Page 1

GOLDONI SERIES

Aster

operation and

maintenance (en)

Page 2

Page 3

Sede Legale e Stabilimento

Indirizzo:

Telefono:

Fax:

Internet:

GOLDONI S.p.A.

Via Canale, 3

41012 Migliarina di Carpi

Modena, Italy

+39 0522 640 111

+39 0522 699 002

www.goldoni.com

Aster 35

Aster 40

Aster 45

3

Page 4

4

Page 5

TABLE OF CONTENTS

Introduction....................................................................................................................9

After sales assistance....................................................................................................9

SAFETY................................................................................... 10

How to read the manual...............................................................................................10

Safety regulations........................................................................................................11

Safety decals ...............................................................................................................14

Information about tractor noise levels..........................................................................15

Standard symbols........................................................................................................16

Ecology........................................................................................................................17

IDENTIFICATION OF THE MACHINE AND COMPONENTS 18

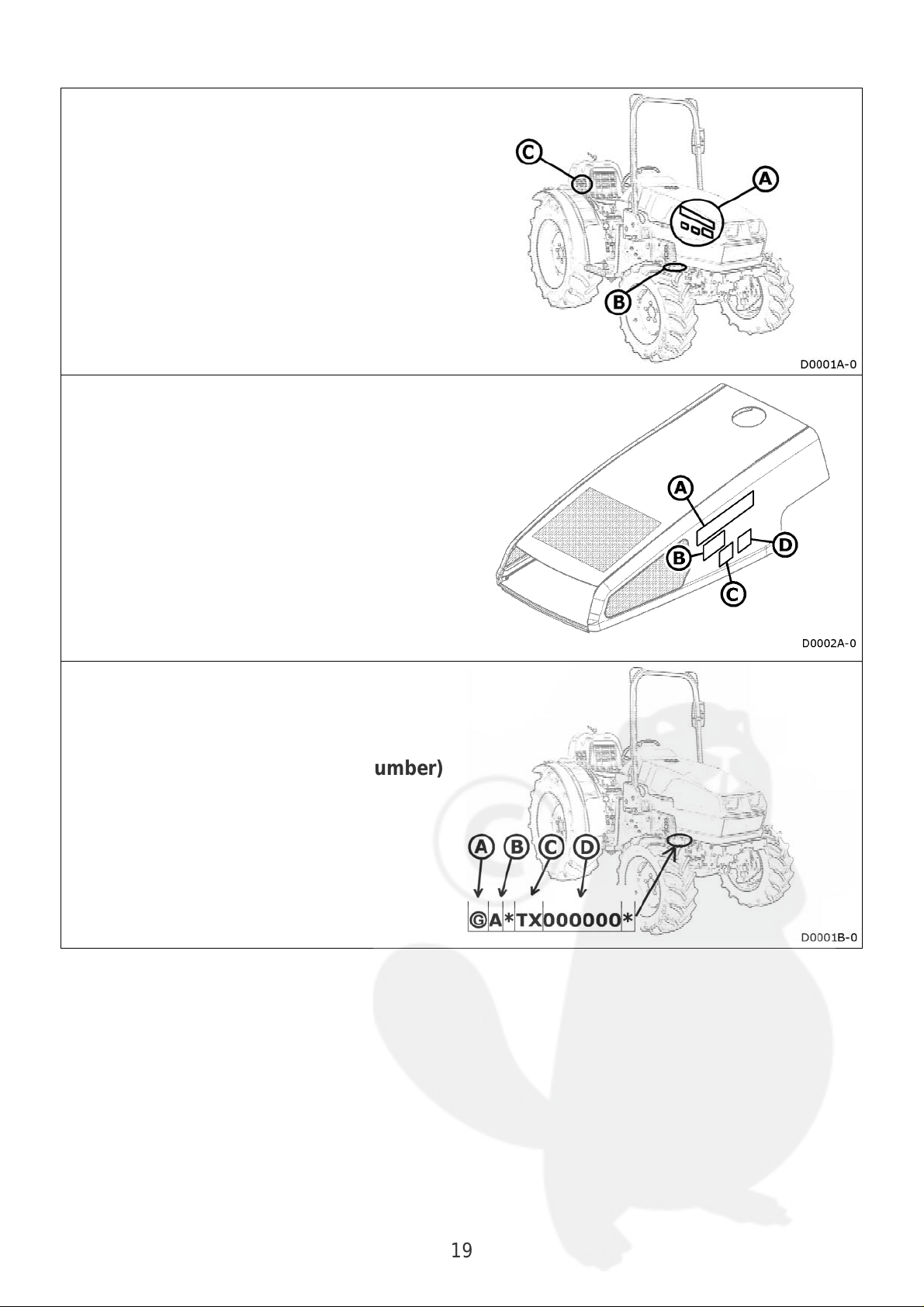

Machine identification ..................................................................................................19

Decals ......................................................................................................................19

Punch marks on chassis ..........................................................................................19

Metal plate................................................................................................................20

Identification of the components..................................................................................21

Engine......................................................................................................................21

Safety frame.............................................................................................................21

Cab...........................................................................................................................21

Towing attachment...................................................................................................21

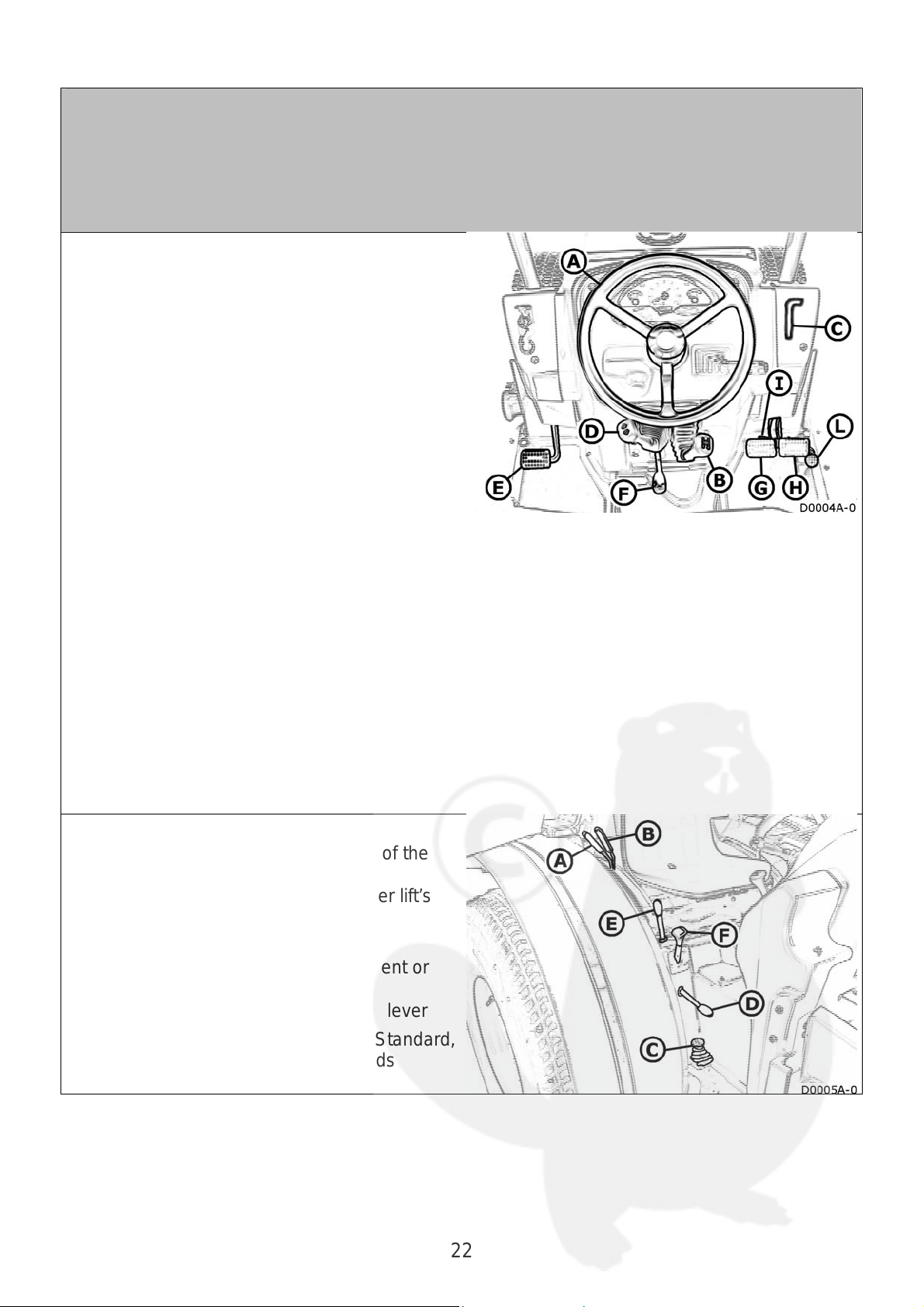

WORK STATION..................................................................... 22

Controls........................................................................................................................22

Controls in front part.................................................................................................22

Controls on RH side.................................................................................................22

Controls on LH side..................................................................................................23

Seat controls ............................................................................................................23

Instruments..................................................................................................................24

Multi-function dashboard..........................................................................................24

Ignition switch...........................................................................................................25

Light switch...............................................................................................................25

Hazard light switch...................................................................................................25

Lights........................................................................................................................26

Lights (with cab).......................................................................................................26

Revolving beacon (optional).....................................................................................26

7-pin trailer socket....................................................................................................27

Battery......................................................................................................................28

Safety frame (roll-bar or ROPS)...................................................................................29

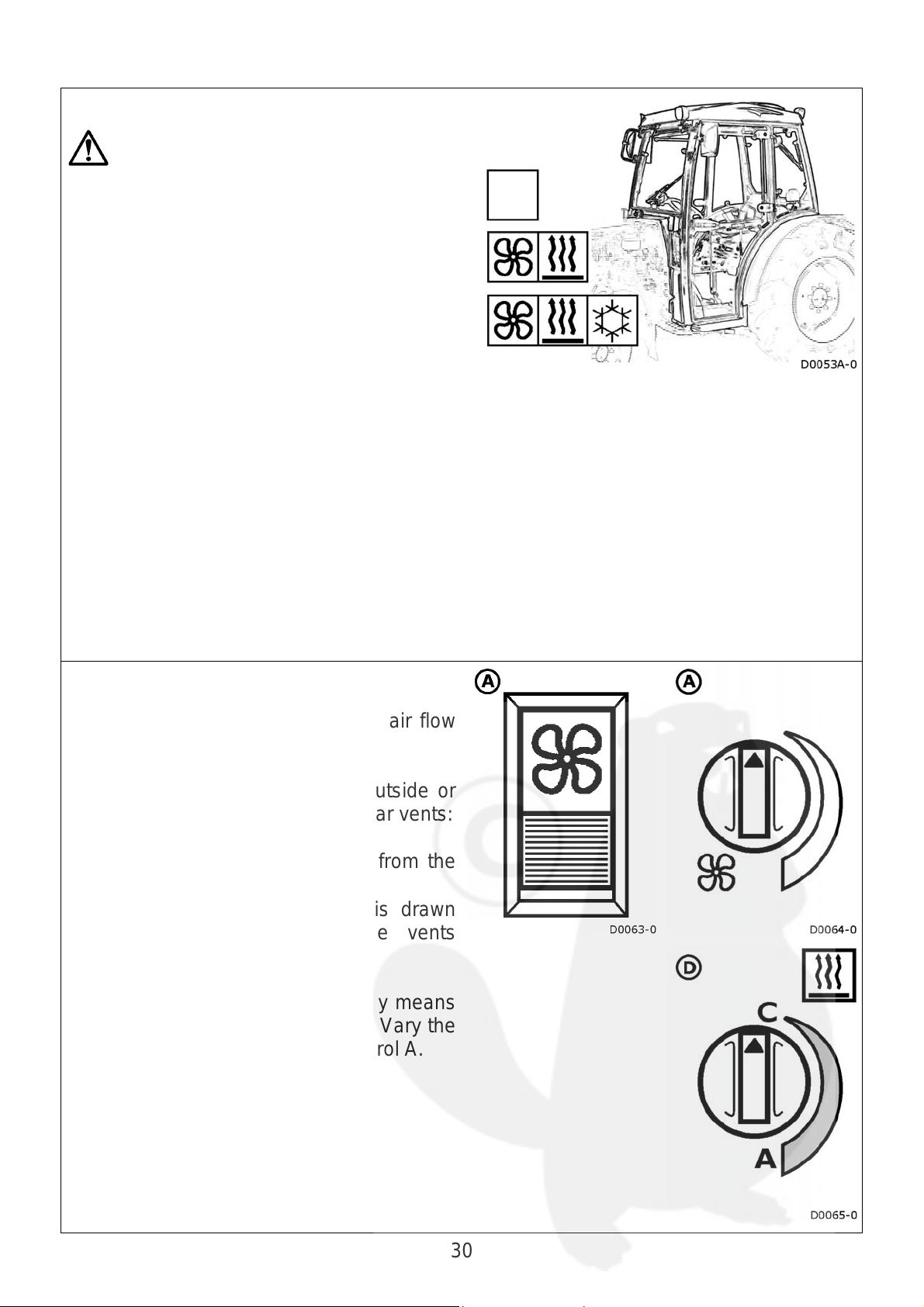

Cab ..............................................................................................................................30

Versions ...................................................................................................................30

Heating and ventilating.............................................................................................30

Air conditioning ............................................................................................................31

5

Page 6

Cab air filter..............................................................................................................32

Cab air filter with activated carbon (optional)...........................................................32

Switches...................................................................................................................32

Cab and safety frame approval....................................................................................33

Safety belts (where applicable)....................................................................................33

Tool box.......................................................................................................................33

OPERATING INSTRUCTIONS ............................................... 34

How to start and stop the machine..............................................................................34

How to start the engine ............................................................................................34

How to start the machine..........................................................................................35

How to stop the machine..........................................................................................35

How to stop the engine.............................................................................................35

How to move off...........................................................................................................36

Main clutch...............................................................................................................36

Gearbox....................................................................................................................36

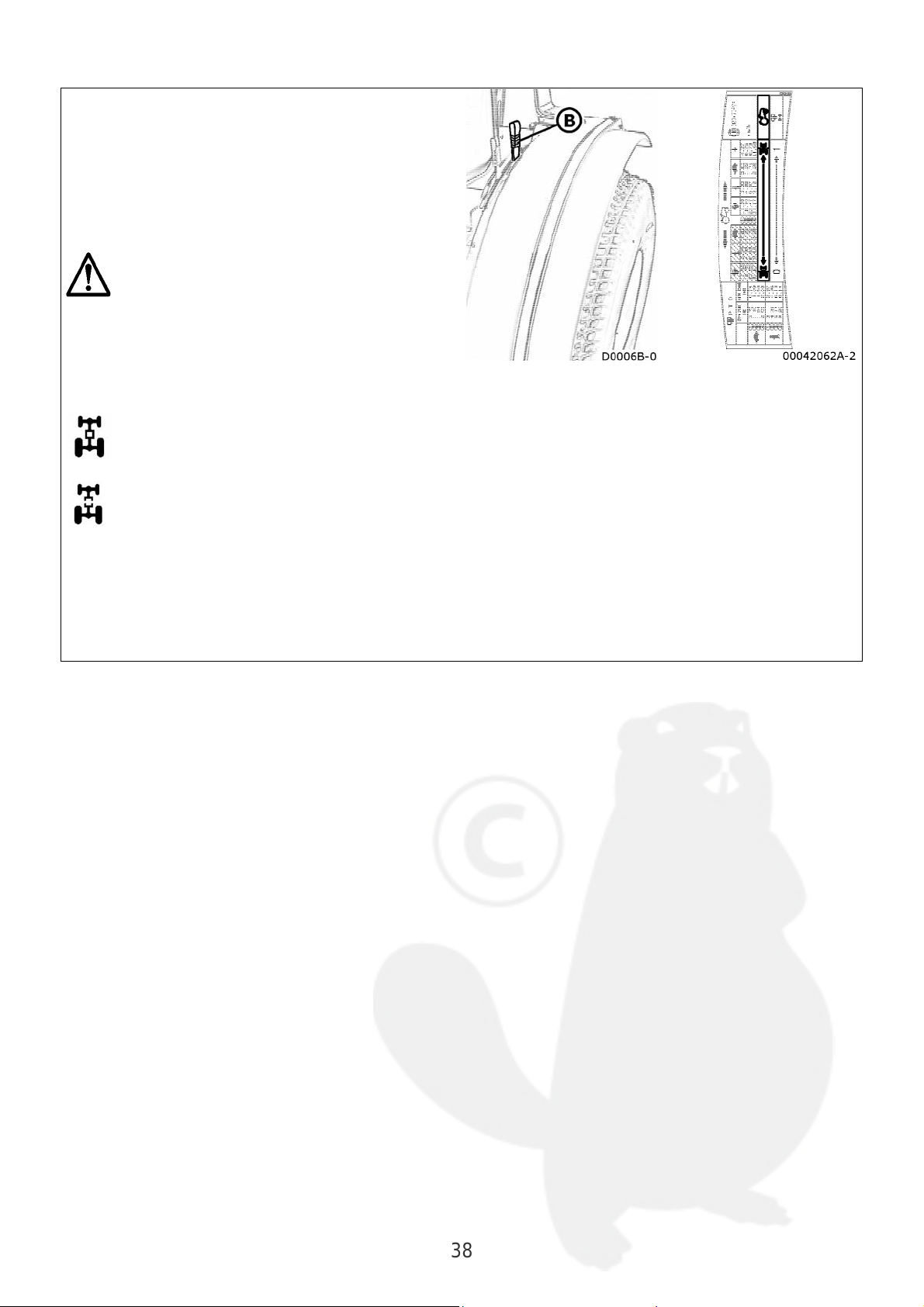

Four wheel drive.......................................................................................................38

Rear diff lock ............................................................................................................39

Power take-off..............................................................................................................39

Rear power take-off (PTO).......................................................................................39

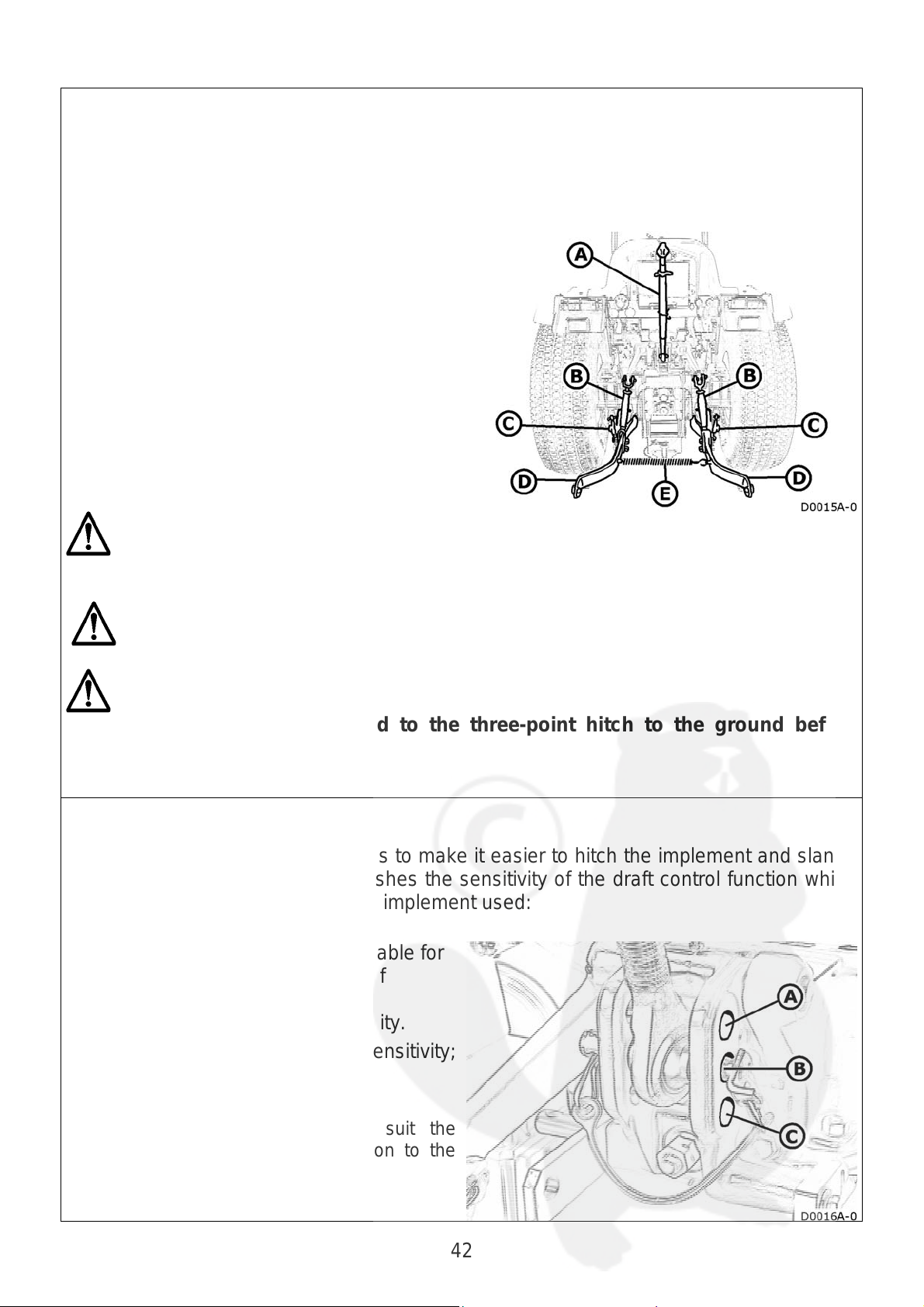

Three-point hitch..........................................................................................................42

Third point link..........................................................................................................42

Adjustable rod (pair).................................................................................................43

Side stabilizer (pair)..................................................................................................43

Universal joint...........................................................................................................43

Rear power lift..............................................................................................................44

Controlled position....................................................................................................44

Draft control..............................................................................................................44

Floating mode..............................................................................................................44

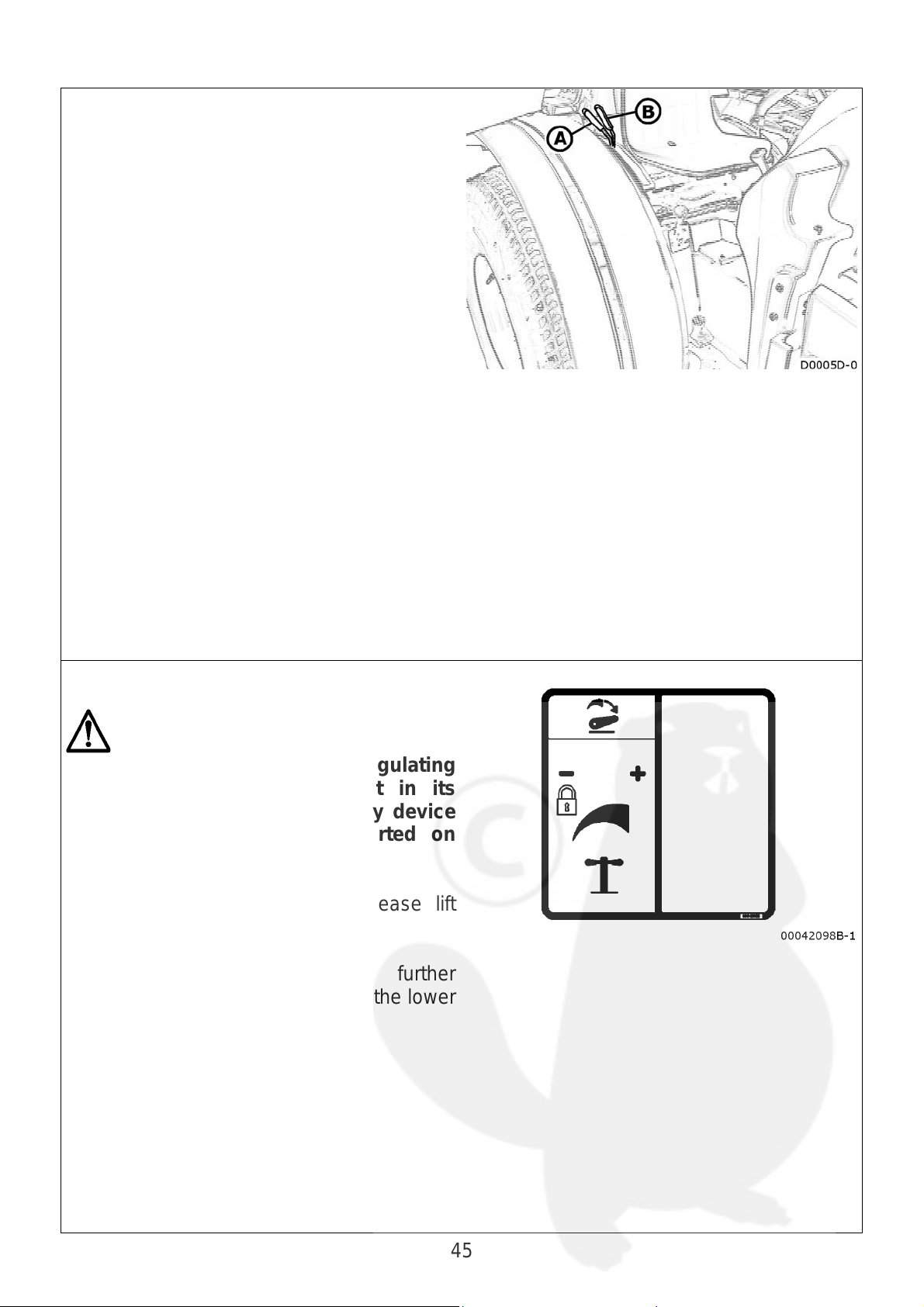

Mixed draft and position mode adjustment ..............................................................45

Regulating lift rate and sensitivity.............................................................................45

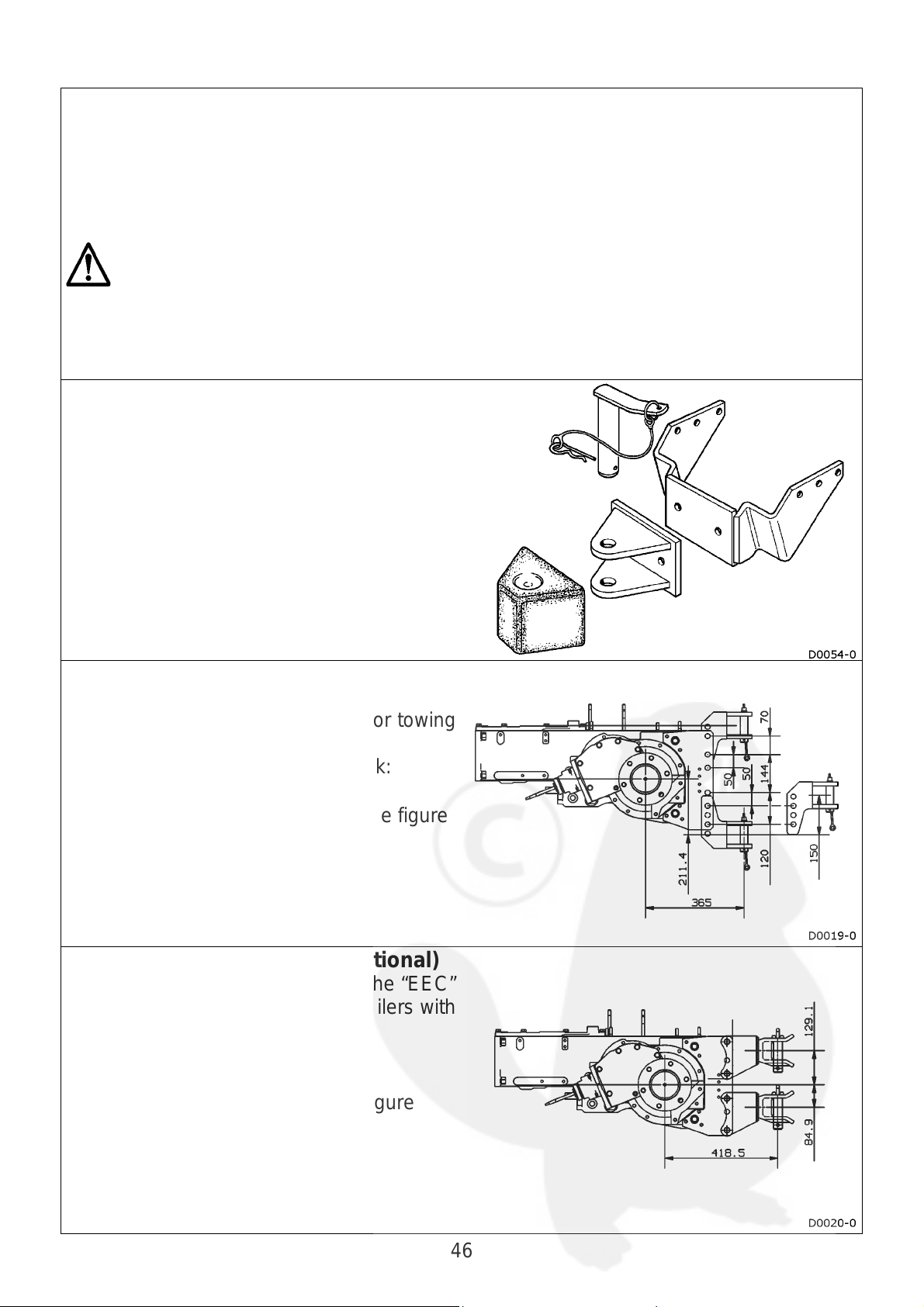

Towing attachments (optional).....................................................................................46

Front tow hook (optional)..........................................................................................46

“Category B” tow hook (optional)..............................................................................46

“EEC Category” tow hook (optional) ........................................................................46

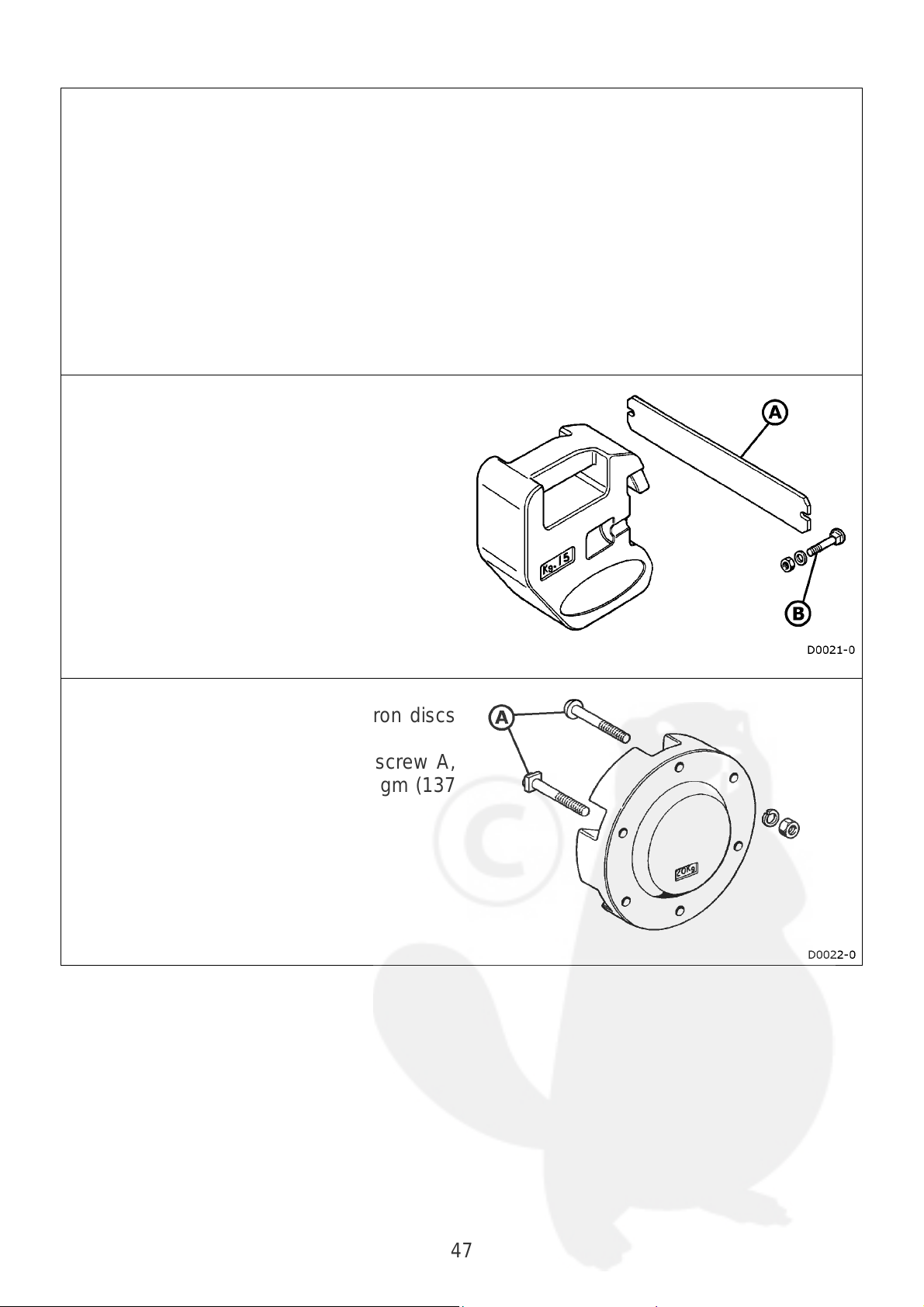

Ballast (optional)..........................................................................................................47

Front ballast (optional)..............................................................................................47

Rear ballast (optional)..............................................................................................47

Wheel ballasting by filling the tyres with fluid...........................................................48

Wheels.........................................................................................................................49

Steering angle..........................................................................................................49

Front wheel toe-in.....................................................................................................49

Track widths.............................................................................................................50

Wheel bolt torque values..........................................................................................50

Transmission ratio....................................................................................................50

Tyres ........................................................................................................................51

How to tow the tractor..................................................................................................51

Transporting the tractor................................................................................................52

6

Page 7

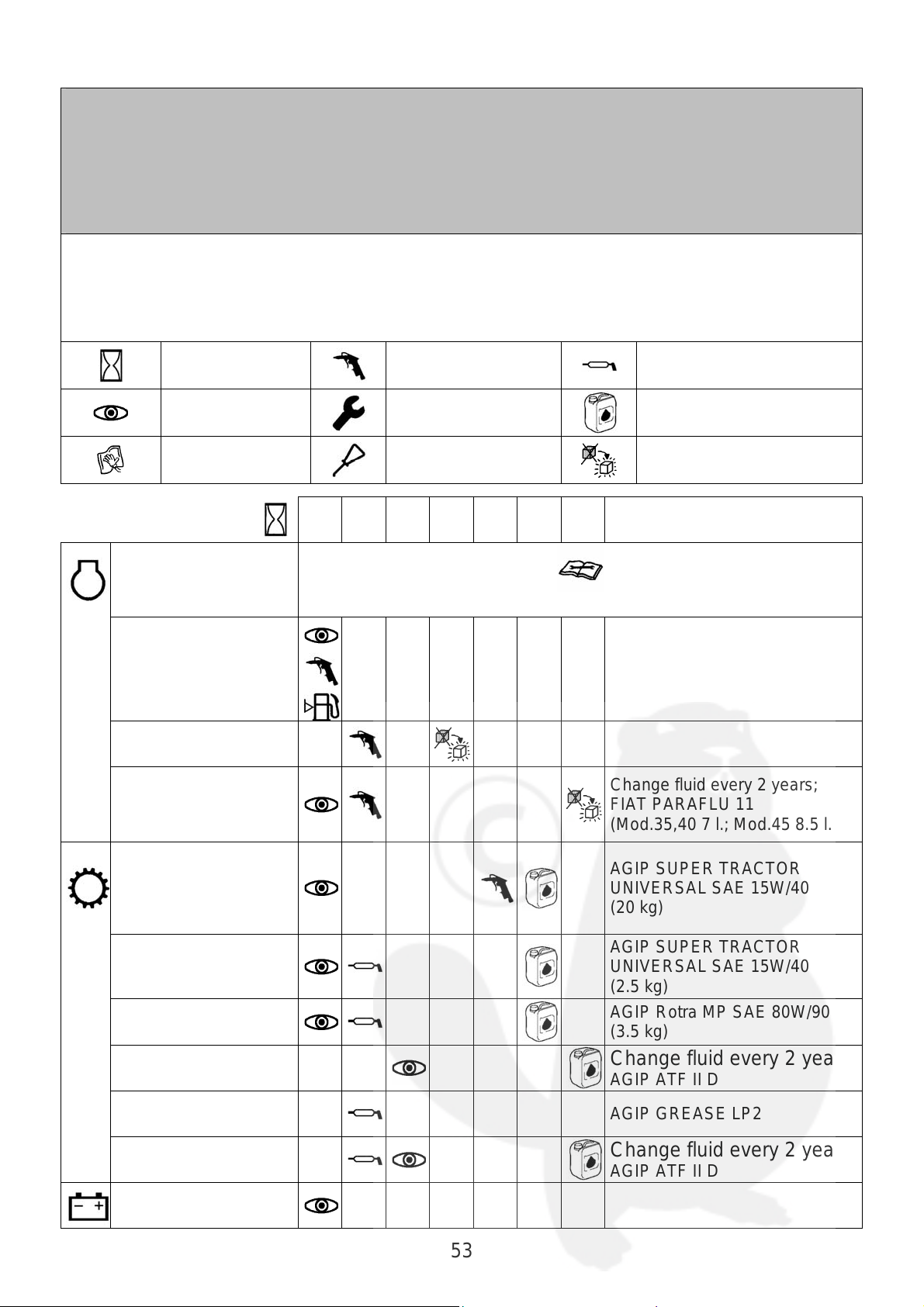

MAINTENANCE ...................................................................... 53

Routine maintenance guide:........................................................................................53

How to open the bonnet...............................................................................................54

Engine assembly..........................................................................................................54

Engine......................................................................................................................54

Fuel tank...................................................................................................................55

Dry air filter...............................................................................................................56

Cooling system.........................................................................................................57

Transmission assembly ...............................................................................................58

Gearbox housing, rear differential, power lift ...........................................................58

Mod.35-40 front axle ................................................................................................60

Mod.45 front axle......................................................................................................61

Main clutch...............................................................................................................62

Rear power take-off clutch .......................................................................................63

Rear differential lock.................................................................................................64

Final drive lever........................................................................................................64

Brakes......................................................................................................................65

Electrical system..........................................................................................................66

Battery......................................................................................................................66

Headlights ................................................................................................................67

Fuses........................................................................................................................68

Engine air filter clogging sensor...............................................................................69

Bodywork..................................................................................................................69

Air conditioning system ............................................................................................70

TECHNICAL SPECIFICATIONS............................................. 71

General specifications..................................................................................................71

Dimensions and weights..............................................................................................72

Speeds.........................................................................................................................73

Recommended lubricants............................................................................................74

7

Page 8

8

Page 9

Introduction

The confidence you have shown in our company by choosing equipment carrying our

trademark will be amply repaid by the excellent service it will give you over the years.

Correct use and normal routine maintenance will generously rewarded in performance,

output and savings.

After sales assistance

Our Assistance and Parts Division provides original spares and specialized personnel to

service our tractors. This is the only Assistance Service authorized to provide under

warranty service and assistance in conjunction with our network of AUTHORIZED

dealers.

The use of Original Spares guarantees unchanging machine performance down the

years and gives owners the right of UNDER WARRANTY service for the prescribed

period.

Attention: check to make sure your tractor

has its identification tag. This is essential

when ordering spares from our Assistance

Centres.

Warranty and spares

Engine: conditions and terms established by the manufacturer.

Tractor: within the terms laid down by our Certificate of Warranty.

To order spares: Visit our Assistance and Spares Centres bringing your machine

identification tag or with following information: tractor model, Series and Number as

stamped on the Serial Plate.

9

Page 10

SAFETY

A

How to read the manual

This manual is your operation and maintenance guide. You are

advised to strictly comply with the instructions herein and to

consider the manual as an integral part of the product: it must be

kept near the machine and consigned to all future users.

The illustrations, descriptions and specifications given in this

Manual are not binding on the manufacturer who, while main

taining the main specifications, reserves the right to make any

and all changes, at any time, in compliance with technical or

commercial requirements without prior notice and without

obligation to make such changes to previously manufactured

equipment.

Consult the specific manuals for the safe operation and

maintenance instructions about those parts of the machine

manufactured by third parties.

ll indications as to the “front”, “rear”, “right” and “left” parts of the

machine refer to the operator seated on the machine.

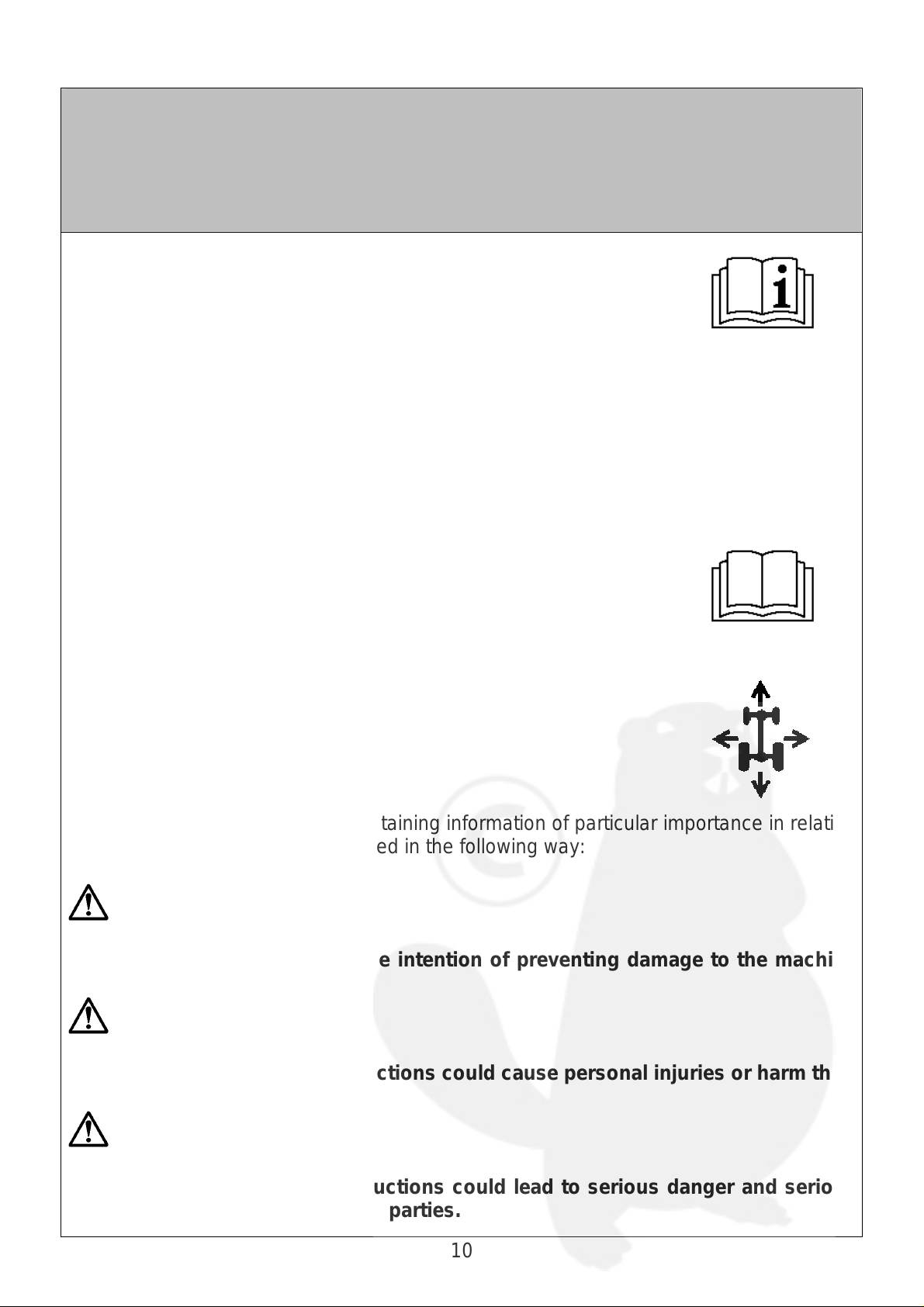

Certain sections of this manual containing information of particular importance in relation

to safety or operation, are highlighted in the following way:

IMPORTANT

The information is given with the intention of preventing damage to the machine

or causing damage.

WARNING

Failure to comply with the instructions could cause personal injuries or harm third

parties.

DANGER

Failure to comply with the instructions could lead to serious danger and serious

personal injuries or harm to third parties.

10

Page 11

Safety regulations

A

There is no substitute for prudence to make your work safer

and to prevent accidents The following cautions are

important for all users of our achines.

Failure to follow the regulations given below exonerates our

firm from all civil and penal responsibility.

Do not tamper with the machine and its equipment in any way.

Before starting the engine make sure that the gear shift and the

PTO are in neutral.

Let out the clutch gradually to prevent the machine from jumping

the clutch.

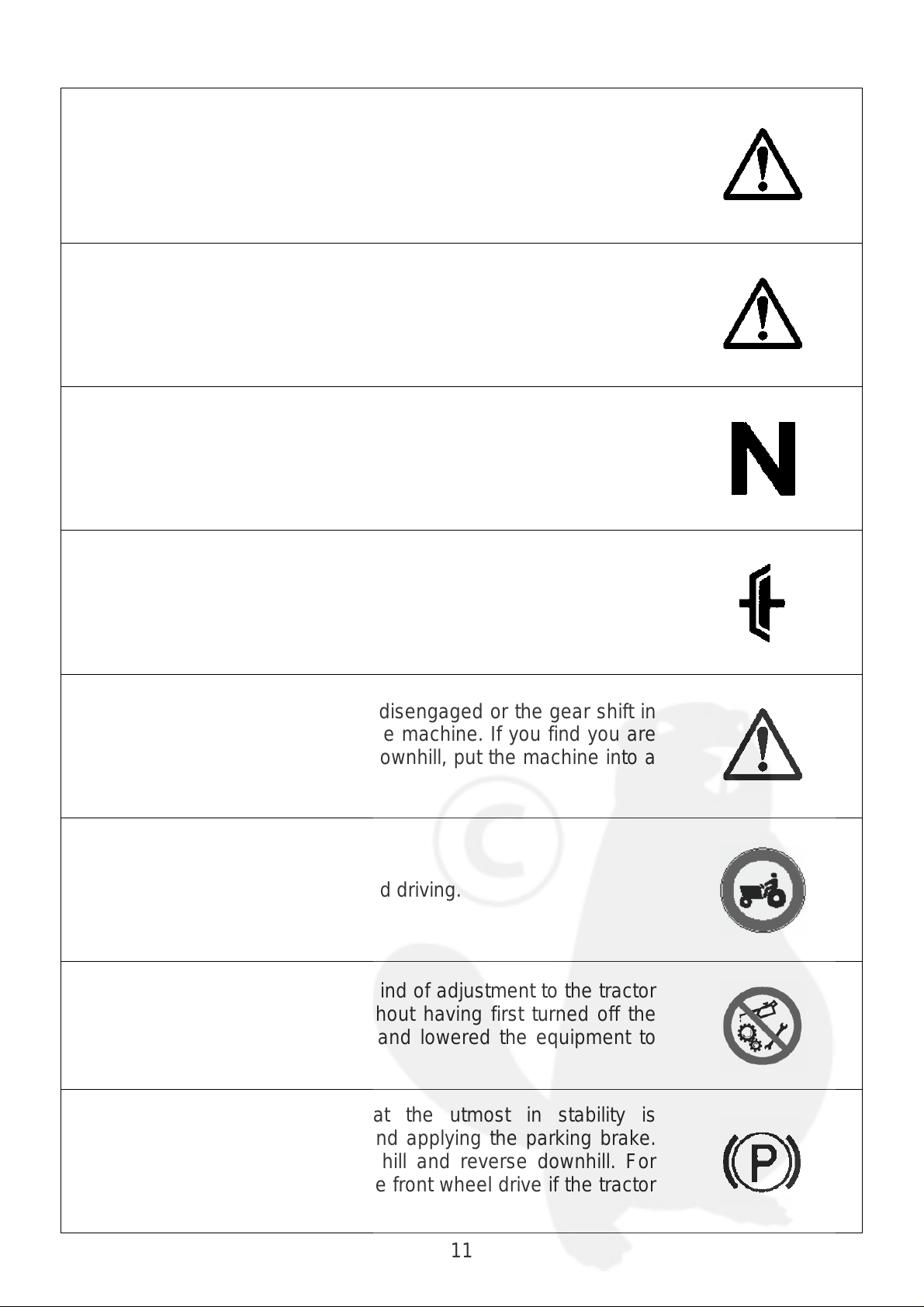

Do not go downhill with the clutch disengaged or the gear shift in

neutral. Use the engine to brake the machine. If you find you are

using the brake a lot when going downhill, put the machine into a

lower gear.

Follow the traffic code when on-road driving.

o not service, repair or make any kind of adjustment to the tractor

or to equipment coupled to it without having first turned off the

engine, removed the ignition key and lowered the equipment to

the ground.

lways park the tractor so that the utmost in stability is

guaranteed by engaging a gear and applying the parking brake.

On gradients engage 1st gear uphill and reverse downhill. For

greater safety use a chock. Engage front wheel drive if the tractor

has it.

11

Page 12

Check to make sure that all revolving parts on the machines

A

(PTO, Cardan couplings, pulleys etc) are fully guarded. Do not

wear clothing which could be pulled into the machine's or the

equipment's moving parts.

Do not run the engine in an enclosed area: the engine exhaust is

poisonous.

Do not leave the machine with engine running near flammable

substances.

Before driving the machine, check to be sure that there are no

bystanders or animals in its working range.

Do not leave the driving seat with the engine running and/or the

key in the ignition.

Whenever the PTO is in use, the drive shaft must be covered by

the special guard.

From time to time, with the engine shut off, wheel and roll bar

fixing nuts and screws.

fter any maintenance work, grease and remove the grease from

the engine to eliminate the risk of a fire.

12

Page 13

Keep hands and other parts of the body away from holes or leaks

A

in the hydraulic system. The hydrualic fluid from the leak is under

pressure and can cause serious injury.

To not carry any other equipment on the machine apart from that

supplied with it. Do not carry passengers in addition t o the driver.

Do not use the differential lock near or in curves and avoid using

it in fast gears or with engine running at high rpm.

Do not get on or off the machine while it is moving.

void tight steering angles when towed implements are mounted

and the drive shaft is under strain since the coupling could be

damaged.

Do not use the 3-point linkage on the lift as a hitch.

Regulate the hitch in its lowest possible positions to prevent the

machine from rearing.

During transhipments with equipment coupled on the 3-point

linkage, tension the chains and keep the lift raised.

13

Page 14

The operator must check if every part of the tractor and,

especially the safety devices, are in good working condition and

perform to specs. They should be kept in perform working

condition. If you note any defects or malfunctioning, fix or repair

them in good time. If necessary contact your nearest Assistance

Centre. Failure to observe these instructions will release the

manufacturer from all liability.

Safety decals

Safety decals have been affixed to various parts of the machine.

They indicate potential dangers.

The decals must be kept clean and legible. If damaged, they must

be replaced.

Some of the machine components can be equipped with the

manufacturer’s specific safety decals.

14

Page 15

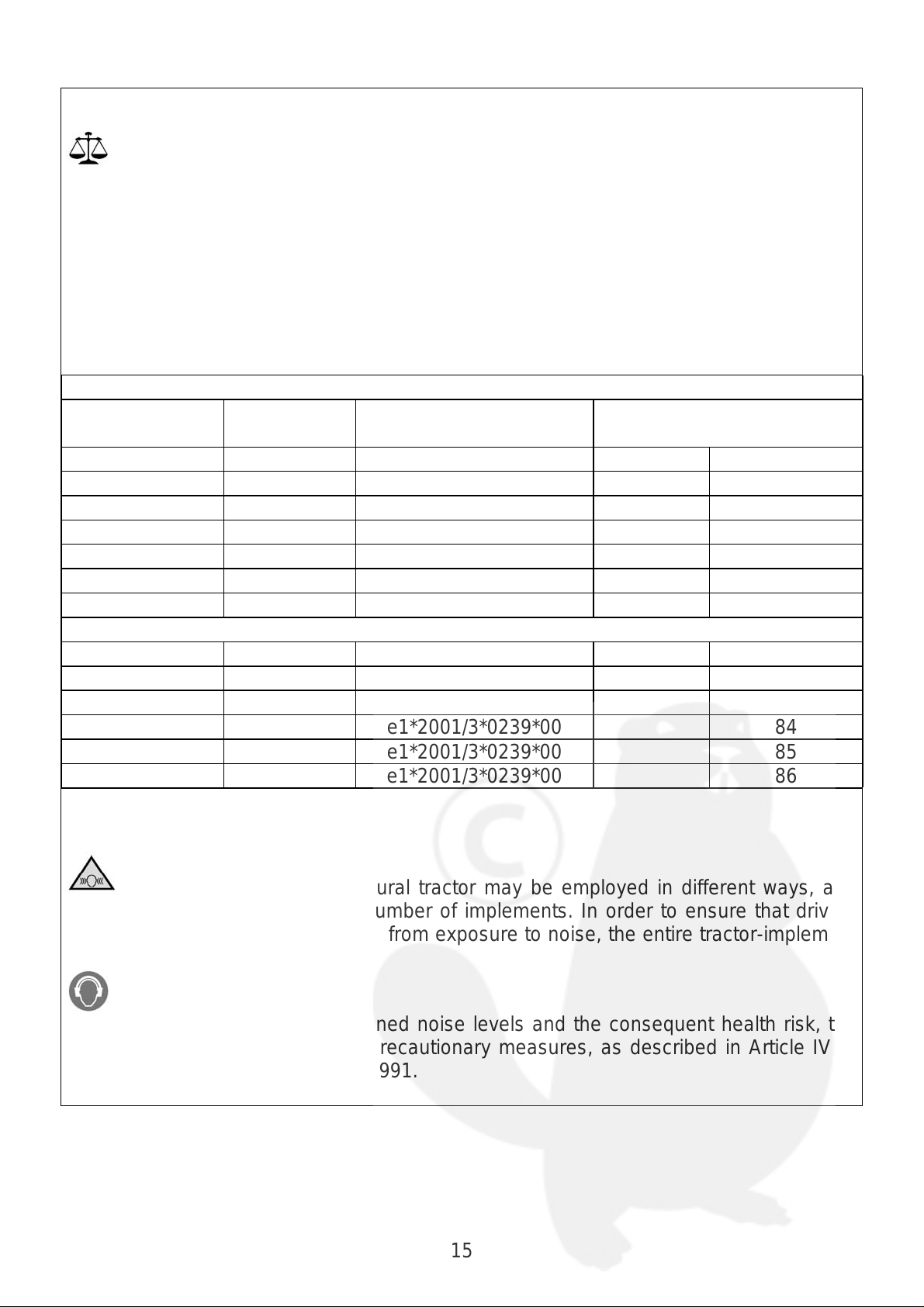

Information about tractor noise levels

This Chart, which provides the noise values produced by the tractors described in

the Guide to Maintenance and Use, has been prepared in order to satisfy the

requirements of Law Decree No. 277 dated 15/08/1991.

Bearing in mind the impossibility of the manufacturer to foresee the normal working

conditions in which the agricultural tractor will be operated, the noise levels have been

defined in accordance with the methods and conditions described in Attachment 8 of

Presidential Decree No. 212 dated 10/02/1981. This conforms to Directive 77/311/CEE

concerning noise levels at the ears of the driver of wheeled agricultural tractors.

TRACTORS with SAFETY BARS

Model Type Type Approval N° Maximum noise level at

the driver’s seat dB (A)

Article I Article II

Aster 35 TX1A -TX1B e1*2001/3*0239*00 83

Aster 40 TX3A -TX3B e1*2001/3*0239*00 83

Aster 45 TX5A e1*2001/3*0239*00 83

Milenio 35C TX1A -TX1B e1*2001/3*0239*00 83

Milenio 40C TX3A -TX3B e1*2001/3*0239*00 83

Milenio 45C TX5A e1*2001/3*0239*00 83

TRACTORS with CAB

Aster 35 TX2A - TX2B e1*2001/3*0239*00 84

Aster 40 TX4A - TX4B e1*2001/3*0239*00 85

Aster 45 TX6A e1*2001/3*0239*00 86

Milenio 35C TX2A - TX2B e1*2001/3*0239*00 84

Milenio 40C TX4A - TX4B e1*2001/3*0239*00 85

Milenio 45C TX6A e1*2001/3*0239*00 86

WARNING TO THE USER

Remember that the agricultural tractor may be employed in different ways, and

may be connected to an infinite number of implements. In order to ensure that drivers

are protected against risks deriving from exposure to noise, the entire tractor-implement

group must be considered.

Bearing in mind the above-mentioned noise levels and the consequent health risk, the

user must adopt the appropriate precautionary measures, as described in Article IV of

Law Decree No. 277 dated 15/08/1991.

15

Page 16

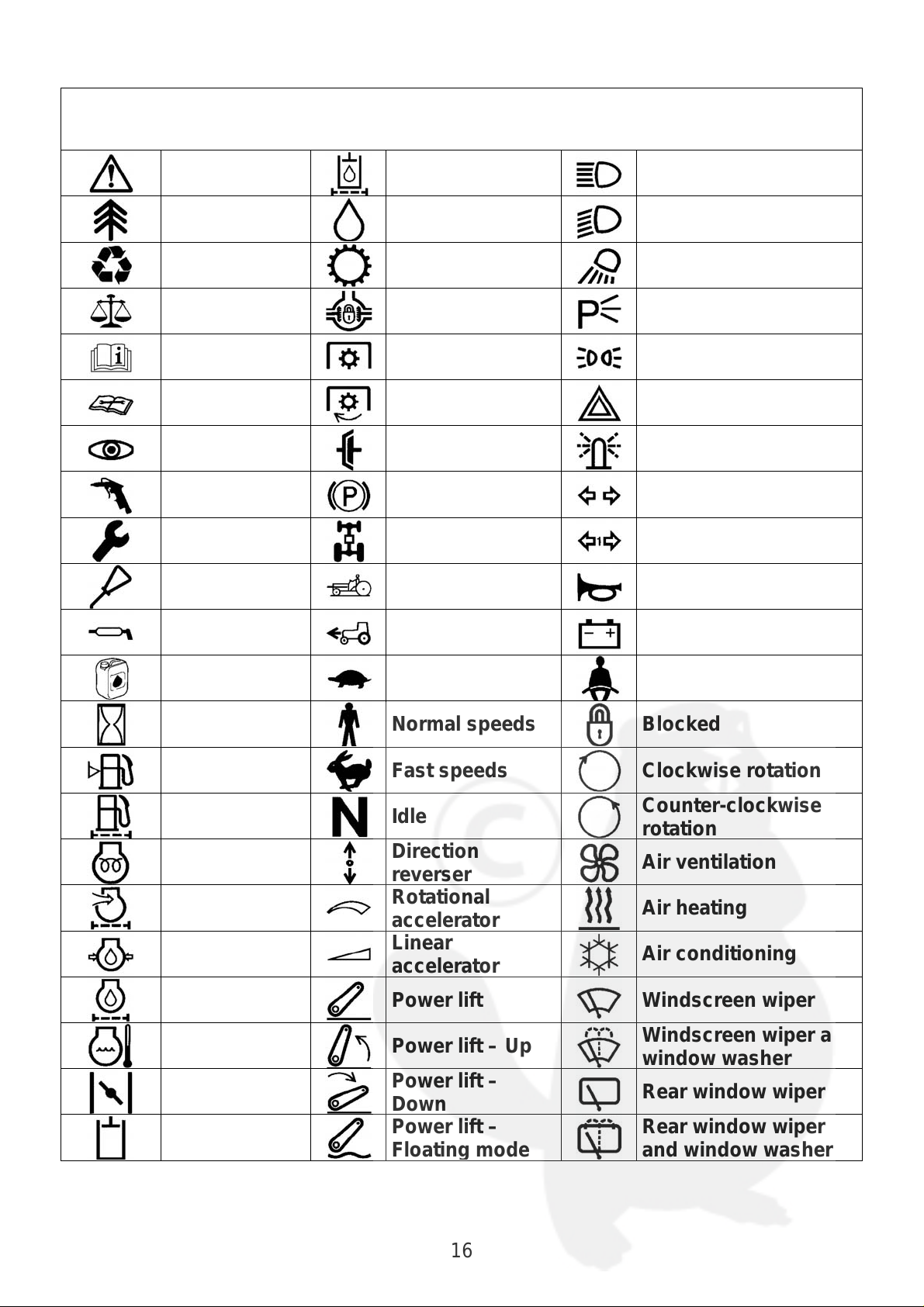

Standard symbols

r

p

p

r

r

r

p

r

r

r

g

r

Standard symbols have been used to ensure the machine is used in the best way.

Warning

Environment Oil Dipped beam

Recycling Transmission Field light

Legislation Differential lock Parking light

Information Power take-off Side lights

Hydraulic circuit

filte

Driving beam

Instructions

Check Clutch Indicator light

Clean with

com

Adjustment Four-wheel drive Trailer turn indicator

Lubrication Guard lowered Horn

Greasing

Change oil Low speeds Safety belts

Work hours Normal speeds Blocked

Fuel level Fast speeds Clockwise rotation

Fuel filter Idle

Engine

Engine air

filte

Engine oil

Engine oil

filte

Engine

coolant

Air valve

Hydraulic

circuit

ressed

reheating

ressure

Power take-off

rotation

Parking brake Turn indicator

Forward

direction

Direction

reverse

Rotational

accelerato

Linear

accelerato

Power lift Windscreen wiper

Power lift – Up

Power lift –

Down

Power lift –

Floatin

mode

Hazard lights

Battery charger

Counter-clockwise

rotation

Air ventilation

Air heating

Air conditioning

Windscreen wiper and

window washe

Rear window wiper

Rear window wiper

and window washe

16

Page 17

Ecology

It is of fundamental importance to safeguard the environment. Incorrect waste disposal

can alter the environment and the ecological system.

Do not discard fluids like fuels, lubricants, coolants or other, in the environment.

Do not use food or dink containers, which could lead to mistakes, to drain off

fluids like fuels, lubricants, coolants or other.

Do not dispose of parts of the cooling system (such as radiators, fluids, tanks,

etc.) in the environment.

Contact an authorized organization or ask your dealer for advice about how to

recycle or dispose of waste products in the correct way.

17

Page 18

IDENTIFICATION OF THE MACHINE AND COMPONENTS

18

Page 19

Machine identification

The machine is identified in three different

ways:

A with decals

B punch marks on chassis

C with a metal plate

Decals

The decals affixed to the bonnet indicate:

A Make

B Series

C Model

D Version

Punch marks on chassis

A Manufacturer’s code

B Production series

C Type of machine

D Identification number (serial number)

19

Page 20

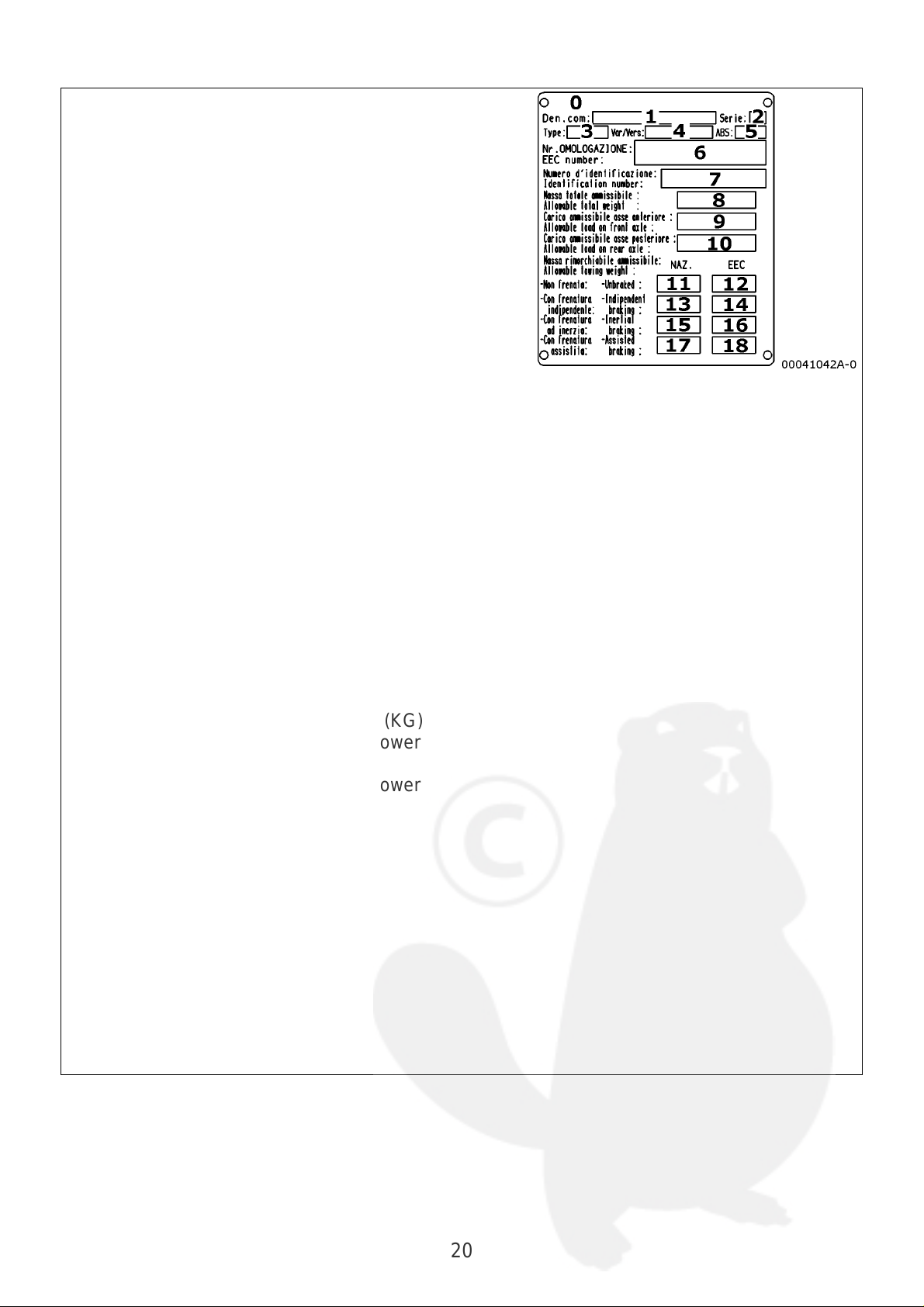

Metal plate

The metal plate gives the following

information:

Manufacturer’s name and address

0

Commercial denomination

1

Production series

2

Type of machine

3

Variant

4

ABC coefficient

5

Approval number

6

Identification number (serial number)

7

Total permissible weight (KG)

8

Permissible load on front axle (KG)

9

Permissible load on rear axle (KG)

10

Non-braked permissible towed weight (in

11

Italy) (KG)

Non-braked permissible towed weight

12

(European) (KG)

Permissible towed weight with

13

independent braking (in Italy) (KG)

Permissible towed weight with

14

independent braking (European) (KG)

Permissible towed weight with

15

overrunning braking (in Italy) (KG)

Permissible towed weight with

16

overrunning braking (European) (KG)

Permissible towed weight with power

17

braking (in Italy) (KG)

Permissible towed weight with power

18

braking (European) (KG)

20

Page 21

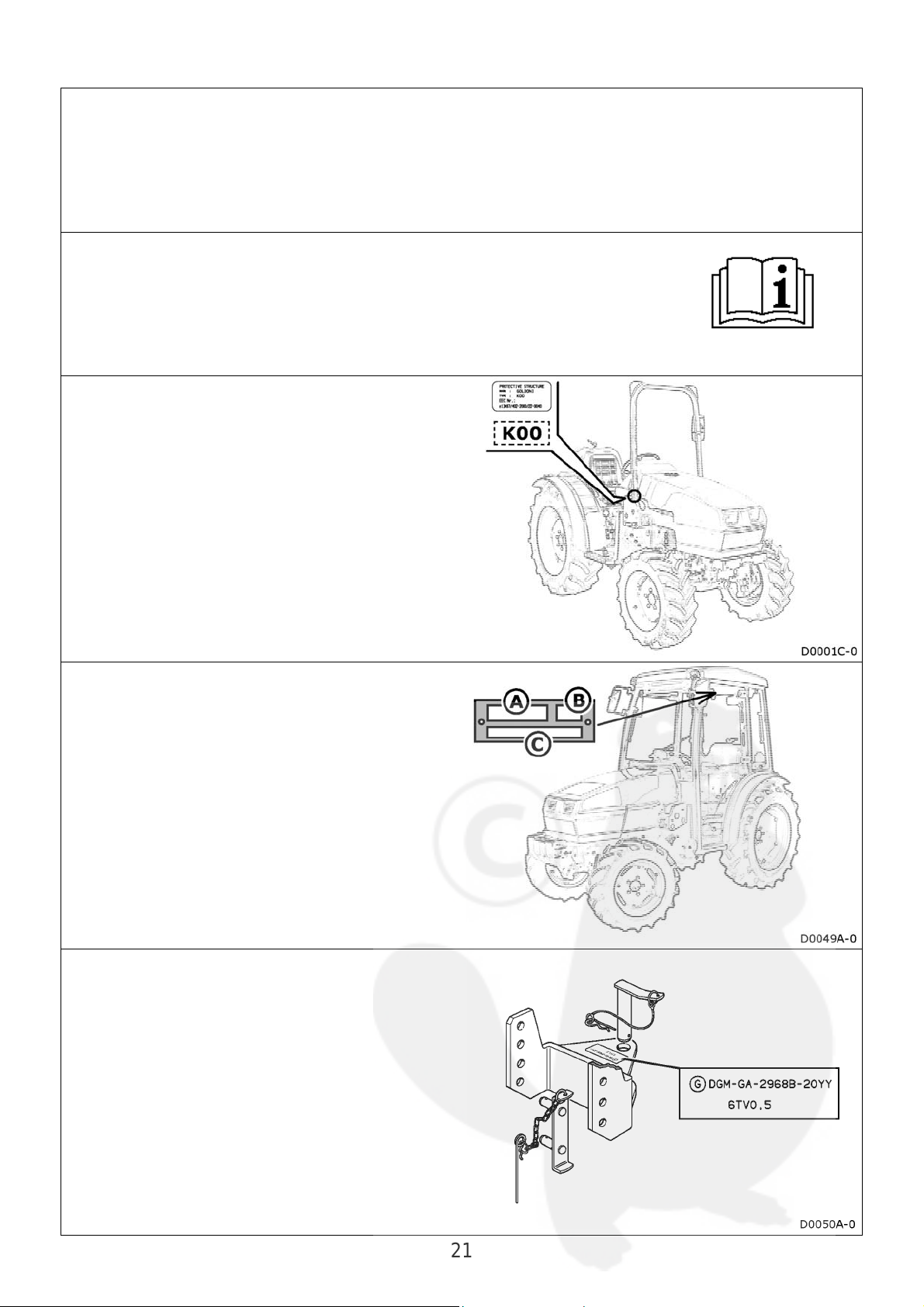

Identification of the components

The machine consists of a series of main components which are

each identified by a metal data plate and/or by punch marks.

Engine

Metal data plate and punched code number.

See engine’s operation and maintenance manual.

Safety frame

• Decal with the Type of safety frame.

• Punched code number on the safety

frame itself.

Cab

Metal data plate on cab:

A Manufacturer

B Type

C Serial number (chassis number)

Towing attachment

Code punched on device:

• Make

• Type of device

21

Page 22

WORK STATION

Controls

Controls in front part

A Steering wheel

B Gearshift lever:

speed selection (1-2-N-3-4)

C

Hand throttle

D Reverse shuttle lever:

for selecting forward, reverse speeds

E Clutch pedal

F Rear PTO clutch lever

G LH brake pedal

H RH brake pedal

I Brake pedal latch

L Accelerator pedal

Controls on RH side

Lever for regulating the position of the

A

rear power lift

Lever for adjusting the rear power lift’s

B

draft

Diff lock pedal

C

Lever for selecting the independent or

D

synchronized rear PTO

Rear supplementary spool valve lever

E

Final drive lever: selects Low, Standard,

F

High speeds and Reverse speeds

22

Page 23

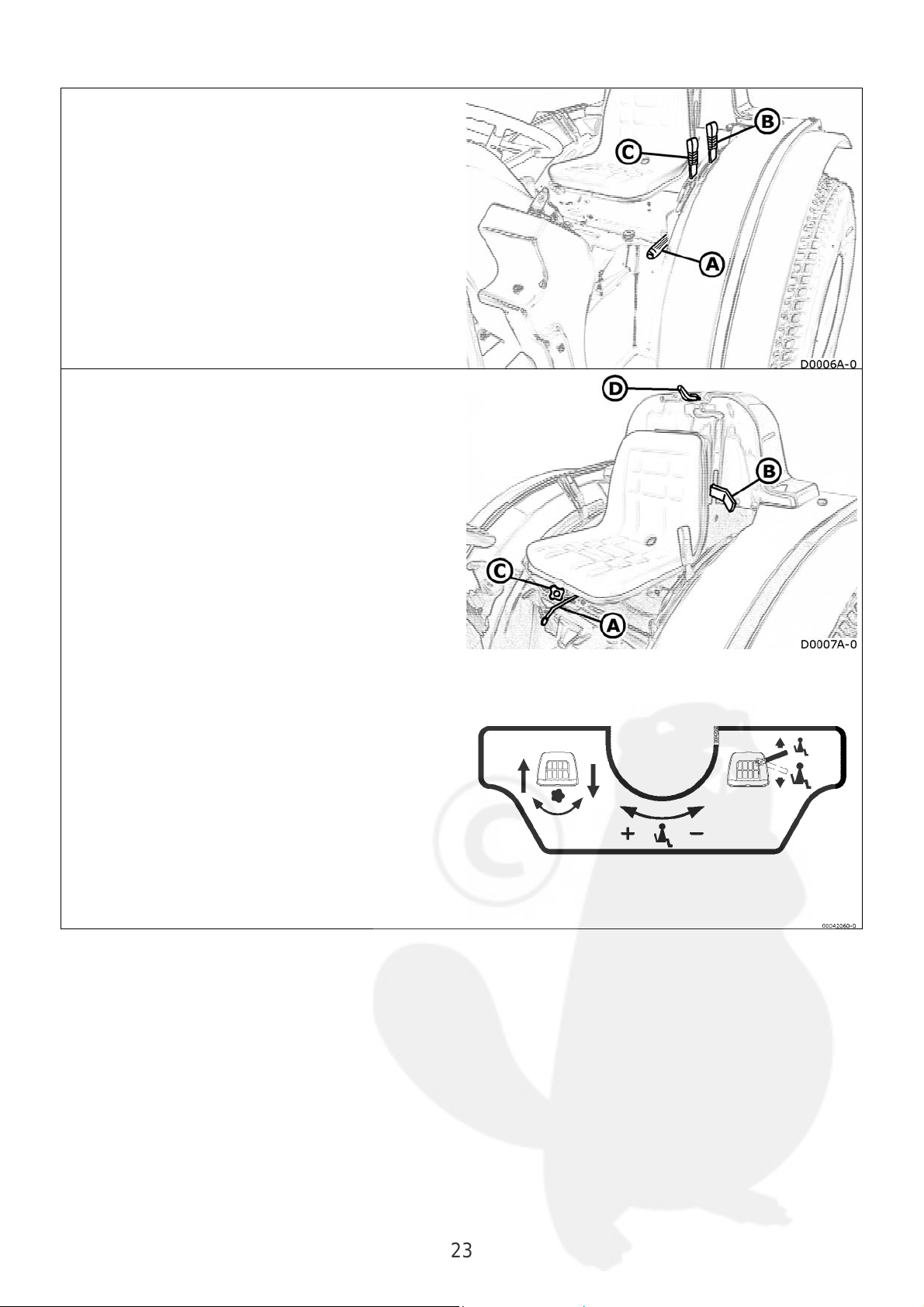

Controls on LH side

A Parking brake lever

B 4 WD lever

C Synchronized rear PTO engaging

lever

Seat controls

A Distance of seat from controls

B Adjustment of seat springs

C Seat height adjustment

D Adjustment of springs

23

Page 24

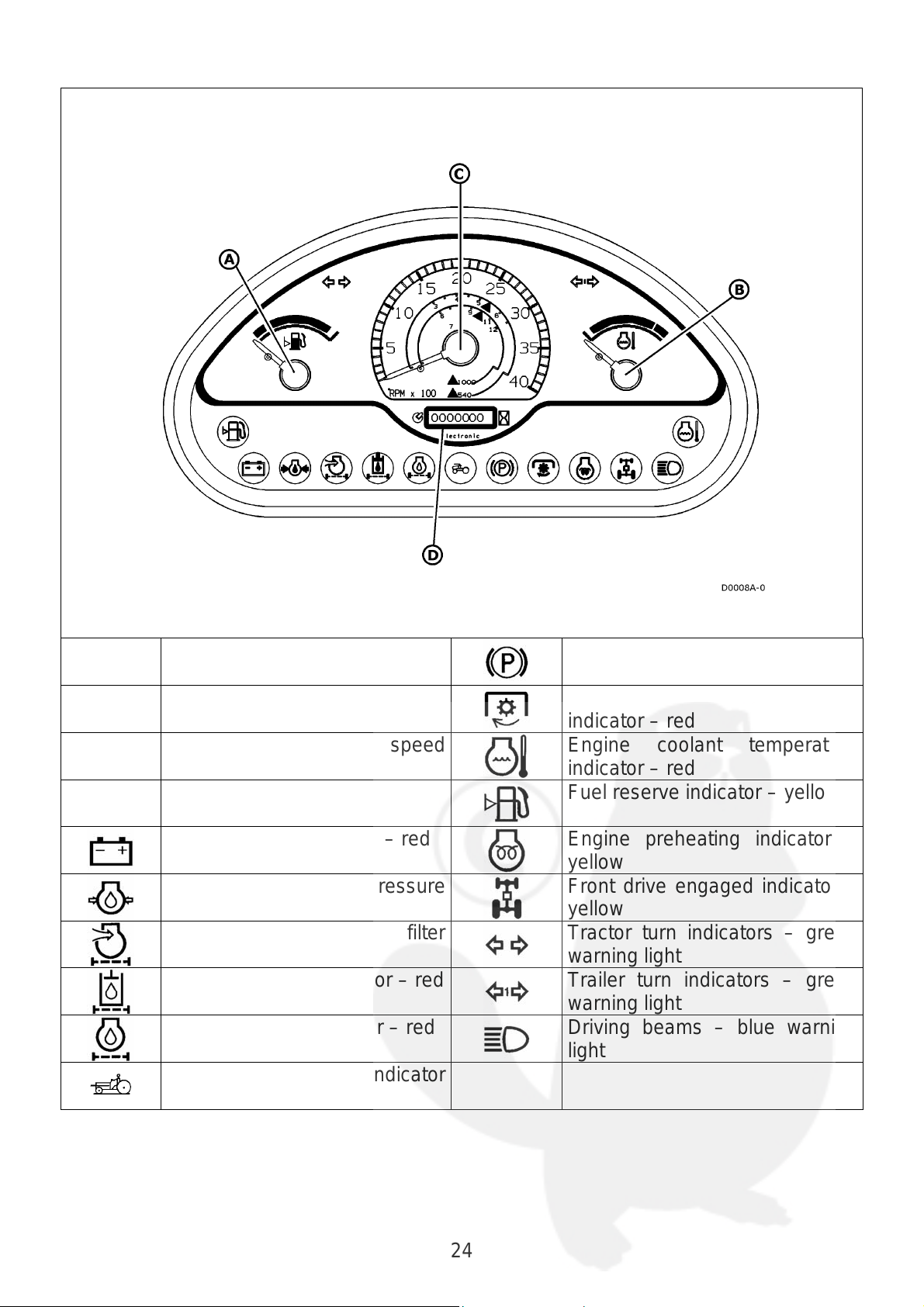

Instruments

Multi-function dashboard

A

B

C

D

Fuel level gauge

Engine coolant temperature

gauge

Engine and PTO speed

indicator

Hour counter

Battery charge indicator – red

Low engine oil pressure

indicator – red

Clogged engine air filter

indicator - red

Clogged oil filter indicator – red

Engine oil level indicator – red

Safety frame lowered indicator

- red

Parking brake engaged

indicator – red

PTO clutch disengaged

indicator – red

Engine coolant temperature

indicator – red

Fuel reserve indicator – yellow

Engine preheating indicator –

yellow

Front drive engaged indicator –

yellow

Tractor turn indicators – green

warning light

Trailer turn indicators – green

warning light

Driving beams – blue warning

light

24

Page 25

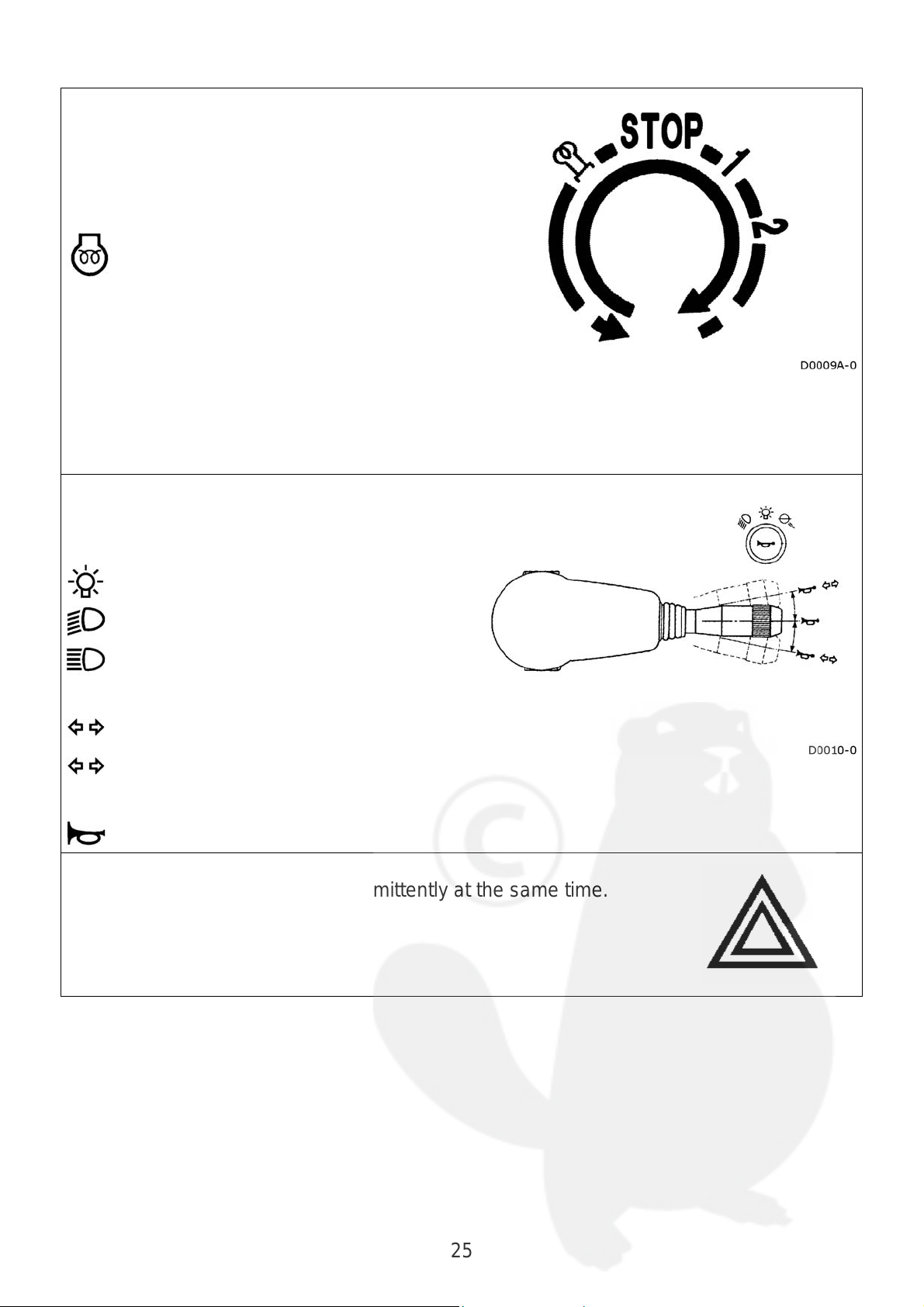

Ignition switch

Engine preheating position

No circuits powered. Key can be

STOP

removed. Turn the key to this position

to switch off the engine.

Operating position. Various users

powered. Indicators and monitoring

1

instruments operative.

Engine starts.

2

Light switch

Light operation:

Lights off

0

Side lights on

Dipped beams

Push: Driving beams

Turn indicator:

Forwards: lh turn indication

Back: rh turn indication

Horn:

Push

Hazard light switch

Flashes all the turn indicators intermittently at the same time.

25

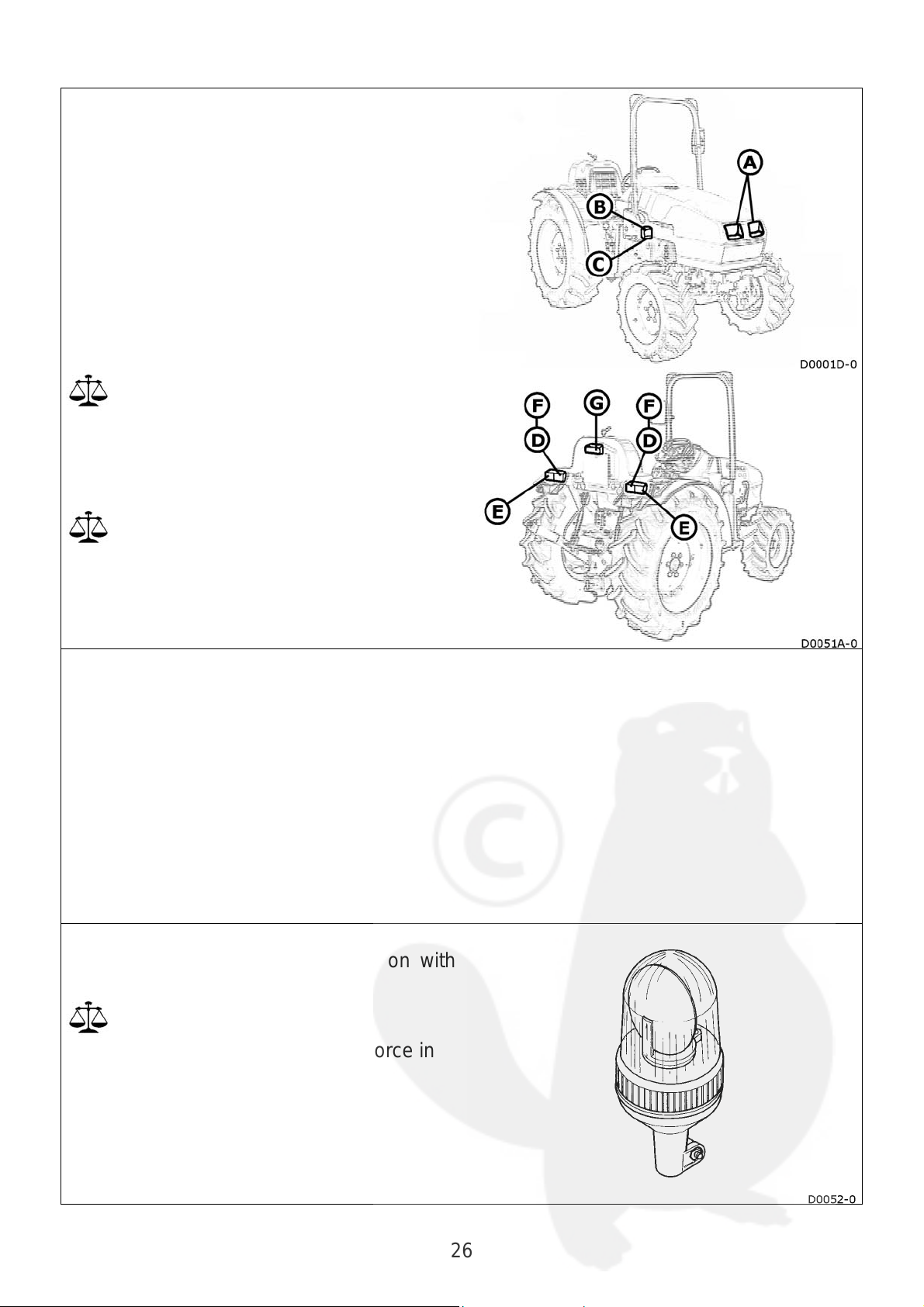

Page 26

Lights

Headlight in dipped/driving positions

A

Front turn indicator

B

Front side light

C

Rear side light

D

Rear turn indicator

E

Rear brake light

F

License plate light

G

The vehicle’s lights must comply with the

Highway Code in force in the relative

country of use for driving on public

thoroughfares.

Use of driving beams is governed by the

Highway Code in force in the country of

use.

Lights (with cab)

Front field light

Rear field light

Revolving beacon (optional)

The revolving beacon is switched on with

button A

Its use is governed by the laws in force in

the country of use.

26

Page 27

7-pin trailer socket

This socket is used to connect lights, turn

indicators and other electrical devices for a

trailer or implement.

Supplementary lights must be used if an

implement obscures the turn indicators or

other lights at the rear of the machine.

Terminal functions:

A Lh turn indicator

B Vacant

C Ground

D Rh turn indicator

E Rh rear light

F Brake lights

G Lh rear light

27

Page 28

Battery

Symbols:

Protect the eyes

Read the instructions

Keep well out of children’s reach

Dangerous corrosive acid

Avoid naked flames and sparks

Danger of explosion

WARNING: The battery may be equipped with the

manufacturer’s instructions for safe use and maintenance.

Read these instructions and contact specialized personnel if

you have any doubts.

28

Page 29

Safety frame (roll-bar or ROPS)

The machine is equipped with a folding safety frame. Always keep the safety frame

mounted in its correct vertical position when you are working. It is absolutely forbidden to

modify the structural components of this type of construction by welding on additional

parts, drilling holes, grinding, etc. Failure to comply with these recommendations could

impair the rigidity of the frame itself.

The safety frame is subjected to considerable stress if the tractor tips over. If this

happens, the structural components must be replaced if they have been bent, deformed

or damaged in some other way.

When in the horizontal position, the safety frame will provide no protection if the

tractor tips up. When working in these conditions, it is of the utmost importance

for the operator to pay the greatest attention when manoeuvring the machine.

Raise the safety frame again as soon as the machine is able to operate in normal

conditions.

To lower the safety frame, on both sides:

• turn the pin through 90° and remove it

• lower the safety frame

• insert the pin into the second housing

and turn it through 90°

29

Page 30

Cab

A

• Always shut the doors before moving

off with the tractor.

• Keep the windows clean to ensure

good visibility.

• The cab is approved as a safety

structure. It is therefore absolutely

forbidden to tamper with it, modify or

add extra equipment and/or

supports.

Versions

The machine can be equipped with a cab in

three different versions:

• Cab without ventilation (Basic version)

• Cab with heating function (Top Calda)

• Cab with heating and air conditioning

(Top Fredda)

ccessories: activated carbon filter and

revolving beacon.

Heating and ventilating

The ventilation function is operated by

means of the control A. Direct the air flow

by positioning front vents.

The air can be drawn from the outside or

from inside the cab by means of rear vents:

• vents closed: the air is drawn from the

outside through the filter.

• vents open: most of the air is drawn

from the inside through the vents

themselves.

The heating function is operated by means

of control D (a =open; c = closed). Vary the

ventilation speed by means of control A.

30

Page 31

Air conditioning

A

The air conditioning system allows you to

obtain fresh, dehumidified air or hot

dehumidified air.

• Never tamper with the air

conditioning system: always contact

specialized personnel.

• Keep naked flames and heat

sources well away from the air

conditioning system.

• Never loosen unions and/or

tamper with pipes: the system is

pressurized.

• The refrigerant can freeze the skin

and eyes.

Starting and stopping the engine

Make sure that the air conditioner and fan

are off before starting the engine.

lways turn off the air conditioner and fan

before stopping the engine.

Operation

To operate the air conditioning system:

1) stop the heating function by means of

knob C (set to position C)

2) use knob A to turn on the ventilation

3) use knob L to turn on the cooling

function.

If the fan on the cab roof fails to start within

one minute once the system has been

turned on, turn it off and check the fuses.

Failure of the rear fan to operate will raise

the pressure of the gas in the air

conditioner’s circuit and could block the

system.

Technical specifications:

Refrigerant fluid: R134a

Quantity: 0.8 kg

31

Page 32

Cab air filter

Warning: the cab air filter has not

been designed to retain harmful

substances! Comply with the

instructions provided by the

manufacturer of the substance used.

The air that enters the cab is always

subjected to a filtering treatment. The filter

is installed in the top front part of the cab.

Cab air filter with activated carbon (optional)

Comply with the use and maintenance instructions supplied with

the filter.

Warning: use of the cab air filter with activated carbon

does not relieve the operators from wearing recommended

personal protective equipment to safeguard against the

harmfulness of the individual substances used.

Switches

The cab switches are installed in the ceiling

of the cab itself, on the right-hand side.

They are used for the following functions

(some of which are optional):

1- 0

Front field lights

Front and rear window wipers and

washers.

Revolving beacon

Rear field lights

- Ceiling light

Rear window wiper

Accessories

Sun shade

Installed on the front window. To unwind, pull on the handgrip situated in the center of

the shade; to rewind, use the red button on the right-hand side of the winder.

Pre-engineering for stereo system

Installed in the rear cab interior. Includes 2 housings for loudspeakers

Document pocket

32

Page 33

Cab and safety frame approval

(Optional)

- For Italy

If the cab and roll bar are installed after the purchase of the tractor, the customer should

ask our Sales Division for the corresponding Approval documents.

With these documents and the registration book and/or Log Book, the customer should

go to his local Ministry of Transport Licencing Office. This office will update or replace

the registration book/Log Book.

- For other countries

If the cab or roll bar are installed after the purchase of the tractor, the owner should refer

to the national approval agencies to have the tractor's registration or log book brought

up to date.

Safety belts (where applicable)

Wear the safety belts when you use the

machine with the safety frame (roll-bar or

ROPS) to reduce the risk of accidents if the

tractor tips up.

Do not wear the seat belt if you use the

machine with the roll-bar in the

horizontal position.

Tool box

The machine has a tool box which can be

accessed by turning the knob.

33

Page 34

OPERATING INSTRUCTIONS

How to start and stop the machine

How to start the engine

Consult the engine’s operation and maintenance manual.

Before starting the engine:

Apply the parking brake

Move the final drive lever to the neutral position

Move the lever used to select the independent or synchronized rear PTO to

the neutral position.

Move the lever used to select the PTO speed to the neutral position

Move the hand throttle lever halfway along its travel

Depress the clutch pedal

Ignition switch:

Insert the key and turn it as described

below:

Glow plug preheating. Keep the key

in this position for 8-10 seconds.

STOP

No circuit powered

Instruments and warning lights on

1

(operating position).

Engine starts.

2

After the engine has started:

• Release the key. It will automatically return to the operating position.

• Release the clutch pedal.

• Check the warning lights and instruments.

34

Page 35

How to start the machine

Before starting the machine, make sure you become familiar with its main

controls: brakes, transmission, PTO, diff lock and how to stop the engine.

Make sure that the brakes are efficient before moving off.

• Depress the clutch pedal.

• Select the transmission ratio (consult the Gearbox chapter).

• Disengage the parking brake.

• Gradually release the clutch pedal.

• Gradually accelerate the engine.

How to stop the machine

• Allow the engine to idle.

• Depress the clutch pedal.

• Stop the machine

• Move the final drive lever to the idle position.

• Apply the parking brake.

How to stop the engine

• Turn the ignition key to position 0.

• Remove the key and put it away in a safe place.

WARNING: The steering action of the power steering system will be reduced if the

engine accidentally stops. Depress the main brake to allow the machine to come to a full

stop.

35

Page 36

How to move off

Main clutch

Transmits drive from the engine to the transmission.

Pedal up = clutch engaged (drive is transmitted)

Pedal down = clutch disengaged (drive not transmitted)

Make gradual engagements and disengagements.

Remove your foot from the clutch pedal when not required.

lengthy clutch disengagements could wear out the thrust bearing.

NEVER attempt to drive up or down slopes with the clutch disengaged.

Gearbox

The machine’s transmission comprises a gearbox, final drive and synchronized reverse

shuttle, each controlled by its own lever.

The speed at which you drive the machine must be chosen to suit:

• the work required

• the implement used

• the type of ground

Information about the ground speeds is given in the “technical specifications” section.

Gearshift lever

(1-2-N-3-4)

The lever can be moved in four positions

(plus neutral):

1 = first speed gear

2 = second speed gear

N = neutral

3 = third speed gear

4 = fourth speed gear

The speed gear selections are

synchronized.

To change gear:

• disengage the main clutch

• select the required position.

36

Page 37

Final drive lever

The lever can be moved in four positions (plus neutral):

Standard speeds (Man)

Low speeds (Tortoise)

High speeds (Hare)

Reverse speeds (REV)

Selection is not synchronized.

To select the required range:

• stop the machine

• disengage the main clutch

• select the required range

Reverse shuttle lever

The lever has two positions (plus neutral):

forward

reverse

Selection is synchronized.

Even though selection is synchronized,

proceed as described below to select the

forward or reverse speeds:

• stop the machine

• disengage the main clutch

• select the forward or reverse speed.

37

Page 38

Four wheel drive

A

The tractor is the four wheel drive type

(front and rear). Four wheel drive is

recommended for ploughing jobs or if one

of the two driving wheels possess

insufficient grip owing to muddy, rugged or

slippery ground.

Do not use four wheel drive on roads as

the tyres will quickly wear out.

The four wheel drive is engaged

mechanically with lever B:

four wheel drive engaged

four wheel drive disengaged

n indicator light will come on to show that

four wheel drive has been engaged.

38

Page 39

Rear diff lock

The tractor is equipped with a rear diff lock which should be used

for ploughing work or if one of the two driving wheels possesses

insufficient grip owing to muddy, rugged or slippery ground.

The diff lock is controlled mechanically with pedal C. It is

disengaged by releasing the pedal.

To get the most out of the device, engage the differential lock

before the wheels begin to slip. Do not engage the lock while one

wheel is already slipping.

Only use the diff lock with the low and standard speed gears

and after having previously slowed the engine rate.

Do not use the diff lock near or round bends.

If the diff lock fails to release, reduce the engine rate, stop

the machine and release it by moving the steering wheel.

Power take-off

Rear power take-off (PTO)

The tractor has two shafts for the rear

power take-off (PTO):

• INDEPENDENT power take-off

• SYNCHRONIZED power take-off

Do not remove or damage protective

plate A

Cover the PTO shaft with guard B when

not used.

39

Page 40

INDEPENDENT power take-off

• Rotation directly connected to the engine.

• Upper shaft.

• Consult the technical specifications section for further details.

The independent PTO is selected

mechanically with lever D

The PTO is engaged mechanically by

pulling guard A and raising clutch lever B.

The PTO is disengaged by pulling guard A

and lowering lever B.

40

Page 41

SYNCHRONIZED power take-off

• Rotation proportional to the tractor’s ground speed

• Lower shaft

• Consult the technical specifications section for further details.

The synchronized PTO is selected

mechanically by moving lever C to the

position with symbol 1

The synchronized PTO is disengaged by

means of clutch pedal E

41

Page 42

Three-point hitch

A

The tractor is equipped with a three-point hitch. To ensure that this system operates

correctly, make sure that the size and weight of the implement used correspond to the

specifications of the power lift and hitch itself.

Consult the technical specifications section for further details.

Components:

A Third point link

B Adjustable rod (pair)

C Side stabilizer (pair)

D Power lift’s lower link (pair)

E Spring

ALWAYS switch off the engine before hitching or adjusting the three-point hitch in

any way.

The third point coupling must NOT be used for towing implem ents.

Lower the implement connected to the three-point hitch to the ground before

getting off the tractor.

Third point link

Coupling

The third point coupling has 3 holes to make it easier to hitch the implement and slant it

at the correct angle. It also establishes the sensitivity of the draft control function which

must be selected to suit the type of implement used:

A

Top hole: less sensitivity; suitable for

implements that create a lot of

tractive effort.

B Central hole: medium sensitivity.

C

Bottom hole: greater sensitivity;

suitable for light implements.

Adjustment

djust the length of the link to suit the

implement’s coupling angle in relation to the

ground.

42

Page 43

Adjustable rod (pair)

The rod can be adjusted so as to level and

align the lower links to suit the implement used

and the type of work required.

Side stabilizer (pair)

The stabilizers must be adjusted to limit the

side swing of the power lift’s lower links:

5-6 cm swing

for ploughs, rotary harrows, etc.

Min. swing

for leveling blades, hoeing attachments,

etc.

0 swing

for transporting implements that are not

working.

Universal joint

Consult the specific manual for the safe operation and

maintenance instructions concerning certain parts of the machine

manufactured by third parties.

43

Page 44

Rear power lift

The following operating conditions can be applied:

• Controlled position

• Controlled draught

• Floating mode

• Combined mode

Controlled position

Ideal for jobs that required constant

implement position (drills, scraper, hitched

manure spreader, etc.).

• Move lever B fully forwards.

• Use lever A, to raise and lower the lift.

Lift raising is proportionate to lever

movement.

Draft control

This is used to keep the lugging power the

tractor must provide constantly under

control without overloading the engine and

keeping slippage within very low limits

(ploughs, cultivators, etc.).

• Move lever A fully forwards.

• Use lever B to adjust the required

amount of draft.

• Use lever A to raise and lower the power

lift.

Floating mode

Ideal when you want to leave the

implement free to follow the contour of the

ground (cultivators, ridgers, scrapers, etc.).

• Move lever B all the way back.

• Use lever A to raise and lower the lift.

44

Page 45

Mixed draft and position mode

adjustment

This operating mode is ideal for jobs

carried out in draft control mode on

irregular ground when the implement is

liable to dig too deeply into the soil.

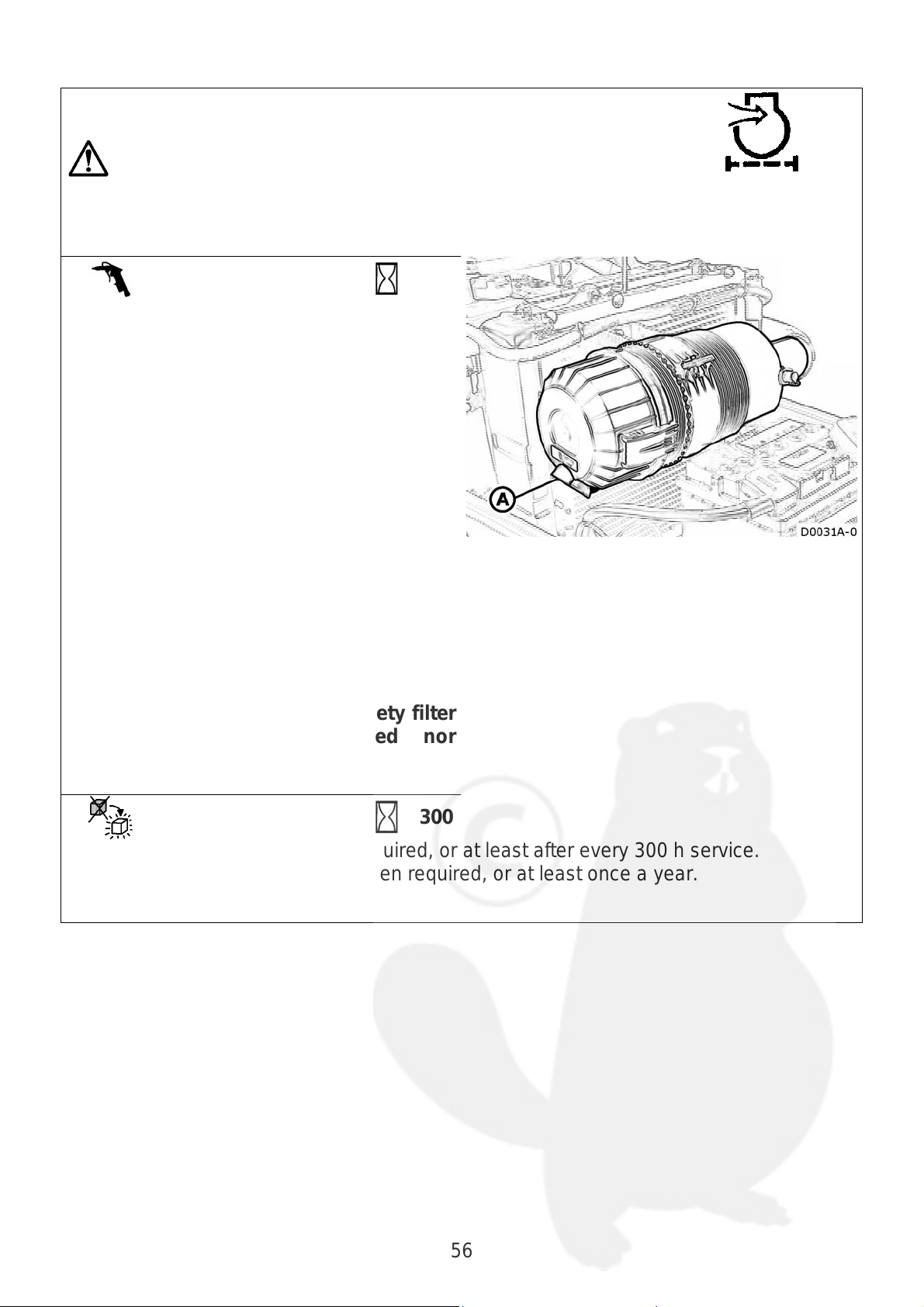

Dig the implement into the ground down to

the desired depth as described for the draft

control mode.

Once the required depth has been

reached, gradually move lever A back

towards the end of travel point until the lift

links begin to slightly raise.

The power lift will operate in the draft

control mode but will stop the implement

from digging too deeply into the soil if it

encounters softer ground. This prevents

the tillage work from becoming irregular.

Only use lever A to raise and dig in the

implement.

Regulating lift rate and sensitivity

Slacken off completely regulating

screw, to lock the implement in its

raised position. This is a safety device

when implements are transported on

road.

Screw out this regulator to increase lift

lowering speed.

3-point hitch sensitivity can be further

increases by attaching it to one of the lower

tractor hitch holes.

45

Page 46

Towing attachments (optional)

Choose the towing attachment to suit the type of trailer or implement towed, in

compliance with the current laws in force.

Ease of driving the tractor also depends on correct use and height adjustment of the

towing attachment.

WARNING: The tractor could tip up if the towing attachment is set in the highest

position.

Keep the drawbar as horizontal as possible when four-wheel drive is used.

Front tow hook (optional)

The tractor can be equipped with a front

tow hook for emergency manoeuvres with

the trailer or for towing the actual tractor

itself.

“Category B” tow hook (optional)

The tractor can be equipped with a rear tow

hook of the “CUNA CAT. B” type for towing

trailers with one or two axles.

To adjust the height of the tow hook:

• remove the pins

• position the hook as shown in the figure

• fix the pins in place

“EEC Category” tow hook (optional)

The tractor can be equipped with the “EEC”

type of rear tow hook for towing trailers with

one or two axles.

To adjust the height of the hook:

• remove the pins

• position the hook as shown in figure

• fix the pins in place

46

Page 47

Ballast (optional)

If very heavy implements are hitched to the tractor, the longitudinal stability of this latter

may be impaired. This can be corrected by using one of the various types of ballast

available as optionals.

WARNING: when you determine the type of ballast to use, make sure that you do not

exceed the following limits between the implement and the ballast itself:

• the permissible load on the front axle (KG)

• the permissible load on the rear axle (KG)

The values are given on the tractor’s metal data plate.

Front ballast (optional)

The front ballast consists of cast iron

plates.

The plates have handles so that they can

be assembled and disassembled.

The ballast is fixed in place with blade A

connected with screw B, which must be

tightened to a 5 Kgm (49 Nm) torque value.

Rear ballast (optional)

The rear ballast consists of cast iron discs

fixed to the wheels.

The ballast is fixed in place with screw A,

which must be tightened to a 14 Kgm (137

Nm) torque value.

47

Page 48

Wheel ballasting by filling the tyres with fluid.

The driving wheels are ballasted by pouring water into the tyres.

Note: it is preferable to use tyres with inner tubes.

Note: if tubeless tyres are used, ask your dealer how to lub ricate the disc correctly so as

to prevent it from rusting.

Note: use water with an antifreeze solution in cold weather (manufacturers recommend

neutral calcium chloride -CaCl

How to pour in the water:

• position the valve at the top

• unscrew the mobile valve union

• pour in the water with a common water

hose

• stop filling every so often, so as to allow

the air to escape

• stop filling altogether when water spills

from the valve.

• the water should fill 75% of the tyre.

• tighten the mobile valve union.

• inflate the tyre to the normal operating

pressure.

How to drain out the water:

• position the valve at the bottom.

• unscrew the mobile valve union.

• allow the water to drain out.

• finish emptying the tyre by means of a

union with a pipe (draw pipe).

• inflate the tyre with air until all the water

has been drained out.

• tighten the mobile valve union.

• inflate the tyre to the normal operating

pressure.

-).

2

48

Page 49

Wheels

Steering angle

The front wheels may interfere with the

body of the machine when the track width

is changed.

To prevent contact, the maximum steering

angle can be regulated with the two limiters

on the front axle:

• raise the front axle by jacking up the

wheels.

• unscrew the two check nuts A.

• work on the two screws B.

• adjust the steering angle by taking the

axle swing into account.

• tighten the two check nuts A.

Note: the steering angle must be the same

on both sides.

Front wheel toe-in

Measure the distance from wheel disc to

wheel disc on the front and rear sides on a

level with the front axle. Distance A must

differ no more than 1.5 mm from distance

B.

Proceed as described below to adjust the

toe-in:

• loosen nut B.

• unscrew or tighten threaded bar A.

• tighten screw B (M18x1.5) with a 34

Kgm (334 Nm) driving torque.

49

Page 50

Track widths

A

The tractor can be equipped with adjustable, reversible wheel discs that allow the track

width to be changed.

Whenever the wheels are reversed, check to make sure that the arrows indicating the

turning direction on the tyre are pointing in the correct direction.

The overall width of the tractor is governed by laws when the tractor is driven on the

roads: comply with the laws in force in the country of use.

WARNING: When disassembling the tyres:

• Take the greatest care

• Use tools and equipment that set the tractor in safe conditions

• Use tools to lift heavy wheels.

Wheel bolt torque values

A The driving torque to fix the flange to the

disc is:

ø 12” = 10Kgm (98Nm)

ø 15”/16” = 15Kgm (147Nm)

ø 18”/20”/24” = 25Kgm (245Nm)

B The driving torque to fix the wheel disc to

the hub is:

Front (M14X1.5) = 15Kgm (147Nm)

Rear (M16X1.5) = 22Kgm (215Nm)

Transmission ratio

The ratio between the tip speed of the front

and rear wheels must be accurately

determined so that the front wheels are in

advance. failing this, the tyres will be

subjected to excessive wear.

sk your dealer for advice when you

change the size of tyres.

50

Page 51

Tyres

Absolutely avoid:

• improper use

• overloading (even localized)

• unsuitable pressures

• unsuitable rim and tyre matches

Tyre life and performance depends on use of the correct operating pressure: if the

pressure is too low, the tyre will quickly wear out while an excessive pressure will reduce

the lugging power and make the wheels more liable to slip.

A correct tyre pressure depends on various factors:

• the operating conditions

• the tractor load

• the tractor model

• the tyre make

• the tyre size

You are therefore advised to consult your dealer or the tyre manufacturer.

The values given below are only approximate as they depend on the conditions

described above:

FRONT: REAR:

2.4 bar 1.6 bar

WARNING: the tyres must only be changed by competent persons in possession

of the necessary equipment and technical know-how.

How to tow the tractor

Only use normal towing attachments (tow bar or hook) for towing both the tractors

(towing and towed).

Only use a safe, strong chain or special rope to connect the two tractors together.

NOTE:

• The tractor must only be towed for short distances and never on the public highways.

• Never drive faster than 10 kph when towing.

• An operator must remain seated in the towed tractor.

51

Page 52

Transporting the tractor

The best way to move a tractor that has broken down is to transport it on the platform of

a truck or trailer.

Fix the tractor to the platform by means of the couplings on this latter and using the tow

hook (front and rear) as a connection point.

Do not fix the chains to the drive shaft, steering cylinders or other components that could

be damaged by the chains themselves.

52

Page 53

MAINTENANCE

Warning! Check the levels:

• Before using the machine

• With the machine at a standstill and the engine off (for at least the past hour).

• On a flat surface.

Routine maintenance guide:

This table briefly outlines the routine maintenance jobs. Consult the following pages for

more details about routine maintenance or information about the variable servicing work

required.

Hours of

service

Cleaning with

compressed air

Greasing

Check

Clean

8 50 150 300 400 800 x

Adjust

Lubricate

Engine

Consult the engine’s operation and maintenance manual

Change oil

Replace

Notes:

Fuel tank

Dry air filter

Cooling circuit

Change fluid every 2 years;

FIAT PARAFLU 11

(Mod.35,40 7 l.; Mod.45 8.5 l.)

Gearbox housing,

rear differential,

power lift

Front axle

mod.35-40

Front axle

mod.45

Rear diff lock

Final drive lever

Brakes

Battery

53

AGIP SUPER TRACTOR

UNIVERSAL SAE 15W/40

(20 kg)

AGIP SUPER TRACTOR

UNIVERSAL SAE 15W/40

(2.5 kg)

AGIP Rotra MP SAE 80W/90

(3.5 kg)

Change fluid every 2 years;

AGIP ATF II D

AGIP GREASE LP2

Change fluid every 2 years;

AGIP ATF II D

Page 54

How to open the bonnet

Pull the knob

Engine assembly

Engine

Consult the specific manual for the safety notes and operation

and maintenance instructions for certain of the components

manufactured by other companies.

54

Page 55

Fuel tank

Do not dispose of fluids like fuels, lubricants, coolants and

various other liquids, in the environment.

Check

Check:

• to make sure that there is sufficient fuel for the whole job.

• to make sure that there are no dents or abrasions on the tank.

Clean

Clean the zone surrounding the tank plug.

Top up level

Use good quality fuel with the technical specifications described in the engine’s

operation and maintenance manual.

8

8

8

WARNING: top up the fuel level when the engine is off and not overheated. Do not

smoke near fuel or when the tank is being filled.

Replace

Replace the fuel plug with a genuine spare

if it is missing or damaged. Replace the

tank with a genuine spare if it has been

damaged by scratches, abrasions or dents.

55

Page 56

Dry air filter

WARNING: Stop the engine and wait until it has cooled down

before proceeding with any servicing operations.

Clean

Clean drain valve A when required, or at

least once a week.

Clean the filter whenever the warning light

comes on or when necessary, after

evaluating the environmental conditions in

which the machine works (dusty, dry, etc.).

Proceed as described below:

• release and remove the cover.

• remove the external filter.

• blow a jet of compressed air (maximum

pressure 3 BAR) from the inside

towards the outside.

• fit the filter back into its housing.

• close with the cover, with the drain valve

in the lowest position.

DO NOT remove the internal safety filter

(it must neither be cleaned nor

damaged).

Replace

Replace the external filter when required, or at least after every 300 h service.

Replace the internal safety filter when required, or at least once a year.

50

300

56

Page 57

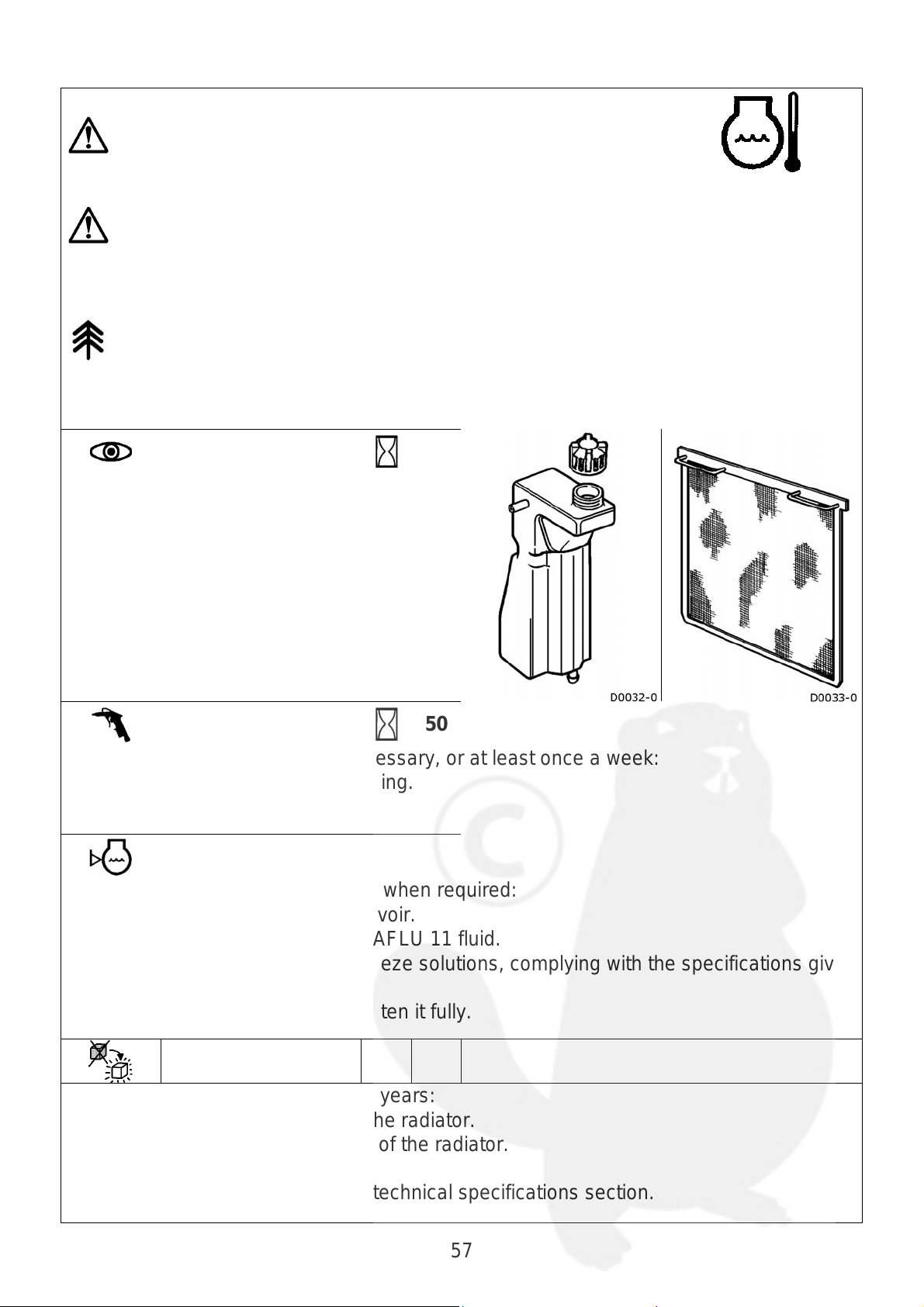

Cooling system

WARNING: Stop the engine and wait until it has cooled down

before proceeding with any servicing operations.

Never open the radiator’s expansion tank whilst the engine is

hot since the cooling fluid could cause burns as it is under

pressure and very hot.

WARNING: Do not dispose of fluids such as fuels, lubricants,

coolants and other various liquids, in the environment.

Check

• Check the level of the cooling fluid.

• Make sure that the radiator guard is

clean.

• Check the belt tension (see engine’s

operation and maintenance manual)

• Every so often, check to make sure that

all the pipe clamps are well tightened.

Clean

Clean the radiator guard when necessary, or at least once a week:

• Remove the guard from its housing.

• Use compressed air.

Top up level

Top up the level of the cooling fluid when required:

• Remove the plug from the reservoir.

• It is advisable to use FIAT PARAFLU 11 fluid.

• It is also advisable to use antifreeze solutions, complying with the specifications given

on the relative package.

• Screw the plug back on and tighten it fully.

8

50

Change

Change the cooling fluid every two years:

• Unscrew the plug at the top of the radiator.

• Unscrew the plug at the bottom of the radiator.

• Empty the circuit.

Capacity of the circuit: consult the technical specifications section.

57

Page 58

Transmission assembly

Gearbox housing, rear differential, power lift

These parts of the tractor use the same oil as the transmission.

WARNING: Do not dispose of fluids such as fuels, lubricants,

coolants and other various liquids, in the environment.

Check

Check the oil level by means of the dipstick

(MIN-MAX )

If necessary, top up with oil of the

recommended type.

Clean

Keep the following parts clean:

• the oil bleeder plug on top of the power lift housing, under the seat.

• the zone surrounding the plug with the dipstick.

50

58

Page 59

Clean

A

A

400

Clean the transmission oil filter:

• after the first 50 hours service

• whenever the oil is changed

• after every 400 hours service

• when the red clogged oil filter indicator

light comes on

To clean the filter:

• unscrew the bolts that fix the cover

• remove the filter

• wash with gasoline or diesel fuel

• dry with compressed air

• fit the cover back on and close it.

Top up level

Check the oil level by means of the dipstick

(MIN-MAX )

If necessary, top up with oil of the

recommended type.

Change

800

Change the transmission oil with 20 kg of

new oil.

The recommended type of oil is

GIP SUPER TRACTOR UNIVERSAL

SAE 15W/40

Oil draining: plug A

Oil filling: plug with dipstick (MIN-MAX )

llow the oil to settle before checking the

new level.

Change the transmission oil filter as

necessary.

59

Page 60

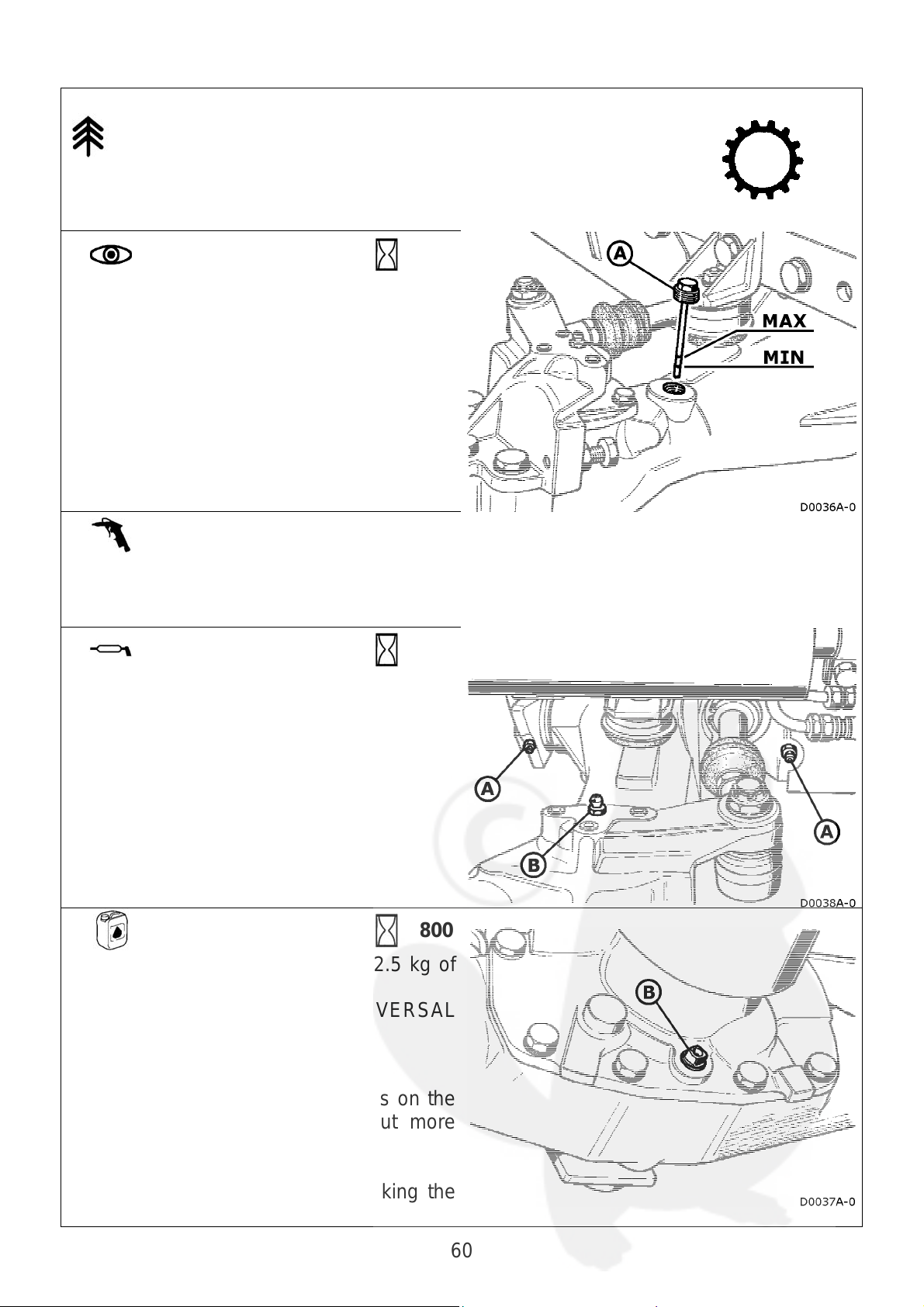

Mod.35-40 front axle

A

A

WARNING: Do not dispose of fluids such as fuels, lubricants,

coolants and other various liquids, in the environment.

Check and

Top up

50

Check the oil level with the dipstick (MINMAX )

If necessary, top up with oil of the

recommended type.

Clean

Keep the following part clean:

• the zone surrounding the plug with dipstick.

Greasing

50

Grease the following parts:

A front axle pivot pin (2 lubricators).

B the hub kingpins

(2 lubricators: right and left)

It is advisable to use

AGIP GREASE LP2

Change

800

Change the transmission oil with 2.5 kg of

new oil. The recommended oil is

GIP SUPER TRACTOR UNIVERSAL

SAE 15W/40

Oil draining: plug B

It is advisable to unscrew the plugs on the

hubs to allow the oil to drain out more

easily.

Oil filling: plug A (MIN-MAX)

llow the oil to settle before checking the

new level.

60

Page 61

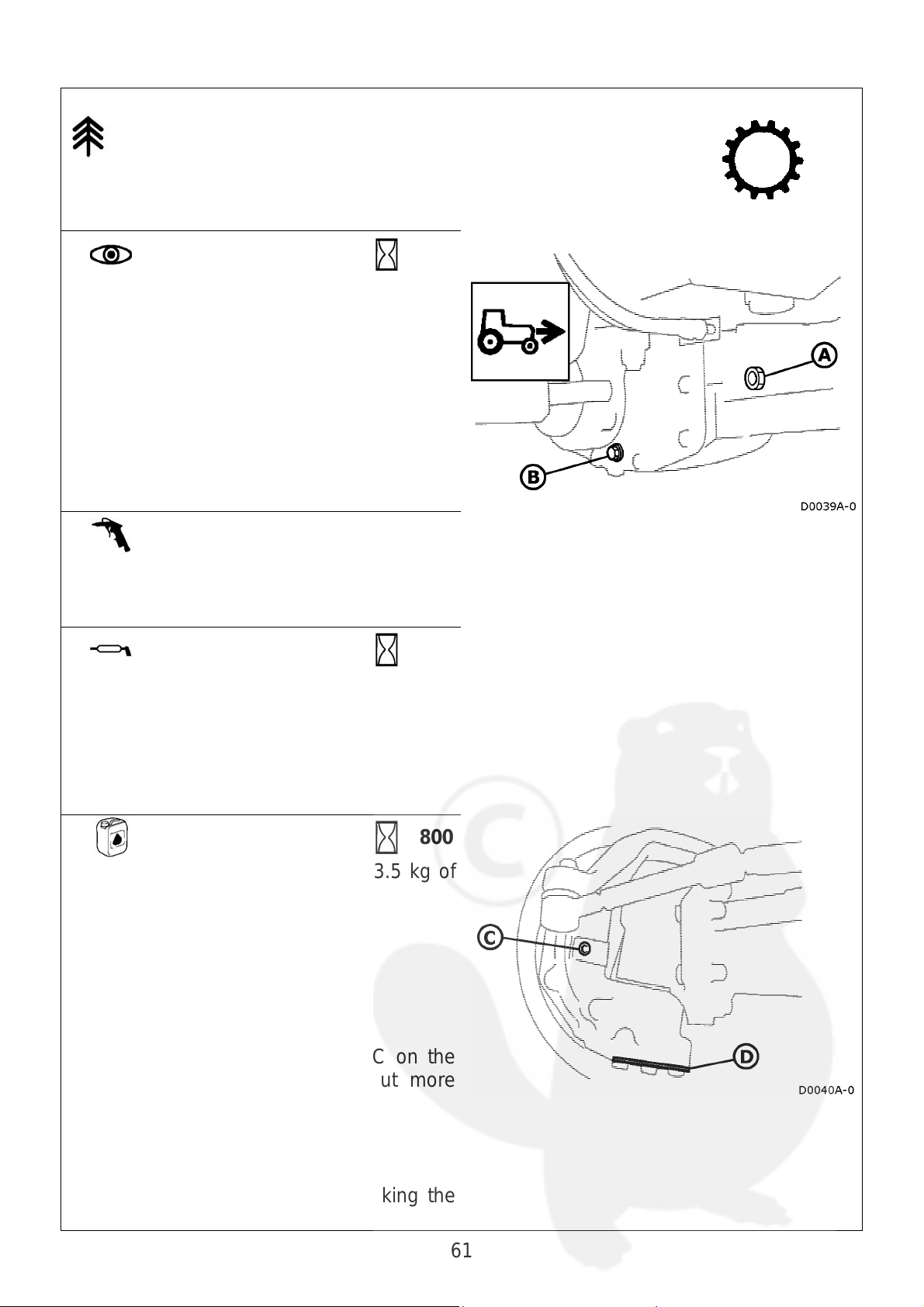

Mod.45 front axle

WARNING: Do not dispose of fluids such as fuels, lubricants,

coolants and other various liquids, in the environment.

Check and

Top up

Check the oil level through plug A

If necessary, top up with oil of the

recommended type.

Clean

Keep the following part clean:

• the zone surrounding plug A.

Greasing

Grease:

• the front axle pivot pin (2 lubricators).

It is advisable to use

AGIP GREASE LP2

50

50

Change

Change the transmission oil with 3.5 kg of

new oil.

The recommended oil is

Agip Rotra MP SAE 80W/90

Oil draining: plugs B and D

It is advisable to unscrew plugs C on the

hubs to allow the oil to drain out more

easily.

Oil filling: plug A

Allow the oil to settle before checking the

new level.

800

61

Page 62

Main clutch

Check

Periodically check the idle travel of the

control pedal.

A = 20mm

Adjust

To adjust the pedal’s travel:

• loosen the check nut

• operate the adjuster

• tighten the check nut

• check the idle travel.

Replace

If necessary, have the clutch assembly replaced by an authorized workshop. Only use a

genuine spare.

62

Page 63

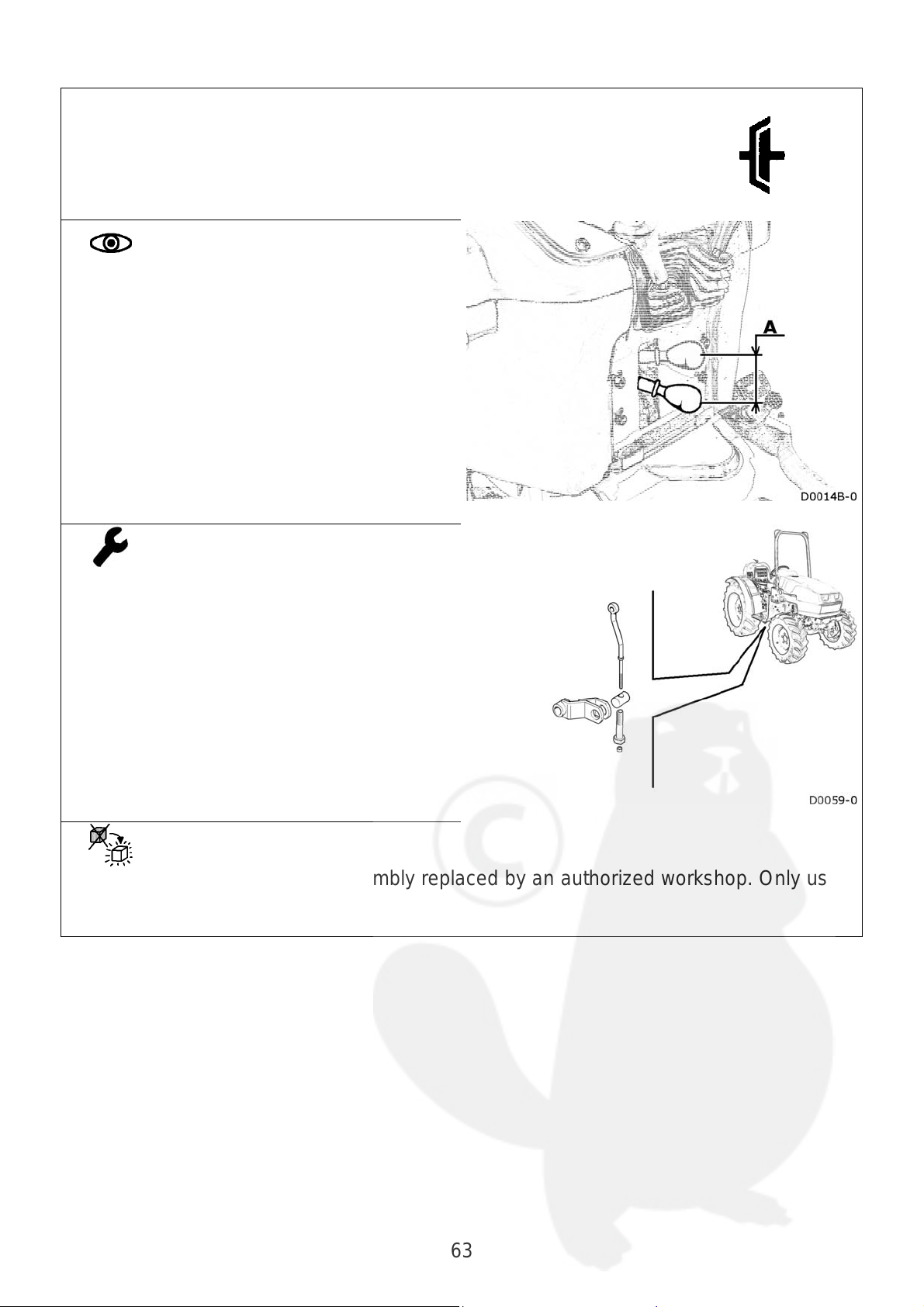

Rear power take-off clutch

Check

Periodically check the idle travel of the

control pedal.

A = 20mm

Adjust

To adjust the pedal’s travel:

• loosen the check nut

• operate the adjuster

• tighten the check nut

• check the idle travel.

Replace

If necessary, have the clutch assembly replaced by an authorized workshop. Only use a

genuine spare.

63

Page 64

Rear differential lock

The differential lock is controlled mechanically by means of a

pedal that operates a hydraulic cylinder.

WARNING: Do not dispose of fluids such as fuels, lubricants,

coolants and other various liquids, in the environment.

Check

Check the level of the hydraulic oil in the

tank.

The tank must be three-quarters full.

Top up level

If necessary, top up the level in the tank.

Recommended oil AGIP ATF II D

Change

The oil in the hydraulic circuit must be changed every 2 years.

Recommended oil AGIP ATF II D

150

X

Final drive lever

Greasing

Grease the final drive lever.

Recommended grease

AGIP GREASE LP2

50

64

Page 65

Brakes

A

The braking system is controlled mechanically by means of two

pedals that operate two hydraulic cylinders.

WARNING: Do not dispose of fluids such as fuels, lubricants,

coolants and other various liquids, in the environment.

Check

Check the level of hydraulic oil in the

reservoir.

The reservoir must be three-quarters full.

Adjust

djust the brakes if brake pedal travel becomes excessive or when one of the wheels

brakes in a different way.

IMPORTANT: Only your dealer or specialized personnel may adjust the braking

system.

150

Top up level

Top up the level in the reservoir when necessary.

Recommended oil

AGIP ATF II D

Change

The oil in the hydraulic circuit must be changed every 2 years.

Recommended oil

AGIP ATF II D

X

65

Page 66

Electrical system

WARNING: Always disconnect the battery’s ground cable (negative pole with the

“-“ symbol) before working on the electrical system.

Battery

WARNING: Work on the battery requires particular care: the

electrolyte is corrosive and the gases released are

inflammable.

DISPOSAL: Exhausted batteries must be consigned to

authorized disposal centers. Do not dispose of batteries in

the environment or in normal urban waste bins.

Check

Make sure that the battery is firmly fixed to the tractor.

Clean

Keep the battery clean with a damp, antistatic cloth.

Keep the battery poles and cable terminals clean.

Greasing

Lightly grease the poles and terminals when necessary.

Use Vaseline-based grease, not normal grease.

50

This type of battery cannot be topped up.

WARNING: DO NOT OPEN THE BATTERY

If the tractor is not used for a long period of time:

• charge the battery as indicated by the manufacturer.

• disconnect both the cables.

• store the battery in a cool, dry, well ventilated place.

If the battery must be replaced, make sure the new one possesses identical technical

specifications (the values are given on the actual battery itself).

Top up level

Idle periods

Replace

66

Page 67

Headlights

If the tractor must be driven on the public highways, the

headlights must comply with the Highway Code regulations in

force in the country of use.

Adjust

Consult specialized personnel in possession of the specific tools required in order to

have the headlights adjusted correctly.

Replace

Replace burnt-out light bulbs with others if identical technical characteristics (see

indications on the bulbs themselves).

Consult specialized personnel if in doubt.

67

Page 68

Fuses

The electrical system is protected by fuses against short circuits

or abnormal power draw.

The tractor has a main fuse. This fuse protects the entire

electrical system.

Replace

Replace burnt-out fuses with others possessing identical technical specifications (the

relative indications are given on the fuses themselves).

Consult specialized personnel if in doubt.

Fuse functions:

N°

A

B

C

D

E

F

G

H

A

Function

20A Power socket power supply

15A Horn power supply

Rh front side light

5A

Lh rear side light

7-pin socket

Lh front side light

License plate light

5A

Rh rear side light

7-pin socket

Brake light power supply

5A

Four-wheel drive switch

PTO switch

Multi-function dashboard

10A

Fuel pump motor

Motor stop coil

7.5A

Lh dipped beam

7.5A

Rh dipped beam

10A 7-pin socket power supply

I

+15 power supply

10A

L

M

N

Hazard light switch

+30 power supply

10A

Hazard light switch

Rh driving beam

15A

Lh driving beam

Main fuse

50

General protection of electrical

A

system

68

Page 69

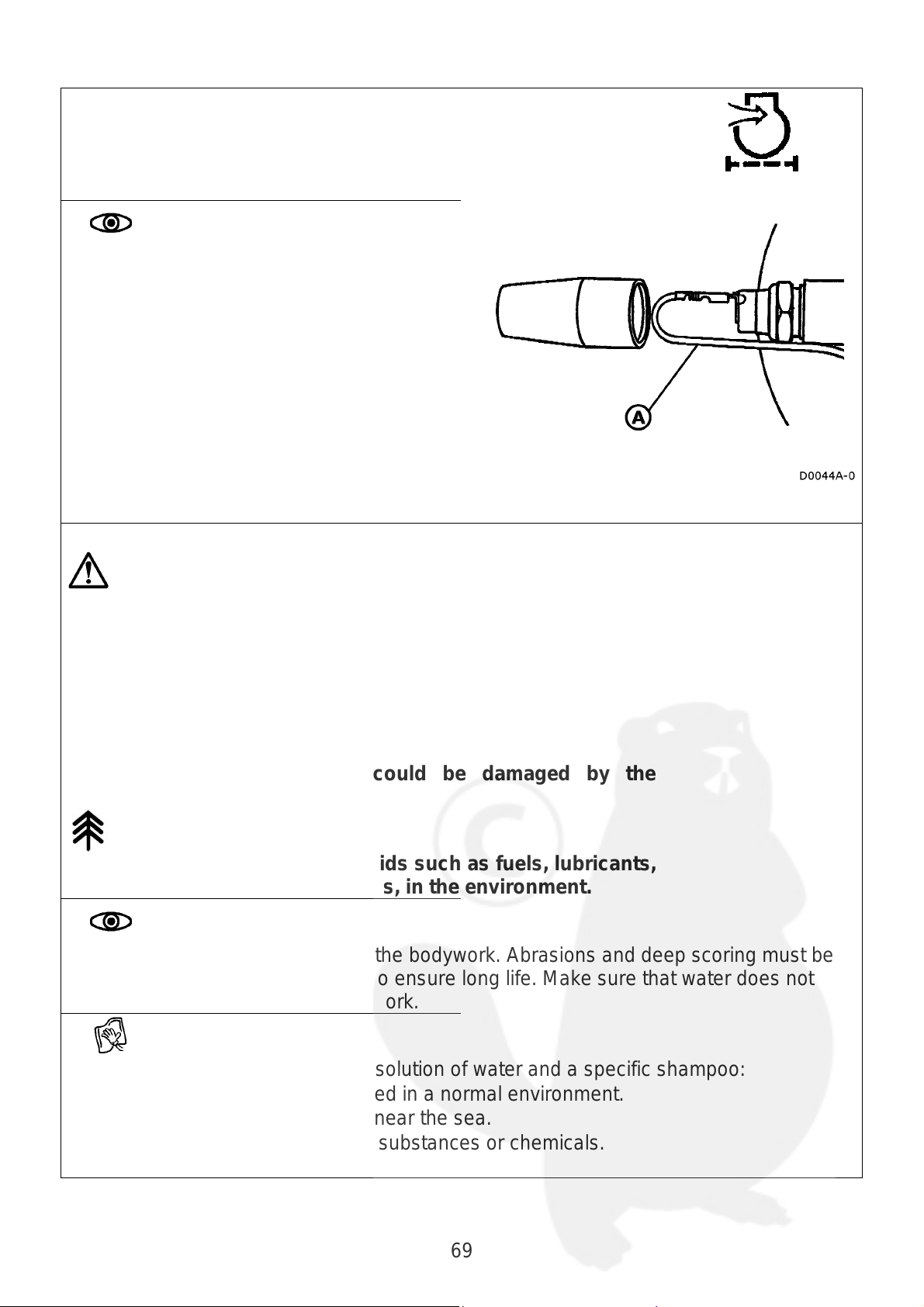

Engine air filter clogging sensor

Check

Check to make sure that the engine air

filter clogging sensor is in the right position.

If servicing is required, make sure that the

sensor is assembled correctly and

protected against adverse weather

conditions as indicated in the figure.

It is essential for cable A, that connects to

the electrical system of the machine, to be

routed through the lower part of the sensor.

If the protection is positioned incorrectly,

this could cause serious damage to the

engine’s air intake circuit.

Bodywork

WARNING: If you use jets of pressurized water for cleaning,

direct the jet well away from:

• tyres

• hydraulic pipes

• radiator

• electrical components

• soundproofing seals

and other components that could be damaged by the

pressure of the water.

WARNING: Do not dispose of fluids such as fuels, lubricants,

coolants and other various liquids, in the environment.

Check

Periodically check the condition of the bodywork. Abrasions and deep scoring must be

repaired by specialized personnel to ensure long life. Make sure that water does not

remain in hidden parts of the bodywork.

Clean

Clean the bodywork with a normal solution of water and a specific shampoo:

• when needed if the tractor is used in a normal environment.

• frequently if it is used in places near the sea.

• immediately after using organic substances or chemicals.

69

Page 70

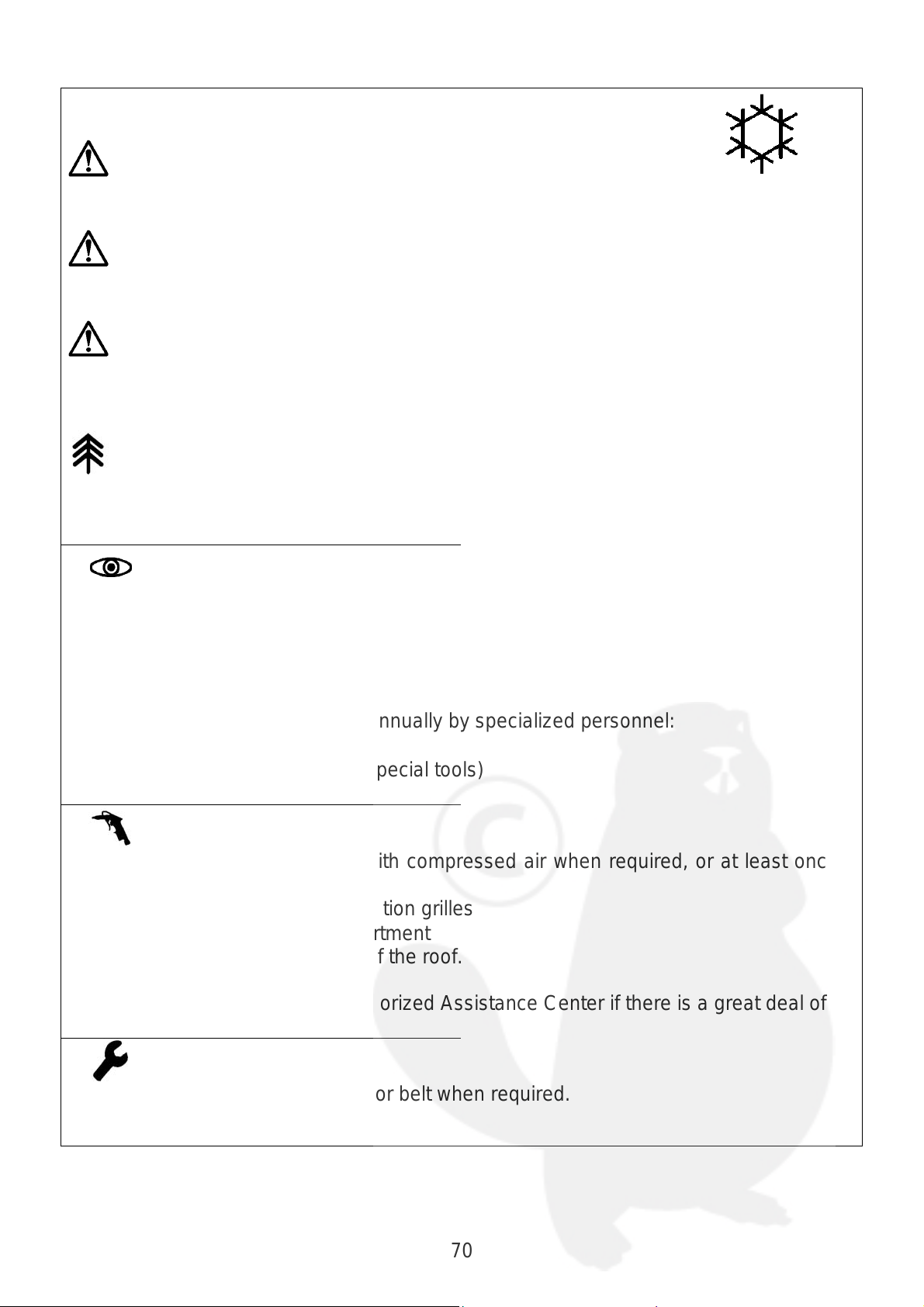

Air conditioning system

WARNING: Never tamper with the air conditioning system:

always contact specialized personnel.

WARNING: Keep naked flames and heat sources well away

from the air conditioning system.

WARNING: Never loosen unions and/or tamper with pipes:

the system is pressurized. The refrigerant can freeze the skin

and eyes.

WARNING: Do not dispose of fluids such as fuels, lubricants,

coolants and other various liquids, in the environment.

Check

Periodically check:

• the condition of the pipes and unions.

• that the pulley and compressor screws are well tightened.

• the tension of the compressor belt.

Have the following parts checked annually by specialized personnel:

• compressor oil level

• tightness of the system (using special tools)

Clean

Clean the following components with compressed air when required, or at least once a

week:

• the cab radiator’s side ventilation grilles

• the cab radiator / fan compartment

They are installed on the top part of the roof.

You are advised to contact an Authorized Assistance Center if there is a great deal of

dirt inside the radiator.

Adjust

Adjust the tension of the compressor belt when required.

70

Page 71

TECHNICAL SPECIFICATIONS

General specifications

Engine

Transmission

Steering

system

Power takeoff

lift

power lift

Hydraulic

circuit

Make

Model

Power rating

Other data

Tank capacity

(reserve)

Cooling system

N° speed gears

Type of clutch

Diameter

Reverse shuttle

Speed

Steering angle

Independent rear PTO

Optional

Shaft profile

Rotation direction

Rear

Synchronized with engine

Shaft profile

Ratio of synchronized

PTO rev. / wheel turn

Lifting capacity

Three-point hitch

Lifting capacity

Three-point hitch

Pump capacity

kW

(CV)

l

l

kph

kg

kg

l /

min.

35 40 45

Lombardini

LDW1503 LDW1603 LDW2204

24 (33) 27 (36) 32 (44)

See engine’s operation and

maintenance manual

40 (5) 40 (5) 40 (5)

7 7 8.5

12 + 4 reverse + 12 with reverse shuttle

Dry

9”

Synchronized

30

55°

540 rpm (with 2518 rpm engine rate)

1000 rpm (with 2500 rpm engine rate)

2000 rpm (with 2500 rpm engine rate)

1” 3/8 ASAE with 6 splines

clockwise

counter-clockwise

1” 1/8 ASAE with 6 splines

21.83

1400 Rear power

Class 1

800 Optional front

Class 1N

33

71

Page 72

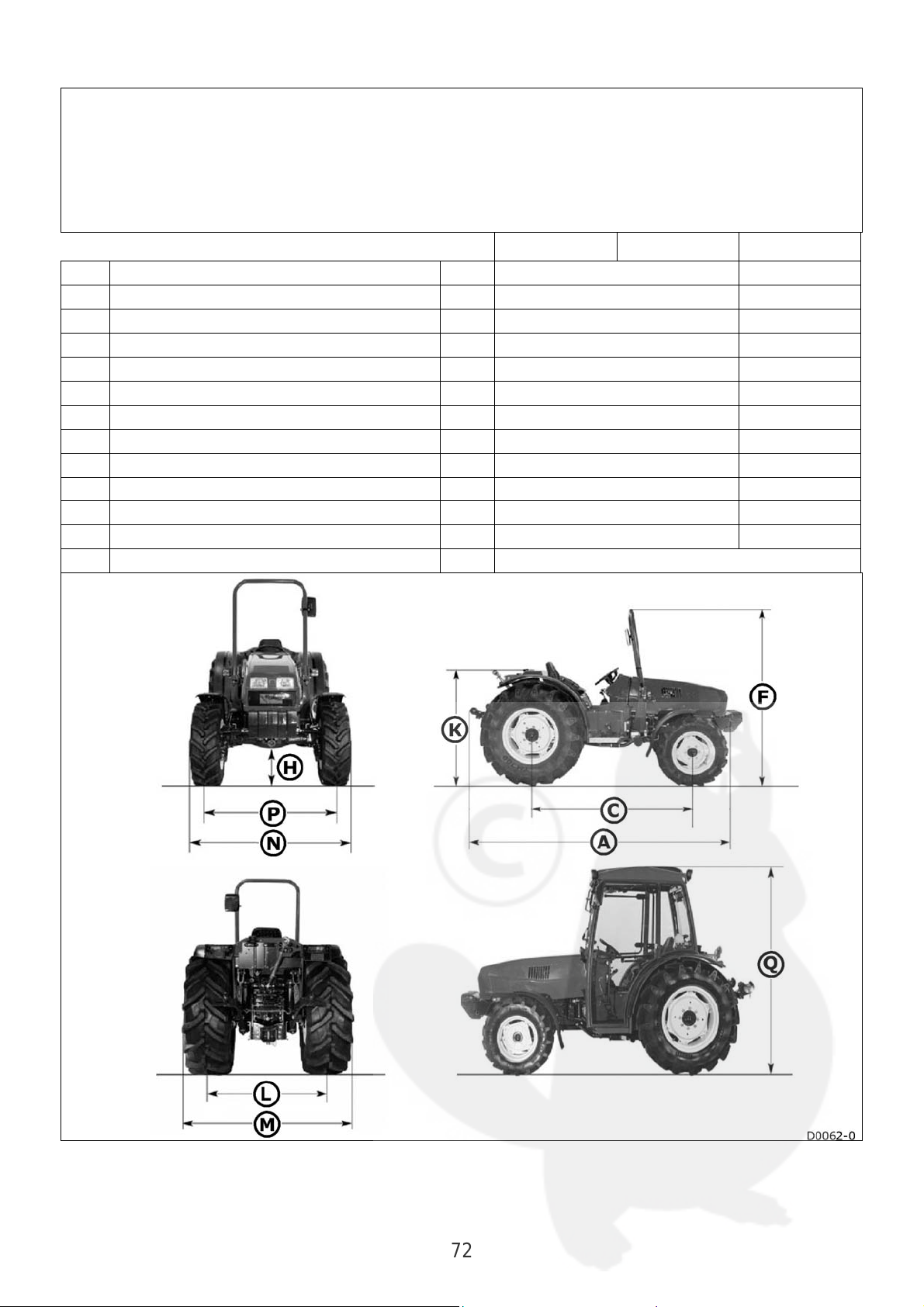

Dimensions and weights

A Min-max length

N/M Min-max width

F Min-max height to chassis

Q Min-max height to cab

K Min-max height to seat

H Min-max ground clearance

C Wheelbase