Page 1

FS 240 E

Operating manual

- 1-

02822400988

5006148-01

Floor saw

FS 240 E

Art.-Nr. der Bedienungsanleitung 02822400988

ZN der Bedienungsanleitung: 5006148-01

Erstellt am : 10 / 2010

Erstellt von: Mireille Szidat

Datei:

K

:\KDV\5006xxx\5006148-Bedienungsanleitung\

5006148-

01-Bedienungsanleitung-doc.doc

GÖLZ GmbH

Dommer sbach 51

53940 Hellenthal-Blum enthal

Telefon: (02482) 120

Telefax: (02482) 12135

Page 2

FS 240 E

Operating manual

- 2-

02822400988

5006148-01

EG-KONFORMITÄTSERKLÄRUNG

EC-DECLARATION OF CONFORMITY

DECLARATION DE CONFORMITE DE LA CE

Die Fi rma

Manufacturer La Société

GÖLZ GmbH

Dommersbach 51, 53940 Hellenthal - Blumenthal

Tel.: (02482) 120 Fax: (02482) 12135

Erklärt in alleiniger Verantwortung, dass

folgendes Produkt:

FS 240 E

Fugenschneider

Hereby certifies on it’s sole responsibility

that the following product:

FS 240 E

Floor saw

Déclare sous sa seule responsabilité que

le produit suiv ant:

FS 240 E

Scie de sol

Seriennum mer / Seri al number / Numéro de série: _______________________

Auf das sic h diese Erklärung bezieht, mit

folgenden Richtlinien bzw. Normen übereinstimmt:

Maschinenrichtlinie 2006/42/EG

Sicherheits- und Gesundheitsanforderung

EMV-Richtlinie 2004/108/EG

Elektromagnetische Verträglichkeit

Richtlinie 2000/14/EG

Geräuschemission

Europäische Normen

EN 13309:2000

EN 13862:2001

DIN EN ISO 3744

EN 61000

Die oben genannte Firma hält Dokumentationen als Nachweis der Erfüllung

der Sicherheitsziele und die wesentlichen Schutzanforderungen zur Einsicht

bereit.

Which is explicitly referred to by this

Declaration meet the following directives

and standard(s):

Directive 2006/42/EC

Safety and health requirement

Directive 2004/108/EC

Electromagne tic compatibility

Directive 2000/14/EC

Noise emission

European Standard

EN 13309:2000

EN 13862:2001

DIN EN ISO 3744

EN 61000

Documented evidence conforming with

the requirements of the Directive is kept

available for inspection at the above

Manufacturer's, address.

Qui fait l‘objet de la présente déclaration

correspond aux directives et normes

suivantes:

Directive 2006/42/CE

Prescriptions sanitaire et sécurité

Directive 2004/108/CE

Compatibilité électromagnétique

Directive 2000/14/CE

Émission de bruit

Norme européenne

EN 13309:2000

EN 13862:2001

DIN EN ISO 3744

EN 61000

Pour faire foi de la conformité et du respect des règles de sécurité, la documentation peut être consultée au siège

de la Société susmentionnée.

Hellenthal, den 01.10.2010

Page 3

FS 240 E

Operating manual

- 3-

02822400988

5006148-01

Contents

1. Preface.......................................................................................................................... 5

2. General safety references.............................................................................................. 5

2.1 Basic operati on and desi gnated use of the machine ...........................................................6

2.2 Organizational measures....................................................................................................6

2.3 Selection and qualif ication of person...................................................................................7

2.4 Normal operation of t he m achine........................................................................................7

2.5 Special work related to the maintenance and repair of the m ac hine ....................................8

2.6 Information about special risks electrical ener gy .................................................................8

2.7 Gas, dust, steam, smoke....................................................................................................9

2.8 Noise .................................................................................................................................9

2.9 Oils, greases and other chemical substances .....................................................................9

2.10 Changing the loc ation of the machine...............................................................................10

3. Description................................................................................................................... 10

3.1 Main parts........................................................................................................................10

3.2 Technical data..................................................................................................................11

4. Transport and storing................................................................................................... 11

4.1 Transport.........................................................................................................................11

4.2 Storing.............................................................................................................................12

5. Starting ........................................................................................................................ 12

5.1 Before starting..................................................................................................................12

5.2 Packing............................................................................................................................12

5.3 Mounting the diam ond blade ............................................................................................12

5.4 Water supply.................................................................................................................... 13

5.5 Power supply ...................................................................................................................13

6. Operation..................................................................................................................... 13

6.1 Cutting line.......................................................................................................................14

6.2 Starting electric motor.......................................................................................................14

6.3 Setting cutting depth.........................................................................................................14

6.4 Feed................................................................................................................................15

6.5 Finish cutting....................................................................................................................15

6.6 Stopping electric motor.....................................................................................................15

7. Maintenance................................................................................................................ 15

7.1 General............................................................................................................................15

7.2 Lubrication chart...............................................................................................................16

7.3 Electric motor...................................................................................................................16

7.4 V-belts .............................................................................................................................16

Page 4

FS 240 E

Operating manual

- 4-

02822400988

5006148-01

8. Troubleshooting........................................................................................................... 17

9. Wearing parts.............................................................................................................. 19

10. Ersatzteilliste/Spare parts list/Liste des pièces de rechange........................................ 20

11. Wiring diagram............................................................................................................ 31

Page 5

FS 240 E

Operating manual

- 5-

02822400988

5006148-01

1. Preface

Thanks for choosi ng a

GÖLZ

-product. T his operating i nstruction i s designed to fam iliarize the user

with the mac hine and its designated use.

The operating i nstruction cont ains important inform ation on how to operate the machine safely, properly and most ef fi cient ly. Observ i ng these i nstruct ions helps to av oi d danger, to r educe repair c osts

and downtimes and to i nc r ease t he r eliability and life of the machine. The operating instruction is to be

supplemented by t he respective nat ional rules and regulati ons for accident prevention and envir onmental protecti on. The operating instruction must always be avai lable wherever the machine is in use.

This operati ng instruction m ust be read and applied by any person i n charge of work with or on the

machine, such as:

- Operation including setting up, troubleshooting in the course of work, evacuation care and

disposal of fuels and consumables.

- Maintenance (servic ing, inspecti on, repair) and/or

- Transport

In addition to the operating instructions and to the mandatory rules and regulations for accident

prevent ion and env ir onment pr otecti on of the country and place of use of t he machi ne, the gener ally

recognized technical rules for safe and proper working conditions and procedures must also be

observed.

2. General safety references

Jedes Ums etzen de r Masc hine außerh alb des Bereic hs, in dem Sc hneidarbeiten dur chgef ührt wer den, darf nic ht mit rotie rendem Werkzeug durchgeführt werden!

It is not allowed to move the machine with rotating blade outside of the area in which cutting works have to be performed!

Tout dépl aceme nt de la mac hine doit s' opérer sans r otation de l'o util (ris que de bless ures ) ceci est également valable sur le

chantier pour les déplacement entre coupes!

Vor Inbetrieb nahm e Betri ebsa nleit ung lesen!

Read owner’s manual before the first initiation!

Lire la notice avant utilisation!

Wichtiger Hinweis!

Important advice!

Indication importante!

Achtung, spielende Kinder!

Be careful with kids on the work side!

Attention aux enfants!

Staubschutz tragen!

Wear dust protection!

Port de masque!

Achtung, Schneidgefahr!

Danger exist to cut oneself!

Attention danger de coupure!

Nicht berühren!

Never touch!

Ne pas toucher!

Gehörschutz tragen!

Wear ear muffs!

Protection acoustique obligat oire!

Schutzschuhe tragen!

Wear safety boo ts!

Chaussures de sécurite obligatoires!

Achtung, Schneidgefahr!

Danger exist to cut oneself!

Attention danger de coupure!

Schutzhelm tragen!

Wear safety helmet!

Port du casque!

Schutzkleidung tragen!

Wear safety clothes!

Vêtements protecteurs obligatoires!

Warnung vor elektrischer Spannung!

Electrical Hazard!

Attention tension électrique!

Augenschutz tragen!

Wear safety glasses!

Port de lunettes!

Schutzhandschuhe tragen!

Wear protective gloves!

Gants obligatoires!

Warnung vor allgemeiner Gefahr!

General danger!

Attention danger particulier!

Page 6

FS 240 E

Operating manual

- 6-

02822400988

5006148-01

2.1 Basic operation and designated use of the machine

The machi ne has been built in acc ordance with state-of-the- art standards and the recognized safety

rules. Nevertheless, its use may constitute a risk to life and limb of the user or of third parties, or cause

damage to the machine and to ot her material property.

The m achi ne m ust only be used in t echni cal ly perf ect condi t ion i n acc ordance wit h it s designated use

and the i nstructions set out in the operating m anual, and only by saf ety-conscious persons who are

full y aware of the ri sks inv olv ed in operating t he machi ne. Any func tional di sorders, especially those

affecting the safety of t he machine, should therefore be rectified immediately.

Separation bui lding implem ents are exclusiv ely designed for sawing of asphalt, concrete and steel

concrete. Using t he machine for purposes other than t hose mentioned above (such as for) is considered contrary to its designated use. The manufacturer cannot be held liable for any damage

resulting f rom such use. The risk of such misuse lies entirely with the user. Operating the machi ne

within the l im its of it s designated use also inv ol v es observi ng the instr ucti ons set out in the operating

manual and complying with the inspection and maintenance directives.

2.2 Organizational measures

This operating manual must always be at hand at the place of use of the product and must be

accessible to the per son operating the mac hine!

In addition to this operating manual, all other generally applicable legal and other mandatory

regulations relevant to accident prevention and environmental protection must be observed! Such

obligati ons may al so comprise the handling of hazardous material s, provisi oning and/ or wearing of

personal protecti ve equipm ent, or r oad traffi c regul at ions. T hi s operating manual must be supplemented by instructions covering the duties involv ed in supervising and notifying special organizational

features, such as job or ganization, work flows or the person entrusted with the work.

Person entrusted with work on the produc t must have read t he operating manual pri or to taking up

work. Thi s applies especiall y to persons working only occ asionally on t he product, e.g. during set-up

or maintenance activities. Check - at least from time to time - whether the personnel is carrying out the

work in compliance with the operating manual and paying attention to risks and safety-relevant factors.

For reasons of safet y, long hair must be ti ed back or otherwise secured, garments must be closefitting and no jeweller y - including rings - may be worn. S evere injury may result from being caught by

mov ing parts of the m achi ne. Personal prot ecti v e equipm ent m ust be used wherever requi red by the

circum stances or by law (e.g. safety glasses, ear protectors, saf ety boots, suitable saf ety clothing).

Observe the regulations for prevention of accidents! Observe all safety precautions and warnings

attached to t he pr oduc t and always keep them i n good and per fectly legible condition.

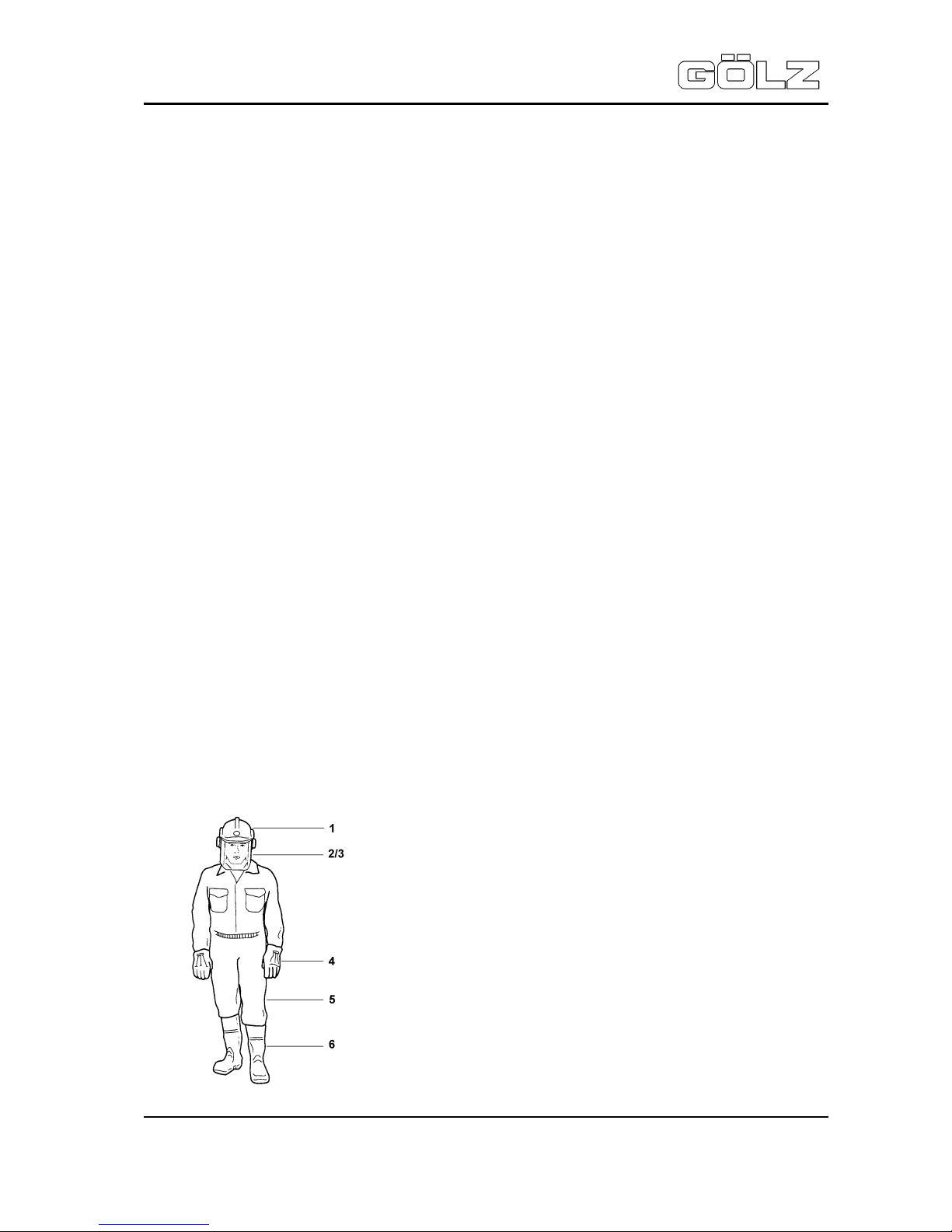

The personal protection equipment should consist of the following parts:

1 Helmet with protection of the ears

2/3 Viso r or safet y glasses / Dust mask

4 Protective gloves

5 Safety clothes

6 Safety boots

Page 7

FS 240 E

Operating manual

- 7-

02822400988

5006148-01

In case event of safety-rel evant modi ficati ons or changes in the behaviour of the product, stop the

product immediat ely and report the malfunc tion to the competent authority/ person.

Do not remove or mak e inoperative any safety devices the pr oduc t is equipped with.

Never make any modifications, additions or conversions which might affect safety without the

manufacturer’s/distributor’s prior approval! This also applies to the installation and adjustment of

safety devices as well as to weldi ng and dr illing work on supporting structur es.

Damaged or worn parts of the product must be r eplaced immediatel y . Use genuine spare parts only.

All spare part s and tools must c ompl y with the t echnical requir ements specif i ed by the manuf actur er/

distributor.

Adhere to the legally prescribed prevent ive maintenance and i nspect ion intervals or those specified in

this operati ng manual!

All m aintenance and repair act ivit ies must be perform ed by qualifi ed personnel using suitable tool s

and other suitabl e workshop equi pment.

Observe the fire alarm and fire fighting measures. The personnel must be made familiar with the

locati on and handling of fire extinguishers!

2.3 Selection and qualification of person

Any work on and with the product must be executed by reli able person only. Statutory minim um age

limits must be observed!

The product must be operated or serviced by trained or properly instructed person onl y . Clearly define

the individual responsibilities of the person for operation, set- up, maintenanc e and r epair.

Make sure that only authorized work on or with t he pr oduc t.

Define t he machine oper ator’s responsibilities -also with regard to observ ing road tr aff ic regulat ions-,

providing the operator with the authority to refuse instructions by third parties that are contrary to

safety.

Do not allow persons to be trai ned or instr ucted or persons taki ng part i n a general tr aining c ourse to

work on or with the product without being perm anently superv ised by an experienced per son.

Work on the electri cal system and equipment of the product must be carried out only by a skilled

electri cian or by proper ly instruct ed persons working under the superv ision and guidance of a skilled

electrician and in accor danc e with electrical engineering rules and regulations.

2.4 Normal operation of the machine

Before begi nning work, f am iliarize yourself with the surroundings and circum stances of the si te, such

as obstacles which might im pede work or traff ic, the soil bearing capacity and the required safety

measures, e.g. barr iers separating the work site from public traffic .

Check the range in gas-, water- and power supply lines bef ore working. Av oid any operational m ode

that might be prejudi c ial to safety!

Take the necessary precaut ions to ensure that the m achine is used only when in a safe and reliabl e

state. Operate the machine only if all protective and safety-oriented devices, such as removable

safety dev ices, emer gency shut-off , sound-proofing el ements and exhausters, are i n place and ful ly

functional.

Each ti m e bef ore y ou start working, check t he product f or obv i ous dam age and def ect s. Any c hanges

(including changes in the performance or behaviour of the product) must be reported to the competent

authority / person imm ediately.

In the event of malfunc tions or changes in the m ac hine’s behaviour , stop the product i mmediately and

secure it against r estarting. Have any defec ts rectif ied immediately !

The machine is designed for use in dayl ight! The m achine operator/ owner must ensure suff icient

workplace li ghting for non-illuminated work sites!

Take precautions to ensure that the operator always has an adequate view of the work. Before leaving

the machine always secure it against inadvert ent movement and unauthorized use!

Page 8

FS 240 E

Operating manual

- 8-

02822400988

5006148-01

During start-up and shut-down procedures always watch the indicators in accordance with the

operating instructions. Before starting up or setting the machine in motion, make sure that nobody is at

risk. Al ways keep at a distance from the edges of building pits and slopes.

2.5 Special work related to the maintenance and repair of the machine

Observe t he adjustment , mai ntenance and inspecti on activ iti es and interv als set out in the operating

manual, including inform ation on the replac ement of par ts or equipment!

These activit ies may be perf ormed by skil led personnel only. Brief the operati ng personnel before

initiating special repair or m aintenance acti vit ies. Appoint a person to supervise such acti vit ies.

In any work concerning the operation, adaptation to production requirements, conversion or

adjustment of the m achine and i t’s safety -orient ed dev ices or any work rel ated to i nspection, mai ntenance and repair, al ways observe the start-up and shut-down procedur es described in the operating

manual as well as the instructions on maintenance activities!

Ensure that the maintenance area i s adequately secured.

The machine is designed for use in dayl ight! The m achine operator/ owner must ensure suff icient

workplace li ghting for non-illuminated work sites!

The fastening of loads and the instructing of crane operators should be entrusted to experienced

persons only. The m ar shaller giving the instructions must be within sight or sound of the operator.

Carry out maint enance and repai r work onl y if the machi ne is positioned on stabl e and lev el ground

and has been secured against inadvertent m ovement and buckling.

If t he machine is compl etely shut down for mai ntenance or repair work, it m ust be secured against

inadvertent restarting.

Clean the machine, especially connections and threaded unions, of any traces of oil, fuel or

preservat ives bef ore carrying out m aintenance or repai r. Never use aggressive detergents. Use lintfree cleaning rags.

Before cleaning the machine with water or other cl eaning agents cover or tape up all openings which for safety and functional reasons- must be protected against the i ngress of water/ steam/ cleaning

agents. After cleaning, r emove all covers and tapes applied for that purpose.

After cleaning, examine the machine for leaks, loose connections, chafe marks or damage. Any

defects found must be rectified without delay.

Always tighten any screwed connections that have been loosened during m aintenance and repair. Any

safety devices rem oved f or set- up, maintenanc e or repair purposes must be refitted and chec k ed

immediately upon c ompleti on of the maintenance and repair work.

2.6 Information about special risks electrical energy

Observe the relevant national regulat ions or standards. Electric al connections must al ways be kept

free f rom di rt and moi sture. Use only ori ginal f uses with the specifi ed rating! Swit ch off the machine

immediately , if t r ouble occurs in the el ec tric power supply!

When working with the machine, mai ntain a safe dist anc e from overhead electric lines. If work is to be

carried out close to overhead lines, the working equipment must be kept well away from them.

Caution, danger! Check out the prescribed safety distances.

If your machine comes into contact with a live wire:

• warn others against approaching and touching the m ac hine

• have t he live wire de-energized

Wor k on the el ect ri cal system or equi pm ent m ay onl y be carr ied out by a skilled electrician himself or

by specially instructed personnel under the control and supervision of such electrician and in

accordance with the applicable engineering rules.

If provided for in the regulations, the power supply to parts of machines and plants, on which

inspection, maintenance and repair work is to be car ried out must be cut of f. Bef ore starting work,

check the de-energi zed part s f or t he presence of power and ground or short-circui t them in addit ion to

insulati ng adjacent li ve parts and elements.

Page 9

FS 240 E

Operating manual

- 9-

02822400988

5006148-01

The electrical equipm ent of machines is to be inspected and checked at regular interv als. Defects

such as loose connections or scorched cables must be rectified immediately.

Necessary work on l ive parts and elements must be carried out only in the presence of a second

person who can cut off the power supply in case of danger by act uating the emergency shut-off or

main power switch. S ecure the working area with a red-and white saf ety chain and a warning sign.

Use insulated tool s onl y .

If mobile electrical equipment, connecting cables and/ or extension/ appliance cords with plug

connectors are used, ensure that such equi pment, c ables and cords are checked for correct functi on

at least once every six months by a qualified electrician or - if sui table testing equipment i s available by a properly instructed person.

Protecti ve instal lations with fault-current protection units used in non-stationary equi pment must be

checked for c or r ec t operation at least once a month by a pr oper ly instructed per son.

Fault-c urrent and f aul t- v ol t age protec ti on uni ts m ust be check ed for correc t operati on by actuati ng the

testing facility:

- once on ev er y working day in the case of mobil e equipment,

- at least once every six months in t he c ase of stationary equipment.

2.7 Gas, dust, steam, smoke

Operate internal combustion engines only on adequately ventilated premises. Before starting the

machine on enc losed premises, make sure that there is suf fici ent ventilation! Danger of life!

Carry out welding, flame-c utting and grinding work on t he machine only of this ahs been expressly

authorized, as ther e may be a risk of explosion and fire.

Before carrying out welding, flame-cutting and grinding operations, clean the machine and its

surroundings from dust and other inflammable substances and make sure that the premises are

adequately ventilated (Risk of explosion). Observe the regulations in force at the respect ive site!

2.8 Noise

Noise Protection devices on the machine must be in the protection position during operation!

Always wear the specified personal hearing prot ec tion (UVV 29 §10)!

2.9 Oils, greases and other chemical substances

When handling hy dr aulic fluids, lubricat ing fluids, greases or preservatives (called operating materials

and lubricant s in the foll owing), the safet y regulations appli cable for t he respectiv e product must be

observed! Avoid prolonged contact of operating mater ials and lubric ants with the skin!

The skin must be c ar efully c leaned of adhering operating m aterials and lubricants!

Exerci se cauti on when handl ing hot operat ing mater ials and l ubricant s, as there is a danger of burns

or scalding. P ar ticularly at liquid temperatures above 60°C, avoid any skin contact with these liquids!

If operat ing m at eri als or l ubri cant s get i nto t he eyes, f l ush thoroughl y wit h dri nki ng water. Then visit a

doctor! Immediately clean up any operating materials and lubricants which have leaked out. Use

absorbent material for this purpose!

Operating m aterials or lubr icants must not be all owed to seep into the soi l or to get into the publi c

sewerage system!

Properly collect, stor e and dispose of operating materials and lubricants which can no longer be used!

Observe and foll ow the respecti ve applic able laws and regulations for handl ing operating mat erials

and lubricants and their disposal in the country in which these substances are used! Obtain

infor mation from the responsible agencies!

Page 10

FS 240 E

Operating manual

- 10-

02822400988

5006148-01

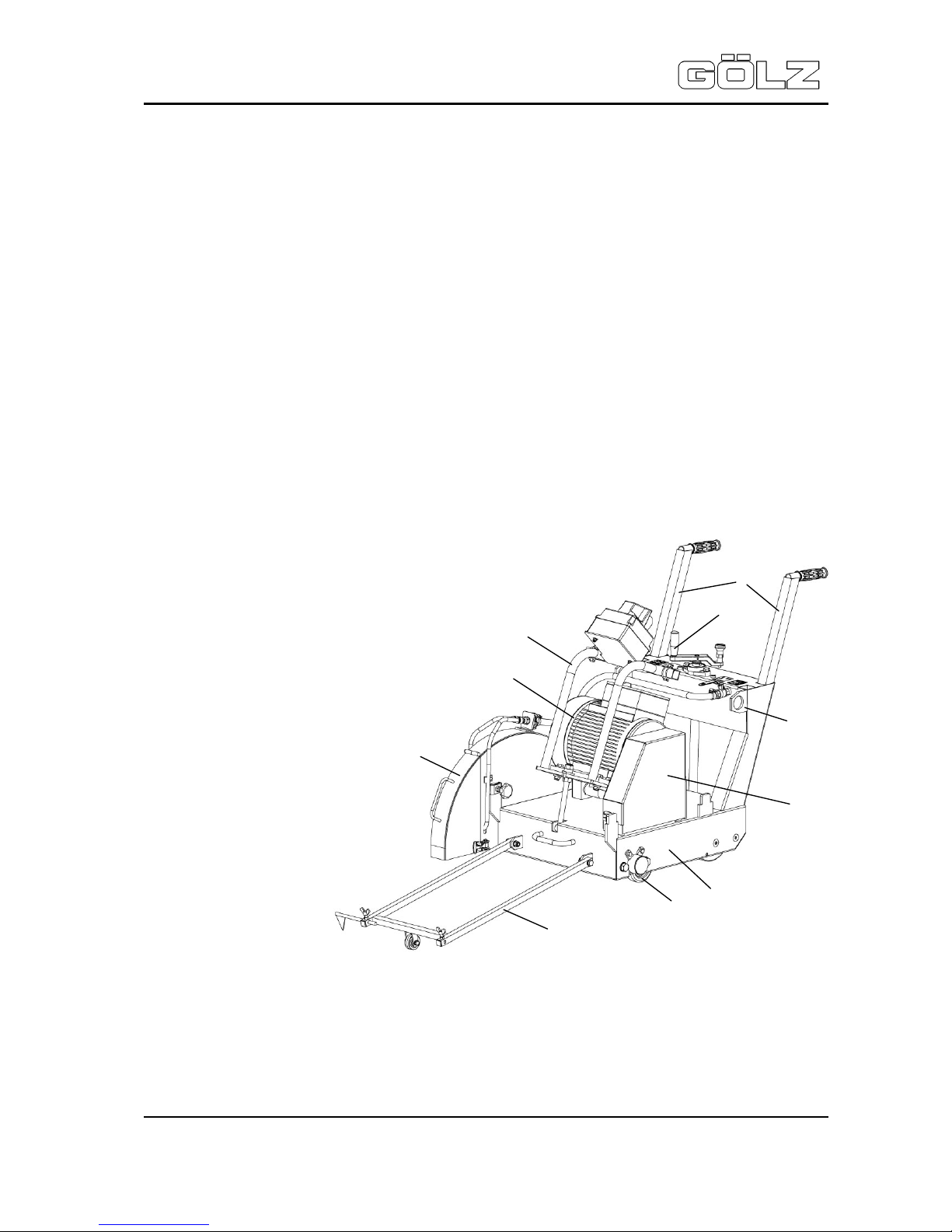

4

5

7

10

2.10 Changing the location of the machine

Use only suitable means of transport and lifting gear of sufficient capacity when loading or transporting

the machine! Appoint an experienced instructor for the lifting operation!

Always observe the i nstruct ions giv en i n the operati ng manual when lif ti ng the machine (use only the

prescribed lifti ng ey es for attachi ng the lifting gear)!

Use only suitable transport vehicles with sufficient load capacity! Secure the load carefully. Use

suitable fastening points for securing!

Before loading the mac hine or part s of it, secure the machi ne/ parts against i nadvert ent mov ement !

Attach a suit able warning sign!

Before using the machine again, make sure that such protection material or devices are properly

removed! P ar ts which had to be removed for t r ansporting of t he machine must be refi tted and secured

carefully befor e the machine is used again!

The recommissioning procedure must be strictly in accor danc e with the operating manual!

Observe the instructions given in the operating manual when reassembling and operating the

machine.

Before sett ing the machine in motion always check that all accessories are safel y stowed.

3. Description

3.1 Main parts

1. Frame

2. Undercarriage

3. V-belt guard

4. Eyebolt

5. Crank handle

6. Adjustable push bow

7. Quick change system

8. Electric motor

9. Blade guard

10. Pointer unit

1

3

6

8

9

2

Page 11

FS 240 E

Operating manual

- 11-

02822400988

5006148-01

3.2 Technical data

Engine 3-phase electri c motor, 400V, 50 Hz, 16 A

Power 7,5 kW (10 HP)

Engine speed 1500 rpm

Blade shaft speed 1500 rpm

Max. cutting speed 47 m/s

Max. blade size Ø 600 mm - Ø 23.6 in.

Flange size Ø 120 mm - Ø 4.275 in.

Blade shaft si z e Ø 25,4 mm - Ø 1 in.

Max. cutting depth 240 mm - 9.42 in.

Cutting dept h sel ec tor Crank handle

Feed Manually

Water supply Connection for external water supply

Weight 160 kg - 352.7 lbs.

Dimensions (L x W x H) 840 x 670 x 600 mm - 33 x 26.38 x 23.62 in.

Vibration ISO 5349 VDMA 03/ 2006 a = 3,7 m/s²

Sound power lev el DIN ISO 6393

No load = 100 dB(A)

Full load = 119 dB(A)

Sound pressure lev el DIN EN ISO 6393

No load = 80 dB(A)

Full load = 100 dB(A)

4. Transport and storing

Danger of down coming parts!

Secure boards and machine on the loading area! Do not stand in the danger zone of

the crane !

4.1 Transport

Before t r ansport ing dismount t he blade and lower the mac hine until to the stop.

Use boards for load and unl oading on a truck. Sec ure the machi ne on the loading area.

Fasten a lifting device (tensile strength 1500 kg (3307 lbs.) to the eyebolts (1) when loading and

unloading with an crane. F or singl e transportati on the el ectri c mot or is detachabl e by a qui ck change

system. Open t he locking (2) of the V-belt guard (3) clap it backwards.

Loosen the counter nut W S 24 (4) of the spindl e (5) and screw down the tension nut W S 24 (6) unti l

the V-belt s are det ac hable. Pull out the push bows (7) and push them over the c ar r y ing bow (8).

Page 12

FS 240 E

Operating manual

- 12-

02822400988

5006148-01

1

3

2

6

5

4

7

8

9

Secure with the l inch pins and lower the elect ric motor. Now the locking (9) is f ree and the electri c

motor is detachable. Rem ount in opposite order and check V -belts for correct tension (see chapter

maintenance).

4.2 Storing

Store the machine in a dry, high or locked place, out of the reach of c hildren or unauthor ized persons.

Clean and preserve the machine with corrosion preventive if storing over a longer time like winter time!

5. Starting

5.1 Before starting

Check daily :

• Reliable condition of the machine and blade!

• Well secur ed blade on the blade shaft!

• Well secur ed safety devices like blade guard, V-belt guard and splash guard!

• Report any changes (incl . changes in t he machi ne`s working behav iour ) to the com petent person

immediately . If necessary, stop the machine immediately and loc k it!

5.2 Packing

The m achine i s packed in f oil on a pal let. Remov e t he packing and recycle i t. Use recycli ng containners.

5.3 Mounting the diamond blade

Dismount bl ade guard. Dism ount washer, fl ange screw and outside flange (l ef t hand threaded if blade

is to be mount ed to the right side) . Make sure that the blade shaft, flange screw, flanges and blade are

not damaged and free of sawdust and slurry.

Page 13

FS 240 E

Operating manual

- 13-

02822400988

5006148-01

Washer

„0“ - Position

WS 24

Pay attention to the correct rotation. Direction signs are on the

blade and blade guard. Mount the outside flange and fix it

correctl y with the washer and the flange screw. Mount the blade

guard and secure it with the star grips.

Danger of losing the diamond blade if not correctly

fixed on the blade shaft!

5.4 Water supply

Connect the ext ernal water supply to the GEKA-coupler at the lef t side of t he tending side. The ball

valve should be closed.

5.5 Power supply

Check the electri cal condi tion, input v olt age 400 V/50 Hz. The used power supply m ust comply with

the regulations of power distribution on building sites (fuse protection over FI-protected switch).

Complet ely uncoil extension cables. The starter lever must be in 0 position. Insert in the m ains plug.

6. Operation

Burning hazard touching hot parts (electric motor)!

Dust when using dry cutting blades!

Danger of down coming parts!

The sound pressure level can exceed 85 dB(A)!

Injury hazard of demolitioining parts!

Injury hazard of drawing in clothes by rotating parts!

Page 14

FS 240 E

Operating manual

- 14-

02822400988

5006148-01

Triangl e posi tion

Phase inv er ter

Star position

Crank handle

Stop bolt ac c eptance

Ball valve

Lower

Lift

Stop bolt

Never touch ro t at ing parts like blade, motor or blade shaft and V-belts!

Before starting the machine must be completely lifted. The blade may not have any

ground contact!

6.1 Cutting line

Mark the cutt ing li ne with chalk. Make sure the soil i s clean and align t he blade with the cutting line.

Hinge down the pointer unit and align the directi on si gn wi th the cutti ng line.

6.2 Starting electric motor

Move the starter lever in star position.

Notice correct rotation of the electric motor (sight on the V-belt pulley - rotation left)!

Wr ong rotati on - pull mai ns plug and turn t he phase inv erter with a screw driv er. Repeat starti ng and

move the starter l ever in triangle posit ion after the electric motor has reached maximum speed.

6.3 Setting cutting depth

Open the ball valv e and turn the cr ank handle counter clockwise. Lower the machine to the desired

cutting depth and latch the cr ank handle in one of the two stop-bolt accept anc es.

Page 15

FS 240 E

Operating manual

- 15-

02822400988

5006148-01

Crank handle

Ball valve

Lower

Lift

„0“ - Position

6.4 Feed

Operate with even feed. The el ect ri c m ot or will overstress and the mac hine might r ise out of cut if the

feed is too high. The segments will become dull if the feed is too low.

Operating with too high feed the machine might rise out of cut!

6.5 Finish cutting

Fully lift the fl oor saw and close the ball v alve.

6.6 Stopping electric motor

Move the start lever to the 0 posit ion.

7. Maintenance

Spare parts must com ply wit h the technical requirem ents specified by the manuf acturer. Spare parts

from

GÖLZ

can be relied to do so! Observe the f ollowing indi c ations:

Cut off electric motor and pull mains plug before maintenance, repair or inspection.

Place machin e on stand and secure i t against fall down. Wo rk on the electrical system

or equipment may only be carried out by a skilled electrician!

7.1 General

After cutting clean the machine and check the machine and specially the blade for damages.

Necessary repairs must be car r ied out im mediatel y ( see spare part s l ist).

Page 16

FS 240 E

Operating manual

- 16-

02822400988

5006148-01

7.2 Lubrication chart

Grease the bearings of the blade shaft, cutting depth selector and the undercarriage every 20-30

working hours with heat r esistance fat . Clean periodi call y lose parts lik e pointer uni t and wheels and

grease them with som e drops of oil.

7.3 Electric motor

To prevent over heat clean periodically t he venti lator cowl and the cooling ribs.

7.4 V-belts

Check peri odic all y t he c orrec t t ension of t he V-bel t s. If t he m achi ne i s new or a new set of V-bel t was

mounted check the tension aft er 8 working hours.

Deflexion in the middle approx. 4 mm (0.16" ) - maximum deflexi on force 19 N. Always use a set of Vbelts. Loosen the counter nut (1) WS 24 of the spindle (3) and tense the V-bel ts with the adjusting nut

(2) WS 24 until the cor r ec t tension is reached and fasten the counter nut (1).

Use always a set of V-belts!

1

2

3

Deflexion 4 mm - 0.16 in.

A

A

= min. 1,3 kg - 2.87 lbs.

A = max. 1,9 kg - 4. 18 lbs. with new V-bel t s

A = max. 1,6 kg - 3. 53 lbs. at retensi on

Page 17

FS 240 E

Operating manual

- 17-

02822400988

5006148-01

8. Troubleshooting

Problem Cause Remedy

Electric mot or

Mains plug not connec ted Check conecti on

Fuse of power distribution on

buildi ng si tes has been released

Check fu ses

Electric mot or does not

operate!

Malf unc tion of electrical installation

The electr ical installation

must be checked only by an

electrician

Lowering

Machine does not fully lower!

Undercarriage or threaded spindle

tight

Check undercarri age and

threaded spindel

Cutting

Dull di amond blade

Sharpen or use softer

diamond blade

Machine ri ses out of cut !

Feed to high Reduce feed

Damaged centering of the blade

shaft

Replace blade shaft

War ped blade shaft Replace

Non circular abrasion o f t he

diamond blade!

Loose or damaged blade shaf t

bearings

Tighten or r eplace

No free cut bec ause of siedwards

wear-out of segments

Replace diamond blade

Diamond blade jams in the cut

Damaged diamond blade core Replace diamond blade

Insufficient water flow

Check hoses for f r ac ture free

laying

Wr ong type of diamond blade

Choose different diamond

blade

Feed too high Reduce feed

Abnormal wear-out of

segments

Cutting in loose underground Reduce cutti ng depth

Insufficient water flow

Check hoses for f r ac ture free

laying

Abnormal bl ade wear-out at

sides of co re!

Cutting in loose underground Reduce cutti ng depth

Slippy V - belts Adjust

Bad cutting performance!

Blunt di amond blade

Sharpen or use softer

diamond blade

Page 18

FS 240 E

Operating manual

- 18-

02822400988

5006148-01

Page 19

FS 240 E

Operating manual

- 19-

02822400988

5006148-01

9. Wearing parts

Wearing parts for construction devices mentioned in the operating manual

such as drilling and sawing machines

Wearing parts are the parts subject to operation-related (natural) wear during proper use of the device.

The wearing time cannot be uniformly defined, and differs according to the intensity of use. The

wearing parts must be adjusted, maintained and, if necessary, replaced for the specific device in

accordance with the manufacturer’s operating manual. Operation-related wear is not a reason for

defect c laims.

• Feed and drive elements such as toothed racks, gearwheels, pi nions, spindles, spindl e

nuts, spindle bearings, cables, chains, sprock ets, belts

• Seals, cables, hoses, packings, connectors, c ouplings and switches for pneumatic, hy dr aulic,

water, electr ical and f uel systems

• Guide elements such as guide strips, guide bushes, guide rails, rollers, bearings, sliding

protection supports

• Clam ping element s for quick-separat ing systems

• Flushing head seal s

• Sli de and r oller bearings t hat do not run in an oil bath

• Shaft oil seals and sealing elements

• Fric tion and safety clutches, braking devi c es

• Carbon brushes, commutators/armatures

• Easy-release rings

• Control potentiometers and manual switching elements

• Securing elements such as plugs, anchors, screws and bolts

• Fuses and lamps

• Auxiliary and operating materials

• Bowden cables

• Discs

• Diaphragms

• Spark plugs, glow plugs

• Parts of the reversing starter such as the starting r ope, starting pawl, star ting roll er and

starting spring

• Seali ng br ushes, rubber seal s, spl ash prot ection cloths

• Filters of all kinds

• Drive roll er s, deflection rollers and bandages

• Cable anti-twist elements

• Running and dri ve wheels

• Water pumps

• Cut-material transport rollers

• Drilling, parting and cutting tools

• Energy storage

Wearing parts of this machi ne are grey marked in t he spare parts list .

Page 20

FS 240 E

Operating manual

- 20-

02822400988

5006148-01

10. Ersatzteilliste/Spare parts list/Liste des pièces de rechange

So bekommen Sie schnell und richtig Ihr Ersatzteil

- für Maschine - Modell - Masch.-Nr.

- Artike lnummer - Bezeichnung des Ersatzteiles

- Anzahl der gewünschten Ersatzteile

- Wohin liefern?

- Womit liefern (Post, Eilpost etc.)?

Always indicate:

- machine/model/serial number

- item number and description of the spare part

- amount of spare parts desired

- full address

- goods to be sent by regular mail, express, etc.

Pour obtenir rapidement les pièces de rechange indiquer :

- Nº de la machine, du modèle

- Nº de l’article / description de la pièce désirée

- Nombre de pièces commandées

- Adresse de livraison

- Mode de livraison (poste, express etc...)

Page 21

FS 240 E

Operating manual

- 21-

02822400988

5006148-01

Page 22

FS 240 E

Operating manual

- 22-

02822400988

5006148-01

Pos Artikelnummer Menge Norm Info Benennung Description Désignation

1 0282 240 0103 1 Grundgestell Frame Châssis

2 0282 150 0008 1

UCFL 202

Ø 15

Flanschlager Bearing Flasque bride

3 0286 570 0047 12

DIN EN

ISO 7090

B 10,5 Scheibe Washer Rondelle

4 0295 000 0293 2

DIN EN

ISO 4017

M 10 x 35 Schraube Screw Vis

5 0286 570 0052 6

DIN EN

ISO 7040

M 10 Mutter Nut Écrou

6 0295 600 1043 1

DIN EN

ISO 7090

B 15 Scheibe Washer Rondelle

7 0282 150 0066 1 Handkurbel kpl. Crank handle assy. Manivelle complete

7.1 0295 000 0011 1 Zylindergriff Bolt Poignée

7.2 0282 150 0069 1 Handkurbel Crank handle Manivelle

7.3 0284 650 0064 1 DIN 1481 5 x 24 Spannhülse Clamping sleeve Manchon

7.4 0282 150 0065 1 Rastbolzen Stop bolt Cheville

8 0282 240 0021 2 M 10 Rastbolzenaufnahme Stop bolt acceptance Logement de la cheville

9 0295 000 0216 2 DIN 7349 A 10,5 Scheibe Washer Rondelle

10 0282 240 0071 2 Schubbügel Push bow Poignée

11 0281 045 0028 2 DIN 6336 M 10 x 25 Sterngriffschraube Star grip screw Vis à poignée-étoile

12 0285 300 0044 2 Kunststoffgriff Handle Revêtement poignée

13 0282 065 0011 2

UCFL 205

Ø 25

Lager Bearing Roulement

14 0282 250 0023 8

DIN EN

ISO 7090

B 17 Scheibe Washer Rondelle

15 0286 570 0058 4

DIN EN

ISO 4017

M 16 x 45 Schraube Screw Vis

16 0282 450 0156 4

DIN EN

ISO 7040

M 16 Mutter Nut Écrou

17 0282 240 0027 1 Schneidwelle Blade shaft Arbre de coupe

18 0282 240 0028 2 DIN 6885 A 8 x 7 x 27 Passfeder Key Clavette

19 0282 240 0029 1 DIN 6885 A 8 x 7 x 58 Passfeder Key Clavette

20 0282 240 0016 2 Lagerbock Pedastal Palier

21 0295 000 0179 4

DIN EN

ISO 4017

M 10 x 25 Schraube Screw Vis

22 0282 240 0019 1

3SPA DW90

x Ø 30

Keilriemenscheibe V-belt pulley Poulie à gorge

23 0285 300 0128 1 Gummiriegel kpl. Locking Verrou en caoutchouc

24 0282 240 0030 1

TK85

6 x M 8

Schneidflansch innen Inside flange Flasque intérieure

25 0282 250 0004 6

DIN EN

ISO 10642

M 8 x 16 Schraube Screw Vis

26 0282 150 0055 2

DIN EN

ISO 4017

M 10 x 45 Schraube Screw Vis

27 0282 240 0020 1

Ø 40 x Ø 17

x 3

Scheibe Washer Rondelle

28 0282 240 0044 1

DIN EN

ISO 8676

M 16 x 1,5

x 50 LH

Schraube Screw Vis

29 0282 240 0041 1

DIN EN

ISO 8676

M 16 x 1,5

x 50

Schraube Screw Vis

30 0282 240 0024 1

Schutzhaube Schneid-

welle

Blade shaft guard

Capot de protection du

disque de coupe

31 0282 250 0005 2

DIN EN

ISO 4017

M 8 x 16 Schraube Screw Vis

Page 23

FS 240 E

Operating manual

- 23-

02822400988

5006148-01

Page 24

FS 240 E

Operating manual

- 24-

02822400988

5006148-01

Pos Artikelnummer Menge Norm Info Benennung Description Désignation

32 0282 240 0026 1 Schneidflansch aussen Outside flange Flasque extérieur

33 0282 240 0008 1 Richtungsanzeiger Pointer unit Tiges de guidage

34 0282 120 0045 2

20 x 20 x

1,5-2

Stopfen Plug Capuchon

35 0282 150 0026 1 Ø 50 x Ø 8 Rad Wheel Roue

36 0282 250 0006 2

DIN EN

ISO 7090

B 8,4 Scheibe Washer Rondelle

37 0281 045 0091 1

DIN EN

ISO 4014

M 8 x 45 Schraube Screw Vis

38 0282 065 0005 1

DIN EN

ISO 7040

M 8 Mutter Nut Écrou

39 0282 150 0034 2 DIN 316 M 8 x 20 Schraube Screw Vis

40 0282 150 0022 1 Richtungspfeil Pointer arrow Flechè de direction

41 0282 150 0047 1 1/2" I Kugelhahn Ball valve Robinet

42 0282 150 0031 1

R 1/2" A

X Ø 13

Schlauchtülle Nozzle Embout à olive

43 0282 170 0032 1 G 1/2" I Geka-Kupplung Geka-Coupler Geka-Raccord

44 0282 170 0031 1 Ø 13 Schlauchtülle Nozzle Embout à olive

45 0282 240 0002 1

Ø 13,2 x

Ø 3,3 x 1000

Schlauch Hose Tuyau

46 0282 250 0112 2 Ø 16 - Ø 25 Schlauchschelle Clip Collier

o.A. 0295 899 0051 1 Typenschild Type plate Plaque d’identification

o.A. 0295 899 0033 1 „Pikto“ Aufkleber Label Macaron

o.A. 0295 899 0042 1 „Auf - Ab“ Aufkleber Label Macaron

o.A. 0295 899 0227 1 LWA Aufkleber Label Macaron

Zubhör für B ündigschnitt - Ac c essory – Ac c esoi r e

Pos Artikelnummer Menge Norm Info Benennung Description Désignation

o.A. 0282 240 0040 1

DIN EN

ISO 8676

M 16 x 1,5

x 30 LH

Schraube Screw Vis

o.A. 0282 240 0042 1

DIN EN

ISO 8676

M 16 x 1,5

x 30

Schraube Screw Vis

Page 25

FS 240 E

Operating manual

- 25-

02822400988

5006148-01

Page 26

FS 240 E

Operating manual

- 26-

02822400988

5006148-01

Pos Artikelnummer Menge Norm Info Benennung Description Désignation

1 0282 240 0022 2

UCFL 204

Ø 20

Flanschlager Bearing Flasque bride

2 0282 520 0118 4

DIN EN

ISO 10642

M 12 x 45 Schraube Screw Vis

3 0282 250 0105 6

DIN EN

ISO 7090

B 13 Scheibe Washer Rondelle

4 0285 300 0015 6

DIN EN

ISO 7040

M 12 Mutter Nut Écrou

5 0282 150 0009 1 Gewindespindel Spindle Axe fileté

6 0282 240 0052 1 Spindelmutter Spindle nut Arbre récepteur

7 0282 240 0014 1 Fahrwerk Undercarriage Châssis

8 0282 140 0002 2

Ø 160 x 60

x Ø 20

Rad Wheel Roue

9 0282 065 0003 2

Ø 100 x 35

X Ø 12

Rad Wheel Roue

10 0282 240 0064 1

DIN EN

ISO 2341

Form B Bol zen Bolt Goujon

11 0282 250 0023 1

DIN EN

ISO 7090

B 17 Scheibe Washer Rondelle

12 0284 650 0046 1

DIN EN

ISO 1234

4 x 25 Splint Split pin Goupille

13 0282 065 0006 1

DIN EN

ISO 4017

M 16 x 60 Schraube Screw Vis

14 0281 045 0051 1

DIN EN

ISO 4032

M 16 Mutter Nut Écrou

Page 27

FS 240 E

Operating manual

- 27-

02822400988

5006148-01

Page 28

FS 240 E

Operating manual

- 28-

02822400988

5006148-01

Pos Artikelnummer Menge Norm Info Benennung Description Désignation

1 0282 240 0005 1 Motoraufnahme hinten Rear mounting plate

Réception arrière du

moteur

2 0282 900 0101 1 Motor Motor Moteur

3 0282 240 0006 1 Motoraufnahme Front mounting pla te Réception moteur

4 0295 000 0216 6 DIN 7349 A 10,5 Scheibe Washer Rondelle

5 0286 570 0052 2

DIN EN

ISO 7040

M 10 Mutter Nut Écrou

6 0282 150 0055 2

DIN EN

ISO 417

M 10 x 45 Schraube Screw Vis

7 0282 250 0023 2

DIN EN

ISO 7090

B 17 Scheibe Washer Rondelle

8 0282 240 0061 2 Ausgleichsbuchse Bushing Douille

9 0282 240 0060 1 Motorverstellspindel Spindle

Ace taraudé de positionnement du moteur

10 0281 045 0051 2

DIN EN

ISO 4032

M 16 Mutter Nut Écrou

11 0282 450 0156 1

DIN EN

ISO 7040

M 16 Mutter Nut Écrou

12 0295 000 0173 2

DIN EN

ISO 4017

M 10 x 30 Schraube Screw Vis

13 0282 300 0116 1

DIN EN

ISO 4017

M 16 x 70 Schraube Screw Vis

14 0285 300 0985 1 DIN 6885

A 10 x 8 x 70

Passfeder Key Clavette

15 0282 240 0018 1

3SPA DW90

x Ø 38

Keilriemenscheibe V-belt pulley Poulie à gorge

16 0282 240 0072 1

XPA-975

LW

Keilriemen Sa tz V-belt set Jeu de Courroie s

17 0282 240 0989 1 Motorschalter Starter

Boîte de comma nde du

moteur

18 0286 570 0069 4

DIN EN

ISO 7090

B 6,4 Scheibe Washer Rondelle

19 0295 000 0084 2

DIN EN

ISO 4762

M 6 x 20 Schraube Screw Vis

20 0281 045 0027 2

DIN EN

ISO 7040

M 6 Mutter Nut Écrou

21 0295 000 0003 2 8 x 45 Rohrklappenstecker Linch pin Goupille articulée

o.A. 0298 100 0061 1 PG16 Mutter Nut Écrou

o.A. 0298 100 0066 1 PG16 7353 Verschraubung Connection Raccord

o.A. 0298 100 0067 1

167MS

/21/16

Reduzierung Reduction Réducteur

o.A. 0298 100 0065 1 PG16 7363 Verschraubung Connection Raccord

o.A. 0282 130 0054 1 Distanzring Distance plate Entretoise

o.A. 0298 100 0207 1 Kabel Cable Câble

Page 29

FS 240 E

Operating manual

- 29-

02822400988

5006148-01

Page 30

FS 240 E

Operating manual

- 30-

02822400988

5006148-01

Pos Artikelnummer Menge Norm Info Benennung Description Désignation

- 0282 240 0100 1 Pos. 1-16 Schutzhaube kpl. Blade guard assy.

Capot de protection

complete

1 0282 240 0104 1 Schutzhaube Blade guard Capot de protection

2 0285 300 0090 1

DIN EN

ISO 7090

B 21 Scheibe Washer Rondelle

3 0282 170 0032 1 1/2" Geka-Kupplung Geka-Coupler Geka-Raccord

4 0282 240 0102 1 Y 1/2" Steckverschraubung Connectin Raccord

5 0285 300 0128 2 Gummiriegel kpl. Locking Verrou en caoutchouc

6 0282 240 0066 1 Spritzlappen Splash guard Bavette

7 0282 250 0006 4

DIN EN

ISO 7090

B 8,4 Scheibe Washer Rondelle

8 0282 150 0035 2

DIN EN

ISO 4017

M 8 x 20 Schraube Screw Vis

9 0282 065 0005 2

DIN EN

ISO 7040

M 8 Mutter Nut Écrou

10 0282 240 0101 2 Ø 12 Schelle Clip Collier

11 0286 570 0069 2

DIN EN

ISO 7090

B 6,4 Scheibe Washer Rondelle

12 0295 000 3530 2

DIN EN

ISO 4017

M 6 x 15 Schraube Screw Vis

13 0282 240 0105 1 6 x 3 x 600 Schlauch Hose Tuyau

14 0282 240 0105 1 6 x 3 x 600 Schlauch Hose Tuyau

15 0281 045 0028 2 DIN 6336 M 10 x 25 Sterngriffschraube Star grip screw Vis à poignée-étoile

16 0295 899 0055 1 „FS240“ Aufkleber Label Macaron

Pos Artikelnummer Menge Norm Info Benennung Description Désignation

o.A. 0295 000 2100 1 Werkzeugtasche Tool bag Trousse à outils

o.A. 0295 000 2012 1 DIN 911 SW 5 Inbusschlüssel All en key Clé

o.A. 0295 000 2011 1 DIN 911 SW 6 Inbusschlüssel All en key Clé

o.A. 0295 000 2036 1 DIN 984 SW 13 Maulschlüssel Wrench Clé platte

o.A. 0295 000 2052 1 DIN 984 SW 24 Maulschlüssel Wrench Clé platte

o.A. 0295 000 2038 1 DIN 984 SW 17 Maulschlüssel Wrench Clé platte

Page 31

FS 240 E

Operating manual

- 31-

02822400988

5006148-01

11. Wiring diagram

Strip terminal (motor)

Switch box

Plug

Loading...

Loading...