goldstein X500A User Manual

.

GAS CONVECTION OVEN

GAS CONVECTION OVEN

GAS CONVECTION OVEN GAS CONVECTION OVEN

PROUDLY AUSTRALIAN MADE

INSTALLATION PROCEDURE – USER MANUAL

SERVICE INSTRUCTION

MODEL X500A

MODEL X500A

MODEL X500A MODEL X500A

ELECTRICAL APPROVAL CS 4049

GAS APPROVAL SC 378

ESTABLISHED 1911

The Cooking Equipment Professionals

www.goldsteineswood.com.au

TABLE OF CONTENTS

1. INTRODUCTION Page 3

2. INSTALLATION Page 4 – 5 & 6

3. COMMISSIONING Page 7

4. OPERATING INSTRUCTIONS Page 8

5, CONTROLS Page 9

6. TECHNICAL INSTRUCTIONS Page 10

7. TECHNICAL DATA Page 11 – 12 - 13

8. ELECTRICAL CONNECTION Page 14

9. GUIDE FOR COOKING TIMES TEMP. Page 15

10. CLEANING INSTRUCTIONS Page 16 & 17

11. PROBLEM SOLVING Page 18 – 19 - 20

12. WIRING DIAGRAM Page 21 & 22

13. CONNECTION DIAGRAM Page 23

14. BLOWER WHEEL FAN Page 24

15. DRAWINGS Page 25

16. SPARE PARTS Page 26

17. WARRANTY Page 27

18. BRANCHES Page 28

2

IM067B2 – June 2010

1. INTRODUCTION

Congratulations for purchasing your Goldstein commercial cooking appliance.

J. Goldstein & Co. is a wholly owned Australian company and has been

operating since 1911, building high quality products. The information in this

manual will assist your installer and ensure correct location and connection.

Thoroughly read the user instructions and the user maintenance sections, as

understanding your products, its operation, and its cleaning and service

requirements will provide you with long and satisfactory service. Failure to do so

could shorten the life of the product and decrease its efficiency. Please ensure

only authorised service technicians are called to any difficulties that may arise.

INTRODUCTION

GOLDSTEIN GAS CONVECTION OVEN

MODEL X500A

GOLDSTEIN GAS CONVECTION OVENS are designed to give long and satisfactory

service and incorporate the best possible materials and workmanship. Proper

installation, adjustment and preventative maintenance are vitally important if efficiency

and appearance are to be maintained.

Read these instructions carefully as they contain important safety information regarding

the installation, use and maintenance of the appliance.

RECEIVING INSPECTION

•

Check crates for handling damage. After carefully uncrating, check for “concealed”

damage. Report any damage immediately to carrier and to dealer.

•

Remove check all loose items from unit and check contents as found on back of

warranty card.

•

Check type and capacity of gas supply & Electrical rating on the rating plate.

•

The type of gas for which this Oven is factory adjusted can be seen on the rating

plate, located on the front bottom panel (below the doors).

“THE EQUIPMENT MUST BE INSTALLED BY A LICENSED GASFITTER AND

LICENSED CONTRACTOR”

3

IM067B2 – June 2010

2. INSTALLATION INSTRUCTIONS

PRE-INSTALLATION OF THE X500

Assemble legs to X500A

To assemble the legs place two pieces of timber approx. the depth of the unit covered

with plastic on the floor beside the unit. Tip the unit over onto these two pieces of

timber exercising care not to jam your hands.

Then proceed to bolt the legs onto each corner after the legs are in place bolt the metal

shelf into place which helps align the legs. When this is complete then carefully raise

the unit up onto its legs.

Levelling of X500A

X500A have a levelling adjustment at the bottom of each leg. Start with this adjustment

screwed all the way in. With a spirit level placed on an oven rack check and level side

to side first, then front to back, this is important as floors can be out 75mm of level.

ELECTRICAL CONNECTION

The electric motor, indicator light and related switch, are all connected to a terminal

block found at the top of the oven. The supply cord must be plugged into a properly

ground three-prong receptacle. Do not cut or remove the grounding prong from the

plug.

Normal factory connections are made for operation on 240 volt AC50 cycle.

VENTILATION

Proper ventilation is essential for good oven operation. When a hood is used as means

of ventilation, it should extend at least 150mm beyond all sides of oven (except against

a wall, if it is a wall installation). Oven must be 50mm off wall.

IMPORTANT

If the oven is to be “built-in”, adequate air space for proper venting of the motor must be

provided at the bottom and top of the unit, or WARRANTY WILL BE VOID.

IM067B2 – June 2010

4

2. INSTALLATION INSTRUCTIONS

Follow these instructions carefully.

1. Have a licensed gas fitter or our local gas company connect the appliance to the

mains pressure supply. The gas inlet connection can be seen in the appendix on

Page 11. The appliance must be installed in accordance with rules of any

authority having jurisdiction as per below. The regulator is built into the gas

control, behind side panel on Page 11.

NOTE: The appliance must be installed by an authorised Gas Fitter and in

accordance with the regulations of the local Gas Authority, AS5601/AG601

and any other authority having jurisdiction. The appliance has been tested

and preset before leaving our factory, but small adjustments may be

necessary to suit local conditions. Correct operation of the appliance must

be tested as part of the installation procedure. Check Page 7

Commissioning.

Licensed Gas Fitter should make connection to main gas line. Install a hand

shut-off valve in gas line to the appliance manifold.

As from 1st January 2005. The new AGA AS4563/AG300 codes states that all L.P.G.

appliance will be supplied with a separate regulator for each appliance.

FAILURE TO DO SO WILL VOID

WARRANTY ON THE EQUIPMENT

PLEASE RETURN YOUR WARRANTY CARD

NOTICE

IM067B2 – June 2010

5

2. INSTALLATION INSTRUCTIONS

INSTALLATION

(FOR AUTHORISED INSTALLER ONLY)

Note: AFTER ANY MAINTENANCE OR ADJUSTING OF GAS CONNECTED

COMPONENTS, A GAS LEAK TEST MUST BE CARRIED OUT, TO ENSURE THERE

ARE NO GAS LEAKING HAZARDS

GAS CONNECTION

The gas pressure regulator is part of the 830 TANDEM - SIT Control and not a separate

item. Note: Any inlet pressure above 2.7 kPa must have an inline gas regulator before

the unit. It is important that adequately sized piping be run directly to point of

connection on oven with as few tees and elbows as possible. Always install an

accessible shut-off valve adjacent to oven.

When making gas pipe connections the pipe joint compound should be resistant to the

action of liquefied petroleum gases.

A. If gas specified on rating plate (located on bottom front panel) does not

correspond with gas supplied, notify your dealer immediately.

B. Check gas pressure at Test nipple on the outlet side of the 830 SIT Control. The

control pressure e.g. as on Page 12 should be 0.92 Kpa on Natural gas and

2.60 Kpa on LP gases. When checking gas Test Point Pressure, be sure other

equipment on the same gas line is “ON”. This will allow you to set the T.P.P.

while the oven is under a high load.

T.P.P. can be adjusted using a screw driver to turn the adjusting screw of the SIT

control 830 in centre of body.

ON SITE OVEN TEST

When the oven has been installed, proceed as follows to check that oven works

according to the manufacturers requirements.

Ensure that the fan turns in the direction indicated on the Fan Motor.. Ensure

that the fan (located in the rear of the oven) cuts off when oven doors are

opened.

Ensure that once oven reaches pre-set temperature that burner flame cuts off,

then cuts back in when oven temperature drops 2-3 degrees below pre-set

temperature.

CAUTION: BEFORE PERFORMING ANY MAINTENANCE ON THIS UNIT,

DISCONNECT FROM MAIN POWER SUPPLY.

IM067B2 – June 2010

6

3. COMMISSIONING INSTRUCTIONS

COMMISSIONING CHECK LIST

1. CHECK FOR DAMAGE AND MISSING PARTS.

2. REMOVE ALL PLASTIC COATING FROM S/STEEL PANELS.

3. MAKE SURE ALL PARTS ARE IN THEIR CORRECT POSITION E.G. TRAYS

BURNERS KNOBS.

4. MAKE SURE ALL GAS CONNECTIONS ARE CORRECT AND TIGHT.

5. LEVEL OFF UNIT LEFT TO RIGHT AND ALSO MAKE SURE THAT FRONT IS

JUST 3-4 MM LOWER TO ALLOW FOR FLUING.

6. TURN ON GAS .

7. ADJUST GAS PRESSURE WITH THREE-QUARTERS OF THE UNIT

RUNNING, ADJUST GAS PRESSURE.

NATURAL GAS 1.00 KPA ) as per pressure shown

LPG 2.60 KPA ) on Rating Plate

8. TURN ON ONE AT A TIME TO MAKE SURE ALL IS WORKING E.G. BURNER,

RADIANT, GRIDDLE AND STEAMER.

9. SHOW CUSTOMER

A) HOW TO WORK EQUIPMENT

B) HOW TO CLEAN

C) HOW TO PULL IT APART E.G. TRAYS, TRIVETS.

D) ALSO WHAT NOT TO DO, E.G. GREASE AND OIL IN CONTROLS.

10. CHECK TO MAKE SURE MANUALS AND WARRANTY CARDS ARE THERE.

ALSO GO THROUGH MANUAL WITH CUSTOMER E.G. LIGHTING,

CLEANING.

NOTE

HOSES SHOULD NEVER BE USED ON THE APPLIANCE.

USE OF HOSES WILL VOID WARRANTY

“DO NOT SPRAY AEROSOLS IN VICINITY OF APPLIANCE WHILST

OPERATING”

7

IM067B2 – June 2010

4. OPERATING INSTRUCTIONS

OVEN OPERATING INSTRUCTIONS

Due to increased efficiency of this oven the temperature of the standard recipes should

be reduced approximately 20°C.

Always load each shelf evenly. Space pans away from each other and from sides and

back of oven to allow a maximum of airflow between them.

The moving air continually strips away thin layers of moisture and cool air from the top

of the goods allowing the heat to penetrate more quickly, thus shortening the cooking

time and permitting use of lower temperatures.

Cook the product in less time than it would take to bake in a Static or Normal oven.

Depending on the item and the type of pan used, time saving may run from 20% to a

high of 50%. A damper lever on the control panel keeps steam in when you want moist

heat – but permits you to let it out fro dry heat.

With stainless steel interiors, this oven is designed to be as maintenance free as

possible. However, for best operating results, the oven should be cleaned regularly and

the controls should be adjusted periodically.

8

IM067B2 – June 2010

operate until the set time has elapsed and the buzzer sounds.

Reset

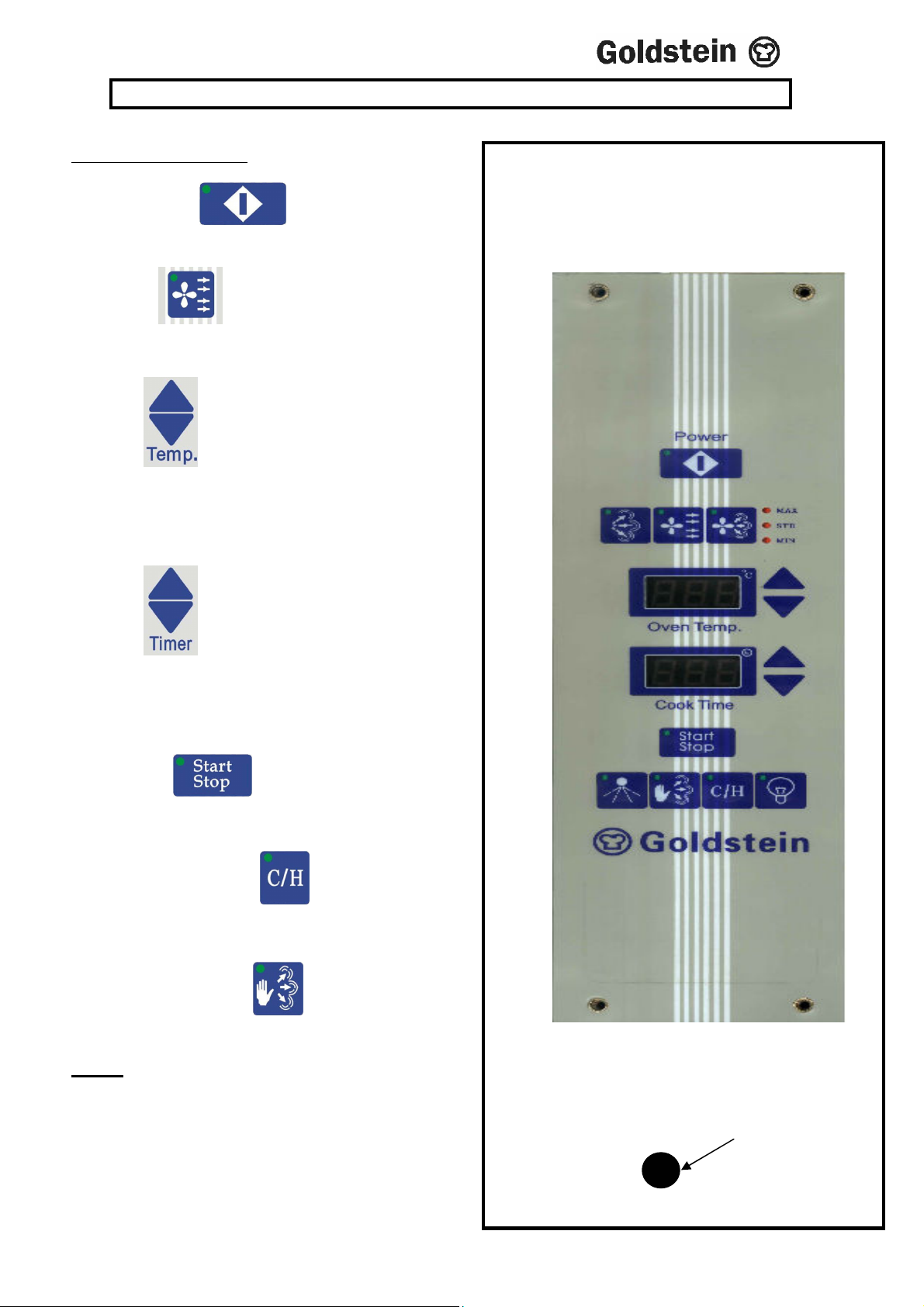

5. CONTROLS

COOKING CYCLE

(i) Turn on Power .

(ii) Select the cooking mode by pressing the

Convection Button

(iii)

Press button up or down to set desired

temperature, the display will flash to indicate the

setting mode, when arrow is released set temperature

will display for 3 seconds and then display will stop

flashing and read actual oven temperature.

(iv)

Press button up or down to set desired

cooking time. Timer display will flash to indicate that

it is in the setting mode, it will stop after the button

has been released and will display the set cooking

time.

X500

(viii) Press the button so that the green LED

lights up. This will start the cooking cycle which will

(ix) Cook & Hold. Press the button. It will hold the

oven temperature at 70ºC after the cooking cycle finishes,

for up to 999 minutes.

(x) Hand Steam. Press the button; it will inject

steam, for 2 seconds.

NOTE

Push the Pilot reset button, if the light is on.

If the light remains ON after 3 or 4 attempts, call

a Service Technician

Pilot

Button

IM067B2 – June 2010

9

Loading...

Loading...