Page 1

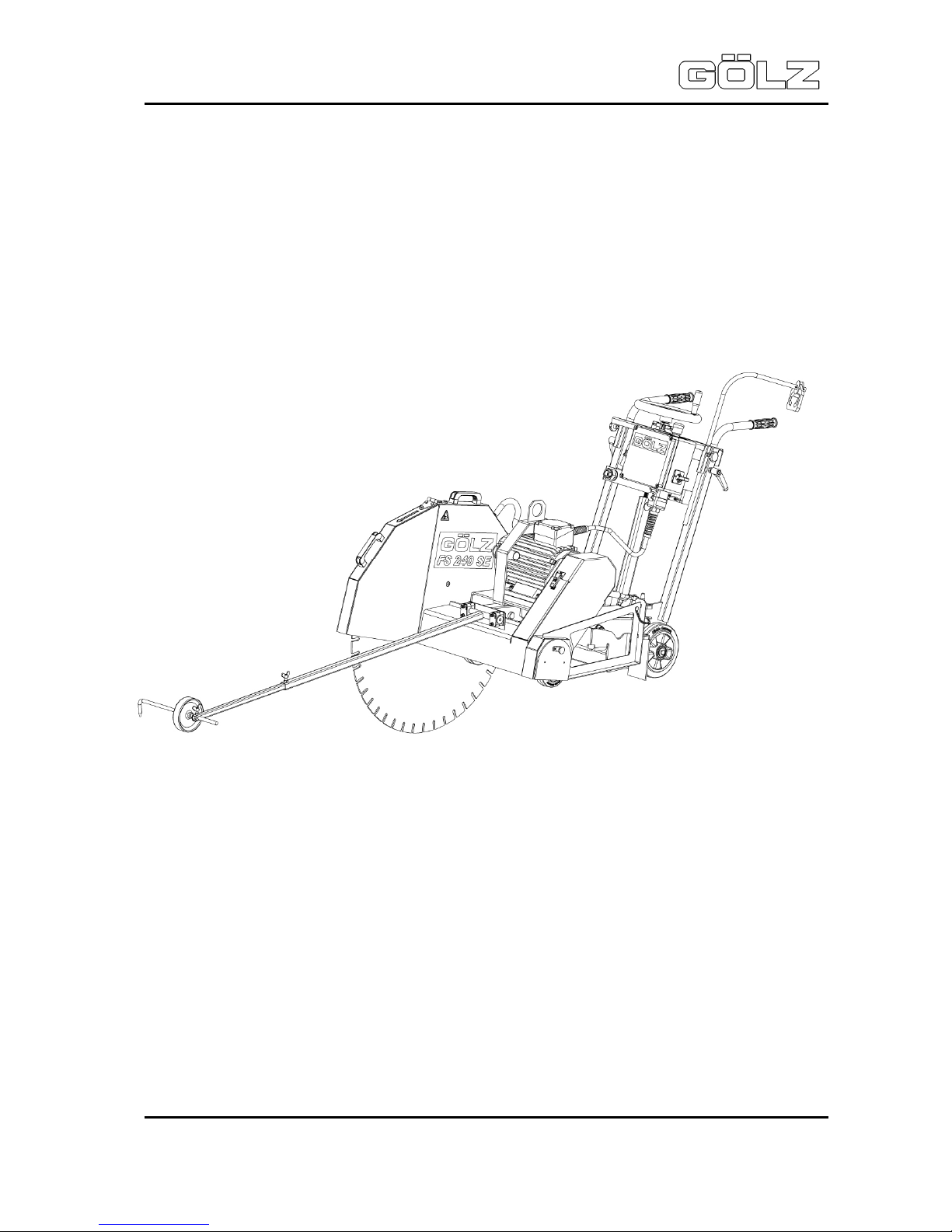

FS 240 SE

Operating instructions

- 1-

02822410998

5006580-00

Floor saw

FS 240 SE

Art.-Nr. der Bedienungsanleitung: 02822410998

ZN der Bedienungsanleitung: 5006580-00

Erstellt am: 04 / 2012

Erstellt von: Julia Großart

Datei: K:\KDV\5006xxx\5006580-Bedienungsanleitung\

5006580-00-Bedienungsanleitung-doc.doc

GÖLZ GmbH

Dommersbach 51

53940 Hellenthal-Blumenthal

Telefon: (02482) 120

Telefax: (02482) 12135

Page 2

FS 240 SE

Operating instructions

- 2-

02822410998

5006580-00

EG-KONFORMITÄTSERKLÄRUNG

EC-DECLARATION OF CONFORMITY

DECLARATION DE CONFORMITE DE LA CE

Die Firma

Manufacturer

La Société

GÖLZ GmbH

Dommersbach 51, 53940 Hellenthal - Blumenthal

Tel.: (02482) 120 Fax: (02482) 12135

Erklärt in alleiniger Verantwortung, dass

folgendes Produkt:

FS 240 SE

Fugenschneider

Hereby certifies on it’s sole responsibility

that the following product:

FS 240 SE

Floor saw

Déclare sous sa seule responsabilité que

le produit suivant:

FS 240 SE

Scie de sol

Seriennummer / Serial number / Numéro de série: _______________________

Auf das sich diese Erklärung bezieht, mit

folgenden Richtlinien bzw. Normen übereinstimmt:

Maschinenrichtlinie 2006/42/EG

Sicherheits- und Gesundheitsanforderung

EMV-Richtlinie 2004/108/EG

Elektromagnetische Verträglichkeit

Richtlinie 2000/14/EG

Geräuschrichtlinie

Europäische Normen

EN 13862:2001

EN 13309:2000

EN 61000

DIN EN ISO 3744

Die oben genannte Firma hält Dokumentationen als Nachweis der Erfüllung

der Sicherheitsziele und die wesentlichen Schutzanforderungen zur Einsicht

bereit.

Which is explicitly referred to by this declaration meet the following directives

and standard(s):

Directive 2006/42/EC

Safety and health requirement

Directive

2004/108

/EC

Electromagnetic compatibility

Directive 2000/14/EC

Noise emission

European Standard

EN 13862:2001

EN 13309:2000

EN 61000

DIN EN ISO 3744

Documented evidence conforming with

the requirements of the Directive is kept

available for inspection at the above

Manufacturer's, address.

Qui fait l‘objet de la présente déclaration

correspond aux directives et normes

suivantes:

Directive 2006/42/CE

Prescriptions sanitaire et sécurité

Directive

2004/108

/CE

Compatibilité électromagnétique

Directive 2000/14/CE

Émission de bruit

Norme européenne

EN 13862:2001

EN 13309:2000

EN 61000

DIN EN ISO 3744

Pour faire foi de la conformité et du respect des règles de sécurité, la documentation peut être consultée au siège

de la Société susmentionnée.

Blumenthal, den 18.04.2012

Page 3

FS 240 SE

Operating instructions

- 3-

02822410998

5006580-00

Contents

1. Preface .......................................................................................................................... 4

2. General safety references.............................................................................................. 4

2.1 Basic operation and designated use of the machine .............................................................. 5

2.2 Organizational measures .................................................................................................... 5

2.3 Selection and qualification of person ................................................................................ 6

2.4 Normal operation of the machine ....................................................................................... 6

2.5 Special work related to the maintenance and repair of the machine ............................. 7

2.6 Information about special risks electrical energy ............................................................ 8

2.7 Noise ...................................................................................................................................... 8

2.8 Oils, greases and other chemical substances .................................................................. 8

2.9 Changing the location of the machine ............................................................................... 9

3. Description ...................................................................................................................10

3.1 Main parts ........................................................................................................................... 10

3.2 Technical data .................................................................................................................... 10

3.3 Safety devices .................................................................................................................... 11

4. Transport ......................................................................................................................12

4.1 Transport............................................................................................................................. 12

4.2 Storing ................................................................................................................................. 13

4.3 Bracket ................................................................................................................................ 13

5. Installation ...................................................................................................................14

5.1 Mounting the blade ............................................................................................................ 15

5.2 Water supply ....................................................................................................................... 16

5.3 Adjusting and operating elements ................................................................................... 17

5.4 Electric power supply ........................................................................................................ 17

5.5 Cutting operation ............................................................................................................... 17

6. Maintenance .................................................................................................................19

6.1 General ................................................................................................................................ 19

6.2 V-belts ................................................................................................................................. 19

6.3 Maintenance plan ............................................................................................................... 20

7. Troubleshooting ............................................................................................................21

8. Wearing parts ...............................................................................................................23

9. Spare parts list ..............................................................................................................24

10. Wiring diagram .............................................................................................................47

Page 4

FS 240 SE

Operating instructions

- 4-

02822410998

5006580-00

Jedes Umsetzen der Maschine außerhalb des Bereichs, in dem Schneidarbeiten durchgeführt werden, darf nicht mit

rotierendem Werkzeug durchgeführt werden!

It is not allowed to move the machine with rotating blade outside of the area in which cutting works have to be performed!

Tout déplacement de la machine doit s’opérer sans rotation de l’outil (risque de blessures) ceci est également valable sur

le chantier pour les déplacement entre coupes!

Vor Inbetriebnahme Betriebsanleitung lesen!

Read owner’s manual before the first initiation!

Lire la notice avant utilisation!

Wichtiger Hinweis!

Important advice!

Indication importante!

Achtung, spielende Kinder!

Be careful with kids on the work side!

Attention aux enfants!

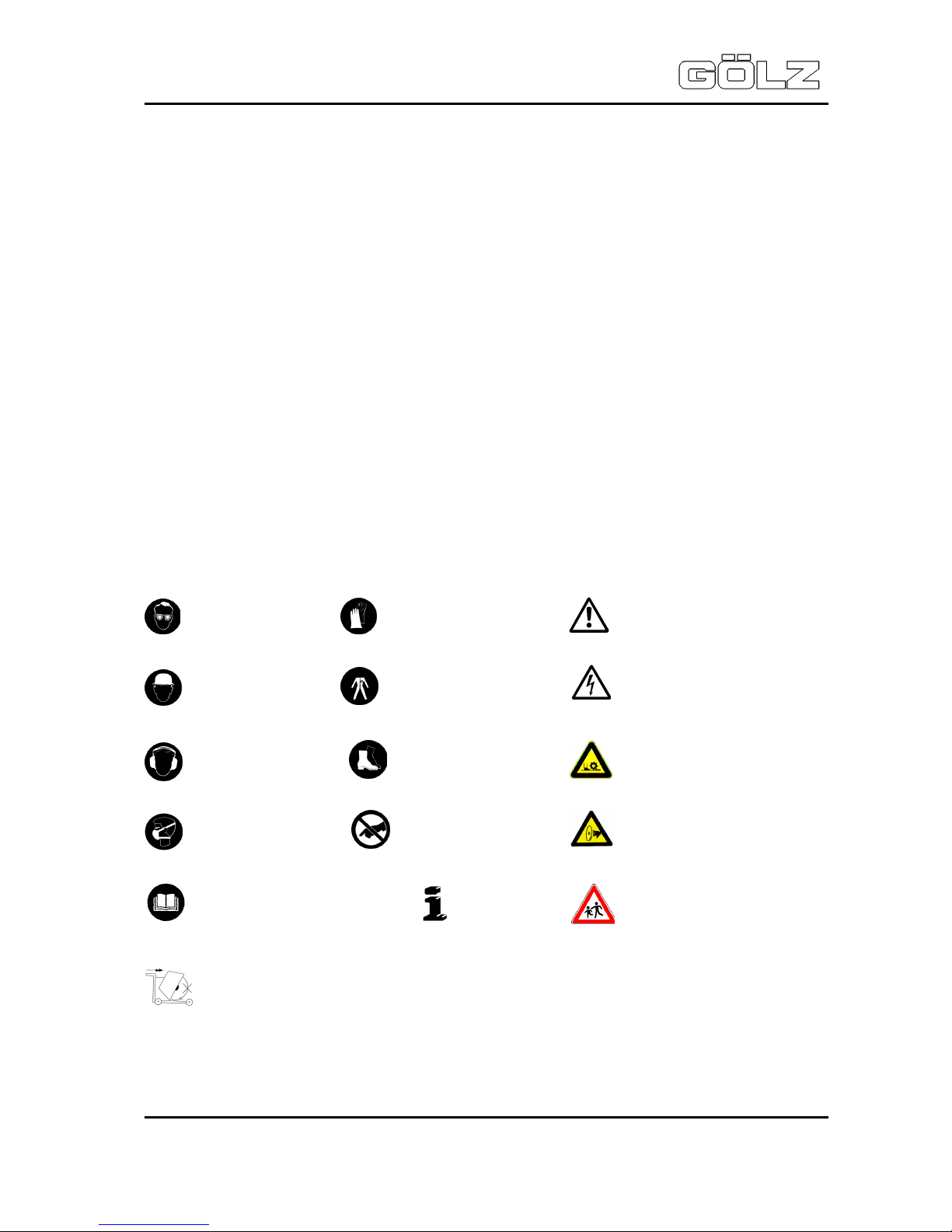

Staubschutz tragen!

Wear dust protection!

Port de masque!

Achtung, Schneidgefahr!

Danger exist to cut oneself!

Attention danger de coupure!

Nicht berühren!

Never touch!

Ne pas toucher!

Gehörschutz tragen!

Wear ear muffs!

Protection acoustique obligatoire!

Schutzschuhe tragen!

Wear safety boots!

Chaussures de sécurite obligatoires!

Achtung, Schneidgefahr!

Danger exist to cut oneself!

Attention danger de coupure!

Schutzhelm tragen!

Wear safety helmet!

Port du casque!

Schutzkleidung tragen!

Wear safety clothes!

Vêtements protecteurs obligatoires!

Warnung vor elektrischer Spannung!

Electrical Hazard!

Attention tension électrique!

Augenschutz tragen!

Wear safety glasses!

Port de lunettes!

Schutzhandschuhe tragen!

Wear protective gloves!

Gants obligatoires!

Warnung vor allgemeiner Gefahr!

General danger!

Attention danger particulier!

1. Preface

Thanks for choosing a

GÖLZ

-product. This operating instruction is designed to familiarize the user

with the machine and its designated use.

The operating instruction contains important information on how to operate the machine safely, properly and most efficiently. Observing these instructions helps to avoid danger, to reduce repair costs

and downtimes and to increase the reliability and life of the machine. The operating instruction is to be

supplemented by the respective national rules and regulations for accident prevention and environmental protection. The operating instruction must always be available wherever the machine is in use.

This operating instruction must be read and applied by any person in charge of work with or on the

machine, such as:

• Operation including setting up, troubleshooting in the course of work, evacuation care and

disposal of fuels and consumables.

• Maintenance (servicing, inspection, repair) and/or

• Transport

In addition to the operating instructions and to the mandatory rules and regulations for accident

prevention and environment protection of the country and place of use of the machine, the generally

recognized technical rules for safe and proper working conditions and procedures must also be

observed.

2. General safety references

Page 5

FS 240 SE

Operating instructions

- 5-

02822410998

5006580-00

2.1 Basic operation and designated use of the machine

The machine has been built in accordance with state-of-the-art standards and the recognized safety

rules. Nevertheless, its use may constitute a risk to life and limb of the user or of third parties, or cause

damage to the machine and to other material property.

The machine must only be used in technically perfect condition in accordance with its designated use

and the instructions set out in the operating manual, and only by safety-conscious persons who are

fully aware of the risks involved in operating the machine. Any functional disorders, especially those

affecting the safety of the machine, should therefore be rectified immediately.

The machine is designed exclusively for sawing of abrasive building material. Using the machine for

purposes other than those mentioned above (such as for) is considered contrary to its designated use.

The manufacturer cannot be held liable for any damage resulting from such use. The risk of such

misuse lies entirely with the user.

Operating the machine within the limits of its designated use also involves observing the instructions

set out in the operating manual and complying with the inspection and maintenance directives.

2.2 Organizational measures

This operating manual must always be at hand at the place of use of the product and must be accessible to the person operating the machine!

In addition to this operating manual, all other generally applicable legal and other mandatory

regulations relevant to accident prevention and environmental protection must be observed! Such

obligations may also comprise the handling of hazardous materials, provisioning and/ or wearing of

personal protective equipment, or road traffic regulations. This operating manual must be supplemented by instructions covering the duties involved in supervising and notifying special organizational

features, such as job organization, work flows or the person entrusted with the work.

Person entrusted with work on the product must have read the operating manual prior to taking up

work. This applies especially to persons working only occasionally on the product, e.g. during set-up

or maintenance activities. Check - at least from time to time - whether the personnel are carrying out

the work in compliance with the operating manual and paying attention to risks and safety-relevant

factors.

For reasons of safety, long hair must be tied back or otherwise secured, garments must be closefitting and no jewellery - including rings - may be worn. Severe injury may result from being caught by

moving parts of the machine. Personal protective equipment must be used wherever required by the

circumstances or by law (e.g. safety glasses, ear protectors, safety boots, suitable safety clothing).

Observe the regulations for prevention of accidents! Observe all safety precautions and warnings

attached to the product and always keep them in good and perfectly legible condition.

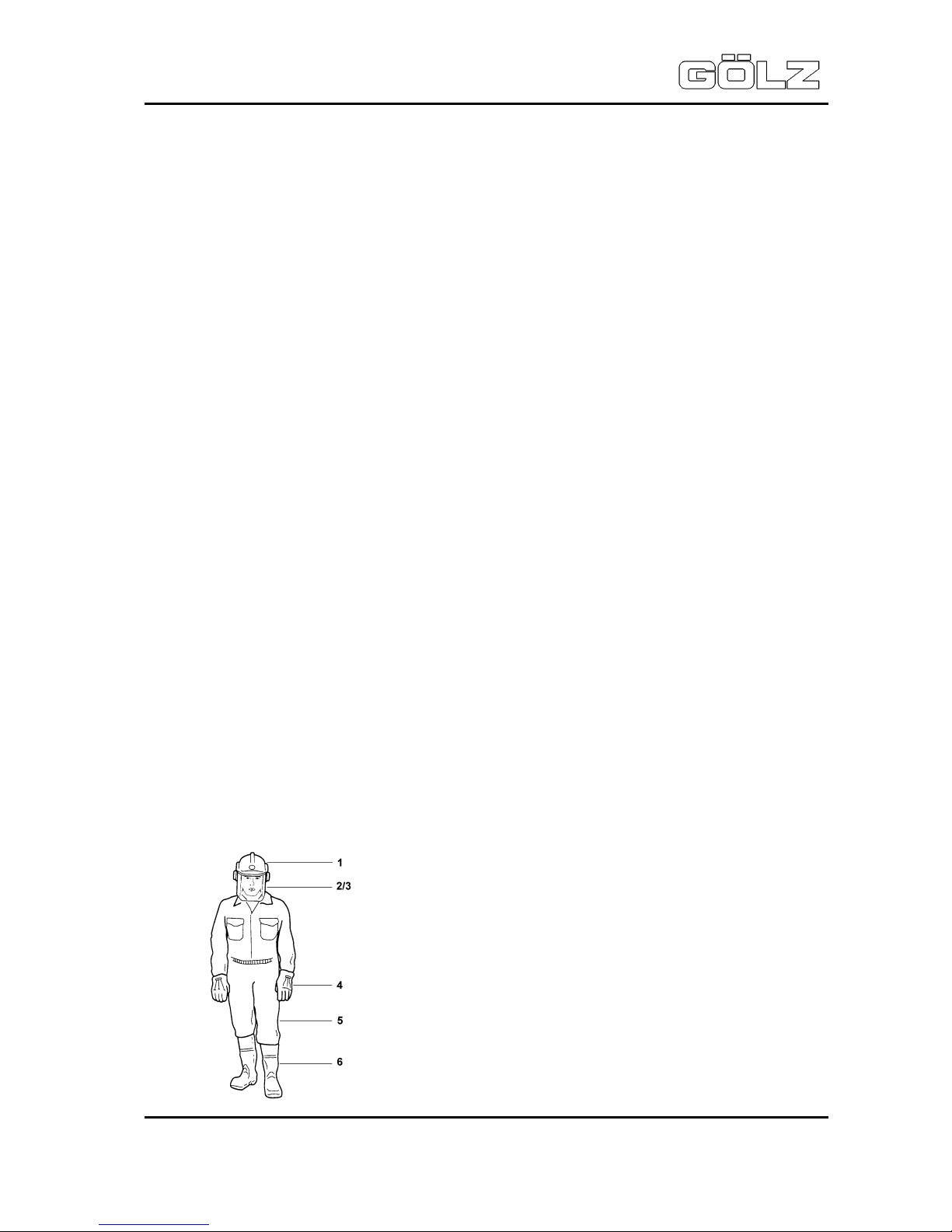

The personal protection equipment should consist of the following parts:

1 Helmet with protection of the ears

2/3 Visor or safety glasses / Dust mask

4 Protective gloves

5 Safety clothes

6 Safety boots

Page 6

FS 240 SE

Operating instructions

- 6-

02822410998

5006580-00

In case event of safety-relevant modifications or changes in the behaviour of the product, stop the

product immediately and report the malfunction to the competent authority/ person.

Do not remove or make inoperative any safety devices the product is equipped with.

Never make any modifications, additions or conversions which might affect safety without the

manufacturer’s / distributor’s prior approval! This also applies to the installation and adjustment of

safety devices as well as to welding and drilling work on supporting structures.

Damaged or worn parts of the product must be replaced immediately. Use genuine spare parts only.

All spare parts and tools must comply with the technical requirements specified by the manufacturer/

distributor.

Adhere to the legally prescribed preventive maintenance and inspection intervals or those specified in

this operating manual!

All maintenance and repair activities must be performed by qualified personnel using suitable tools

and other suitable workshop equipment.

Observe the fire alarm and fire fighting measures. The personnel must be made familiar with the

location and handling of fire extinguishers!

2.3 Selection and qualification of person

Any work on and with the product must be executed by reliable person only. Statutory minimum age

limits must be observed!

The product must be operated or serviced by trained or properly instructed person only. Clearly define

the individual responsibilities of the person for operation, set-up, maintenance and repair.

Make sure that only authorized work on or with the product.

Define the machine operator’s responsibilities -also with regard to observing road traffic regulations-,

providing the operator with the authority to refuse instructions by third parties that are contrary to

safety.

Do not allow persons to be trained or instructed or persons taking part in a general training course to

work on or with the product without being permanently supervised by an experienced person.

Work on the electrical system and equipment of the product must be carried out only by a skilled

electrician or by properly instructed persons working under the supervision and guidance of a skilled

electrician and in accordance with electrical engineering rules and regulations.

2.4 Normal operation of the machine

Before beginning work, familiarize yourself with the surroundings and circumstances of the site, such

as obstacles which might impede work or traffic, the soil bearing capacity and the required safety

measures, e.g. barriers separating the work site from public traffic.

Avoid any operational mode that might be prejudicial to safety. Check the range in gas-, water- and

power supply lines before working.

Take the necessary precautions to ensure that the machine is used only when in a safe and reliable

state. Operate the machine only if all protective and safety-oriented devices, such as removable

safety devices, emergency shut-off, sound-proofing elements and exhausters, are in place and fully

functional.

Check the machine at least once per working shift for obvious damage and defects. Report any

changes to the competent person immediately. If necessary, stop the machine immediately and lock it.

In the event of malfunctions or changes in the machine’s behaviour, stop the product immediately and

secure it against restarting. Have any defects rectified immediately!

Take precautions to ensure that the operator always has an adequate view of the work. Before leaving

the machine always secure it against inadvertent movement and unauthorized use!

Cutting has to be operated wet in order to prevent the occurrence of harmful particulate matter and to

increase the lifetime of the cutting tool.

During start-up and shut-down procedures always watch the indicators in accordance with the

operating instructions.

Page 7

FS 240 SE

Operating instructions

- 7-

02822410998

5006580-00

Noise protection equipment on the machine has to be in protective position during operation. Wear the

prescribed personal ear protection!

Avoid any operation that might be a risk to machine stability. Always keep at a distance from the

edges of building pits and slopes.

The machine is designed for use in daylight! The machine operator/ owner must ensure sufficient

workplace lighting for non-illuminated work sites!

Before leaving the machine always secure the machine against inadvertent movement and

unauthorized use.

2.5 Special work related to the maintenance and repair of the machine

Observe the adjustment, maintenance and inspection activities and intervals set out in the operating

manual, including information on the replacement of parts or assemblies! These activities may be

performed by skilled personnel only.

Brief the operating personnel before initiating special repair or maintenance activities. Appoint a

person to supervise such activities. In any work concerning the operation, adaptation to production

requirements, conversion or adjustment of the machine and it’s safety-oriented devices or any work

related to inspection, maintenance and repair, always observe the start-up and shut-down procedures

described in the operating manual as well as the instructions on maintenance activities!

If necessary, secure a large area around the location where maintenance of the machine is to be

performed. Maintenance and repair work may be carried out only if the machine is placed on level and

solid ground and secured against inadvertent movement.

If the machine is completely shut down for maintenance or repair work, it must be secured against

inadvertent restarting.

When using a lifting gear for replacing individual parts or large assemblies make sure that the parts/

assemblies are carefully attached to the lifting gear and secured in place to avoid hazardous

conditions. Use only suitable and technically perfect lifting gear and suspension systems with

adequate lifting capacity! Never work or stand under suspended loads! The fastening of loads and the

instructing of crane/industrial truck operators should be entrusted to experienced persons only!

The instructor must be within sight or sound of the operator. Use an intercom system if necessary.

When carrying out overhead work always use specially designed or other safety-oriented ladders and

working platforms. Never use machine parts as a climbing aid!

Wear a safety harness when performing maintenance work at greater heights! Keep all handles, steps,

handrails, platforms, landings and ladders in a clean condition!

Before performing any maintenance/ repair activities clean the machine, especially the connectors and

screwed joints, and remove any oil, dirt and preservative agents. Never use aggressive detergents!

Use lint-free cleaning rags!

Before cleaning the machine with water or other cleaning agents cover or tape up all openings which for safety and functional reasons- must be protected against the ingress of water/ steam/ cleaning

agents. Special care must be taken with bearings, electric motors and electronic systems. After

cleaning, make sure to remove all covers/ tapes from the openings.

After cleaning, check all cables for leaks, loose connections, chafe marks and damage! Have any

defects found rectified immediately! Always retighten any screwed connections that have been

loosened during maintenance/repair activities!

Any safety devices removed for set-up, maintenance or repair purposes must be refitted and checked

immediately upon completion of the set-up, maintenance or repair work.

Avoid any operation that might affect the stability of the machine. Always keep a sufficient distance

from the edges of excavations, ditches and slopes!

Before leaving the machine always secure it against inadvertent movement and unauthorized use!

Ensure that all process materials and replaced parts are disposed of safely and with minimum environmental impact!

Page 8

FS 240 SE

Operating instructions

- 8-

02822410998

5006580-00

2.6 Information about special risks electrical energy

Observe the relevant national regulations or standards. Electrical connections must always be kept

free from dirt and moisture. Use only original fuses with the specified rating! Switch off the machine

immediately, if trouble occurs in the electric power supply!

When working with the machine, maintain a safe distance from overhead electric lines. If work is to be

carried out close to overhead lines, the working equipment must be kept well away from them.

Caution, danger! Check out the prescribed safety distances.

If your machine comes into contact with a live wire:

• warn others against approaching and touching the machine

• have the live wire de-energized

Work on the electrical system or equipment may only be carried out by a skilled electrician himself or

by specially instructed personnel under the control and supervision of such electrician and in

accordance with the applicable engineering rules. If provided for in the regulations, the power supply

to parts of machines and plants, on which inspection, maintenance and repair work is to be carried out

must be cut off. Before starting work, check the de-energized parts for the presence of power and

ground or short-circuit them in addition to insulating adjacent live parts and elements.

The electrical equipment of machines is to be inspected and checked at regular intervals. Defects

such as loose connections or scorched cables must be rectified immediately.

Necessary work on live parts and elements must be carried out only in the presence of a second

person who can cut off the power supply in case of danger by actuating the emergency shut-off or

main power switch. Secure the working area with a red-and white safety chain and a warning sign.

Use insulated tools only.

If mobile electrical equipment, connecting cables and/ or extension/ appliance cords with plug

connectors are used, ensure that such equipment, cables and cords are checked for correct function

at least once every six months by a qualified electrician or - if suitable testing equipment is available by a properly instructed person.

Protective installations with fault-current protection units used in non-stationary equipment must be

checked for correct operation at least once a month by a properly instructed person.

Fault-current and fault-voltage protection units must be checked for correct operation by actuating the

testing facility:

• once on every working day in the case of mobile equipment,

• at least once every six months in the case of stationary equipment.

2.7 Noise

Noise Protection devices on the machine must be in the protection position during operation!

Always wear the specified personal hearing protection (UVV 29 §10)!

2.8 Oils, greases and other chemical substances

When handling hydraulic fluids, lubricating fluids, greases or preservatives (called operating materials

and lubricants in the following), the safety regulations applicable for the respective product must be

observed! Avoid prolonged contact of operating materials and lubricants with the skin!

The skin must be carefully cleaned of adhering operating materials and lubricants!

Exercise caution when handling hot operating materials and lubricants, as there is a danger of burns

or scalding. Particularly at liquid temperatures above 60°C, avoid any skin contact with these liquids!

If operating materials or lubricants get into the eyes, flush thoroughly with drinking water. Then visit a

doctor! Immediately clean up any operating materials and lubricants which have leaked out. Use

absorbent material for this purpose!

Operating materials or lubricants must not be allowed to seep into the soil or to get into the public

sewerage system!

Page 9

FS 240 SE

Operating instructions

- 9-

02822410998

5006580-00

Properly collect, store and dispose of operating materials and lubricants which can no longer be used!

Observe and follow the respective applicable laws and regulations for handling operating materials

and lubricants and their disposal in the country in which these substances are used! Obtain

information from the responsible agencies!

2.9 Changing the location of the machine

Use only suitable means of transport and lifting gear of sufficient capacity when loading or transporting

the machine! Appoint an experienced instructor for the lifting operation!

Always observe the instructions given in the operating manual when lifting the machine (use only the

prescribed lifting eyes for attaching the lifting gear)! Use only suitable transport vehicles with sufficient

load capacity! Secure the load carefully. Use suitable fastening points for securing!

Before loading the machine or parts of it, secure the machine/ parts against inadvertent movement!

Attach a suitable warning sign!

Before using the machine again, make sure that such protection material or devices are properly

removed! Parts which had to be removed for transporting of the machine must be refitted and secured

carefully before the machine is used again! Even when the transport of the machine only involves a

minor relocation, disconnect it from all external power supply lines!

Before using the machine again, make sure that the connection to such external supply lines is reestablished properly. The recommissioning procedure must be strictly in accordance with the operating manual! Observe the instructions given in the operating manual when reassembling and operating

the machine. Before setting the machine in motion always check that all accessories are safely

stowed.

Note that a non-fixed but mounted and standing machine will fall forward.

While carrying heavy weights, avoid stooping down.

Page 10

FS 240 SE

Operating instructions

- 10-

02822410998

5006580-00

3. Description

Operate the machine only using tools in accordance with the manufacturer’s instruction. Using other

tools is considered contrary to its designated use. The manufacturer cannot be held liable for any

damage resulting from such use. The risk of such misuse lies entirely with the user.

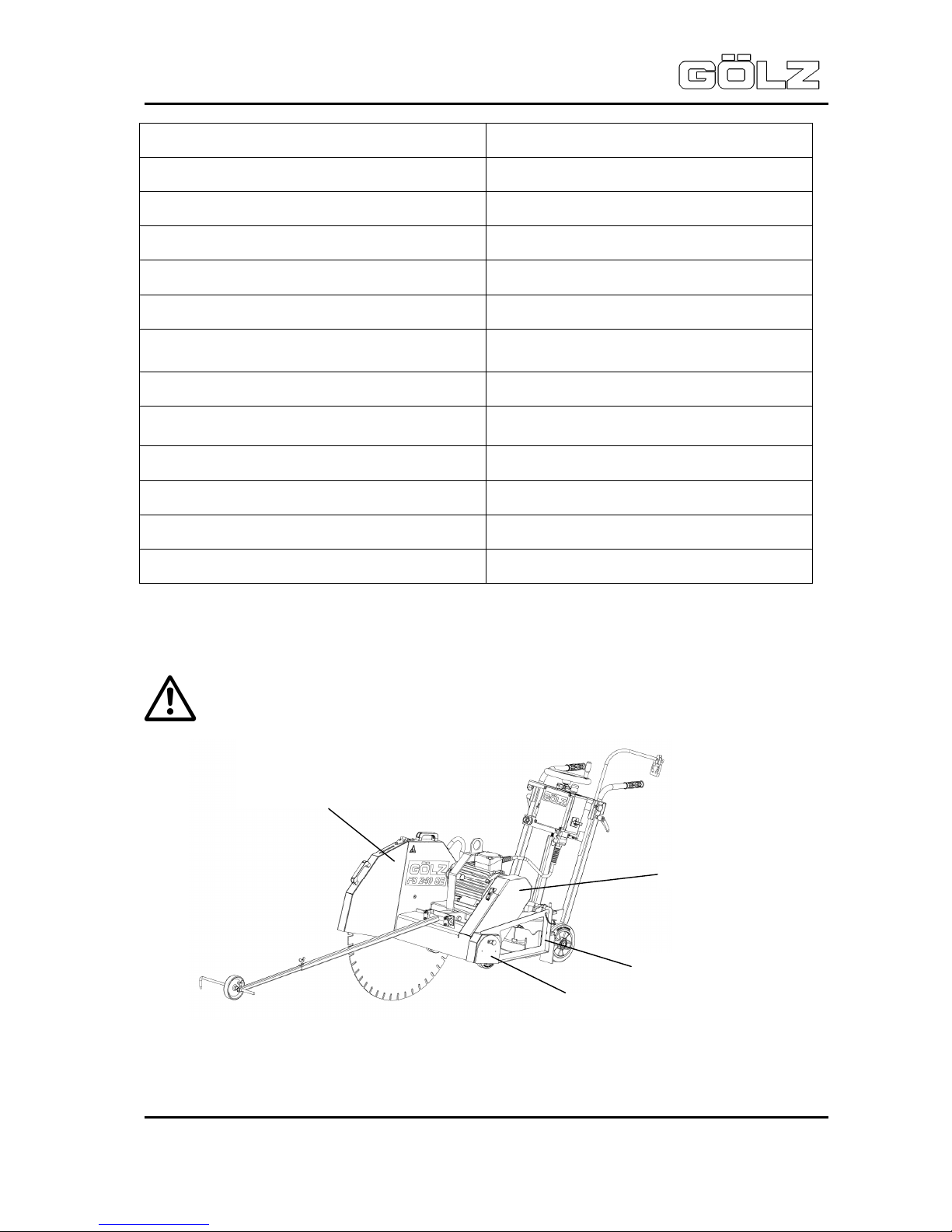

3.1 Main parts

1. Control panel 7. Electric motor 12. Water connection

2. Chassis 8. Switch box with 13. Eyebolt and

3. Undercarriage electrical connection Engine bracket

4. Flange guard 9. Blade guard 14. Blade guard pulley

5. Pointer unit 10. Connecting rod

6. Blade 11. Strain relief

3.2 Technical data

Max. cutting depth 330 mm - 13 in.

Max. blade-Ø 800 mm - 31,5 in.

Flange size Ø 120 mm - 4,7 in.

Blade shaft size Ø 25,4 mm - 1 in.

Engine

3-phases-motor

7,5kW (10 HP), 14,4 A

3

8

13

5

9

10

6 2

12

Page 11

FS 240 SE

Operating instructions

- 11-

02822410998

5006580-00

Max. cutting speed with blade 60 m/s

Engine shaft speed 2860 rpm

Blade shaft speed 1430 rpm

Feed Manual

Excavation Manual (hand crank)

Cutting depth control Scale on frame

Water supply Connection for external water supply

V-belt tension Manual

Dimensions (L x W x H)

approx. 1650 x 733 x 989 mm - 65 x 28,9 x

178,7 in.

Weight (without water tank and blade) ca. 187 kg - 415,5 lbs.

Sound power level after DIN ISO 6393

No load = 100 dB(A)

Full load = 119 dB(A)

Sound pressure level after DIN ISO 6393

No load = 80 dB(A)

Full load = 100 dB(A)

Vibration after ISO 5349 VDMA 03/2006 a = 3,7 m/s²

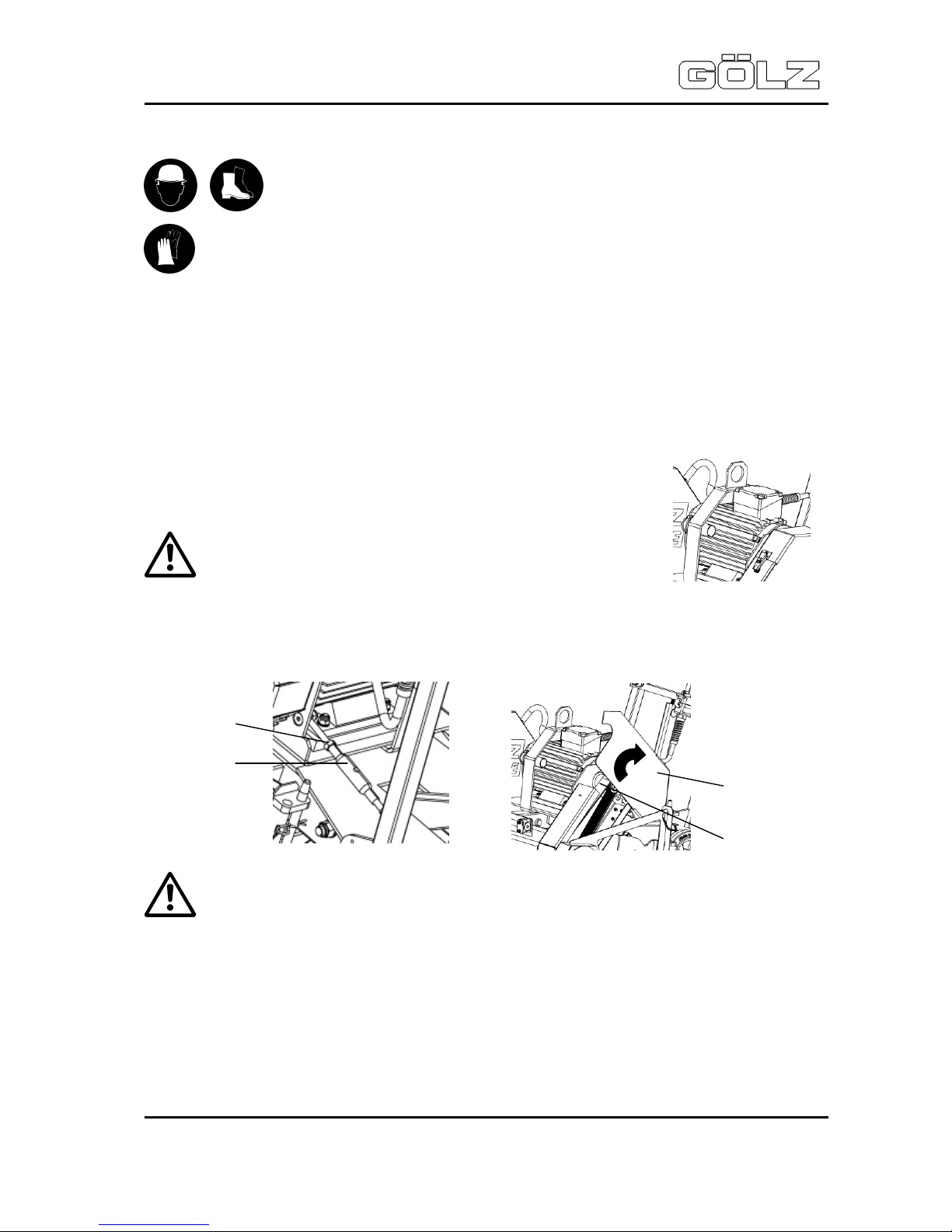

3.3 Safety devices

Danger: During cutting or displacing the machine, all safety devices shown below

must be mounted!

Blade guard for

max. blade size of

Ø 800 mm - 31.5 in.

with blade shaft protection

V-belt

guard

Flange guard

Blade shaft protection

Page 12

FS 240 SE

Operating instructions

- 12-

02822410998

5006580-00

4. Transport

Danger of down coming parts!

Injury hazard: Sharp edges!

4.1 Transport

Before transport the emergency stop switch is to be pressed and the brake is to be actuated.

Dismount the blade and attach again the blade guard. Lower the machine until the end stop. Check

that all parts of the machine are well fastened before transporting. After loading the machine is to be

secured with suitable lashing material.

For loading only use lifting gear and tackle of sufficient capacity (Allow the kerb

weight of the machine).

Lift the machine using the lifting eye.

Danger: Only use the lifting eye for lifting the machine!

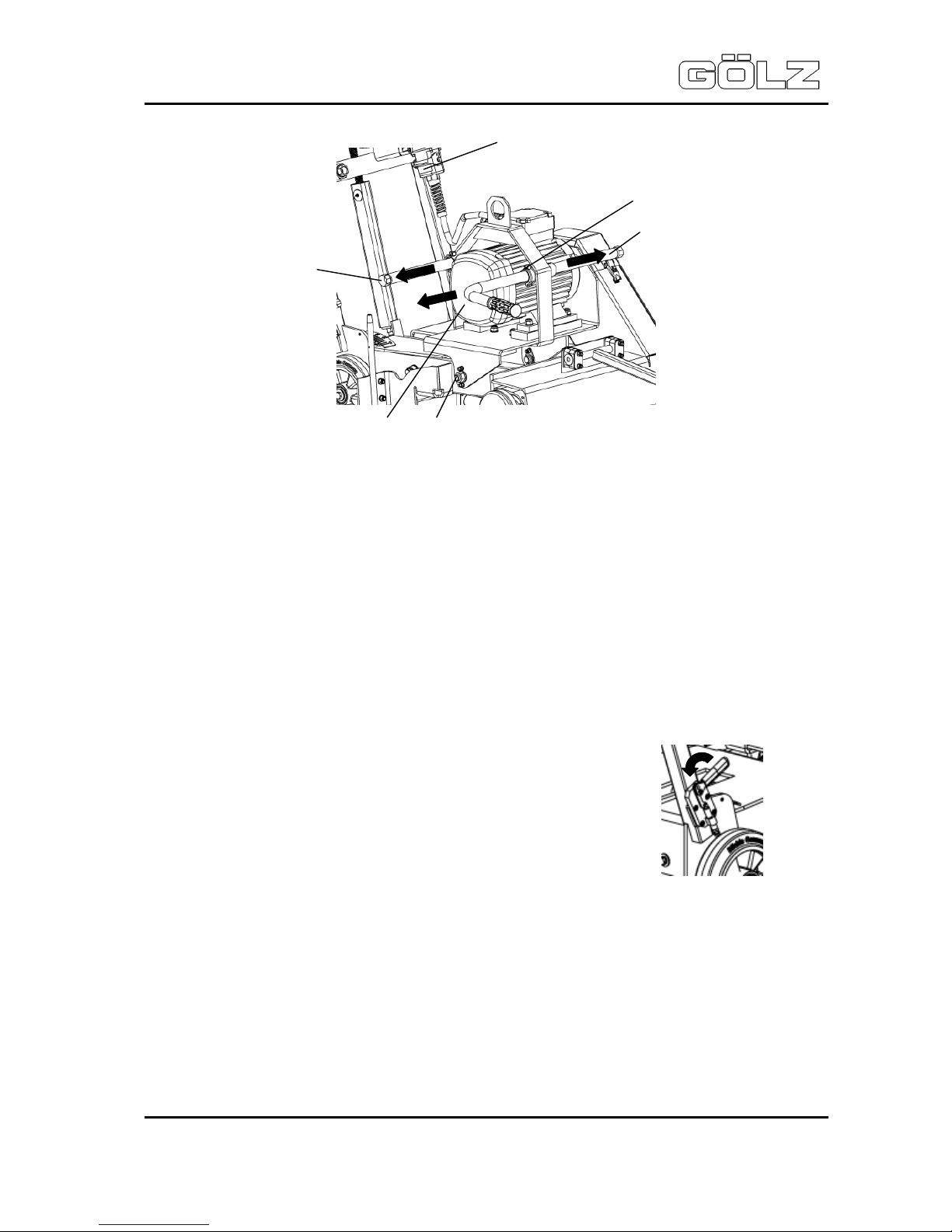

To make transport easier, the motor can be removed together with the motor bracket.

Loosen the lock nut M10 (Pos.1) and turn the turnbuckle nut (Pos. 2) off. Open the V-belt protective

hood (Pos. 3) in order to remove the V-belt (Pos. 4) from the V-belt pulley of the motor.

Caution: The motor bracket can tilt!

Loosen the hexagonal nut M16 (Pos. 5) and remove the washer (Pos. 6). Disconnect the motor plug

(Pos. 7) from the switch box.

Position the pushing rods (Pos. 8) in the collets of the motor bracket and secure them with the pipe

locking pins (Pos. 9).

3

4

2

1

Page 13

FS 240 SE

Operating instructions

- 13-

02822410998

5006580-00

The motor (Pos. 10) can now be removed sideways from the axes over the pushing rods together with

the motor bracket and be carried by two people.

For mounting, proceed in reverse order. After mounting, ensure the correct V-belt tension!

4.2 Storing

Store the machine in a dry, high or locked place, out of the reach of children or unauthorized persons.

Clean and preserve the machine with corrosion preventive if storing over a longer time like winter time!

4.3 Bracket

When the machine is not in use, the brake is to be actuated as a matter of

principle.

9

10

8

7

5

/ 6

8

Page 14

FS 240 SE

Operating instructions

- 14-

02822410998

5006580-00

5. Installation

Information: Unconditional observe the owner’s manual of the engine manufacturer!

Danger: Never touch rotating parts like blade shaft or blade while operating!

Danger: Rotating parts may pull in clothing! Wear tightly clothing!

Danger: Down coming parts can cause injuries to the operator!!

Place the machine on an even, firm and stable ground. Have the working area well lightened. Keep

the working area clean, cluttered areas invite injuries. Observe the manufacturer’s information for

connecting power and water supply. Lay all lines or cables that damages will be prevented.

Mount the blade to the manufacturer’s odds (Observe the min. flange-Ø; use only original screws or

nuts). Use only blade diameters which are allowed by the manufacturer.

The working area is reserved only for the operator. Keep unauthorized persons out of the working

area. Make sure the operator always has well sight to the working area. He always has to intervene in

the working process.

Never operate the machine without mounted safety devices. Check the blade is well fastened before

beginning to operate. Check the correct water flow to the blade. If harmful or explosive stuffs like dust,

milk-of-lime arise while cutting, observe local regulations.

If there is a risk that, during the cutting process, material particles can be accelerated outwards, wear

safety goggles.

Danger: Demolition parts can cause injuries to the operator while cutting!

When travelling on public roads, ways and places always observe the valid traffic regulations and, if

necessary, make sure beforehand that the machine is in a condition compatible with these regulations.

After operating secure the machine against unintentional moving. If there is a risk due to increased

noise exposure during the cutting process at the workplace, wear ear protection.

Danger: The sound pressure may exceed 85 dB(A)!

Appropriate to the application of the machine it could be necessary to wear further protective equipment.

Danger: Down coming parts at the building site can cause injuries to the operator!

Page 15

FS 240 SE

Operating instructions

- 15-

02822410998

5006580-00

5.1 Mounting the blade

In the cutting speed range all used blades must be designed for the max. rpm of the machine. Never

use faulty or damaged blades.

Danger: Damaged cutting discs can cause serious personal injury!

Note: Wrong direction of rotation leads to drastically increased wear of the cutting disc!

Danger: Wrong direction of rotation can result in the detachment of a segment of the

cutting disc and thus cause serious personal injury!

Depending on the material to be machined, the machining process and the nature of work to be

carried out, use the cutting discs according to manufacturer's / supplier's specifications.

Note: Before mounting the cutting disc, thoroughly clean all the fastening elements relating to the cutting disc such as flanges, threads of the cutting shaft,

screws or nuts!

Each time a cutting disc is mounted or changed, the joint cutter is to be shut down first and the

emergency stop switch is to be pressed or to be disconnected from any energy source.

Pull out the spring cotter pin (Pos. 2) so that you

can remove the cutting disc guard (Pos. 1) from

the machine. Clean the inner flange (3) before

mounting the blade.

Mount the cutting disc (max. Ø 800 mm, Pos. 4) with the correct

mounting holes (Ø 25.4 mm)

Make sure that the rotational direction is correct! There are

directions of rotation arrows on the cutting disc guard as well as

on the cutting disc itself.

Fit the outer cutting flange (Pos. 5) and secure it with screw M

16 (Pos. 6) SW 24.

In the cutting shaft, there is a left-hand thread in the direction of

motion on the right; in the direction of motion on the left, there is

a right-hand thread.

6

5

4

1

3

2

Page 16

FS 240 SE

Operating instructions

- 16-

02822410998

5006580-00

After mounting, fit the cutting disc guard again and fit the spring

cotter pin again to its mounting hole. Make sure that the guard

plate cutting shaft (Pos. 7) is in position.

5.2 Water supply

Screw the connecting piece (Pos. 1 SW26) of the water hose of the cutting

disc guard to the double nipple (Pos. 2 SW39) on the control panel.

Connect, with the help of a GEKA-coupling, the existing coupling (Pos. 3)

on the right operator's side of the machine. Make sure that the mini ball

valve (Pos. 4) is closed (valve lever in 90° position to the flow direction).

The water supply connection of the wall-flush hood is the same as the

connection of the cutting disc guard.

Please note that, for left-hand or right hand cutting, the water connection of the

water-flush hood is to be changed accordingly (SW39 and SW26).

1

7

1 2

3

4

Connection

Control Panel

Connection

Right Cut

Connection

Left Cut

Page 17

FS 240 SE

Operating instructions

- 17-

02822410998

5006580-00

5.3 Adjusting and operating elements

1. CEE-plug

2. star-delta connection switch

3. Emergency stop switch

4. Main emergency stop switch

5. Connection motor cable

5.4 Electric power supply

Ensure power-supply matches with details from motor rating-plate:

• Input voltage: V / 50 Hz,

• Fuse protection: A

The used power supply has to conform the instructions of assembly for construction site (ACS) (Error

current protective circuit, who works until max. 30 mA by main error current).

Only use extension cable with protective conductor (5-wire) and

adequate wire cross section (min.

4mm²). Always unwind the whole cable roller.

Connect the motor cable (Pos. 1) by means of the plug-in

system to the switch box (Pos. 2)

Before you connect the power plug of the cable to the appliance

inlet (Pos. 3) of the machine, the emergency stop switch (Pos.

4) must be pressed.

Make sure that the star-delta connection switch is turned to "0"

and that the main emergency switch is turned to "Off".

After you have connected the power supply unit to the machine,

the emergency stop switch (Pos. 4) is to be unlocked. Attach the

cable to the strain-relief clamp (Pos. 5).

The strain-relief clamp is two-sided pluggable in the control

panel and can be adjusted angularly by means of the star grip.

5.5 Cutting operation

Danger: Operating with too high feed the machine might rise out of cut! In

emergency situations shut down the machine immediately by pushing the

emergency shut-off!

Each relocating of the machine between sawing operations has to be carried out

with non-rotating cutting disc, i.e. when the drive motor is idle.

Before starting the cutting operation, the water supply is to be connected according to section 5.2

"Water Supply", the cutting disc is to be mounted according to section 5.1 "Mounting the blade" and

the power supply is to be connected according to section 5.4 "Power Supply".

4

2

5

3

1

5

4

3

2 1

Page 18

FS 240 SE

Operating instructions

- 18-

02822410998

5006580-00

In order to ensure trouble-free motor start, raise the machine, before you start it, by means of the hand

crank (Pos. 4) to such extent that the cutting disc has no soil contact.

Then turn the main emergency stop switch (Pos. 1) from "Off" to "On". To start the motor, turn the stardelta connection switch (Pos.. 2) from "0" to "Star" and wait until the motor has reached its full speed.

Make sure that the rotational direction of the cutting disc is correct! As the circumstances require, the

rotational direction of the drive motor is to be reversed. Turn the star-delta connection switch (Pos. 2)

again to "0", press the emergency stop switch (Pos. 3) and pull off the power plug.

With a suitable screwdriver, the phase inverter in the appliance inlet can be turned. Connect the power

supply unit to the machine again, as described above, and start the machine again.

As soon as the motor has reached its full speed and full power, the star-delta connection switch (Pos.

2) can be turned from "Star" to "Triangle".

Before you lower the machine by means of the hand crank (Pos. 4), the mini ball valve (Pos. 5) is to

be opened. Lower the machine to such extent that you reach the desired cutting depth (Cutting Depth

Label). Pull then the indexing plunger (Pos. 6) on the control panel, so that it snaps into the catch disk

in order to fix the desired cutting depth.

Work with a steady feed pressure. Too high feed pressure leads to an overload of the motor and there

is the risk that the machine loses contact with the ground. Too low feed pressure can polish the

segments and make them blunt.

After the cutting operation raise the machine again by means of the hand crank (Pos. 4). Stop the

water feed, turn the star-delta connection switch (Pos. 2) again to "0".

Before transporting the machine, before changing the cutting disc or doing maintenance work, the

emergency stop switch (Pos. 3) is also to be pressed and the main emergency stop switch (Pos. 1) is

to be turned to "Off".

6

5

3 2

1

4

Page 19

FS 240 SE

Operating instructions

- 19-

02822410998

5006580-00

6. Maintenance

6.1 General

Information: Clean the machine after every operation. Observe local environmental

regulations!

For your security and for a trouble-free operation of the machine, professional care and maintenance

is indispensable.

Maintenance and repair work is, as far as possible, generally to be carried out when the machine is

shut down and the power plug pulled off. For maintenance jobs which must be done while the floor

saw is running, the blade has to be dismounted before beginning the job. Electrical work is only to be

carried out by skilled electricians.

In accordance to the given cycles, the subsequently described maintenance work has to be enforced.

Also the wearing parts subject to no certain maintenance-intervals have to be checked regularly for

wear and to adjust if necessary or to exchange. With I.C. engines, the maintenance work has to be

enforced in accordance with the separate maintenance-instruction of the engine manufacturer.

Before each

start-up

After work

Once a week

Once a year

In case of failure

In case of damage

Complete machine

Visual inspecion

(condition, ab-sence

of leaks)

X X X

Clean

X

Flange and blade

acceptance

Clean

X

V-belts

Check

X

X

X X

Replace

X

Water nozzle and

feeding hoses

Clean

X X

Tools Check

X X X

6.2 V-belts

The multiple V-belt and the V-belt drive are retightened manually.

Loosen the counter nut M10 (Pos. 1) and turn the turnbuckle nut (Pos.

2) allowing you to tighten the motor and the multiple V-belt. Tighten the

counter nut M10 (Pos. 1) again.

2

1

Page 20

FS 240 SE

Operating instructions

- 20-

02822410998

5006580-00

To make it easier to change the multiple V-belt, raise the machine slightly by means of the hand crank.

Before you continue to work, press the emergency stop switch and pull off the power plug.

Loosen the counter nut M10 (Pos. 1) and slightly turn off the turnbuckle nut (Pos. 2) in order to remove

the tension from the multiple V-belt.

Remove the flange protection (Pos. 3) and open the V-belt protective hood (Pos. 4) in order to remove

the loosened multiple V-belt (Pos. 5) from the V-belt pulleys.

Position the new multiple V-belt on the V-belt pulleys and tighten it by turning the turnbuckle nut (Pos.

1) in the opposite direction until the required V-belt tension is reached. Tighten the counter nut (Pos.

2) again.

Shut the V-belt protective hood again and fit the flange protection again. If during operation, the V-belt

tension decreases to such extent that there is a slip between the multiple V-belt and the V-belt pulleys,

the multiple V-belt must be retightened.

6.3 Maintenance plan

1. Flange bearing of the spindle shaft: Clean from time to time, lubricate.

2. Shaft: Clean from time to time, lubricate.

3

5

4

Page 21

FS 240 SE

Operating instructions

- 21-

02822410998

5006580-00

7. Troubleshooting

Attention: In the event of changes in the behaviour of the machine during operation,

stop the machine immediately and report the malfunction to the competent authority

/ person!

Problem Cause Remedy

Engine

Engine does not run!

Power plug is not properly

connected

Check for correct connection

Fuses (from ACS or machine) have

triggered

Check fuses

Malfunction on electric installation

Electric installation needs to

be checked by a qualified

person

Lowering

Joint cutter can neither be

lowered nor be raised

Undercarriage or threaded spindle

tight.

Check undercarriage and

threaded spindle

Cutting

Machine rises out of cut

Dull diamond blade

Sharpen or use softer

diamond blade

Feed too high Reduce feed

Non circular abrasion of the

diamond blade

Damaged centering of the blade

shaft

Replace blade shaft

Warped blade shaft Replace

Loose or damaged blade shaft

bearings

Tighten or replace

Diamond blade jams in the cut

No free cut because of sideward

wear-out of segments

Check hoses for fracture free

laying

Damaged diamond blade core Replace diamond blade

Abnormal wear-out of

segments

Insufficient water flow

Check hoses for fracture free

laying

Wrong type of diamond blade

Choose different diamond

blade

Feed too high Reduce feed

Cutting in loose underground Reduce cutting depth

Bad cutting performance

Slippy V-belts Adjust

Blunt diamond blade

Sharpen or use softer

diamond blade

Page 22

FS 240 SE

Operating instructions

- 22-

02822410998

5006580-00

Page 23

FS 240 SE

Operating instructions

- 23-

02822410998

5006580-00

8. Wearing parts

Wearing parts for construction devices mentioned in the operating manual

such as drilling and sawing machines

Wearing parts are the parts subject to operation-related (natural) wear during proper use of the device.

The wearing time cannot be uniformly defined, and differs according to the intensity of use. The

wearing parts must be adjusted, maintained and, if necessary, replaced for the specific device in

accordance with the manufacturer’s operating manual. Operation-related wear is not a reason for

defect claims.

• Feed and drive elements such as toothed racks, gearwheels, pinions, spindles, spindle

nuts, spindle bearings, cables, chains, sprockets, belts

• Seals, cables, hoses, packings, connectors, couplings and switches for pneumatic, hydraulic,

water, electrical and fuel systems

• Guide elements such as guide strips, guide bushes, guide rails, rollers, bearings, sliding

protection supports

• Clamping elements for quick-separating systems

• Flushing head seals

• Slide and roller bearings that do not run in an oil bath

• Shaft oil seals and sealing elements

• Friction and safety clutches, braking devices

• Carbon brushes, commutators/armatures

• Easy-release rings

• Control potentiometers and manual switching elements

• Securing elements such as plugs, anchors, screws and bolts

• Fuses and lamps

• Auxiliary and operating materials

• Bowden cables

• Discs

• Diaphragms

• Spark plugs, glow plugs

• Parts of the reversing starter such as the starting rope, starting pawl, starting roller and

starting spring

• Sealing brushes, rubber seals, splash protection cloths

• Filters of all kinds

• Drive rollers, deflection rollers and bandages

• Cable anti-twist elements

• Running and drive wheels

• Water pumps

• Cut-material transport rollers

• Drilling, parting and cutting tools

• Energy storage

Wearing parts of this machine are grey marked in the spare parts list.

Page 24

FS 240 SE

Operating instructions

- 24-

02822410998

5006580-00

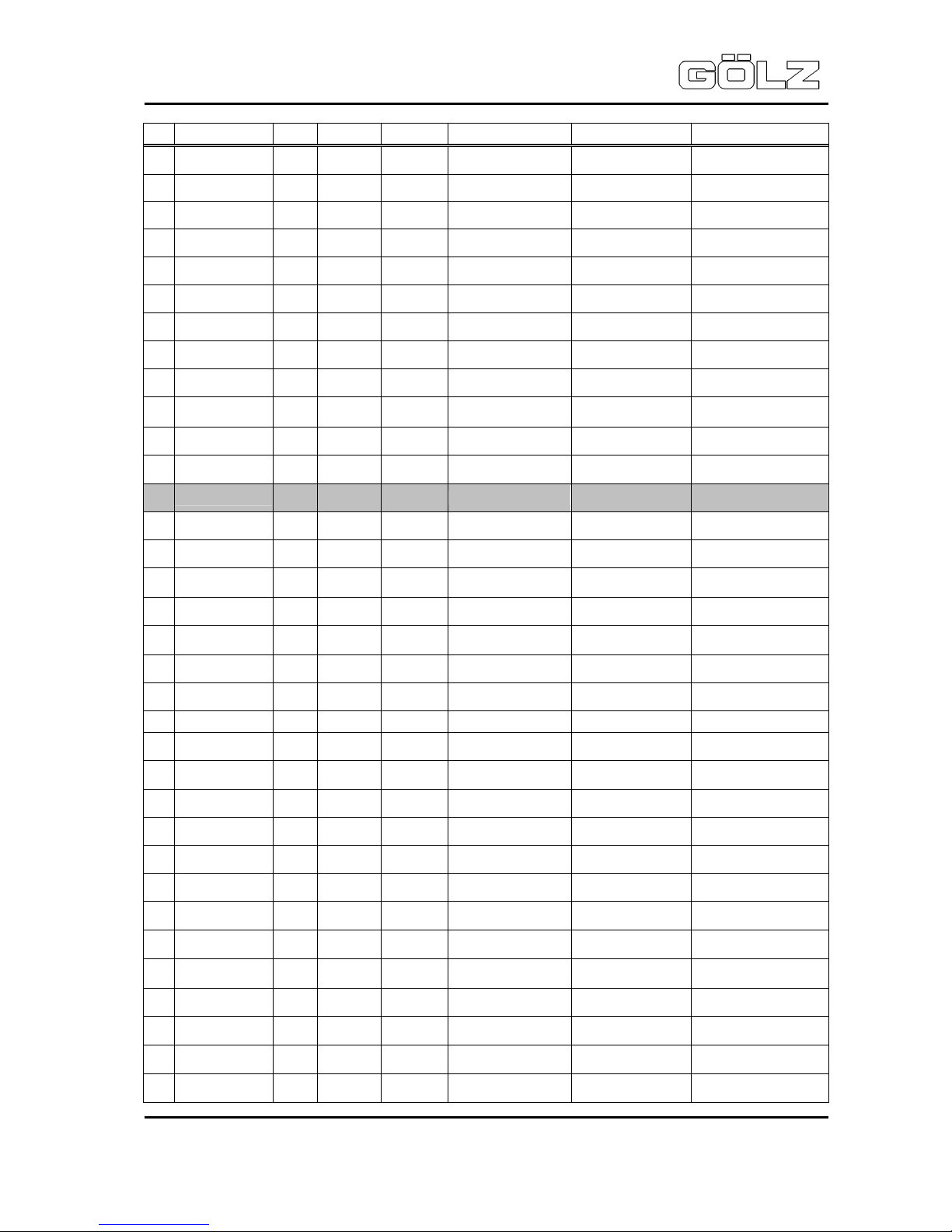

9. Spare parts list

So bekommen Sie schnell und richtig Ihr Ersatzteil

- für Maschine - Modell - Masch.-Nr.

- Artikelnummer - Bezeichnung des Ersatzteiles

- Anzahl der gewünschten Ersatzteile

- Wohin liefern?

- Womit liefern (Post, Eilpost etc.)?

Always indicate:

- machine/model/serial number

- item number and description of the spare part

- amount of spare parts desired

- full address

- goods to be sent by regular mail, express, etc.

Pour obtenir rapidement les pièces de rechange indiquer :

- Nº de la machine, du modèle

- Nº de l’article / description de la pièce désirée

- Nombre de pièces commandées

- Adresse de livraison

- Mode de livraison (poste, express etc...)

Page 25

FS 240 SE

Operating instructions

- 25-

02822410998

5006580-00

Page 26

FS 240 SE

Operating instructions

- 26-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

1

0282 241 0087

1 Bedienpult Control panel Pupitre de commande

2

0282 241 0001

2

Ø 200 x 60

x Ø 25

Rad Wheel Roue

3

0298 900 0010

2

DIN EN

ISO 7093

A 10,5 Scheibe Washer Rondelle

4

0295 000 0187

2

DIN EN

ISO 4017

M 10 x 20 Schraube Screw Vis

5

0298 900 0008

1

DIN EN

ISO 7093

A 8,4 Scheibe Washer Rondelle

6

0282 241 0026

1 Lagergehäuse Bearing housing Logement du palier

7

0282 241 0012

2 Ø 30 Gleitfolie Sliding film Glissière

8

0282 241 0013

4

DIN EN

ISO 4762

M 6 x 80 Schraube Screw Vis

9

0281 045 0027

4

DIN EN

ISO 7040

M 6 Mutter Nut Écrou

10

0282 240 0022

1

UCFL 204

Ø 20

Flanschlager Flange bearing Roulement avec flasque

11

0285 300 0018

2

DIN EN

ISO 4017

M 12 x 45 Schraube Screw Vis

12

0285 300 0015

2

DIN EN

ISO 7040

M 12 Mutter Nut Écrou

13

0282 241 0106

1 Tr 20 x 4 Spindel Shaft Fuseau

14

0282 250 0020

4 DIN 471 20 x 1,2 Sicherungsring Circlip Circlip

15

0282 241 0020

1 DIN 6885 6 x 6 x 14 Passfeder Key Clavette

16

0282 241 0008

1 Rastscheibe Locking disc Rondelle d’arrêt

17

0282 241 0101

1 Handrad Handwheel Volant

18

0282 150 0035

1

DIN EN

ISO 4017

M 8 x 20 Schraube Screw Vis

19

0295 230 0013

1 Federriegel Locking bar Boulon d’arrêt

20

0295 230 0032

1

DIN EN

ISO 8675

M 20 x 1,5 Mutter Nut Écrou

21

0282 241 0068

1 Bremse Bracket Frein

22

0285 300 0142

1

DIN EN

ISO 4032

M 6 Mutter Nut Écrou

23

0295 000 3530

1

DIN EN

ISO 4017

M 6 x 16 Schraube Screw Vis

24

0282 250 0321

4

DIN EN

ISO 4762

M 5 x 10 Schraube Screw Vis

25

0295 600 0533

1 DIN 6885 5 x 5 x 12 Passfeder Key Clavette

26

0282 250 0105

4

DIN EN

ISO 7090

B 13 Scheibe Washer Rondelle

27

0295 600 1034

1

DIN EN

ISO 4026

M 6 x 30 Gewindestift Grub screw Vis sans tête

o.A.

0295 899 0273

1

Umplatzieren

Aufkleber Label Macaron

o.A.

0295 899 0033

1

Piktogramme

Aufkleber Label Macaron

o.A.

0295 899 0228

1 LWA111dB Aufkleber Label Macaron

o.A.

0282 241 0076

1 Typenschild Label Plaque d’identification

Page 27

FS 240 SE

Operating instructions

- 27-

02822410998

5006580-00

Page 28

FS 240 SE

Operating instructions

- 28-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

1

0282 241 0002

2

Ø 20 Kompaktbuchse Bushing Douille

2

0282 241 0003

2

Gehäuselager Bearing housing Logement du palier

3

0282 241 0004

1

Chassis Chassis Châssis

4

0298 900 0008

8

DIN EN

ISO 7093

A 8,4 Scheibe Washer Rondelle

5

0282 150 0036

4 DIN 127 A 8 Federring Spring washer Rondelle-ressort

6

0282 250 0073

8

DIN EN

ISO 4017

M 8 x 25 Schraube Screw Vis

7

0281 045 0027

6

DIN EN

ISO 7040

M 6 Mutter Nut Écrou

8

0282 252 0142

1

ZSB-Scharnier Hinge Charnière

9

0295 000 3530

6

DIN EN

ISO 4017

M6 x 16 Schraube Screw Vis

10

0282 241 0044

1

Keilriemenschutzhaube

Blade guard pulley

Capot de protection

poulie

11

0282 241 0046

1

Spannverschluss Fastener Tendeur

12

0267 112 5636

4

DIN EN

ISO 1207

M 4 x 16 Schraube Screw Vis

13

0267 112 5646

4 DIN 127 A 4 Federrring Spring washer Rondelle-ressort

14

9210 260 0600

4

DIN EN

ISO 4032

M 4 Mutter Nut Écrou

15

0282 241 0047

2 Spritzschutz Splash guard

Protection contre le

réfrigérant

16

0282 065 0005

4

DIN EN

ISO 7040

M 8 Mutter Nut Écrou

17

0282 241 0110

1 Schnitttiefenanzeige Scale acceptance Logement gamme

18

0282 250 0006

4

DIN EN

ISO 7090

B 8,4 Scheibe Washer Rondelle

19

0286 570 0069

4

DIN EN

ISO 7090

B 6,4 Scheibe Washer Rondelle

20

0285 300 0142

2

DIN EN

ISO 4032

M 6 Mutter Nut Écrou

21

0295 000 0152

2

DIN EN

ISO 4017

M 6 x 25 Schraube Screw Vis

Page 29

FS 240 SE

Operating instructions

- 29-

02822410998

5006580-00

Page 30

FS 240 SE

Operating instructions

- 30-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

1

0282 241 0002

2

Ø 20 Kompaktbuchse Bushing Douille

2

0282 241 0005

1

Fahrwerk Carriage Châssis

3

0282 241 0010

1

Fahrwerkachse Carriage shaft Axe de châssis

4

0282 250 0023

2

DIN EN

ISO 7090

B 17 Scheibe Washer Rondelle

5

0282 450 0156

2

DIN EN

ISO 7040

M 16 Mutter Nut Écrou

6

0282 241 0109

1 DIN 648 Gelenkkopf

7

0282 241 0015

1

Schelle Clamp Étrier

8

0295 000 0174

2 DIN 127 B 6 Federring Spring washer Rondelle-ressort

9

0281 045 0092

2

DIN EN

ISO 4017

M 6 x 45 Schraube Screw Vis

10

0282 241 0006

1

Führungsstange Guide bar Barre de guidage

11

0282 250 0004

1

DIN EN

ISO 10642

M 8 x 16 Schraube Screw Vis

12

0282 241 0017

1

DIN EN

ISO 8752

Ø 8 x 60 Spannhülse Clamping sleeve Douille de serrage

13

0282 241 0018

2

Rad Wheel Roue

14

0286 570 0047

2

DIN EN

ISO 7090

B 10,5 Scheibe Washer Rondelle

15

0282 300 0019

2

DIN EN

ISO 10642

M 6 x 12 Schraube Screw Vis

16

0282 241 0108

1

Spindelaufnahme Support Levé

17

0285 300 0015

1

DIN EN

ISO 7040

M 12 Mutter Nut Écrou

18

0282 250 0127

1

DIN EN

ISO 4017

M 12 x 80 Schraube Screw Vis

19

0295 000 0178

1

DIN EN

ISO 4032

M 12 Mutter Nut Écrou

20

0282 241 0107

1 Tr 20 x 4 Spindelmutter Trapezoid nut Écrou de filet acme

21

0285 300 0010

1 M 6 Schmiernippel Grease fitting Graisseur

22

0282 250 0105

2

DIN EN

ISO 7090

B 13 Scheibe Washer Rondelle

Page 31

FS 240 SE

Operating instructions

- 31-

02822410998

5006580-00

Page 32

FS 240 SE

Operating instructions

- 32-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

1

0295 000 0187

1

DIN EN

ISO 4017

M 10 x 20 Schraube Screw Vis

2

0286 570 0047

12

DIN EN

ISO 7090

B 10,5 Scheibe Washer Rondelle

3

0281 045 0027

4

DIN EN

ISO 7040

M 6 Mutter Nut Écrou

4

0286 570 0069

8

DIN EN

ISO 7090

B 6,4 Scheibe Washer Rondelle

5

0295 000 0152

4

DIN EN

ISO 4017

M 6 x 25 Schraube Screw Vis

6

0282 241 0025

2

Ø 20 Flanschlager Flange bearing Roulement avec flasque

7

0282 241 0091

1

Motorkonsole Engine bracket Console du moteur

8

0295 000 0003

2

8 x 45 Rohrklappenstecker Tube linch pin Esse d’essieu

9

0295 000 0181

1

DIN EN

ISO 7089

A 17 Scheibe Washer Rondelle

10

0281 045 0051

1

DIN EN

ISO 4032

M 16 Mutter Nut Écrou

11

0282 241 0027

2

Distanzstück Distance piece Pièce intercalaire

12

0282 241 0074

1

Motor Motor Moteur

13

0286 570 0052

7

DIN EN

ISO 7040

M 10 Mutter Nut Écrou

14

0281 073 0030

2

DIN EN

ISO 4014

M 10 x 60 Schraube Screw Vis

15

0284 650 0093

1

DIN EN

ISO 10642

M 10 x 40 Schraube Screw Vis

16

0295 000 0325

2

DIN EN

ISO 4017

M 10 x 65 Schraube Screw Vis

17

0286 570 0046

2

DIN EN

ISO 4032

M 10 Mutter Nut Écrou

18

0284 650 0053

1 DIN 444 M 10 x 75 Schraube Screw Vis

19

0282 241 0028

1 DIN 71751

M 10 x 20 LH

Gabelkopf Fork head Fourchette

20

0282 241 0032

1 DIN 1478 M 10 Spannschloßmutter Spanner nut Écrou de tension

21

0282 241 0084

1

55PJ20 Poly-V-Scheibe V-belt pulley

Poulie pour courroie

trapézoidale

0282 241 0033

1

55PK16

Bis Ma.-Nr.

2410005

Poly-V-Scheibe V-belt pulley

Poulie pour courroie

trapézoidale

22

0282 241 0078

1

DIN EN

ISO 7094

Ø 11 x Ø 34

x 3

Scheibe Washer Rondelle

23

0282 241 0030

1

M 10 x 80 LH

Gewindestange Threaded bolt Tige filetée

24

0282 241 0102

1 Transportbügel Lifting bow Anneau de levage

25

0295 000 0173

2

DIN EN

ISO 4017

M 10 x 30 Schraube Screw Vis

26

0282 241 0086

1

20PJ-955 Poly-V-Riemen V-belt Courroie trapézoidale

0282 241 0073

1

12PK-962

Bis Ma.-Nr.

2410005

Poly-V-Riemen V-belt Courroie trapézoidale

24

0282 241 0079

1

Motorkabel konf. Motor lead Câble du Moteur

Page 33

FS 240 SE

Operating instructions

- 33-

02822410998

5006580-00

Page 34

FS 240 SE

Operating instructions

- 34-

02822410998

5006580-00

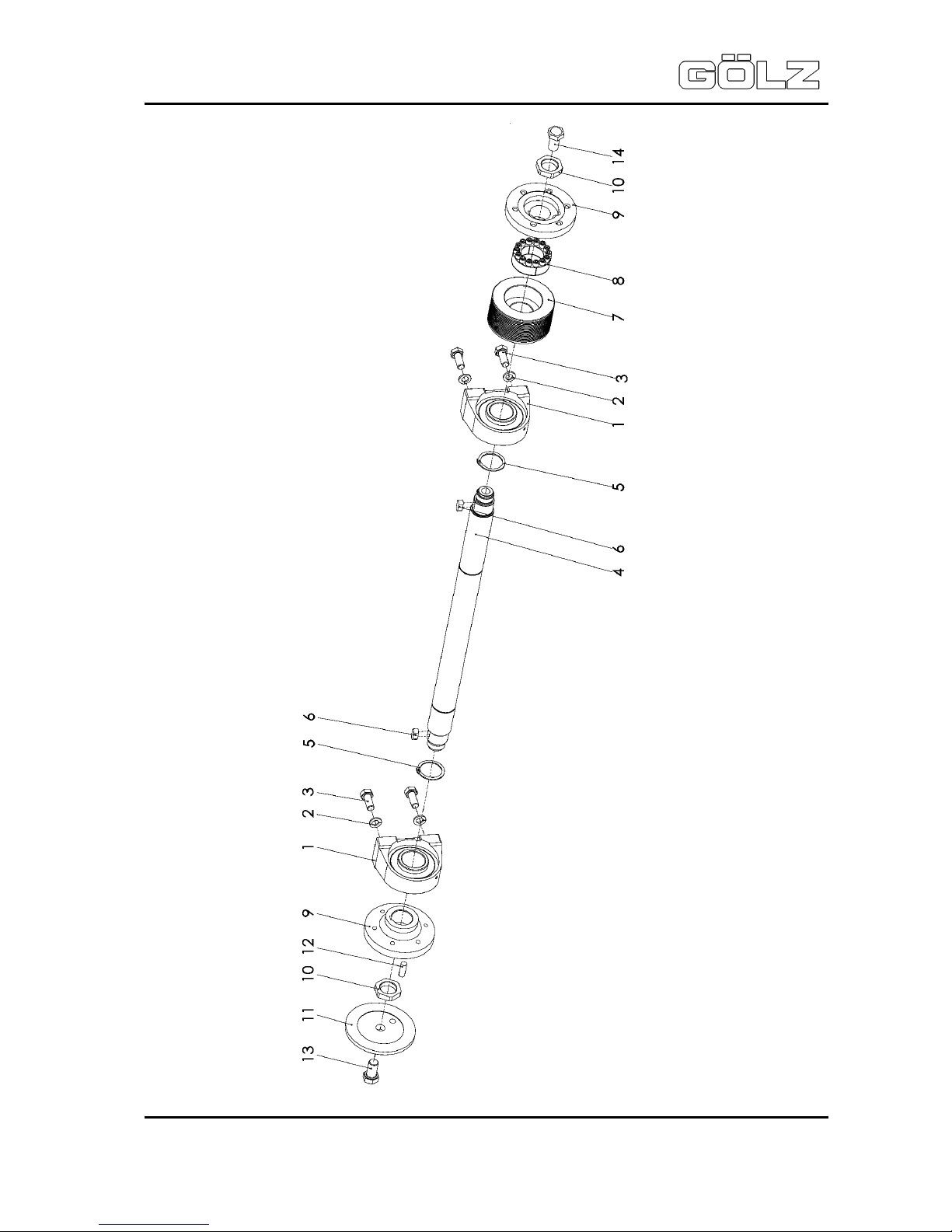

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

1

0282 241 0072

2

UCPG208 Stehlager Pedestal bearing Chaise palier

2

0286 570 0025

4 DIN 127 A 12 Federring Spring washer Rondelle-ressort

3

0286 570 0020

4

DIN EN

ISO 4017

M 12 x 30 Schraube Screw Vis

4

0282 241 0035

1

Schneidwelle Blade shaft Arbre de coupe

5

9455 621 4330

2 DIN 471 40 x 1,75 Sicherungsring Circlip Circlip

6

0282 520 0032

2 DIN 6885

A 10 x 8 x 22

Paßfeder Key Clavette

7

0282 241 0085

1 110PJ20 Poly-V-Scheibe V-belt pulley

Poulie pour courroie

trapézoidale

0282 241 0037

1

110PK12

Bis Ma.-Nr.

2410005

Poly-V-Scheibe V-belt pulley

Poulie pour courroie

trapézoidale

8

0282 241 0036

1

COM Ø 40 Spannsatz Clamping set Jeu de serrage

9

0282 241 0038

2 Schneidflansch innen Inner flange

Flasque de fixation

intérieure

10

0282 241 0039

2

M 30 x 1,5

Flanschmutter

Flange nut Écrou

11

0282 241 0040

1 Schneidflansch außen Outer flange

Flasque de fixation

extérieure

12

0282 241 0041

1

DIN EN

ISO 2338

10 m6 x 30 Zylinderstift Dowel pin Goupille cylindrique

13

0282 240 0042

1

DIN EN

ISO 8676

M 16 x 1,5

x 30 LH

Schraube Screw Vis

14

0282 240 0040

1

DIN EN

ISO 8676

M 16 x 1,5

X 30

Schraube Screw Vis

Page 35

FS 240 SE

Operating instructions

- 35-

02822410998

5006580-00

Page 36

FS 240 SE

Operating instructions

- 36-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

1

0281 045 0027

4

DIN EN

ISO 7040

M 6 Mutter Nut Écrou

2

0286 570 0069

8

DIN EN

ISO 7090

B 6,4 Scheibe Washer Rondelle

3

0282 250 0649

2

Ø 20 Befestigungsschelle Mounting clamp Collier de fixation

4

0282 250 0804

4

DIN EN

ISO 4017

M 6 x 60 Schraube Screw Vis

5

0282 252 0148

1

Aufnahme

Richtungsanzeiger

Indicator acceptance

Levé d’indicateur de

direction

6

0282 150 0034

2 DIN 316

M 8 x 20

Schraube Screw Vis

7

0282 252 0107

1

Verlängerung

Richtungsanzeiger

Indicator extension

Rallongement d’indicateur de direction

8

0282 241 0062

1

Richtungspfeil Directional arrow Indicateur de direction

9

0282 250 0777

1

Ø 125 Rad Wheel Roue

10

0295 000 0167

2 DIN 471 12 x 1

Sicherungsring

Circlip Circlip

Page 37

FS 240 SE

Operating instructions

- 37-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

1

0284 000 0352

1 1/2” I/A Doppelnippel, lösbar

Double nipple,

removeable

Double raccord fileté,

soluble

2

0282 301 0136

2

DIN EN

ISO 7090

B 23 Scheibe Washer Rondelle

3

0282 120 0040

1 R 1/2“ I Minikugelhahn Ball valve

Robinet à tournant

sphérique

4

0282 250 0549

1

1/2“ A GEKA-Kupplung GEKA-coupler GEKA-Accouplement

Page 38

FS 240 SE

Operating instructions

- 38-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

1

0282 241 0090

2

Schubstange Connecting rod Jambe de force

2

0285 300 0044

2

Kunststoffgriff Handle Poignée

3

0282 241 0095

2

M 10 x 16 Klemmhebel Clamp lever Levier de serrage

Page 39

FS 240 SE

Operating instructions

- 39-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

1

0282 190 0224

1 DIN 6336 M 8 x 20 Sterngriffschraube Star grip screw Vis de poignée-étoile

2

0282 241 0097

1

Kabelhalter Cable support Cadre support du câble

3

0282 241 0096

1

Zugentlastung Strain relief Décharge de traction

4

0285 300 0027

2

DIN EN

ISO 8752

4 x 32 Spannhülse Clamping sleeve Douille de serrage

5

0298 900 0017

2

DIN EN

ISO 7093

A 17 Scheibe Washer Rondelle

Page 40

FS 240 SE

Operating instructions

- 40-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

1

0282 241 0045

1 Flanschschutzhaube Flange cover

Carter de protection du

flasque

2

0282 301 0183

1 DIN 11024 Ø 4 Federstecker Spring connector Goupille a ressort

3

0282 241 0034

1 DIN 7337 Ø 4,8 x 10 Blindniet Blind rivet Rivet

4

0282 241 0077

1

0,25 m Knotenkette Knotted link chain Chaîne à nousées

5

0282 241 0049

1

Schutzblech Schneidwelle

Blade shaft protection

Protection d’arbre de

coupe

6

0282 241 0056

1

Rastbolzen Locking pin Boulon d’arrêt

7

0283 300 0278

2

DIN EN

ISO 10642

M 4 x 8 Schraube Screw Vis

8

0295 230 0033

2

DIN EN

ISO 4762

M 6 x 8 Schraube Screw Vis

Page 41

FS 240 SE

Operating instructions

- 41-

02822410998

5006580-00

Page 42

FS 240 SE

Operating instructions

- 42-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

-

0282 241 0055

1 Pos. 1-23 Schutzhaube kpl. Cover assy.

Carter de protection

compl.

1

0282 241 0048

1 Schutzhaube hinten Cover, back

Carter de protection,

derrière

2

0282 252 0142

1

Scharnier Hinge Charnière

3

0282 241 0052

1 Schutzhaube vorne Cover, front

Carter de protection,

à l'avant

4

0281 045 0027

10

DIN EN

ISO 7040

M 6 Mutter Nut Écrou

5

9008 319 1280

6

DIN EN

ISO 4017

M 6 x 16 Schraube Screw Vis

6

0282 250 0775

2

Griff Handle Poignée

7

0282 250 0084

4

DIN EN

ISO 4762

M 6 x 25 Schraube Screw Vis

8

0282 150 0031

2

R 1/2“ Schlauchtülle Hose clip Embout à olive

9

0282 241 0053

1

Wassergabel Water fork Conduit d’eau

10

0282 240 0039

2

DIN EN

ISO 10642

M 8 x 20 Schraube Screw Vis

11

0295 010 0052

2

2-Ohr-Schelle Clamp Étrier

12

0298 100 0106

1

1 m Schlauch Hose Tuyau

13

0282 301 0183

1 DIN 11024 Ø 4 Federstecker Spring connector Goupille a ressort

14

0282 241 0077

1

0,25 m Knotenkette Knotted link chain Chaîne à nousées

15

0282 241 0034

1 DIN 7337 Ø 4,8 x 10 Blindniet Blind rivet Rivet

16

0295 899 0009

1

Pfeil Aufkleber Label Macaron

17

0295 899 0314

1

Fräswelle Aufkleber Label Macaron

18

0295 899 0346

2

Handver-

letzung

Aufkleber Label Macaron

19

0282 241 0054

2

Gölz Aufkleber Label Macaron

20

0282 241 0049

1

Schutzblech

Schneidwelle

Blade shaft protection

Portection d'arbre de

coupe

21

0282 241 0056

1

Rastbolzen Locking pin Boulon d'arrêt

22

0283 300 0278

2

DIN EN

ISO 10642

M 4 x 8 Schraube Screw Vis

23

0295 230 0033

2

DIN EN

ISO 4762

M 6 x 8 Schraube Screw Vis

Page 43

FS 240 SE

Operating instructions

- 43-

02822410998

5006580-00

Page 44

FS 240 SE

Operating instructions

- 44-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

-

0282 241 0061

1 Pos. 1-19 Schutzhaube kpl. Cover assy.

Carter de protection

compl.

1

0282 241 0051

1 Schutzhaube Cover Carter de protection

2

0282 250 0775

1

Griff Handle Poignée

3

0282 250 0084

2

DIN EN

ISO 4762

M 6 x 25 Schraube Screw Vis

4

0286 570 0069

2

DIN EN

ISO 7090

B 6,4 Scheibe Washer Rondelle

5

0281 045 0027

2

DIN EN

ISO 7040

M 6 Mutter Nut Écrou

6

0283 900 5002

1

6A-15

1,55 m

Abdichtbürste Seal brush Étanchéité

7

0298 100 0022

24 DIN 7337 Ø 3 x 8 Blindniet Blind rivet Rivet

8

0282 241 0059

2

Wassergabel Water fork Conduit d’eau

9

0282 241 0060

2

Wassergabelaufnahme Water fork support Conduit d'eau levé

10

0282 250 0004

2

DIN EN

ISO 10642

M 8 x 16 Schraube Screw Vis

11

0282 241 0070

2 1/2” I/A Doppelnippel, lösbar

Double nipple,

removeable

Double raccord fileté,

soluble

12

0282 150 0031

2

R 1/2“ Schlauchtülle Hose clip Embout à olive

13

0298 100 0106

1

1 m Schlauch Hose Tuyau

14

0295 010 0052

2

Ø 17-20 2-Ohr-Schelle Clamp Étrier

15

0282 241 0071

1

R 1“ Verschlussstopfen Closing plug Bouchon d'étanchéité

16

0282 241 0054

1

Gölz Aufkleber Label Macaron

17

0282 301 0183

2 DIN 11024 Ø 4 Federstecker Spring connector Goupille a ressort

18

0282 241 0077

2

0,25 m Knotenkette Knotted link chain Chaîne à nousées

19

0282 241 0034

2 DIN 7337 Ø 4,8 x 10 Blindniet Blind rivet Rivet

Page 45

FS 240 SE

Operating instructions

- 45-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

1

0282 241 0092

1

Gehäuse Box Boîte

2

0282 252 0259

1

Not-Aus-Pilztaster Emergency shut-off Bouton d’arrêt d’urgence

3

0282 252 0261

1

Öffnerkontakt Contact block Bloc en contact

4

0282 650 0148

1 Stern-Dreieck-Schalter Star-Delta connection

Commutateur étoiletriangle

Page 46

FS 240 SE

Operating instructions

- 46-

02822410998

5006580-00

Pos. Artikelnummer Menge Norm Info Benennung Description Désignation

5

0282 650 0147

1

Haupt-Not-Ausschalter Main switch Commutateur principal

6

0282 252 0164

1 180 mm Hutschiene Cap rail Profilé-support

7

0282 252 0164

1 165 mm Hutschiene Cap rail Profilé-support

8

9307 021 0120

4

DIN EN

ISO 7093

A 5,3 Scheibe Washer Rondelle

9

0282 252 0274

1

Sicherungssockel Fuse base Socle de fusible

10

0282 241 0042

3 16A Passeinsatz Neozed

Screw-in sleeve

socket

Vis de calibrage

11

0282 241 0043

3

16A Sicherung Neozed Fuse Fusible

12

0282 241 0082

3

D02 Feder Schraubkappe Spring screw cap Ressort bouchon fileté

13

0282 252 0275

3 32°

Sicherungsschraubkappe

Safety screw cap Bouchon fileté du sécurité

14

0282 252 0268

2 Endstück End cap Bloc d’extrémité

15

0282 301 0212

1

2,5 / 4 mm

34A

Reihenklemme Terminal Bornier

16

0282 241 0111

1 DILM17-10 Schütz Contactor Contacteur

17

0295 510 0990

1

Dichtung Seal Joint

18

0295 510 0640

1

H-B 6 Epic Anbaugehäuse Mounting case Boîte

19

0295 510 0681

1

Rahmen Frame Cadre

20

0267 112 5648

10

DIN EN

ISO 7089

A 4,3 Scheibe Washer Rondelle

21

0295 001 0130

1

DIN EN

ISO 4762

M 4 x 30 Schraube Screw Vis

22

0283 300 0570

2 DIN 6797 A 4,3 Zahnscheibe Lock washer Disque denté

23

9210 260 0600

7

DIN EN

ISO 4032

M 4 Mutter Nut Écrou

24

0298 100 0076

2 DIN 46237

M 4,

1,5-2,5²

Ringkabelschuh Ring terminal Serre-câble

25

0267 112 5646

2 DIN 127 A 4 Federring Spring washer Rondelle-ressort

26

0281 100 0014

3

DIN EN

ISO 4762

M 4 x 20 Schraube Screw Vis

27

0295 510 0051

2

5-polig Modul Buchse Module bushing Module Douille

28

0295 510 0017

9

2,5² Buchsenkontakt Bushing contact Contact de douille

29

0282 241 0075

1

Gölz Aufkleber Label Macaron

30

0267 112 5641

4

DIN EN

ISO 4762

M 6 x 40 Schraube Screw Vis

31

0286 570 0069

4

DIN EN

ISO 7090

B 6,4 Scheibe Washer Rondelle

32

0281 045 0027

4

DIN EN

ISO 7040

M 6 Mutter Nut Écrou

33

0295 000 0129

1

DIN EN

ISO 4762

M 4 x 16 Schraube Screw Vis

34

0282 241 0094

1

16A, CEE Stecker Plug Prise mâle

35

0295 000 0313

4

DIN EN

ISO 4792

M 5 x 25 Schraube Screw Vis

36

0295 000 0170

4

DIN EN

ISO 7089

A 5,3 Scheibe Washer Rondelle

37

0295 000 0177

4

DIN EN

ISO 7040

M 5 Mutter Nut Écrou

38

-

1

Kabel Cable Câble

Page 47

FS 240 SE

Operating instructions

- 47-

02822410998

5006580-00

10. Wiring diagram

Loading...

Loading...