained or to be instructed or that is serving a general training is only to be permitted to

operate the machine under the supervision of an experienced person.

To operate the machine you must be rested, in good physical condition and mental health. If you have any

condition that might be aggravated by strenuous work, check with your doctor before operating with the

machine. Do not operate the machine if you are under the influence of any substance (drugs, alcohol) which

might impair vision, dexterity or judgment.

Works on electrical, pneumatic, combustion and hydraulic fittings and equipment are only to be carried out by

qualified personnel or instructed people being directed and supervised by qualified personnel in compliance with

the respective rules!

3.5 Safety instructions governing specific operational phases

Before work

Avoid any operational mode that might be prejudicial to safety!

Before beginning work, familiarize yourself with the surroundings and circumstances of the site, such as

obstacles in the working and travelling area, the soil bearing capacity and any barriers separating the

construction site from public roads.

Take the necessary precautions to ensure that the machine is used only when in a safe and reliable state.

Operate the machine only if all protective and safety-oriented devices, such as removable safety devices,

emergency shut-off equipment, sound-proofing elements and exhausters, are in place and fully functional.

Regard all safety specifications!

Check the machine at least once per working shift for obvious damage and defects. Report any changes (incl.

changes in the machine’s working behaviour) to the competent organization/ person immediately. If necessary,

stop the machine immediately and lock it. Have any defects rectified immediately.

At any time, ensure the operator has sufficient view to his working area, in order to have intervention to the

working process.

Wet drilling is to be accomplished while working. This prevents the appearance of particulate matter and

increases the life-time of the diamond tool.

During start-up and shut-down procedures always watch the indicators in accordance with the operating

instructions!

Before starting or setting the machine in motion, make sure that nobody is at risk. Keep children and

unauthorized persons away from the work area.

Noise protection equipment on the unit must be in protective position during operation. Wear the required

individual ear protection!

Attention: Persons with pacemakers only: The ignition system of your machine produces

an electromagnetic field of a very low intensity. This field may interfere with some

pacemakers. GÖLZ® recommends that persons with pacemakers consult their physician

and the pacemaker’s manufacturer to reduce any health risk.

®

- 15-

5006892-01

BA-E

Page 16

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

Always keep at a distance from the edges of building pits and slopes. Avoid any operation that might be a risk to

machine stability! Keep the work area clean. Cluttered areas and benches invite injuries! Do not operate when

you are tired! Watch what you are doing! Risk of stumpling! Cables and hoses must complete rolling up. After

assembly do not leave any tools, a wrench for example, on the unit.

Check to see that the tools are removed from the drill rig before operating! Damaged drill bits have to be

changed immediately. Use only recommended drill bits from the GÖLZ® GmbH.

Control the working area for water-, gas- and electrical lines!

During work

Make sure, that the drill rig is well fastened before and while drilling!

Never touch rotating parts like drill spindle or drill bit!

After work

Before leaving the machine always secure it against unauthorized use!

3.6 Special work related to the maintenance and repair of the machine

Observe the adjustment, maintenance and inspection activities and intervals set out in the operating

instructions, including information on the replacement of parts and equipment! These activities may be executed

by skilled personnel only. Brief operating personnel before beginning special operations or maintenance work,

and appoint a person to supervise the activities.

In any work concerning the operation, conversion or adjustment of the machine and it’s safety-oriented devices

or any work related to maintenance, inspection and repair, always observe the start-up and shut-down

procedures described in the operating instructions and the information on maintenance work. Ensure that the

maintenance area is adequately secured.

Carry out maintenance and repair work only of the machine is positioned on stable and level ground and has

been secured against inadvertent movement and buckling. If the machine is completely shut down for

maintenance and repair work, it must be secured against inadvertent starting.

To avoid the risk of accidents, individual parts and large assemblies being moved for replacement purposes

should be carefully attached to lifting tackle and secured. Use only suitable and technically perfect lifting gear

and suspension systems with adequate lifting capacity. Never work or stand under suspended loads.

The fastening of loads and the instructing of crane operators should be entrusted to experienced persons only.

The marshaller giving the instructions must be within sight or sound of the operator.

For carrying out overhead assembly work always use specially designed or otherwise safety-oriented ladders

and working platforms. Never use machine parts as a climbing aid. Wear safety harness when carrying out

maintenance work at greater heights.

Clean the machine, especially connections and threaded unions, of any traces of oil, fuel or preservatives

before carrying out maintenance / repair. Never use aggressive detergents. Use lint-free cleaning rags.

Before cleaning the machine with water, steam jet or detergents, cover or tape up all openings which -for safety

and functional reasons - must be protected against water, steam or detergent penetration.

Do not clean the machine with a high-pressure cleaner. The hard water jet can put damage to parts of the

machine. After cleaning, remove all covers and tapes applied for that purpose.

After cleaning check the machine for loose connections, chafe marks and damage! Have identified defects

repaired immediately!

Always tighten any screwed connections that have been loosened during maintenance and repair.

Any safety devices removed for set-up, maintenance or repair purposes must be refitted and checked

immediately upon completion of the maintenance and repair work. Ensure that all consumables and replaced

parts are disposed of safely and with minimum environmental impact.

Important: Wet drilling is to be accomplished while working! This prevents the appearance

of particulate matter and increases the life-time of the diamond tool!

Attention: Do not clean with high-pressure / splash water! Water / Dirt must not attain into

the exhaust system - engine damage!

®

- 16-

5006892-01

BA-E

Page 17

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

3.7 Information about special risks with electrical energy

Observe the relevant national regulations or standards. Electrical connections must always be kept free from dirt

and moisture.

Use only original fuses with the specified rating! Switch off the machine immediately, if trouble occurs in the

electric power supply!

If your machine comes into contact with a live wire:

• warn others against approaching and touching the machine

• have the live wire de-energized

When working with the machine, maintain a safe distance from overhead electric lines. If work is to be carried

out close to overhead lines, the working equipment must be kept well away from them. Caution, danger to life!

• Check out the prescribed safety distances.

• Work on the electrical system or equipment may only be carried out by a skilled electrician himself or by

specially instructed personnel under the control and supervision of such electrician and in accordance with

the applicable engineering rules.

• If provided for in the regulations, the power supply to parts of machines and plants, on which inspection,

maintenance and repair work is to be carried out must be cut off.

• Before starting work, check the de-energized parts for the presence of power and ground or short-circuit

them in addition to insulating adjacent live parts and elements.

The electrical equipment of machines is to be inspected and checked at regular intervals. Defects such as loose

connections or scorched cables must be rectified immediately.

Necessary work on live parts and elements must be carried out only in the presence of a second person who

can cut off the power supply in case of danger by actuating the emergency shut-off or main power switch.

Secure the working area with a red-and white safety chain and a warning sign. Use insulated tools only.

If mobile electrical equipment, connecting cables and/ or extension/ appliance cords with plug connectors are

used, ensure that such equipment, cables and cords are checked for correct function at least once every six

months by a qualified electrician or - if suitable testing equipment is available - by a properly instructed person.

Protective installations with fault-current protection units used in non-stationary equipment must be checked for

correct operation at least once a month by a properly instructed person.

Fault-current and fault-voltage protection units must be checked for correct operation by actuating the testing

facility:

• once on every working day in the case of mobile equipment,

• at least once every six months in the case of stationary equipment.

3.8 Gas, dust, steam, smoke

Operate combustion engines only in well-ventilated rooms! Before starting the unit in closed rooms, make sure

that the room is sufficiently ventilated and use the exhaust gas hose!

Welding, burning and grinding operations on the machine are only to be carried out if this is explicitly authorized

(there is the danger of fire and explosion)!

Before welding, burning and grinding operations clean the machine and its surrounding area from dust and

flammable substances and care for sufficient ventilation (danger of explosion)!

When working in confined spaces observe any existing national regulations!

3.9 Noise

During operation sound protection devices on the machine must be in safe position. Wear the prescribed

personal ear protection! (UVV 29 § 10, Article 29 of the Accident Prevention regulations).

The use of noise emitting machines may be restricted to certain times by national or local regulations.

®

- 17-

5006892-01

BA-E

Page 18

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

3.10 Illumination

The machine is designed for use in daylight! The machine operator / owner must ensure sufficient workplace

lighting for non-illuminated work sites!

3.11 Oils, greases and other chemical substances

When handling hydraulic fluids, lubricants, greases or preservatives (referred to hereinafter as fuels and

lubricants), the safety regulations which apply to the respective machine are to be observed!

Avoid long contact of the fuels and lubricants with your skin! Careful cleaning of the skin from adhering fuels and

lubricants is necessary.

Be careful when handling hot consumables (risk of burning or scalding) particularly at liquid temperatures above

60°C, avoid any skin contact with these liquids!

If you get fuels or lubricants in your eyes, rinse them immediately and carefully with potable water. Then consult

a doctor.

Remove flown out fuels and lubricants immediately! Therefore use a binder.

Fuels and lubricants must not seep into the soil or into the public sewage system! Fuels and lubricants which

can no longer be used are to be collected, properly stored and to be properly disposed of.

The respective regulations and laws for handling fuels and lubricants which are valid in the country of use are to

be observed and adhered to. This also applies to the disposal of such fuels and lubricants. To inform yourself

turn to the responsible authorities.

3.12 Transport

Use only suitable means of transport and lifting gear of sufficient capacity when loading or transporting the

machine! Appoint an experienced instructor for the lifting operation!

Always observe the instructions given in the operating manual when lifting the machine (use only the prescribed

lifting eyes for attaching the lifting gear)!

Use only suitable transport vehicles with sufficient load capacity! Secure the load carefully. Use suitable

fastening points for securing!

Before loading the machine or parts of it, secure the machine against inadvertent movement! Attach a suitable

warning sign!

The drill bit must be removed for transport. Even in case of a minor change of location, the engine must be

stopped!

Before using the machine again, make sure that such protection material or devices are properly removed!

Parts which had to be removed for transporting of the machine must be refitted and secured carefully before the

machine is used again!

Before setting the machine in motion always check that all accessories are safely stowed.

The recommissioning procedure must be strictly in accordance with the operating instruction! Observe the

instructions given in the operating instruction when reassembling and operating the machine.

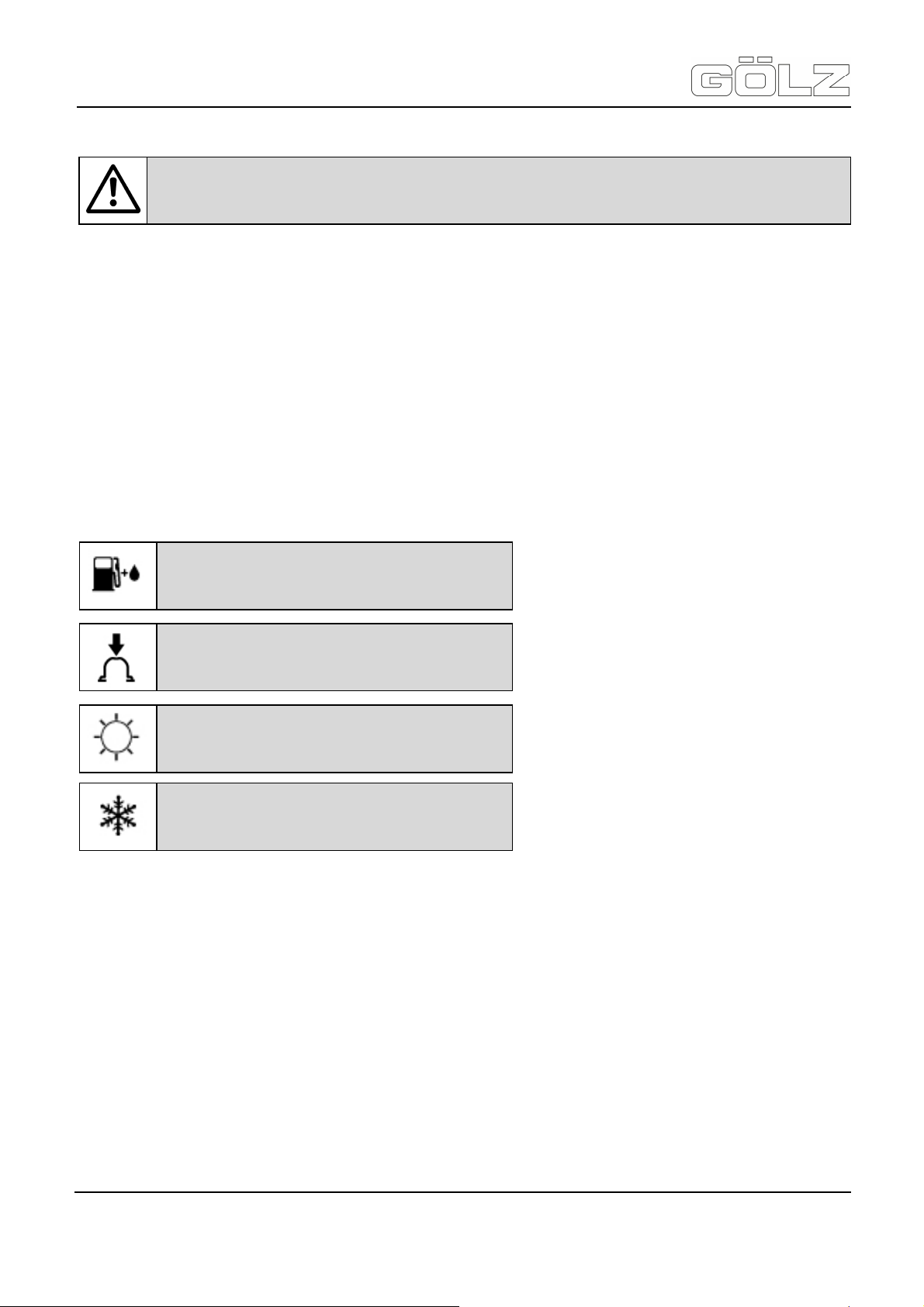

Lifting eye

Attention: Check that all parts of the machine are well fastened

before transporting.

Before transport the drill bit must be removed!

For loading only, use lifting gear and tackle of sufficient capacity.

Lift the machine using the lifting eye.

- 18-

5006892-01

BA-E

®

Page 19

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

3.13 Store

Store the machine in a dry, high or locked place, out of the reach of children or unauthorized persons. Clean

and preserve the machine with corrosion preventive if storing over a longer time like winter time!

Note: store not mounted drill bits in a dry, high or locked place, out of the reach of children or unauthorized

persons!

Drill bits with a small diameter are only to be stored in a horizontal position, drill bits with a large diameter only in

a vertical position. Do not place any other parts or components on the drill bits.

®

- 19-

5006892-01

BA-E

Page 20

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

4. Bringing into service

4.1 Export checking

Remove the transport packaging and place the unit vertically on a horizontal, flat and stable surface.

Dispose of the transport packaging according to environmental regulations. Since the unit is delivered

completely assembled, you need only check if it is complete and intact.

For the scope of delivery, see "Technical Data and Accessories". In addition, check the travel path of the drill

carriage for proper movement.

4.2 Petrol drill motor FS560

The meanings of the pictrograms attached to the machine:

4.2.1 M-Tronic

The M-Tronic controls fuel feed and ignition timing electronically in all operating conditions. M-Tronic guarantees

simple and fast starts. The engine is started in the Start ▲ position irrespective of climatic conditions or engine

temperature.

After starting, the Start ▲ position can be maintained until the engine runs smoothly. M-Tronic ensures optimum

engine power at all times, very good acceleration and automatic adjustment to suit changing conditions. For this

reason there is no need to change the carburetor setting - the carburetor has no adjusting screws.

If the usual good running behavior and engine power are not reached after an extreme change in operating

conditions, contact your servicing dealer for assistance. GÖLZ® recommends that you have servicing and repair

work carried out exclusively by an authorized GÖLZ® servicing dealer.

Attention: Do not yet turn the engine on! The following work is to be done with the drill

motor being stopped!

Fuel tank

Fuel mixture of gasoline and engine oil

Operate manual fuel pump

Intake air for summer operation

Intake air for winter operation

®

- 20-

5006892-01

BA-E

Page 21

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

4.2.2 Fuel

The engine requires a mixture of gasoline and engine oil. Unsuitable fuels or a mixing ratio that deviates from

the specification can lead to severe engine damage. The engine, seals, fuel lines and fuel tank may be

damaged if poor quality gasoline or engine oil is used. Use only high-quality gasoline with an octane rating of at

least 90 ROC - leaded or unleaded.

For reasons of health and for environmental reasons unleaded petrol is to be preferred. If fuel with an octane

number below 90 RON is used, glow ignition (causing "pinging" in the engine) and a rise of temperature may be

the result. This in turn can lead to damage to the driving mechanism on account of "piston jamming".

Mixing fuel

For preparing the fuel mixture only branded two-stroke engine oils are allowed! We particularly recommend the

STIHL-two-stroke engine oil 1:50; this oil is specifically blended for use in STIHL-engines. Mixing ratio: with

STIHL 1:50 two-stroke engine oil: 1:50, 1 part oil + 50 parts petrol, with other branded two-stroke engine oils

classification TC: 1:25, 1 part oil + 25 parts petrol.

When preparing the mixture, first fill in oil, then petrol.

Storing fuel mixture

Fuel mixture ages! Mix only as much as needed for a few weeks! Store in approved safety fuel canisters only in

a dry, cool and secure place protected against light and sunlight.

Do not store fuel mixture for longer than three months. The fuel mixture can become unusable faster if exposed

to light, sunlight or low or high temperatures. Fuel mixture that stagnates for a longer time unmixes. Therefore

shake the can containing the fuel mixture well before you fill it up again.

The fuel tank and the canister in which fuel mixture is stored should be cleaned thoroughly from time to time.

Residual fuel and the liquid used for cleaning must be disposed of in accordance with regulations and without

harming the environment!

Refuelling

Before refuelling stop the engine. Do not refuel as long as the engine is hot - fuel can overflow - fire hazard!

Open the fuel cap carefully so that overpressure is slowly reduced and no fuel spurts out.

Refuel only at well-ventilated places. If some fuel was spilled, immediately clean the motorized equipment - let

no fuel get in contact with your clothing, otherwise change your clothes immediately.

Thus the risk is reduced that the fuel cap unscrews on account of the vibration of the engine and fuel runs out.

Pay attention to leaks - if fuel runs out, do not start the engine - Danger to life on account of burns!

Attention: Avoid direct skin contact with and breathing in of gasoline fumes!

Attention: Pressure can build up insie the canister - open carefully!

Attention: Petrol is extremely flammable - keep it away from open fire - do not spill any fuel

- do not smoke!

Attention: After re-fuelling tighten the screw cap as tightly as possible.

- 21-

5006892-01

BA-E

®

Page 22

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

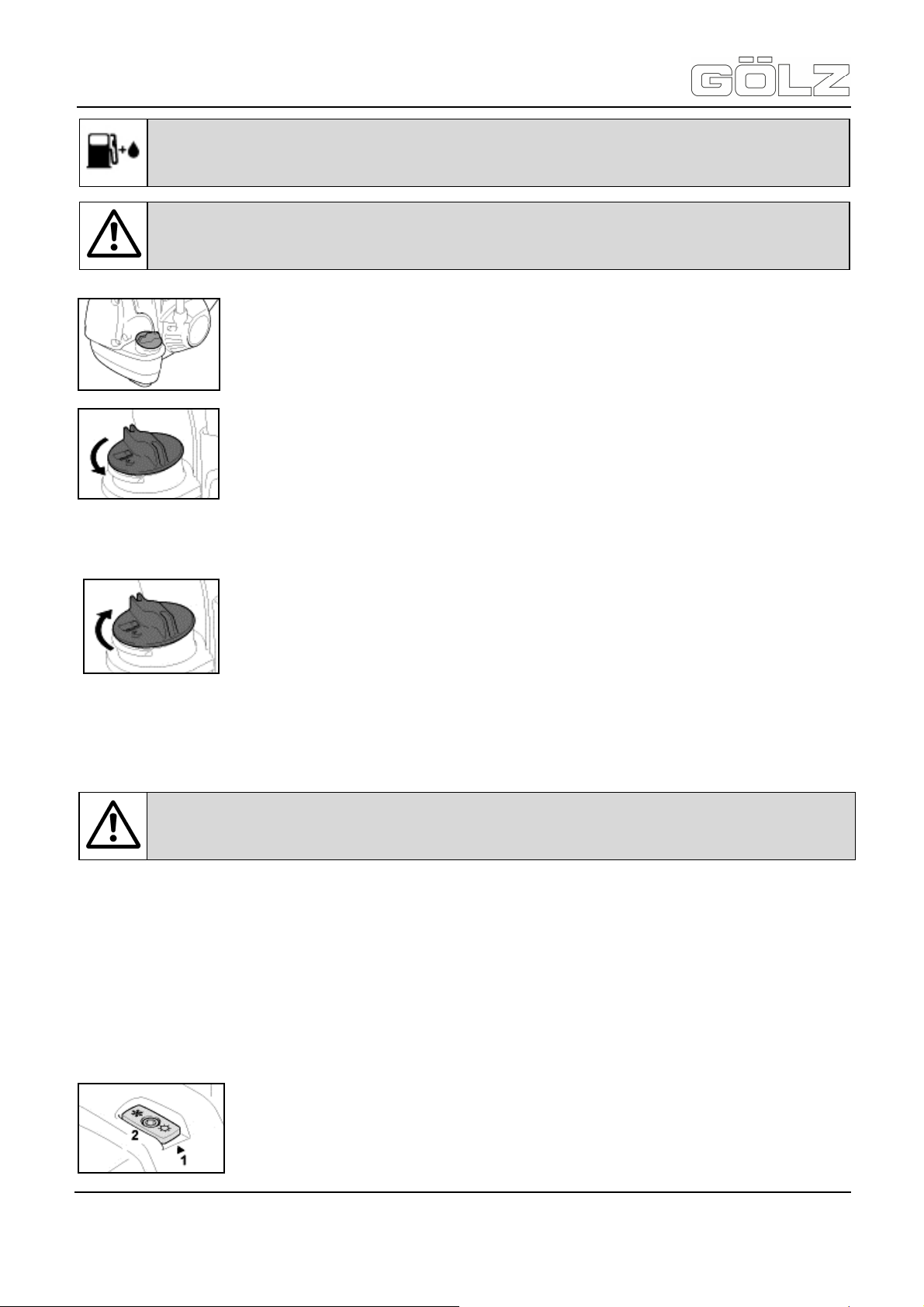

Filling up with fuel

Take care not to spill fuel while fueling and do not overfill the tank!

4.2.3 Air filter

The filter has a very long service life.

Dirty air filters reduce engine power, increase fuel consumption and make starting more difficult.

Replacing the air filter: Only if there is a noticeable loss of engine power!

4.2.4 Winter operation

At temperatures below +10°C

Preheating the carburettor. Repositioning a shutter allows heated air to be drawn in from around the cylinder

and mixed with cold air. This helps prevent carburettor icing.

Fuelling

Attention: When fuelling on a slope, always position the machine with the filler cap facing

uphill!

Preparations

On level ground, position the machine so that the filler cap is facing up. Before fueling,

clean the filler cap and the area around it to ensure that no dirt falls into the tank.

Opening screw-type tank cap

Turn the cap counterclockwise until it can be removed from the tank opening.

Remove the cap.

Cosing screw-type tank cap

Place the cap in the opening.

Turn the cap clockwise as far as stop and tighten it down as firmly as possible by hand.

Attention: Do not remove the filter cover or replace the air filter as long as there is no

noticeable loss of power!

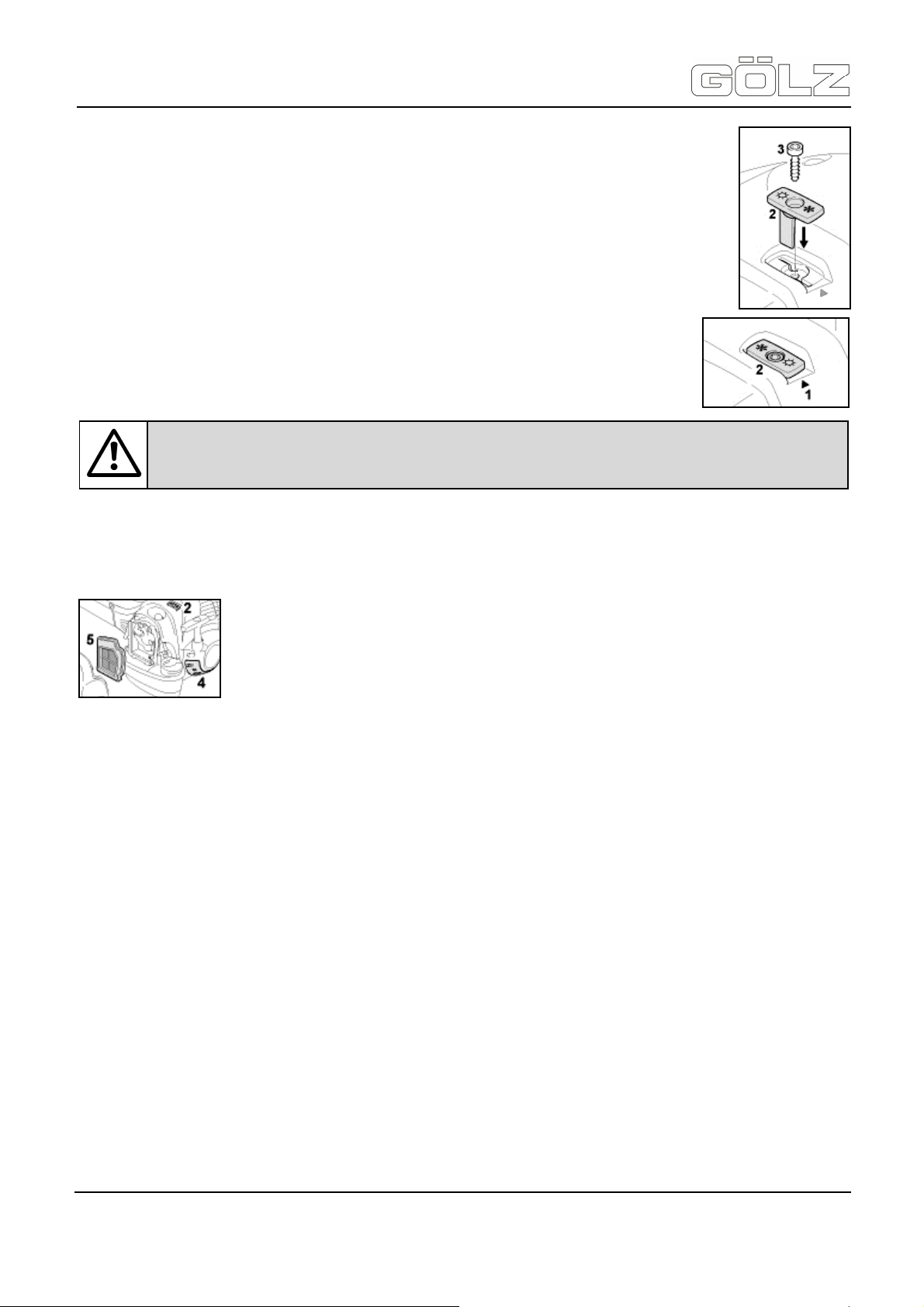

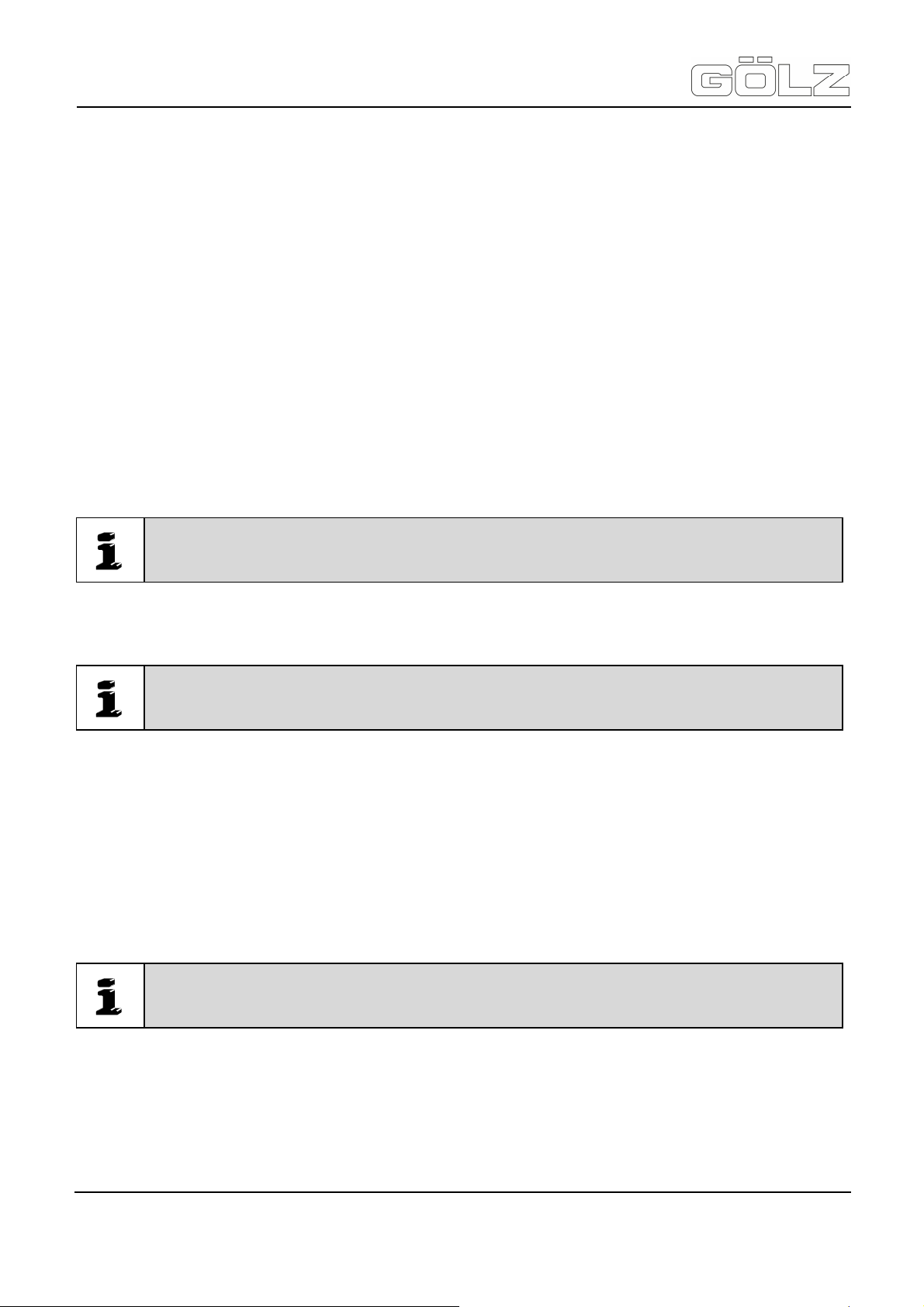

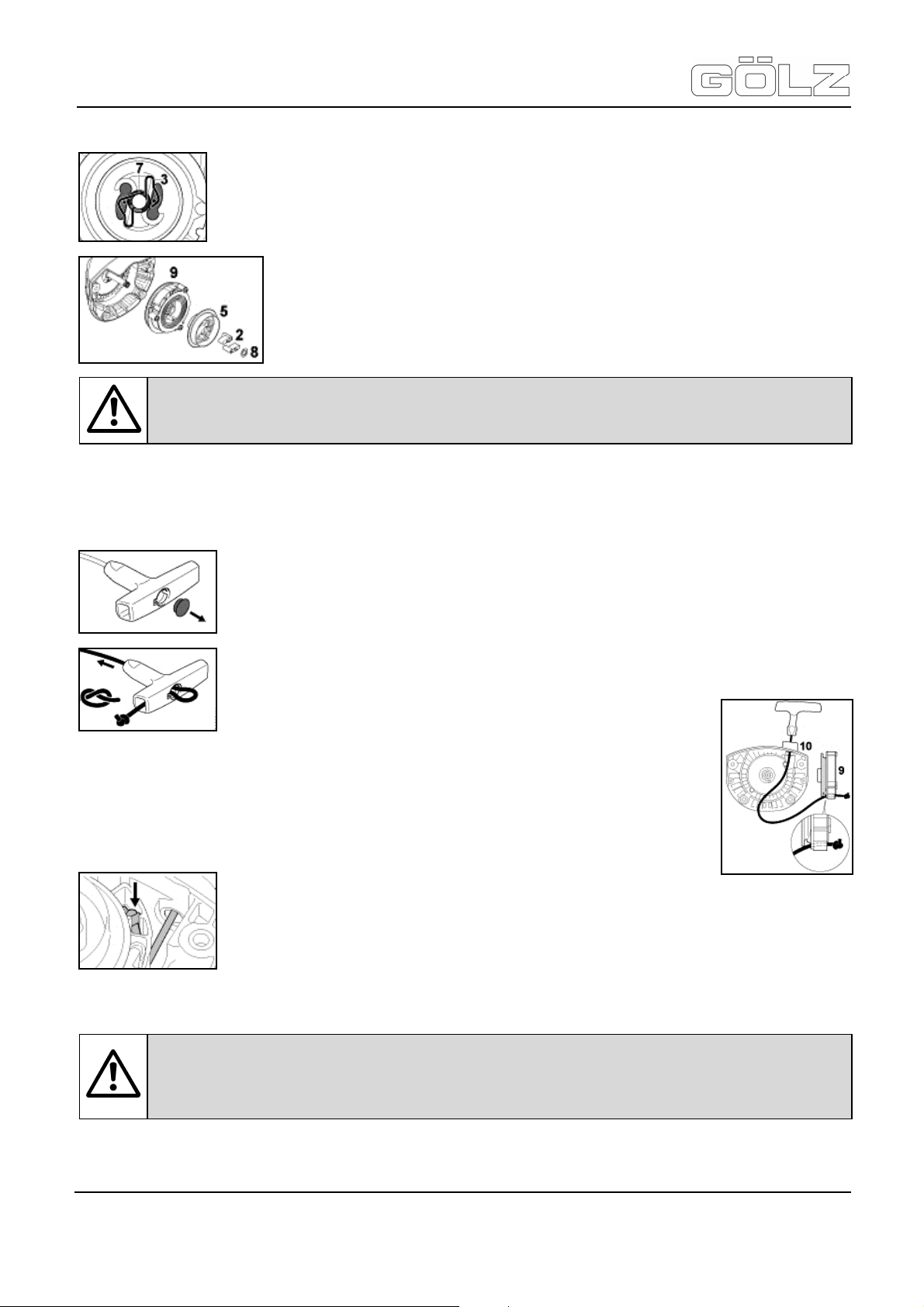

An arrow (Pos. 1) on the shroud indicates the setting of the shutter (Pos. 2) for summer

or winter operation.

Symbol sun = summer operation

Symbol snowflake = winter operation

- 22-

5006892-01

BA-E

®

Page 23

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

• Remove the screw (Pos. 3) from the shutter (Pos. 2).

• Pull the shutter (Pos. 2) out of the shroud.

• Rotate the shutter (Pos. 2) from the summer position to the winter position and refit it.

• Secure the shutter in position with the screw (Pos. 3).

At temperatures between +10°C and +20°C

The machine can normally be operated in this temperature range with the shutter (Pos. 2) in

the summer position. Change the position of the shutter if necessary.

At temperatuers above +20°C

Always return the shutter (Pos.2) to the summer position.

At temperatures below -10°C

In extreme wintry conditions:

• Temperatures below -10°C

• Powder or drifting snow

After installing the cover plate kit set the shutter (Pos. 2) to the winter position.

At temperatures above -10°C

Remove the parts of the cover plate kit and refit the standard parts for summer operation. Depending on the

ambient temperature set the shutter (Pos. 2) to the summer or winter position.

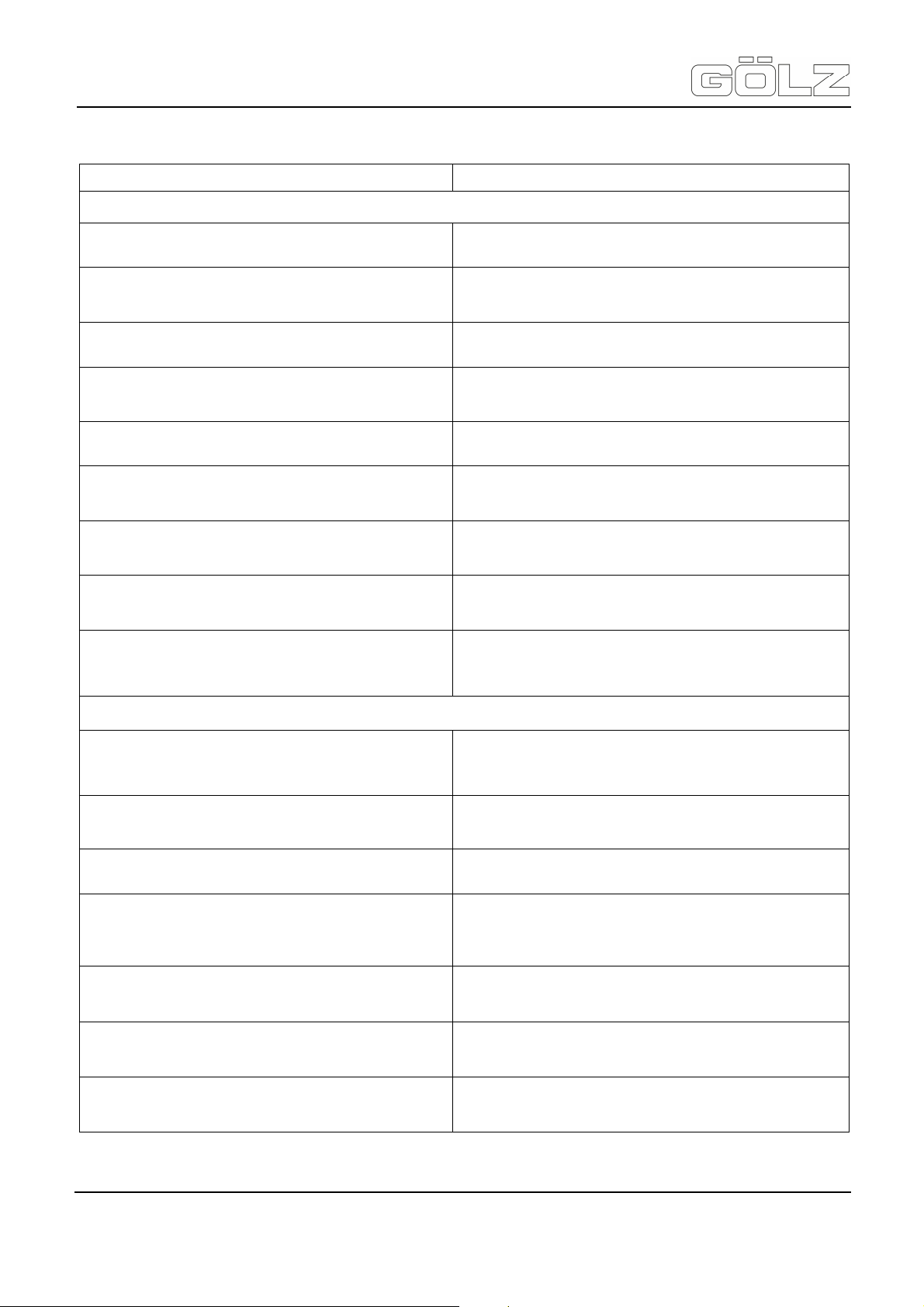

4.2.5 Spark plug

If the engine is down on power, difficult to start or runs poorly at idle speed, first check the spark plug. Fit a new

spark plug after about 100 operating hours or sooner if the electrodes are badly eroded. Install only suppressed

spark plugs of the type approved “specifications”.

4.2.6 Adjusting the throttle cable

Correct adjustment of the throttle cable is a precondition for correct operation of the machine in all modes, from

starting to full throttle. It may be necessary to readjust the throttle cable after assembling the machine or after a

prolonged period of operation.

Check the adjustment of throttle cable

The control handle must be in the normal operating position.

In the following adjustments do not produce the required result, have your servicing dealer repair the machine.

Attention: Do not operate the machine in the winter position at temperatures above +20°C

because there is otherwise a risk of engine running problems and overheating!

It is advisable to use the optional ”cover plate kit“.

The cover plate kit contains the following parts for converting the machine:

• Pos. 4: cover plate partially blanks off the slots in the starter housing.

• Pos. 5: Synthetic fabric filter element for the air filter.

- 23-

5006892-01

BA-E

®

Page 24

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

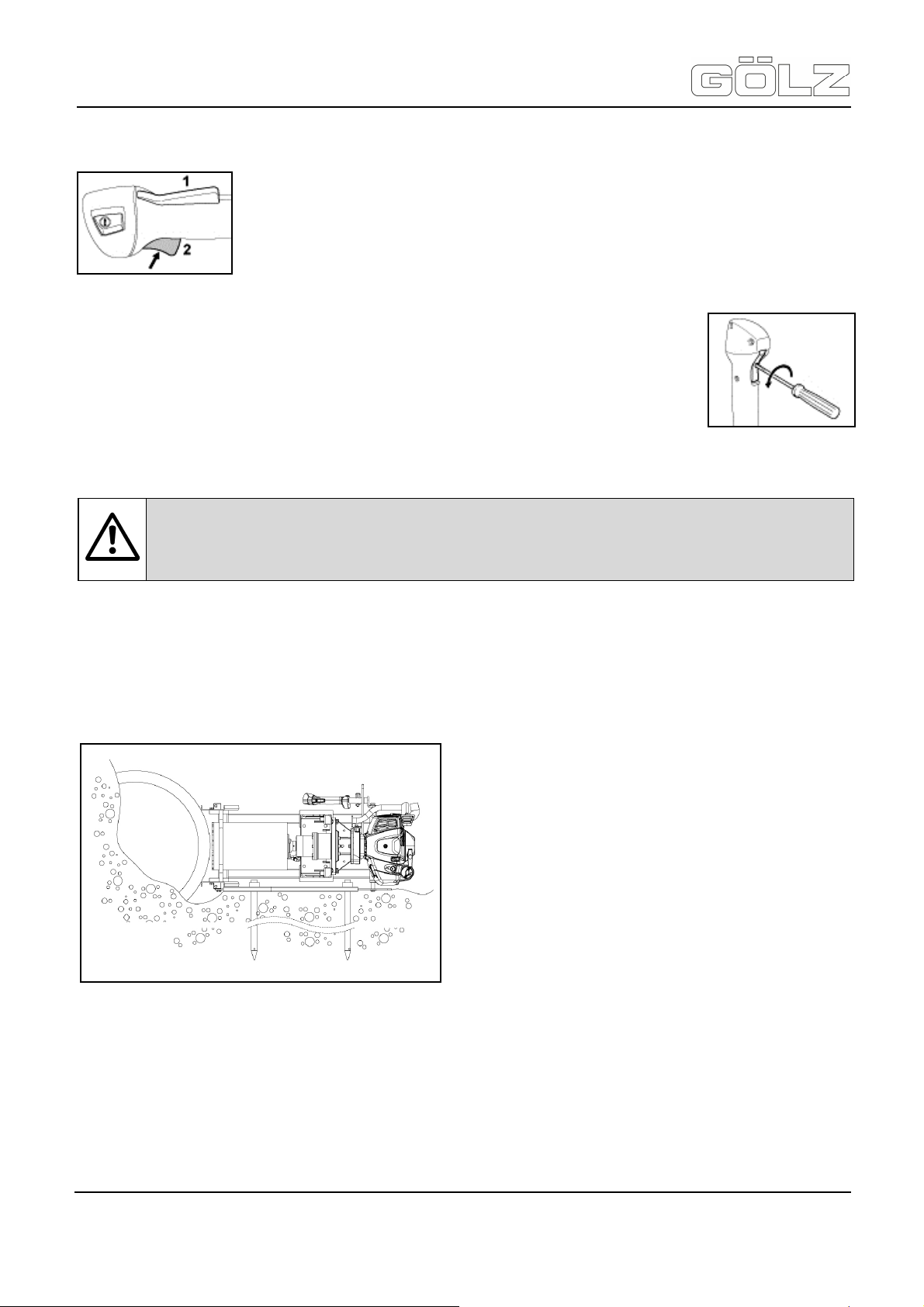

Error: Engine speed increases when only the throttle trigger is depressed.

• Starting the engine.

• Depress the throttle trigger (Pos. 2). Do not press down the throttle trigger lockout

(Pos. 1).

If the engine speed increases or if the cutting attachment rotates, the throttle cable has

to be adjusted.

• Stopping the engine

Adjusting the throttle cable

Depress the throttle trigger lockout (Pos. 1) and the throttles trigger (Pos. 2) as far as

stop and hold them in that position.

Apply only sufficient pressure to hold the levers against their stops.

• Rotate screw in throttle trigger ½ turn counter clockwise.

• Release the throttle trigger and throttle trigger lockout.

• Start the engine and check the adjustment.

• Shut down the engine and repeat adjustment if necessary.

Have the muffler checked by a servicing dealer for contamination!

4.3 Fixing the machine

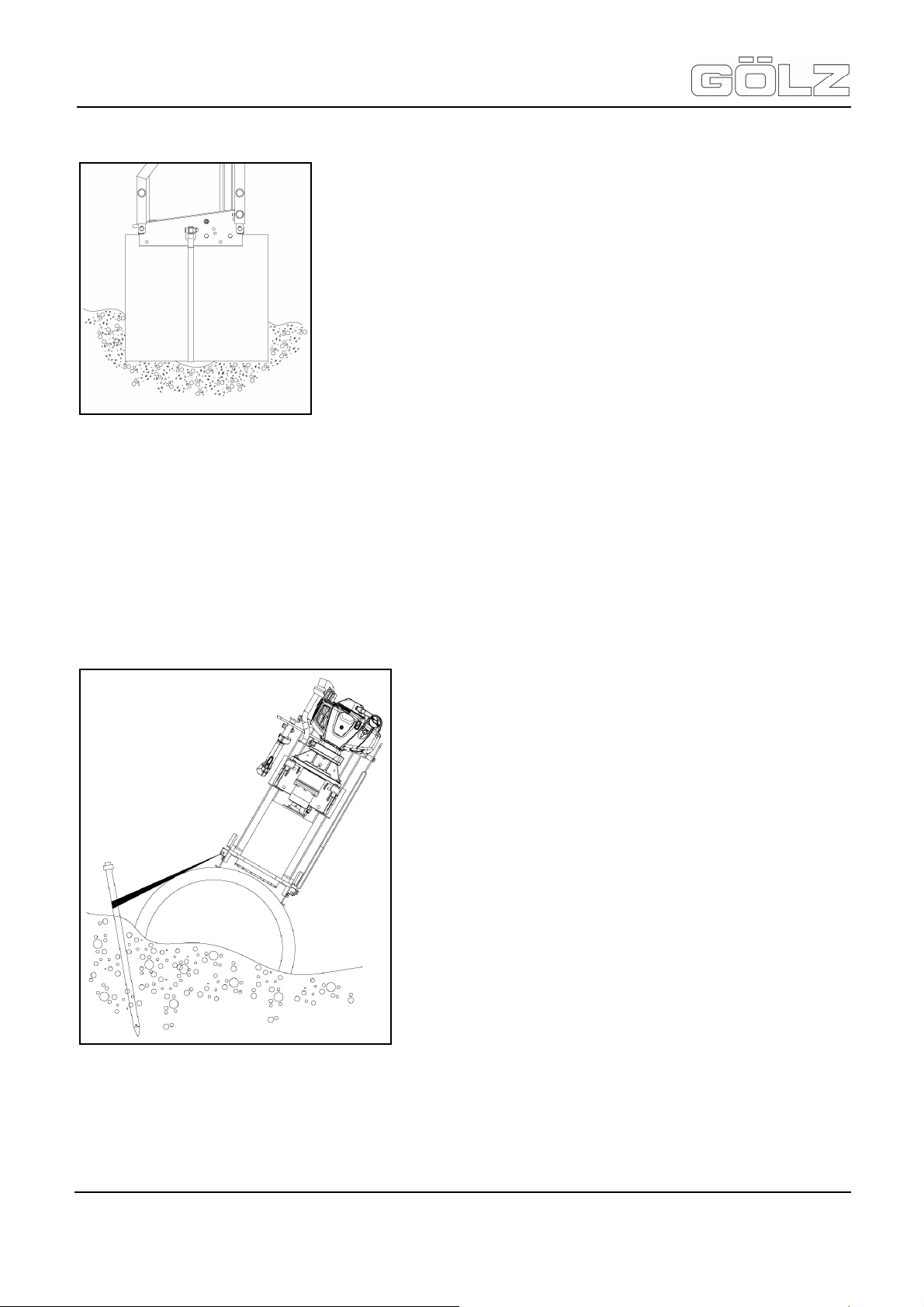

4.3.1 Placed on the ground secured by spikes

Place the machine so that pipe base fits tight to the pipe. Back fill or remove material underneath the frame if

necessary.

The pipe base is centering the machine automatically. Secure the ground frame with minimum two ground

frame.

Attention: Attention: If engine running behaviour is still unsatisfactory after servicing the air

filter and adjusting the throttle cable, teh cause may be the muffler.

®

- 24-

5006892-01

BA-E

Page 25

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

4.3.2 By strap and ratchet at exposed pipe

This application is only possible, if the pipe is completely exposed, so that the strap can be wrapped around the

pipe.

The end of the strap that has an „eye“ is attached to the holder by means of a shackle to the notch at the pipe

base. Attach the ratchet to the notch. Pull the strap through the split in the ratchet and stretch the strap by

moving the flap of the ratchet. Pull strap under the pipe. Do not twist the strap!

Releasing the ratchet: Pull up the pawl in the ratchet tensioner. Stretch the ratchet to the point the handle

engages.

4.3.3 Combination of ground spikes and strap

If the ground-condition at the drill-hole side are not convenient you can try a combination of Spikes and Strap as

follows:

• Hit one or two ground spikes on other side of pipe into the ground and wrap the strap around it (them) and

mount the shackle and the ratchet in the two outer notches on the pipe-base and stretch the strap.

• While drilling the operator’s weight should hold the machine down against the pipe. Reduced feed-pressure

should be obtained during this way of operation!

- 25-

5006892-01

BA-E

®

Page 26

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

4.3.4 Fixing with dowels

Set up of the machine on walls or flat surfaces one can choose two ways: Dowel plates or dowel base.

• Dowel plates are attached with bolts to the pipe base.

• Drill dowel holes, mount the dowel and set up the machine with bolts into the dowels. Please follow the

instructions of the dowel-producer!

• Use screws with a minimum length of 140 mm (51/2") when using dowel plates.

• Dowel base is consisting of 2 L-formed plates. The dowel base is attached into the holes of the pipe base,

so first the pipe-base has to be removed and then the two dowel base-plates are mounted instead of the

pipe base.

4.3.5 Fixing with vacuum hold down

• Remove the ground frame and place the machine with the pipe base onto the pipe.

• Attach the vacuum pads to the left and to the right of the pipe-frame, but do not tighten the bolts yet!

• Start the vacuum pump and wait until gauge on vacuum pump shows a minimum of 0,7 bar (10 PSi).

• Connect one male coupler of the vacuum system to one of the vacuum pads and wait until vacuum is built-

up.

• Repeat this operation to the second vacuum pad. Tighten all the bolts that connect the pads to pipe frame.

Fixing with dowel plates

Fixing with dowel base

Note: Vacuum is built up faster and safer if the pipe-surface is wetted with water before

attaching a pad.

Note: Read and observe the operating instructions to the vacuum suction plates!

®

- 26-

5006892-01

BA-E

Page 27

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

4.3.6 Frame extension

The frame extension is used to attach the machine on pipes less than 380mm (15 in.).

Fasten the frame extension with the added screws at the drill rig. Attach the drill rig as described with strap and

spikes.

®

Frame extension Ø 270 - 180 mm

Frame extension Ø 380 - 270 mm

4.4 Assembling a drill motor

4.4.1 Assembling a drill motor with gear box

The gear carrier is fitted to the drill carriage by default.

Place the motor via the gear box onto the gear carrier and screw the

components with four M10x45 screws, SW17, as well as eight washers

and four nuts.

Provide the water supply to the gear box. The water supply is ensured via a

plug connection between the gear carrier and the gear box.

Attention: The following work is to be done with the drill motor being stopped!

With the combustion engine FS560 you can attach the operating handle to the support of the

operating handle and secure with the clip splint.

- 27-

5006892-01

BA-E

Page 28

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

4.4.2 Changing a drill motor with gear box

Loosen the connection of the water supply to the gear box. The water supply

is ensured via a plug connection between the gear carrier and the gear box.

Loosen the plug connector on the gear box and pull out the water hose.

Loosen the four M10x45 screws, SW17, between the gear box and the

gear carrier.

Remove the four screws as well as the eight washers and the four nuts.

You can remove the drill motor with the gear box from the gear carrier.

With the combustion engine FS560 make sure that the operating handle

is no longer attached to the support of the operating handle.

Assembling a drill motor with gear box

Fit the new drill motor as described under „Assembling a drill motor with

gear box".

4.5 Water supply

The water supply at the interface ensures that the tool is cooled, the dust of the material is bound and the drill

hole is rinsed out.

4.5.1 With water tank-pressurzied type

New delivery: mount first the pressure-hose into the bottom-side-hole and tighten well.

Operation:

• Always make sure that there is no pressure left in the tank before you open the water-filling hole - so lift

• Depress pump-handle and turn handle left (anticlockwise).

• Fill approx. 10 litres (2.64 US gallons) but do not fill up completely. Put back hand pump and tighten

• Pump up a pressure of approx. 2 bar (29 PSI).

• During drilling a constant pressure of minimum 0,5 bar (7 PSI) is needed to guarantee a frequent water

Important: Wet drilling is to be accomplished while working! This prevents the appearance

of particulate matter and increases the life-time of the diamond tool!

Attention: Tools which are only designed for wet cutting, are never to be used without

water supply! Always ensure sufficient water supply!

Attention: For cutting only use water which is free from coarse impurities! Do not use salt

water!

red button on top-lock and release eventual existing pressure.

clockwise.

flow.

- 28-

5006892-01

BA-E

®

Page 29

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

Connection to core drilling machine

Connect Female Coupler on pressure hose to Male Nipple at the water-tap of the core drilling machine. The

water flow is increased or reduced by the water tap.

Release the female-coupler

The water hose is disconnected by pulling the outer sleeve of the female-coupler backwards and pulling off the

connection of the nipple

Safety regulations

Check periodically the pressure-relief-valve for proper function!

The maximum pressure is 6 bar (87 PSI). If the pressure is not released at max., pressure automatically, the

valve has to be replaced immediately. Any sort of damage on the tank (bottle) cracks or bumps, the bottle must

be changed and taken out of operation.

No repairs on the tank are permitted.

Do not expose the filled water tank to sun for a longer time, increased water temperature results in increased

internal pressure! Store water tank empty and protect against freezing!

4.5.2 Public water mains

Connect a 1/2" water hose to the water tap of the core drilling machine. The flow of water is to be regulated by

the tap.

4.6 Angle-drilling

Upon delivery the unit is in the 90°-position. Do the angle adjustment as follows:

Note: Read and observe the operating instructions to the pressurized water container!

Ground frame in delivery position

90°-position

Ground frame turned 180° around

55°-position

®

- 29-

5006892-01

BA-E

Page 30

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

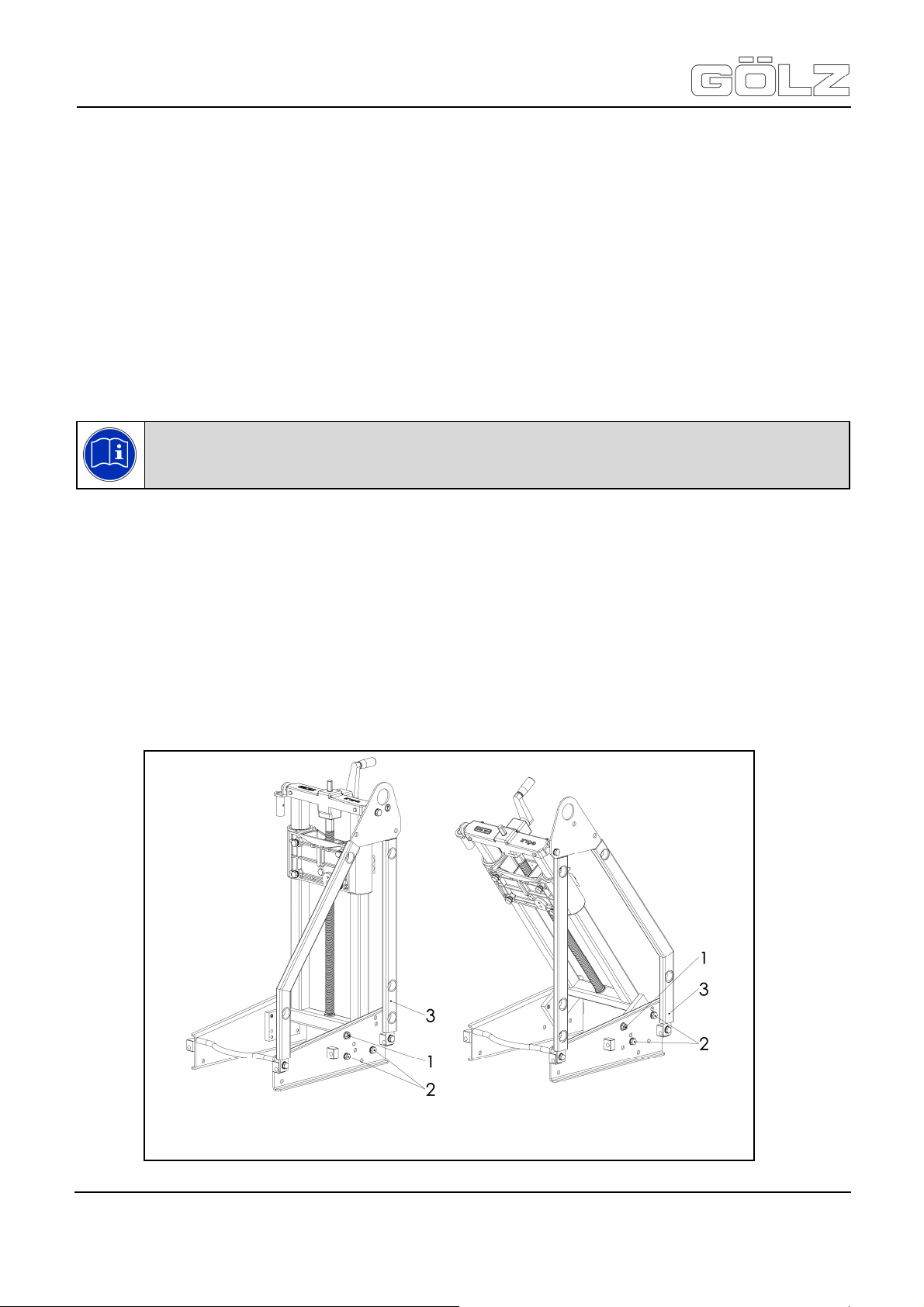

• Remove the bolts holding the ground frame (3) and remove frame

• Loosen the Nuts (1), left and right of pipe-base, but do not remove!

• Remove 4 Bolts (2) (2 on each side)

• Holding column, to base and tilt the column into required angle

• Secure 4 Bolts by hand

• Turn the ground-frame (3) around the other way and tighten bolts and nuts well.

4.7 Drill bit

The drill bits must meet the specifications of GÖLZ® GmbH. Use the appropriate bits depending on the material

to be processed, the working process and the type of work to be carried out! In case of non-intended use, no

liability is assumed for any damage resulting thereof.

All the bits which are used must, as far as their maximum admissible cutting speed is concerned, be designed

for the maximum drive speed of the unit. For units with a variable drive speed use drill bits which, as far as their

maximum admissible cutting speed is concerned, correspond to the respective drive speed. Ensure the right

rotational direction of the drill motor and of the drill bit!

Check the drill bits for proper fit. Defective drill bits must be immediately replaced!

Each time a drill bit is fitted or changed, the drill motor is to be stopped first. After assembly do not leave any

tools, a wrench for example, on the unit.

4.7.1 With UNC-Adapter

Fit the UNC-Adapter firmly to the gear box. Fit the adapter to the gearshaft in such a way that the serration

meshes and screw the two set screws in the adapter into the gearshaft.

Now wind the drill carriage up, but only to such point that the drill bit easily fits under the adapter.

When fitting the drill bit, please observe the following order:

• first the brass disc

• then the O-ring

• finally the drill bit

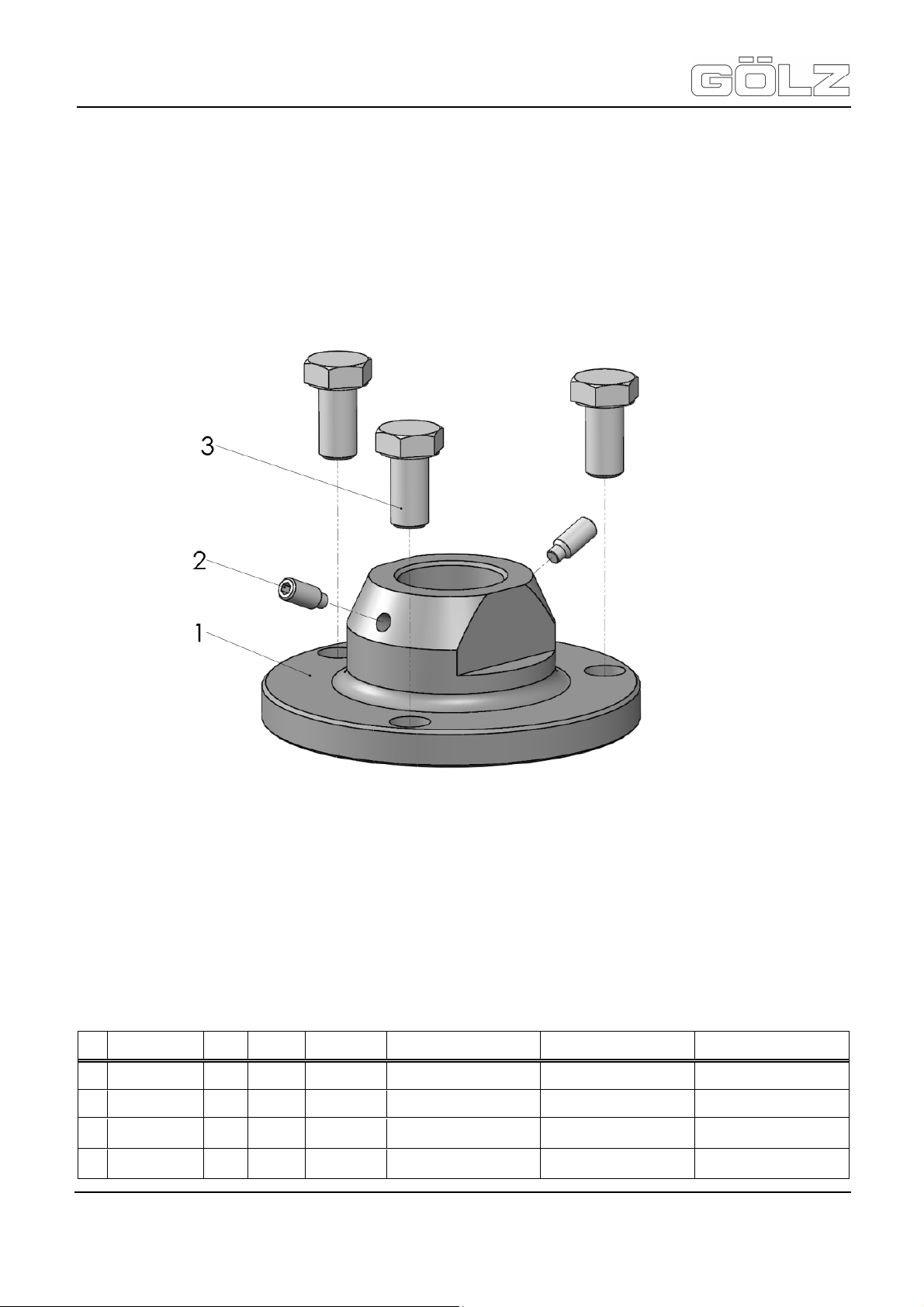

4.7.2 With 3-hole flange

Important: Before fitting the drill bit, carefully clean all the fastening elements!

Important: The connection threads must be clean!

Important: The connection flanges must be clean!

®

Fit the 3-hole flange to the gear box. Fit the flange to the gearshaft in such a way that the serration meshes and

screw the two set screws in the flange into the gearshaft. Now wind the drill carriage up, but only to such point

that the drill bit easily fits under the flange.

Then, with a wrench SW 17, screw the three screws M 10 x 20 through the flange into the holes of the drill bit.

Lock the flange with a SW 41 wrench.

- 30-

5006892-01

BA-E

Page 31

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

5. Operation

5.1 Before starting

Check that your machine is properly assembled and in good condition:

• All parts must be assembled properly and securely.

• The stop switch must move freely.

• Smooth action of choke knob, throttle trigger lockout and throttle trigger - the throttle trigger must return

• Check that the spark plug boot is secure - a loose boot may cause arcing that could ignite combustible

• Never attempt to modify the controls or safety devices in any way.

Do not operate your machine if it is damaged or not properly assembled!

Pay attention to the whereabouts of the cooling and rinsing water as well as of cutting slurries. Cutting slurries

must be collected, filtered and disposed of. Attach the unit according to the drilling problem. Move the drill bit

with the hand crank to 5mm to the drilling surface.

5.2 Starting the engine

Start the engine at least 3 meters from the fuelling spot. When work in closed or below

ground level it is absolutely necessary to use the exhaust hose!

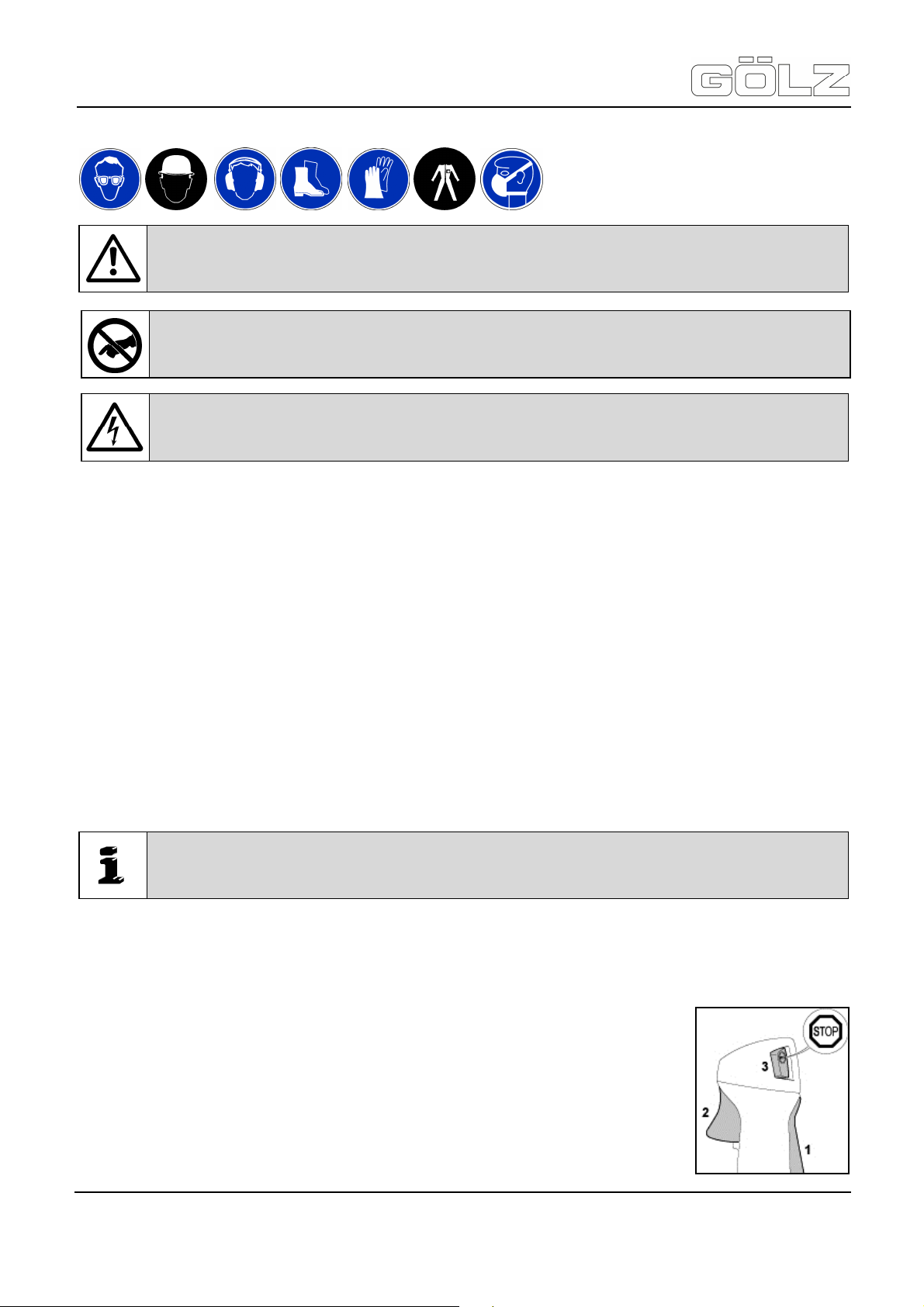

1. Throttle trigger lockout

2. Throttle trigger

3. Stop switch - with run and stop positions. Press the momentary contact stop switch

to switch off the ignition.

Attention: Make the site free of parts that might obstruct the operation! Make sure, the drill

bit is well mounted! Make sure, only authorized personnel is in the working area!

Warning: Never touch rotating parts like drill spindle and drill bit!

Attention: Make sure, that there are no mains in the material and location of the hole to be

drilled!

automatically to the idle position. The choke knob must spring back from the ▲ position to the run position I

when the throttle trigger lockout and throttle trigger are squeezed.

fumes and cause a fire!

Important: Fit the exhaust gas hose when working in closed rooms or below ground level!

- 31-

5006892-01

BA-E

®

Page 32

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

Function of stop switch and ignition system

The stop switch is normally in the run position: Ignition is on in this position - the engine is ready to start and

may be started. The ignition is switched off when the stop switch is depressed. It is automatically switched on

again after the engine comes to a standstill.

Symbols on choke knob

• Start ▲: the engine is started in this position.

• Normal run position I : engine runs or can fire.

Start the engine

• Press the fuel pump bulb (Pos. 4) at least five times. Even if the bulb is filled with fuel.

• Depress in the outer edge (arrows) of the choke knob (Pos. 5) and then turn it to start

▲.

• Hold the starter grip with your hand.

• Do not pull out the starter rope all the way - it might otherwise break!

• Do not let the starter grip snap back. Guide it slowly back into the housing so that the

starter rope can rewind properly.

• Continue cranking until the engine runs.

As soon as the engine runs: Make sure the engine runs smoothly.

If the engine stalls: continue cranking until the engine runs.

As soon as the engine runs smoothly

After a cold start, allow the engine to warm up in the start ▲ position.

If you have started the machine for the first time, refer to the notes on “starting for first time”.

• Depress throttle trigger lockout and pull the throttle trigger - the choke knob moves

to the run I position.

If the spindle rotates when the engine is idling, refer to notes in chapter “adjusting the throttle cable” or have the

machine serviced by your dealer.

Starting for first time

Attention: The spindle must not rotate in the run I position with the engine at idling speed!

• Depress the throttle trigger - do not press down the throttle trigger lockout.

If engine speed increases or the cutting attachment rotates:

• Go to section “stopping the engine“.

• Go to chapter ”adjusting the throttle cable“.

If the engine speed does not increase, your machine is ready for operation.

®

- 32-

5006892-01

BA-E

Page 33

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

At very low outside temperatures

• Set the engine to winter operation if necessary.

• If the machine is very cold (frost on machine), allow the engine to warm up in the start ▲ position after

starting until normal operating temperature is reached. Warning: the spindle rotates in this position!

At very high outside temperatures

• If the engine does not start after 10 pulls in the start ▲ position:

• Start the engine in the run I position.

If the engine does not start

• Check that all settings are correct.

• Check that there is fuel in the tank and refuel if necessary.

• Check that the spark plug boot is properly connected.

• Repeat the starting procedure.

Fuel tank runs until completely dry

• After refuelling, press the fuel pump bulb at least five times. Even if the bulb is filled with fuel.

• Start the engine.

5.3 Operating instructions engine

During break-in period

A factory-new machine should not be run at high revs (full throttle off load) for the first three tank fillings. This

avoids unnecessary high loads during the break-in period. As all moving parts have to bed in during the break-in

period, the frictional resistances in the engine are greater during this period. The engine develops its maximum

power after about 5 to 15 tank fillings.

During operation

After a long period of full throttle operation, allow the engine to run for a short while at idle speed so that engine

heat can be dissipated by the flow of cooling air. This protects engine-mounted components (ignition,

carburettor) from thermal overload.

After finishing work

Storing for a short period: Wait for the engine to cools down. Empty the fuel tank and keep the machine in a dry

place, well away from sources of ignition, until you need it again.

• For longer out-of-service periods: For periods of 3 months or longer:

• Drain and clean the fuel tank in a well-ventilated area.

• Dispose of fuel properly in accordance with local environmental requirements.

• Run the engine until the carburettor is dry. This helps prevent the carburettor diaphragms sticking together!

• Remove, clean and inspect the machine!

• Store the machine in a dry and secure location - out of the reach of children and other unauthorized

persons.

5.4 Start drilling

Important: Observe all the previous chapters in this manual, in particular the safety and

warning instructions!

Warning: Never touch rotating parts like drill spindle and drill bit!

®

- 33-

5006892-01

BA-E

Page 34

KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

Care for safety clearance regarding third persons and take the operator's station behind the unit or slightly right

or left of it.