Page 1

OPERATION AND MAINTENANCE

Serie JOKER

06381198 Edition 02 (English)

Technology as a passion.

Registered offices and plant

GOLDONI S.p.A.

Address:

Via Canale, 3

41012 Migliarina di Carpi

Modena, Italy

Telephone: +39 0522 640 111

Fax: +39 0522 699 002

Internet:

www.goldoni.com

MANUFACTURER

GOLDONI S.p.A.

JOKER

EN Inglese

61

MANUFACTURER

Page 2

JOKER 8 DS

JOKER 10 DS

JOKER 12 S

MODELS AND VERSIONS

GOLDONI S.p.A.

JOKER

EN Inglese

62

MANUFACTURER

Page 3

TABLE OF CONTENTS

MANUFACTURER

MODELS AND VERSIONS 62

GENERAL INFORMATION

INTRODUCTION 65

HOW TO READ THE MANUAL 66

Manual update

67

Copyright

67

Standard symbols

68

MACHINE IDENTIFICATION 69

Model identification table 69

Identification criteria

69

Decals 69

Punch marks on chassis

69

Metal plate

70

DECLARATION OF CONFORMITY 71

IDENTIFICATION OF THE COMPONENTS 71

Engine 71

A

FTER SALES 71

Warrant

y

71

A

ssistance 71

Spares 71

SAFETY

SAFETY REGULATIONS 72

SAFETY OPERATIONS 74

Trainin

g

74

Preparation 75

Operation 76

Maintenance and Storage 78

Putting back into service after storage 78

Parking Safel

y

78

A

void Tippin

g

79

Stay Clear of Rotatin

g

80

Checking Wheel Hardware 80

Wear Appropriate Clothin

g

80

Practice Safe Maintenance 81

Prevent Fires 82

Tire Safet

y

82

Handling Fuel Safel

y

83

Handling Waste Product and Chemicals 84

ECOLOGY 84

SAFETY DEVICES 85

SAFETY DECALS 85

TECHNICAL SPECIFICATIONS

INFORMATION ON THE MACHINE 86

Intended uses

86

Description 86

TECHNICAL SPECIFICATIONS 87

DIMENSIONS AND WEIGHTS 88

Table of Machine Dimensions and

Weights 88

Engine 88

WHEELS 89

Tyres

89

Table of tyre inflation pressures

89

SPEEDS 90

Speed Chart 90

NOISE AND VIBRATIONS 91

Noise level information

91

Recommendations for the user

91

OPERATING INSTRUCTIONS

CONTROLS AND INSTRUMENTS 92

Gear Sto

p

92

Handlebar controls

93

Engine controls

94

STARTING AND STOPPING THE ENGINE 95

Before starting the engine

95

How to start the engine

95

Ignition switch

95

Engine stop switch

96

How to stop the engine

96

HOW TO START AND STOP THE

MACHINE 97

Handlebars

97

Safety frame

99

Hand throttle

99

How to start the machine

99

How to stop the machine

99

TRANSMISSION 100

Gearbox

100

Gearshift lever

100

Reverse shuttle lever

101

Differential lock 101

Wheel release 102

Track width adjustment

102

POWER TAKE-OFF 103

Rear power take-off (PTO

)

103

TOWING ATTACHMENTS 104

Tow hook

104

BALLAST 104

Ballast (optional

)

104

GOLDONI S.p.A.

JOKER

EN Inglese

63

TABLE OF CONTENTS

Page 4

SCHEDULED SERVICING

Routine scheduled maintenance

108

ENGINE UNIT 110

Engine 110

Fuel tank

110

Dry air filter

111

A

ir filter in oil bath

112

TRANSMISSION UNIT 113

Gearbox housin

g

113

Gear Sto

p

114

Hand throttle

114

Wheel release 115

Differential lock 115

ELECTRICAL SYSTEM 116

Batter

y

116

RECOMMENDED LUBRIFICANTS AND

FLUIDS 117

Original lubricants

117

Original protective fluids

117

GOLDONI S.p.A.

JOKER

EN Inglese

64

TABLE OF CONTENTS

Page 5

ORIGINAL INSTRUCTIONS

This manual contains a description of how the machine operates and instructions about how to correctly

use the machine and perform the main routine and supplementary servicing operations.

This manual is divided into chapters for practical consultation.

This manual must always be consigned together with the machine if this is transferred or sold. If the

manual is damaged or lost, order a new copy from the manufacturer or from the previous owner. This

manual is an integral part of the machine

The confidence you have shown in our company by choosing equipment carrying our trademark will be

amply repaid by the excellent service it will give you over the years.

Correct use and normal routine maintenance will generously rewarded in performance, output and

savings.

GENERAL INFORMATION

INTRODUCTION

GOLDONI S.p.A.

JOKER

EN Inglese

65

GENERAL INFORMATION

Page 6

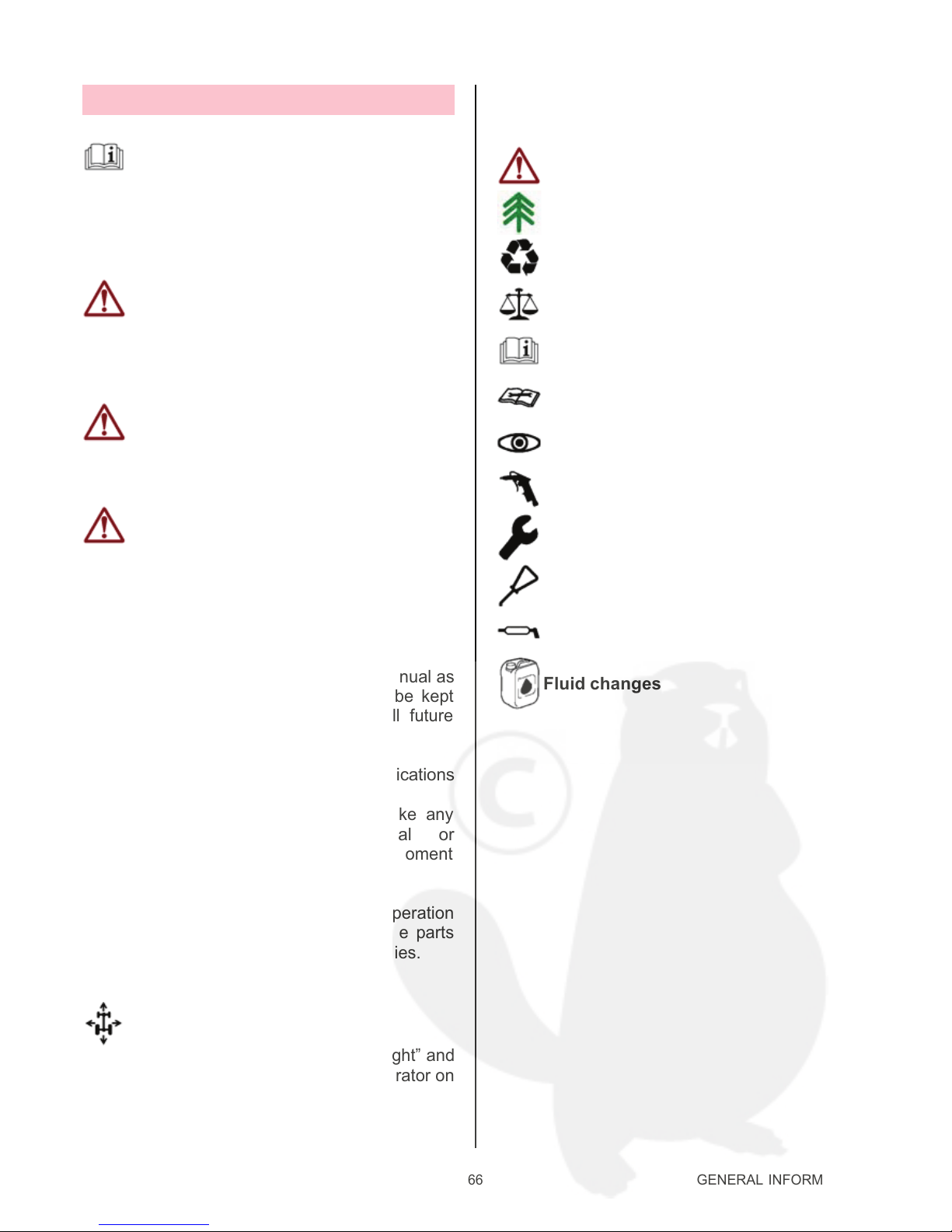

Certain sections of this manual containing

information of particular importance in relation to

safety or operation, are highlighted in the

following way:

This manual is your operation and maintenance

guide.

You are advised to strictly comply with the

instructions herein and to consider the manual as

an integral part of the product: it must be kept

near the machine and consigned to all future

users.

The illustrations, descriptions and specifications

in this manual are not binding.

Our Company reserves the right to make any

modifications dictated by technical or

commercial requirements at any moment

considered necessary.

Consult the specific manuals for safe operation

and maintenance instructions about those parts

of the machine manufactured by third parties.

A

ll indications as to the “front”,“rear”,“right”and

“

left”parts of the machine refer to the operator on

the machine.

HOW TO READ THE MANUAL

DANGER

Failure to comply with the instructions

could lead to serious danger and

serious personal injuries or harm to

third parties.

WARNING

Failure to comply with the instructions

could cause personal injuries or harm

third parties.

IMPORTANT

The information is given with the

intention of preventing damage to the

machine or causing damage.

A

series of symbols have been make to make the

texts easier to understand. Their meanings are

described below:

Warning

Environment

Recycling

Legislation

Information

Instructions

Check

Clean with compressed

Adjustment

Lubrication

Greasing

Fluid changes

GOLDONI S.p.A.

JOKER

EN Inglese

66

GENERAL INFORMATION

Page 7

The information, descriptions and illustrations in

this manual reflect the state-of-the-art at the time

the machine was marketed.

The manufacturer reserves the right to make any

modifications dictated by technical or

commercial requirements at any time.

Such modifications do not oblige the

manufacturer to modify the vehicles marketed up

to that time nor to consider this publication to be

inadequate.

A

ny integrations the manufacturer may provide

must be kept together with the manual and will be

considered an integral part of this latter.

Manual update

The copyrights of this manual belong to the

manufacturer of the machine. This manual

contains texts, drawings and illustrations of a

technical kind that can neither be wholly nor partly

disclosed or transmitted to third parties without

written authorization from the manufacturer of the

machine.

Copyright

GOLDONI S.p.A.

JOKER

EN Inglese

67

GENERAL INFORMATION

Page 8

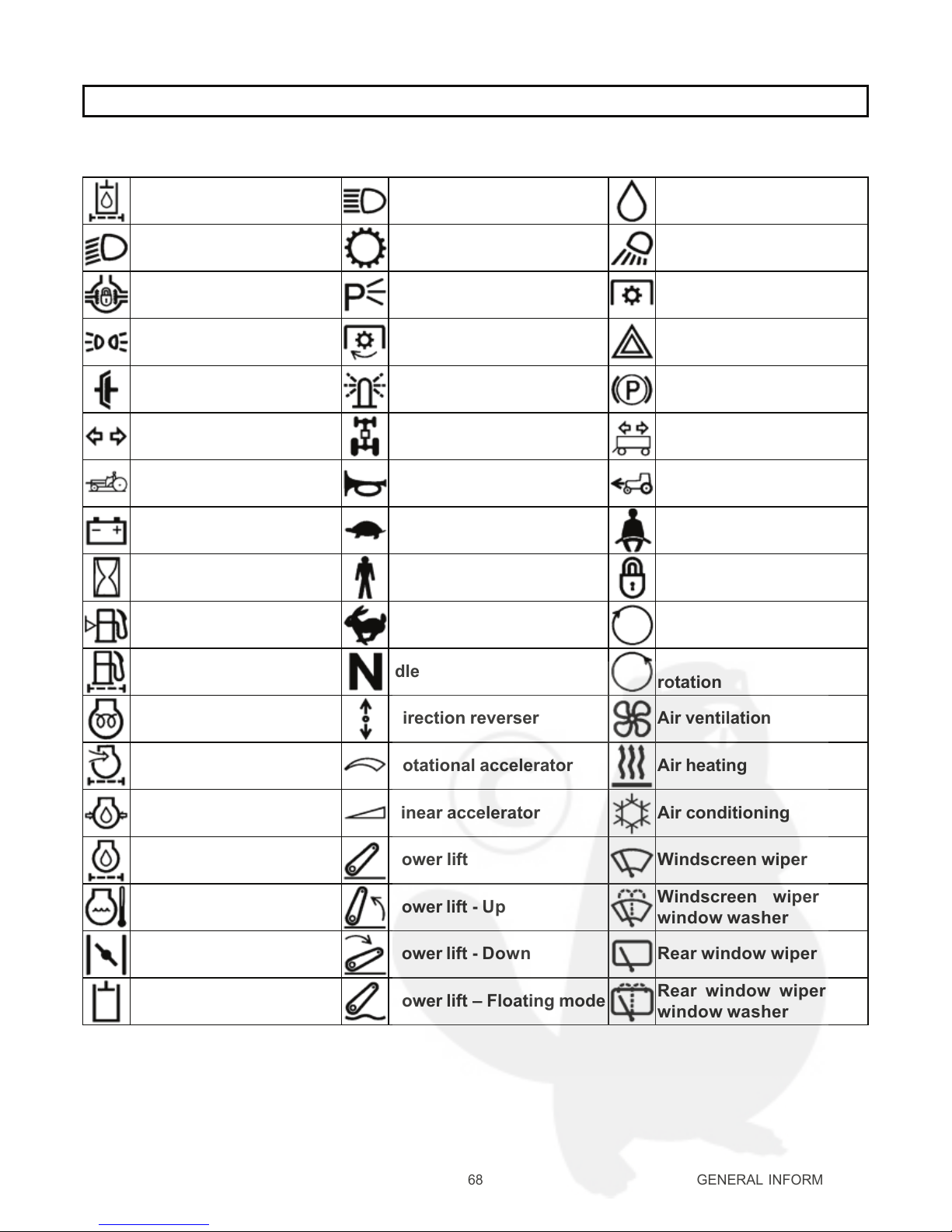

Standard symbols have been used to ensure the machine is used in the best way.

Standard symbols

Hydraulic circuit filter Driving beam

Oil

Dipped beam Transmission Field light

Differential lock Parking light Power take-off

Side lights. Power take-off rotation Hazard lights

Clutch Indicator light Parking brake

Turn indicator Four-wheel drive Trailer turn indicator

Guard lowered Horn. Forward direction

Battery charger Low speeds Safety belts

Work hours Normal speeds

Idle

Fuel level Fast speeds Clockwise rotation

Fuel filter

Idle

Counter-clockwise

rotation

Engine preheating Direction reverser

Air ventilation

Engine air filter Rotational accelerator Air heating

Engine oil pressure Linear accelerator Air conditioning

Engine oil filter Power lift Windscreen wiper

Engine coolant

temperature

Power lift - Up

Windscreen wiper and

window washer

Air valve

Power lift - Down Rear window wiper

Hydraulic circuit Power lift – Floating mode

Rear window wiper and

window washer

GOLDONI S.p.A.

JOKER

EN Inglese

68

GENERAL INFORMATION

Page 9

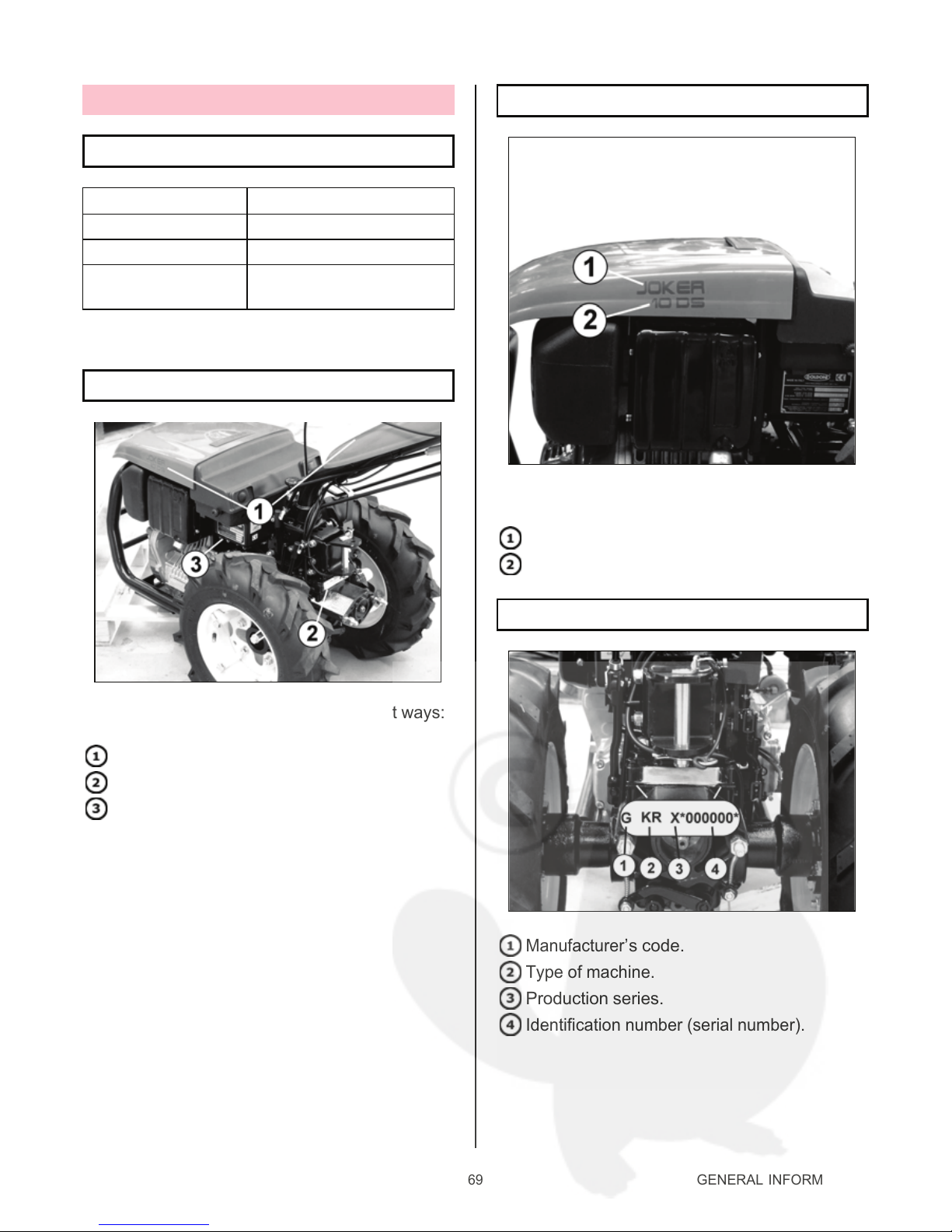

The machine is identified in three different ways:

MACHINE IDENTIFICATION

Model identification table

Model Type of machine.

JOKER 8 DS KR60

JOKER 10 DS KRA0

JOKER 12 S

KR90

KR90F

Identification criteria

With decals.

Punch marks on chassis.

With a metal plate.

The decals affixed to the bonnet indicate:

Decals

Series

Model

Punch marks on chassis

Manufacturer

’s code.

Type of machine.

Production series.

Identification number (serial number).

GOLDONI S.p.A.

JOKER

EN Inglese

69

GENERAL INFORMATION

Page 10

The metal plate is placed on top of the tools box.

Metal plate

The metal plate gives the following information:

To find the CE certificate of conformity of the

machine you have purchased, find the "Machine

Type"

on the metal data plate and compare it

with the "Machine Type" value on the various

different certificates provided.

CE marking

Manufacturer

’s code.

Commercial denomination

Type of machine.

Production series.

Identification number (serial number).

Weight with std wheels and tiller

Power rating in kW according to SAE J 1349

Honda GX 340

Power rating in kW according to 80/1296/EC

-

ISO 1585

Lombardini 15LD 315

Lombardini 15LD

400

Year of production

GOLDONI S.p.A.

JOKER

EN Inglese

70

GENERAL INFORMATION

Page 11

Declaration of conformity are at the end o

f

the manual.

The machine consists of a series of main

components which are each identified by a metal

data plate and/or by punch marks.

Metal data plate and punched code number.

See engine’

s operation and maintenance

manual.

DECLARATION OF CONFORMITY

IDENTIFICATION OF THE

COMPONENTS

Engine

Engine:

conditions and terms established by the

manufacturer

Tractor:

within the terms laid down by our

Certificate of Warranty.

Contact the AUTHORIZED sales network

The Assistance Service provides specialized

personnel able to work on our products. It is the

only Service authorized to work on products

covered by the warranty.

Use of Genuine Spare Parts and compliance with

the scheduled servicing operations according to

the prescribed frequency will preserve the

qualities of the machine over time and will entitle

you to the WARRANTY that covers the product

throughout the established period.

To order spares: Contact our Spares

A

ssistance centres with the following information:

model,series and serial number of the

machine

, punched on the data plate.

AFTER SALES

Warranty

Assistance

Spares

GOLDONI S.p.A.

JOKER

EN Inglese

71

GENERAL INFORMATION

Page 12

SAFETY

WARNING

Correct use of the machine, strict compliance with the regulations described in this

publication and with all the precautions able to avoid dangerous situations will prevent

accidents or injuries, allow the machine to operate better and for much longer and will

reduce the risk of faults to the minimum.

WARNING

GOLDONI S.p.A. declines all objective and subjective liability for failure to apply and

comply with the rules of conduct described in this manual

SAFETY REGULATIONS

DANGER

There is no substitute for prudence to

make your work safer and to prevent

accidents.

The following recommendations are

important for all users of our machines:

IMPORTANT

Failure to follow the regulations

relieves our firm from all liability.

DANGER

Do not go downhill with the clutch

disengaged or the gear shift in neutral.

Use the engine to brake the machine.

DANGER

Check to make sure that all revolving

parts on the machines (PTO, cardan

couplings, pulleys etc.) are fully

guarded.

DANGER

Do not wear loose clothing, jewelry,

neck chains or bracelets and take care

if your hair is very long as it could

become caught up in parts of the

machine and implements.

DANGER

Do not leave the engine running in an

closed room: the exhaust fumes are

poisonous.

DANGER

Do not leave the machine with engine

running near flammable substances.

DANGER

A

fter any maintenance work, grease

and remove the grease from the engine

to prevent the risk of a fire.

DANGER

The machine must only be used by one

operator.

Never use the machine to transport

persons, animals or things.

WARNING

Do not tamper with the machine or the

implements in any way.

WARNING

Before starting the engine make sure

that the gear shift and the PTO are in

neutral.

WARNING

Engage the clutch gradually to prevent

the machine from suddenly moving off

or pitching up at the front.

WARNING

A

lways stop the engine before

proceeding with any maintenance,

repairs or other operations on the

machine or implements and if present

the electrical start, remove the ignition

key.

WARNING

A

lways park the tractor so that its

GOLDONI S.p.A.

JOKER

EN Inglese

72

SAFETY

Page 13

stability is guaranteed by engaging a

gear (1st gear uphill and reverse

downhill). Use a chock for greater

safety.

WARNING

Before driving the machine, check to

be sure that there are no bystanders or

animals within its range of action.

WARNING

Do not leave the machine unattended

with the engine running and if present

the electrical start, the ignition key on

the dashboard

WARNING

Whenever the PTO is in use, the drive

shaft must be covered by the special

guard.

WARNING

The operator must check to make sure

that all parts of the tractor, especially

the safety devices, are in a good

working condition and that they always

comform to the purpose for which they

were designed. They should be kept in

a perfectly efficient condition. If you

note any defects or faults, fix or repair

them in good time. If necessary contact

your nearest Assistance Centre.

IMPORTANT

Follow the traffic code when driving on

the roads.

IMPORTANT

Check the nuts and bolts of the wheels

and safety frame from time to time,

always with the engine shut off.

IMPORTANT

Do not use the differential lock near or

in bends and avoid using it in fast

gears or with engine running at a high

rate.

DANGER

Do not drink fuels / lubricants / fluids. I

f

these substances accidentally splash

into the eyes, thoroughly rinse the

affected part with plenty of water.

WARNING

Lengthy or repeated contact of the skin

with fuels / lubricants / fluids should be

avoided as skin disorders or other

damage could ensue.

GOLDONI S.p.A.

JOKER

EN Inglese

73

SAFETY

Page 14

● Read the instructions carefully.

Become familiar with the controls and

how to correctly use the machine.

● The machine must only be used by

authorized and properly trained

persons. Besides having read the

instructions in this manual, the

operator must have received sufficient

training on how to use the machine

correctly. The operator should consult

the manufacturer if he has any doubts

about how to use the machine or if he

fails to understand any of the

instructions in this manual.

● The machine is only suitable for use in

the agricultural / forestal sectors.

Use differing from that specified is

considered improper.

● Never ever allow children or persons

who are unfamiliar with these

instructions to use the machine. Local

regulations can restrict the age of the

operator.

●

Do not use the machine if you are tired,

unwell or under the influence o

f

medicines, alcohol or drugs.

● Remember that the operator or the user

is responsible for any accidents or

risks to which third parties or their

property may be subjected.

●

The manual must always be ready to

hand, so that it can be consulted when

necessary. Ask the manufacturer for a

replacement if the manual is lost or

damaged.

The main reasons for loss of control are:

● insufficient wheel grip;

● driving too fast;

SAFETY OPERATIONS

Training

● the type of machine is unsuitable for its

task;

● lack of awareness of the effect of the

ground conditions, especially slopes.

GOLDONI S.p.A.

JOKER

EN Inglese

74

SAFETY

Page 15

● Check the machine with care before

starting up each time

● The decals affixed to the machine

provide important information: it is in

the interests of your safety to comply

with these indications.

● Make sure that the safety decals are in

a good condition. If the decals are

damaged or illegible, they must be

replaced with other originals obtained

from the manufacturer and affixed in

the positions indicated in the operation

and maintenance manual.

● Arbitrary modifications to this machine

will relieve the manufacturer from all

liability for resulting damage or injuries

to the operators, to third parties and to

things.

● The manufacturer cannot make

provisions for every rreasonably

foreseeable improper use able to lead

to a potential danger.

● Always wear substantial footwear and

long trousers. Do not operate the

equipment when barefoot or wearing

open sandals.

●

Thoroughly inspect the area where the

equipment is to be used.

● WARNING

-

Fuel is highly flammable.

● Store fuel in containers specifically

designed for this purpose.

● Refuel outdoors only and do not

smoke while refueling.

To avoid the risk of the machine

catching fire, periodically check the fuel

pipe and replace it if it appears to be

damaged to an extent that could impair

its tightness.

●

Refuel before starting the engine.

Never remove the plug of the fuel tank

or add fuel while the engine is running

or hot.

● If fuel is spillt, do not attempt to start

Preparation

the engine but move the machine away

from the place of spillage and avoid

creating any source of ignition until fuel

vapors have dissipated.

● Securely tighten the plugs on the tank

and containers.

● Replace faulty silencers.

● Clean all foreign materials from the

machine (dirt, tools, objects in general)

that could impair the way it operates or

injure the operator.

GOLDONI S.p.A.

JOKER

EN Inglese

75

SAFETY

Page 16

● Do not operate the engine in a confined

space where dangerous monoxide

fumes can collect.

● Operate only in daylight or in good

artificial light.

● Before attempting to start the engine,

disengage all the PTOs, shift the gear

and reverse shuttle to the neutral

position and DO NOT press the Gear

Stop lever.

● Take the greatest care when changing

direction or when pulling the machine

towards yourself.

● Before beginning to use the machine,

check to make sure that the safety

systems function correctly. Do not

begin work unless they function

correctly.

●

It is absolutely forbidden to remove or

tamper with the safety

devices. Modifications to the machine

could lead to safety problems. In such

cases, solely the user will be

responsible for any deriving accidents.

● Whenever the handlebars are adjusted

or turned, make sure that the safety

components fully perform their

functions.

● If you must cross a steep slope,

consult section: Danger of tipping

over.

Remember there is no such thing as a safe

slope. Driving up and down grassy slopes

requires particular care to avoid overturning:

● do not stop or start suddenly when

driving on slopes;

● engage the clutch slowly. Always keep

the gear engaged, especially when

traveling downhill;

● maintain a low speed on slopes and

Operation

around tight turns;

● stay alert for humps and hollows and

other hidden hazards;

● take the greatest care when working

across the face of a slope.

Use care when pulling loads or using heavy

equipment:

● limit loads to those you can safely

control;

● do not turn sharply;

● take care when reversing;

● use counterweights or wheel ballast to

increase the stability.

● Watch out for traffic when crossing or

driving alongside roads.

● Do not allow anyone near the machine

while it is operating.

● Never operate the machine with

defective guards or without the

protective safety devices in their

correct positions.

● Do not change the engine governor

settings or over

-

rev the

engine. Operating the engine at an

excessive speed can increase the

hazard of personal injury.

Before leaving the operator

’

s position:

● disengage the drive to any attachments

and lower them;

● change into neutral;

● turn off the engine.

Disengage the drive to the implements, stop

the engine, disconnect the spark plug wires

and if the electrical start is present, remove

the ignition key

● before clearing blockages;

● before checking, cleaning, or working

on the machine;

● after striking a foreign object. Inspect

the machine for damage and make

repairs before restarting and operating

the equipment;

● if the machine starts to vibrate

abnormally (check immediately).

GOLDONI S.p.A.

JOKER

EN Inglese

76

SAFETY

Page 17

● Disengage the drive to the implements

when transporting or not in use.

Switch off the engine and disengage drive to

attachment:

● before refueling;

● before adjusting the implements.

● Reduce the speed of the engine before

stopping it. Shut off the fuel supply

once you have stopped working if the

engine is equipped with a shut

-

of

f

valve.

● Read, understand and follow all

instructions in the manual and on the

machine before starting.

● Inspect the machine before each

job. Only use original spare parts to

repair or replace damaged, very worn

or missing components. Make the

necessary adjustments before you

start work.

● Make sure that all drives are in neutral

before starting the engine.

●

Start the engine with care and keep

your feet well away from the tools.

●

Stop the machine if anyone enters the

area in which you are working.

● Never leave machine unattended when

it is running.

● Take care when approaching blind

corners, shrubs, trees, or other objects

that may impair visibility.

● Only use the accessories and

implements recommended by the

manufacturer of the machine. Keep the

safety decals visible when accessories

or implements are fitted. Make sure that

you have fully read the Instruction

Manual of that accessory and/or of that

implement and comply with the relative

safety instructions.

● Do not use the machine if you are

under the influence of

medicines, alcohol or drugs.

● Walk, do not run with the machine.

● Do not wear headphones to listen to

music or the radio. Safe service and

operation requires your full attentionDo

not wear radio or music headphones.

Safe service and operation requires

your full attention.

GOLDONI S.p.A.

JOKER

EN Inglese

77

SAFETY

Page 18

● Keep all nuts, bolts and screws

perfectly tightened so as to be sure that

the machinery operates in safe

conditions.

● Never store the equipment with fuel in

the tank inside a building where fumes

could reach an open flame or spark.

● Allow the engine to cool before storing

the machine in a closed place.

● To reduce the risk of fire, keep the

engine, silencer, battery compartment

and fuel storage area free of grass,

leaves, or excessive grease.

● For safety reasons, replace worn or

damaged parts.

● If the fuel tank has to be drained, this

should be done outdoors.

● When machine is to be parked, stored

or left unattended, lower the

attachment unless a positive

mechanical lock in used.

Maintenance and Storage

Comply with the following instructions

before using the machine for the first time or

after a long idle period:

● Make sure that the machine is not

damaged in any way.

● Check the mechanical components,

which must be in a good condition with

no signs of rust.

● Carefully grease all mobile parts.

● Make sure that there are no oil leaks.

● Check the engine oil level.

● Check the transmission oil level.

● Make sure that all the protections are in

their correct places.

● Stop the machine on level ground, not

on a slope. Fit a chock under the

wheels if necessary.

● Disengage PTO and stop the

attachments.

● Lower the implements to the ground.

● Turn off the engine and if the ectrical

start is present, remove the ignition

key.

● Wait until the engine and all moving

parts have stopped before you leave

the operator

’

s station.

● Close the fuel shut

-

off valve if the

machine is equipped with this

component.

Putting back into service after

storage

Parking Safely

GOLDONI S.p.A.

JOKER

EN Inglese

78

SAFETY

Page 19

● Slopes are a major factor related to loss

of control and tip

-

over accidents, which

can result in severe injury or even

death.

All operations that take place on

sloping ground require extra caution.

● Do not work on muddy or soft ground.

● Do not work on excessively steep

slopes.

● Take the greatest care when working

on slopes.

● Always make sure that you have a firm

foothold on slopes.

● Always work the soil across slopes,

never in the uphill or downhill

directions.

● Watch out for holes, ruts, bumps, rocks

or other hidden objects. Uneven terrain

could cause the machine to

overturn. Tall grass can hide obstacles.

● Take the utmost care on wet

grass. Tires may lose their grip on

slopes even though the brakes are

functioning properly.

● Choose a low ground speed so you will

not have to stop or shift gear on the

slope.

● Always keep the gear engaged when

going down slopes. Never coast

downhill with the machine in neutral.

● Avoid starting, stopping or turning on

slopes. If the tires lose their grip,

Avoid Tipping

disengage the PTO and proceed

slowly, straight down the slope.

● Keep all movement on slopes slow and

gradual. To not make sudden changes

in speed or direction as this could

cause the machine to tip over.

● Take the greatest care when using the

machine near ravines, ditches,

embankments or bodies of water. The

machine could suddenly tip over if a

wheel goes over the edge or the edge

caves in. Allow for a safety area

between the machine and any hazard.

● The risk of tipping over increases to a

considerable extent if the tires have

been regulated with a narrow track

width and the machine is driven at high

speed.

● Comply with the manufacturer

’

s

recommendations for wheel weights or

counterweights, which can increase

stability when work is carried out on

slopes or when front or rear-mounted

implements are used. Remove the

weights when they are not required.

● Slopes are a major factor related to loss

of control and tip

-

over accidents, which

can result in severe injury or even

death. All operations that take place on

sloping ground require extra caution.

GOLDONI S.p.A.

JOKER

EN Inglese

79

SAFETY

Page 20

● Entanglement in rotating driveline can

cause serious injury or death.

● Wear close fitting clothing.

● Stop the engine and make sure that

the PTO driveline has stopped before

going near the PTO shaft.

●

A serious accident could occur

causing serious injury unless the

wheel hardware is securely tightened.

● Check the tightness of the wheel

hardware often during the first 100

hours of operation.

● The wheel hardware must be tightened

to the specified torque value using the

correct procedure whenever it works

loose.

Stay Clear of Rotating

Checking Wheel Hardware

● Wear close fitting clothing and safety

equipment appropriate for the job.

● The following equipment is required:

-

safety goggles or safety glasses with

side shields

-

a hard hat when working with the

machine

-

protective gloves (in neoprene for

chemical products, in leather for heavy

-

duty work)

-

protective ear muffs or ear plugs

-

respirator or filtering mask

-

close fitting, waterproof clothing

-

reflecting garments

-

safety footwear

Wear Appropriate Clothing

GOLDONI S.p.A.

JOKER

EN Inglese

80

SAFETY

Page 21

● The only authorized interventions are

the ones described in the

MAINTENANCE chapter. All other

interventions must be carried out by

the technicians of workshops

authorized. Your dealer will be able to

provide information about your nearest

authorized servicing center.

● Routine servicing of the machine may

only be carried out by qualified, trained

adults Become fully familiar with the

procedure before performing servicing

work.

● Do not operate the machine in a

confined space where dangerous

monoxide fumes can collect.

● Keep all nuts, bolts and screws

perfectly tightened so as to be sure that

the machinery operates in safe

conditions.

● Never ever tamper with the safety

devices. Check them regularly to make

sure that they function properly.

● Prevent grass, leaves and other debris

from building up on the machine. Clean

up spilt oil or fuel and remove any fuel

-

soaked debris. Allow the machine to

cool before storing.

● Never make adjustments or repairs

with the engine running. Wait for all

movement in the machine to stop

before making adjustments, cleaning or

repairing.

● Replace the safety instruction decals i

f

damaged.

Practice Safe Maintenance

● Keep hands, feet, clothing, jewelry and

long hair well away from moving parts

and control levers to prevent them from

getting caught.

● Securely support any machine

components that must be raised for

service work. Use stands or lock

service latches to support the

components when needed.

● Remove the spark plug wire (for

gasoline engines) before making any

repairs. If the electrical start is present,

disconnect the battery, first disconnect

the negative terminal and then the

positive one. First install the positive

terminal and then the negative one.

● Before servicing the machine or

implement, carefully relieve the

pressure from all components with

stored energy, such as hydraulic

components or springs.

● Keep all parts in a good condition and

properly installed. Repair all damage

immediately. Replace worn or broken

parts.

● Charge the batteries in an open, well

ventilated area, well away from

sparks. Unplug the battery charger

before connecting or disconnecting it

to or from the battery. Wear protective

clothing and use insulated tools.

GOLDONI S.p.A.

JOKER

EN Inglese

81

SAFETY

Page 22

● Remove grass and debris from the

engine compartment and silencer area

before and after using the machine.

● Always shut off the fuel valve, i

f

installed, when the machine is stored

or transported.

● Do not park the machine neas an open

flame or source of ignition, such as a

water heater or a boiler.

● Frequently check the fuel lines, the

tank, plugs and fittings for cracks or

leaks. Replace them if necessary

● Never store the machine with fuel in the

tank inside a building where fumes

could reach an open flame or spark.

● Allow the engine to cool before storing

the machine in a closed place.

Prevent Fires

Explosive separation of a parts of tire and

rim can cause serious injury or death:

● Never attempt to mount a tire without

the proper equipment and experience

to perform the job.

● Always maintain the correct tire

pressure. Do not inflate the tires above

the recommended pressure. Never

weld or heat a wheel and tire assembly.

Heat can cause an increase in air

pressure resulting in a tire explosion.

Welding can structurally weaken or

deform the wheel.

● When inflating tires, use a clip

-

on

chuck and extension hose long

enough to allow you to stand on one

side and NOT in front of or over the tire

assembly.

● Check tires for low pressure, cuts,

blisters, damaged rims or missing lug

bolts and nuts.

Tire Safety

GOLDONI S.p.A.

JOKER

EN Inglese

82

SAFETY

Page 23

To avoid personal injury or property

damage, use extreme care in handling fuel.

Fuel is extremely flammable and fuel vapors

are explosive.

● Extinguish all cigarettes, cigars, pipes,

and other sources of ignition.

● Use only approved non

-

metal, portable

fuel containers. If using a funnel, make

sure it is plastic and has no screen or

filter.

● Never remove the fuel tank cap or add

fuel with the engine running. Allow

engine to cool before refueling.

● Never add fuel to or drain fuel from the

machine indoors. Move machine

outdoors and provide adequate

ventilation.

● Clean up spilled fuel immediately. If fuel

is spilled on clothing, change clothing

immediately. If fuel is spilled near

machine, do not attempt to start the

engine but move the machine away

from the area of spillage. Avoid creating

any source of ignition until fuel vapors

have dissipated.

● Never store the machine or fuel

container where there is an open flame,

spark. or pilot light such as on a water

heater or other appliance.

● Prevent fire and explosion caused by

static electric discharge. Static electric

discharge can ignite fuel vapors in an

ungrounded fuel container.

● Never fill containers inside a vehicle or

Handling Fuel Safely

on a truck or trailer bed with a plastic

liner. Always place containers on the

ground away from your vehicle before

fueling.

● Remove fuel

-

powered equipment from

the truck or trailer and refuel it on the

ground. If this is not possible, then

refuel such equipment with a portable

container, rather than from a fuel

dispenser nozzle.

● Keep the nozzle in contact with the rim

of the fuel tank or container opening at

all times until the fueling is complete.

Do not use a nozzle lock

-

open device.

● Never overfill fuel tank. Replace fuel

tank cap and tighten securely.

● Replace all fuel container caps

securely after use.

● For gasoline engines, do not use gas

with methanol.

Methanol is harmful to your health and

to the environment.

GOLDONI S.p.A.

JOKER

EN Inglese

83

SAFETY

Page 24

Waste products, such as, used oil, fuel,

coolant, brake fluid, and batteries, can harm

the environment and people:

● Never ever use beverage containers for

waste fluids: someone may drink from

them.

● Contact your local Recycling Center or

authorized dealer for information about

how to recycle or dispose of waste

products.

● Use oil must be collected and must not

be dispersed in the environment since,

in accordance with the current laws, it

is classified as dangerous waste and

as such, must be taken to an

authorized collection center.

Handling Waste Product and

Chemicals

ECOLOGY

It is of fundamental importance to

safeguard the environment. Incorrect

waste disposal can alter the

environment and the ecological

system.

Do not discard fluids like fuels,

lubricants, coolants or other, in the

environment.

Do not use food or dink containers,

which could lead to mistakes, to drain

off fluids like fuels, lubricants,

coolants or other.

Do not dispose of parts of the cooling

system (such as radiators, fluids,

tanks, etc.) in the environment.

Contact an authorized organization or

ask your dealer for advice about how

to recycle or dispose of waste

products in the correct way.

ALWAYS place a vessel under the

drain hole so as to collect the fluid

when draining a tank or reservoir.

GOLDONI S.p.A.

JOKER

EN Inglese

84

SAFETY

Page 25

The machine is equipped with the following

safety devices.

● Device that prevents the last reverse

speed from being engaged when the

machine is used in the soil working or

ploughing direction.

This device is necessary because this

speed would exceed the limits allowed

by the Machinery Directive 2006/42.

● Device that prevents the reverse speed

from being engaged when the PTO is

engaged.

● Gear Stop device that disengages the

clutch if the operator accidentally

abandons the handlebars.

SAFETY DEVICES

SAFETY DECALS

DANGER

Safety decals have been affixed to

various parts of the machine. They

indicate potential dangers.

IMPORTANT

The decals must be kept clean and

legible. If damaged, they must be

replaced.

IMPORTANT

Some of the machine components can

be equipped with the manufacturer

’

s

specific safety decals.

GOLDONI S.p.A.

JOKER

EN Inglese

85

SAFETY

Page 26

TECHNICAL SPECIFICATIONS

The two-wheeled tractor is a self-propelle

r

agricultural machine with one axle, equipped with

a rotating soil-working unit.

These machines are used for preparing the soil

(breaking up the grassy turf, weeding, surface

cultivation) in places that cannot be reached by

tractors with larger implements. They are

therefore used for small areas, between the rows

in orchards, on the edge of ditched and in

confined spaces (greenhouses).

The machine consists of a bearing frame fitted

with an internal combustion engine that drives the

wheels, a PTO to which a cultivator with a

horizontal shaft is generally connected, but which

can also be connected to other tools (snow

ploughs, mowing bars, etc.).

The machine is controlled by an operator on the

ground, who steers it by means of a handlebar on

which most of the controls are installed.

All uses of the machine differing from

those described above are to be considered

unauthorized and dangerous.

INFORMATION ON THE MACHINE

Intended uses

Description

Engine

Driving wheels

Handlebars

GOLDONI S.p.A.

JOKER

EN Inglese

86

TECHNICAL SPECIFICATIONS

Page 27

TECHNICAL SPECIFICATIONS

JOKER 8 DS JOKER 10 DS JOKER 12 S

Engine

Type

Lombardini 15LD 315 Lombardini 15LD 400 Honda GX 340

Diesel Gasoline

Rated power

Kw (hp) / rpm

5,0 (6,8) / 3600 7,3 (10) / 3600 7,1 (9,5) / 3600

Cylinders

N

1

Engine starts.

Electrical

Pull

Pull

JOKER 8 DS JOKER 10 DS JOKER 12 S

Transmission

N° speed gears

4 FWD + 3 REV with reverse shuttle

Soil working direction

4 FWD + 2 REV with reverse shuttle

Mowing direction

Clutch

Dry plate with manual control by means of Gear Stop

Differential lock

Operated with a lever

Wheel release

Operated with a lever

Safety device Engagement of last reverse gear inhibited

JOKER 8 DS JOKER 10 DS JOKER 12 S

Power take-off

Type

With 1 speed, independent of the machine's ground speed.

Safety device Reverse gear inhibited with PTO engaged

JOKER 8 DS JOKER 10 DS JOKER 12 S

Driver’s

position

Handlebars

Assembled on elastic shock absorbers, adjustable in 9 height

positions.

Single column that swivels through 180°. Can be adjusted in 3

positions in the soil working direction and 2 positions in the mowing

position.

Safety device Gear Stop

Implement hitch

end fitting

Fixed

GOLDONI S.p.A.

JOKER

EN Inglese

87

TECHNICAL SPECIFICATIONS

Page 28

DIMENSIONS AND WEIGHTS

Table of Machine Dimensions and Weights

JOKER 8 DS JOKER 10 DS JOKER 12 S

Max length

mm

1768 1822

Min- max width

mm

5.00x10"

Adjustable disc

555- 668

Weight with std wheels

Kg 132 153 116

For the engine dimensions and weights:

See engine’

s operation and maintenance

manual.

Engine

GOLDONI S.p.A.

JOKER

EN Inglese

88

TECHNICAL SPECIFICATIONS

Page 29

● Improper use.

● Overloads (even localized).

● Unsuitable pressure.

● Unsuitable rim and tyre couplings.

Tyre life and performance depends on use of the correct operating pressure: if the pressure is too low,

the tyre will quickly wear out while an excessive pressure will reduce the lugging power and make the

wheels more liable to slip.

A

correct tyre pressure depends on various factors:

●

The operating conditions.

●

Machine load.

●

Machine model.

●

The tyre make.

●

The tyre size.

You are therefore advised to consult your dealer or the tyre manufacturer.

The values given below are only approximate as they depend on the conditions described above:

WHEELS

Tyres

WARNING

The tyres must only be changed by competent persons in possession of the necessary

equipment and technical know-how.

DANGER

It is absolutely essential to avoid:

Table of tyre inflation pressures

Tyre Bar (MAX) kPa (MAX)

5.00x10" 1,2 120

6.50/80x12" 1,2 120

GOLDONI S.p.A.

JOKER

EN Inglese

89

TECHNICAL SPECIFICATIONS

Page 30

In

km/h- with engine at 3600 Rpm (the values are purely indicative).

The data are calculated with wheels:

5.00x10"

In

km/h- with engine at 3600 Rpm (the values are purely indicative).

The data are calculated with wheels:

6.50/80x12"

SPEEDS

Speed Chart

Soil working direction

First speed gear. Second speed gear. Third speed gear. Fourth speed gear.

Forward 1.12 1.72 4.24 6.18

Reverse 0.79 1.21 2.99

/

Mowing direction

First speed gear. Second speed gear. Third speed gear. Fourth speed gear.

Forward 0.79 1.21 2.99 4.35

Reverse 1.12 1.72

/ /

Soil working direction

First speed gear. Second speed gear. Third speed gear. Fourth speed gear.

Forward 1.33 2.05 5.05 7.36

Reverse 0.93 1.44 3.56

/

Mowing direction

First speed gear. Second speed gear. Third speed gear. Fourth speed gear.

Forward 0.93 1.44 3.56 5.18

Reverse 1.33 2.05

/ /

GOLDONI S.p.A.

JOKER

EN Inglese

90

TECHNICAL SPECIFICATIONS

Page 31

Refer to the certificates of conformity supplied with the machine for information about the noise levels.

Refer to the certificates of conformity supplied with the machine for information about the vibration levels.

NOISE AND VIBRATIONS

Noise level information

The values of the noise produced by

the two wheeled tractors described in

the Operation and Maintenance

Manual, are given in compliance

with Directive 2006/42 concerning

noise levels perceived by the driver of

two wheeled tractors.

Since it is impossible for the

manufacturer to foresee the normal

working conditions in which the two

wheeled tractors will be operated by

the user, the noise levels have been

defined in accordance with the

methods and conditions described in

Machine Directive 2006/42 concerning

noise levels perceived by the driver of

two wheeled tractors.

Recommendations for the user

IMPORTANT

Remember that the agricultural

tractor may be employed in

different ways, and may be

connected to an infinite number

of implements. In order to ensure

that drivers are protected against

risks deriving from exposure to

noise, the entire tractor

implement group must be

considered.

IMPORTANT

In view of the aforementioned

noise levels and the consequent

health risk, the user must take

the appropriate precautions, as

described in Machine Directive

2006/42 and implementing norm

EN 709: 2010.

GOLDONI S.p.A.

JOKER

EN Inglese

91

TECHNICAL SPECIFICATIONS

Page 32

OPERATING INSTRUCTIONS

CONTROLS AND INSTRUMENTS

The Gear Stop is a safety system that comprises

two levers to be operated in sequence.

To move the lever

need to unlook the safety

lever

first.

When in the released position with the lever

raised, the clutch is disengaged, the two-wheeled

is at a standstill and, if on, the engine will not

switch off.

When in the work position with the lever lowered,

the clutch is engaged, the two-wheeled enbloc

with the gearbox and with the PTO if engaged.

A

ccidental release of the handlebars or the Gear

Stop allows the clutch to can be disengaged and

the two-wheeled tractor to consequently stop.

Gear Stop

IMPORTANT

To use the two-wheeled tractor in

stationary conditions (for pumps,

circular saws, etc.) that require the

PTO, move the gearshift lever to the

neutral position, select the PTO lever

and accelerate the engine to a medium

rate.

Gradually depress the Gear Stop and

connect the retainer latch

IMPORTANT

To tow trailers or the tanks of spraying

e

quip

ment that require the engine to be

running but for which the machine

must remain at a standstill for long

periods of time, release the Gear Stop,

move the gearshift and reverse shuttle

to the neutral position then slowly

depress the Gear Stop and lock it in the

work position with the retainer latch

A

TTENZIONE

The operation of the Gear Stop should

always be carried out gradually to

avoid too rapid maneuvers.

GOLDONI S.p.A.

JOKER

EN Inglese

92

OPERATING INSTRUCTIONS

Page 33

Handlebar controls

PTO control rod

Reverse shuttle lever: forward, neutral,

reverse selection.

Vertical handlebar release lever

Speed selector rod

Handlebar rotation releasing knob

Left handlebar

JOKER 8 DS

JOKER 10 DS

JOKER 12 S

Gear Stop lever

Engine stop switch

GOLDONI S.p.A.

JOKER

EN Inglese

93

OPERATING INSTRUCTIONS

Page 34

Right handlebar

Differential lock lever

Hand throttle.

Wheel releasing lever

Ignition switch

Battery charge indicator - red.

Engine oil pressure indicator.

1-pin socket 12V

See engine’

s operation and maintenance

manual.

Engine controls

GOLDONI S.p.A.

JOKER

EN Inglese

94

OPERATING INSTRUCTIONS

Page 35

To start the engine, it is advisable to shift the

gears, the PTO and the reverse shuttle to the

neutral position and leave the Gear Stop

lever in the raised position so as to disengage

the clutch. Move the red engine stop switch

to

the ON position.

See engine’

s operation and maintenance

manual.

STARTING AND STOPPING THE

ENGINE

Before starting the engine

How to start the engine

IMPORTANT

Carefully follow the instructions to start

the engine pulling strap

●

Insert the key and turn it as described

below:

Each starting attempt should last for just a few

seconds.

Do not make consecutive attempts to start the

engine without having waited at least 20 sec.

between one attempt and the next, otherwise the

battery will quickly run down and the starter motor

could be damaged.

A

fter the engine has started:

●

Release the key. It will automatically return

to the operating position

Ignition switch

Forward

0

No circuit powered.

Forward

1

Insert the key and turn it

clockwise to the first position (the

electrical circuit will be powered).

Forward

2

Engine starts.

WARNING

Do not keep operating the starter motor

when the engine has already started.

Damage to the starter motor due to

failure to comply with these

instructions will not be covered by the

warranty.

GOLDONI S.p.A.

JOKER

EN Inglese

95

OPERATING INSTRUCTIONS

Page 36

The motor stop switch is on the rh handlebar

connected to the throttle lever. It is red in colour

and can be turned to one ON position for starting

the engine or to two OFF positions to turn off the

engine.

JOKER 12 S

Before the engine is stopped, the Gear Stop

lever

must be raised so as to disengage the

clutch. Allow the engine to idle, move the

gearshift lever to the idle position, remember to

disengage the PTO if used then move the red

engine stop switch

to any of the two OFF

positions.

Engine stop switch

How to stop the engine

JOKER 8 DS

JOKER 10 DS

●

Allow the engine to idle.

●

Release the Gear Stop lever.

●

Move the gearshift lever to the idle position.

● Remember to disengage the PTO if used.

●

Turn the ignition key to position 0

●

Pull the knob

Engine stop switch

GOLDONI S.p.A.

JOKER

EN Inglese

96

OPERATING INSTRUCTIONS

Page 37

The handlebars can be adjusted vertically, with

the lever

.

Vertical adjustment comprises 9 work positions.

HOW TO START AND STOP THE

MACHINE

Handlebars

IMPORTANT

To prevent accidents and dangerous

situations, the machine settings and

adjustments must only be made when

the machine is off.

The adjustments must always be made

in compliance with the instructions in

this operation and maintenance

manual.

The handlebar is horizontal adjustable pulling the

knob

.

Left handlebar

Right handlebar

Horizontal rotation comprises 3 positions in the

soil working condition and 2 positions in the

mowing condition.

IMPORTANT

In this position, the speed selector rod

must be removed from its retainer

block by taking out the split pin, then

fitted back into the same block but from

the opposite side, by turning it through

180°.

GOLDONI S.p.A.

JOKER

EN Inglese

97

OPERATING INSTRUCTIONS

Page 38

●

Release and remove the cover.

●

Release the two rods from their housings

on the handlebars

●

Reverse handlebars in the clockwise

direction.

IMPORTANT

The handlebars turn through 180° in

the clockwise direction after the split

pins that hold the linkage in place

have been detached. They must be set

back in place in the inverted position

once the handlebars have been turned.

Reverse shuttle lever: forward, neutral,

reverse selection.

Fit the two rods back in their seats in the

handlebars

Fit the reverser rod back in place and lock it with

the split pins

Fit the cover back on the handlebars

IMPORTANT

When the handlebars are turned from

the mowing position to the normal one

(soil working direction), make sure that

the safety systems, e.i. the pin that

prevents the PTO from being engaged

when the macine is reversing and the

reverse gear from being engaged when

the PTO is engaged, operate in the

correct way.

GOLDONI S.p.A.

JOKER

EN Inglese

98

OPERATING INSTRUCTIONS

Page 39

The machine is equipped with a front guard to

protect the engine from damage caused by

impact.

The throttle lever is located in the front right-hand

side of the machine.

Increase or decrease the engine rate by gradually

moving the lever.

Safety frame

Hand throttle

●

Allow the engine to idle.

●

Release the Gear Stop lever.

●

Select the transmission ratio (consult the

Gearbox chapter).

●

Gradually depress the Gear Stop lever to

disengage the safety linkage in the device.

●

Gradually accelerate the engine.

●

Allow the engine to idle.

●

Release the Gear Stop lever.

●

Move the gearshift lever to the idle position.

● Remember to disengage the PTO if used.

How to start the machine

DANGER

The machine could respond in a

dangerous way if the Gear Stop lever is

depressed too sharply.

IMPORTANT

Before starting the machine, make sure

you become familiar with its main

controls: transmission, PTO, diff lock,

how to stop the engine and the Gear

Stop.

IMPORTANT

Lengthy clutch disengagements could

wear out the thrust bearing.

How to stop the machine

GOLDONI S.p.A.

JOKER

EN Inglese

99

OPERATING INSTRUCTIONS

Page 40

TRANSMISSION

The machine consists of a transmission

comprising a gearbox, PTO and reverse shuttle,

each controlled by a lever.

The speed at which you drive the machine must

be chosen to suit:

●

The work required.

●

The implement used.

●

The type of ground.

Consult the

TECHNICAL SPECIFICATIONS

Gearbox

Gearshift lever

The lever can be moved in four positions

(plus neutral):

Second speed gear.

Neutral.

First speed gear.

Neutral.

Third speed gear.

Neutral.

Fourth speed gear.

Selection is not synchronized.

To shift gear:

●

Release the Gear Stop lever.

●

Select the required range.

●

Gradually depress the Gear Stop lever to

disengage the safety linkage in the device.

WARNING

Engagement of the reverse gear and/or

the consequent engagement of the

forward speed gear must ALWAYS be

performed with the engine idling and

with the wheels of the machine at a

standstill.

GOLDONI S.p.A.

JOKER

EN Inglese

100

OPERATING INSTRUCTIONS

Page 41

Forward.

Neutral.

Reverse.

Selection is not synchronized.

Proceed as described to select the forward or

reverse speed:

●

Release the Gear Stop lever.

●

Stop the machine.

● Select the forward or reverse speed.

●

Gradually depress the Gear Stop lever to

disengage the safety linkage in the device.

Reverse shuttle lever

The lever has two positions (plus neutral):

The tractor is equipped with a mechanical

differential lock on both axles.

Use recommended for ploughing work or if one of

the two driving wheels possesses insufficient grip

owing to muddy, rugged or slippery ground.

The diff lock is mechanically controlled by means

of the lever. It is unlocked by releasing the lever.

To get the most out of the device, engage

the differential lock before the wheels begin

to slip. Do not engage the lock while one

wheel is already slipping.

Differential lock

DANGER

When the differential lock is engaged,

the tractor cannot be steered.

IMPORTANT

Do not use the differential lock near or

in bends and avoid using it in fast

gears or with engine running at a high

rate.

GOLDONI S.p.A.

JOKER

EN Inglese

101

OPERATING INSTRUCTIONS

Page 42

The wheels can be released by means of the

lever

to allow the machine to be moved when

the engine is off.

Wheel release

The wheel track can be changed by moving the

wheel disc on his flange.

● Models with fitted wheel axle

The track width is adjusted by means of the

screw

Track width adjustment

GOLDONI S.p.A.

JOKER

EN Inglese

102

OPERATING INSTRUCTIONS

Page 43

The PTO

is engaged by means of the

PTO lever

and, when the machine is at a

standstill, with the Gear Stop raised.

POWER TAKE-OFF

Rear power take-off (PTO)

WARNING

when the PTO is not used, move the

mode selector lever to the Neutral or

Independent position (depending on

the model or version). This prevents

the shaft of the PTO and other spinning

components from accidentally turning.

WARNING

Do not remove or damage the

protective plate

WARNING

Cover the PTO shaft with the guard

when not in use.

Power take-off

Implement coupling bolts.

The tractor is equipped with a rear power take-of

f

able to function in the following mode:

● Independent.

The PTO operates at a speed of 923 RPM.

20x17 DIN 5482 profile

Turning direction: clockwise.

IMPORTANT

The two-wheeled tractor is equipped

with a safety device that prevents the

reverse gear from being engaged when

the PTO is engaged, in the normal

operating direction. Set the PTO to the

neutral position before engaging the

reverse gear.

GOLDONI S.p.A.

JOKER

EN Inglese

103

OPERATING INSTRUCTIONS

Page 44

The ease with which the machine can be driven

also depends on the correct use and successive

height adjustment of the towing device.

The machine can be equipped tow hook for the

use of small trailers or the tanks of spraying

equipment.

TOWING ATTACHMENTS

Tow hook

If very heavy implements are hitched to the

tractor, the longitudinal stability of this latter may

be impaired. This can be corrected by using one

of the various types of ballast available as

optionals.

20 kg front ballast is recommended for ploughing

work

The weights can be applied in pairs to wheels for

a total 42 kg.

BALLAST

Ballast (optional)

WARNING

when the machine is used for light

work or for travelling or towing on the

roads, the ballast would stress the

moving parts unnecessarily and

should therefore be removed.

GOLDONI S.p.A.

JOKER

EN Inglese

104

OPERATING INSTRUCTIONS

Page 45

SCHEDULED SERVICING

The user must have the machine itself regularly serviced to ensure that it continues to function correctly,

and to benefit from the manufacturer annual warranty coverage. Most especially, the user must, at this

expense, have all the following routine servicing work performed on his machine by his manufacturer

area "Dealer" or "Authorized Workshop" in accordance with the peremptory conditions and terms

indicated below.

A

series of symbols have been make to make the texts easier to understand. Their meanings are

described below:

SCHEDULED SERVICING

WARNING

Check the levels:

● Before using the machine

● With the machine at a standstill and the engine off (for at least the past hour).

● On a flat surface.

Instructions

Check

Clean with compressed

Adjustment

Lubrication

Greasing

Fluid changes

Part replacements

Set intervals

Washing

Work hours

When necessary.

Top up the level

Top up the level

Top up the level

GOLDONI S.p.A.

JOKER

EN Inglese

105

SCHEDULED SERVICING

Page 46

DANGER

Do not wear loose clothing, jewelry,

neck chains or bracelets and take care

if your hair is very long as it could

become caught up in parts of the

machine and implements.

DANGER

Do not leave the engine running in an

closed room: the exhaust fumes are

poisonous.

DANGER

Do not leave the machine with engine

running near flammable substances.

DANGER

After any maintenance work, grease

and remove the grease from the engine

to prevent the risk of a fire.

WARNING

Do not tamper with the machine or the

implements in any way.

WARNING

Always stop the engine before

proceeding with any maintenance,

repairs or other operations on the

machine or implements and if present

the electrical start, remove the ignition

key.

WARNING

Always park the tractor so that its

stability is guaranteed by applying the

parking brake and engaging a gear (1st

gear uphill abd reverse downhill)and

applying the parking brake. Use a

chock for greater safety.

WARNING

Before driving the machine, check to

be sure that there are no bystanders or

animals within its range of action.

WARNING

Do not leave the machine unattended

with the engine running and if present

the electrical start, the ignition key on

the dashboard

WARNING

The operator must check to make sure

that all parts of the tractor, especially

the safety devices, are in a good

working condition and that they always

comform to the purpose for which they

were designed. They should be kept in

a perfectly efficient condition. If you

note any defects or faults, fix or repair

them in good time. If necessary contact

your nearest Assistance Centre.

IMPORTANT

Check the nuts and bolts of the wheels

and safety frame from time to time,

always with the engine shut off.

DANGER

Safety decals have been affixed to

various parts of the machine. They

indicate potential dangers.

IMPORTANT

The decals must be kept clean and

legible. If damaged, they must be

replaced.

It is of fundamental importance to

safeguard the environment. Incorrect

waste disposal can alter the

environment and the ecological

system.

Do not discard fluids like fuels,

lubricants, coolants or other, in the

environment.

Do not use food or dink containers,

which could lead to mistakes, to drain

off fluids like fuels, lubricants,

coolants or other.

Contact an authorized organization or

ask your dealer for advice about how

to recycle or dispose of waste

products in the correct way.

GOLDONI S.p.A.

JOKER

EN Inglese

106

SCHEDULED SERVICING

Page 47

Do not dispose of parts of the cooling

system (such as radiators, fluids,

tanks, etc.) in the environment.

ALWAYS place a vessel under the

drain hole so as to collect the fluid

when draining a tank or reservoir.

GOLDONI S.p.A.

JOKER

EN Inglese

107

SCHEDULED SERVICING

Page 48

Extraordinary Maintenance:

Routine scheduled maintenance

WARNING

The following table shows the maintenance intervals.

JOKER 12 S

:

Internal vent carburetor with dual element type only.

Cyclone type every 6 months or 150 hours.

:

Cyclone type every 2 years or 600 hours.

Working hours

Hours 20 10 50 50 100 150 300 400 800

Months 1 3 6 12 12

Engine oil

Fuel filter

Fuel tank

Dry air filter

Air filter in oil bath

Spark plugs

Gearbox housing

Gear Stop

Cables.

Electrical system

GOLDONI S.p.A.

JOKER

EN Inglese

108

SCHEDULED SERVICING

Page 49

JOKER 8 DS

JOKER 10 DS

Working hours

Hours 50 10 16 50 150 250 400 500 800

Months 12 6 12 12

Engine oil

Engine oil filter

Fuel filter

Fuel tank

Dry air filter

Air filter in oil bath

Gearbox housing

Gear Stop

Cables.

Electrical system

GOLDONI S.p.A.

JOKER

EN Inglese

109

SCHEDULED SERVICING

Page 50

Consult the specific manual for the safety notes

and operation and maintenance instructions for

certain of the components manufactured by other

companies.

●

Pull upwards in the relative groove in the

bonnet.

See engine’

s operation and maintenance

manual.

ENGINE UNIT

Engine

Fuel tank

Check:

●

To make sure that there is sufficient fuel for

the whole job.

●

To make sure that there are no dents or

abrasions on the tank.

Clean the zone surrounding the tank plug.

Use good quality fuel with the technical

specifications described in the engine’s

operation and maintenance manual.

Replace the fuel plug with a genuine spare if it is

missing or damaged.

Replace the tank with a genuine spare if it has

been damaged by scratches, abrasions or dents.

Check

Clean

Top up level

WARNING

Top up the fuel level when the engine is

off. Do not smoke near fuel or when the

tank is being filled.

Replace

Do not discard fluids like fuels,

lubricants, coolants or other, in the

environment.

GOLDONI S.p.A.

JOKER

EN Inglese

110

SCHEDULED SERVICING

Page 51

See engine’

s operation and maintenance

manual.

Figure 1

Figure 2

Dry air filter

WARNING

Stop the engine and wait until it has

cooled down before proceeding with

any servicing operations.

Check 10

Figure 3

Keep the following parts clean:

Unscrew the knob that fixes the protection (figure

1), remove the protection (figure 2), take out the

filter (figure 3) and clean it:

carefully tap the filter on a hard, flat surface with

the perforated part pointing downwards.

Gently blow compressed air at a pressure of

no

more than 7 bar

through all the pleats (figure 4)

in the direction opposite to that of the arrow

stamped on the filter itself.

The internal filter changes colour when dirty

Clean with compressed

Replace

GOLDONI S.p.A.

JOKER

EN Inglese

111

SCHEDULED SERVICING

Page 52

See engine’

s operation and maintenance

manual.

JOKER 12 S

Figure 1

Figure 2

Figure 3

Air filter in oil bath

WARNING

Stop the engine and wait until it has

cooled down before proceeding with

any servicing operations.

Check 10

Keep the following parts clean:

Unscrew the knob that fixes the protection (figure

1), and remove the filter from the oil reservoir.

Clean the filter by lightly blowing compressed air

at a pressure of not more than 7 bar

through all

the pleats (figure 2).

Replace the oil in the basket

(figure 3)

JOKER 8 DS

JOKER 10 DS

Keep the following parts clean:

Uncouple the two levers

, and remove the

filter

from the oil reservoir.

Clean the filter

by lightly blowing

compressed air at a pressure of not more than

7 bar

through all the pleats.

Replace the oil in the basket

Clean with compressed

Replace

Check 10

Clean with compressed

Replace

GOLDONI S.p.A.

JOKER

EN Inglese

112

SCHEDULED SERVICING

Page 53

These parts of the tractor all use the same oil.

Check the oil level by means of the dipstick (MIN

-

MAX )

If necessary, top up with oil of the recommended

type.

We recommend Arbor oil by FL Selenia: GEAR

SYNT 220 PG

Keep the following parts clean:

●

The outside of the plug and the surrounding

area.

Plug oil draining

TRANSMISSION UNIT

Gearbox housing

Check 50

Clean with compressed 400

Replace

Replace the oil in the casing, which requires

about 2 liters of fluid.

We recommend Arbor oil by FL Selenia: GEAR

SYNT 220 PG

IMPORTANT

The service must only be carried out by

the dealer or by specialized

technicians.

GOLDONI S.p.A.

JOKER

EN Inglese

113

SCHEDULED SERVICING

Page 54

Periodically check the idle travel of the command.

Use the adjuster

if there is too much play

Gear Stop

WARNING

The Gear Stop is an important part of

the machine, its proper functioning is

essential.

Frequently inspect the proper

functioning of the Gear Stop and adjust

if necessary.

A

djustment

JOKER 8 DS

JOKER 10 DS

JOKER 12 S

Periodically check the idle travel of the command.

The travel of the throttle lever is regulated with the

adjuster screws at the end of the accelerator

cable, on the engine.

See engine’

s operation and maintenance

manual.

Hand throttle

Adjustment

GOLDONI S.p.A.

JOKER

EN Inglese

114

SCHEDULED SERVICING

Page 55

Periodically check the idle travel of the command.

There must be 2 mm free travel on the lever

before the wheels begin to release.

This play is adjusted by means of the screw

.

Wheel release

A

djustment

Periodically check the idle travel of the command.

The idle travel of the diff lock lever

must be 2

-

4 mm in the LOCKED position.

It must be completely released when the lever is

in the RELEASED position.

Use the adjuster screw

to regulate the correct

travel.

Differential lock

Adjustment

GOLDONI S.p.A.

JOKER

EN Inglese

115

SCHEDULED SERVICING

Page 56

Figure 1

ELECTRICAL SYSTEM

WARNING

Always disconnect the battery’s

ground cable (negative pole with the “

“ symbol) before working on the

electrical system.

Battery

WARNING

Work on the battery requires particular

care: battery acid is corrosive and the

gases released are inflammable.

To access the battery open the bonnet and

remove the protection removing the two side

knobs (figure 1)

Make sure that the terminals are fixed to the

battery poles

Make sure that the battery is firmly fixed to the

machine.

Keep the battery clean with a damp, antistatic

cloth.

Keep the battery poles and cable terminals clean.

Lightly grease the poles and terminals when

necessary.

Use Vaseline-based grease, not normal grease.

If the machine remains idle for a long period of

time:

●

Charge the battery as indicated by the

manufacturer.

●

Disconnect both the cables.

●

Store the battery in a cool, dry, well

ventilated place.

If the battery must be replaced, make sure the

new one possesses identical technical

specifications (the values are given on the actual

battery itself).

Check 150

Clean

Greasing

Idle periods

Replace

GOLDONI S.p.A.

JOKER

EN Inglese

116

SCHEDULED SERVICING

Page 57

Genuine Lubricants ARBOR by FL SELENIA

A

RBOR UNIVERSAL 15W

-

40 oil

● Viscosity at 40° C (mm2/s) 110

● Viscosity at 100° C (mm2/s) 14

● Viscosity at

-

15° C (mPa.s) 3450

●

Index of viscosity 135

● Flash point V.A. (°C) 220

●

Pour point (°C) -36

● Mass Volume at 15 °C (kg/l) 0.886

GEAR SYNT 220 PG oil

● Viscosity at 40° C (mm2/s) 220

● Viscosity at 100° C (mm2/s) 37

●

Index of viscosity 219

● Flash point V.A. (°C) 225

●

Pour point (°C) -33

● Mass Volume at 15 °C (kg/l) 1.002

A

RBOR TRW 90 oil

● Viscosity at 40° C (mm2/s) 135

● Viscosity at 100° C (mm2/s) 14.3

● Viscosity at

-

26° C (mPa.s) 108000

●

Index of viscosity 104

● Flash point V.A. (°C) 220

●

Pour point (°C) -27

● Mass Volume at 15 °C (kg/l) 0.895

A

RBOR MTA 90 oil

● Viscosity at

-

40° C (mPa.s) 28000

● Viscosity at 40° C (mm2/s) 35.5

● Viscosity at 100° C (mm2/s) 7.5

●

Index of viscosity 160

● Flash point V.A. (°C) 200

●

Pour point (°C) -40

● Mass Volume at 15 °C (kg/l) 0.870

●

Colour red

A

RBOR MP Extra grease

●

NLGI grade 2

●

Manipulated penetration (60)(dmm) 285