Goldstar Ma-1302s Service Manual

MICROWAVE OVEN

SERVICE MANUAL

MODEL: MA-1302S

CAUTION

BEFORE SERVICING THE UNIT, READ THE

SAFETY PRECAUTIONS IN THIS MANUAL.

http://www.LGEservice.com

This device is to be serviced only by properly qualified service personnel.

Consult the service manual for proper service procedures to assure continued safety operation and for precautions to be

taken to avoid possible exposure to excessive microwave energy.

PRECAUTIONS TO BE OBSERVED BEFORE AND

DURING SERVICING TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

A) Do not operate or allow the oven to be operated with the door open.

B) Make the following safety checks on all ovens to be serviced before activating the magnetron or other

microwave source, and make repairs as necessary; (1) interlock operation, (2) proper door closing, (3)

seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or loosening of hinges and

latches, (5) evidence of dropping or abuse.

C) Before turning on microwave power for any service test or inspection within the microwave generating

compartments, check the magnetron, wave guide or transmission line, and cavity for proper alignment,

integrity, and connections.

D) Any defective or misadjusted components in the interlock, monitor, door seal, and microwave generation

and transmission systems shall be repaired, replaced, or adjusted by procedures described in this manual

before the oven is released to the owner.

E) A microwave leakage check to verify compliance with the CSA Standard should be performed on each

oven prior to release to the owner.

SAFETY PRECAUTIONS

(Page)

SAFETY PRECAUTIONS

---------------------------------------------------------------------

Inside front cover

SPECIFICATIONS

-----------------------------------------------------------------------------------------------------

1-1

CAUTIONS

--------------------------------------------------------------------------------------------------------------

2-1

INSTALLATIONS

------------------------------------------------------------------------------------------------------

3-1

OPERATING INSTRUCTIONS

------------------------------------------------------------------------------------

4-1

FEATURES

------------------------------------------------------------------------------------------------------------------------

4-1

CONTROL PANEL

-------------------------------------------------------------------------------------------------------------

4-1

OPERATING SEQUENCE

----------------------------------------------------------------------------------------------------

4-2

SCHEMATIC DIAGRAM

------------------------------------------------------------------------------------------------------

4-3

CIRCUIT DESCRIPTION

-----------------------------------------------------------------------------------------------------

4-4

SERVICE INFORMATION

------------------------------------------------------------------------------------------

5-1

TOOLS AND MEASURING INSTRUMENTS

---------------------------------------------------------------------------

5-1

MICROWAVE LEAKAGE TEST

--------------------------------------------------------------------------------------------

5-1

MEASUREMENT OF MICROWAVE POWER OUTPUT

-----------------------------------------------------------

5-3

DISASSEMBLY AND ADJUSTMENT

-------------------------------------------------------------------------------------

5-3

INTERLOCK CONTINUITY TEST

------------------------------------------------------------------------------------------

5-8

COMPONENT TEST PROCEDURE

--------------------------------------------------------------------------------------

5-9

TROUBLE SHOOTING

------------------------------------------------------------------------------------------------------

5-13

EXPLODED VIEW

-----------------------------------------------------------------------------------------------------

6-1

REPLACEMENT PARTS LIST

------------------------------------------------------------------------------------

7-1

SCHEMATIC DIAGRAM OF P.C.B.

------------------------------------------------------------------------------

8-1

PRINTED CIRCUIT BOARD

-------------------------------------------------------------------------------------------------

8-2

P.C.B. PARTS LIST

---------------------------------------------------------------------------------------------------

9-1

CONTENTS

1-1

This microwave oven is designed for household use only.

It is not recommended for commercial purposes.

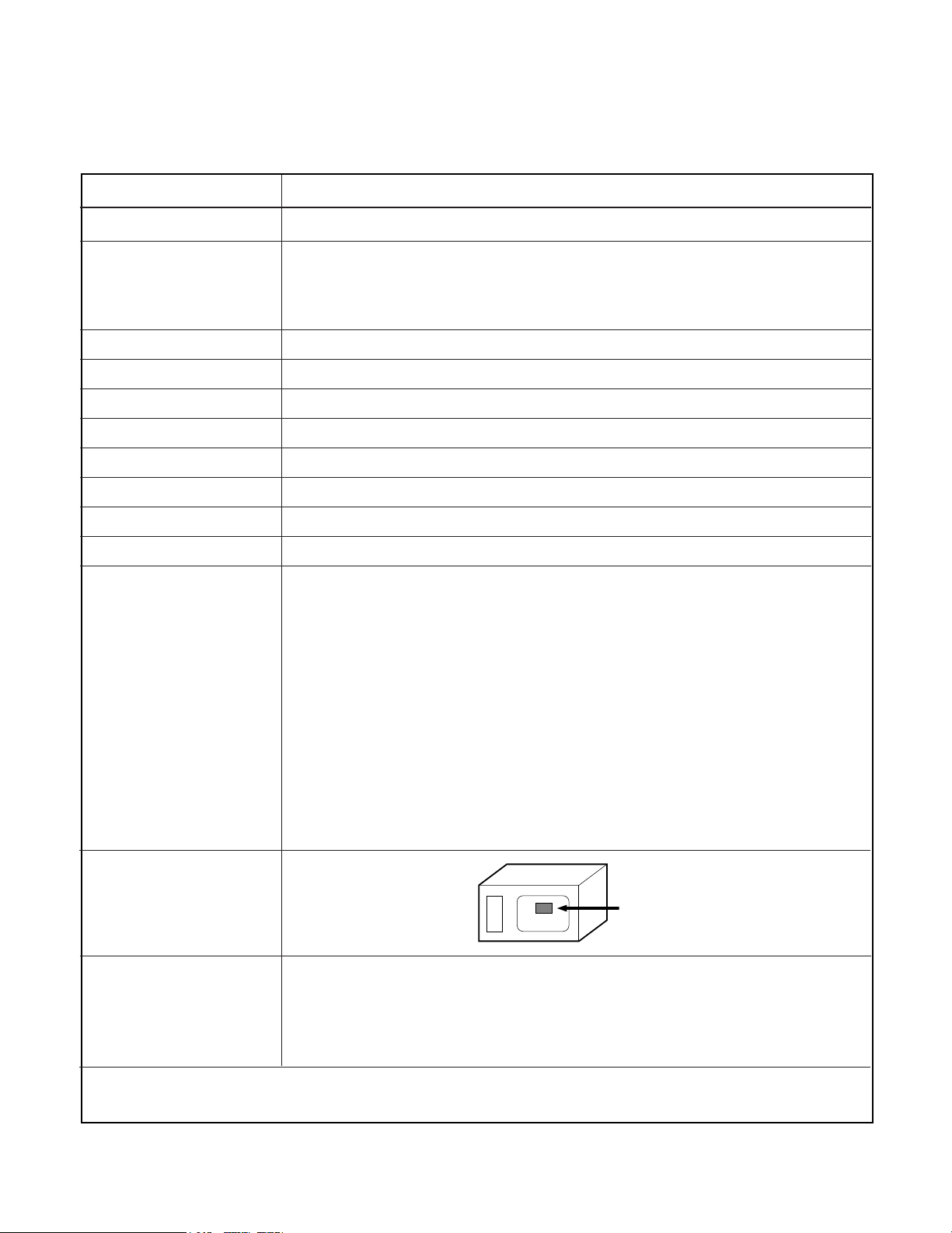

ITEM

MODEL

Power Requirement

Power Output

Microwave Frequency

Magnetron

Timer

Outside Dimensions

Cavity Dimensions

Net Weight

Shipping weight

Control Complement

Nameplate Location

Accessories

DESCRIPTION

MA-1302S

120 Volts AC 60 Hz

1,550 Watts (13.6A)

Single phase, 3 wire grounded

1,150 Watts full microwave power (IEC705)

2,450 MHz

2M246

0 ~ 99 min. 99 sec.

217/8" (W) x 125/8" (H) x 171/4"(D)

143/4" (W) x 91/4" (H) x 16" (D)

38.6 lbs (approx.)

41.9 lbs (approx.)

Touch Control System

Clock : 1:00 - 12:59

Microwave Power for Variable Cooking

Power level

HIGH

-------------------------------

Full power throughout the cooking time

9 (Saute)

------

approx. 90% of Full power, 8 (Reheat)

--------

approx. 80%

7 (Med.-High)

--------------

approx. 70%, 6 (Medium)

--------

approx. 60%

5 (Med.-Low)

---------------

approx. 50%, 4 (Defrost)

---------

approx. 40%

3 (Low)

--------------------

approx. 30%, 2 (Simmer)

---------

approx. 20%

1 (Warm)

------------------

approx. 10%

Owner's manual & cooking guide

Glass turntable

Rotating ring

Back Side

SPECIFICATIONS

¥ DO NOT operate on a 2-wire extension cord during

repair and use.

¥ NEVER TOUCH any oven components or wiring during

operation.

¥ BEFORE TOUCHING any parts of the oven, always

remove the power plug from the outlet.

¥ For about 30 seconds after the oven stops, an electric

charge remains in the high voltage capacitor. When

replacing or checking, you must discharge the high

voltage capacitor by shorting across the two terminals

with an insulated screwdriver.

¥

Remove your watches whenever working close to or

replacing the Magnetron.

¥ DO NOT touch any parts of the control panel circuit. A

resulting static electric discharge may damage this

P.C.B.

¥ NEVER operate the oven with no load.

¥ NEVER injure the door seal and front plate of the oven

cavity.

¥ NEVER put iron tools on the magnetron.

¥ NEVER put anything into the latch hole and the

interlock switches area.

¥ Proper operation of the microwave oven requires that

the magnetron be assembled to the waveguide and

cavity. Never operate the magnetron unless it is

properly installed.

¥ Be sure that the magnetron gasket is properly

installed around the dome of the tube whenever

installing the magnetron.

2-1

CAUTIONS

Unlike other appliances, the microwave oven is

high-voltage and high-current equipment.

Though it is free from danger in ordinary use,

extreme care should be taken during repair.

THE OVEN IS TO BE SERVICED ONLY

BY PROPERLY QUALIFIED SERVICE

PERSONNEL.

MICROWAVE RADIATION

Personnel should not be exposed to the

microwave energy which may radiate from the

magnetron or other microwave generating

device if it is improperly used or connection.

All input and output microwave connections,

waveguide, flange, and gasket must be secure

never operate the device without a microwave

energy absorbing load attached.

Never look into an open waveguide or antenna

while the device is energized.

Gasket

ANTENNA

COOLING FIN

MAGNETRON

CHASSIS GROUND

FILAMENT

TERMINALS

MAGNETRON

INSTALLATIONS

3-1

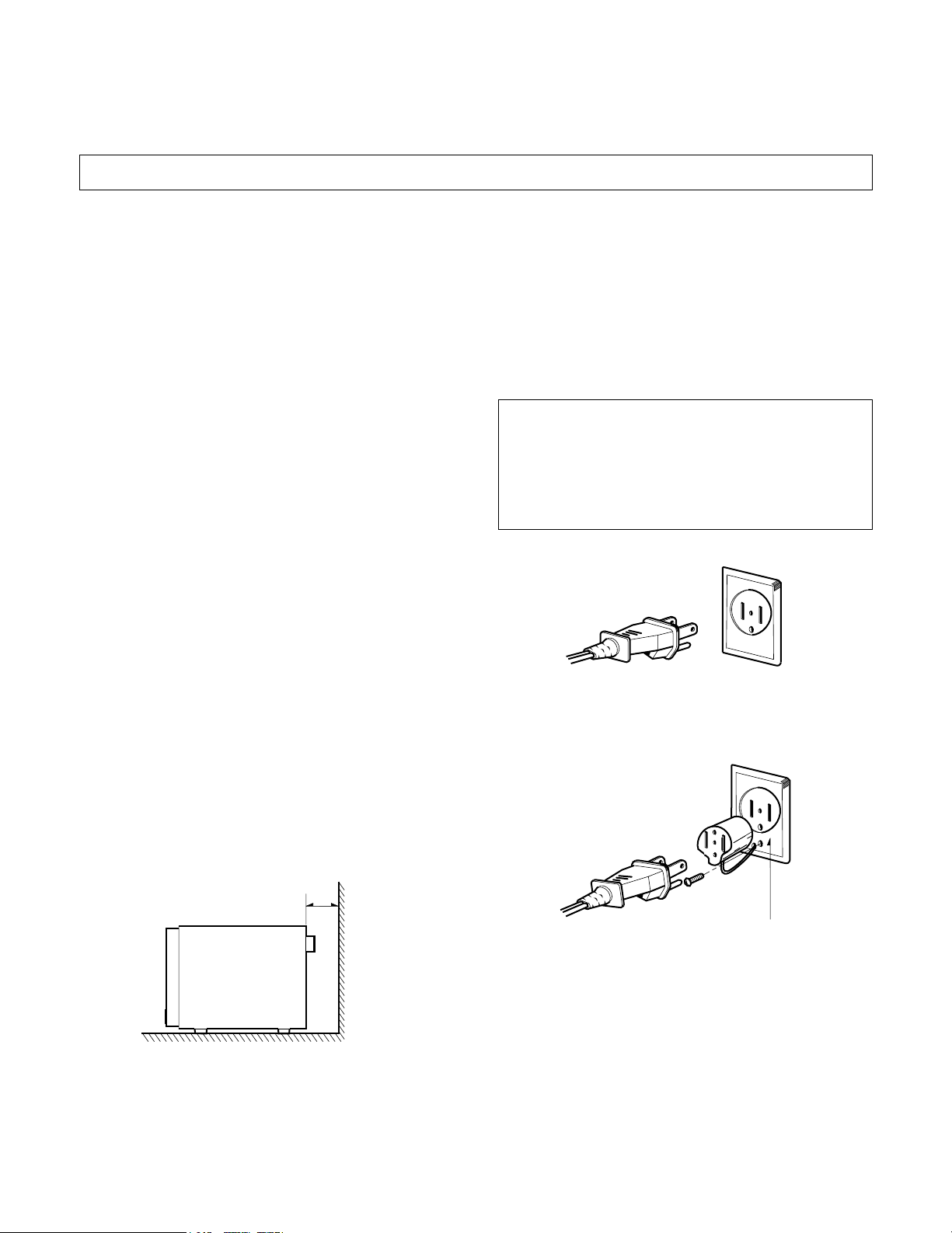

INSTALLING

1. Empty the microwave oven and clean inside it with

a soft, damp cloth. Check for damage such as

misaligned door, damage around the door or dents

inside the cavity or on the exterior.

2. Put the oven on a counter, table, or shelf that is

strong enough to hold the oven and the food and

utensils you put in it. (The control panel side of the

oven is the heavy side. Use care when handling.)

3. Do not block the vent and the air intake openings.

Blocking vent or air intake openings can cause

damage to the oven and poor cooking results.

Make sure the microwave oven legs are in place to

ensure proper air flow.

4. The oven should not be installed in any area where

heat and steam are generated, because they may

damage the electronic or mechanical parts of the

unit.

Do not install the oven next to a conventional

surface unit or above a conventional wall oven.

5. Use microwave oven in an ambient temperature

less than 104¡F(40¡C).

6. Place the microwave oven on a sturdy and flat

surface at least 10 cm(4 inches) from the wall.

7. Place the microwave oven as far away as possible

from TV, RADIO, COMPUTER, etc., to prevent

interference.

GROUNDING INSTRUCTIONS

For personal safety, this appliance must be fully

grounded at all times.

In the event of an electrical short circuit, grounding

reduces the risk of electrical shock.

The plug must be plugged into an outlet that is

properly installed and grounded.

BEFORE YOU BEGIN, READ THE FOLLOWING INSTRUCTIONS COMPLETELY AND CAREFULLY.

WARNING

Improper use of the grounding plug can result in a

risk of electric shock.

Do not, under any circumstances, cut or remove

the third ground prong from the power cord plug.

PREFERRED METHOD

INSURE PROPER GROUND

EXISTS BEFORE USE

10cm

TEMPORARY METHOD

(ADAPTER PLUGS ARE NOT

PERMITTED IN CANADA)

ALIGN LARGE PRONGS/SLOTS

INSURE PROPER GROUND AND

FIRM CONNECTION BEFORE USE

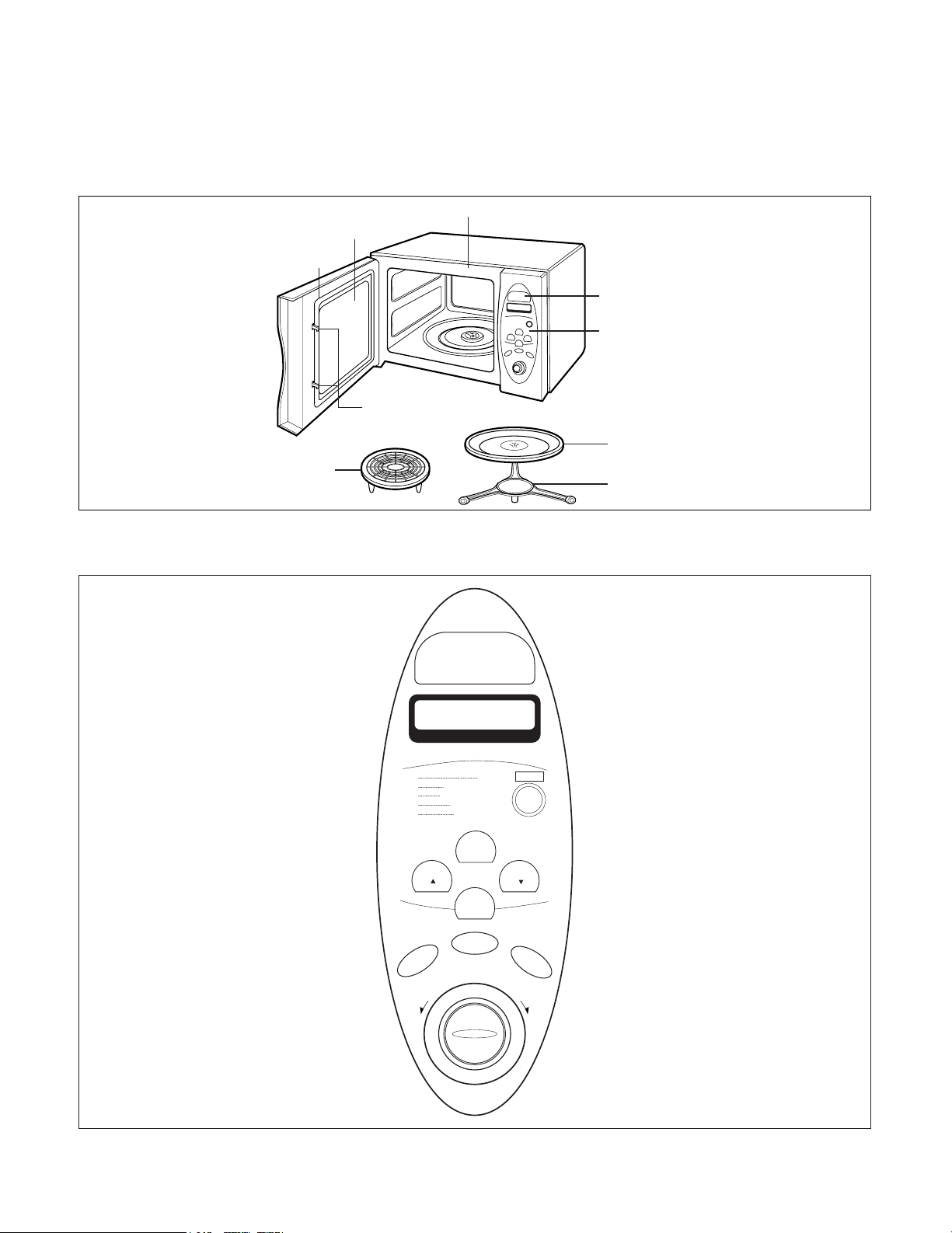

FEATURES

4-1

OPERATING INSTRUCTIONS

Oven Front Plate

Window Door Screen

Door Seal

Safety Door lock System

Control Panel

Display Window

Turntable

Defrost Rack

Rotating Ring

START

EZ ON

1

2

3

4

5

Sensor Cook

Defrost Hot

Potato

Fresh Vegetable

Frozen Vegetable

Frozen Entree

Ground Meat

Beverage

S

e

n

s

o

r

C

o

o

k

C

o

o

k

T

i

m

e

Power

Stop/

Clear

Timer

Popcorn

Auto Cook

Sensor

Reheat

More

Sensor

Defrost

Less

CONTROL PANEL

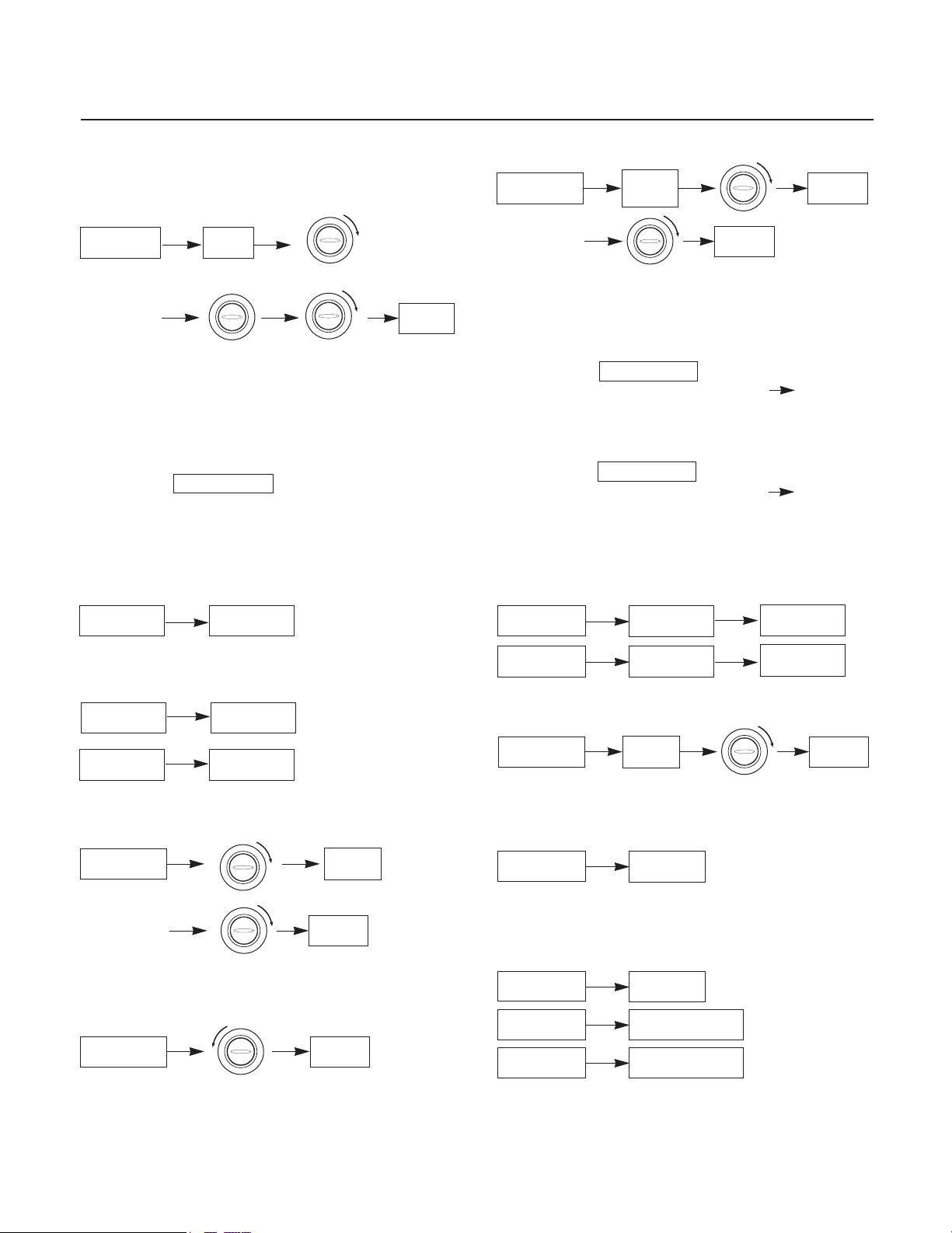

OPERATING SEQUENCE

The following is a description of component functions

during oven operation.

1. SETTING THE CLOCK

NOTE: 1) This is a 12 hour clock.

2) Clock will operate as long as power is

applied to the oven.

2. CANCEL FUNCTION

Touch the pad whenever you need to

cancel an entry or a function currently in use.

The display will either return to the last item entered

or to the clock.

3. EZ ON

4. SENSOR TOUCH

5. TIME COOKING

6. SENSOR COOK

7. AUTO COOKING

8. CHILD LOCK

This oven has a CHILD LOCK feature

TO SET CHILD LOCK

¥ Touch the pad

¥ Touch and hold STOP/CLEAR pad LOCKED

appear on the display.

TO CANCEL CHILD LOCK

¥ Touch the pad

¥ Touch and hold STOP/CLEAR pad LOCKED

disappears.

9. MORE / LESS

The cook time is adjustable by MORE pad or LESS

pad

10. TIMER

11. SENSOR POPCORN

12. SENSOR BEVERAGE / REHEAT

/ DEFROST

4-2

STOP/CLEAR TIMER

For 3 seconds Time setting

once

STOP/CLEAR REHEAT

STOP/CLEAR DEFROST

STOP/CLEAR EZ on

STOP/CLEAR

COOKING

STOP/CLEAR

POPCORN

STOP/CLEAR

BEVERAGE

STOP/CLEAR

SENSOR REHEAT

STOP/CLEAR

SENSOR DEFROST

MORE

STOP/CLEAR COOKING

LESS

STOP/CLEAR

STOP/CLEAR POWER

START

STOP/CLEAR START

STOP/CLEAR

STOP/CLEAR

STOP/CLEAR TIMER START

STOP/CLEAR

AUTO

COOK

START

START

Push

START

EZ ON

Minute setting

START

EZ ON

START

START

EZ ON

START

EZ ON

START

EZ ON

EZ ON

START

START

EZ ON

START

EZ ON

START

EZ ON

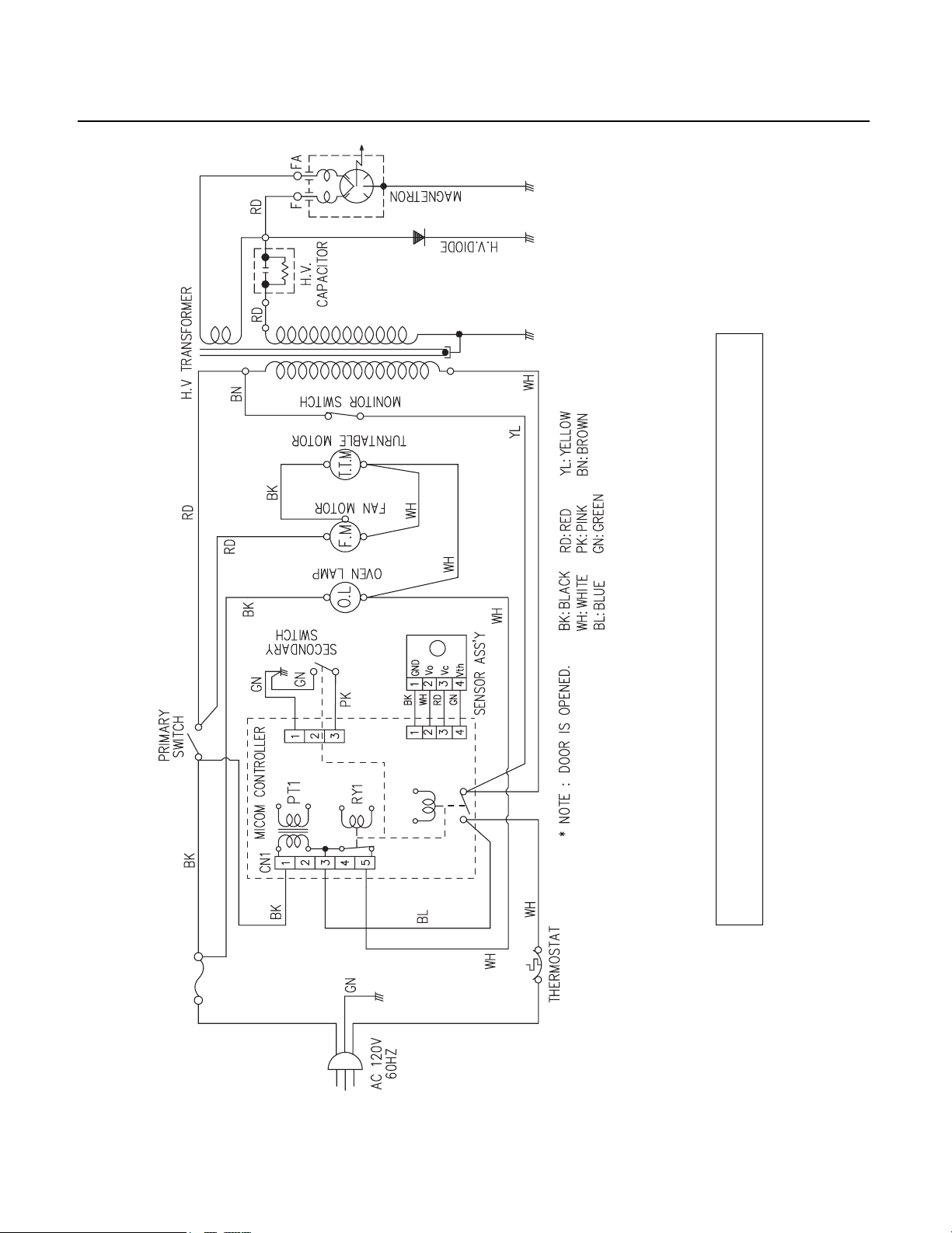

SCHEMATIC DIAGRAM

4-3

IMPORTANT SAFETY NOTE: THE SHADED AREAS ON THIS SCHEMATIC DIAGRAM INCORPORATE SPECIAL FEATURES

))) IMPORTANT FOR PROTECTION FROM MICROWAVE RADIATION, FIRE, ELECTRICAL SHOCK, AND

HAZARDS. WHEN SERVICING IT IS ESSENTIAL THAT ONLY MANUFACTURER'S SPECIFIED PARTS

BE USED FOR THE CRITICAL COMPONENTS IN THE SHADED AREAS OF THE SCHEMATIC DIAGRAM.

NOTICE: SINCE THIS IS BASIC SCHEMATIC DIAGRAM, THE VALUES OF COMPONENTS AND

SOME PARTIAL CONNECTIONS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

L

N

FUSE 20A

CN3

RY2

CN2

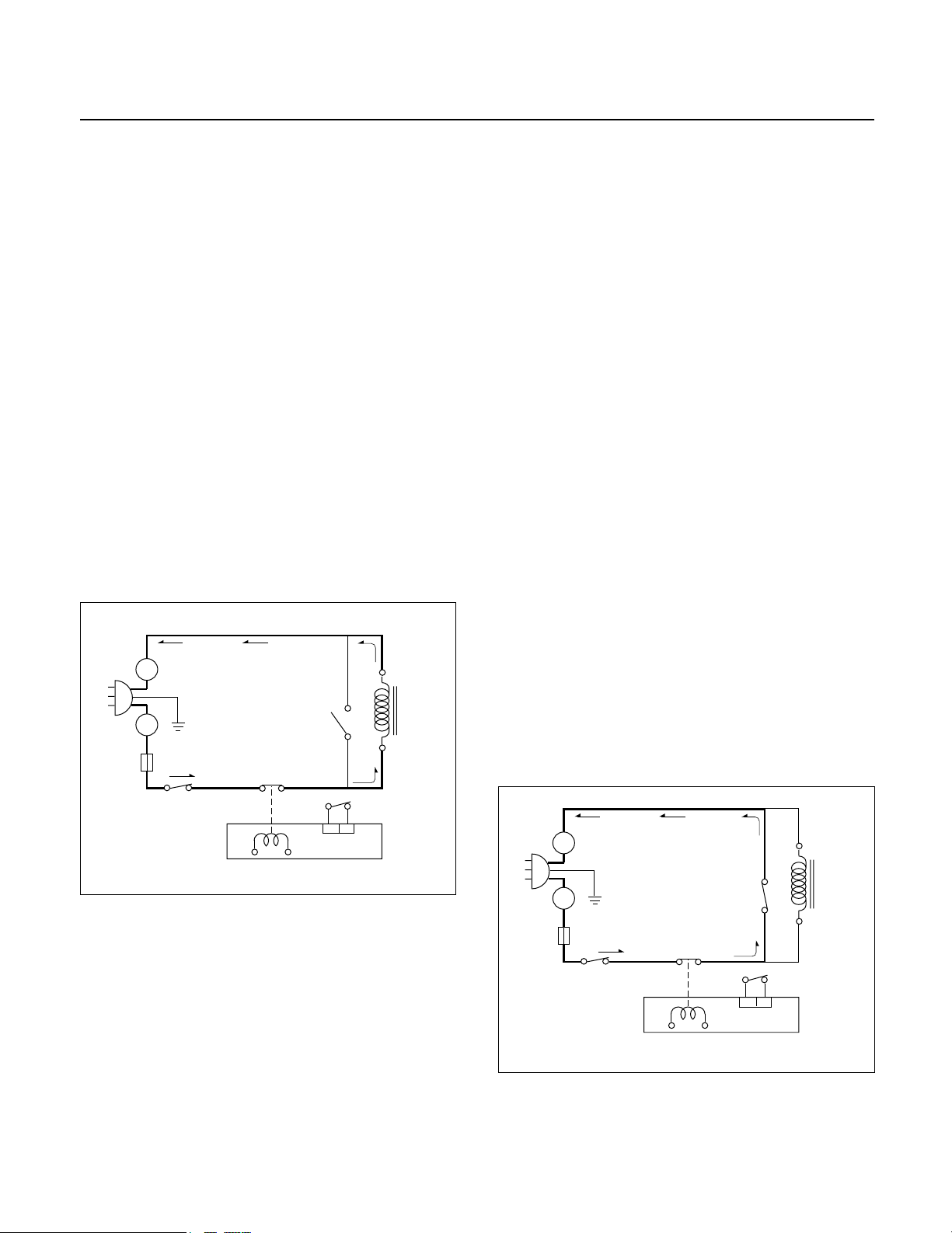

CIRCUIT DESCRIPTION

GENERAL DETAILS

¥ The low voltage transformer supplies the necessary

voltage to the micom controller when power cord is

plugged in.

¥ When the door is closed, the primary switch is ON, the

secondary switch is ON, and the monitor switch opens

(contact COM and NO).

WHEN SELECTING COOKING POWER

LEVEL AND TIME

¥ The micom controller memorizes the function you set.

¥ The time you set appears in the display window.

¥ Each indicator light turns on to indicate that the stage

has been set.

WHEN TOUCHING THE START PAD

¥ The coil of the relay is energized by the micom

controller.

¥ Power input is supplied to the high voltage transformer

through the fuse to the primary switch and relay 2.

¥ Turntable rotates.

¥ The fan motor rotates and cools the magnetron by

blowing the air (coming from the intake on the baseplate).

¥ The air is also directed into the oven to exhaust the

vapor in the oven through the upper plate.

¥ Cooking time starts counting down.

¥ 3.3 volts AC is generated from the filament winding of

the high voltage transformer. This 3.3 volts is applied to

the magnetron to heat the magnetron filament through

two noise-preventing choke coils.

¥ A high voltage of approximately 2100 volts AC is

generated in the secondary of the high voltage

transformer which is increased by the action of the high

voltage diode and charging of the high voltage

capacitor.

¥ The negative 4,000 Volts DC is applied to the filament

of the magnetron.

WHEN THE OVEN IS SET AT ANY LEVEL

EXCEPT MAXIMUM.

¥ The micom controller controls the ON-OFF time of

relay 2 by the applied signal to vary the average output

power of microwave oven as POWER LEVEL.

(refer to page 1-1)

¥ One complete cycle of relay 2 is 22 seconds.

WHEN THE DOOR IS OPENED DURING

COOKING

¥ Both the primary switch and relay 2 cut off the primary

winding voltage of the high voltage transformer.

¥ ON-OFF of relay 2 is coupled electrically with opening

and closing of the secondary switch.

¥ When the door is opened, the secondary switch is

opened and when the door is closed, the secondary

switch is closed.

¥ The cooking time stops counting down.

¥ Relay stops functioning.

¥ As the door is opened, if the contact of primary switch

and relay2 and/or secondary switch fail to open, the

fuse opens due to the large current surge caused by

the monitor switch activation, which in turn stops

magnetron oscillation.

4-4

FUSE

H.V.

TRANS-

FORMER

RELAY 2

MICOM CONTROLLER

SECONDARY

SWITCH

MONITOR

SWITCH

N

PRIMARY

SWITCH

L

FUSE

N

L

PRIMARY

SWITCH

MONITOR

SWITCH

RELAY 2

MICOM CONTROLLER

H.V.

TRANS-

FORMER

SECONDARY

SWITCH

CAUTIONS

¥ Be sure to check microwave leakage prior to

servicing the oven if the oven is operative prior to

servicing.

¥ The service personnel should inform the

manufacture importer, or assembler of any

certified oven unit found to have a microwave

emission level in excess of 5 mW/cm2and should

repair any unit found to have excessive emission levels

at no cost to the owner and should ascertain the cause

of the excessive leakage. The service personnel

should instruct the owner not to use the unit until the

oven has been brought into compliance.

¥ If the oven operates with the door open, the service

personnel should:

- Tell the user not to operate the oven.

- Contact the manufacturer.

¥ The service personnel should check all surface and

vent openings for microwave leakage.

¥ Check for microwave leakage after every servicing.

The power density of the microwave radiation leakage

emitted by the microwave oven should not exceed

4 mW/cm2. Always start measuring of an unknown field

to assure safety for operating personnel from radiation

leakage.

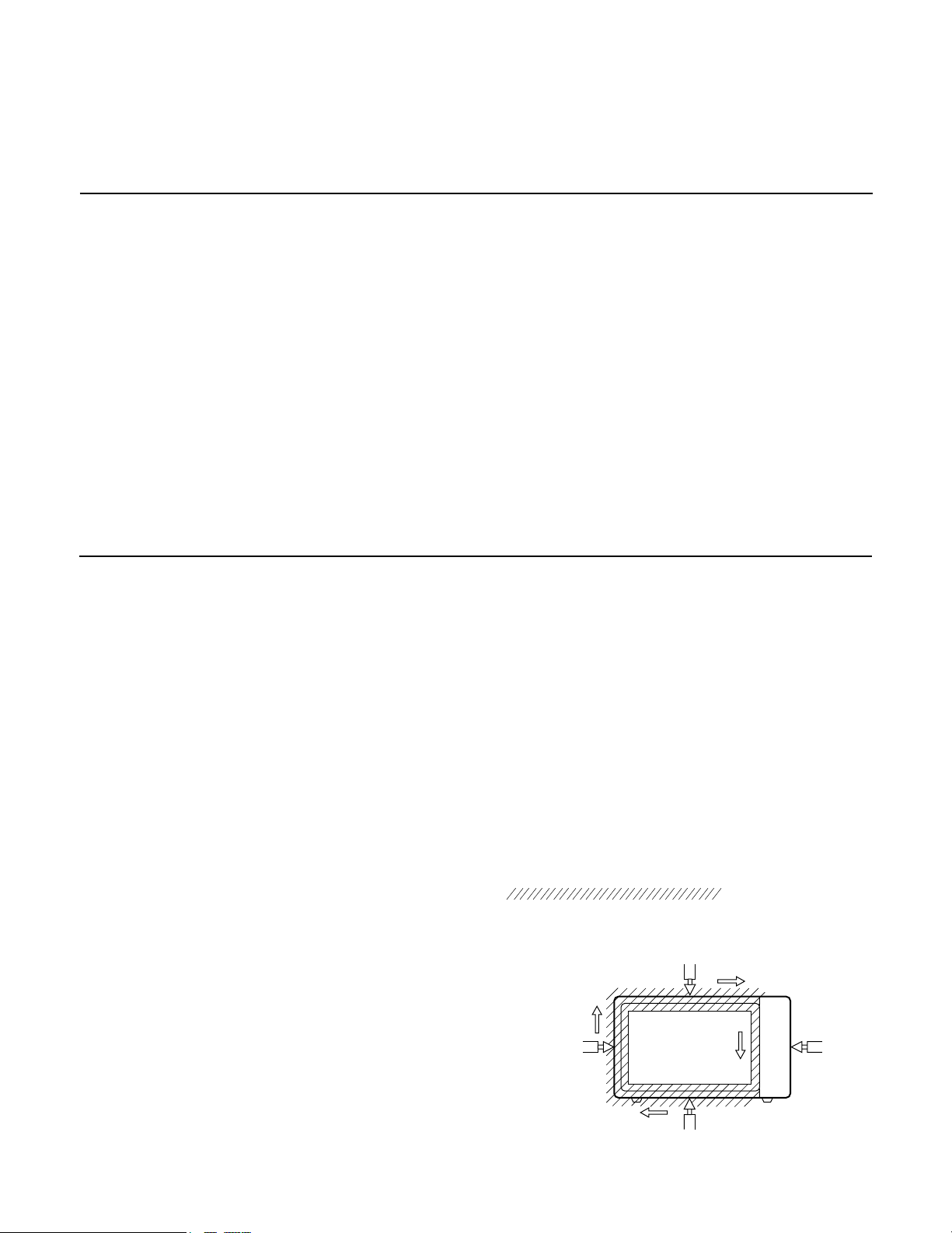

MEASURING MICROWAVE ENERGY

LEAKAGE

¥ Pour 275±15cc of 20±5¡C(68±9¡F) water in a beaker

which is graduated to 600 cc, and place the beaker

on the center of the turntable.

¥ Set the energy leakage monitor to 2,450 MHz and

use it following the manufacturer's recommended

test procedure to assure correct result.

¥ When measuring the leakage, always use the 2-

inch (5cm) spacer supplied with the probe.

¥ Operate the oven at its maximum output.

¥ Measure the microwave radiation using and

electromagnetic radiation monitor by holding the

probe perpendicular to the surface being measured

Move probe along shaded area

Probe scanning speed

Less than 2.5 cm/sec

( 1in/sec)

5-1

SERVICE INFORMATION

TOOLS AND MEASURING INSTRUMENTS

MICROWAVE LEAKAGE TEST

NECESSARY TOOLS

Tools normally used for TV servicing are sufficient.

Standard tools are listed below.

¥ Diagonal pliers

¥ Long nose pliers

¥ Phillips screwdriver

¥ Flat blade screwdriver

¥ Wrench (size 5mm)

¥ Nutdriver (size 5mm)

¥ Adjustable wrench

¥ Soldering iron

¥ Solder

¥ Vinyl insulation tape

¥ Polishing cloth

NECESSARY MEASURING INSTRUMENTS

¥ TESTER (VOLTS-DC, AC, Ohmmeter)

¥ Microwave survey meter

- Holaday HI-1500

HI-1501

- Narda 8100

8200

¥ Inch scale

¥ 600 cc non conductive material beaker (glass or plastic),

inside diameter: approx. 8.5 cm (3

1

/2 in.)

¥ Cylindrical and made of borosilicate glass vessel.

max. thickness: 3 mm

outside diameter: approx. 190mm

height: approx. 90mm

¥ Glass thermometer: 100¡C or 212¡F (1 deg scale)

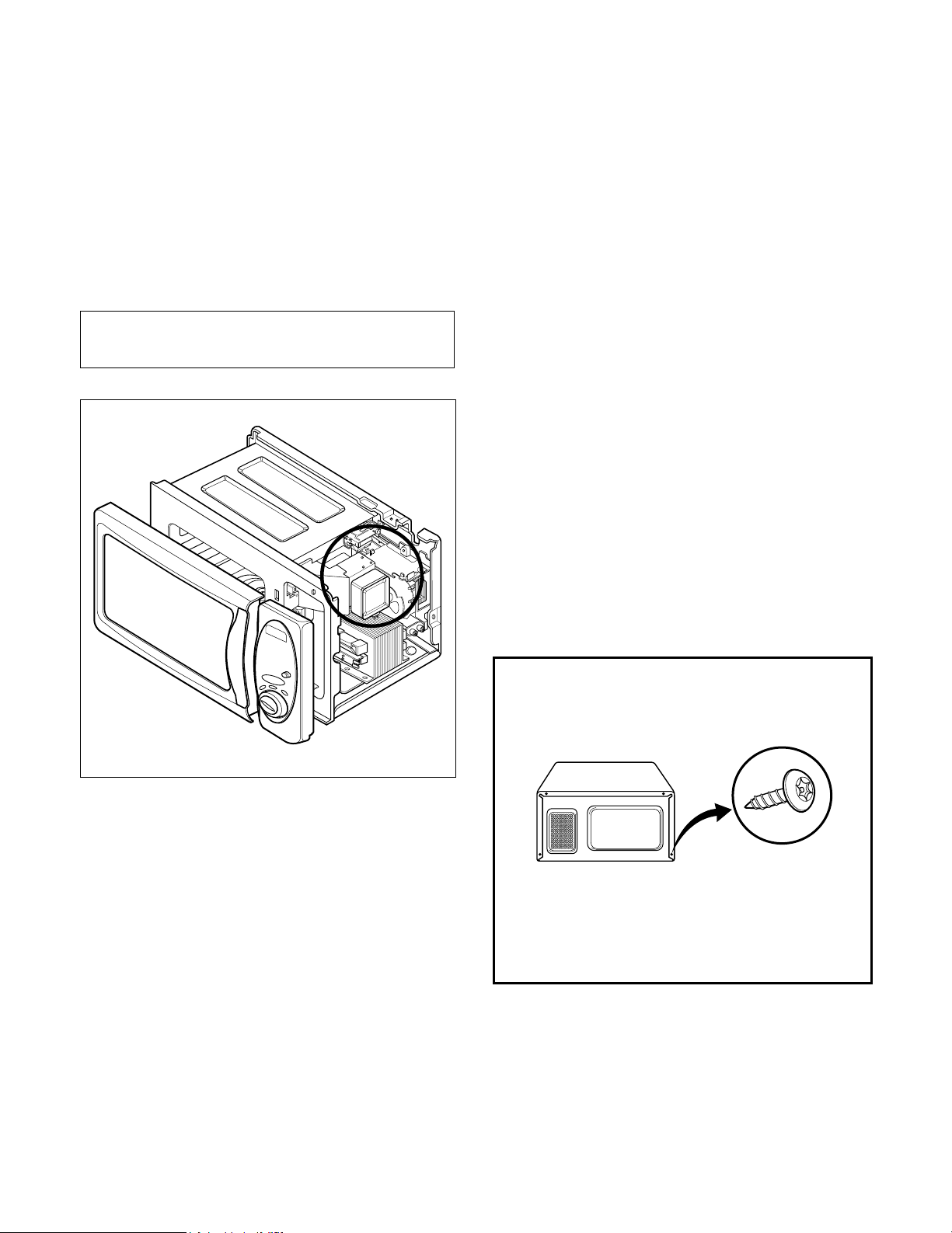

MEASUREMENT WITH OUTER CASE

REMOVED

¥ When you replace the magnetron, measure for

microwave energy leakage before the outer case is

installed and after all necessary components are

replaced or adjusted.

Special care should be taken in measuring the

following parts. (Circled area of Fig. below)

- Around the magnetron

- The waveguide

MEASUREMENT WITH A FULLY

ASSEMBLED OVEN

¥ After all components, including the outer case, are fully

assembled, measure for microwave energy leakage

around the door viewing window, the exhaust opening,

and air inlet openings.

¥ Microwave energy leakage must not exceed the values

prescribed below.

NOTE: Leakage with the outer case removed less than

5 mW/cm.sq. Leakage for a fully assembled

oven (Before the latch switch (primary) is

interrupted) with the door in a slightly opened

position-less than 2 mW/cm.sq.

NOTES WHEN MEASURING

¥ Do not exceed meter full scale deflection.

¥ The test probe must be removed no faster than

1 inch/sec (2.5 cm/sec) along the shaded area,

otherwise a false reading may result.

¥ The test probe must be held with the grip portion of the

handle.

A false reading may result if the operator's hand is

between the handle and the probe.

¥ When testing near a corner of the door, keep the probe

perpendicular to the surface making sure the probe

horizontally along the oven surface; this may possibly

cause probe damage.

RECORD KEEPING AND NOTIFICATION

AFTER MEASUREMENT

¥ After adjustment and repair of any microwave energy

interruption or microwave energy blocking device,

record the measured values for future reference. Also

enter the information on the service invoice.

¥ The microwave energy leakage should not be more

than 4 mW/cm.sq. after determining that all parts are in

good condition, functioning properly and genuine

replacement parts which are listed in this manual have

been used.

¥ At least once a year, have the electromagnetic energy

leakage monitor checked for calibration by its

manufacturer.

5-2

WARNING : AVOID CONTACTING ANY

HIGH VOLTAGE PARTS

SPECIAL TIP

¥ This oven used the button head screws.

¥ When you remove the screws, using the

tamper-resistant Torx driver have a

pin-in-head.

Button Head

(Torx style 2)

Loading...

Loading...