IMPORTANT SAFETY INFORMATION

This symbol is to alert you to important operating

or servicing instructions that appear in your

instructions. Always follow basic safety

precautions when using this product to reduce

the risk of injury, fire or electric shock.

TEN YEAR LIMITED WARRANTY

Golight, Inc. warrants the GXL

that are due to workmanship for parts or faulty materials, for

ten years from date of original purchase. This warranty to the

GXL® does not cover damage resulting from unreasonable use

or misuse, unreasonable maintenance or loss, or labor costs.

®

against any deemed defects

®

This light is for off road and utility use only. It is not

designed for road use as a driving light.

Warranty information may be filled out online at:

www.golight.com/products/registration.html

®

If the GXL

specification, send the light, and all necessary accessories

postage paid, plus $9.95 for shipping and handling to Golight,

Inc., Service Department, 37146 Old Hwy 17, Culbertson, NE

69024. No C.O.D.’s accepted. Only the above manufacturer is

authorized to perform warranty repair or replace product.

Any consequential damages to person or property are excluded

from this warranty. Some states do not allow the exclusion

and limitation of incidental or consequential damages, therefore, the above limitations or exclusions may not apply to you.

This warranty gives you specific legal rights and you may also

have other rights.

does fail to operate under warranted

Golight Inc

37146 Old Hwy 17

Culbertson, NE 69024

800.557.0098 | 308.278.3131

www.golight.com | info@golight.com

Instruction Guide

Congratulations

You are now the owner of one of the finest lighting products

available today. Thank you for letting Golight® assist you in

your lighting application needs.

We’re proud of our products and the technology that we’ve

developed to ensure our customers the most durable,

versatile and powerful lights in the industry.

Please read these

instructions before

using your new

Golight® GXL®.

The GXL® is an LED, fixed-mount work light offering incredible

intensity and durability in a small package. Utilizing the latest in

LED, lens and reflective technology, the GXL® casts light where

you need it.

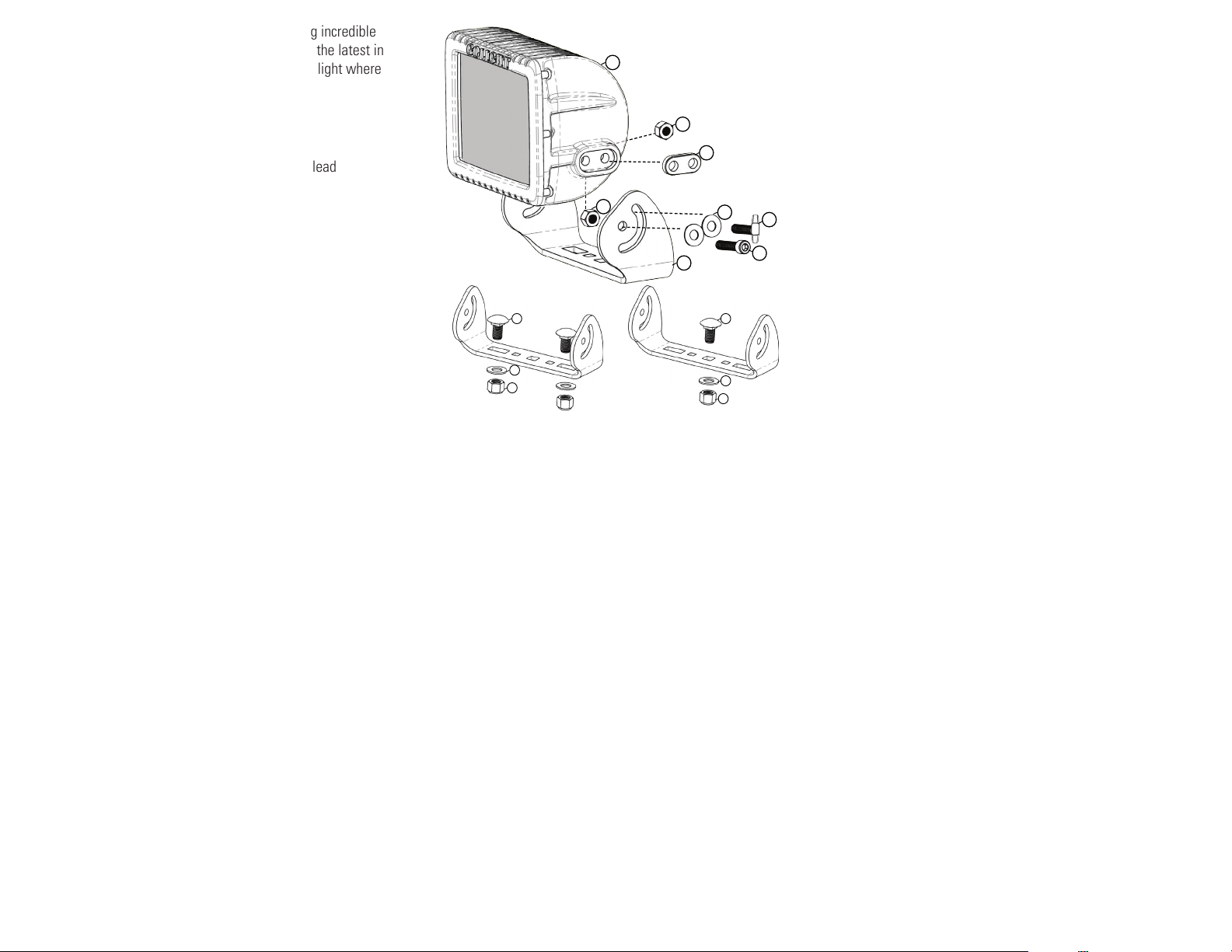

Contents:

Bracket to mounting surface hardware:

1. Qty. 1: GXL® light head with 3ft., 2 wire power lead

2. Qty. 1: Mounting bracket

3. Qty. 2: 3/8” x 1 ¼” carriage bolts

4. Qty. 2: Large flat washers

5. Qty. 2: 3/8 in. lock nuts

Bracket attachment hardware:

6. Qty. 2: Spacers

7. Qty. 4: 1/4” x 1 1/8” socket head cap screws (allen screws)

8. Qty. 4: Locknuts

9. Qty. 4: Small flat washers

10. Qty. 2: Thumb Screws (optional)

Mounting / Installation:

1. Determine a suitable mounting location for the light.

2. Once a location has been decided upon, use the mounting

bracket as a template to mark appropriate bolt-hole locations—

note that the vertical adjustment channel on the bracket indicates

the posterior side of the bracket/light(refer to diagram).

3. The GXL® can be mounted using one or both of the provided

carriage bolts. If future adjustment along the horizontal access is

desired, the light should be affixed using one bolt inserted through

the center mounting hole. If the light is to remain static along the

horizontal axis, both bolts should be used to affix the light and

should utilize the holes nearest the vertical arm on the either side

of the mounting bracket.

1

8

6

8

3 3

4

5

or

9

10

2

7

4

5

4. Drill mounting holes using a 7/16” drill bit.

**Before attaching the mounting bracket to the surface, attach

the mounting bracket to the GXL® :

5. When attaching the mounting bracket to the GXL® , the

included oval spacers must be installed between the bracket

and GXL® to ensure a proper fit.

6. After inserting the spacers into their receptacle on the right

and left lateral of the GXL® (refer to diagram) the arms of the

mounting bracket can be positioned over the spacers with the

pivot hole and vertical channel aligned with the corresponding

attachment holes.

7. The mounting bracket should be affixed using the allen screws

and lock nuts provided. Slide the inward facing lock nuts into the

channels molded into the heat sink on the back of the light. The

channels are molded in such a manner that no tool is required

to hold the nut in place while tightening. The included thumb

screws may be utilized in place of the socket head cap screws

in the vertical channel to facilitate easier vertical adjustment.

Installation of the thumb screw should follow the same procedure

as the socket head cap screw. Take care not to over tighten the

associated hardware in the pivot hole.

8. Insert the allen screws through the holes and thread them into

their corresponding nut.

9. After attaching the mounting bracket to the GXL® align the

bracket with the pre-drilled hole/holes and affix the unit with the

supplied carriage bolt/bolts.

10. Adjust GXL® to desired position and tighten all hardware.

Wiring Procedure and Power Requirements:

1. Extend the red (+) wire to a customer supplied on/off switch

2. Extend another wire from the on/off switch to the positive (+)

terminal of the vehicle battery. Installation of an in-line 7-10 amp

fuse is recommended.

3. Extend the black (-) wire to the negative (-) terminal of the

vehicle battery or to a solid chasis ground.

4. Please take note that appropriately sized (awg) must be

installed according to the length of wire and the necessary

capacity. The GXL will draw 5.5 amps (nominal) at 12V DC and

2.5 amps (nominal) at 24V DC. The GXL® will accept voltage

between 9V-36V DC.

Loading...

Loading...