Page 1

MICROW AVE OVEN

SER VICE MANUAL

MODEL: MA-1303BRV

CAUTION

BEFORE SERVICING THE UNIT, READ THE

SAFETY PRECAUTIONS IN THIS MANUAL.

http://www.LGEservice.com

e-mail:techsupport@LGEservice.com

Page 2

This device is to be serviced only by properly qualified service personnel.

Consult the service manual for proper service procedures to assure continued safety operation and for precautions to be

taken to avoid possible exposure to excessive microwave energy.

PRECAUTIONS TO BE OBSERVED BEFORE AND

DURING SERVICING TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

A) Do not operate or allow the oven to be operated with the door open.

B) Make the following safety checks on all ovens to be serviced before activating the magnetron or other

microwave source, and make repairs as necessary; (1) interlock operation, (2) proper door closing, (3)

seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or loosening of hinges and

latches, (5) evidence of dropping or abuse.

C) Before turning on microwave power for any service test or inspection within the microwave generating

compartments, check the magnetron, wave guide or transmission line, and cavity for proper alignment,

integrity, and connections.

D) Any defective or misadjusted components in the interlock, monitor, door seal, and microwave generation

and transmission systems shall be repaired, replaced, or adjusted by procedures described in this manual

before the oven is released to the owner.

E) A microwave leakage check to verify compliance with the Federal Performance Standard and CSA should

be performed on each oven prior to release to the owner.

SAFETY PRECAUTIONS

Page 3

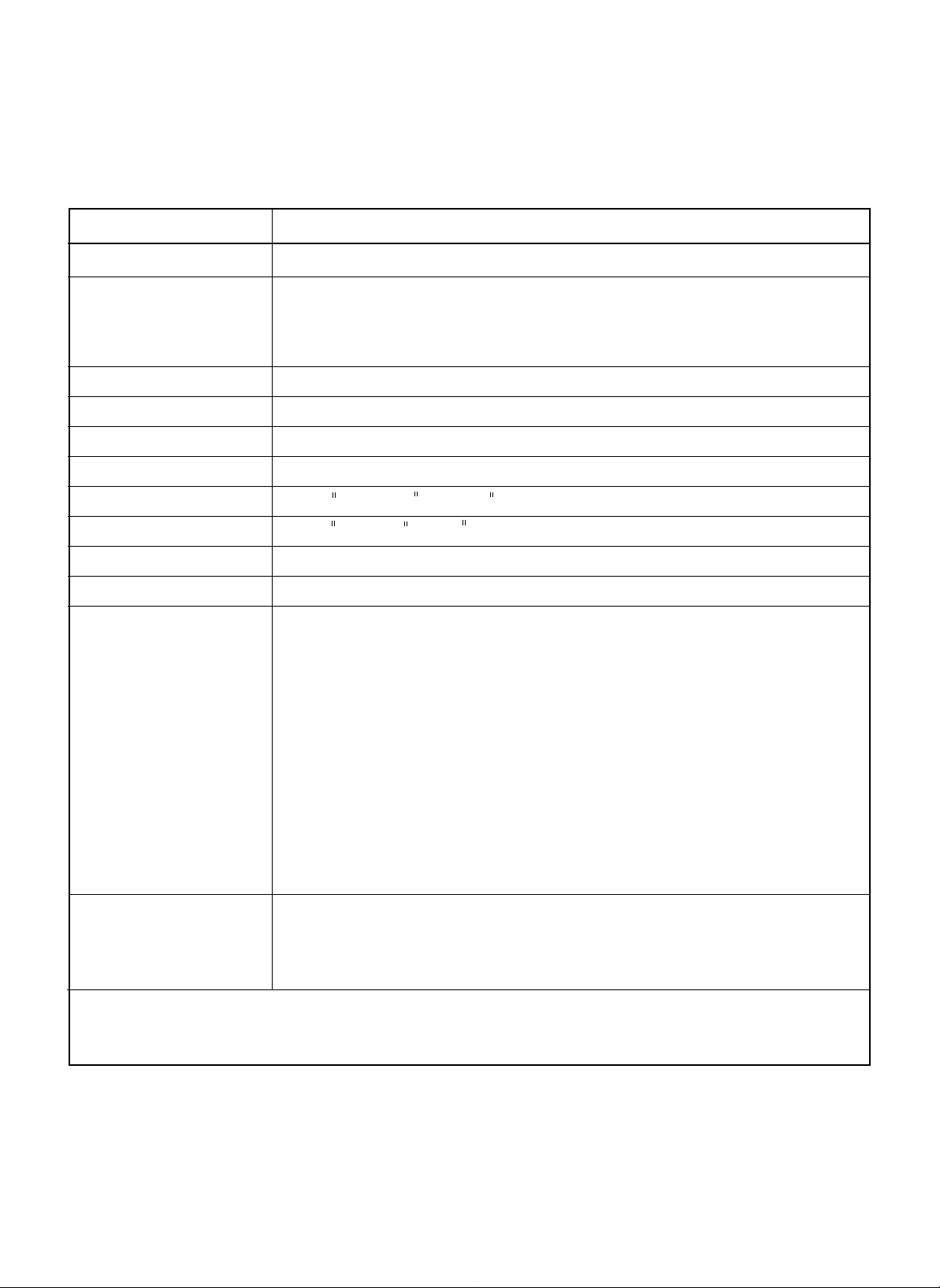

1-1

It is not recommended for commercial purposes.

ITEM

MODEL

Power Requirement

Power Output

Microwave Frequency

Magnetron

Timer

Outside Dimensions

Cavity Dimensions

Net Weight

Shipping weight

Control Complement

Accessories

DESCRIPTION

MA-1303BRV

120 Volts AC 60 Hz

1,300 Watts (12.0A)

Single phase, 3 wire grounded

900 Watts full microwave power (IEC705)

2,450 MHz

2M214

0 ~ 99 min. 99 sec.

217/8

˝ (W) x 125/8˝ (H) x 171/4˝ (D)

14

3/4˝ (W) x 91/4˝ (H) x 16˝ (D)

37 lbs (approx.)

40 lbs (approx.)

Touch Control System

Clock : 1:00 - 12:59

Microwave Power for Variable Cooking

Power level

HIGH

-------------------------------

Full power throughout the cooking time

9 (Saute)

------

approx. 90% of Full power, 8 (Reheat)

--------

approx. 80%

7 (Med.-High)

--------------

approx. 70%, 6 (Medium)

--------

approx. 60%

5 (Med.-Low)

---------------

approx. 50%, 4 (Defrost)

---------

approx. 40%

3 (Low)

--------------------

approx. 30%, 2 (Simmer)

---------

approx. 20%

1 (Warm)

------------------

approx. 10%

Owner's manual

Glass turntable

Rotating ring

SPECIFICATIONS

Page 4

FEATURES

CONTROL PANEL

1. DISPLAY WINDOW

2. ONE TOUCH COOK: This menu has been pre

programmed to cook food automatically by one touch.

3. MORE / LESS: All of the one touch cook and TIMED

COOK can be adjusted to cook food for a longer or shorter

time.

MORE Pressing MORE will add 10 seconds to the

cooking time.

LESS Pressing LESS will subtract 10 seconds of

cooking time.

4. AUTO DEFROST: This feature provides you with the best

defrosting method for frozen foods.

5. NUMBER: These used to set for time of day, cooking time,

power level, or defrost weight.

6. STOP/CLEAR: It used to stop oven and clear all entries

except time of day.

7. CUSTOM COOK: This feature allows you to set and

execute a frequently used single stage program.

8. CLOCK: It is used to set the time of day.

9. Kg/Lbs

10. POWER: You can select the desired power level for

cooking.

11. TIME: You can set the desired cook time.

12. EZ ON: You can extend cooking time in multiples of 30

seconds by repeatedly touching this pad during cooking.

13. START: This feature allows oven to begin functioning.

4-1

OPERATING INSTRUCTIONS

Oven Front Plate

Window Door Screen

Door Seal

Control Panel

Door Open Button

Safety Door Lock System

Turntable

Rotating Ring

Display Window

1

4

7

5

6

83

2

9

11

10

12

13

Page 5

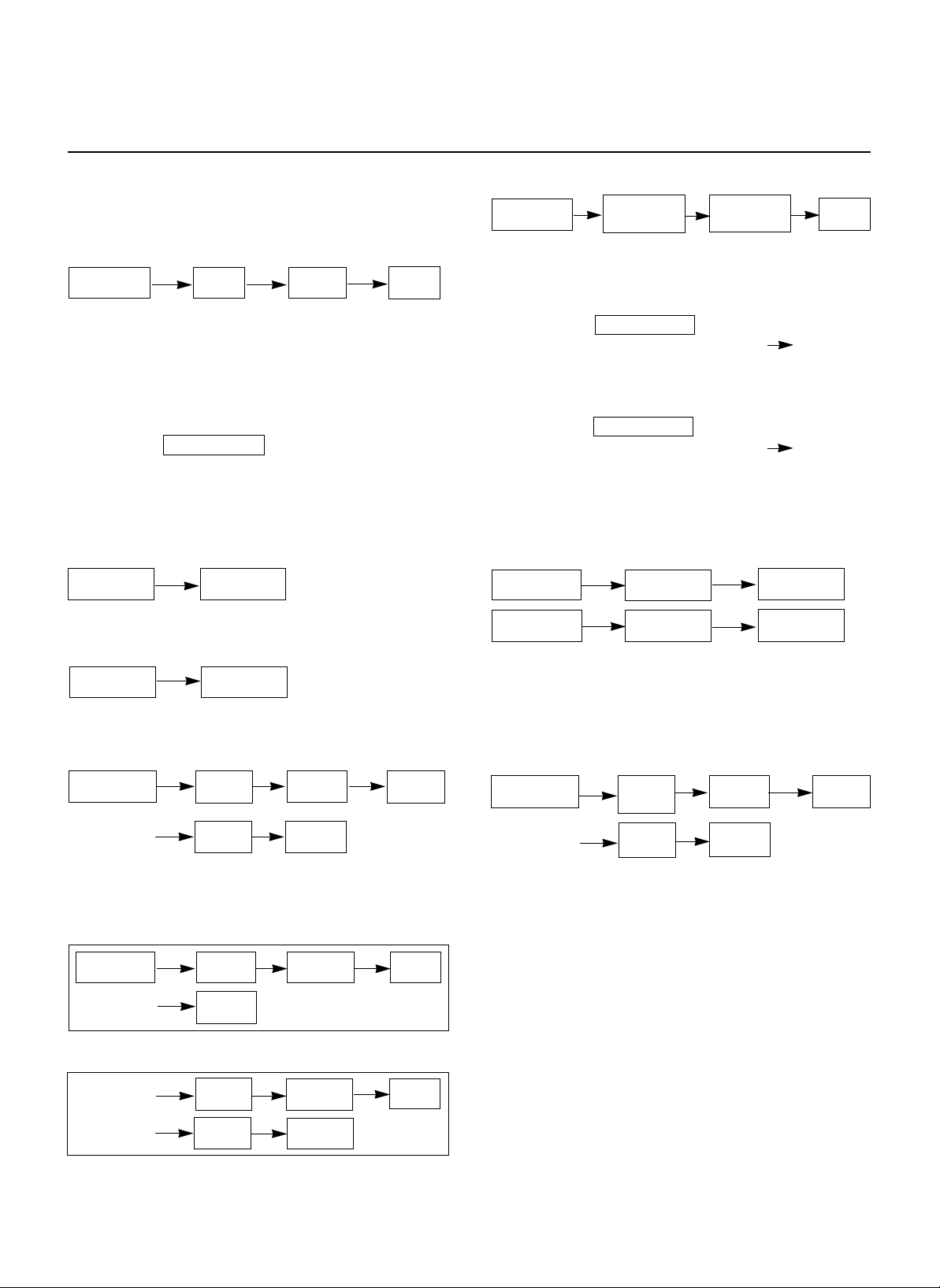

OPERATING SEQUENCE

The following is a description of component functions

during oven operation.

1. SETTING THE CLOCK

ex.) To set 4:30, touch number key [4],[3], and [0].

NOTE: 1) This is a 12 hour clock.

2) Clock will operate as long as power is

applied to the oven.

2. CANCEL FUNCTION

Touch the pad whenever you need to

cancel an entry or a function currently in use.

The display will either return to the last item entered

or to the clock.

3. EZ ON

4. ONE TOUCH COOKING

NOTE: Heat only 1 package at a time

5. TIME COOKING

6. MULTI-STAGE COOKING

7. AUTO WEIGHT DEFROST COOKING

8. CHILD LOCK

This oven has a CHILD LOCK feature

TO SET CHILD LOCK

• Touch the pad

• Touch and hold STOP/CLEAR pad LOCK

appear on the display.

TO CANCEL CHILD LOCK

• Touch the pad

• Touch and hold STOP/CLEAR pad LOCK

disappears.

9. MORE / LESS

The cook time is adjustable by MORE pad or LESS

pad

10. CUSTOM COOK

You can program the cook time and power level by

using CUSTOM COOK pad.

ex) To set cook time 10 mine 30seconds, touch

number key [1],[0],[3], and [0]

4-2

STOP/CLEAR CLOCK

NUMBER

STOP/CLEAR POPCORN

STOP/CLEAR EZ on

STOP/CLEAR

COOKING

MORE

STOP/CLEAR COOKING

LESS

STOP/CLEAR

1ST STAGE

CLOCK

STOP/CLEAR

AUTO WEIGHT

DEFROST

NUMBER OF

WEIGHT

START

STOP/CLEAR

CUSTOM

COOK

NUMBER POWER

NUMBER

START

STOP/CLEAR

TIME

NUMBER

POWER

NUMBER START

STOP/CLEAR

TIME

NUMBER POWER

NUMBER

2ND STAGE

TIME

NUMBER

POWER

NUMBER

START

STOP/CLEAR

STOP/CLEAR

Page 6

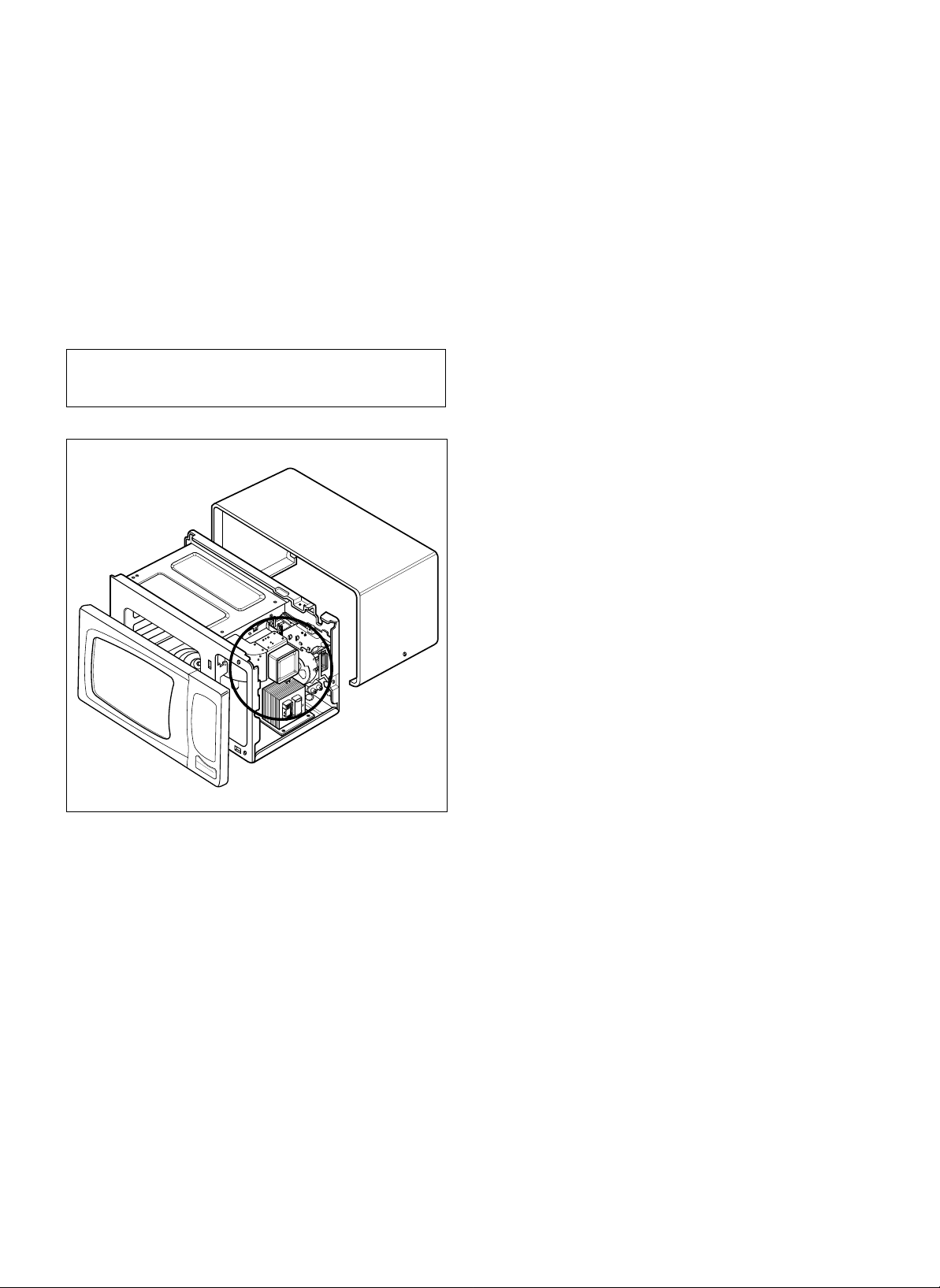

MEASUREMENT WITH OUTER CASE

REMOVED

• When you replace the magnetron, measure for

microwave energy leakage before the outer case is

installed and after all necessary components are

replaced or adjusted.

Special care should be taken in measuring the

following parts. (Circled area of Fig. below)

- Around the magnetron

- The waveguide

MEASUREMENT WITH A FULLY

ASSEMBLED OVEN

• After all components, including the outer case, are fully

assembled, measure for microwave energy leakage

around the door viewing window, the exhaust opening,

and air inlet openings.

• Microwave energy leakage must not exceed the values

prescribed below.

NOTE: Leakage with the outer case removed less than

5 mW/cm.sq. Leakage for a fully assembled

oven (Before the latch switch (primary) is

interrupted) with the door in a slightly opened

position-less than 2 mW/cm.sq.

NOTES WHEN MEASURING

• Do not exceed meter full scale deflection.

• The test probe must be removed no faster than

1 inch/sec (2.5 cm/sec) along the shaded area,

otherwise a false reading may result.

• The test probe must be held with the grip portion of the

handle.

A false reading may result if the operator's hand is

between the handle and the probe.

• When testing near a corner of the door, keep the probe

perpendicular to the surface making sure the probe

horizontally along the oven surface; this may possibly

cause probe damage.

RECORD KEEPING AND NOTIFICATION

AFTER MEASUREMENT

• After adjustment and repair of any microwave energy

interruption or microwave energy blocking device,

record the measured values for future reference. Also

enter the information on the service invoice.

• The microwave energy leakage should not be more

than 4 mW/cm.sq. after determining that all parts are in

good condition, functioning properly and genuine

replacement parts which are listed in this manual have

been used.

• At least once a year, have the electromagnetic energy

leakage monitor checked for calibration by its

manufacturer.

5-2

WARNING : AVOID CONTACTING ANY

HIGH VOLTAGE PARTS

Page 7

• Microwave power output measurement is made with

the microwave oven supplied at its rated voltage and

operated at its maximum microwave power setting with

a load of (1000±5) g of potable water.

• The water is contained in a cylindrical borosilicate glass

vessel having a maximum material thickness of 3 mm

and an outside diameter of approximately 190mm.

• The oven and the empty vessel are at ambient

temperature prior to the start of the test.

• The initial temperature (T1) of the water is (10±2)°C It

is measured immediately before the water is added to

the vessel. After addition of the water to the vessel,

the load is immediately placed on the center of the

turntable which is in the lowest position and the

microwave power switched on.

• The time T for the temperature of the water to rise by a

value ∆ T of (10±2)°K is measured, where T is the time

in seconds and ∆T is the temperature rise. The initial

and final water temperatures are selected so that the

maximum difference between the final water

temperature and the ambient temperature is 5°K.

• The microwave power output P in watts is calculated

from the following formula :

4187 x (∆T)

T

is measured while the microwave generator is

operating at full power. Magnetron filament heat-up

time is not included. (about 3 sec)

• The water is stirred to equalize temperature throughout

the vessel, prior to measuring the final water

temperature.

• Stirring devices and measuring instruments are

selected in order to minimize addition or removal of

heat.

A. OUTER CASE REMOVAL

1) Disconnect the power supply cord from the outlet.

2) Remove the screws from the rear of the case.

The outer case must be moved backward to be lifted

off.

B. POWER SUPPLY CORD

1) Remove the outer case.

2) Disconnect two terminals, and remove one screw of

the ground terminal.

C. CONTROL PANEL ASSEMBLY

1) Open the door.

2) Disconnect the leadwire from RELAY(RY2) of the

PCB SUB ASS’Y.

3) Lift up and pull out control panel assembly carefully

from the cavity.

4) Disconnect the leadwire from connector(CN1) of the

PCB SUB ASS’Y.

CAUTION: DISCHARGE THE HIGH VOLTAGE

CAPACITOR BEFORE SERVICING

(refer to page 2-1)

5-3

WATER LOAD

TURNTABLE

MEASUREMENT OF MICROWAVE POWER OUTPUT

P =

Remove the screw

Lift up and pull out control panel

DISASSEMBLY AND ADJUSTMENT

ground screw

Page 8

D. PCB ASSEMBLY REMOVAL

1) Remove the control panel assembly from the

cavity. (Refer to control panel assembly removal

on previous page.)

2) Remove screws which hold the PCB SUB ASS’Y to

the control panel.

3) Disconnect the flat cable from the PCB SUB

ASS’Y and take off the PCB SUB ASS’Y

E. DOOR MAIN ASSEMBLY REMOVAL

1) Open the door.

2) Remove the choke cover cap very carefully with a

flat-blade screwdriver.

CAUTION : Be careful not to damage door seal plate

with the screwdriver.

3) Lift up and push the door.

NOTE:

1. After replacing the door, be sure to check that the

primary switch, monitor switch, and secondary switch

operate normally.

2. After replacing the door, check for microwave energy

leakage with a survey meter. Microwave energy must

be below the limit of 4 mW/cm. (with a 275 ml water

load)

3. When mounting the door assembly to the oven

assembly, be sure to adjust the door assembly parallel

to the chassis. Also adjust so the door has no play

between the inner door surface and oven frame

assembly. If the door assembly is not mounted

properly, microwaves may leak from the clearance

between the door and the oven.

5-4

Remove choke cover cap

Remove door

Spacer

Control Panel

Key Membrane

Button Spring

Door Open Button

PCB Sub Asm

Release

Lever

Page 9

F. AIR DUCT ASSEMBLY REMOVAL

1) Disconnect the leadwire from the lamp.

2) Remove the mounting screw to the magnetron.

G. MAGNETRON REMOVAL

1) Disconnect the leadwire from the magnetron.

2) Carefully remove the mountinth eg screws holding

the magnetron and the waveguide.

3) Remove the magnetron ASS’Y until the tube is

clear from the waveguide.

NOTE:

1. When removing the magnetron, make sure its

dome does not hit any adjacent parts, or it may be

damaged.

2. When replacing the magnetron, be sure to install

the magnetron gasket in the correct position and

be sure that the gasket is in good condition.

3. After replacing the magnetron, check for microwave

leakage with a survey meter around the

magnetron. Microwave energy must be below the

limit of 5 mW/cm2. (With a 275 ml. water load).

Make sure that gasket is rigidly attached to the

magnetron. To prevent microwave leakage,

tighten the mounting screws properly, making sure

there is no gap between the waveguide and the

magnetron.

H. REMOVING THE TURNTABLE MOTOR

1) Remove the turntable.

2) Remove the turntable shaft VERY CAREFULLY.

3) Lay the unit down on its back.

4) Remove the turntable motor cover.

The turntable base cover is easily removed by

pinching the six parts with a wire cutting.

5) Disconnect the leadwire from the turntable motor

terminals.

6) Remove the screw securing the turntable motor to

the oven cavity ASS’Y

7) After repairing the motor, rotate the removed

turntable motor cover.

NOTE:

1. Remove the wire lead from the turntable motor

VERY CAREFULLY.

2. Be sure to grasp the connector, not the wires, when

removing.

5-5

Waveguide

Dome

Waveguide

Bracket

Magnetron

Gasket

Magnetron

Magnetron

Air Duct

Wire Leads

Turntable Motor

Page 10

5-6

K. HIGH VOLTAGE

TRANSFORMERREMOVAL

1) Discharge the high voltage capacitor.

2) Disconnect the leadwire from magnetron, high

voltage transformer, and capacitor.

3) Remove the screw holding the high voltage

transformer to the baseplate.

J. FAN MOTOR ASSEMBLY REMOVAL

1) Discharge the high voltage capacitor.

2) Disconnect the leadwire from magnetron, high

voltage capacitor.

3) Remove the two screws holding the the suction

guide ASS’Y to the oven cavity and remove the

high voltage diode earth screw.

4) Remove the two screws holding the fan motor

ASS’Y to the suction guide ASS’Y.

K. HIGH VOLTAGE CAPACITOR AND

DIODE REMOVAL

1) Discharge the high voltage capacitor.

2) Disconnect the leadwire from fan motor and high

voltage capacitor.

3) Remove the screw holding the suction guide ASS’Y

to the oven cavity and remove the high voltage

diode earth screw.

4) Remove the screw holding the high voltage

capacitor bracket.

L. INTERLOCK SYSTEM

1) INTERLOCK MECHANISM

The door lock mechanism is a device which has

been specially designed to eliminate completely

microwave activity when the door is opened during

cooking and thus to prevent the danger resulting

from the microwave leakage.

L. INTERLOCK SYSTEM

1) INTERLOCK MECHANISM

The door lock mechanism is a device which has

been specially designed to eliminate completely

microwave activity when the door is opened during

cooking and thus to prevent the danger resulting

from the microwave leakage.

2) MOUNTING OF THE PRIMARY/MONITOR/

SECONDARY SWITCHES TO THE LATCH

BOARD

3) INSTALLATION AND ADJUSTMENT OF THE

LATCH BOARD TO THE OVEN ASSEMBLY

• Mount the latch board to the oven assembly.

• Adjust the latch board in the arrow direction so

that oven door will not have any play in it when

the door is closed.

• Tighten the mounting screw.

• Check for play in the door by pushing the door

release button. Door movement should be less

than 0.5 mm. (1/64 inch)

Don't push the door release button while making

adjustment. Make sure that the latch moves

smoothly after adjustment are completed and that

the screws are tight. Make sure the primary,

monitor, and secondary switches operate properly

by following the continuity test procedure.

H.V.

Transformer

Suction

Guide

Noise Filter

H.V.

Diode

H.V.

Capacitor

Fan Motor

ASS’Y

PRIMARY

SWITCH

ADJUSTMENT

DIRECTION

MONITOR

SWITCH

SECONDARY

SWITCH

Page 11

DOOR PARTS

LATCH BOARD PARTS

CONTROL PANEL PARTS

INTERIOR PARTS

BASE PLATE PARTS

OVEN CAVITY PARTS

6-1

EXPLODED VIEW

INTRODUCTION

Page 12

6-2

13213A

13552A

13581A

13536A

14026A

14970A

13352A

13720D

DOOR PARTS

Page 13

6-3

26638A

23572A

268711

WTP

018

24970A

250201

24781M

23550D

24510L

CONTROLLER PARTS

Page 14

6-4

OVEN CAVITY PARTS

33390G

35889A

WTT021

33112U

340511

WTT010

WTT020

36549S

WTP013

33052M

948501

33461Z

Page 15

6-5

LATCH BOARD PARTS

43501A

WSZ085

43500A

466001

466001

466003

Page 16

6-6

INTERIOR PARTS

568771

56930V

56411A

54974S

WSZ196

WTT028

WSZ085

WSZ002

56549F

WTT037

WSZ002

WTT028

WSZ002

55900A

56851D

54810C

55262A

56912C

50CZZH

56324A

WSZ002

WSZ002

56201A

50

FZZA

Page 17

6-7

BASE PLATE PARTS

63302L

948501

63302R

56170D

WSZ002

WSZ002

WSZ002

647781

647781

Page 18

P/NO.:3828W5S1550

April, 2000

Printed in Korea

Loading...

Loading...