Page 1

FS175

Translation of the original operating instruction and spare parts list

- 1-

5007287-00

BA-E

®

Floor saw

FS 175

ZN der Bedienungsanleitung: 5007287-00

Erstellt am: 03 / 2014

Erstellt von: Sabrina Linden

Datei: K:\KDV\5007xxx\5007287-Bedienungsanleitung\

5007287-00-Bedienungsanleitung-E.doc

GÖLZ® GmbH

Dommersbach 51

D-53940 Hellenthal

Telefon: +49 (0) 2482 12 200 / Telefax: +49 (0) 2482 12 222

E-Mail: info@goelz.de / Internet: www.goelz.de

Page 2

FS175

Translation of the original operating instruction and spare parts list

- 2-

5007287-00

BA-E

®

Page 3

FS175

Translation of the original operating instruction and spare parts list

- 3-

5007287-00

BA-E

®

All rights reserved according to DIN ISO 16016.

No part of this document (instruction manual and spare parts list) may be reproduced, adapted, transmitted,

transcribed, stored on a data medium or be translated into another language without prior written approval of

GÖLZ

®

GmbH

Dommersbach 51

D-53940 Hellenthal

Guarantee

We reserve the right to amend any information included in this document (manual instruction and spare parts

list) at any time and without prior notice.

GÖLZ

®

assumes no warranty for these documents.

GÖLZ

®

shall not be liable for errors in this document (manual instruction and spare parts list) or for any

collateral or consequential damage in connection with shipment, performance or use of the material.

Page 4

FS175

Translation of the original operating instruction and spare parts list

- 4-

5007287-00

BA-E

®

EC-DECLARATION OF CONFORMITY

Manufacturer

GÖLZ® GmbH

Dommersbach 51, D-53940 Hellenthal

Tel.: +49 (0) 2482 12 200 / Fax: +49 (0) 2482 12 222

Declare hereby certifies on its sole responsibility that the following product:

FS 175

Floor saw

Serial number:____________________

which is explicitly referred to by this declaration meet the following directives:

2006/42/EC Safety and health requirement

2004/108/EC Electromagnetic compatibility

97/68/EG i.d.F. 2002/88/EC Exhaust emission directive

2000/14/EC Noise emission

meet the follwing standards:

EN 12100-1 / EN 12100-2 , EN 13862:2001, EN 13309:2000, EN 61000, DIN EN ISO 3744-1995

Documented evidence conforming to the requirements of the directives is kept available for inspection at the

above manufacturer’s address.

Hellenthal, den 13.03.2014 ………………………………………

General Manager

B. Schmitz

Page 5

FS175

Translation of the original operating instruction and spare parts list

- 5-

5007287-00

BA-E

®

Contents

Preface ................................................................................................................................ 7

Warning signs and symbols ............................................................................................. 7

1. Machine description ................................................................................................... 8

1.1 Intended use-description ................................................................................................. 8

1.2 Technical data ................................................................................................................. 8

1.3 Shipment and provided accessory ................................................................................... 9

1.4 Main parts........................................................................................................................ 9

1.5 Safety devices ............................................................................................................... 10

2. Basic safety instructions ......................................................................................... 11

2.1 Intended use .................................................................................................................. 11

2.2 Operating range ............................................................................................................ 11

2.3 Organisational measures ............................................................................................... 11

2.4 Selection and qualification of person ............................................................................. 13

2.5 Safety instructions governing specific operational phases ............................................. 13

2.6 Special work related to the maintenance and repair of the machine .............................. 14

2.7 Information about special risks with electrical energy .................................................... 14

2.8 Gas, dust, steam, smoke ............................................................................................... 15

2.9 Noise ............................................................................................................................. 15

2.10 Illumination .................................................................................................................... 15

2.11 Oils, greases and other chemical substances ................................................................ 16

2.12 Transport ....................................................................................................................... 16

2.13 Store .............................................................................................................................. 17

3. Preparing for Operation ........................................................................................... 18

3.1 Export checking ............................................................................................................. 18

3.2 Installation ..................................................................................................................... 18

3.3 Blade ............................................................................................................................. 18

3.3.1 Mounting the blade ..................................................................................................................... 19

3.4 Water supply ................................................................................................................. 19

4. Operation ................................................................................................................... 21

4.1 Before starting the machine ........................................................................................... 21

4.2 Starting the machine ...................................................................................................... 22

4.3 Cutting operation ........................................................................................................... 22

4.4 Stop cutting operation .................................................................................................... 23

4.5 Changing the blade ....................................................................................................... 23

5.

Maintenance .............................................................................................................. 24

5.1 General ......................................................................................................................... 24

Page 6

FS175

Translation of the original operating instruction and spare parts list

- 6-

5007287-00

BA-E

®

5.2 Lubricating chart ............................................................................................................ 24

5.3 Poly-V belt ..................................................................................................................... 24

5.4 Machine ......................................................................................................................... 25

5.5 Blade ............................................................................................................................. 25

6. Taper bushes installation instructions ................................................................... 26

6.1 To assemble .................................................................................................................. 26

6.2 Removal ........................................................................................................................ 26

7.

Troubleshooting ....................................................................................................... 27

8. Spare parts list .......................................................................................................... 28

8.1 Using the spare parts list ............................................................................................... 28

8.1.1 Safety regulation ......................................................................................................................... 28

8.1.2 Ordering information ................................................................................................................... 28

8.1.3 Distribution agencies ................................................................................................................... 29

8.2 Wearing parts ................................................................................................................ 30

9. Exploded view and spare parts list ......................................................................... 31

9.1 Undercarriage ................................................................................................................ 31

9.2 Push bow ...................................................................................................................... 33

9.3 Shaft .............................................................................................................................. 37

9.4 Shaft support ................................................................................................................. 39

9.5 Water tank 30L .............................................................................................................. 40

9.6 Blade guard / Water supply ........................................................................................... 41

9.6.1 Blade guard ................................................................................................................................. 43

9.7 Engine ........................................................................................................................... 45

9.8 Pointer unit .................................................................................................................... 49

Page 7

FS175

Translation of the original operating instruction and spare parts list

- 7-

5007287-00

BA-E

®

Preface

Thanks for choosing a

GÖLZ®-product. This operating instruction is designed to familiarize the user with

the machine and its designated use.

The operating instruction contains important information on how to operate the machine safely, properly and

most efficiently. Observing these instructions helps to avoid danger, to reduce repair costs and downtimes

and to increase the reliability and life of the machine. The operating instruction is to be supplemented by the

respective national rules and regulations for accident prevention and environmental protection. The

operating instruction must always be available wherever the machine is in use. This operating instruction

must be read and applied by any person in charge of work with or on the machine, such as:

• Operation including setting up, troubleshooting in the course of work, evacuation care and disposal of

fuels and consumables.

• Maintenance (servicing, inspection, repair) and/or

• Transport

In addition to the operating instructions and to the mandatory rules and regulations for accident prevention

and environment protection of the country and place of use of the machine, the generally recognized

technical rules for safe and proper working conditions and procedures must also be observed.

In dieser vorliegenden Bedienungsanleitung sind alle für den bestimmungsgemäßen Einsatz notwendigen

Informationen enthalten. Sollten dennoch spezielle Fragen auftauchen, so wenden Sie sich bitte

an ihre Vertretung, an einen unserer Außendienstmitarbeiter oder direkt an uns:

GÖLZ® GmbH

Dommersbach 51, D-53940 Hellenthal

Telefon: +49 (0) 2482 12 200 / Telefax: +49 (0) 2482 12 222

E-Mail: info@goelz.de / Internet: www.goelz.de

Warning signs and symbols

Wear safety boots!

Wear safety glasses! Wear ear muffs!

Wear hard hat!

Wear safety clothes!

Wear dust protection!

Wear protective

gloves!

Read owner’s manual

before first initiation!

Important advice!

Never touch!

General danger!

Danger exists

to cut oneself!

It is not allowed to move the machine with rotating blade outside of the area in which

cutting works have to be performed!

Page 8

FS175

Translation of the original operating instruction and spare parts list

- 8-

5007287-00

BA-E

®

1. Machine description

1.1 Intended use-description

The FS 175 is a floor saw with a cutting depth of up to 165 mm.

Its operating range includes the concrete and asphalt road construction, but mainly for transverse,

longitudinal and expansion joints.

Operate the machine only using tools in accordance with the manufacturer’s instruction. Using other tools is

considered contrary to its designated use. The manufacturer cannot be held liable for any damage resulting

from such use. The risk of such misuse lies entirely with the user. Der FS 175 is equipped with a petrol

engine Honda GX390 and should be operated with the fuel specified by the manufacturer.

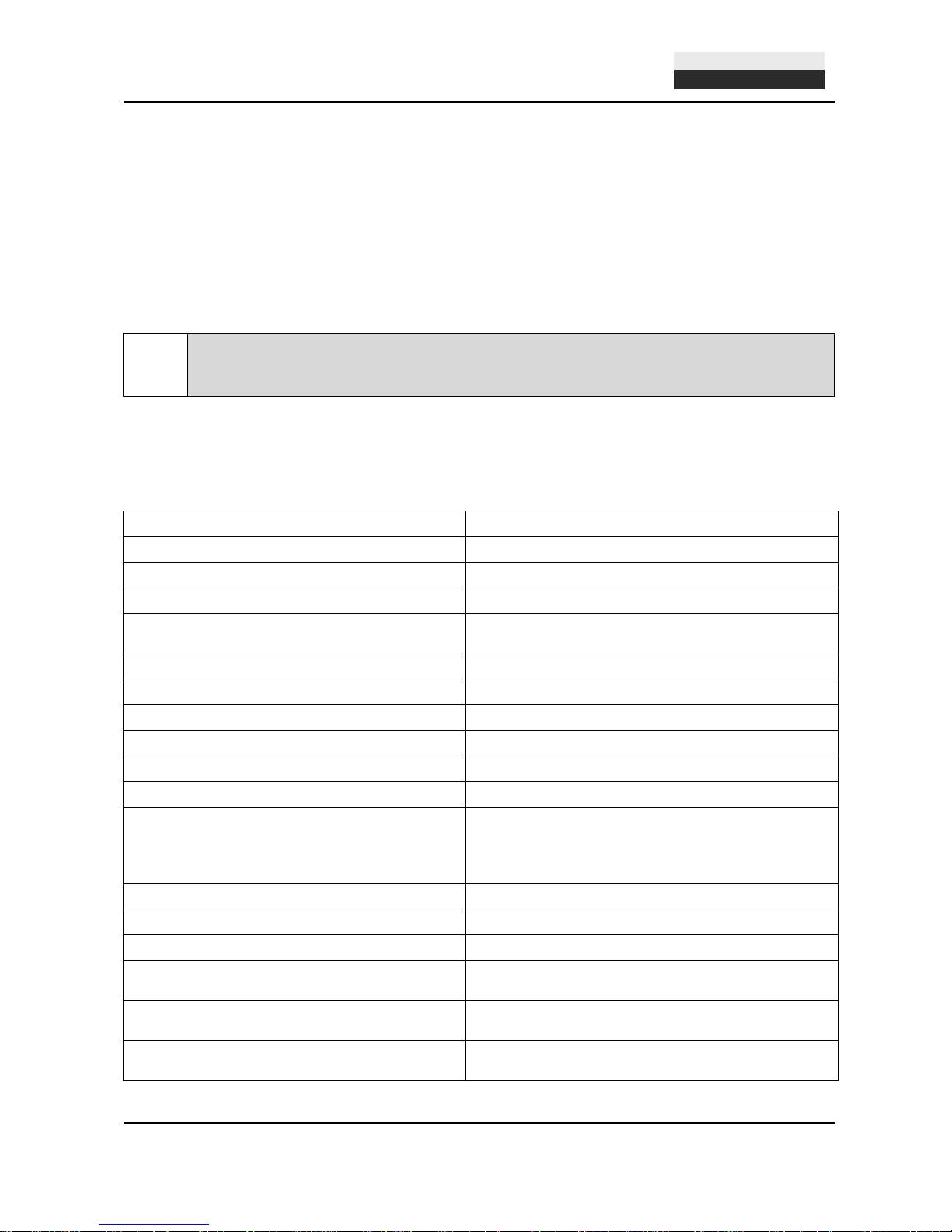

1.2 Technical data

Max. cutting depth 165 mm - 6.5 in.

Max. blade-Ø 450 mm - 17.7 in.

Flange size Ø 100 mm - 3.9 in.

Blade shaft size Ø 25,4 mm - 1 in.

Engine

Gasoline engine HONDA GX390

8,7kW (11,8 PS)

Max. cutting speed with blade 63,5 m/s

Engine shaft speed 3600 min-1

Blade shaft speed 2691 min-1

Feed manual

Excavation Manual with foot pedal

Cutting depth control Scale on frame

Water supply

30l Water tank, for dry cutting blades

Connection for external water supply wet cutting

diamond blades

Poly-V-belt tension manual

Dimensions (L x W x H) approx. 588 x 910 x 1009 mm - 23.1 x 35.8 x 39.7 in.

Weight (without water tank and blade) approx. 86 kg - 189.6 lbs.

Sound power level after DIN ISO 6393

No load = 104 dB(A)

Full load = 114 dB(A)

Sound pressure level after DIN ISO 6393

No load =88 dB(A)

Full load =98 dB(A)

Vibration ISO 5349 VDMA 03/2006 a = 4,5 m/s²

Information: Unconditional observe the owner’s manual of the engine manufacturer,

which is added!

Page 9

FS175

Translation of the original operating instruction and spare parts list

- 9-

5007287-00

BA-E

®

1.3 Shipment and provided accessory

• Floor saw FS175 without blade

• Wrench SW 17, SW 30 and SW 32

• Operating instruction and spare parts list floor saw

• Operating instruction engine

For the item number of accessories, please refer to the current catalogue of GÖLZ®

If accessories are used which do not correspond to GÖLZ® specifications, no liability is assumed for any

damage resulting hereof.

For details regarding the selection of the right GÖLZ® diamond blades, please refer to the current GÖLZ

®

catalogue for diamond tools.

1.4 Main parts

The base frame (1) is the basis for the floor saw. All other components are built on the base frame.

The floor saw FS 175 is equipped with a petrol engine of Honda (2). For any other information, please refer

to the attached operating manual of the engine manufacturer.

The height adjustable push bar (3) allows a non-fatiguing working.

In order to allow dust formation during cutting respectively cooling of the cutter blade, the floor saw is

equipped with a pluggable water tank (4).There is also the possibility to cool directly by means of the water

supply network respectively to bind the dust.

1. Frame

2. Engine

3. Push bow

4. Water tank 30l

5. Blade guard

6. Cutting depth indicator

7. Poly-V belt guard

8. Pointer unit

9. Hand wheel

4

1

3

9

5

8

7

2

6

Page 10

FS175

Translation of the original operating instruction and spare parts list

- 10-

5007287-00

BA-E

®

The cutting disc guard (5) provides the operator and the persons in his working area with optimum protection

during the cutting process.

By means of the convenient cutting depth setting (6), the operator can read, at any time, the cutting depth.

The rib drive is protected by a protective hood (7). Thus, the risk of injury is reduced by the rib drive.

Furthermore, the rib drive is also protected from impurity during the cutting process.

The route indicator (8) allows precise cuts.

Thanks to the direction indicator the operator can monitor and respect the cutting direction.

Der Aushub des Sägeblattes erfolgt beim FS175 über ein Handrad (9) welches mit einer Trapezspindel

verbunden ist.

The digging of the blade is using by a hand wheel (9) which is connected with a trapezoidal spindle.

1.5 Safety devices

Danger: During cutting or displacing the machine, all safety devices shown below must

be mounted!

Blade guard

Poly-V belt guard

Page 11

FS175

Translation of the original operating instruction and spare parts list

- 11-

5007287-00

BA-E

®

Note / Important: Contains important information which stands out from the other text!

2. Basic safety instructions

In this manual the following terms and symbols are used for particular important information:

Important text passages are highlighted in italics or bold or can be found in a grey highlighted text field.

2.1 Intended use

The machine has been built in accordance with state-of-the-art standards and the recognized safety rules.

Nevertheless, its use may constitute a risk to life and limb of the user or of third parties, or cause damage to

the machine and to other material property.

The machine must only be used in technical perfect condition in accordance with its designated use and the

instructions set out in the operating manual, and only by safety-conscious persons who are fully aware of the

risks involved in operating the machine. Any functional disorders, especially those affecting the safety of the

machine, should therefore be rectified immediately!

The machine is designed exclusively for cutting in concrete, reinforced concrete, natural stone, cast stone

and brickwork. Using the machine for purposes other than mentioned above (such as cutting in wood and so

on) is considered contrary to its designated use. The GÖLZ® GmbH cannot be held liable for any damage

resulting from such use. The risk of such misuse lies entirely with the user.

Only use gear drives and motors, which are provided by GÖLZ® GmbH. Also attend those operating

manuals.

Operating the machine within the limits of its designated use also involves observing the instructions set out

in the operating manual and complying with the inspection and maintenance directives

2.2 Operating range

Do not modify, add components to or retrofit the unit in a way which could affect its safety and do not use

non-official accessories! This is not allowed without prior approval of GÖLZ® GmbH!

2.3 Organisational measures

This operating manual must always be at hand at the place of use of the machine and must be accessible to

the person operating the machine!

In addition to this operating manual, all other generally applicable legal and other mandatory regulations

relevant to accident prevention and environmental protection must be observed! Such obligations may also

comprise the handling of hazardous materials, provisioning and/ or wearing of personal protective

equipment, or road traffic regulations.

Attention: Read and observe all the operating instructions which belong to this unit!

Attention: Contains instructions which must be strictly observed to prevent damage from

the unit and the operator!

Page 12

FS175

Translation of the original operating instruction and spare parts list

- 12-

5007287-00

BA-E

®

This operating manual must be supplemented by instructions covering the duties involved in supervising and

notifying special organizational features, such as job organization, work flows or the person entrusted with

the work. Person entrusted with work on the machine must have read the operating manual prior to taking up

work. This applies especially to persons working only occasionally on the machine, e.g. during set-up or

maintenance activities.

Check - at least from time to time - whether the personnel is carrying out the work in compliance with the

operating manual and paying attention to risks and safety-relevant factors.

For reasons of safety, long hair must be tied back or otherwise secured, garments must be close-fitting and

no jewellery - including rings - may be worn.

Severe injury may result from being caught by moving parts of the machine. Personal protective equipment

must be used wherever required by the circumstances or by law (e.g. safety glasses, ear protectors, safety

boots, suitable safety clothing). Observe the regulations for prevention of accidents! Observe all safety

precautions and warnings attached to the machine and always keep them in good and perfectly legible

condition.

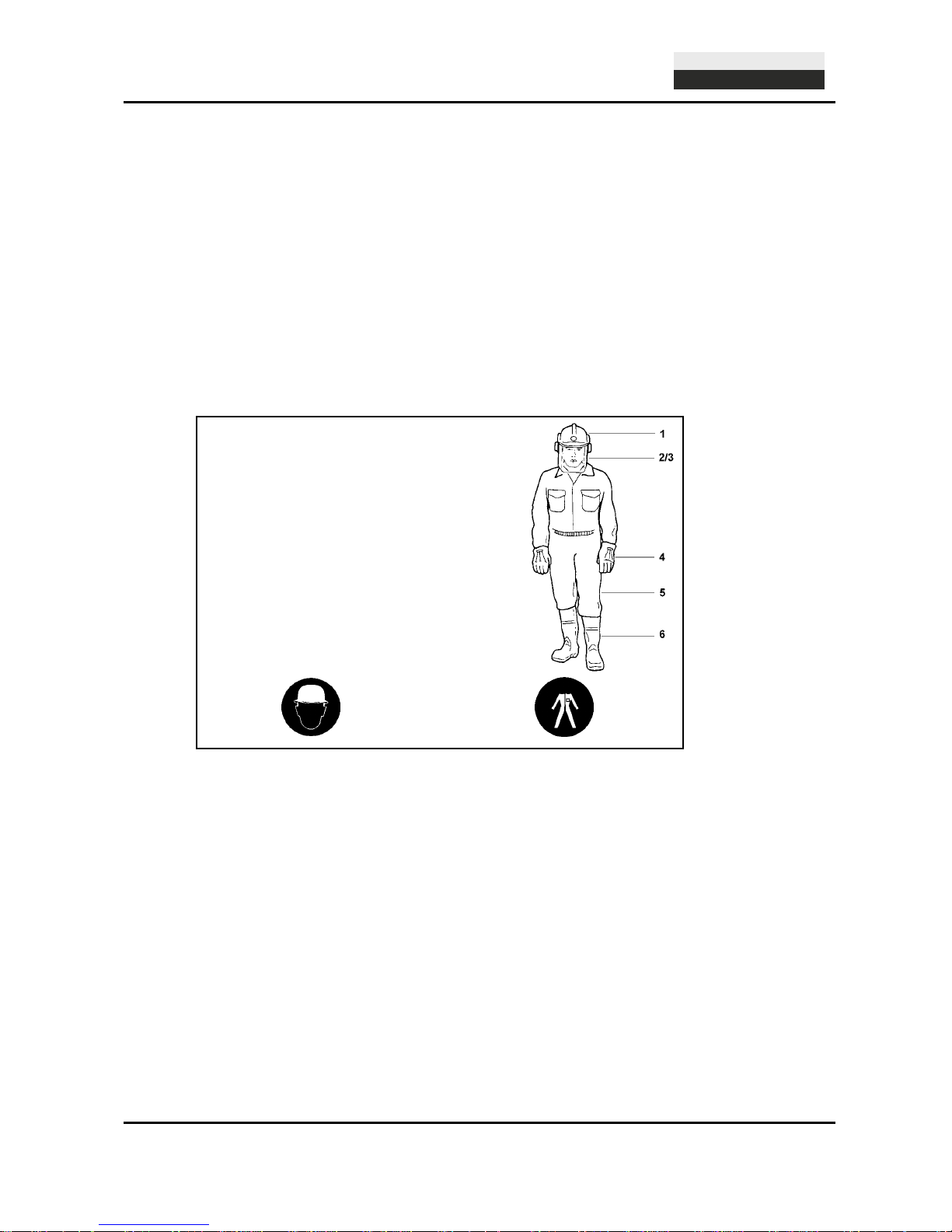

The personal protection equipment should consist of the following parts:

In case event of safety-relevant modifications or changes in the behaviour of the machine, stop the machine

immediately and report the malfunction to the competent authority/ person. Do not remove or make

inoperative any safety devices the machine is equipped with.

Never make any modifications, additions or conversions which might affect safety without GÖLZ® GmbH

prior approval! This also applies to the installation and adjustment of safety devices as well as to welding and

cutting work on supporting structures.

Damaged or worn parts of the product must be replaced immediately. Use genuine spare parts only.

All spare parts and tools must comply with the technical requirements specified by the manufacturer/

distributor. Adhere to the legally prescribed preventive maintenance and inspection intervals or those

specified in this operating manual!

Hydraulic hose pipes must be changed within the specified or appropriate intervals, even if no safetyrelevant defects are visible.

All maintenance and repair activities must be performed by qualified personnel using suitable tools and other

suitable workshop equipment. Observe the fire alarm and fire fighting measures. The personnel must be

made familiar with the location and handling of fire extinguishers!

1) Helmet with protection of the ears

2) Visior or safety glasses

3) Dust mask

4) Protective gloves

5) Safety clothes

6) Safety boots

Page 13

FS175

Translation of the original operating instruction and spare parts list

- 13-

5007287-00

BA-E

®

Important: Wet cutting is to be accomplished while working! This prevents the appearance of particulate matter and increases the life-time of the diamond tool!

2.4 Selection and qualification of person

Only permitted personnel is allowed to work on and with the machine! The legal minimum age is to be

observed!

Only assign trained and instructed personnel! Clearly define the responsibilites of the personnel with regard

to operating, setting-up, maintaining and repairing the machine! The GÖLZ® GmbH can assist you in training

your personnel.

Make sure that only instructed and competent personnel works on the machine. Define the responsibility of

the machine operator, also in terms of traffic regulations and enable him to refuse instructions of third parties

which breach safety regulations.

Personnel that is to be trained or to be instructed or that is serving a general training is only to be permitted

to operate the machine under the supervision of an experienced person.

To operate the machine you must be rested, in good physical condition and mental health. If you have any

condition that might be aggravated by strenuous work, check with your doctor before operating with the

machine. Do not operate the machine if you are under the influence of any substance (drugs, alcohol) which

might impair vision, dexterity or judgment.

Works on electrical, pneumatic, combustion and hydraulic fittings and equipment are only to be carried out

by qualified personnel or instructed people being directed and supervised by qualified personnel in

compliance with the respective rules!

2.5 Safety instructions governing specific operational phases

Before work

Avoid any operational mode that might be prejudicial to safety!

Before beginning work, familiarize yourself with the surroundings and circumstances of the site, such as

obstacles in the working and travelling area, the soil bearing capacity and any barriers separating the

construction site from public roads.

Take the necessary precautions to ensure that the machine is used only when in a safe and reliable state.

Operate the machine only if all protective and safety-oriented devices, such as removable safety devices,

emergency shut-off equipment, sound-proofing elements and exhausters, are in place and fully functional.

Regard all safety specifications!

Check the machine at least once per working shift fo

r obvious damage and defects. Report any changes

(incl. changes in the machine’s working behaviour) to the competent organization/ person immediately. If

necessary, stop the machine immediately and lock it. Have any defects rectified immediately. At any time,

ensure the operator has sufficient view to his working area, in order to have intervention to the working

process.

Wet cutting is to be accomplished while working. This prevents the appearance of particulate matter and

increases the life-time of the diamond tool. During start-up and shut-down procedures always watch the

indicators in accordance with the operating instructions!

Before starting or setting the machine in motion, make sure that nobody is at risk. Keep children and

unauthorized persons away from the work area.

Noise protection equipment on the unit must be in protective position during operation. Wear the required

individual ear protection!

Always keep at a distance from the edges of building pits and slopes. Avoid any operation that might be a

risk to machine stability! Keep the work area clean. Cluttered areas and benches invite injuries! Do not

operate when you are tired! Watch what you are doing! Risk of stumbling! Cables and hoses must complete

rolling up. After assembly do not leave any tools, a wrench for example, on the unit.

Check to see that the tools are removed from the machine before operating! Damaged blades have to be

changed immediately. Use only recommended blades from the GÖLZ® GmbH.

Control the working area for water-, gas- and electrical lines!

Page 14

FS175

Translation of the original operating instruction and spare parts list

- 14-

5007287-00

BA-E

®

During work

Make sure, that the machine is well fastened before and while cutting!

Never touch rotating parts like blade shaft or blade!

After work

Before leaving the machine always secure it against unauthorized use!

2.6 Special work related to the maintenance and repair of the machine

Observe the adjustment, maintenance and inspection activities and intervals set out in the operating

instructions, including information on the replacement of parts and equipment! These activities may be

executed by skilled personnel only.

Brief operating personnel before beginning special operations or maintenance work, and appoint a person to

supervise the activities.

In any work concerning the operation, conversion or adjustment of the machine and it’s safety-oriented

devices or any work related to maintenance, inspection and repair, always observe the start-up and shutdown procedures described in the operating instructions and the information on maintenance work. Ensure

that the maintenance area is adequately secured.

Carry out maintenance and repair work only of the machine is positioned on stable and level ground and has

been secured against inadvertent movement and buckling. If the machine is completely shut down for

maintenance and repair work, it must be secured against inadvertent starting.

To avoid the risk of accidents, individual parts and large assemblies being moved for replacement purposes

should be carefully attached to lifting tackle and secured. Use only suitable and technically perfect lifting gear

and suspension systems with adequate lifting capacity. Never work or stand under suspended loads.

The fastening of loads and the instructing of crane operators should be entrusted to experienced persons

only. The marshaller giving the instructions must be within sight or sound of the operator.

For carrying out overhead assembly work always use specially designed or otherwise safety-oriented ladders

and working platforms. Never use machine parts as a climbing aid. Wear safety harness when carrying out

maintenance work at greater heights.

Clean the machine, especially connections and threaded unions, of any traces of oil, fuel or preservatives

before carrying out maintenance / repair. Never use aggressive detergents. Use lint-free cleaning rags.

Before cleaning the machine with water, steam jet or detergents, cover or tape up all openings which -for

safety and functional reasons - must be protected against water, steam or detergent penetration.

Do not clean the machine with a high-pressure cleaner. The hard water jet can put damage to parts of the

machine. After cleaning, remove all covers and tapes applied for that purpose.

After cleaning check the machine for loose connections, chafe marks and damage! Have identified defects

repaired immediately!

Always tighten any screwed connections that have been loosened during maintenance and repair.

Any safety devices removed for set-up, maintenance or repair purposes must be refitted and checked

immediately upon completion of the maintenance and repair work. Ensure that all consumables and replaced

parts are disposed of safely and with minimum environmental impact.

2.7 Information about special risks with electrical energy

Observe the relevant national regulations or standards. Electrical connections must always be kept free from

dirt and moisture.

Use only original fuses with the specified rating! Switch off the machine immediately, if trouble occurs in the

electric power supply!

If your machine comes into contact with a live wire:

• warn others against approaching and touching the machine

• have the live wire de-energized

Page 15

FS175

Translation of the original operating instruction and spare parts list

- 15-

5007287-00

BA-E

®

When working with the machine, maintain a safe distance from overhead electric lines. If work is to be

carried out close to overhead lines, the working equipment must be kept well away from them. Caution,

danger to life!

• Check out the prescribed safety distances.

• Work on the electrical system or equipment may only be carried out by a skilled electrician himself or by

specially instructed personnel under the control and supervision of such electrician and in accordance

with the applicable engineering rules.

• If provided for in the regulations, the power supply to parts of machines and plants, on which inspection,

maintenance and repair work is to be carried out must be cut off.

• Before starting work, check the de-energized parts for the presence of power and ground or short-circuit

them in addition to insulating adjacent live parts and elements.

The electrical equipment of machines is to be inspected and checked at regular intervals. Defects such as

loose connections or scorched cables must be rectified immediately.

Necessary work on live parts and elements must be carried out only in the presence of a second person who

can cut off the power supply in case of danger by actuating the emergency shut-off or main power switch.

Secure the working area with a red-and white safety chain and a warning sign. Use insulated tools only.

If mobile electrical equipment, connecting cables and/ or extension/ appliance cords with plug connectors are

used, ensure that such equipment, cables and cords are checked for correct function at least once every six

months by a qualified electrician or - if suitable testing equipment is available - by a properly instructed

person.

Protective installations with fault-current protection units used in non-stationary equipment must be checked

for correct operation at least once a month by a properly instructed person.

Fault-current and fault-voltage protection units must be checked for correct operation by actuating the testing

facility:

• once on every working day in the case of mobile equipment,

• at least once every six months in the case of stationary equipment.

2.8 Gas, dust, steam, smoke

Operate combustion engines only in well-ventilated rooms! Before starting the unit in closed rooms, make

sure that the room is sufficiently ventilated and use the exhaust gas hose!

Welding, burning and grinding operations on the machine are only to be carried out if this is explicitly

authorized (there is the danger of fire and explosion)!

Before welding, burning and grinding operations clean the machine and its surrounding area from dust and

flammable substances and care for sufficient ventilation (danger of explosion)!

When working in confined spaces observe any existing national regulations!

2.9 Noise

During operation sound protection devices on the machine must be in safe position. Wear the prescribed

personal ear protection! (UVV 29 § 10, Article 29 of the Accident Prevention regulations).

The use of noise emitting machines may be restricted to certain times by national or local regulations.

2.10 Illumination

The machine is designed for use in daylight! The machine operator / owner must ensure sufficient workplace

lighting for non-illuminated work sites!

Page 16

FS175

Translation of the original operating instruction and spare parts list

- 16-

5007287-00

BA-E

®

Attention: Check that all parts of the machine are

well fastened before transporting. Before

transporting the blade must be removed!

For loading, only use lifting gear and tackle of

sufficient capacity. Lift the machine using the

lifting eye.

2.11 Oils, greases and other chemical substances

When handling hydraulic fluids, lubricants, greases or preservatives (referred to hereinafter as fuels and

lubricants), the safety regulations which apply to the respective machine are to be observed!

Avoid long contact of the fuels and lubricants with your skin! Careful cleaning of the skin from adhering fuels

and lubricants is necessary.

Be careful when handling hot consumables (risk of burning or scalding) particularly at liquid temperatures

above 60°C, avoid any skin contact with these liquids!

If you get fuels or lubricants in your eyes, rinse them immediately and carefully with potable water. Then

consult a doctor.

Remove flown out fuels and lubricants immediately! Therefore use a binder.

Fuels and lubricants must not seep into the soil or into the public sewage system! Fuels and lubricants which

can no longer be used are to be collected, properly stored and to be properly disposed of.

The respective regulations and laws for handling fuels and lubricants which are valid in the country of use

are to be observed and adhered to. This also applies to the disposal of such fuels and lubricants. To inform

yourself turn to the responsible authorities.

2.12 Transport

Use only suitable means of transport and lifting gear of sufficient capacity when loading or transporting the

machine! Appoint an experienced instructor for the lifting operation!

Always observe the instructions given in the operating manual when lifting the machine (use only the

prescribed lifting eyes for attaching the lifting gear)!

Use only suitable transport vehicles with sufficient load capacity! Secure the load carefully. Use suitable

fastening points for securing!

Before loading the machine or parts of it, secure the machine against inadvertent movement! Attach a

suitable warning sign!

The blade must be removed for transport. Even in case of a minor change of location, the engine must be

stopped!

Before using the machine again, make sure that such protection material or devices are properly removed!

Parts which had to be removed for transporting of the machine must be refitted and secured carefully before

the machine is used again!

Before setting the machine in motion always check that all accessories are safely stowed.

The recommissioning procedure must be strictly in accordance with the operating instruction! Observe the

instructions given in the operating instruction when reassembling and operating the machine.

During cuts displace the machine only with non-rotating blade (not running engine)!

Lifting eye

Page 17

FS175

Translation of the original operating instruction and spare parts list

- 17-

5007287-00

BA-E

®

Injury hazard: Down coming parts!

Attention: Store blades just standing or hanging!

2.13 Store

Store the machine in a dry, high or locked place, out of the reach of children or unauthorized persons. Clean

and preserve the machine with corrosion preventive if storing over a longer time like winter time!

Note: Store dismounted blades so, that the blades not exposed to mechanical damages and harmful

environmental conditions (UV radiation, temperature, humidity, etc.).

Page 18

FS175

Translation of the original operating instruction and spare parts list

- 18-

5007287-00

BA-E

®

Attention: Read and observe all operating instructions which are relevant for the

machine (floor saw, engine ...)!

Attention: Before starting up, check the engine oil level and fill up the fuel!

3. Preparing for Operation

3.1 Export checking

Remove the transport packaging and dispose of it in an environmentally responsible way. Check the

machine for completeness and intactness. For the scope of delivery, see "Scope of delivery and provided

accessory"

Secure the machine against accidental start-up and rolling away.

The machine is supplied with engine oil but without fuel.

3.2 Installation

Place the machine on an even, firm and stable ground. Have the working area well lightened. Keep the

working area clean, cluttered areas invite injuries. Operating the machine on enclosed premises, make sure

that there is sufficient ventilation. Observe the regulations in force at the respective site.

3.3 Blade

The cutting discs must meet the specification of GÖLZ® GmbH. Use the corresponding cutting discs

depending on the material to be processed, the machining process and the type of work to be performed!

When not used properly, no liability is assumed for damages resulting therefrom.

All used cutting discs must be designed, regarding their maximum admissible cutting speed, for the max.

drive speed of the machine. For machines with variable drive speed, use cutting discs which, regarding their

maximum admissible cutting speed, correspond to the respective maximum drive speed of the machine.

Never use faulty or damaged blades. Check the correct rotation of the blade to the spindle shaft!

Check the blade is well fastened before beginning to operate. Defective cutting discs must be replaced

immediately!

Cut off the engine or disconnect the power supply before mounting or changing blade. After mounting, do not

leave any tools, such as open-end spanners, on the machine.

Use only blades suitable to the blade acceptance (arbor hole, flanges).

Note: If the oil level is too low, fill up the engine according to the operating manual of the

engine manufacturer! Fill up the fuel for the engine according to the operating manual of

the engine manufacturer!

Danger: Faulty or damaged blades can cause injuries to the operator and other persons!

Page 19

FS175

Translation of the original operating instruction and spare parts list

- 19-

5007287-00

BA-E

®

Information: Wrong rotation of the blade will result in more wear of the blade!

Information: Clean all fastening devices of the blade (flanges, thread of the blade shaft,

screws and nuts) before mounting the blade!

Important: The operation is to be carried out in wet cutting, in order to prevent the

occurrence of harmful particulate matter and to increase the lifetime of the cutting tool.

3.3.1 Mounting the blade

Blade mounting:

• Mount the blade to the manufacturer’s odds (Observe the min. flange-Ø; use only original screws or

nuts).

• Use only blade diameters which are allowed by the manufacturer.

Remove the cutting disc guard and unscrew the outer clamping

flange SW 32, left-hand thread.

All clamping surfaces must be clean and undamaged.

Fit the cutting disc. Pay attention to the correct direction of

rotation!

Observe the direction of rotation arrows on the cutting disc and

the cutting disc guard.

Mount the outer clamping flange again, fit the cutting disc

guard and secure it with the screw.

3.4 Water supply

Danger: Wrong rotation of the blade may result in segments cracking off and can cause

injuries to the operator or other persons!

SW32

Danger: It is not allowed to operate the machine without cutting disc blade guard!

Attention: Tools which are only designed for wet cutting technique, must never be used

without water supply! Always make sure that there is enough water supply!

Page 20

FS175

Translation of the original operating instruction and spare parts list

- 20-

5007287-00

BA-E

®

The supply of water at the cut ensures that the tool is cooled, the dust of the material is bound and the cut is

rinsed out.

Cutting with wet-cutting blades:

Connect the water supply to the GEKA-coupler (1) of the machine. Check the ball valve (2) is closed (ball

valve lever in 90°-position to the water flow).

For cutting open the ball valve (2) (ball valve lever in the water flow position).

Cutting with dry-cutting blades:

Fill the water tank with clean water. Connect the GEKA-coupler of the water tank to the GEKA-coupler of the

machine. Check the ball valve is closed (ball valve lever in 90°-position to the water flow).

For cutting open the ball valve (ball valve lever in the water flow position) and the valve of the water tank (3).

3

2

Attention: Use only water for cutting which is free from coarse impurities! Do not use salt

water!

Danger: Do not use the attached water tank when cutting with wet cutting diamond

blades. The segments may crack off and cause injuries to the operator or bystanders!

Page 21

FS175

Translation of the original operating instruction and spare parts list

- 21-

5007287-00

BA-E

®

Information: Unconditional observe the owner’s manual of the engine manufacturer!

Danger: Never touch rotating parts like blade shaft or blade while operating!

4. Operation

4.1 Before starting the machine

Check the machine for safe operating condition.

• All components must be properly mounted.

• The functions of the combustion engine must function properly.

• Do not make any changes on operating elements and safety devices.

The machine may only be operated in safe operating condition.

Lock the push bars so that the machine can be operated in a favorable posture.

If work is carried out where harmful or explosive substances, such as dust, sludge occur, observe the

applicable national regulations.

If there is a risk that, during the cutting process, material particles are accelerated outwards, wear safety

goggles.

When travelling on public roads, ways and places always observe the valid traffic regulations and, if

necessary, make sure beforehand that the machine is in a condition compatible with these regulations.

After operating secure the machine against unintentional moving.

Appropriate to the application of the machine it could be necessary to wear further protective equipment.

The working area is reserved only for the operator. Keep unauthorized persons out of the working area.

Make sure the operator always has well sight to the working area. He always has to intervene in the working

process. Never operate the machine without mounted safety devices.

Danger: Demolition parts can cause injuries to the operator while cutting!

Danger: Down coming parts at the building site can cause injuries to the operator!

Danger: The sound pressure may exceed 85 dB(A)!

Page 22

FS175

Translation of the original operating instruction and spare parts list

- 22-

5007287-00

BA-E

®

Danger: As soon as the combustion engine is started, the cutting shaft, respectively the

cutting disc, starts rotating too!

Careless handling can lead to life-threatening injuries caused by the rotating cutting disc. Only operate the

machine with fully mounted blade guard.

Nobody is allowed to remain in the working area nor in the area where falling segments of the cutting disc

can be accelerated outwards (minimum safety distance 10m). If this safety distance cannot be respected, the

danger zone must be closed or be marked by warning signs.

Care for the whereabouts of cooling and rinsing water as well as of cutting sludge.

Cutting sludge must be collected, filtered and disposed of.

4.2 Starting the machine

Completely rise the machine (blade may have no ground contact). Start the engine as described in the

engines manual.

4.3 Cutting operation

Connect the water supply and slowly lower the machine with the hand wheel (1) till the blade has ground

contact. Putting down the machine to the desired cutting depth which is displaying on the cutting depth

indicator (2).

Before you lower the machine by means of the hand wheel (1), the mini ball valve is to be opened. Lower the

machine to such extent that you reach the desired cutting depth (2).

Pull then the indexing plunger (3) on the control panel, so that it snaps into the catch disk in order to fix the

desired cutting depth.

Work with even feed pressure. Too high feed pressure leads to overload of the engine, there is a risk that the

machine raises. Too low feed pressure polishes the segments and they become blunt.

During cuts displace the machine only with non-rotating blade (not running engine)!

Danger: Operating with too high feed the machine might rise out of cut! In emergency

situations cut off the engine as described in the engines manual!

1

2 3

Page 23

FS175

Translation of the original operating instruction and spare parts list

- 23-

5007287-00

BA-E

®

Note: Do not lower the cutting disc forcibly, this could lead to damage to the cutting disc

and to the machine.

In order to produce a clean cutting line, do not carry out the entire cutting depth in one

cutting process.

4.4 Stop cutting operation

After cutting completely raise the machine and cut off the engine as described in the engines manual.

4.5 Changing the blade

The blade must be changed if:

• the diamond segments of the blade are completely worn

• the material to be cut changes

• the blade turns irregularly

• the diamond segments are damaged or broken

For fitting a new blade, proceed as described in the chapter "Mounting the blade".

Attention: In order to avoid damage to the machine and the cutting disc, please observe

the maximum cutting depth!

Danger: Some parts of the combustion engine become very hot during operation, risk of

burns!

Page 24

FS175

Translation of the original operating instruction and spare parts list

- 24-

5007287-00

BA-E

®

Attention: When handling oil, grease and other chemical substances, observe the

product-related safety regulations!

Information: Clean the machine after every operation. Observe local environmental regulations!

5. Maintenance

5.1 General

For maintenance jobs the machine has to be shut down. For maintenance jobs which must be done while the

machine is running, the blade has to be dismounted before beginning the job.

In accordance to the given cycles, the subsequently described maintenance work has to be enforced. Also

the wearing part subject to no certain maintenance-intervals has to be checked regularly for wear and to

adjust if necessary or to exchange. With I.C. engines, the maintenance work has to be enforced in

accordance with the separate maintenance-instruction of the engine manufacturer.

Before

starting

work

After

work

Weekly Yearly

In the event of

a malfunction

If

damaged

Complete machine

Visual inspection

(condition, absence of

leaks)

X X X

clean X

Flange and blade holder clean X

Poly-V belt

check X X X X

replace X

Water nozzle and

feeding hoses

clean X

Tools

check X X

clean X

replace X

5.2 Lubricating chart

Grease the blade shaft bearings after 20 working hours with heat resistance fat. From time to time clean the

foot pedal, pointer unit and wheels and grease them with some drops of oil.

5.3 Poly-V belt

Unscrew the screws that fix the motor (4x M10x30, DIN EN ISO 4017) and the screw that fixes the eccentric.

Move the motor forwards by turning the eccentric counter clockwise. In this position the poly-V belt can be

replaced easily.

Stress the poly-V belt by turning eccentric clockwise. To fix the motor, screw down the M10x30 screws.

Information: Unconditional observe the owner’s manual of the engine manufacturer,

which is added!

Page 25

FS175

Translation of the original operating instruction and spare parts list

- 25-

5007287-00

BA-E

®

5.4 Machine

Clean the machine after each duty and check all functions. Replace all necessary parts that are out of order

or worn out immediately.

5.5 Blade

When ending a cutting job - check blade as follows:

Check segments for cracks or break-outs, Cracks between segment and core barrel, Deformation

and out of round wear.

In case of doubt, send the blade for repair.

Page 26

FS175

Translation of the original operating instruction and spare parts list

- 26-

5007287-00

BA-E

®

6. Taper bushes installation instructions

6.1 To assemble

Clean and de-grease the bore and taper surfaces of the bush and the tapered bore of the pulley. Insert the

bush in the pulley hub and line up the holes (half thread holes must line up with half straight holes).

Lightly oil the grub screws or the cap screws and screw them in, do not tighten yet.

Clean and de-grease the shaft. Fit pulley with taper bush on shaft and locate in desired position.

When using a key it should first be fitted in the shaft Keyway. There should be a top clearance between the

key and the keyway in the bore.

Using a hexagon socket wrench gradually tighten the grub/cap screws in accordance with the torques as

listed in the schedule of screw tightening torques. When the drive has been operating under load for a short

period (half to one hour) check and ensure that the screws remain at the appropriate tightening torque. In

order to eliminate the ingress of dirt fill all empty holes with grease.

6.2 Removal

Slacken all screws. Depending on the size of the bush remove one or two. After oiling point and thread of

grub screws or under head and thread of cap screws, insert them into the jacking off holie(s) in bush.

Tighten screw (s) uniformly and alter neatly until the bush is loose in the hub and pulley is free on the shaft.

Remove pulley bush assembly from shaft.

Bush Screw tightening torques (Nm)

Screw

Quantity Size

1008

1108

5.6 2

1/4“

BSW

1310

1315

20 2

3/8“

BSW

1210

1215

20 2

3/8“

BSW

1610

1615

20 2

3/8“

BSW

2012 31 2

7/16“

BSW

2517 48 2

1/2“

BSW

3020

3030

90 2

5/8“

BSW

3535 112 3

1/2“

BSW

4040 170 3

5/8“

BSW

4545 192 3

3/4“

BSW

5050 271 3

7/8“

BSW

Page 27

FS175

Translation of the original operating instruction and spare parts list

- 27-

5007287-00

BA-E

®

7. Troubleshooting

Problem Cause Remedy

Engine

Engine does not start!

Fuel tank empty Fill up

Dirty fuel lines Clean

Bad engine performance!

Dirty air cleaner Clean

Lowering

Machine lowers

without

actuating the foot pedal!

Faulty gas pressure spring Replace

Machine does not fully lower!

Undercarriage or gas pressure

spring tight

Check undercarriage and gas

pressure spring

Cutting

Machine rises

out of cut!

Dull diamond blade

Sharpen or use softer diamond

blade

Faulty gas pressure spring Replace

Feed too high Reduce feed

Non circular abrasion

of the diamond blade!

Damaged centring of the blade

shaft

Replace blade shaft

Warped blade shaft Replace

Loose or damaged blade shaft

bearings

Tighten or replace

Diamond blade jams

in the cut!

No free cut because of sidewards

wear-out of segments

Replace diamond blade

Damaged diamond blade core Replace diamond blade

Abnormal wear-out of

segments!

Insufficient water flow Check hoses for fracture free laying

Wrong type of diamond blade Choose different diamond blade

Feed too high Reduce feed

Cutting in loose underground Reduce cutting depth

Abnormal blade wear out at

sides of core!

Insufficient water flow Check hoses for fracture free laying

Cutting in loose underground Reduce cutting depth

Bad cutting performance!

Slippy V-belts Adjust

Blunt diamond blade

Sharpen or use softer diamond

blade

Attention: In the event of changes in the behaviour of the machine during operation, stop

the machine immediately and report the malfunction to the competent authority/person!

Note: For more fault finding refer the operating instruction of the engine

manufacturer which is enclosed!

Page 28

FS175

Translation of the original operating instruction and spare parts list

- 28-

5007287-00

BA-E

®

Danger: Mounting or dismounting assembly groups can give rise to risks which are not

mentioned in the spare parts list!

Danger: Non-observance of this instruction can result in injury which, in the worst case,

can result in death!

Note: In order to avoid wrong deliveries the information the ordering information should

be checked for accuracy and completeness before sending it! Completely indicate the

delivery address!

8. Spare parts list

8.1 Using the spare parts list

The spare parts list is not a mounting or dismounting instruction. The only purpose of the spare parts list is to

easily and quickly find spare parts which can be ordered with distribution agencies, see chapter 8.1.3

"Distribution agencies".

8.1.1 Safety regulation

Using this spare parts list for mounting or dismounting purposes is not permitted. For assembly and

disassembly work exclusively the corresponding descriptions in this operating manual are to be followed.

8.1.2 Ordering information

Page 29

FS175

Translation of the original operating instruction and spare parts list

- 29-

5007287-00

BA-E

®

So bekommen Sie schnell und

richtig Ihr Ersatzteil

Always indicate

Pour obtenir rapidement les

pièces de rechange indiquer

• Maschinentyp gemäß

Typenschild

• Baujahr gemäß Typenschild

• Artikelnummer gemäß

Ersatzteilliste

• Maschinennummer gemäß

Typenschild

• machine type according to

nameplate

• year of manufacture

according to nameplate

• order number according to

spare part list

• serial number according to

nameplate

• type de la machine conforme de

plaque d'identification

• Année de construction selon

plaque d'identification

• Numéro de l'article selon la liste

des pièces de rechange

• numéro de la machine conforme

de plaque d'identification

Für Bestellungen, Fragen und In-

formationen wenden Sie sich bitte

an die zuständigen Stellen.

For orders, questions and

information, please contact the

competent departments.

Pour les commandes, questions et

informations, veuillez-vous

adresser aux points de ventes

correspondants.

8.1.3 Distribution agencies

Deutschland – Germany - Allemagne

GÖLZ® GmbH

Dommersbach 51

DE-53940 Hellenthal

Tel: +49 (0)2482-12 200

Fax: +49 (0)2482-12 222

E-Mail: info@goelz.de / Internet: www.goelz.de

Österreich - Austria - Autriche

GÖLZ® Ges.m.b.H

Samstraße 52

A-5020 Salzburg

Tel: +43 (0) 662 - 43 81 75

Fax: +43 (0) 662 - 43 07 34

E-Mail: info@goelz.at / Internet: www.goelz.at

Frankreich - France - France

GÖLZ® S.A.S.

1, rue de la Mairie

F-67370 Berstett

Tel: +33 (0)3.88.59.43.00

Fax: +33 (0)3.88.59.47.77

E-Mail: info@golz.fr / Internet: www.golz.fr

Großbritannien - Great Britain - Grande-Bretagne

GÖLZ® (UK) Ltd.

Unit A5, Springhead, Enterprise Park

Northfleet

Kent DA11 8HB

Tel: +44 1 474321679

Fax: +44 1 474321477

E-Mail: info@goelz.co.uk / Internet: www.goelz.co.uk

Benelux

GÖLZ® Benelux

Eupener Straße 61

BE-4731 Raeren-Eynatten

Tel: +49 (0)2482-12 200

Fax: +49 (0)2482-12 222

E-Mail: benelux@goelz.de / Internet: www.goelz-online.com

Australien - Australia - Australie

GOLZ® Pty Ltd.

44 Stanley Street

Peakhurst, NSW 2210

Tel: +61 (0) 2 9534 5599

Fax: +61 (0) 2 9534 5588

E-mail: info@golz.com.au / Internet: www.golz.com.au

USA

GOLZ® L.L.C.

5860 East Osage Ridge Lane

Columbia MO 65203-6018

Tel: +1 573 474 4961

E-Mail: info@golzusa.com / Internet: www.goelz-online.com

Page 30

FS175

Translation of the original operating instruction and spare parts list

- 30-

5007287-00

BA-E

®

8.2 Wearing parts

Wearing parts for construction devices mentioned in the operating manual such as drilling and

sawing machines.

Wearing parts are the parts subject to operation-related (natural) wear during proper use of the device. The

wearing time cannot be uniformly defined, and differs according to the intensity of use. The wearing parts

must be adjusted, maintained and, if necessary, replaced for the specific device in accordance with the

manufacturer’s operating manual. Operation-related wear is not a reason for defect claims.

Wearing parts of this machine are grey marked in the spare parts list.

• Feed and drive elements such as toothed racks, gearwheels, pinions, spindles, spindle nuts, spindle

bearings, cables, chains, sprockets, belts

• Seals, cables, hoses, packings, connectors, couplings and switches for pneumatic, hydraulic, water,

electrical and fuel systems

• Guide elements such as guide strips, guide bushes, guide rails, rollers, bearings, sliding

protection supports

• Clamping elements for quick-separating systems

• Flushing head seals

• Slide and roller bearings that do not run in an oil bath

• Shaft oil seals and sealing elements

• Friction and safety clutches, braking devices

• Carbon brushes, commutators / armatures

• Easy-release rings

• Control potentiometers and manual switching elements

• Securing elements such as plugs, anchors, screws and bolts

• Fuses and lamps

• Auxiliary and operating materials

• Bowden cables

• Discs

• Diaphragms

• Spark plugs, glow plugs

• Parts of the reversing starter such as the starting rope, starting pawl, starting roller and

starting spring

• Sealing brushes, rubber seals, splash protection cloths

• Filters of all kinds

• Drive rollers, deflection rollers and bandages

• Cable anti-twist elements

• Running and drive wheels

• Water pumps

• Cut-material transport rollers

• Drilling, parting and cutting tools

• Energy storage

Page 31

FS175

Translation of the original operating instruction and spare parts list

- 31-

5007287-00

BA-E

®

9. Exploded view and spare parts list

9.1 Undercarriage

Page 32

FS175

Translation of the original operating instruction and spare parts list

- 32-

5007287-00

BA-E

®

Pos

K.-Art.-

Nr.

Art.-Nr. Qty. Norm Info Bezeichnung Description Désignation

- 5007264

0282170 6100

1 Fahrwerk kpl.

Undercarriage

complete

Châssis complète

1 5007265

0282 175 6124

1 Fahrwerk Undercarriage Châssis

2 5007274

0282 175 6123

2

GSM-

2023-20

Gleitlager Slide bushing

Roulement

coulissant

3 5002427

0282 130 0017

2

Ø 125 x

44 x Ø 15

Rad Wheel Roue

4 5000344

0295 600 1043

2

DIN EN

ISO 7090

B 15 Scheibe Washer Rondelle

5 5000853

0282 250 0074

2

DIN EN

ISO 7040

M14 Sicherungsmutter lock nut Écrou de blocage

6 5007213

2821706103

2

Ø200-

Ø20x60

Hinterrad Back wheel Roue arrière

7 5000346

0285 300 0090

2

DIN EN

ISO 7090

B 21 Scheibe Washer Rondelle

8 5000317

0284 650 0008

2

DIN EN

ISO 1234

5 x 32 Splint split-pin goupille

9 5002471

0281 045 0073

2 Ø 20 Stopfen Stopple Bouchon

Page 33

FS175

Translation of the original operating instruction and spare parts list

- 33-

5007287-00

BA-E

®

9.2 Push bow

Page 34

FS175

Translation of the original operating instruction and spare parts list

- 34-

5007287-00

BA-E

®

Pos

K.-Art.-

Nr.

Art.-Nr. Qty. Norm Info Bezeichnung Description Désignation

1 5007273

0282 175 6102

2

Ø20/Ø23/

Ø30x16,5

Bundbuchse Bushing Douille

2 5007272

0282 175 6104

1 Achse Axle Arbre

3 5000346

0285 300 0090

4

DIN EN

ISO 7090

B 21 Scheibe Washer Rondelle

4 5000317

0284 650 0008

2

DIN EN

ISO 1234

5 x 32 Splint split-pin goupille

5 5007288

0282 175 6107

1 Spindel kpl. Shaft assy. Arbre complet

6 5007289

0282 175 6108

1

Spindelaufnahme

kpl.

Shaft support

assy.

Fixation de la

broche complet

7 5006071

0282 241 0107

1 Tr20x4 Spindelmutter Trapezoid nut

Écrou de filet

acmé

8 5006100

0285 300 0010

1 M6

Kegelschmiernippel

Grease fitting Graisseur

9 5004873

0295 002 0022

4

25,5 x 22;

2 x M8 I;

55° Shore

Maschinenfuss machine foot Machine à pied

10 5007052

0282 170 6105

4 GN352

Ø25 x 30 -

M6 I- 55°

Shore

Gummipuffer Bump rubber Patin

11 5000341

0282 250 0006

8

DIN EN

ISO 7090

B 8,4 Scheibe Washer Rondelle

12 5000833

0282 170 0061

8

DIN EN

ISO 4017

M 8 x 10 Schraube Screw Vis

13 5000340

0286 570 0069

5

DIN EN

ISO 7090

B 6,4 Scheibe Washer Rondelle

14 5000707

0282 170 0067

4

DIN EN

ISO 4017

M 6 x 10 Schraube Screw Vis

15 5007227

0282 170 6112

1

Aufnahme

Führungsstange

Receiving part

guiding rod

16 5005795

0282 241 0095

1 M10 x 16 Klemmhebel clamping lever Levier de serrage

17 5007292

0282 175 6110

1 Schubstange kpl. Push rod complete

Bielle Compilation

complet

18 5002174

0282 190 0346

2 Griffbezug Soft grip

Revêtement de

poignée

19 5007294

0282 175 6115

1

Schnitttiefenanzeiger

Cutting depth

indicator

Couper indicateur

de profondeur

20 5000362

0286 570 0043

2 DIN 127 A10 Federring Spring washer Rondelle élastique

21 5000731

0295 000 0187

4

DIN EN

ISO 4017

M 10 x 20 Schraube Screw Vis

22 5007297

0282 175 6114

1

DIN EN

10131

Zeiger pointer Pointer

23 5000708

0295 000 0370

1

DIN EN

ISO 4017

M 6 x 12 Schraube Screw Vis

24 5007363

0282 175 6121

1

GN6336.4

-SK-32M6-16

Sterngriffschraube Star knob screw

Vis de la molette

étoiles

25 5007298

0282 175 6116

1 Bremse Brake Freinage

26 5001284

0298 900 0010

2

DIN EN

ISO 7093

A 10,5 Scheibe Washer Rondelle

27 5000753

0295 080 0028

1

DIN EN

ISO 4017

M12 x 65 Schraube Screw Vis

28 5000858

0285 300 0015

1

DIN EN

ISO 7040

M 12 Mutter Nut Écrou

29 5000857

0286 570 0052

2

DIN EN

ISO 7040

M 10 Mutter Nut Écrou

30 5000342

0286 570 0047

2

DIN EN

ISO 7090

B 10,5 Scheibe Washer Rondelle

Page 35

FS175

Translation of the original operating instruction and spare parts list

- 35-

5007287-00

BA-E

®

Page 36

FS175

Translation of the original operating instruction and spare parts list

- 36-

5007287-00

BA-E

®

Pos

K.-Art.-

Nr.

Art.-Nr. Qty. Norm Info Bezeichnung Description Désignation

31 5000734

0295 000 0293

2

DIN EN

ISO 4017

M 10 x 35 Schraube Screw Vis

32 5007232

36100-ZH8-

W41

1

Motor-StopSchalter

motor-stop-switch

MoteurInterrupteur

d'arrêter

33 5007196

0282 175 6122

1

160 x 32 x

0,5

Typenschild Name plate

Plaque

signalétique

34 5007198

0282 170 6106

4

DIN EN

ISO 8746

Ø2 x 8 Kerbnagel Grooved pin Goupille cannelée

35 5000217

0295 899 0033

1 Pikto Aufkleber Sticker Autocollant

36 5002528

0295 899 0273

1

Aufkleber Sticker Autocollant

37 5007317

0295 000 2038

1 DIN 894 SW 17 Maulschlüssel wrench Clé

38 5002805

0295 000 2031

1 DIN 894 SW 30 Maulschlüssel Wrench Clé plate

39 5002804

0295 000 2044

1 DIN 894 SW 32 Maulschlüssel Wrench Clé plate

40 5001491

0295 230 0013

1 Federriegel Spring latch Verrous à ressort

41 5000403

0295 230 0032

1

DIN EN

ISO 8675

M 20 x 1,5 Mutter Nut Écrou

o.A. -

0282 130 0094

1

Verbinder für

Handausschalter

Connector for

hand circuit

breaker

Connecteur

marche/arrêt

Page 37

FS175

Translation of the original operating instruction and spare parts list

- 37-

5007287-00

BA-E

®

9.3 Shaft

Page 38

FS175

Translation of the original operating instruction and spare parts list

- 38-

5007287-00

BA-E

®

Pos

K.-Art.-

Nr.

Art.-Nr. Qty. Norm Info Bezeichnung Description Désignation

- 5007288

0282 175 6107

1 Spindel kpl. Shaft assy. Arbre complet

1 5003829

0282 240 0022

1

UCFL 204

Ø20

Flanschlager Flange bearing

Roulement avec

flasque

2 5006099

0282 241 0106

1 DIN 103 Tr20x4 Spindel Shaft Fuseau

3 5000419

0282 250 0020

4 DIN 471 20 x 1,2 Sicherungsring Circlip Circlip

4 5001033

2956000533

1 DIN 6885 A5x5x12 Passfeder Key Clavette

5 5006026

0282 241 0101

1 Handrad kpl.

Hand wheel

complete

Volant complet

6 5001256

0298 900 0008

1

DIN EN

ISO 7093

A 8,4 Scheibe Washer Rondelle

7 5000721

0282 150 0035

1

DIN EN

ISO 4017

M 8 x 20 Schraube Screw Vis

8 5005391

0282 241 0020

1 DIN 6885 6x6x14 Passfeder Key Clavette

9 5005392

0282 241 0008

1

DIN EN

10060

Rastscheibe Locking disc Rondelle d'arrêt

Page 39

FS175

Translation of the original operating instruction and spare parts list

- 39-

5007287-00

BA-E

®

9.4 Shaft support

Pos

K.-Art.-

Nr.

Art.-Nr. Qty. Norm Info Bezeichnung Description Désignation

- 5007289

0282 175 6108

1

Spindelaufnahme

kpl.

Shaft support

assy.

Fixation de la

broche complet

1 5006068

0282 241 0108

1 Spindelaufnahme Support Levé

2 5000793

0295 000 0178

1

DIN EN

ISO 4032

M 12 Mutter Nut Écrou

3 5006069

0282 241 0109

1 DIN 648 Ø12xM12 Gelenkkopf Joint head Chape articulée

Page 40

FS175

Translation of the original operating instruction and spare parts list

- 40-

5007287-00

BA-E

®

9.5 Water tank 30L

Pos

K.-Art.-

Nr.

Art.-Nr. Qty. Norm Info Bezeichnung Description Désignation

- 5002524

0282 130 0528

1 30L Wassertank kpl. Water Tank assy.

Réservoir d’Eau

complet

1 0003847

0282 130 0100

1 - 30L Wassertank Water tank Réservoir d'eau

2+3 5002516

4201 007 1046

1 -

Teilesatz 1

Wasserbehälter

Set water tank Set réservoir d'eau

2 5002518

-

1 Behälterdeckel Cap

Couvercle du

réservoir

3 5002517

4201 007 1046

1 -

Teilesatz

Wasserbehälter

Set water tank Set réservoir d'eau

3.1 5000949

0282 140 0074

1 DIN 3771 O-Ring O-ring Joint torique

3.2 5002520

4201 703 2600

1 - Absperrschieber Stop valve Vanne d'arrêt

3.3 5002521

4201 701 8800

1 - Ventil Valve Valve

3.4 5000396

0282 130 0525

1

DIN EN

ISO 8675

M 16 x 1,5 Mutter Nut Ecrou

4 4003851

0282 130 0525

1 -

Verlängerung

Tankverschluss

Lengthening piece Allonge

5 5000596

0282 130 0533

1

DIN EN

ISO 4026

M3x4 Gewindestift Set screw Vis sans tête

6 5002523

0295 899 0002

1 - GÖLZ Haftetikette Label Autocollant

Page 41

FS175

Translation of the original operating instruction and spare parts list

- 41-

5007287-00

BA-E

®

9.6 Blade guard / Water supply

Page 42

FS175

Translation of the original operating instruction and spare parts list

- 42-

5007287-00

BA-E

®

Pos

K.-Art.-

Nr.

Art.-Nr. Qty. Norm Info Bezeichnung Description Désignation

1 5000792

0286 570 0046

2

DIN EN

ISO 4032

M 10 Mutter Nut Écrou

2 5000736

0282 150 0055

2

DIN EN

ISO 4017

M 10 x 45 Schraube Screw Vis

3 5002524

0282 130 0528

1 30L Wassertank kpl. Water Tank assy.

Réservoir d’Eau

Cpl.

4 5000340

0286 570 0069

4

DIN EN

ISO 7090

B 6,4 Scheibe Washer Rondelle

5 5007281

0282 175 6112

1 S-Haube kpl.

Blade guard

complete

Capot de

protection

complet

6 5000343

0282 250 0105

2

DIN EN

ISO 7090

B 13 Scheibe Washer Rondelle

7 4003827

0282 120 0521

1

Tankanschluss -

stutzen

Connection piece Raccord

8 5000947

0295 000 0176

1 14 x 2,5 O-Ring O-ring Joint torique

9 5004923-

0281 230 0021

2

1/4" 90°

I/A

Winkel Elbow Raccord d'équerre

10 5001641

0295 000 0326

1 R 1/4 ", I-I Minikugelhahn Mini ball valve

Robinet à rotule

mini

11 5001368

0295 000 3016

1 1/4 " Anschlußstück Coupling Raccord

12 5002652

0295 000 3013

1

Wasser

Stop

Schlauchkupplung Water coupler

Dispositif

d’accouplement

13 5003692

0282 252 0196

1 Spanngurt Tension belt Sangle

14 5007390

0282 175 6117

1

Befestigungswinkel

Spritzschutz

Mounting bracket

splash guard

Support de fixation

pareéclaboussures

15 5000690

0295 000 3530

4

DIN EN

ISO 4017

M 6 x 16 Schraube Screw Vis

16 5007299

0282 175 6118

1 Spritzschutz Splash guard

Protection

contre le

réfrigérant

17 5007247

0282 175 6120

1

DG-PVC

16/E3

Membrandurch-

führung

through

membrane

Grâce à

membrane

18 5007279

0298 100 0103

1

Ø9 x 3 x

1200

Schlauch Hose Tuyau

19 5007401

0295 899 0026

2 FS170 Aufkleber Sticker Autocollant

Page 43

FS175

Translation of the original operating instruction and spare parts list

- 43-

5007287-00

BA-E

®

9.6.1 Blade guard

Page 44

FS175

Translation of the original operating instruction and spare parts list

- 44-

5007287-00

BA-E

®

Pos

K.-Art.-

Nr.

Art.-Nr. Qty. Norm Info Bezeichnung Description Désignation

- 5007281

0282 175 6112

1 S-Haube kpl.

Blade guard

complete

Capot de

protection complet

1 5007282

0282 175 6111

1 Schutzhaube Blade guard Capot protecteur

2 5007146

0282 130 0523

1

6 x 2 x

600

Schlauch klar Hose Tuyau

3 5001555

0282 130 0527

1

RY 6 - 8 -

6

Y-Verteiler Y-Distribution Y-Distributeur

4 5002487

0282 130 0532

1 Ø 15 Schelle Clamp Collier

5 5001558

0282 240 0101

2 Ø 12 Schelle Clamp Collier

6 5007410

0295 899 0020

1 GÖLZ Aufkleber Sticker Autocollant