Page 1

FB 20 P

GB

ZN der Bedienungsanleitung: 5006194-00

Erstellt am: 07/2015

Erstellt von: Sabrina Linden

Datei: K:\KDV\5006xxx\5006194-Bedienungsanleitung\

5006194-00-Bedienungsanleitung-E.doc

GÖLZ® GmbH

Dommersbach 51

D-53940 Hellenthal

Telefon: +49 (0) 2482 12 200 / Telefax: +49 (0) 2482 12 222

E-Mail: info@goelz.de / Internet: www.goelz.de

Original operating instruction and spare parts list

Diamand wet core drill machine

- 1-

5006194-00

BA-E

Page 2

FB 20 P

All rights reserved according to DIN ISO 16016.

No part of this document (instruction manual and spare parts list) may be reproduced, adapted, transmitted,

transcribed, stored on a data medium or be translated into another language without prior written approval of

GÖLZ® GmbH

Dommersbach 51

D-53940 Hellenthal

Guarantee

We reserve the right to amend any information included in this document (manual instruction and spare parts list)

at any time and without prior notice.

GÖLZ® assumes no warranty for these documents.

GÖLZ® shall not be liable for errors in this document (manual instruction and spare parts list) or for any collateral

or consequential damage in connection with shipment, performance or use of the material.

- 2-

5006194-00

BA-E

Page 3

FB 20 P

EG-KONFORMITÄTSERKLÄRUNG EC-DECLARATION OF CONFORMITY

Die Firma Manufacturer La Société

GÖLZ® GmbH

Dommersbach 51, D-53940 Hellenthal

Tel.: +49 (0) 2482 12 200 / Fax: +49 (0) 2482 12 222

erklärt in alleiniger Verantwortung dass

folgende Maschine:

Declare hereby certifies on its sole

responsibility that the following product:

FB 20 P

Diamant-Nass-Kernbohrmaschine

Diamond wet core drill machine

Carotteuse diamant sous arrosage

Seriennummer / Serial number / Numéro de série : ___________________________

auf das sich diese Erklärung bezieht, mit

folgenden Richtlinien übereinstimmt:

2006/42/EG

Sicherheits- und

Gesundheitsanforderung

2004/108/EG

Elektro-Magnetische Verträglichkeit

2006/95/EG

Niederspannungsrichtlinie

2011/65/EU

RoHS

mit folgenden Normen übereinstimmt:

EN 50144-1

EN 50144-2-1

EN 55014-1

EN 6100-3-2

EN 61000-3-3

EN 55014-2

EN 61029-1

Die oben genannte Firma hält

Dokumentation als Nachweis der

Erfüllung der Sicherheitsziele und die

wesentlichen Schutzanforderungen zur

Einsicht bereit.

which is explicitly referred to by this

declaration meet the following directives:

2006/42/EG

Safety and health requirement

2004/108/EG

Electromagnetic compatibility

2006/95/EC

Low voltage directive

2011/65/EU

RoHS

meet the following standards:

EN 50144-1

EN 50144-2-1

EN 55014-1

EN 6100-3-2

EN 61000-3-3

EN 55014-2

EN 61029-1

Documented evidence conforming to the

requirements of the directives is kept

available for inspection at the above

manufacturer’s address.

DECLARATION DE CONFORMITE DE

LA CE

déclare sous sa seule responsabilité

que le produit suivant:

Qui fait l’objet de la présente

déclaration correspond aux directives

suivantes:

2006/42/EG

Prescriptions sanitaire et sécurité

2004/108/EG

Compatibilité électromagnétique

2006/95/CE

Directive basse pression

2011/65/EU

RoHS

aux normes suivantes:

EN 50144-1

EN 50144-2-1

EN 55014-1

EN 6100-3-2

EN 61000-3-3

EN 55014-2

EN 61029-1

Pour faire foi de la conformité et du

respect des règles de sécurité, la documentation peut être consultée au siège

de la Société susmentionnée.

…………………………………………………………………………………

Hellenthal, den 03.07.2015

Geschäftsführer / General Manager /

Président-directeur général

B. Schmitz

- 3-

5006194-00

BA-E

Page 4

FB 20 P

Contents

1. Symbol- and Pictograph description .......................................................................... 5

1.1 Function description ................................................................................................ 5

2. General instructions .................................................................................................... 5

2.1 Application .............................................................................................................. 5

2.2 Safety ...................................................................................................................... 6

3. Transport and storage ................................................................................................. 6

3.1 Transport ................................................................................................................. 6

3.2 Storage ................................................................................................................... 6

4. Main dimensions and technical data .......................................................................... 7

4.1 Dimensions ............................................................................................................. 7

4.2 Technical data ......................................................................................................... 7

5. Commissioning ............................................................................................................ 8

5.1 Changing gear ........................................................................................................ 8

5.2 Safety coupling ....................................................................................................... 8

5.3 Core bits .................................................................................................................. 9

5.4 To change a core bit ............................................................................................... 9

6. Safety instructions ....................................................................................................... 9

7. Servicing and care ..................................................................................................... 10

7.1 Daily care .............................................................................................................. 10

7.2 After approx. 150 hours of use .............................................................................. 10

7.3 After approx. 250 hours of use .............................................................................. 10

7.4 Quarterly ............................................................................................................... 10

8. Speed adjustment dependent on the cutting speed ............................................... 11

9. Warranty ...................................................................................................................... 12

10. General safety instructions ....................................................................................... 12

11. Spare parts list ........................................................................................................... 14

11.1 Using the spare parts list ....................................................................................... 14

11.1.1 Safety regulation...................................................................................................... 14

11.1.2 Ordering information ................................................................................................ 14

11.1.3 Distribution agencies ............................................................................................... 15

11.2 Wearing parts ........................................................................................................ 16

12. Exploded view and spare parts list .......................................................................... 17

- 4-

5006194-00

BA-E

Page 5

FB 20 P

Special designs and versions may differ from the standard models in terms of their technical details. If any points

are unclear, we urgently recommend that you contact GÖLZ® GmbH, indicating the machine type and machine

number.

1. Symbol- and Pictograph description

1.1 Function description

2. General instructions

2.1 Application

The machine may be used in accordance with the data shown on the model plate. The details in the quotation

and order confirmation also apply for the use of special machines.

The machines generally comply with safety class II, this alone ensures the complete protection of the RCCB or

PRCD.

When using suitable core bits it is possible to drill holes in the most diverse materials:

• Concrete (even with thick reinforcement steel)

• Sandstone and limestone

• All building materials for solid walls

• Asphalt floors

It is compulsory to observe the safety instructions included in this manual!

This sign tells you rules, if you not pay attention for this your health and the function of the

machine is in danger. You have no warranty if the machine breaks down because you not

looking about this.

Gear control

Drill-spindle

Handle

Switch on/off

Handle

- 5-

5006194-00

BA-E

Page 6

FB 20 P

persons who have suitable training and qualifications.

For stand-mounted drilling the machine may have the following

• a personnel safety switch (RCCB or PRCD) on the machine itself or

• a coded (1 h) plug, which is connected to the 115 V mains via a safety box (IP44) with an RCCB.

The FB 20 P has in both types, voltage 110 V and 230 V, an integrated PRCD-safety switch in the cable.

The core drilling machines comply with the regulations of the “Stone and Earth” professional association dated

July 1989. They are machines of category II, which means that they must be mounted on stands and stable

(pursuant to DIN 57100 and VDE 0100), and the stand must be fitted with the following

• reversing lock

• water extraction device.

2.2 Safety

The following points are to be given special attention:

• the technical data and details of the permitted use of the machine (commissioning, ambient and

• the relevant accident prevention regulations

• the correct use of tools

• the use of personal safety equipment

3. Transport and storage

3.1 Transport

3.2 Storage

If possible, the storage site should be dry, clean and have a constant temperature. To ensure that the film of

lubricant in the bearings and sealing system is not lost, the motor shaft should be turned through several

revolutions by hand after a lengthy period of storage, for example at monthly intervals. The roller bearings in the

motors should be replaced (or regreased) if the period between delivery and commissioning is over four years. If

the machines are stored in adverse conditions, this period may differ considerably.

The machine is a pure wet drill machine.

Dry drilling can cause damage to the shaft sealing rings.

Before using the machine for the first time, check that the conformity of the data on the

model plate with the mains voltage and frequency. Voltage deviations of ± 5 % and/or

voltage deviations of ± 2 % are permissible. Repairs must only be completed by quality

operating conditions) which are set out in the catalogue, the operating manual, the model plate data and

other product information,

The machine is to be checked for signs for transport damage on receipt. Any damage must

be documented in writing.

- 6-

5006194-00

BA-E

Page 7

FB 20 P

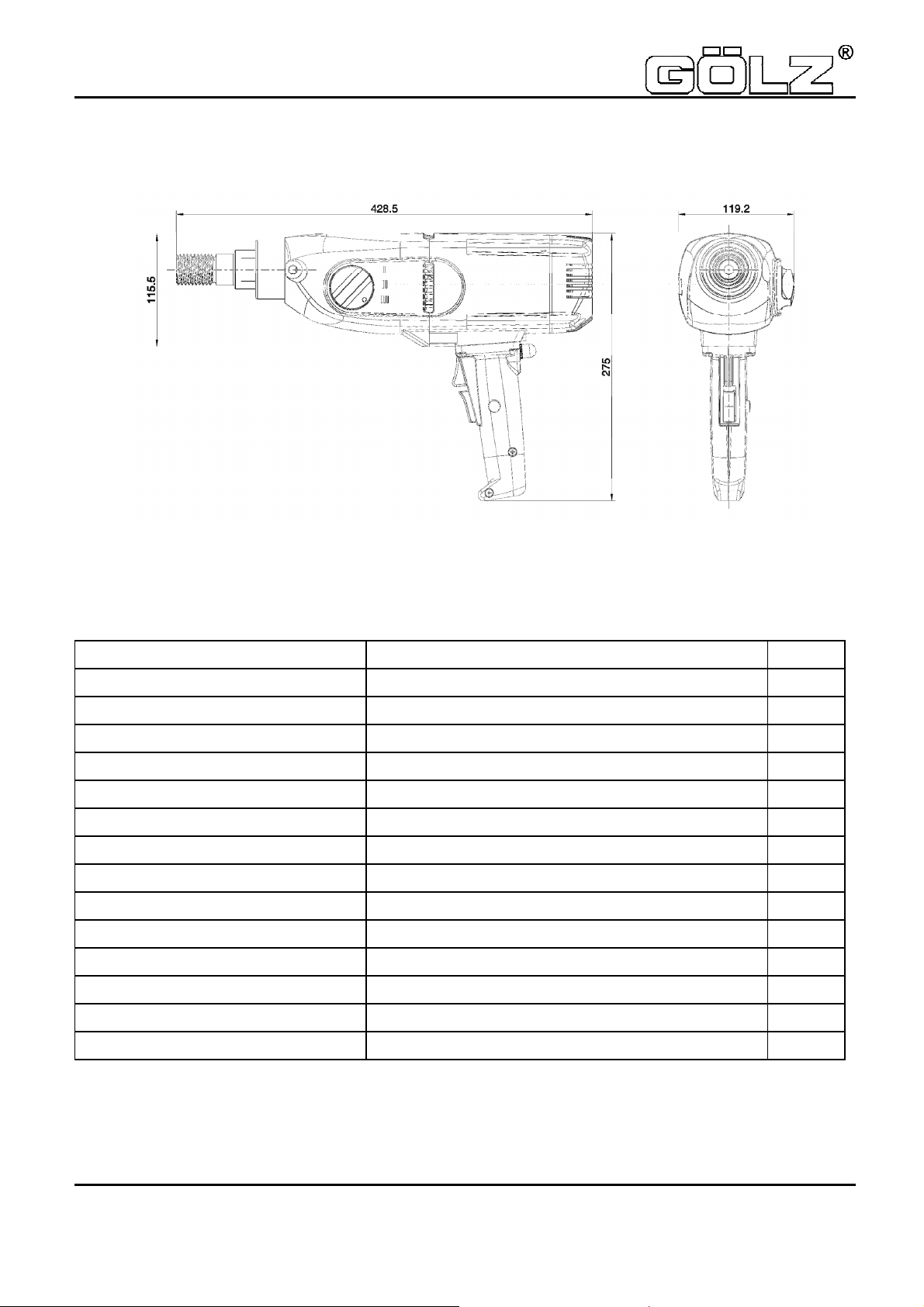

4. Main dimensions and technical data

4.1 Dimensions

(Representation without additional handle)

4.2 Technical data

Rated voltage 230 V

Current consumption 10 A

Power requirement 2200 W

Frequency 50 - 60 Hz

Idling speed 950 / 2150 / 4450 min-1

Full speed 500 / 1200 / 2500 min-1

Output rating 1300 W

Torque 25 / 10,5 / 5 Nm

Drilling diameter 150 / 50 / 15 mm

Weight 7,4 kg

Core bit connection UNC 1 ¼ / R ½ “

Overload coupling torque 12 Nm

Noise pressure level (EN 50144) 89 dB (A)

Sound power level (EN 50144) 102 dB (A)

Vibration (EN 50144) < 2,5 m/s²

- 7-

5006194-00

BA-E

Page 8

FB 20 P

5. Commissioning

Check that the mains voltage is identical to the voltage specified on the model plate.

Stand-mounted:

Secure the machine and the water collection device on the drill stand with a reverse lock. The drill stand should

have high rigidity and precise, low-play guides. Ensure that the machine axis is parallel to the drill stand axis.

Insert the core bit and set the speed. Setting instructions are given in chapter 8.

Connect the water supply. Important: Do not exceed the max. water pressure of 3 bar.

Both voltage versions of FB 20 P (110V and 230V) are equipped with a PRCD-safety switch in the cable, so the

FB 20 P can be directly connected to the main supply.

Manually controlled:

When drilling a hole ensure that you are on a secure surface. Make particularly sure the core bit is not bent

during the drilling process and hold the core drilling machine as rigid as possible. Concentrate hard on the work

since if the core bit suddenly blocks, despite the low setting of the safety slip clutch, high forces may be

generated. If you let go of the core drilling during the drilling process, you may suffer serious injury.

Only used three-core extension cables with a protective conductor and an adequate cross-section. If the crosssection is too low you may suffer excessive power loss and the motor and cable may overheat. An extension

cable must be secured with an overload switch. Recommended cable cross-sections:

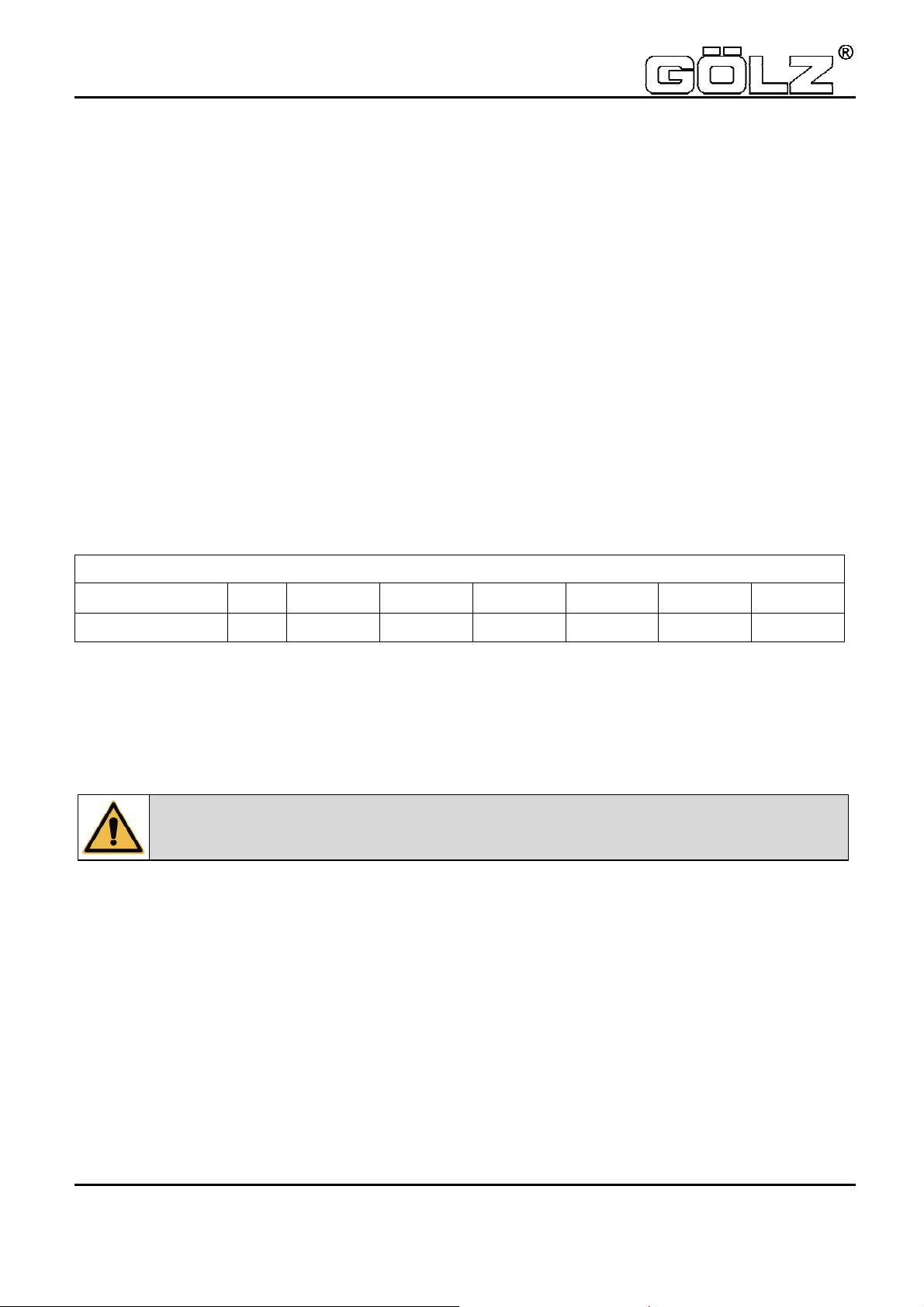

Recommended cable cross-sections:

Rated current = 9 A

Cable length m 7,5 15 25 30 45 60

Cable cross-section mm2 2,5 2,5 2,5 2,5 2,5 4

When drilling a hole ensure that you have sufficient cooling water. Only use clean tap water, do not use dirty or

waste water. Adjust the supply to the core bit diameter and drive rating of the core drill so that you do not exceed

the rated current.

5.1 Changing gear

Move the gear switch handle by approx. 40° to the next higher or lower gear. If necessary (if it is difficult to

engage the gear) turn the drive spindle briefly by hand until the gear engages easily. Never use tools (pliers,

hammer, etc.) to change gear since otherwise gear damage will be inevitable.

Never change gear using force and only do so when the machine is slowing down or at a

standstill.

5.2 Safety coupling

The values set out in the table are theoretical values and may be used to provide a rough guide for gear

changing. Since a whole range of other parameters also plays a major role in adjusting the speed, we cannot

offer any guarantee if the tool is damaged when using the values in the table. Drilling work for which the speeds

are outside the range of the core drill (values printed in italics), should only be completed with extreme care and

by trained personnel.

- 8-

5006194-00

BA-E

Page 9

FB 20 P

5.3 Core bits

All core bits with a connection thread of UNC 1 ¼ “ or R ½ “ can be used.

Adapters can be supplied to allow core bits with other connection systems to be used. Only use core bits that are

suitable for the type of stone.

You will keep the machine in good condition if you only use core bits that are concentric and not deformed ones.

Ensure that the diamond segments have an adequate undercut against the core bit body.

5.4 To change a core bit

The drill spindle has a right-handed thread.

Always use a 32 mm open-ended spanner to hold against the drill spindle. Never release the core bit with

(hammer) blows since this will damage the machine.

The core bit can be removed more easily if you apply a little waterproof grease to the drill spindle thread.

6. Safety instructions

• if you intend to leave the machine unsupervised,

• for attachment and disconnection work,

• if the voltage drops (below 200 V),

• for adjustments or for fitting an accessory,

Switch off the machine if it stops for any reason. This will prevent its starting suddenly when it is not under

supervision.

Do not use the machine if

• part of the casing is missing or defective,

• If water drips out of the overflow hole, stop work and have the machine inspected by an authorized

• Only drill above your head with suitable safety equipment (water collector), RCD and transformer

• After a fault do not switch on the machine again until the core bit can be turned easily.

• Check the area you wish to drill with a line detector to prevent drilling through electric cables, water

• or gas lines, etc.

• the switch, lead or plug connector has suffered damage (conduct a visual inspection every day).

• Cooling water must not be allowed to ingress into the motor or the electrical components when operating

• the core drill in any position.

Do not expose the tool to rain and use not in humidity or wet environment. Use a good lightning. Do not use

the tool near flammable fluids or gas air mixes.

To use wrong tools or accessories is danger for your life.

Only use the machine under supervision. Disconnect the mains plug and check that the

switch has been turned off,.

service contractor.

protection class II.

- 9-

5006194-00

BA-E

Page 10

FB 20 P

7. Servicing and care

7.1 Daily care

Ensure that no water escapes from the overflow hole. This will cause gear damage and may reduce the electrical

safety of the machine. In this case please contact an authorised service centre.

Inspection the machine for signs of damage to the switch, mains lead or plug connector.

After completing the drilling work clean the machine. Grease the core bit mounting thread. The ventilation slits

must be kept clean and open at all times. Ensure that no water gets into the machine whilst you are cleaning it.

To ensure that the sealing function is maintained, oil the drill spindle:

• Disconnect the machine from the water supply. Open the water connection shut-off cock and insert a

7.2 After approx. 150 hours of use

After the first 150 hours of use, the gearbox oil must be changed.

7.3 After approx. 250 hours of use

Have the carbon brushes checked, and replaced if necessary, by an electrician.

Remove the screws. Pull the cap off the motor casing. Remove the carbon brushes screws, raise the carbon

brushes retaining springs and take out the carbon brushes. Clean the carbon brush holder and collector with a

paintbrush.

Fit new carbon brushes following the above instructions in reverse. Position the cap and secure it with the

screws. Fit the cap on the motor casing by tapping it gently with a rubber mallet or the like. Tighten the screws.

Release the stress by tapping the cap twice. Avoid adjusting the carbon retaining springs. Only use original spare

parts.

7.4 Quarterly

Have the cable, switch and plugs inspected by an expert (pursuant to VBG4) and document the process.

Replacing the gearbox oil will considerably extend the service life of the gear.

Before starting any servicing or repair work always disconnect the mains plug.

After all repairs you must have the core drilling machine inspected by an electrician

(statutory regulation pursuant to VBG4 since 1.1.1990).

drop of oil, close the shut-off cock, place a few drops of oil into the overflow hole and turn the machine

briefly by hand.

- 10-

5006194-00

BA-E

Page 11

FB 20 P

3 4 5 6 7 [m/s]

Bit

capacity

Ø concrete

concrete

rock

[mm]

reinforced

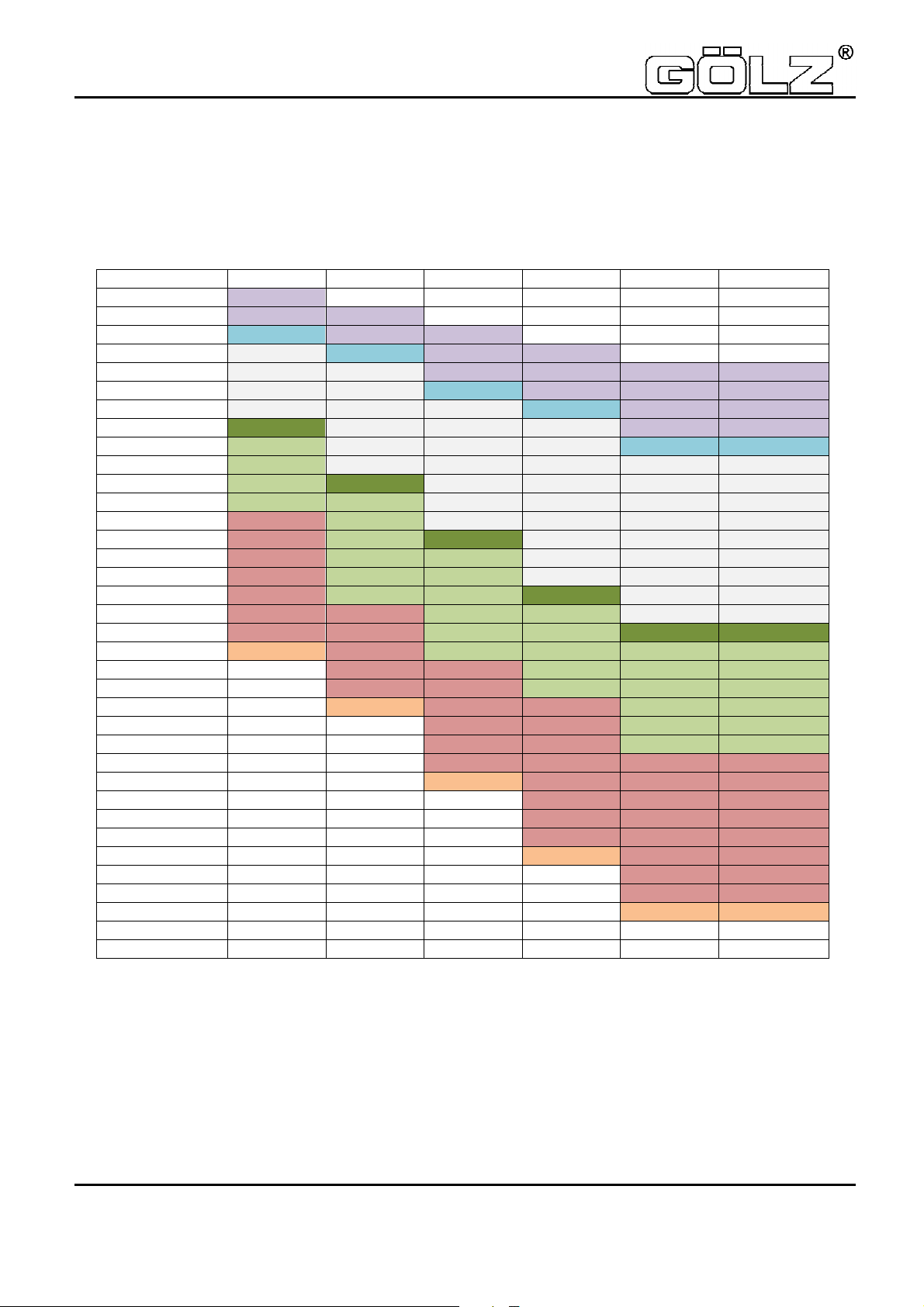

8. Speed adjustment dependent on the cutting speed

The values set out in the table are theoretical values and may be used to provide a rough guide for gear

changing. Since a whole range of other parameters also plays a major role in adjusting the speed, we cannot

offer any guarantee if the tool is damaged when using the values in the table. Drilling work for which the speeds

are outside the range of the machine (values printed in italics), should only be completed with extreme care and

by trained personnel.

15 3820

20 2900 3820

25 2500 3056 3820

30 1910 2500 3183 3820

35 1637 2183 2728 3274 3820 3rd gear

40 1432 1910 2500 2865 3342 3rd gear

45 1273 1698 2122 2500 2971 3rd gear

50 1200 1528 1910 2292 2674 3rd gear

55 1042 1400 1736 2083 2500 3rd gear

60 955 1273 1592 1910 2228 2 or 3

65 881 1200 1400 1763 2057 2 or 3

70 819 1091 1364 1637 1910 2 or 3

75 764 1019 1273 1528 1783 2 or 3

80 716 955 1200 1400 1671 2 or 3

85 674 899 1123 1348 1573 2 or 3

90 637 849 1061 1273 1485 2 or 3

95 603 804 1005 1200 1400 2 or 3

100 573 764 955 1146 1337 2 or 3

110 521 694 868 1042 1200 2nd gear

120 500 637 796 955 1114 1 or 2

130

140

150

160

170

180

190

200

210

220

230

240

250

260

441

409

382

358 477

337 449

318 424

302 402

286 382 477

273 364 455

260 347 434

249 332 415

239 318 398 477

229 306 382 458

220 294 367 441

5093 6366 7639 8913

4775 5730 6685

4584 5348

4456

588 735 881 1028 1 or 2

546 682 819 955 1 or 2

500 637 764 891 1 or 2

597 716 836 1 or 2

562 674 786 1 or 2

531 637 743 1st gear

500 603 704 1st gear

573 668 1st gear

546 637 1st gear

521 608 1st gear

500 581 1st gear

557 1st gear

535 1st gear

500 1st gear

3rd gear

3rd gear

3rd gear

3rd gear

- 11-

5006194-00

BA-E

Page 12

FB 20 P

9. Warranty

In keeping with our terms of sale, we offer a warranty for six months from the date of sale. This refers to the free

repair of material and workmanship defects, which were verifiably caused before the sale.

An original purchase document must always be submitted in case of a warranty claim. It has to contain the full

address of the dealer, the date of purchase and the type designation of the product. The operating instructions of

the particular product and the safety instructions must have been followed.

Damages resulting from operational faults cannot be acknowledged as warranty cases.

The products of the manufacturer have been developed and produced for specific applications. No warranty

claim is accepted in case of non-compliance with the due employment according to the operating instructions, in

case of the employment for other purposes than originally intended or the employment of inadequate

accessories.

The periodical maintenance and cleaning of the products according to the directions of the operating instructions

is absolutely necessary. The intervention of third persons (opening the machine) renders any warranty claim void.

Maintenance and cleaning operations cannot be claimed on the basis of warranty.

Make sure only original spare parts and original accessories are used. They are available at the authorized

specialized product dealer. If non-original parts are used, consequential damages and increased hazard cannot

be ruled out. The producer is not liable for such damages. Disassembled or partially disassembled hand saws

and those repaired with non-original parts are excluded from the warranty.

Certain components, such as carbon brushes, ball bearings, switches, power-supply lines, gaskets, etc., are

exposed to usage dependent or to normal wear. These wearing parts are not object of this warranty.

Wearing parts are marked on the spare parts lists.

10. General safety instructions

Read and follow these instructions before you use the tool. Keep these safety instructions in a safe place.

Keep your workplace tidy. Untidiness in the workplace can cause accidents.

Protect yourself from electric shocks. Refer to the applicable regulations. Avoid physical contact with earthed

parts, such as pipes, heaters, furnaces and refrigerators.

Keep children away. Do not allow other people to touch the tool or cable, keep them away from where you are

working.

Keep your tools in a safe place. Unused tools should be kept in a dry, locked room out of the reach of children.

Do not overload your tool. It will work better and more safely in the specified capacity range.

Use the correct tool. Do not use tools that are too weak or mounted tools for heavy work. Do not use tools for

purposes and work for which they have not been designed.

Wear suitable clothing. Do not wear excessively baggy clothing or jewellery, which may be caught by moving

parts. For working outdoors, we recommend the use of rubber gloves and sturdy shoes. Wear a hairnet if you

have long hair.

Use goggles. Use a breathing mask for work that generates dust.

Do not use the cable for any purpose other that that for which it is designed. Do not carry the tool by the cable

and do not use it to pull the plug out of the socket. Protect the cable from heat, oil and sharp edges.

Check the connection lead and plug every time before you use the tool for signs of damage. If they are damaged,

have them replaced by a specialist. Always keep the connection lead away from the working area of the machine.

Secure the workpiece. Use clamps or a vice to hold the workpiece. This will make it more secure that if you hold

it in your hand and will allow you to use both hands to control the machine.

Do not overstretch yourself. Avoid abnormal body positions. Ensure that you have a stable area on which to

stand and keep your balance at all times.

Look after your materials with care. Keep your tools sharp and clean so that they produce good safe results.

Check the plug and cable at regular intervals and have them replaced by a specialist if they suffer any damage.

Check the extension cable at regular intervals and replace damaged cables.

Keep the handles free of oil and grease.

Disconnect the mains plug from the supply when the tool is not in use and when changing the tool.

Do not leave a tool spanner on the tool. Before switching on the tool check that the wrench and setting tools have

been removed.

Avoid the machine starting when you do not intend it to. Do not carry a tool that is connected to the mains supply

with your finger on the switch. Ensure that the switch is turned off when you connect the tool to the mains supply.

- 12-

5006194-00

BA-E

Page 13

FB 20 P

Electric tools outdoors and in wet areas: Mobile tools which are used outdoors should be connected to the mains

supply using a residual-current circuit breaker or the like for added safety. This is particularly important when

working with freehand tools. If there is a water supply, you should use an isolation transformer and a voltage

supply of 115 V; please specify in your order.

For outdoors work, only use extension cables, which are approved for this purpose and marked accordingly.

Be vigilant at all times. Watch your work. Proceed sensibly. Do not use the tool if you are not concentrating fully

on what you are doing.

Important:

Safety equipment (such as overcurrent protection devices, undervoltage trips, safety couplings etc.) are tools but

do not offer guaranteed safety. As a responsible manufacturer we tailor these tools to each other so that they

offer the best possible protection. But without the care and caution of the use, these tools may even cause

damage it they are not used properly. Have the slip couplings, in particular, checked during the quarterly

inspection to ensure that it is correctly adjusted and functions properly. This inspection should be conducted by

the manufacturer or an authorised service outlet and documented.

Check the machine every day for signs of damage, conduct a visual inspection:

Before reusing the tool, carefully check the safety equipment or slightly damaged parts to ensure that they offer

perfect and proper function. Check that all moving parts function correctly, that they do not jam and that none of

the parts are damaged. All parts must be correctly fitted and satisfy all the conditions to ensure the perfect

operation of the tool. Damaged safety equipment and parts must be repaired or replaced properly by a specialist

service contractor. Do not use any tools, which cannot be switched on and off using the switch. Pay particular

attention to ensuring electrical safety: Cables? Plugs? Switches? Do all the components satisfy safety

regulations?

Repairs may only be completed by trained personnel. Before being used for the first time and after all repair

work, the safety of electric tools must be checked by an electrician pursuant to VBG 4, § 5. This inspection must

also be conducted and documented at regular intervals – at least once per year.

Please note that as the operator you are responsible for complying with any additional regulations. For example if

electric tools are used in a wet and/or damp environment, the regulations of the ”Stone and Earth” Professional

Association must be satisfied.

- 13-

5006194-00

BA-E

Page 14

FB 20 P

11. Spare parts list

11.1 Using the spare parts list

The spare parts list is not a mounting or dismounting instruction. The only purpose of the spare parts list is to

easily and quickly find spare parts which can be ordered with distribution agencies, see chapter 11.1.3

"Distribution agencies".

11.1.1 Safety regulation

Using this spare parts list for mounting or dismounting purposes is not permitted. For assembly and disassembly

work exclusively the corresponding descriptions in this operating manual are to be followed.

Danger: Mounting or dismounting assembly groups can give rise to risks which are not

mentioned in the spare parts list!

Danger: Non-observance of this instruction can result in injury which, in the worst case,

can result in death!

11.1.2 Ordering information

Note: In order to avoid wrong deliveries the information the ordering information should be

checked for accuracy and completeness before sending it! Completely indicate the delivery

address!

500 1200 2500

- 14-

5006194-00

BA-E

Page 15

FB 20 P

So bekommen Sie schnell und

richtig Ihr Ersatzteil

• Maschinentyp gemäß

• machine type according to

Typenschild

• Baujahr gemäß Typenschild

• year of manufacture according

• Artikelnummer gemäß

• order number according to

Ersatzteilliste

• Maschinennummer gemäß

• serial number according to

Typenschild

Für Bestellungen, Fragen und In-

formationen wenden Sie sich bitte

an die zuständigen Stellen

11.1.3 Distribution agencies

Deutschland – Germany - Allemagne

GÖLZ® GmbH

Dommersbach 51

DE-53940 Hellenthal

Tel: +49 (0)2482-12 200

Fax: +49 (0)2482-12 222

E-Mail: info@goelz.de / Internet: www.goelz.de

Always indicate

nameplate

to nameplate

spare part list

nameplate

For orders, questions and

information, please contact the

competent departments.

Pour obtenir rapidement les

pièces de rechange indiquer

• type de la machine conforme

de plaque d'identification

• Année de construction selon

plaque d'identification

• Numéro de l'article selon la liste

des pièces de rechange

• numéro de la machine conforme de plaque d'identification

Pour les commandes, questions et

informations, veuillez-vous

adresser aux points de ventes

correspondants.

Österreich - Austria - Autriche

GÖLZ® Ges.m.b.H

Samstraße 52

A-5020 Salzburg

Tel: +43 (0) 662 - 43 81 75

Fax: +43 (0) 662 - 43 07 34

E-Mail: info@goelz.at / Internet: www.goelz.at

Großbritannien - Great Britain - Grande-Bretagne

GÖLZ® (UK) Ltd.

Unit A5, Springhead, Enterprise Park

Northfleet

Kent DA11 8HB

Tel: +44 1 474321679

Fax: +44 1 474321477

E-Mail: info@goelz.co.uk / Internet: www.goelz.co.uk

Australien - Australia - Australie

GOLZ® Pty Ltd.

44 Stanley Street

Peakhurst, NSW 2210

Tel: +61 (0) 2 9534 5599

Fax: +61 (0) 2 9534 5588

E-mail: info@golz.com.au / Internet: www.golz.com.au

Frankreich - France - France

GÖLZ® S.A.S.

1, rue de la Mairie

F-67370 Berstett

Tel: +33 (0)3.88.59.43.00

Fax: +33 (0)3.88.59.47.77

E-Mail: info@golz.fr / Internet: www.golz.fr

Benelux

GÖLZ® Benelux

Eupener Straße 61

BE-4731 Raeren-Eynatten

Tel: +49 (0)2482-12 200

Fax: +49 (0)2482-12 222

E-Mail: benelux@goelz.de / Internet: www.goelz-online.com

USA

GOLZ® L.L.C.

5860 East Osage Ridge Lane

Columbia MO 65203-6018

Tel: +1 573 474 4961

E-Mail: info@golzusa.com / Internet: www.goelz-online.com

- 15-

5006194-00

BA-E

Page 16

FB 20 P

11.2 Wearing parts

Wearing parts for construction devices mentioned in the operating manual such as drilling and sawing

machines.

Wearing parts are the parts subject to operation-related (natural) wear during proper use of the device. The

wearing time cannot be uniformly defined, and differs according to the intensity of use. The wearing parts must

be adjusted, maintained and, if necessary, replaced for the specific device in accordance with the manufacturer’s

operating manual. Operation-related wear is not a reason for defect claims.

Wearing parts of this machine are grey marked in the spare parts list.

• Feed and drive elements such as toothed racks, gearwheels, pinions, spindles, spindle nuts, spindle

bearings, cables, chains, sprockets, belts

• Seals, cables, hoses, packings, connectors, couplings and switches for pneumatic, hydraulic, water,

electrical and fuel systems

• Guide elements such as guide strips, guide bushes, guide rails, rollers, bearings, sliding

protection supports

• Clamping elements for quick-separating systems

• Flushing head seals

• Slide and roller bearings that do not run in an oil bath

• Shaft oil seals and sealing elements

• Friction and safety clutches, braking devices

• Carbon brushes, commutators / armatures

• Easy-release rings

• Control potentiometers and manual switching elements

• Securing elements such as plugs, anchors, screws and bolts

• Fuses and lamps

• Auxiliary and operating materials

• Bowden cables

• Discs

• Diaphragms

• Spark plugs, glow plugs

• Parts of the reversing starter such as the starting rope, starting pawl, starting roller and

starting spring

• Sealing brushes, rubber seals, splash protection cloths

• Filters of all kinds

• Drive rollers, deflection rollers and bandages

• Cable anti-twist elements

• Running and drive wheels

• Water pumps

• Cut-material transport rollers

• Drilling, parting and cutting tools

• Energy storage

- 16-

5006194-00

BA-E

Page 17

FB 20 P

12. Exploded view and spare parts list

- 17-

5006194-00

BA-E

Page 18

FB 20 P

l

actuating wheel

Pos. K.-Art.-Nr. Art.-Nr.

Menge

Qty.

Norm Info Bezeichnung Description Désignation

- 03P31000

1

- 03P32000 110V

2 - 73P31400 1 - -

3 - 80410061 1 6005 2RS - Rillenkugellager

4 - 80201531 1 JV47 - Sicherungsring Locking ring Circlip

5 - 7B301213 1 - -

6 -

7 -

8 - 80200806 1 - - Druckfeder

9 - 80410081 2 Ø5 - Kugel Ball Balle

10 - 80201492 1 AV 25 - Sicherungsring Locking ring Circlip

11 - 83000219 2 25x42x7 - Wellendichtring Shaft seal ring

12 - 80201493 1 JV 40 - Sicherungsring Locking ring Circlip

13 - 83000226 1 25x40x7 - Wellendichtring Shaft seal ring

14 - 7B401104 1 Losrad, kpl.

15 - 7B300774 1 Schaltrad 1

16 - 7B401105 1 Lagerhülse Bearing sleeve Douille

-

-

1 1

- - - -

- - - -

230V

FB20 P FB20 P FB20 P

Getriebegehäuse

Bohrspindel,

kpl.

gearbox

housing

Grooved ball

bearing

Drill spindle

Compression

spring

Loose wheel

complete

Switchactuating whee

Carter de boîte

de vitesses

Roulement

rainuré à billes

Axe de perçage

complète

Ressort à

pression

Bague

d’étanchéité

Bague

d’étanchéité

Roue de

commande

complète

Roue de

commande 1

17 - 80201641 1 15x21x1 Paßscheibe Fitting washer Clavette

18 - 80201322 1 15x1 Sicherungsring Locking ring Circlip

19 - 80201637 1 A4x4x45 Paßfeder Fitting key Clavette

20 - 73P31480 1 Schaltrad

21 -

22 -

23 -

24 - 80200524 1

25 - 80700506 1 Schaltgriff Switch button

26 - 83000224 1 24x2 O-Ring O-ring Joint torique

27 - 7B401781 1 Hülse Bush Douille

28 - 7B401842 1 Schalthebel, kpl.

29 -

30 -

-

-

-

-

-

- - - -

- - - -

- - - -

Ausgleichsscheibe

- - - - - -

- - - - - -

Switch-

Disc

Gear lever

complete

Roue de

commande

Levier de

contrôle

Levier de

contrôle

complète

- 18-

5006194-00

BA-E

Page 19

FB 20 P

- 19-

5006194-00

BA-E

Page 20

FB 20 P

Pos. K.-Art.-Nr. Art.-Nr.

31 - 80201536 1 40x16 PT-Schraube PT-screw Vis PT

32 - 80420131 1 HK1210 Nadelhülse

33 - 80410099 1 6200 Rillenkugellager

34 - 73T11493 1 Kupplung, kpl.

35 - 73T11500 1 Vorlegewelle Countershaft

36 - 83000042 1 KEIV 15x21x3 Wellendichtring

37 - 85000259 2 Bremsscheibe Braking disk

38 - 73T22440 1 Vorlegerad

39 - 7B401041 1 Lagerhülse

40 - 73T2244U 1 Vorlegerad, kpl.

41 - 85000260 1 Druckscheibe

42 - 80200716 2 28x14x1,5 Tellerfeder

43 - 80201007 1 M10x1 Mutter

44 - 80420105 1 HK0808 Nadelhülse

45 - 80200582 1 4x12 Steckkerbstift

46 - 73P31610 1

47 - 83000173 1 90x2 O-Ring O-ring Joint torique

Menge

Qty.

Norm Info Bezeichnung Description Désignation

Getriebelagerschild

Needle

sleeve

Grooved ball

bearing

Clutch

complete

Shaft seal

ring

Reduction

wheel

Bearing

sleeve

Reduction

wheel

complete

Pressure

washer

Spring

washer

Hexagonal

nut

Needle

sleeve

Notched pin

plug

End shield of

gearing

Cage à aiguilles

Roulement à

billes

Accouplement

complet

Axe de

réduction

Bague

d’étanchéité

Disque

d’embrayage

Roue de

réduction

Douille

Roue de

réduction

complète

Disque de

pression

Ressort à

disque

Ecrou

Cage à aiguilles

Goupille

cannelée

Couvercle de

réducteur

48 - 83000106 1 1/8" Dichtring Seal ring Joint

49 - 80201406 1 1/8"

- 73T22100

50

- 73T23100 110V

51 -

52 - 80410021 1 6000 2Z Rillenkugellager

53 - 83000031 1 Lagerkappe Bearing cap

54 - 85000027 1 Lagerscheibe Bearing cover

55 - 80410032 1 6001 2RS Rillenkugellager

56 - 73334435 1 Dichthülse

57 - 80200742 1 SW 10 Sprengring Circlip Circlip

58 - 80201457 2 M4x14 Schraube

59 - 83000019 2 3,68x1,78 NBR O-Ring O-ring Joint torique

60 - 80700504 1 Motorgehäuse

-

1

- - - - - -

230V

Verschlußschraube

Läufer, kpl. Rotor complete Rotor complet

Cap screw Bouchon

Grooved ball

bearing

Grooved ball

bearing

Sealing

sleeve

Lens head

screw

Motor

housing

Roulement

rainuré à billes

Couvercle de

roulement

Bague de

roulement

Roulement

rainuré à billes

Bague

d’étanchéité

Vis

Bâti moteur

- 20-

5006194-00

BA-E

Page 21

FB 20 P

- 21-

5006194-00

BA-E

Page 22

FB 20 P

Stator complete

Cable grommet

Over current trip

Connecting wire

Pos. K.-Art.-Nr. Art.-Nr.

Menge

Qty.

Norm Info Bezeichnung Description Désignation

- 73P31150

61

- 73P32150 110V

62 - 80700503 1 Luftleitring

63 - 80201540 4 M5x80 Schraube Screw Vis

64 - 80201199 2

65 - 80201252 4 HC 2,9x13 Blechschraube

- 80700019

66

- 80700040 6,3x16x20L41F13 110V

67 - 80600306 1 Füllstück

68 - 73P31208 1 Libelle Level Niveau

69 - 73P31240 1 Kappe Cap Carter arrière

70 - 80201413 4 40x12 PT-Schraube PT-screw PT-vis

71 - 85003012 1 Libelle Level Niveau

72 - 80900232 1 Handgriffhälfte Handle

73 - 80600507 1 Schalter Switch Interrupteur

74 - 80500008 1 220nF

- 83000004

75

- 83000228 110V

76 - 85000020 1

77 - 80201270 2 HC4,2x13 Blechschraube

- 80500045

78

- 80500019 16A 110V

79 80601020 1 Schutzkappe Dust cap

80 73P31268 1 Handgriffhälfte Handle Poignée

1

6,3x16x20L82F10 230V

2

230V

1

10A 230V

1

230V

Polring, kpl.

Air guiding

ring

Taschenbürstenhalter

kpl.

Kohlebürste Pair of brushes Balai

Entstörkondensator

Kabelausführungsmuffe

Zugentlastungsschelle

Überstromschalter

Brush holder Support de balai

Self tapping

screw

Contact

washer

Snti parasite

condenser

Wire locking

flange

Self tapping

screw

Stator complet

Cage d’aérateur

Vis parker

Habillage

Moitié de

poignée

Condensateur

antiparasite

Protection câble

électrique

Collier de

serrage

Vis parker

Disjoncteurprotecteur

Capuchon de

protection

81 80201539 4 5x18 PT-Schraube PT-screw Vis PT

82 80201271 2 HC4,2x16 Blechschraube

7660A262

83

7660Q262

73P31182

84

73P32182 110V

85 73P31695 1 Stützgriff, kpl. Side handle Poignée

1

1

PRCD 2x1,5²

2x1,5mm², 5 m

PRCD 2x2,5²

32A, 5m, 4h-St.

230V

230V

Anschlußleitung

110V

Verbindungslitze

Self tapping

screw

Connecting

cable

Vis parker

PRCD

Câble électrique

- 22-

5006194-00

BA-E

Page 23

FB 20 P

- 23-

5006194-00

BA-E

Page 24

FB 20 P

ater connector

Pos. K.-Art.-Nr. Art.-Nr.

86 73T15950 1

87 83000107 2 G 1/4" Dichtring Seal ring Joint

88 83000117 1 Minikugelhahn Mini ball valve

89 83000124 1 Gardena Anschlußstück

90 7B800415 1 Schlauch, kpl. Hose complete Tuyau complet

Menge

Qty.

Norm Info Bezeichnung Description Désignation

Wasseranschluss, kpl.

W

complete

Connecting

piece

Raccordement

de l’eau

complète

Robinet à rotule

mini

Raccord

- 24-

5006194-00

BA-E

Loading...

Loading...